Device and system for ultrasonic inspection

a technology of ultrasonic inspection and probe devices, applied in the field of ultrasonic inspection, can solve the problems of limiting the size and/or scope of the actuating mechanism of the system, limiting the proper cabling and/or peripheral devices, and limiting the use of actuating mechanisms. the effect of signal communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

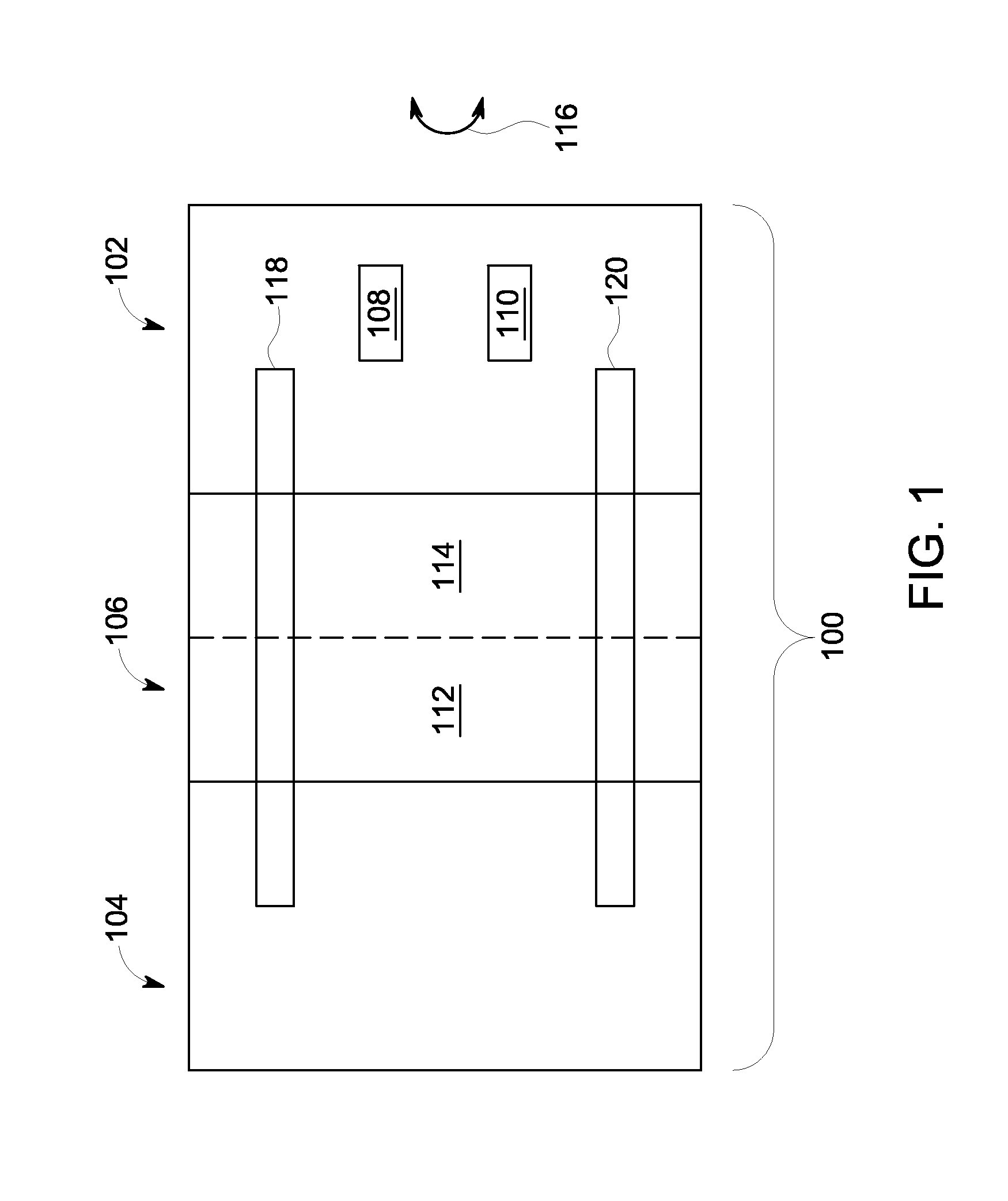

[0023]FIG. 1 illustrates a schematic diagram of an exemplary embodiment of a probe assembly 100 that can generate ultrasonic signals for use in non-destructive inspection. The probe assembly 100 includes a probe component 102, an interface component 104, and a rotary component 106, which couples the probe device 102 to the interface component 104. The probe component 102 includes one or more probe elements (e.g., a first probe element 108) and a probe control component 110 that can exchange signals (e.g., electrical signals) with the first probe element 108. The rotary component 106 has a stationary part 112 and a rotating part 114. Examples of the parts 112, 114 can actively rotate the probe device 100, as generally indicated by the enumerated arrow 116. The probe assembly 100 also has one or more operating components (e.g., a fluid component 118 and a signal component 120). The operating components 118, 120 conduct inputs and outputs (e.g., fluids, electrical signals, etc.) between t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap