Rebar corrosion monitoring sensor based on acoustic surface wave

A technology for monitoring sensors and surface acoustic wave devices, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. Low accuracy and other problems, to achieve the effect of enhancing environmental adaptability, high measurement accuracy, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

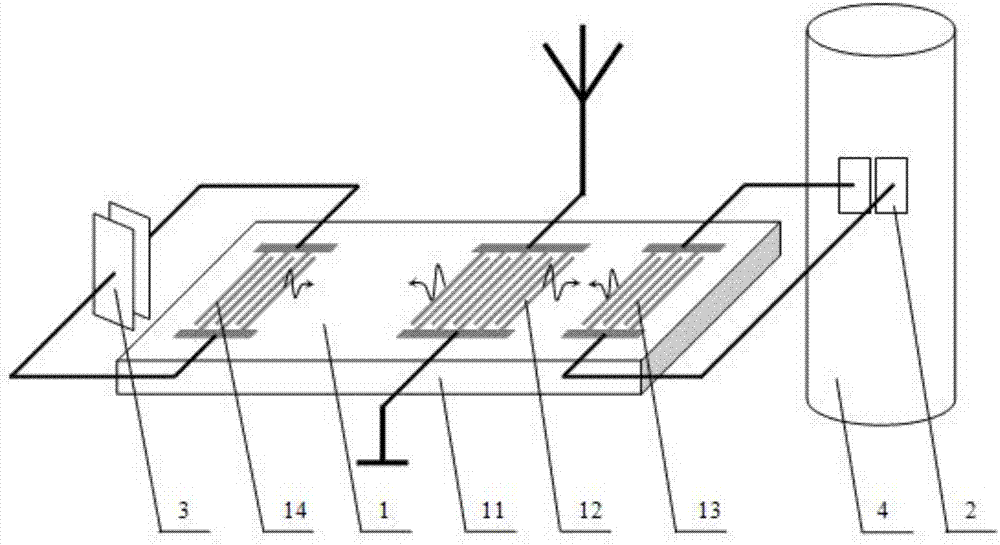

[0019] Such as figure 1 As shown, the steel bar corrosion monitoring sensor based on the surface acoustic wave of the present invention includes a surface acoustic wave device 1, a sensing electrode 2 and a reference electrode 3;

[0020] One end of the surface acoustic wave device 1 is electrically connected to the sensing electrode 2, and the other end is electrically connected to the reference electrode 3;

[0021] The sensing electrode 2 is arranged around the steel bar 4 to be tested, and the reference electrode 3 is arranged in the same environment as the steel bar 4 to be tested;

[0022] The sensing electrode 2 is used to sense the impedance change caused by the corrosion of the steel bar 4 to be measured;

[0023] The reference electrode 3 is used to sense the impedance change caused by the same environment as the steel bar 4 to be tested.

[0024] Preferably, the surface acoustic wave device 1 includes a piezoelectric substrate 11, a transducer 12 placed in the middle

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap