Pipe inspection system with selective image capture

a technology of image capture and inspection system, applied in the field of electrical and mechanical systems and methods, can solve problems such as disorientation of video images, and achieve the effect of improving communication and enhancing imaging capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

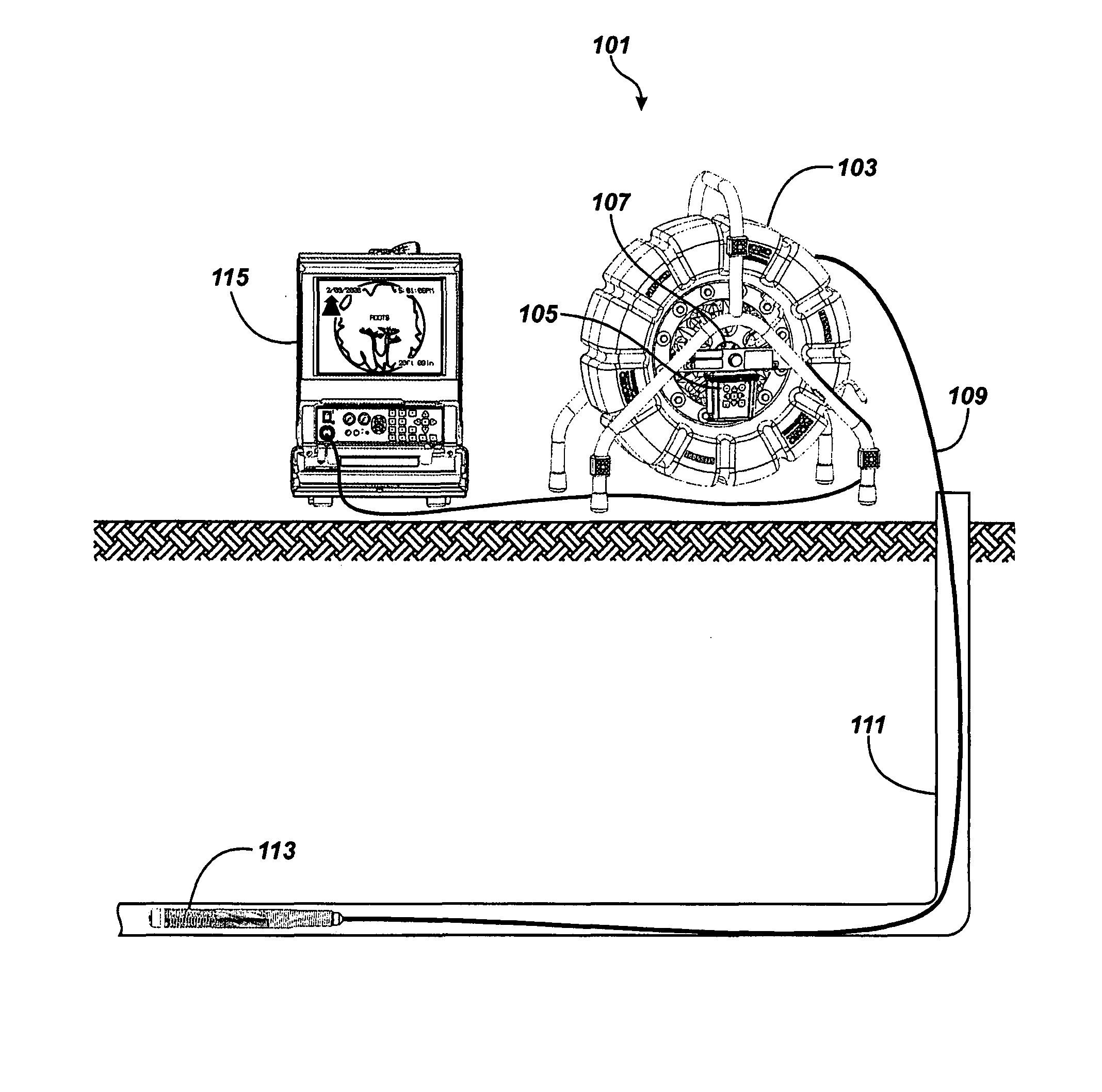

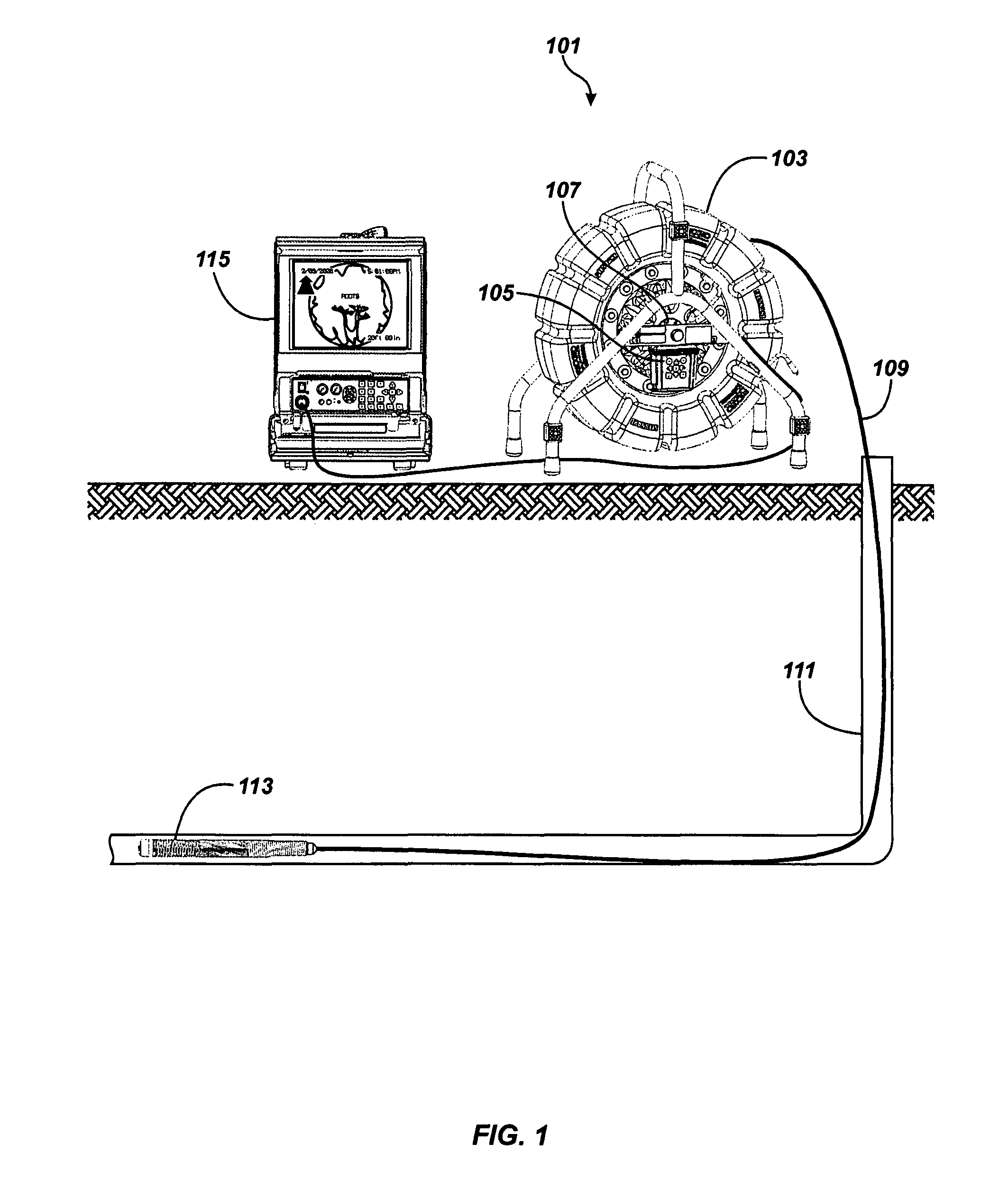

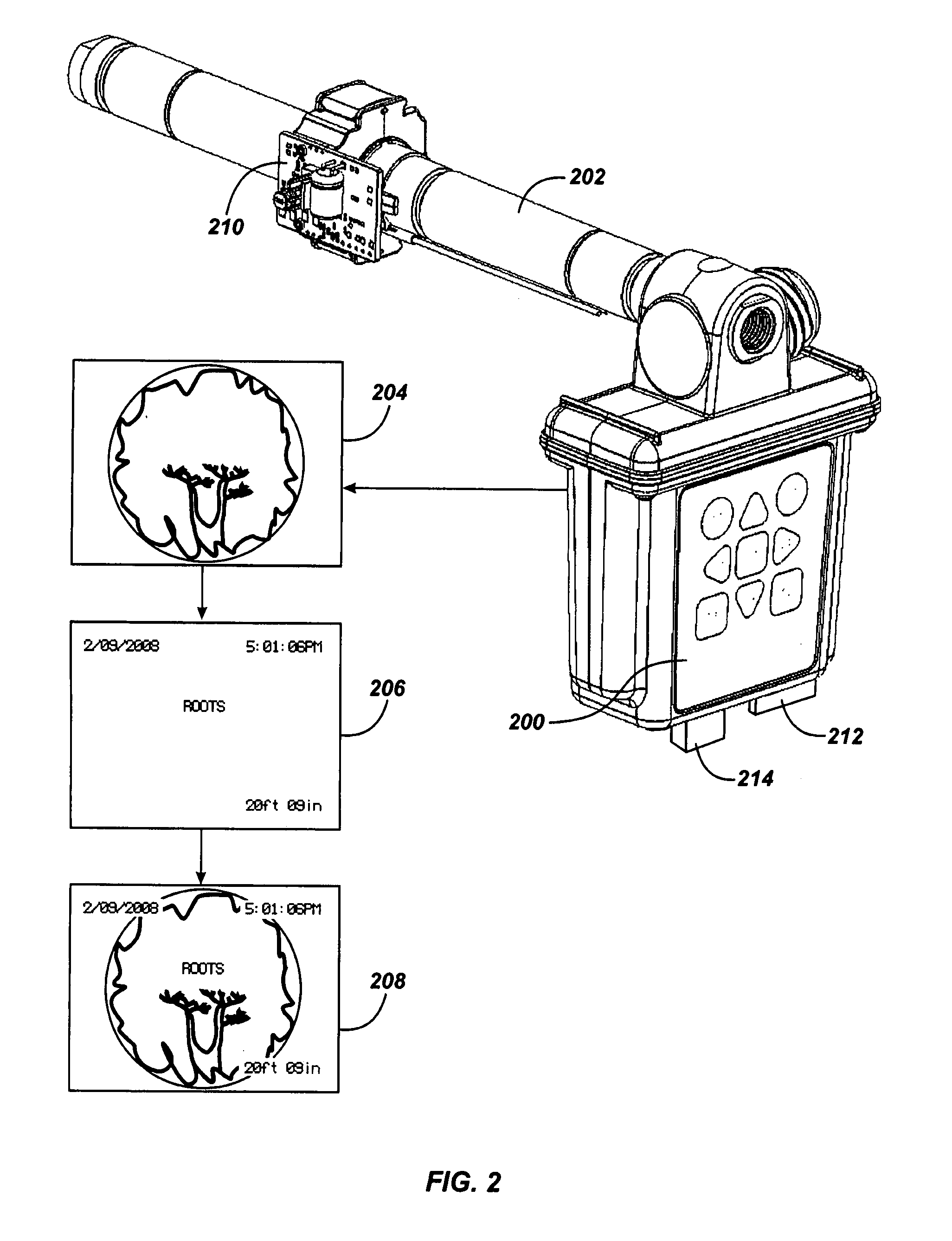

[0022]In one embodiment the present invention provides a pipe inspection system that automatically captures images at user-defined increments of distance traveled down the pipe, as well as display overlays. The overlays can indicate the current distance measurement and direction of travel (downward or upward) of the camera head in the pipe being inspected. It additionally provides advantages in managing images, adding comments and date stamps to images, and storing images to removable media at user discretion.

[0023]The present invention also provides a pipe inspection system that allows for storage of images in a readily removable portable storage device. The storage device can be used to transfer images showing their measured distance or location to a portable printer for immediate inclusion in an inspection debrief or report, using a conventional portable computer. Electronic transfer through wireless, USB cable, Fire-wire or other means may be used.

[0024]In another embodiment of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap