Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about "Analysing solids using sonic/ultrasonic/infrasonic waves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

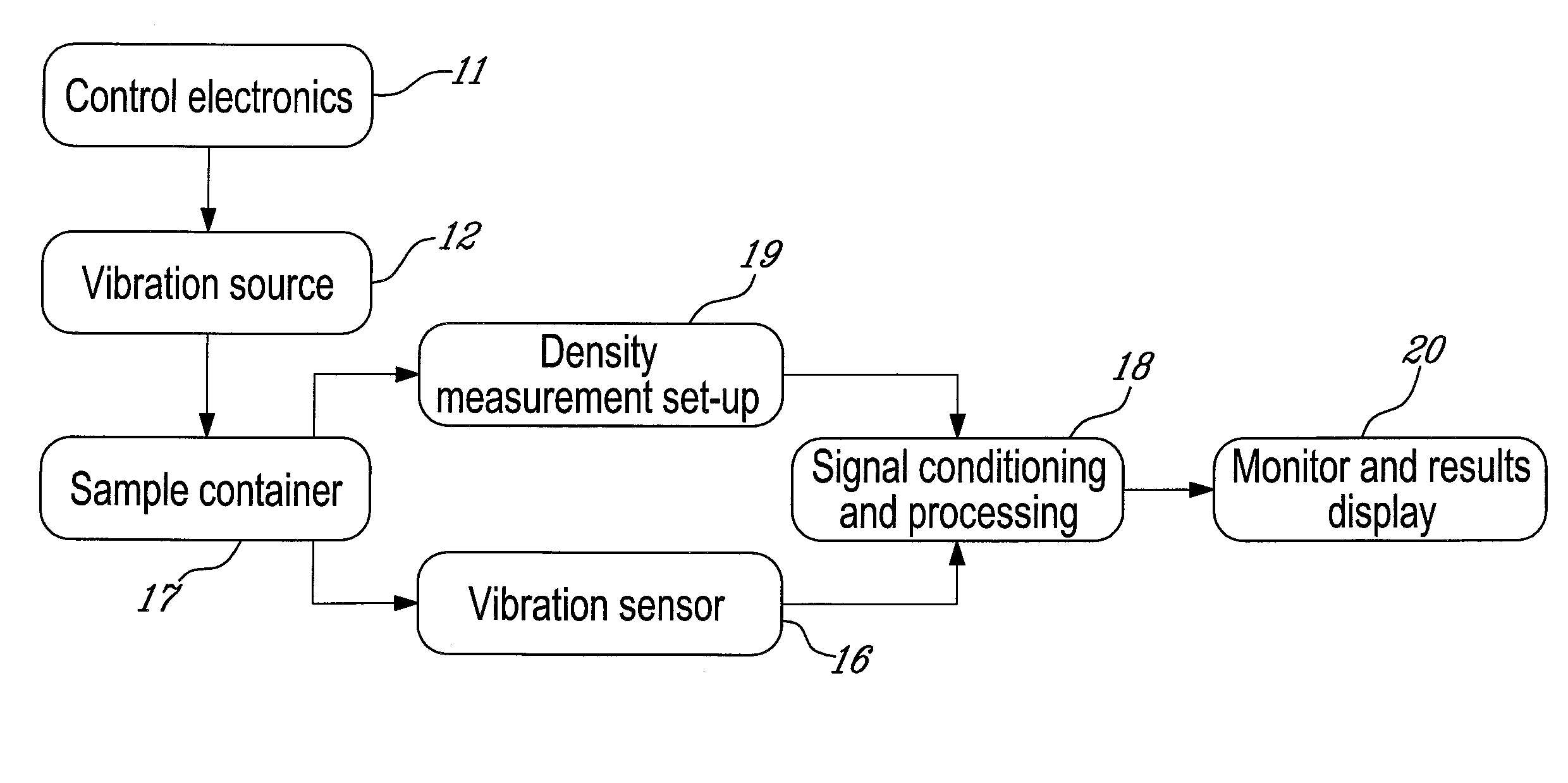

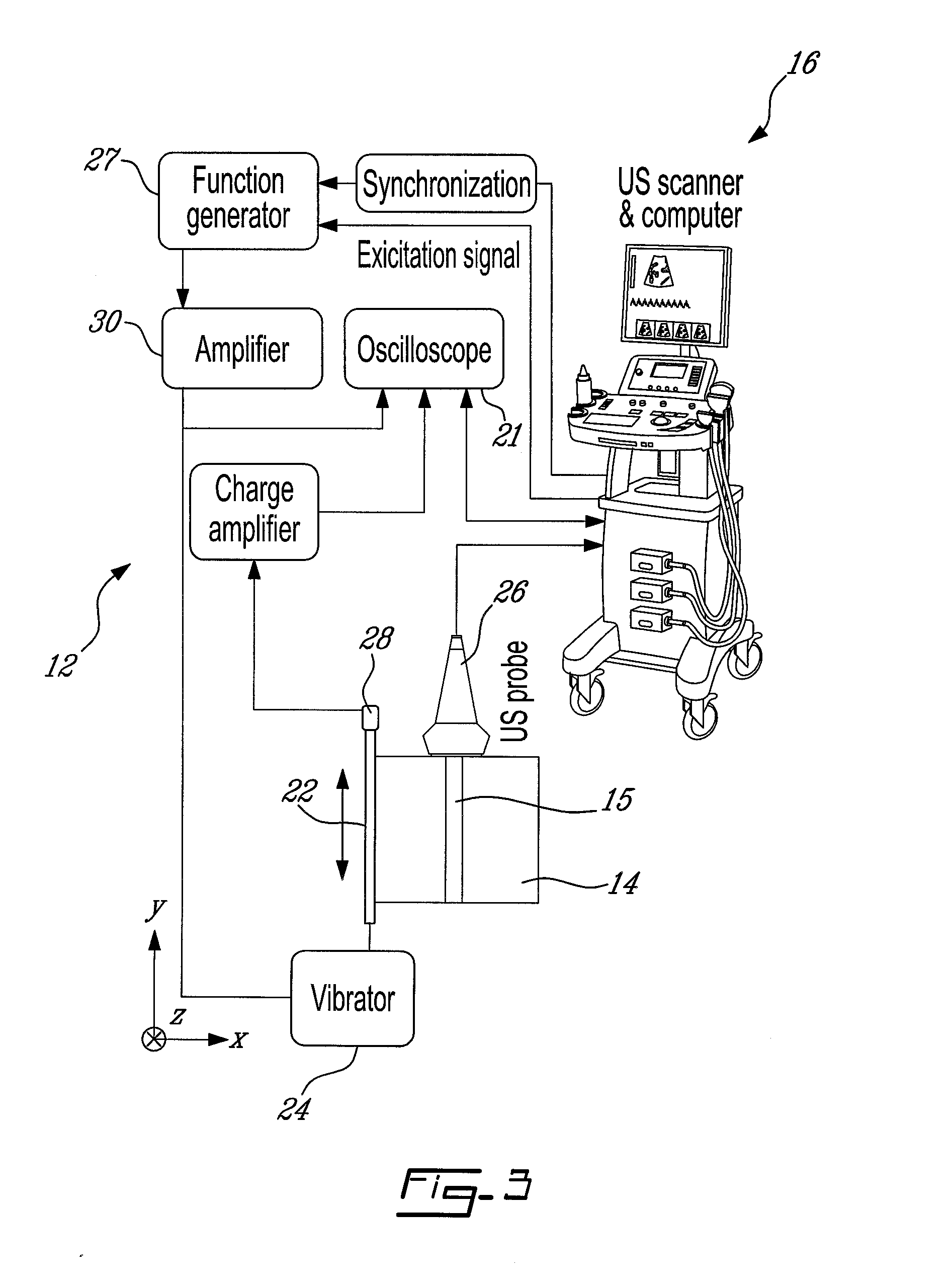

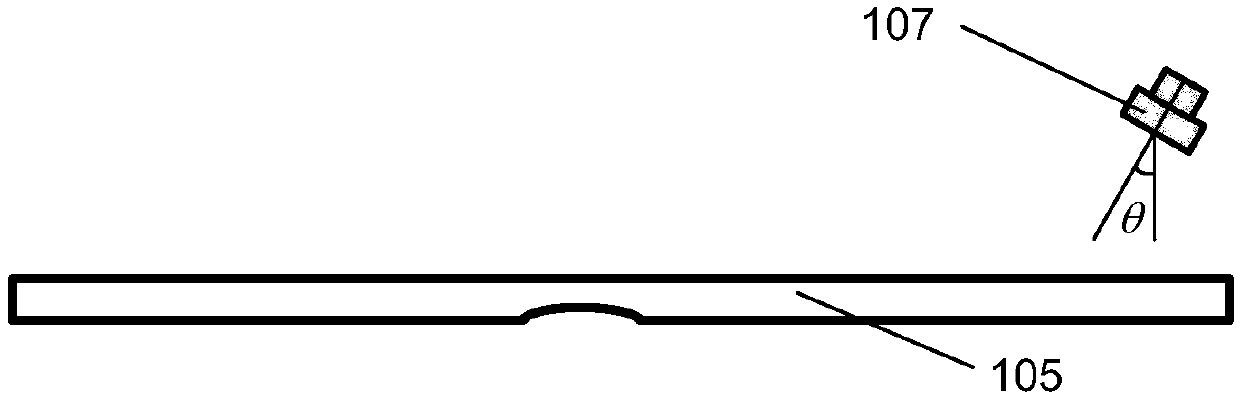

System and method for detection, characterization and imaging of heterogeneity using shear wave induced resonance

InactiveUS20110130660A1Ultrasound therapyAnalysing solids using sonic/ultrasonic/infrasonic wavesMechanical resonanceAcoustics

Owner:VAL CHUM PARTNERSHIP

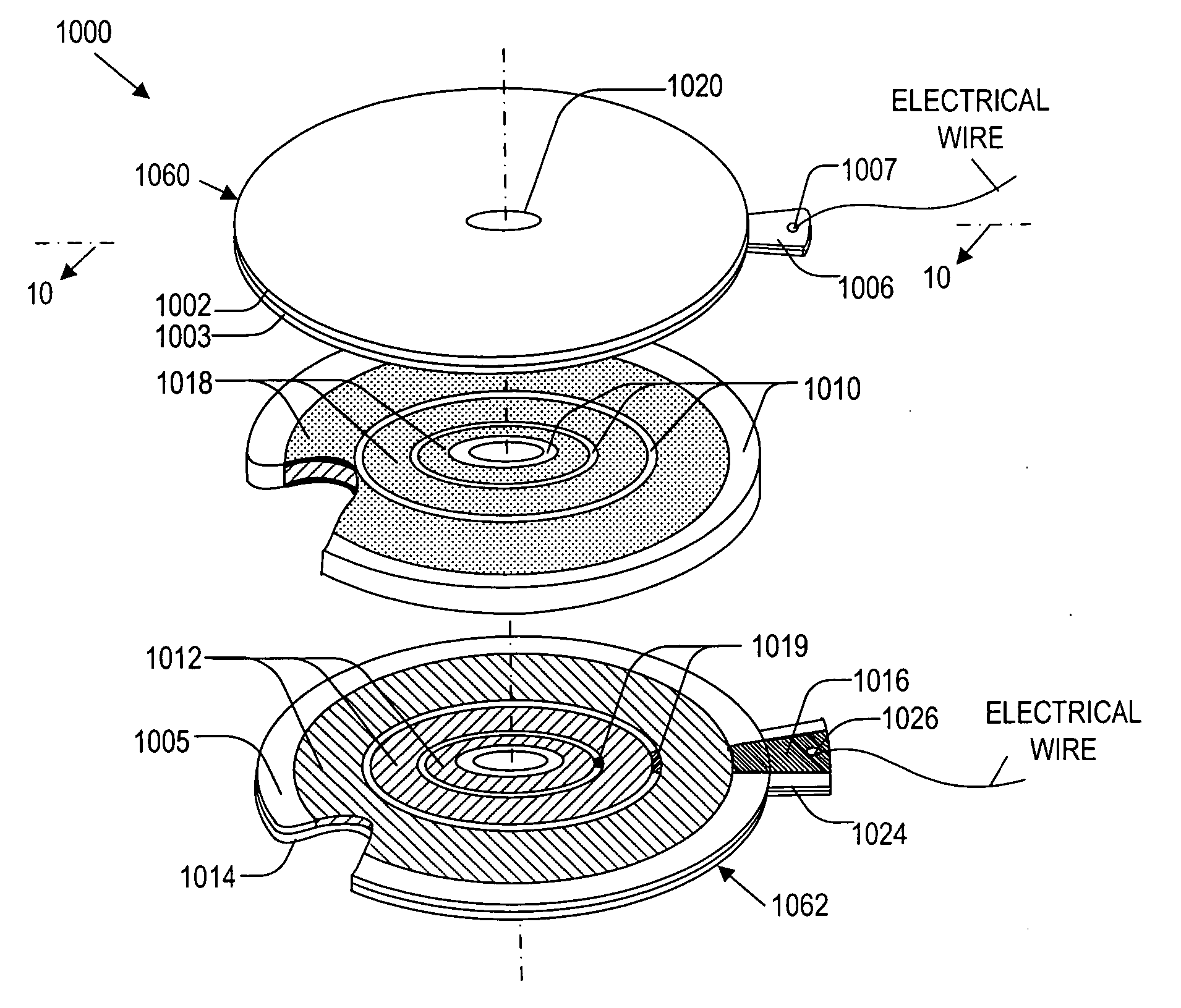

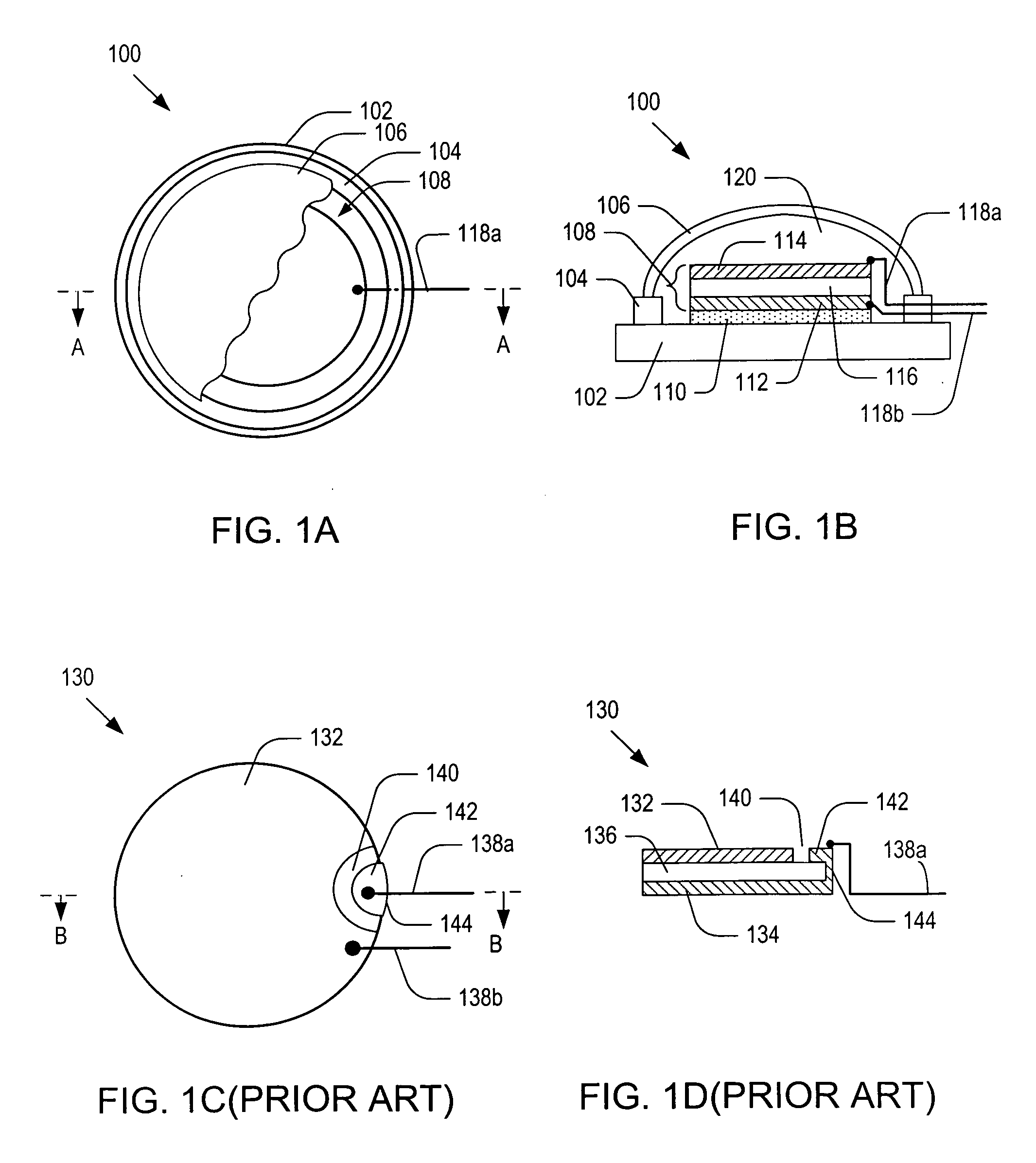

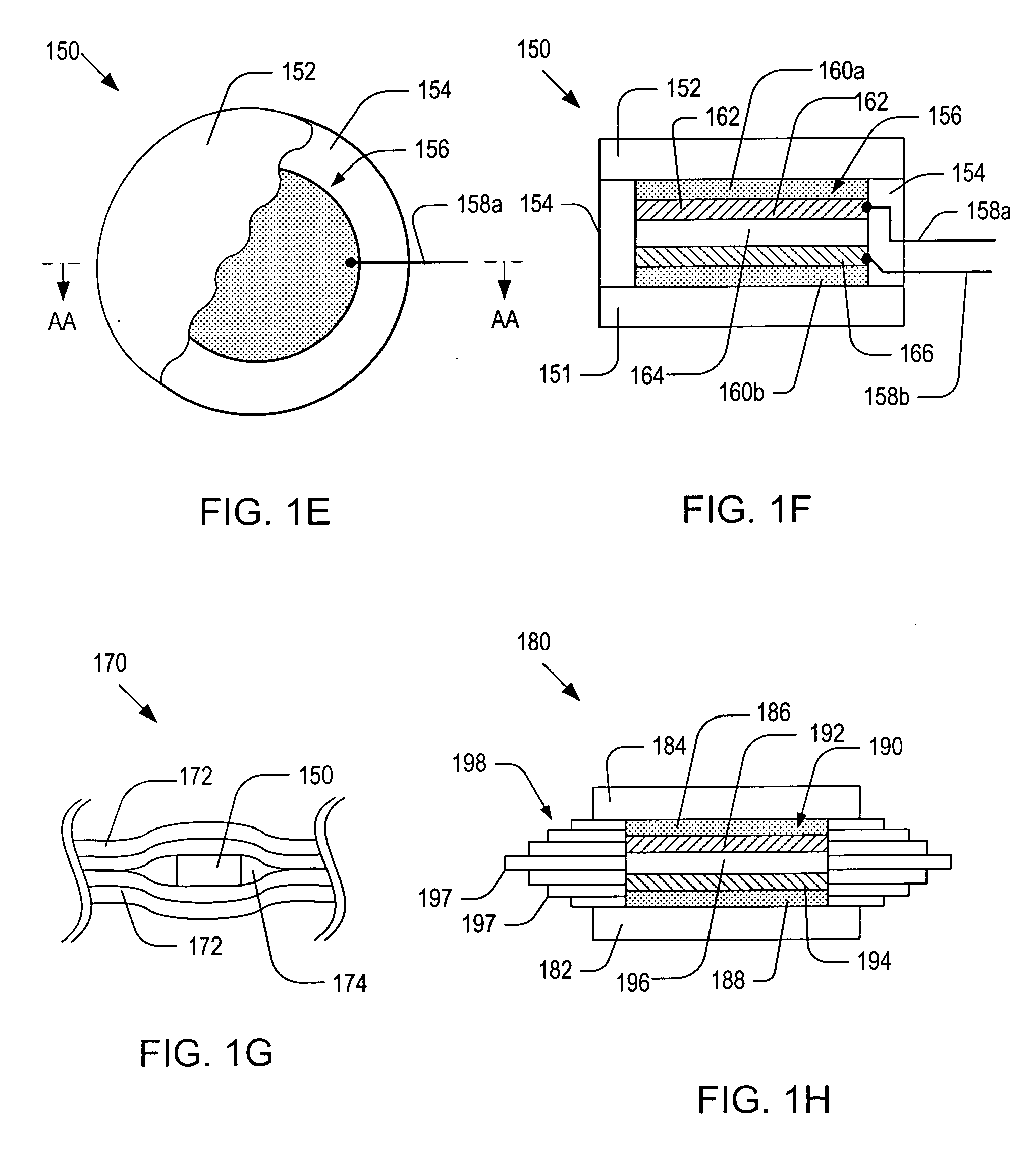

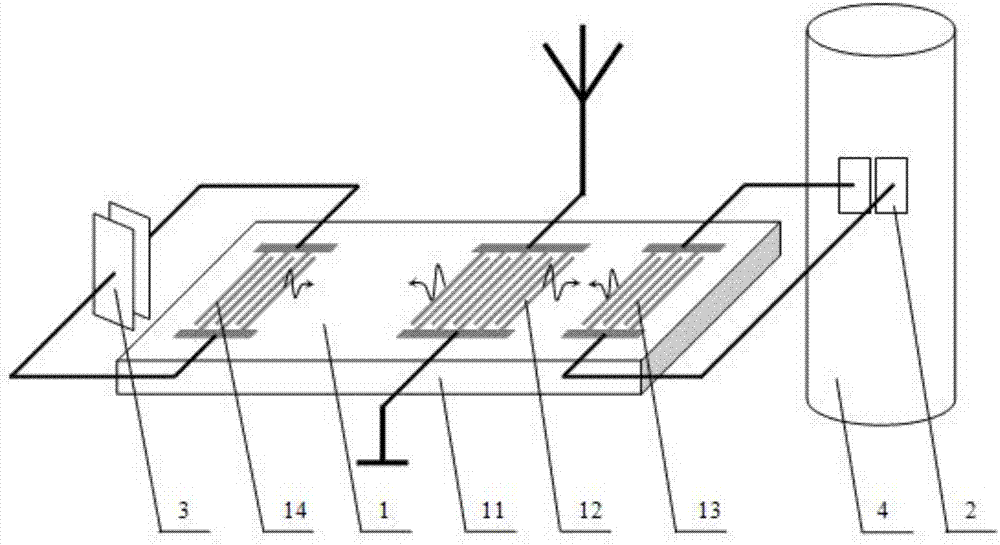

Interrogation network patches for active monitoring of structural health conditions

InactiveUS20070012111A1Vibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityActive monitoring

Owner:ADVANCED STRUCTURE MONITORING

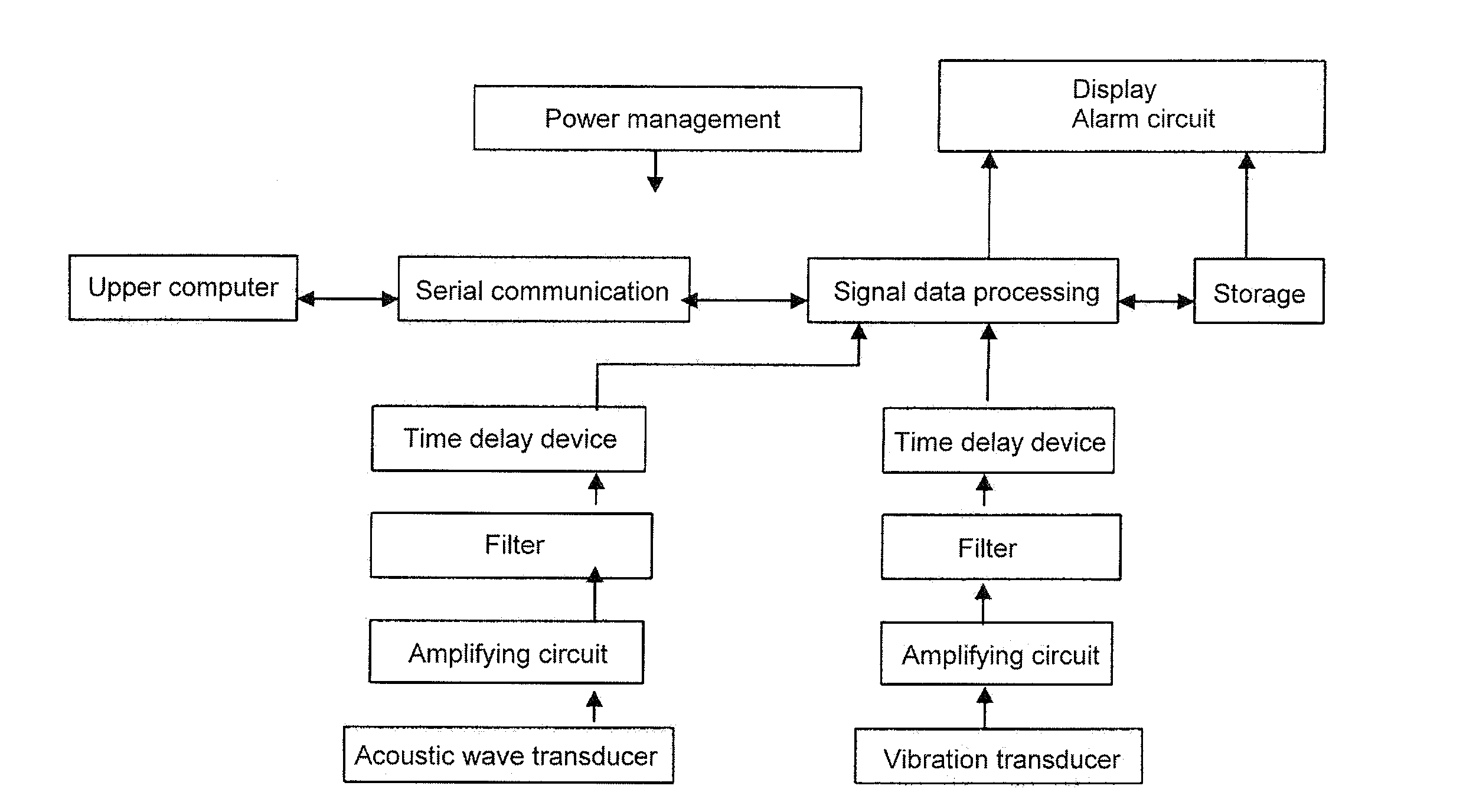

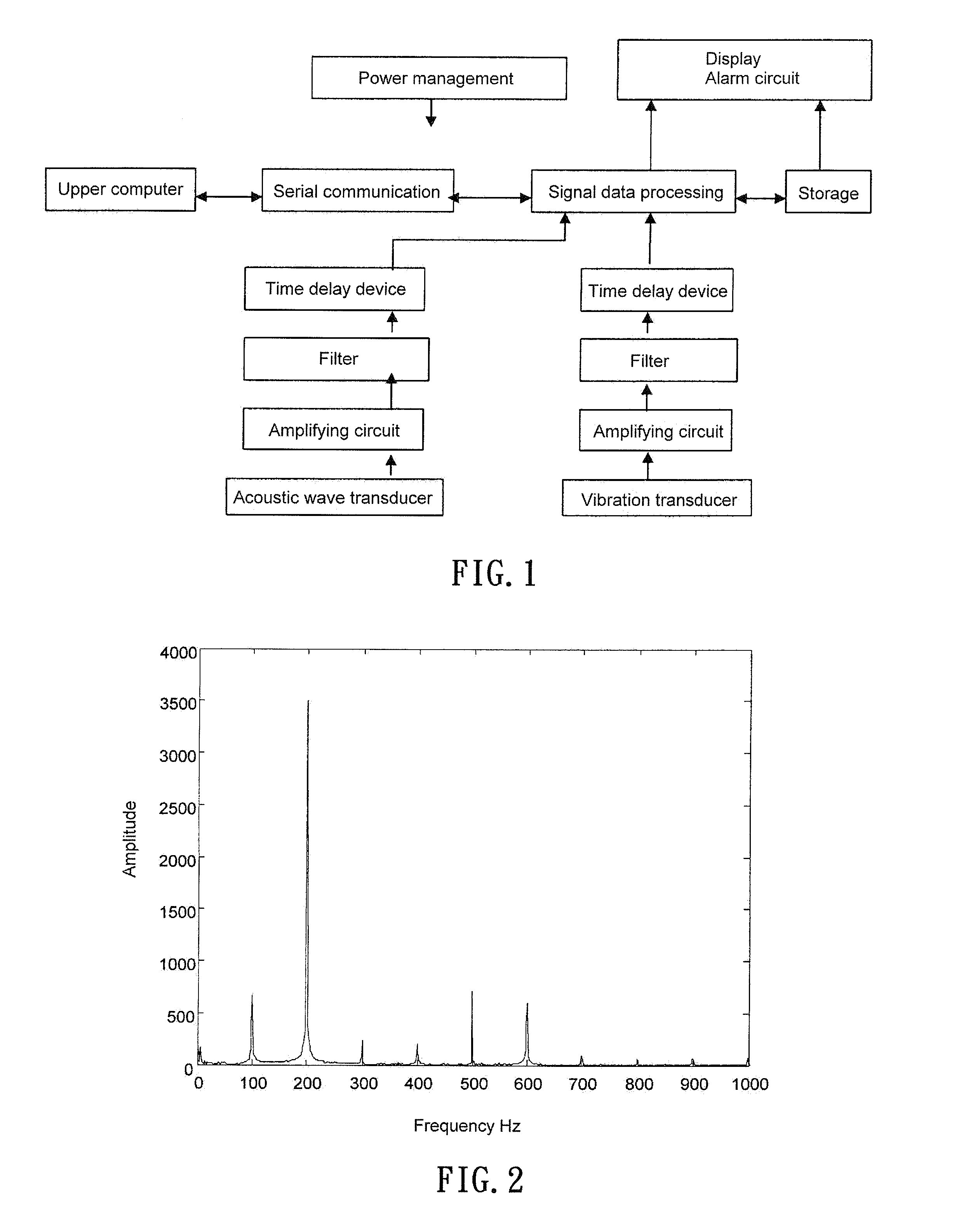

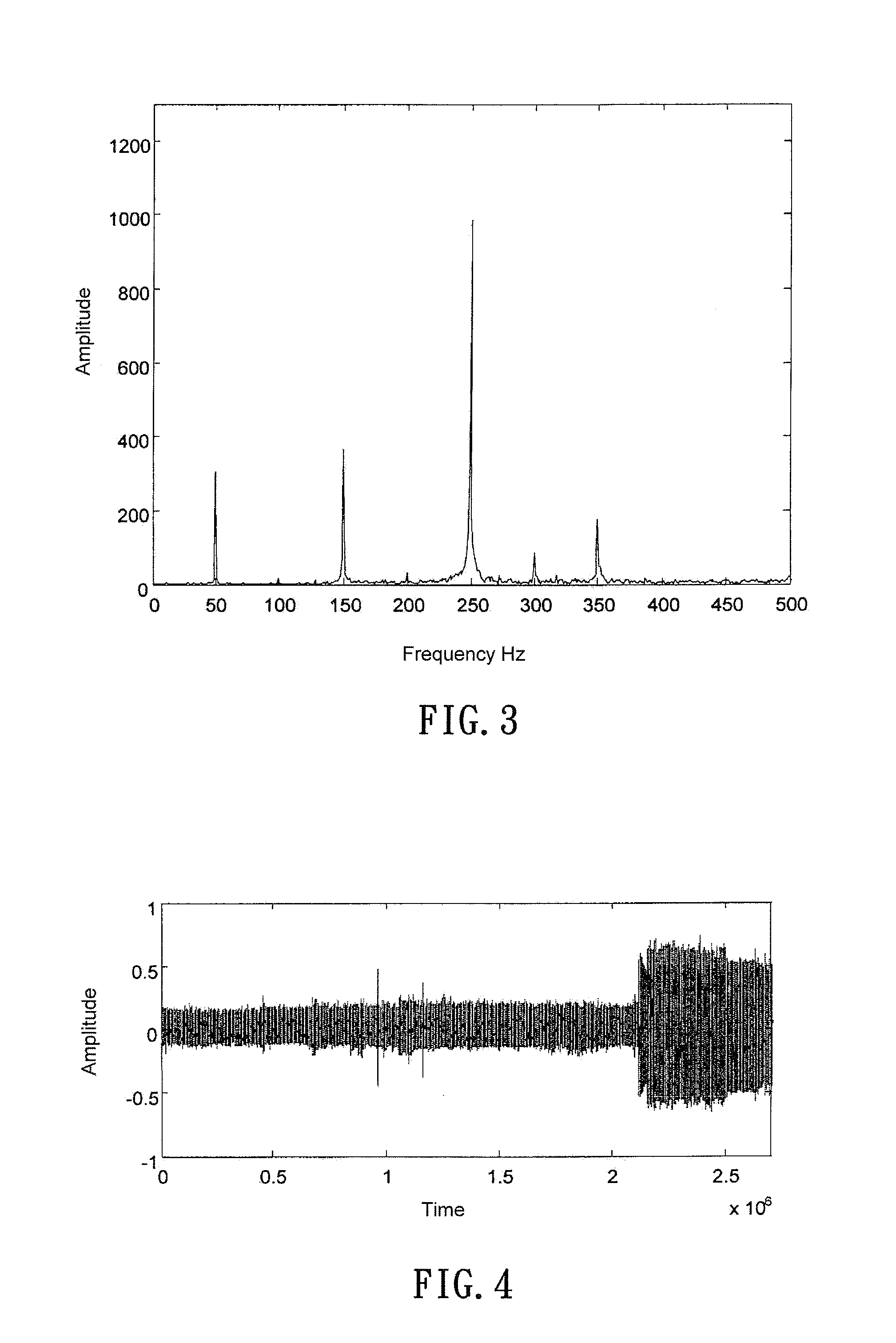

Method for Determining Arc Discharge as well as Failure of Mechanical Vibration and Abnormal Displacement in Power Equipment Using Acoustic Energy Feature

InactiveUS20140216157A1Achieve effectVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesSound sourcesInterference resistance

Owner:WANG LEE TZU FENG

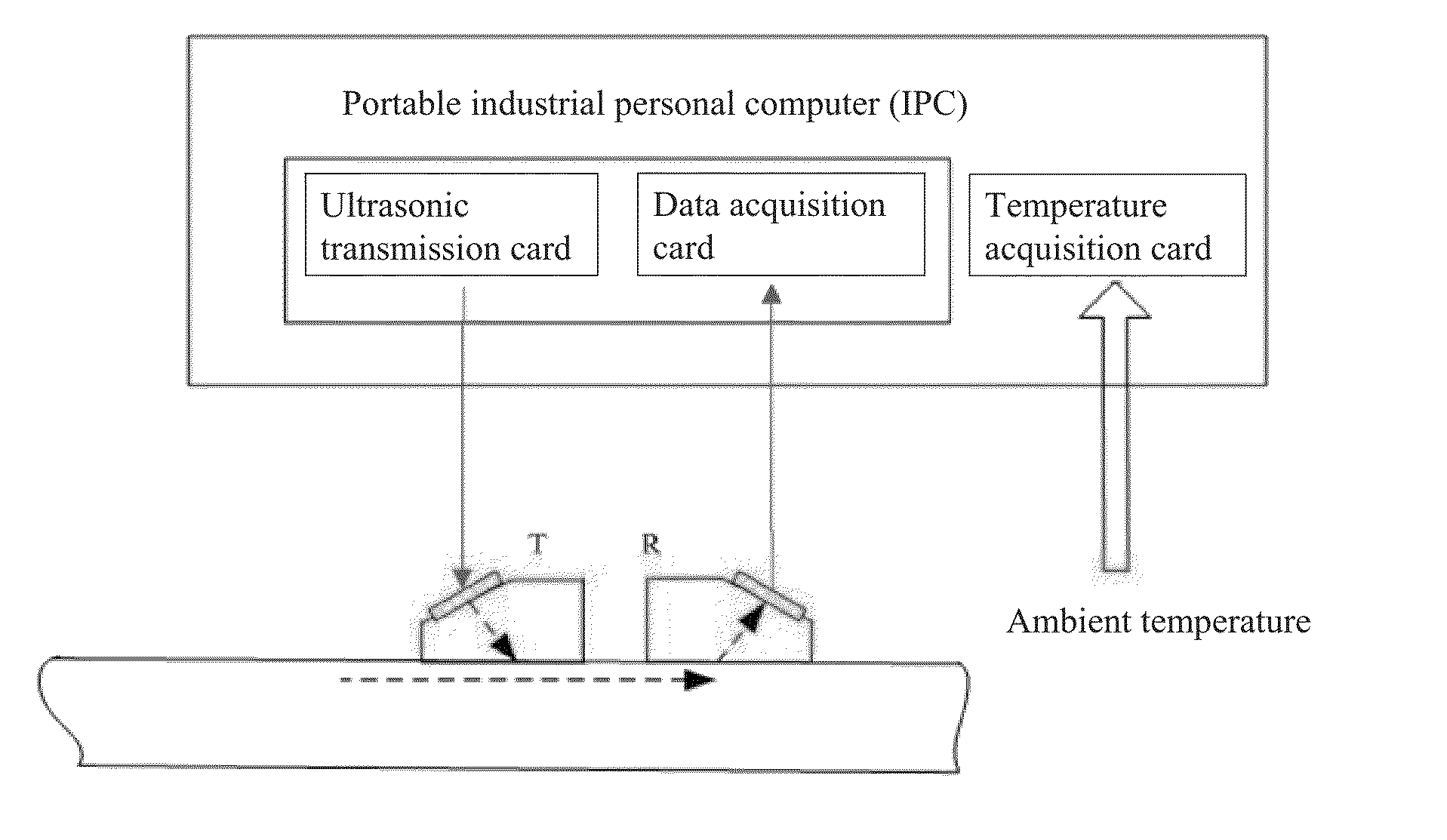

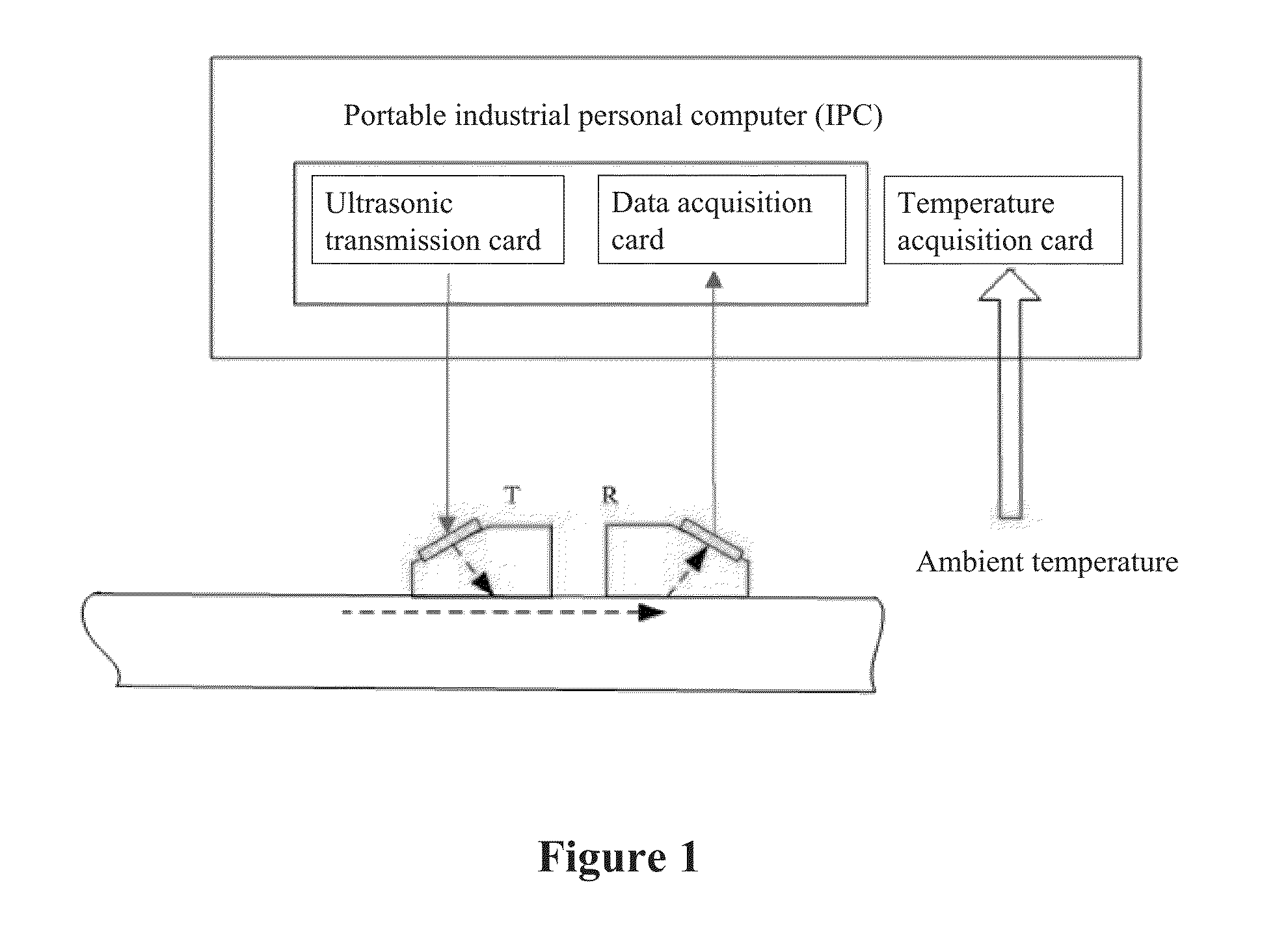

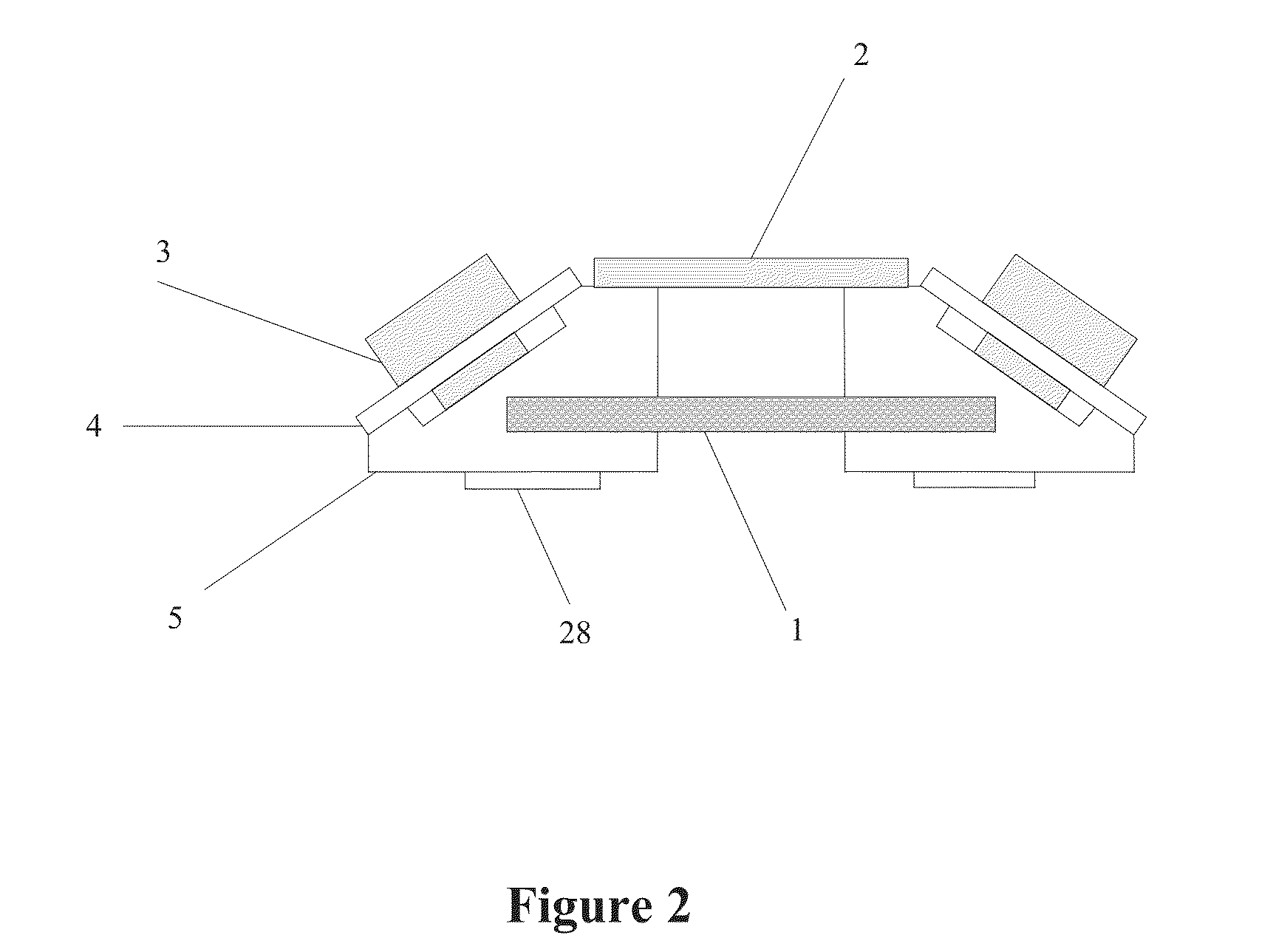

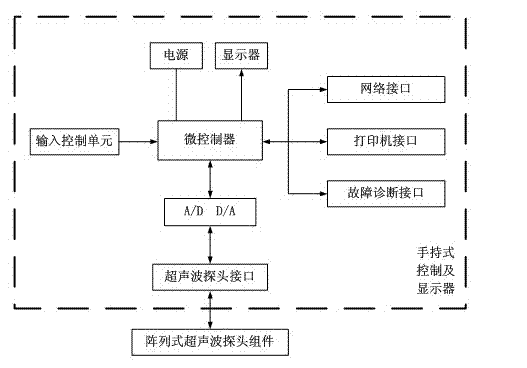

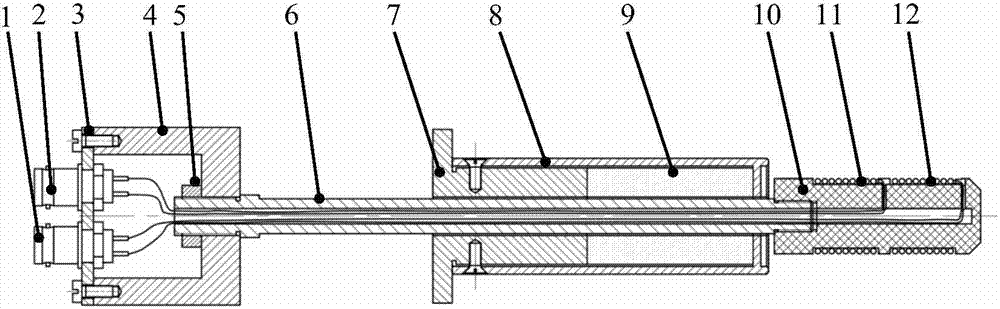

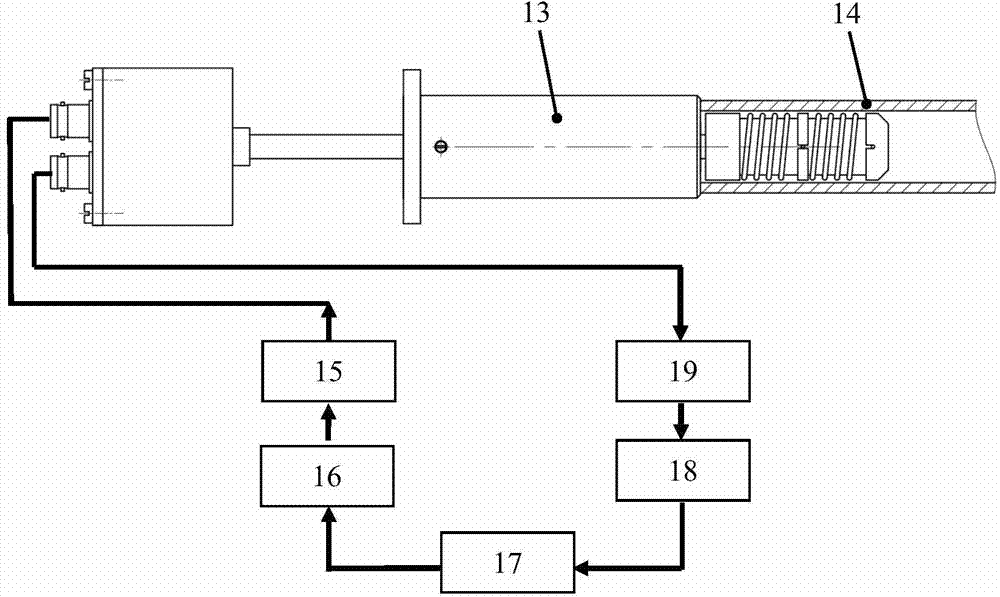

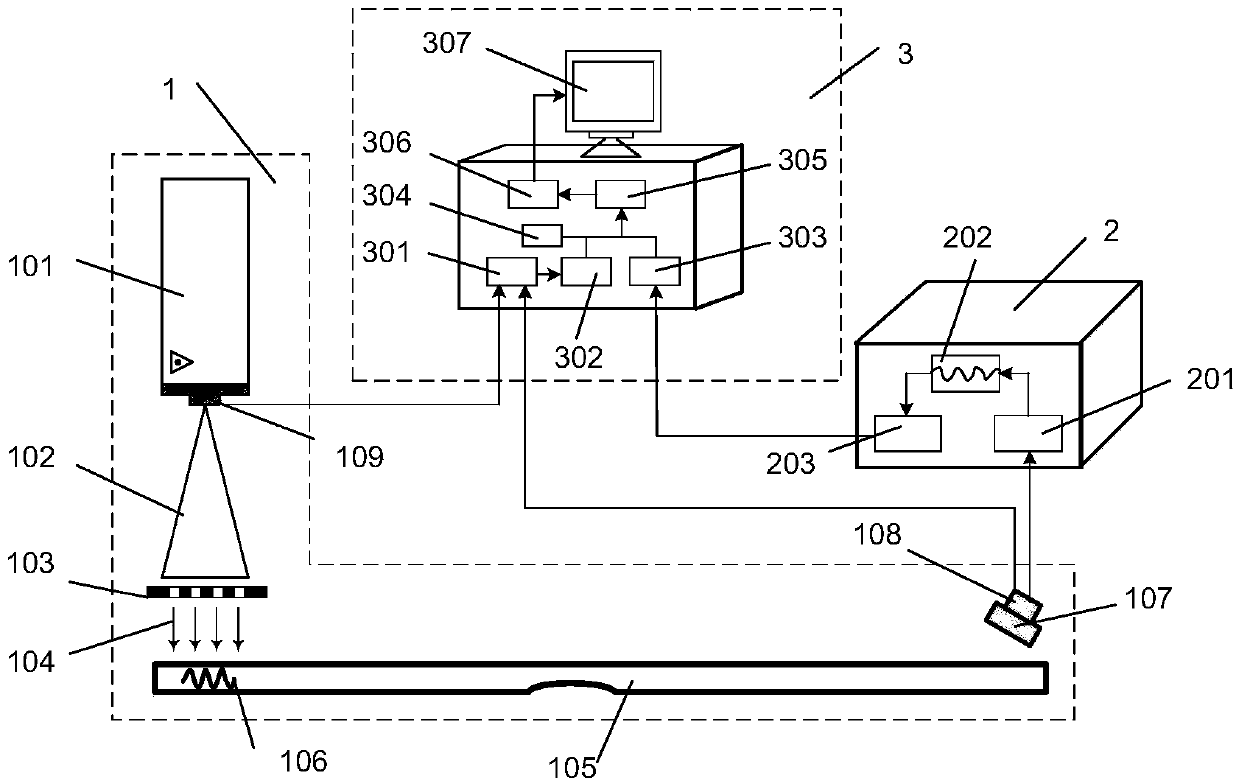

Sensor device and residual stress detection system employing same

ActiveUS20150300897A1Easy to integrateImprove reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerData acquisition

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Ultrasound thickness measuring method and device based on broadband frequency-modulation and receiving compensation

InactiveCN102865839AFrequency information is stableAvoid near-field blind spotsAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansDisplay deviceTransducer

Owner:SOUTH CHINA UNIV OF TECH

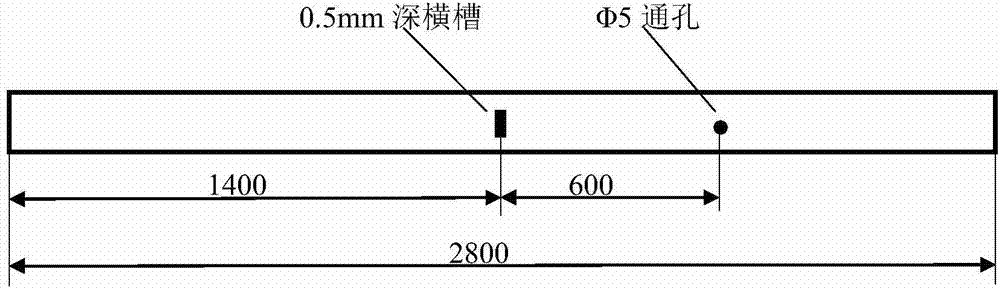

Fiber reinforced composite material parameter identifying method based on laser nondestructive scanning, and device

ActiveCN106950280AAvoid enteringReduce experimental errorAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionShear modulusResonance amplitude

Owner:NORTHEASTERN UNIV

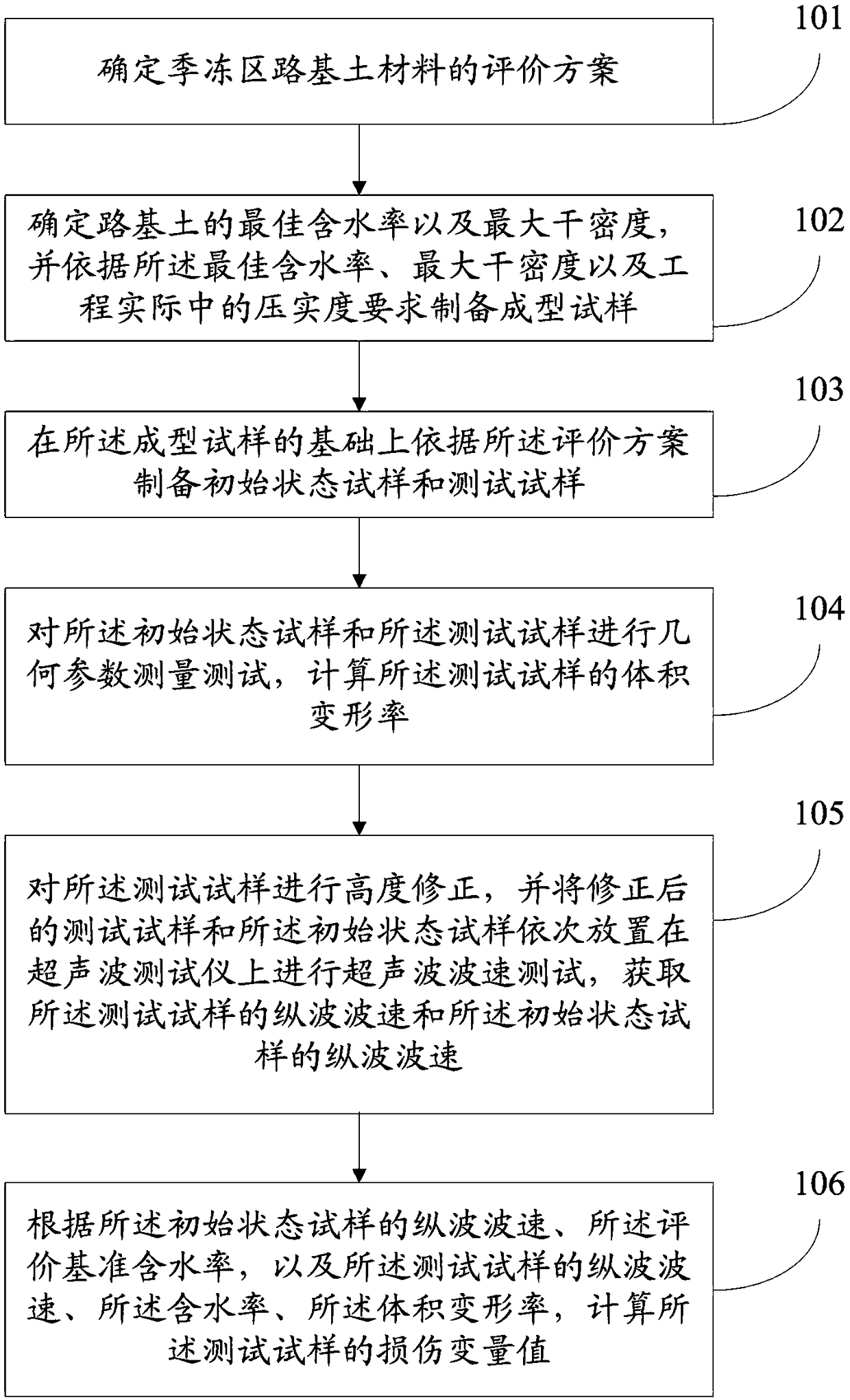

Ultrasonic technology-based method for detecting and evaluating damage of subgrade soil materials in seasonal frozen regions

ActiveCN108645676AComprehensive evaluationAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationFreeze and thawMoisture

Owner:JILIN JIANZHU UNIVERSITY +1

Detection sensor based on magnetostriction guide waves, detection system and application

InactiveCN104122329ASimple structureShorten the lengthAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

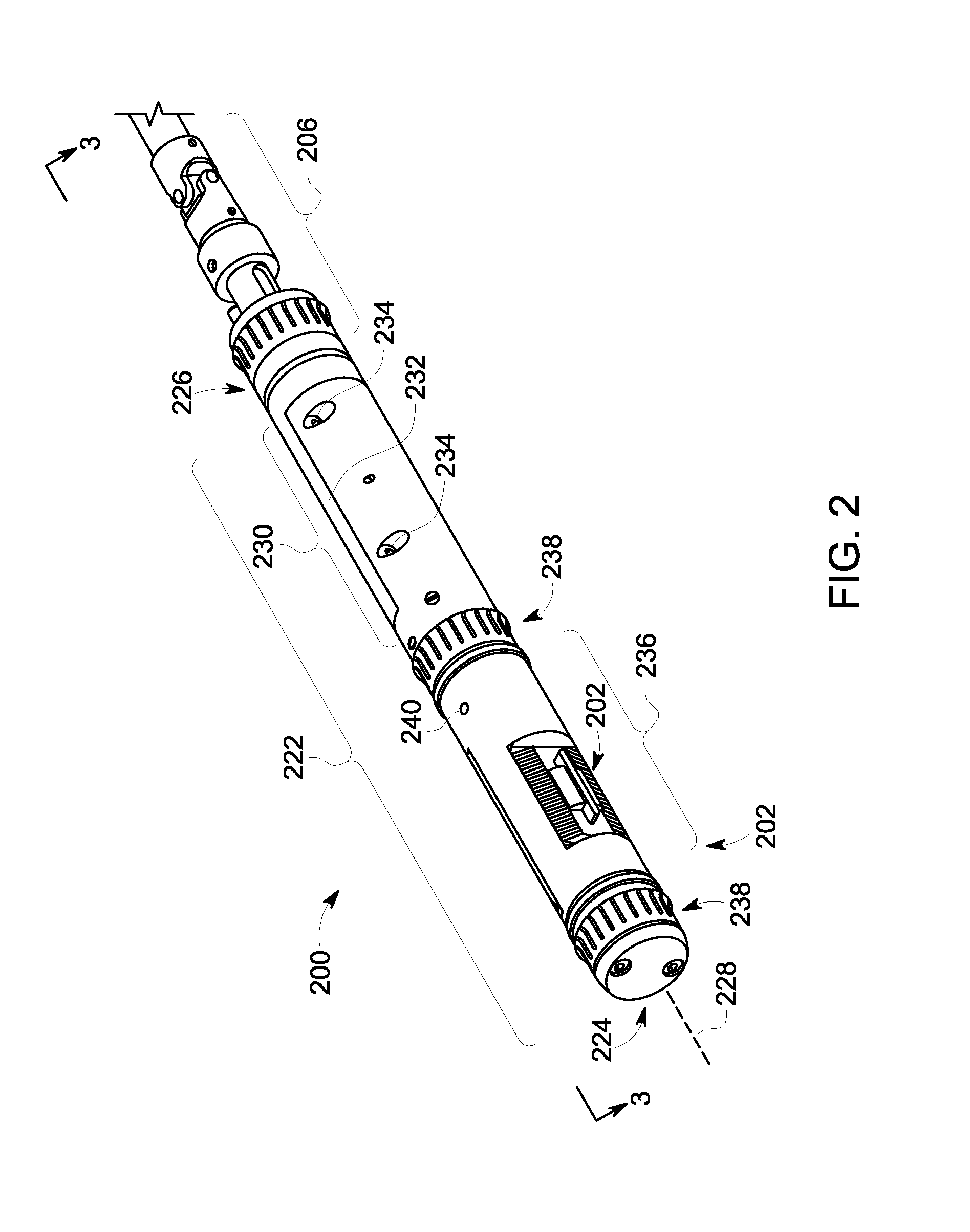

Method for determining boiler tube cold side cracking and article for accomplishing the same

InactiveCN103728372AAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansCold sideWaveguide

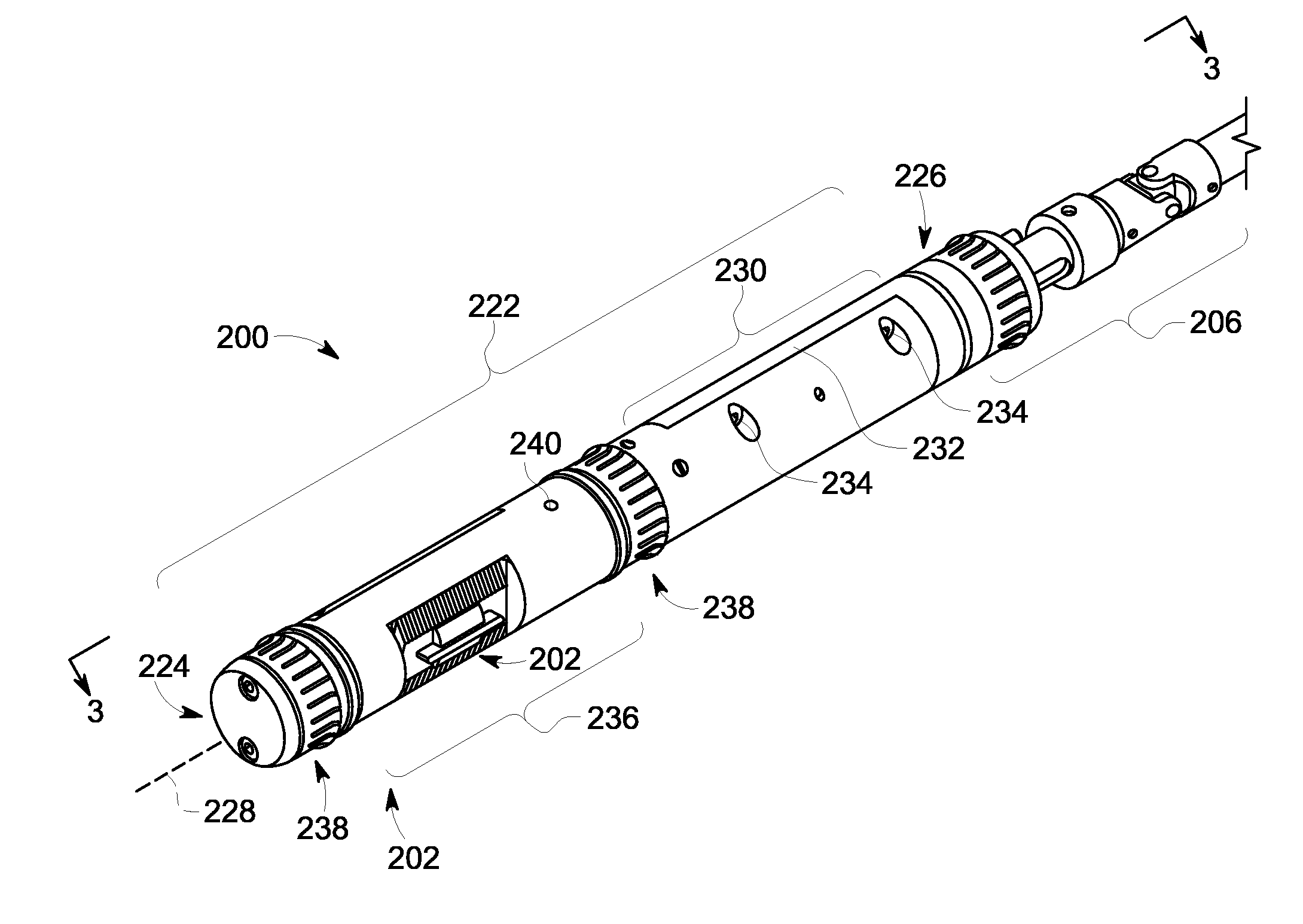

Disclosed herein is a scanning device for performing ultrasonic nondestructive testing of a tube, comprising a housing; the housing having bottom surface that is concavely curved with cavities to accommodate a waveguide assembly and an encoder assembly; where the waveguide assembly comprises a waveguide and a probe that are in communication with one another; the waveguide having at least one surface that is contoured to match an outer surface of the tube; where the waveguide facilitates the transmission of ultrasonic signals into the tube generated by the probe; and where the encoder assembly comprises a spring loaded wheel that contacts the tube; and where the encoder assembly provides a signal indicative of a location of the probe relative to a position on the tube as the scanning device is moved in a direction of a longitudinal axis of the tube.

Owner:GENERAL ELECTRIC TECH GMBH

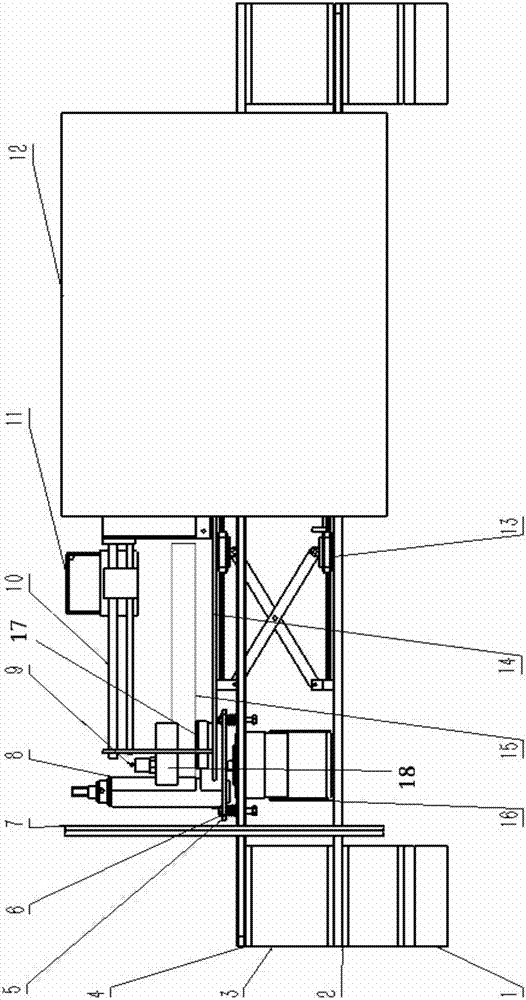

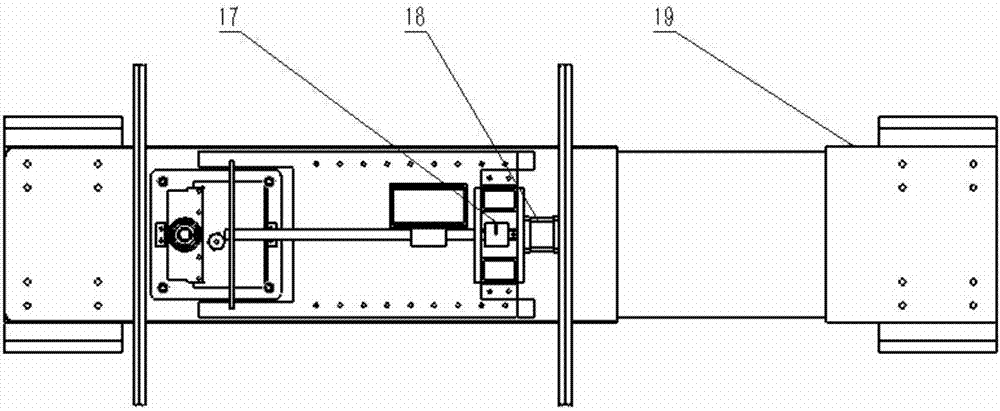

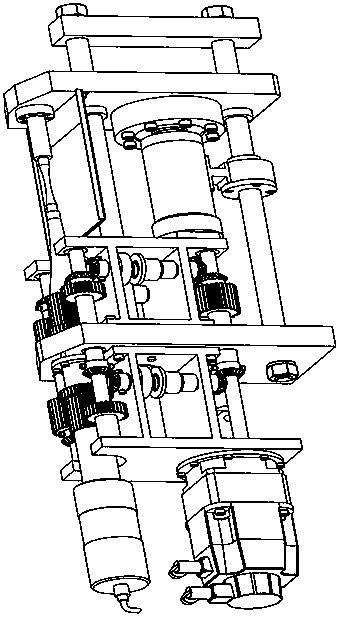

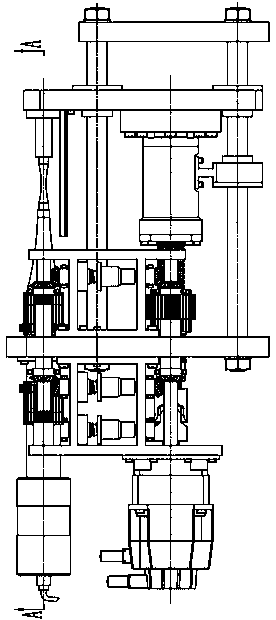

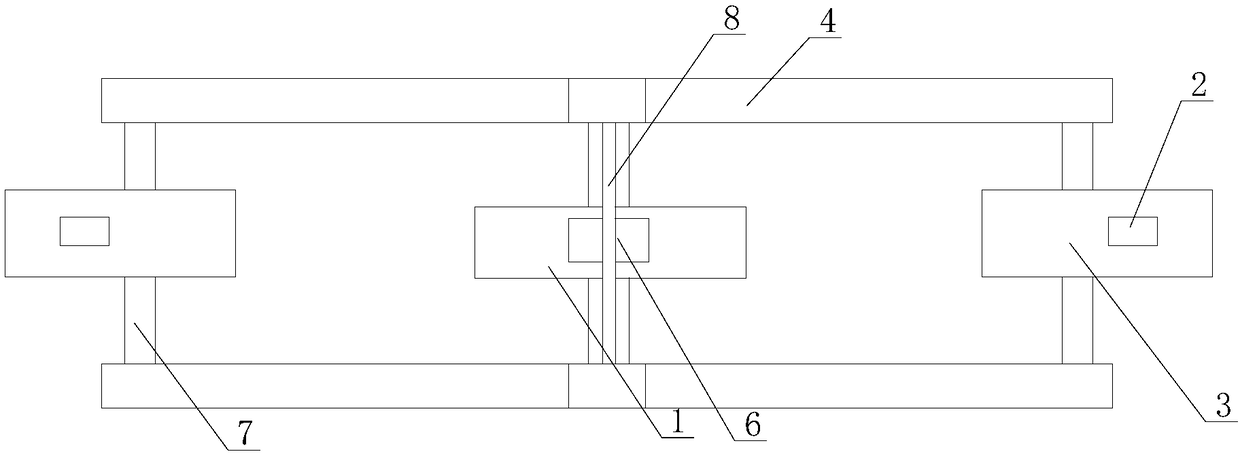

Ground empty drum knocking device for engineering technology detection

InactiveCN109521091AAvoid damageGuaranteed accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesDrive wheelArchitectural engineering

The invention discloses a ground empty drum knocking device for engineering technology detection. The ground empty drum knocking device comprises a supporting plate, a driving motor, a worm, a knocking hammer and a rotary disc, wherein the two sides of the bottom of the front of the supporting plate are respectively and rotatably connected to driven wheels; the two sides of the bottom of the backof the supporting plate are respectively and rotatably connected to driving wheels; a driving motor is fixedly arranged on the top of the back of the supporting plate; the output end of the driving motor is rotatably connected to the worm; a bearing at the end of the worm is rotatably connected to a bracket; the top of the front of the worm is meshed with a first worm wheel; the first worm wheel is rotatably connected to the upper end of a holder; the upper end of the bracket is rotatably connected to a residual gear; the residual gear is connected to the first worm wheel through a synchronousbelt I, partially has teeth and partially has no teeth; a part of the residual gear with the teeth is meshed with a rack plate; the rack plate is fixed to the side surface of an expansion link; the expansion link is a square link; a square sleeve for passing of the expansion link is fixed to the surface of the supporting plate; the knocking hammer is fixedly connected to the lower end of the expansion link; a sleeve is nested on the upper part of the expansion link; a spring is fixed inside the sleeve; and the lower end of the spring is fixed to the upper end of the expansion link.

Owner:CHUZHOU HONGTU CONSTR CO LTD

Device and system for ultrasonic inspection

ActiveUS20140352439A1Facilitate communicationEasy to checkVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerCoupling system

Owner:BAKER HUGHES INC

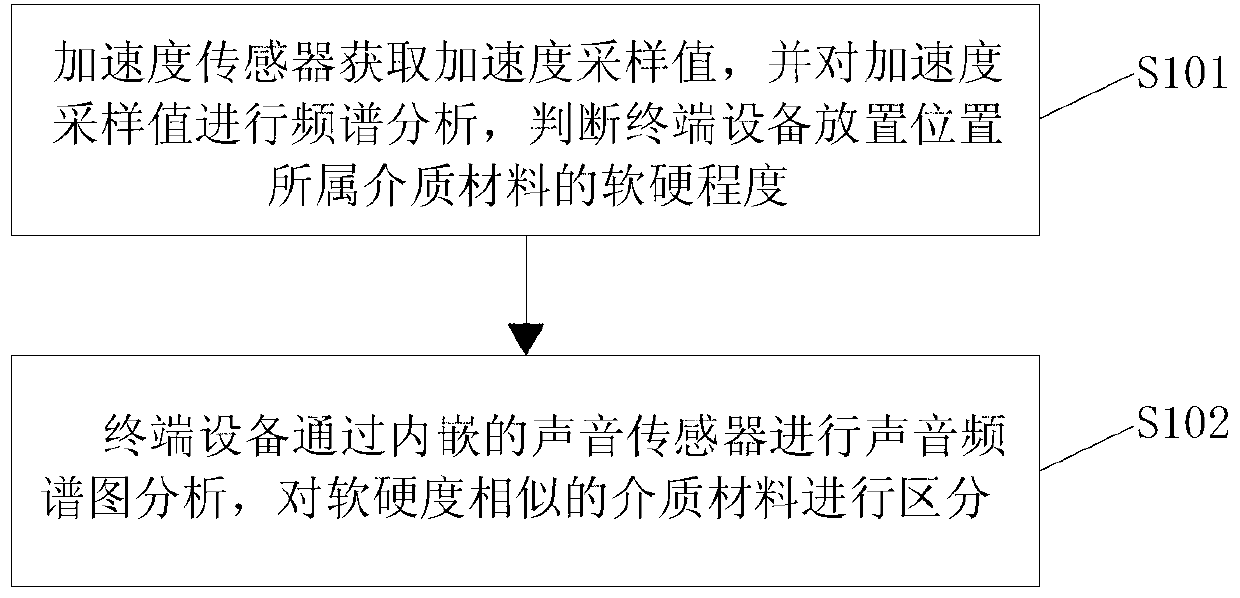

Method for detecting type of medium material of part for receiving terminal equipment

InactiveCN103344703ACalculation method is simpleStrong practical significanceAnalysing solids using sonic/ultrasonic/infrasonic wavesFrequency spectrumTerminal equipment

Owner:WUXI TSINGHUA NAT LAB FOR INFORMATIONSCI & TECH INTERNET OF THINGS TECH CENT

Method for detecting a perturbation by hysteretic cycle using a nonlinear electromechanical resonator and device using the method

A method is provided for detecting a perturbation with respect to an initial state, of a device comprising at least one resonant mechanical element exhibiting a physical parameter sensitive to a perturbation such that the said perturbation modifies the resonance frequency of the said resonant mechanical element. A device is provided for detecting a perturbation by hysteretic cycle comprising at least one electromechanical resonator with nonlinear behaviour and means for actuation and for detection of the reception signal via a transducer so as to analyse the response signal implementing the method. A mass sensor and a mass spectrometer using the device are also provided.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +3

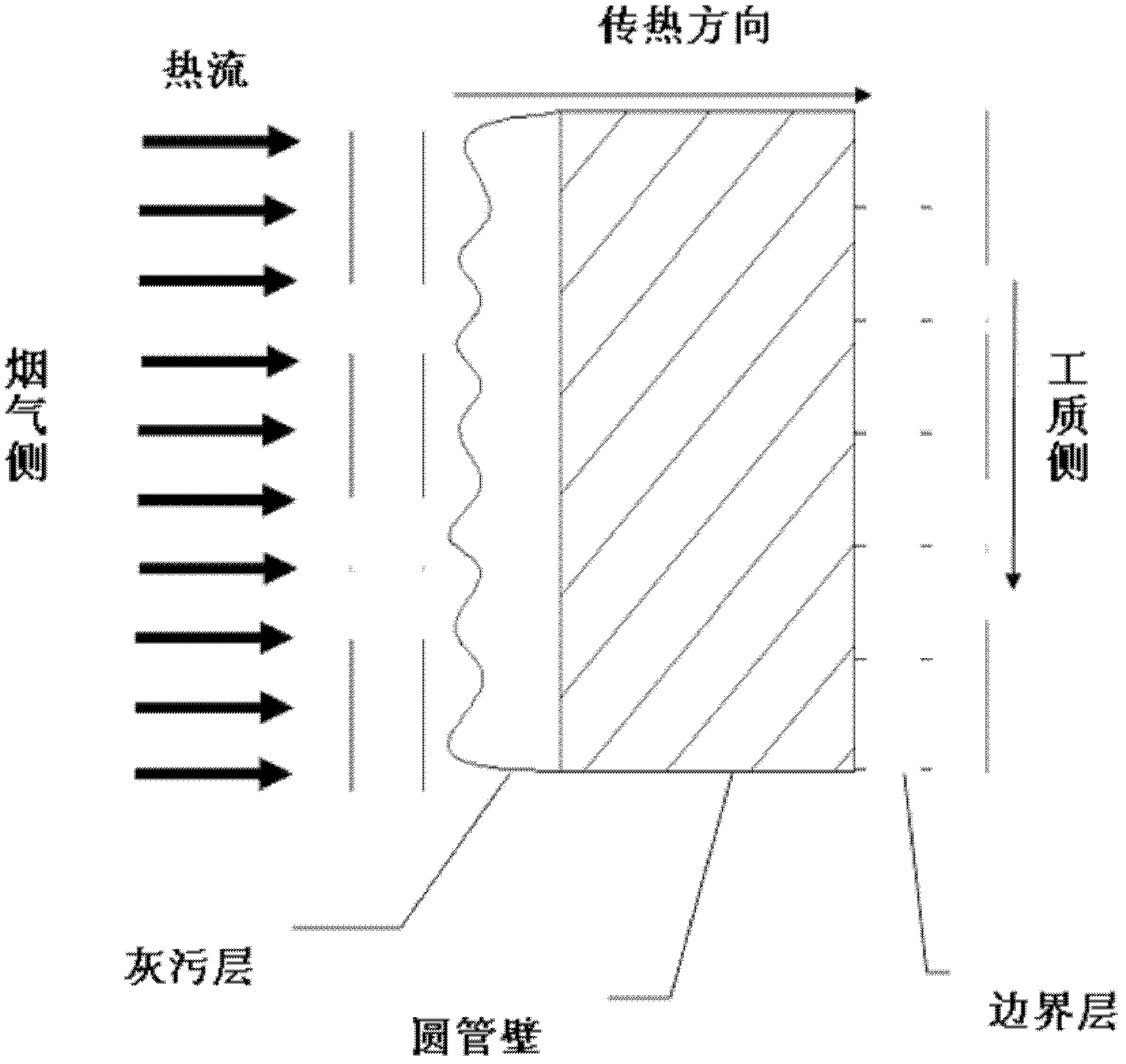

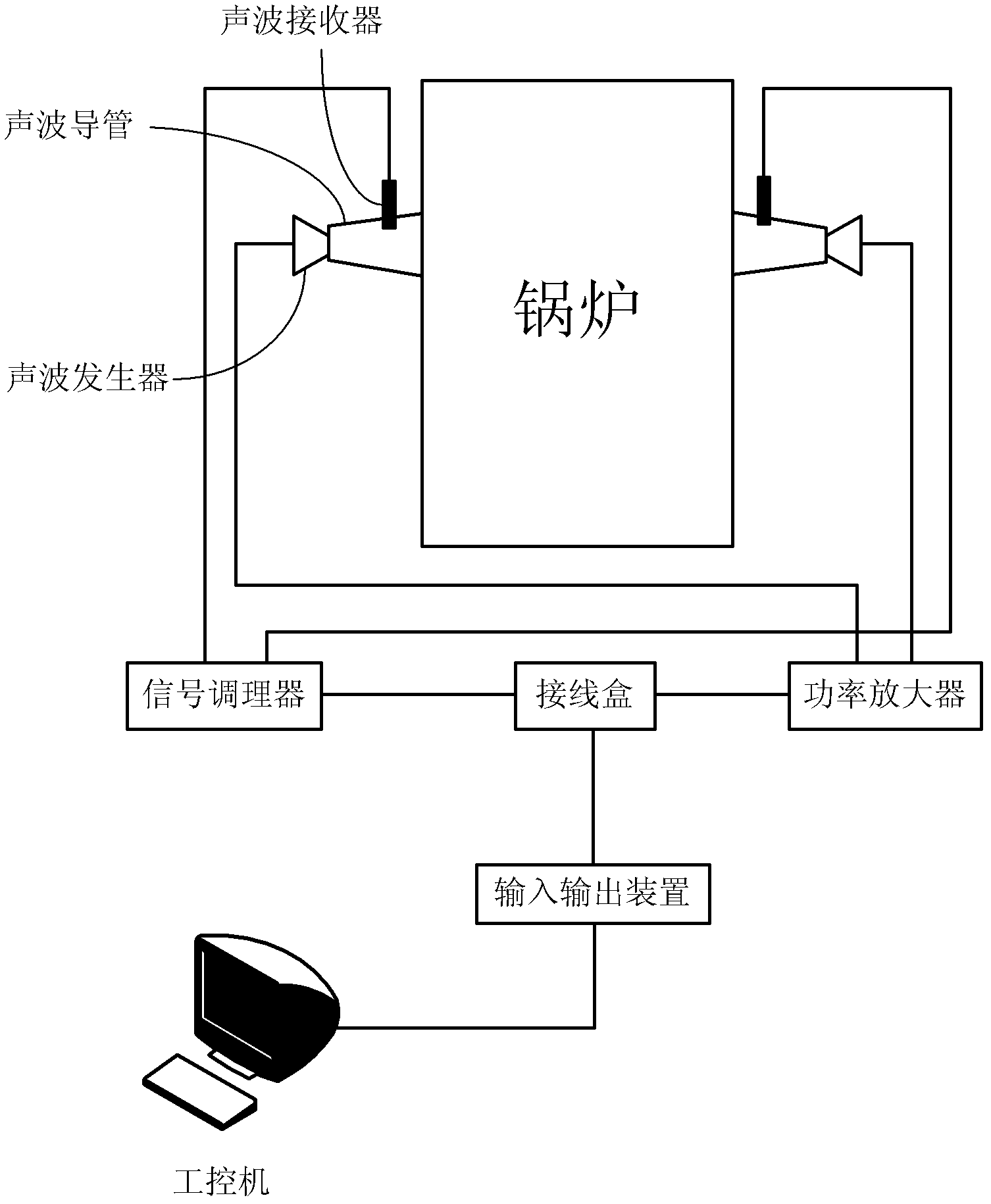

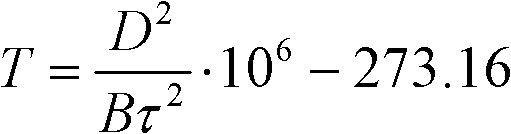

Method and device for monitoring ash dirt on convection heating surface of boiler

InactiveCN102353720AAvoid economic lossEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringHearth

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

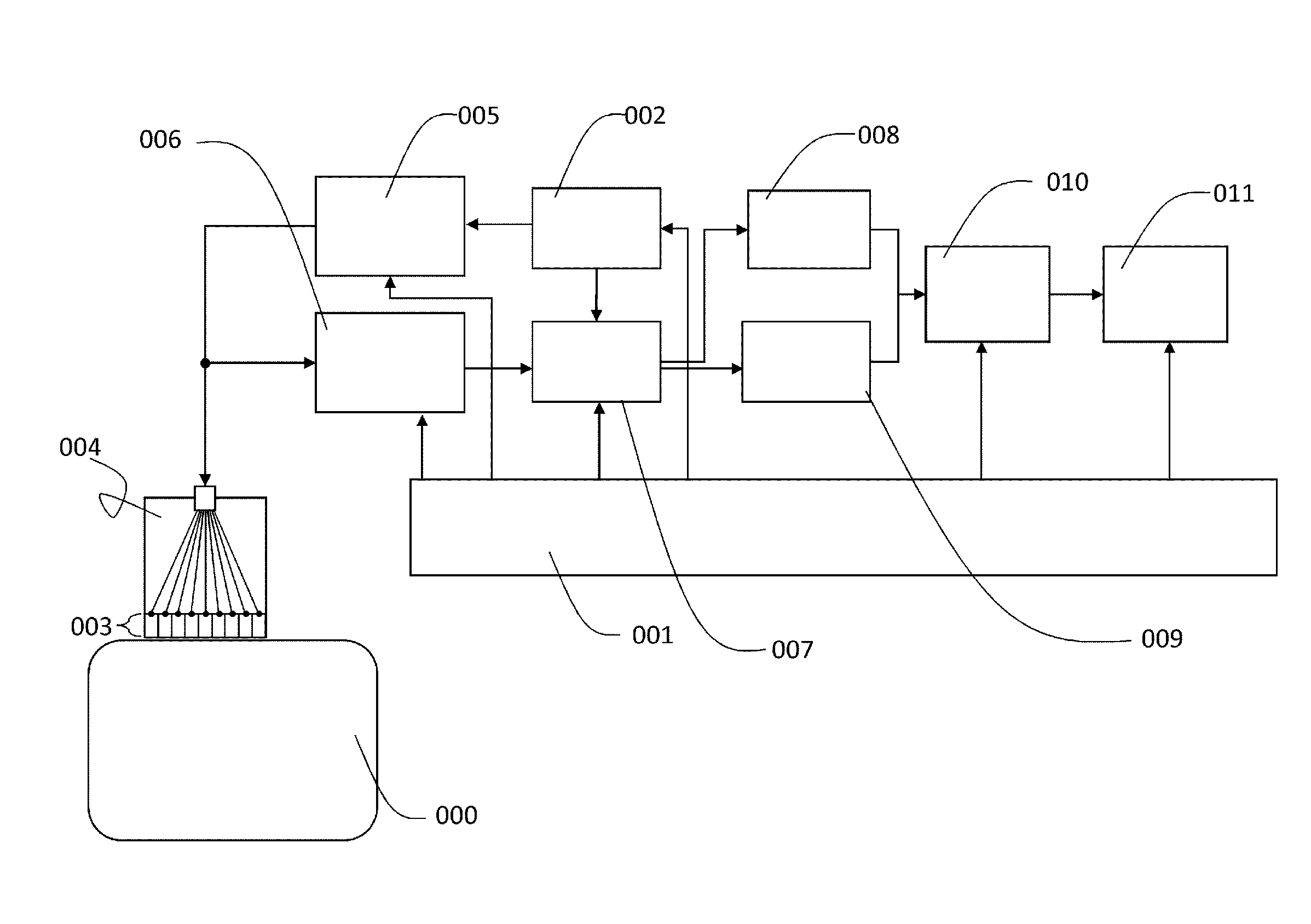

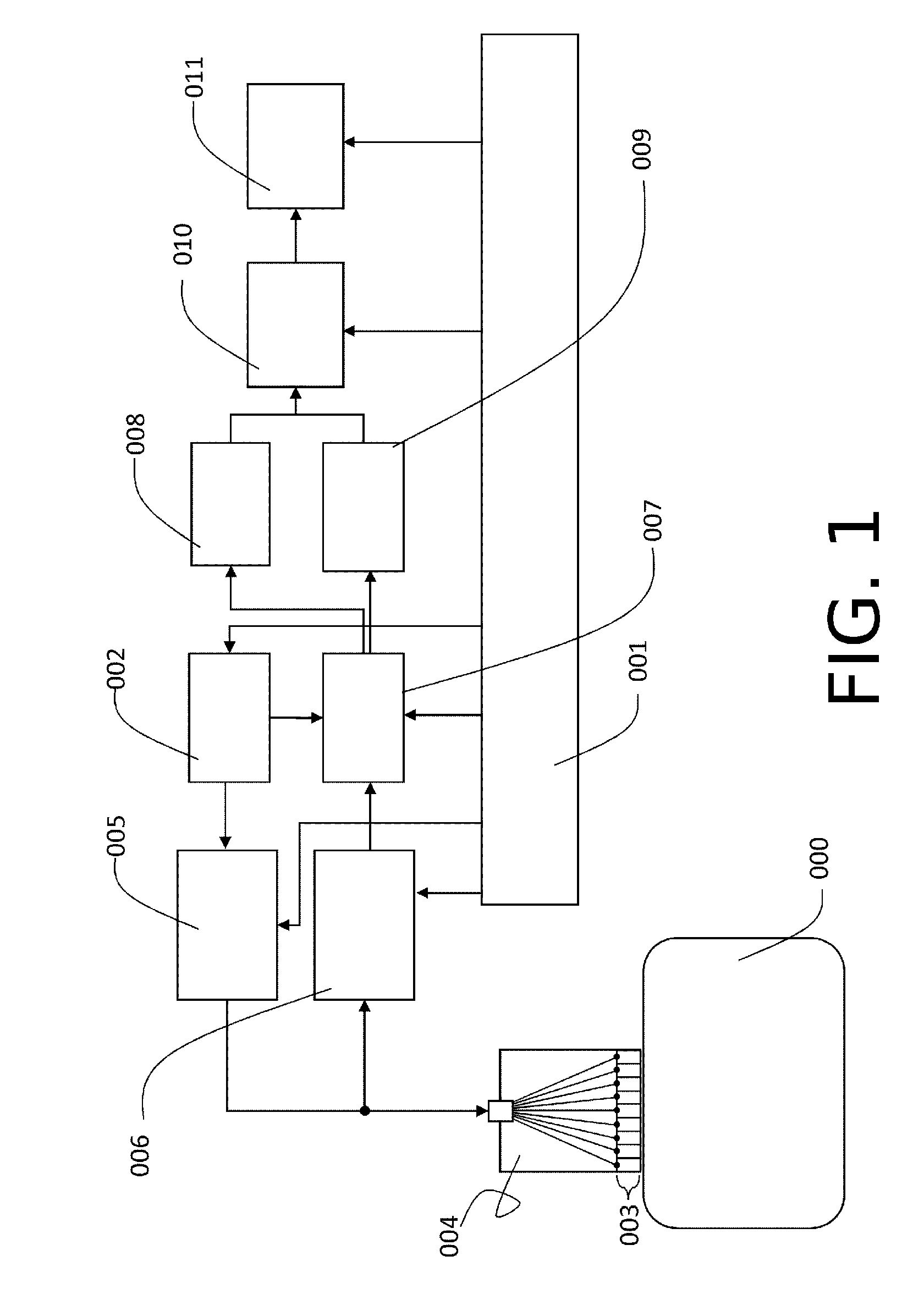

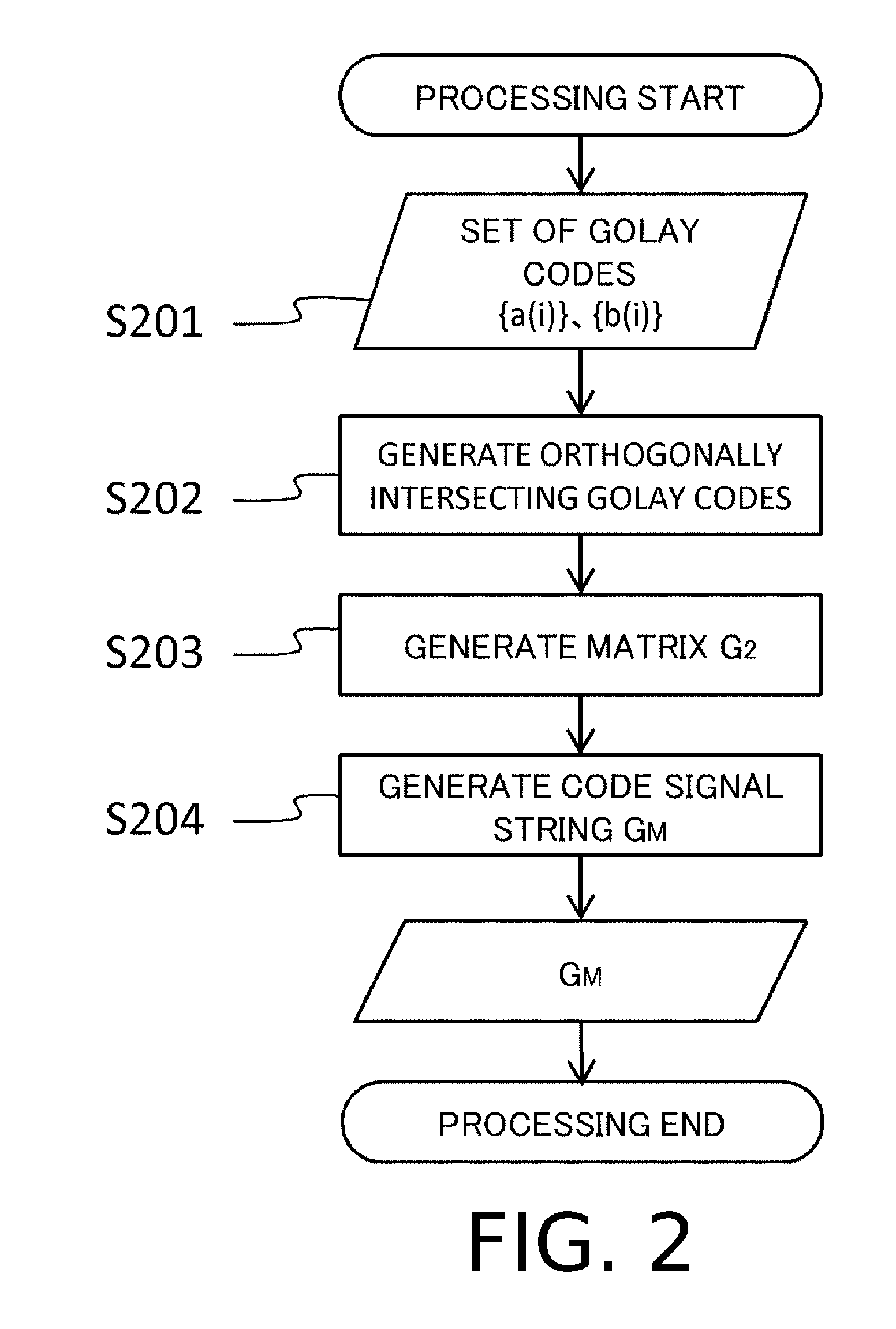

Object information acquiring apparatus

ActiveUS20140245836A1Improve accuracyUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesReflected wavesElectric signal

Disclosed is an apparatus that transmits an elastic wave to an object and receives a reflected wave, this apparatus including: a transmitting and receiving unit having elements for converting an elastic wave to an electric signal, and being arranged at least in one direction; an element controlling unit that inputs an electric signal to the element and causes the element to transmit an elastic wave; and a detecting unit that detects a reflected wave to be received by the element, wherein the electric signal to be inputted to the element is an encoded pulse signal encoded among the elements, and the detecting unit decodes the reflected wave and executes at different time points aperture synthesis processing of synthesizing the decoded reflected wave with respect to the intersections of two axes at different time points.

Owner:CANON KK

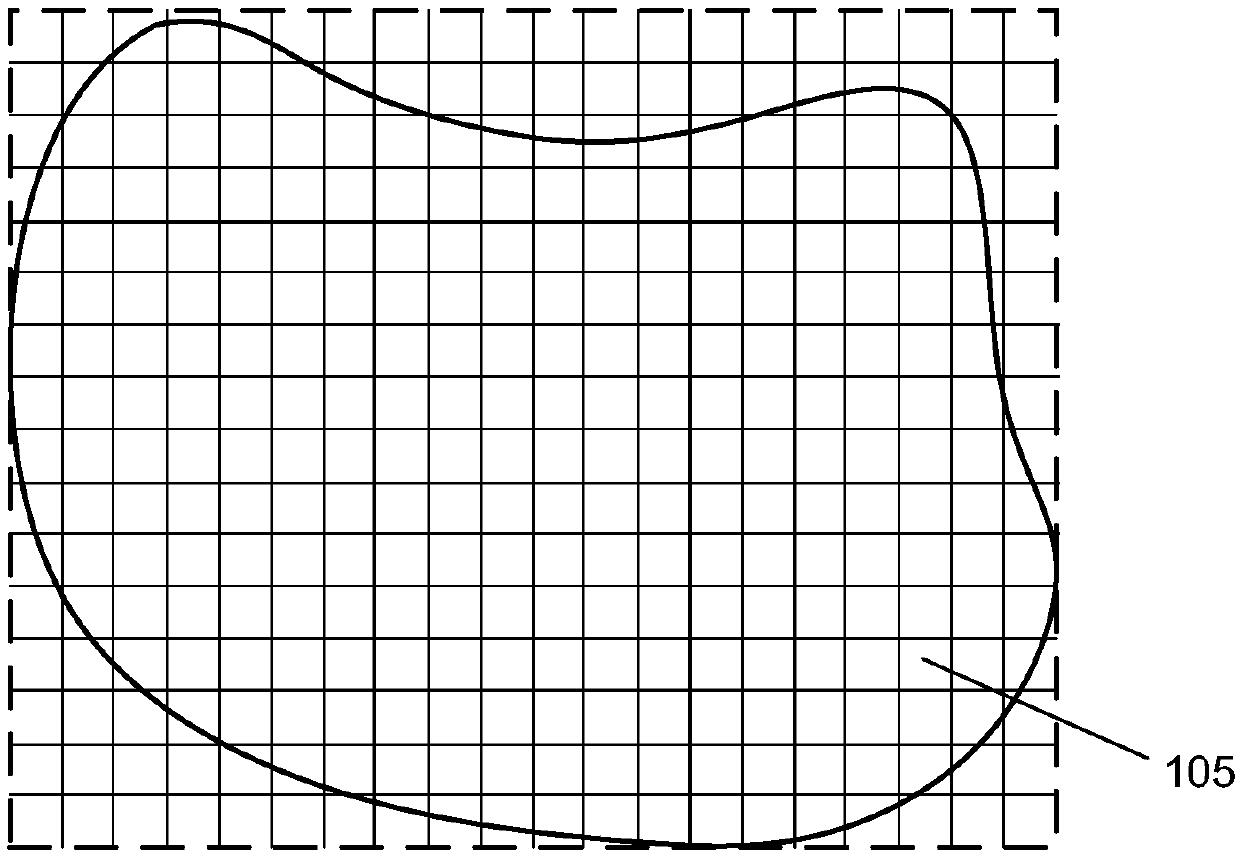

Non-contact Lamb wave defect detection imaging method of any scanning trace

InactiveCN109632962AAvoid corrosionPrevent rustAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalDiagnostic Radiology ModalityClassical mechanics

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Contact type rolling machine integrated compaction sound wave detection system and method

PendingCN113933394AReal-time calculation of compactionAccurate and effective detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesDisplay deviceData acquisition

A contact type rolling machine integrated compaction sound wave detection system comprises a sound emission sensor, an industrial personal computer, a data acquisition instrument, a GPS / BDS receiver and the like, when a filling layer is rolled, a sound wave field time domain signal formed near the rolling layer is received by the sound emission sensor vertically installed on a support directly connected with a vibration wheel, and a sound wave field digital signal is formed through sampling; meanwhile, the GPS / BDS receiver provides a space signal related to a rolling position, filtering and spectral analysis are carried out on the sampled sound wave signal, an effective sound signal harmonic amplitude is obtained, a contact type sound compaction index is established according to the correlation between the amplitude ratio and the compaction degree of the filling material, and a space-time compactness distribution diagram of a rolling area is displayed on an airborne display in combination with GPS space position information. The system has the advantages of being accurate, continuous, real-time, small in discreteness, low in cost and the like and is suitable for continuous compaction quality control of filling materials, and the intelligent continuous compaction function can be easily achieved by controlling operation parameters of the rolling machine through compaction degree feedback.

Owner:UNIV OF SCI & TECH BEIJING +2

Method for determining service life and reliability of high-temperature high-pressure component by utilizing ultrasonic

InactiveCN101509898ADetermine service lifeAnalysing solids using sonic/ultrasonic/infrasonic wavesProperty distributionState parameter

The invention discloses a method used for obtaining the service life and the reliability of a high-temperature high-pressure component by utilizing ultrasonic, belonging to the technical field of high-temperature component service life prediction. The method is characterized by comprising the steps of obtaining the ultrasonic velocity V1 in the material to be detected by using an ultrasonic apparatus; according to the ultrasonic velocity V1, obtaining a material damage state parameter Dv, and further obtaining a mean value * of the deviation of high-temperature permanent properties of the damaged material; and according to * is equal to A plus f (P (tr, T)) minus log (Sigma), calculating the service life tr of the component under the set temperature t and the stress Sigma, wherein A is a permanence property distribution parameter and obtained by the following formula: R is equal to Phi (A / s), wherein R is the selected reliability, Phi (A / s) is a normal distribution function, and s is distribution variance. The invention has the beneficial effects that the method not only can determine the service life of the high-temperature high-pressure component under the set reliability, but also can be used for determining the service reliability of the high-temperature high-pressure component under the set temperature, stress and service time.

Owner:DALIAN UNIV OF TECH

Maintenance system for gear flaw detection

ActiveCN110514737AMake sure to meshReliable design basisAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesElectric machineThreaded rod

The invention discloses a maintenance system for gear flaw detection. The system comprises a base, a case and a flaw detector, the case is fixedly mounted at the upper end of the base, a PLC is fixedly mounted on one side of the outer wall of the base, a box door is hinged to one side of the outer wall of the machine box, a first motor and two bearing seats are fixedly installed in one side of thebottom end in the machine box, a threaded rod is rotatably installed between the two sets of bearing seats, a threaded sliding seat is installed on the outer portion of the threaded rod in a threadedmode, and a supporting rod is fixedly installed at the upper end of the threaded sliding seat through a containing and carrying plate. According to the invention, a driving gear is installed, staticnondestructive flaw detection operation can be carried out on the gear, hidden structural dangers existing in gear production and machining can be found in time, structural flaw detection operation can be carried out on the gear under the dynamic operation condition, and therefore the stress and deformation conditions of the gear structure under the operation state can be mastered, and the detection effect is effectively improved.

Owner:BEIJING MAGNETIC FLUX EQUIP MFG

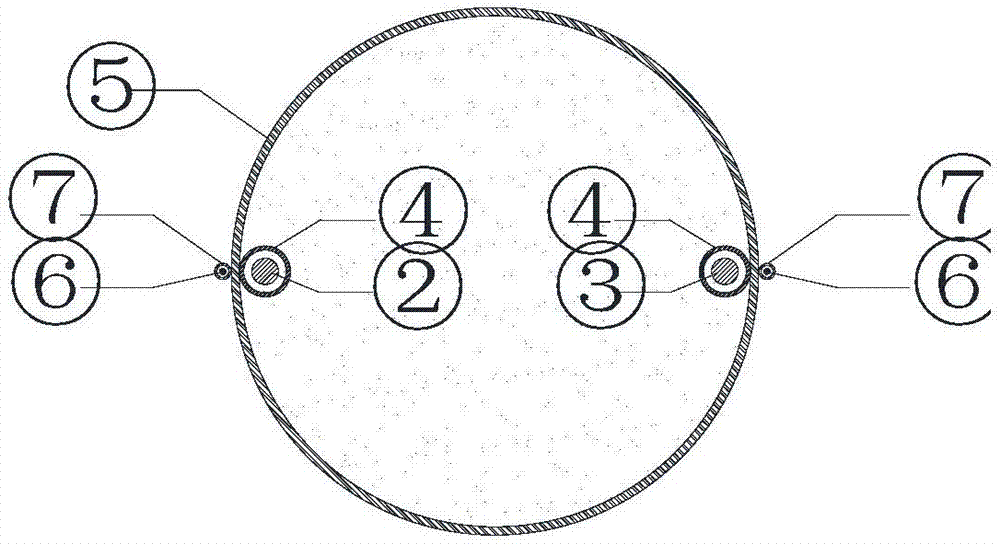

Rebar corrosion monitoring sensor based on acoustic surface wave

Owner:ARMY ENG UNIV OF PLA

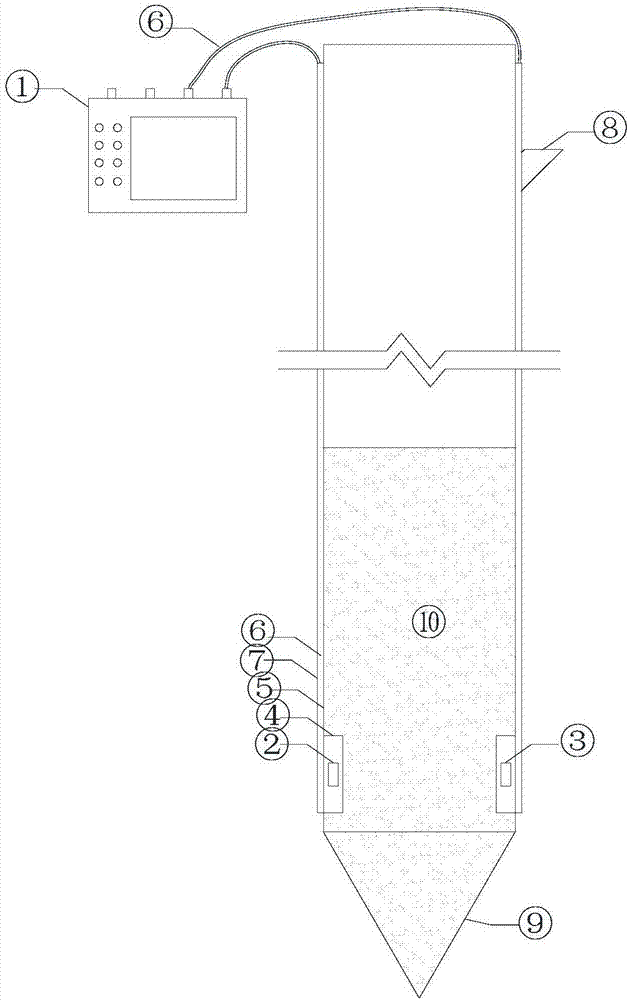

Supersonic wave monitoring system used for real-time control of sand pile quality and method thereof

PendingCN107884311AReal-time monitoring of sound velocityReal-time monitoring of real-time densityAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecific gravity measurementImmersed tubeSteel casing pipe

Owner:CHINA STATE CONSTR HARBOR CONSTR

IGBT module bonding wire fracture detection method based on ultrasonic reflection

InactiveCN112505146ALow costHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalData acquisitionAcoustics

The invention discloses an IGBT module bonding wire fracture detection method based on ultrasonic reflection. The IGBT module bonding wire fracture detection method comprises the following steps of S1, building a data acquisition platform, S2, collecting ultrasonic reflection output signals of an IGBT module with the same specification as the target IGBT module under different bonding wire breakage conditions, and performing frequency domain transformation, S3, according to the collected signal data, establishing a database of the relationship between the target IGBT module bonding wire fracture number and the ultrasonic reflection output frequency domain signal, and S4, acquiring an ultrasonic reflection output signal of the target IGBT, comparing the ultrasonic reflection output signal in the established database, and judging the number of broken bonding wires of the IGBT. Ultrasonic reflection is adopted to detect the bonding wire fracture condition of the IGBT module. Compared withother existing detection methods, ultrasonic reflection is used for detecting the bonding wire breakage condition of the IGBT module, and the method has the advantages that the cost is low, the precision is high, and the detection process does not depend on the working point of the IGBT.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

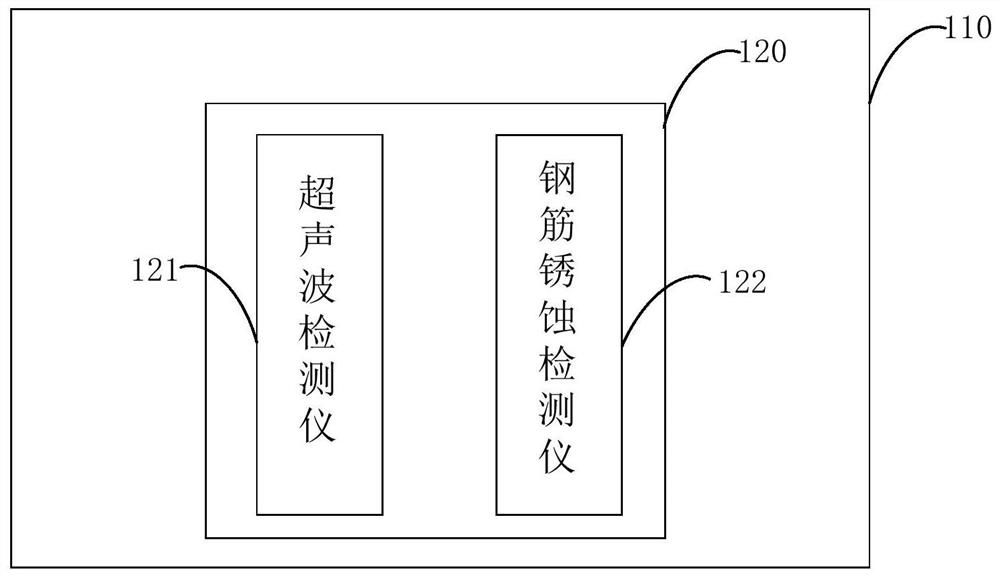

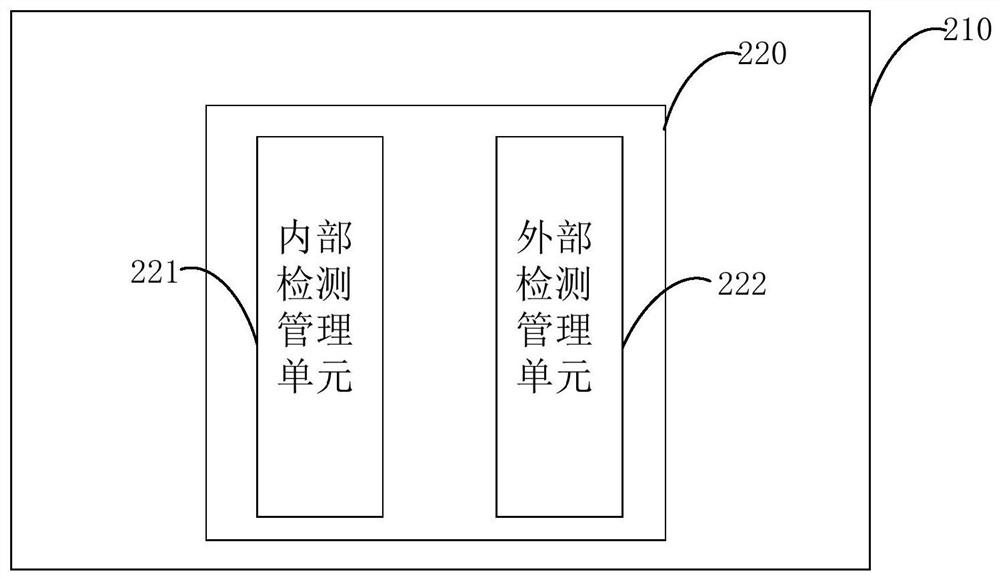

Bridge detection system

PendingCN112540120AAnalysing solids using sonic/ultrasonic/infrasonic wavesElasticity measurementClimbing robotsWall climbing

Owner:CRCC HIGH TECH EQUIP CORP LTD

Frequency adaptive ultrasonic fatigue tester

Owner:SOUTHWEST PETROLEUM UNIV

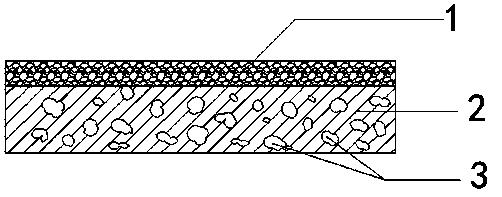

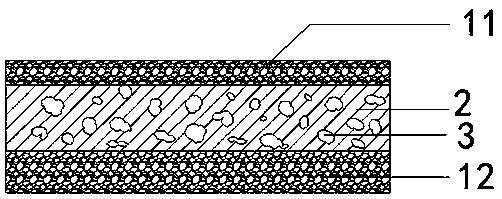

Composite board

PendingCN111572125AAnalysing solids using sonic/ultrasonic/infrasonic wavesWater-setting substance layered productArchitectural engineeringStructural engineering

Owner:广东金绿能科技有限公司 +1

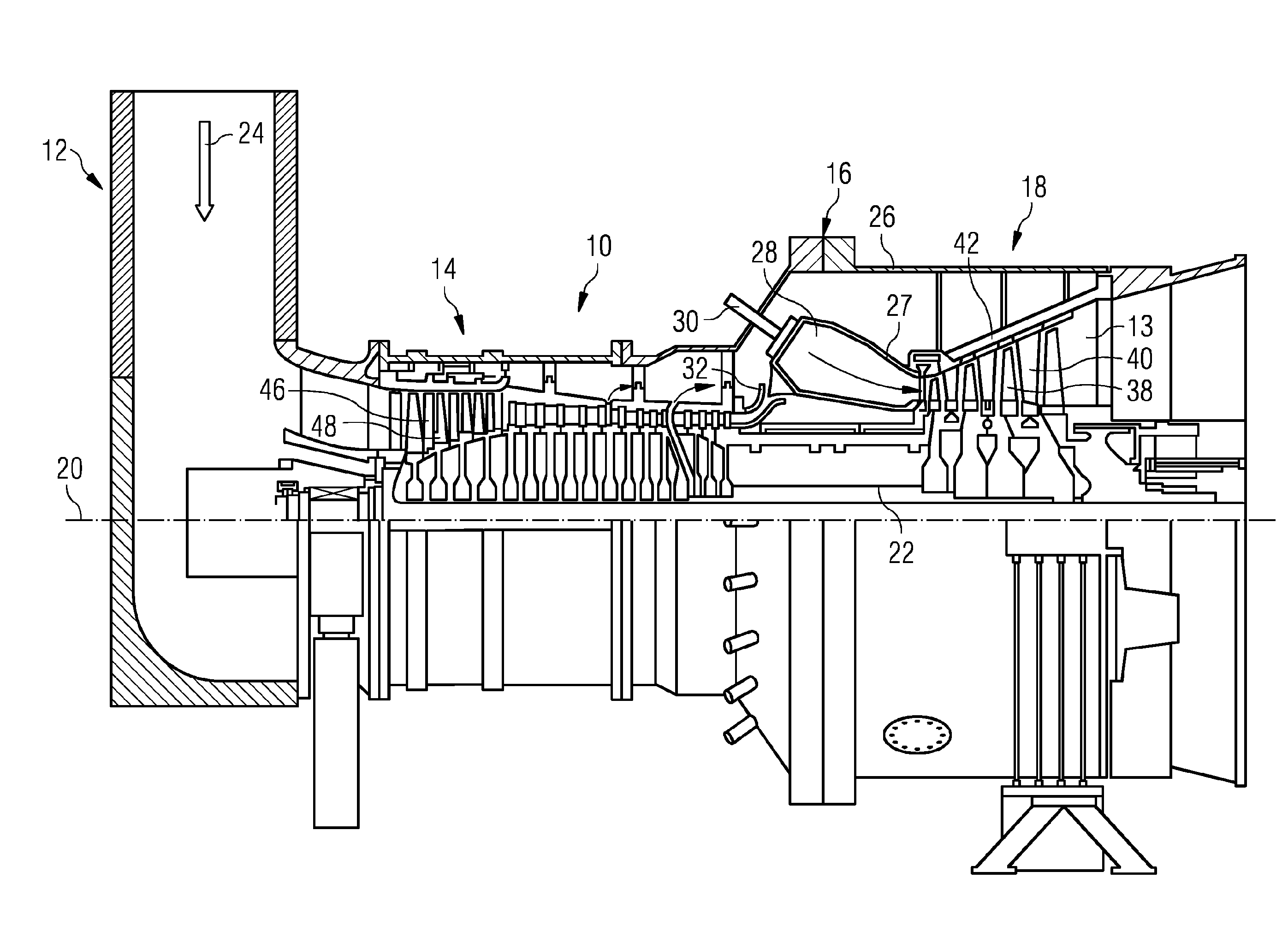

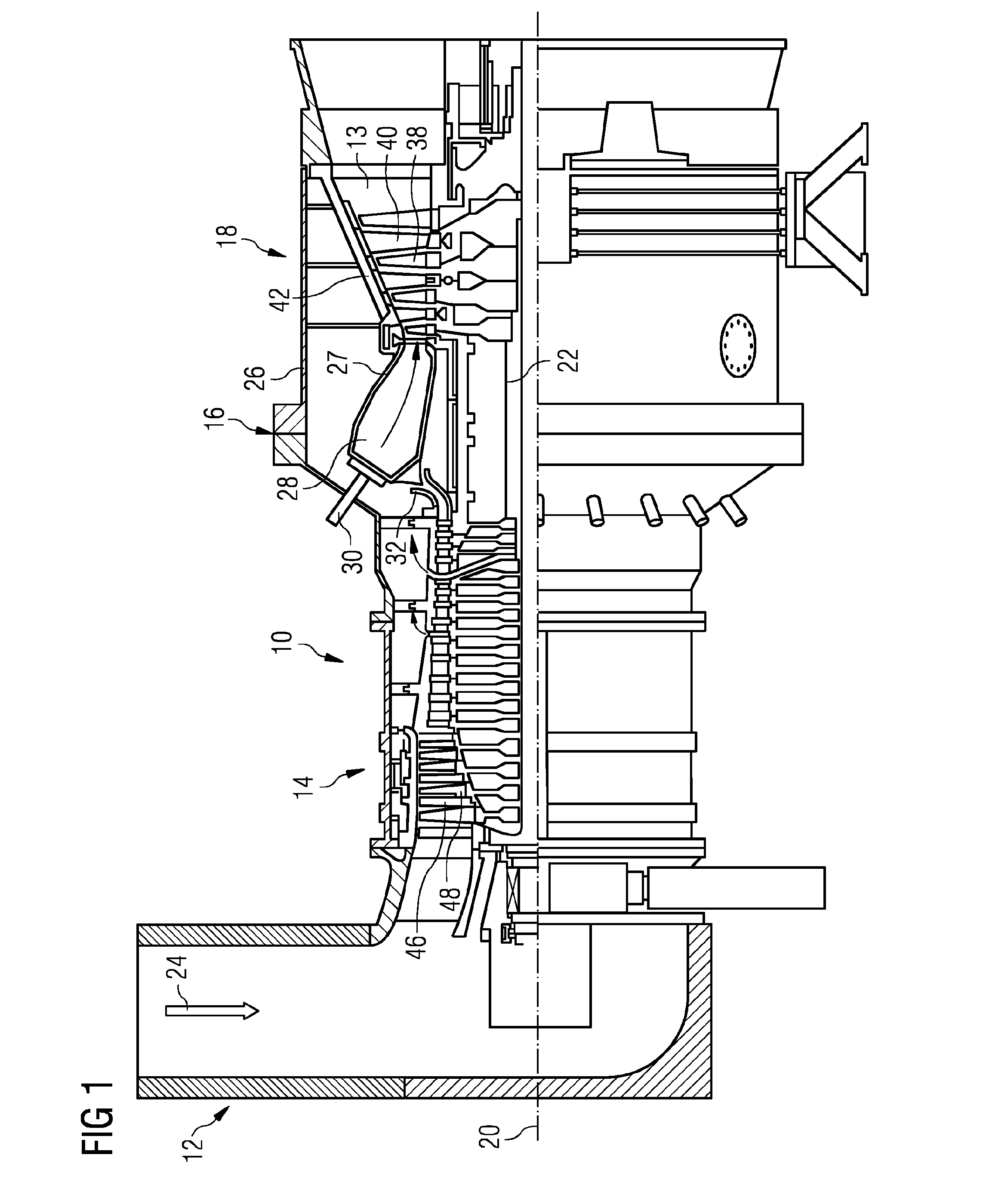

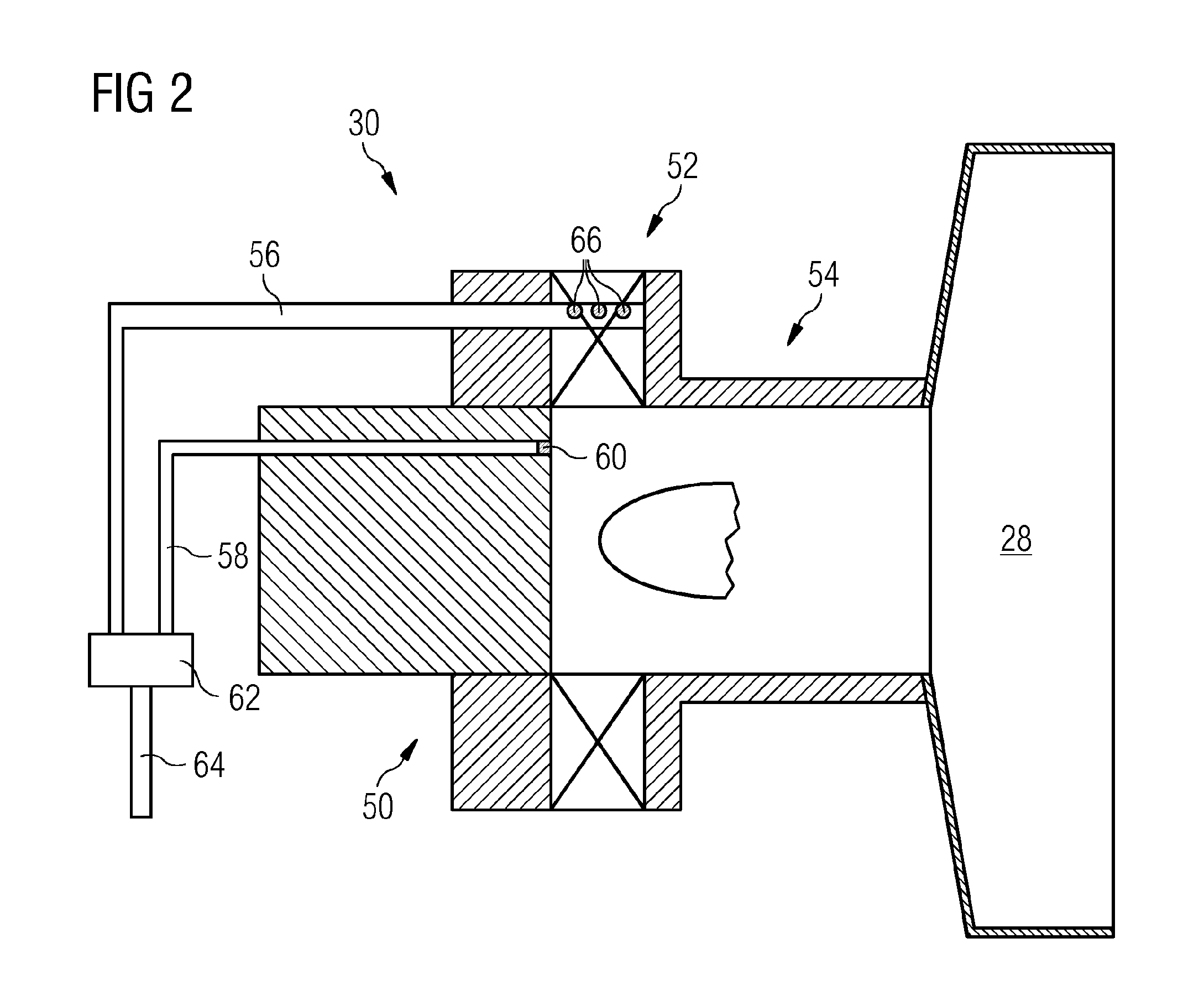

Method for monitoring a combustor

InactiveUS20170009598A1BurnersAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringCombustor

Owner:SIEMENS AG

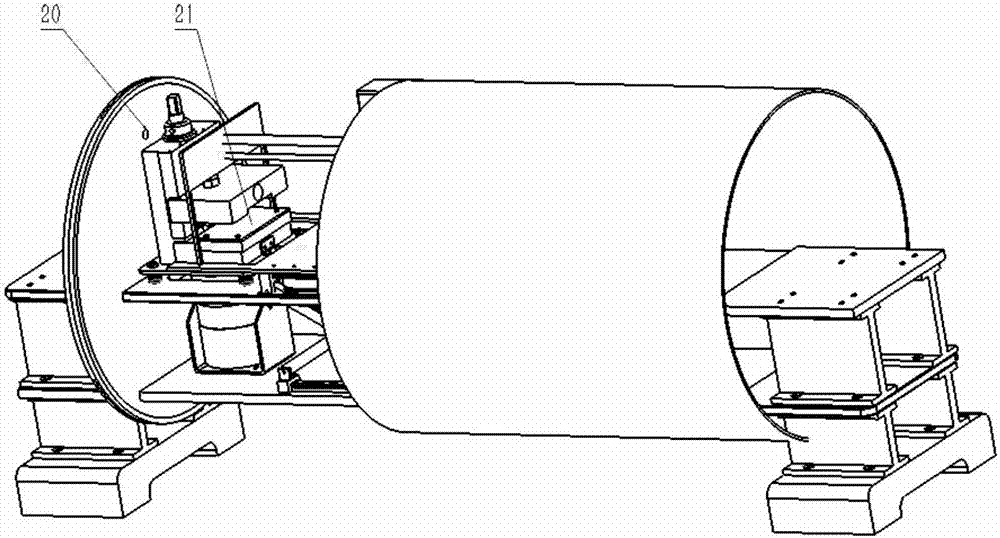

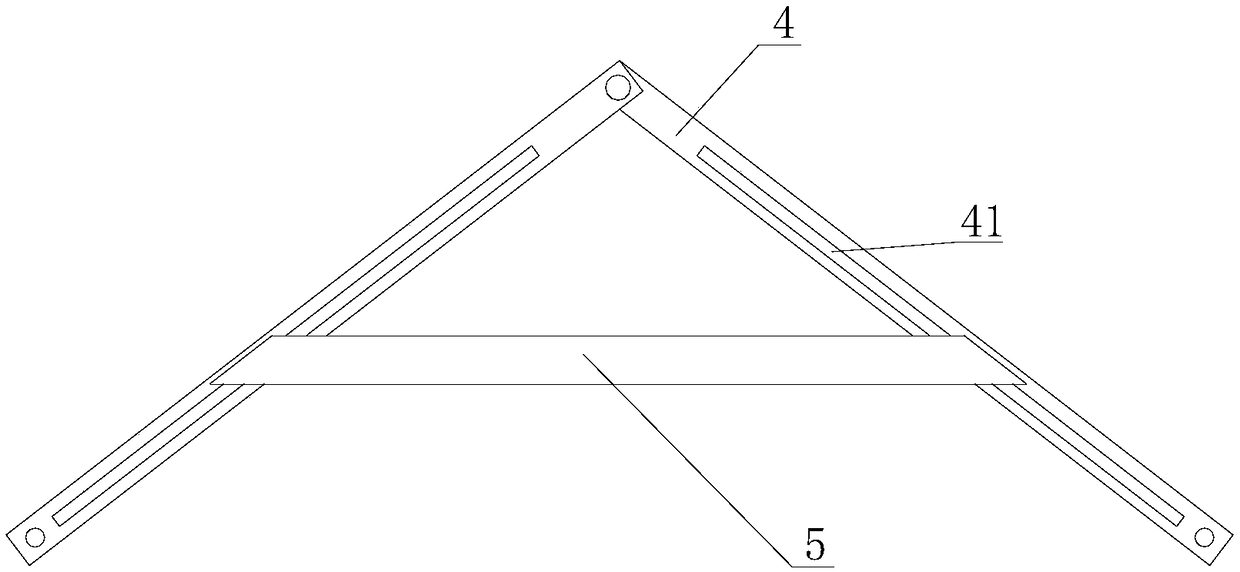

Manual ultrasonic detection device for large pipe diameter

InactiveCN108226285ARealize full-section non-destructive testingQuick scanAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasoundData lines

The invention discloses a manual ultrasonic detection device for large pipe diameters. The manual ultrasonic detection device comprises an ultrasonic phase control array detector, a creeping wave probe and a mounting rack, wherein the creeping wave probe is mounted on a creeping wave probe wedged block; the ultrasonic probe of the ultrasonic phase control array detector is mounted on an ultrasonicprobe wedged block; the ultrasonic phase control array detector is connected with the creeping wave probe and the ultrasonic probe through data wires; the mounting rack consists of a limiting rod andtwo pressing rods; one ends of the two pressing rods are hinged together; the other ends of the pressing rods are respectively hinged to the creeping wave probe wedged block; the ultrasonic phase probe wedged block is fixed on the limiting rod; and the limiting rod is arranged between the two pressing rods in a sliding manner. The manual ultrasonic detection device for large pipe diameters, whichis disclosed by the invention, is simple in structure, simple to operate and high in detection rate.

Owner:XIANGTAN HONGYUAN ELECTRONICS SCI & TECH CO LTD

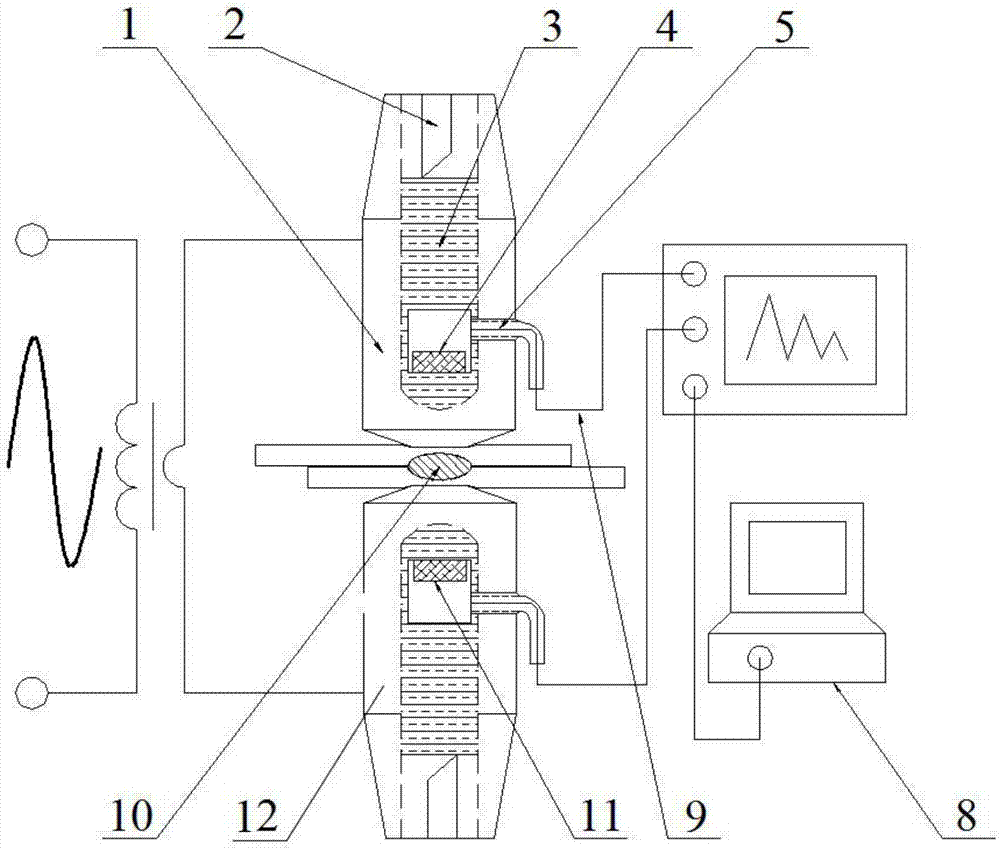

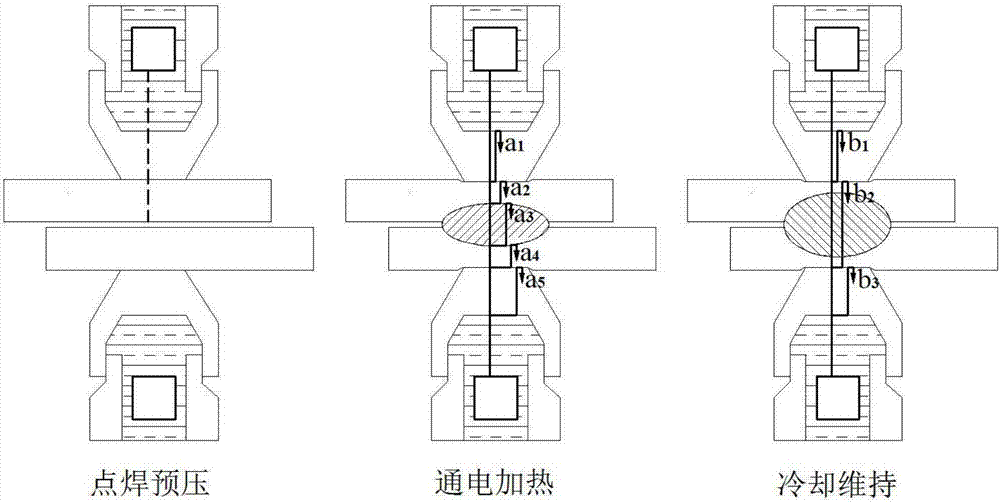

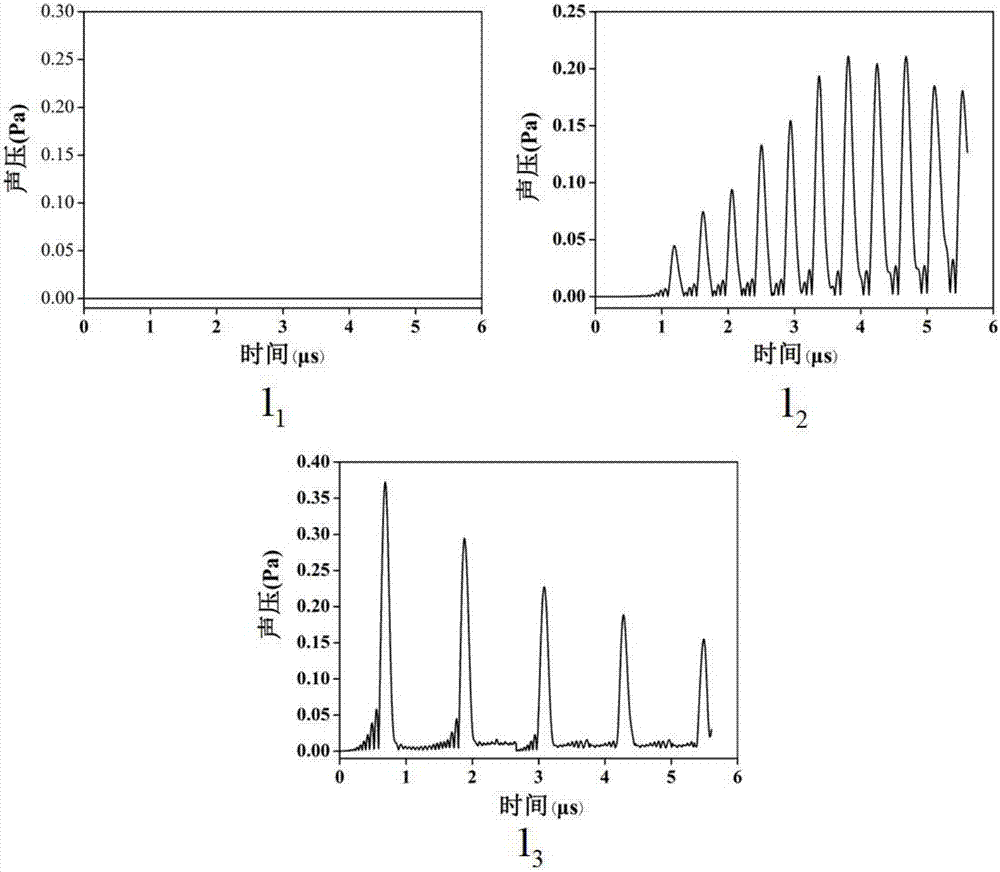

Device and method for detecting spot welding quality in real time through ultrasonic penetration signal

InactiveCN107478720AAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasonic transmission

Owner:WUHAN UNIV OF TECH

Vehicle sound absorption and insulation performance tester

InactiveCN109425491AVehicle testingAnalysing solids using sonic/ultrasonic/infrasonic wavesData acquisitionEngineering

The invention relates to a vehicle sound absorption and insulation performance tester which comprises a data processor and first and second data collectors. The first data collector is mounted in an engine during use, the second data collector is mounted in a compartment during use, both the first and second data collectors are in communication connection with the data processor, and each data collector comprises a sound pressure measuring probe. The tester can measure the sound insulation effect of the whole vehicle, can move with the vehicle, and measures sound absorption and insulation performances of the vehicles in different conditions of practical operation, and a measurement result can be used to reflect the practical sound insulation effect of the vehicle more.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Lightweight high-density pavement performance detection method

ActiveCN112834625AEasy to testAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using single impulsive forceHigh densityAir pump

The invention discloses a lightweight high-density road surface performance detection method. The method comprises the steps: installing a road surface detector in a to-be-detected area, starting a telescopic device of the road surface detector, driving a knocking hammer to knock a to-be-detected road surface, acquiring and recording a knocking sound frequency by an audio collector, according to the received knocking sound frequency, starting a pressurizing pump to inject quantitative water into a pressurizing cylinder, reading and metering road surface water seepage time, and calculating a road surface water seepage coefficient; starting a high-pressure air pump to inflate pressure gas into the pressurizing cylinder, observing and detecting whether water leaks from the road surface or not within a time interval, recording the pressure of the pressure gas when water leaks, and judging whether the water seepage performance of the road surface is qualified or not; and judging whether the road surface compactness, the structural strength, the road surface water permeability coefficient and the road surface water permeability performance are qualified or not by testing the knocking frequency, the pressurized water permeability test and the pressurized gas permeability test. The road is not damaged in the test, and the test is convenient and rapid.

Owner:CHANGAN UNIV +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap