Method for Determining Arc Discharge as well as Failure of Mechanical Vibration and Abnormal Displacement in Power Equipment Using Acoustic Energy Feature

a technology of acoustic energy feature and arc discharge, which is applied in the direction of instruments, specific gravity measurement, furniture, etc., can solve the problems of affecting the accuracy of determination, inability to determine the operating condition, and inability to reflect mechanical performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

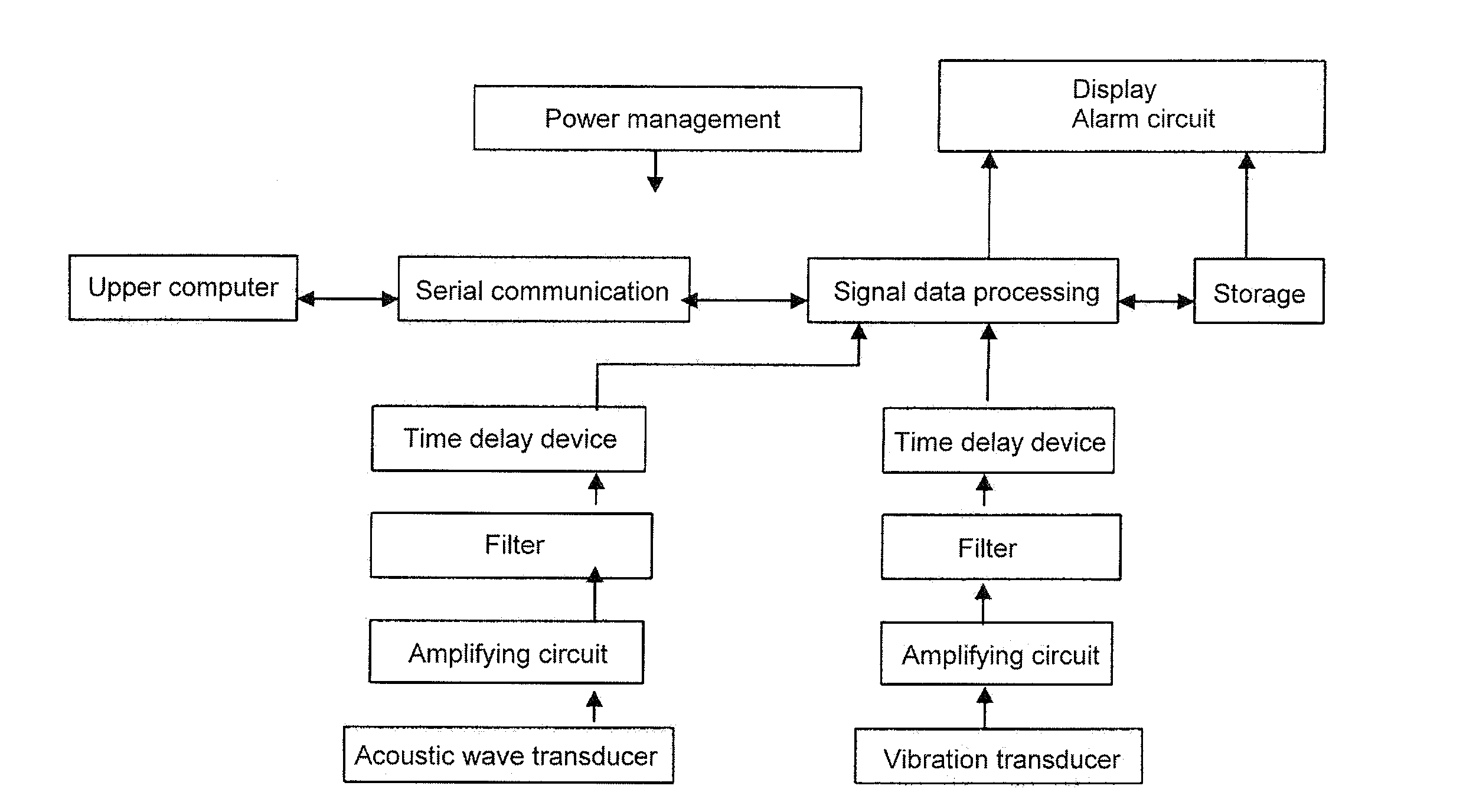

[0020]A method for determining arc discharge as well as failure of mechanical vibration and abnormal displacement in power equipment using acoustic energy feature devised in the present invention is based on principles, the first one of which is the utilization of acoustic wave and vibration wave, in such a way that power equipment may be inspected to determine arc discharge and mechanical failure therein. A transformer is a “heart” of a substation. Taking the transformer as an example, the vibration of the main body of the transformer is determined by the vibration of core entirely, while the vibration of core may be approximated to magnetostriction of silicon steel. The magnetostrictive vibration of core may be transmitted to the wall of oil tank via two paths through either the pad of core or insulating oil medium, such that acoustic wave may be generated by the vibration of wall of oil tank and then emitted in all directions. It is demonstrated that, in the research on several (110

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap