Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Galvanometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A galvanometer is an electromechanical instrument used for detecting and indicating an electric current. A galvanometer works as an actuator, by producing a rotary deflection (of a "pointer"), in response to electric current flowing through a coil in a constant magnetic field. Early galvanometers were not calibrated, but their later developments were used as measuring instruments, called ammeters, to measure the current flowing through an electric circuit.

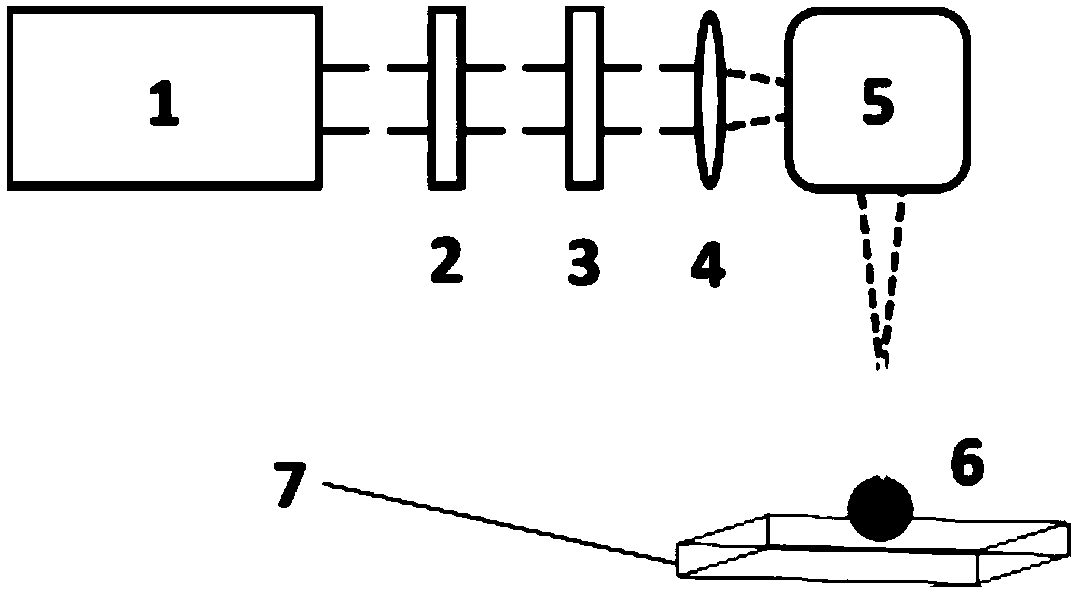

Sub-micron scale glass subsurface defect detection device and method

ActiveCN105842257AGuaranteed Quantitative MeasurementsGuaranteed stabilityMaterial analysis by optical meansMicron scaleGrating

The invention discloses a sub-micron scale glass subsurface defect detection device and method. A light source part of the device comprises a super-continuum luminous spectrum light source and a single-mode optical fiber circulator; a reference arm and sample arm part comprises a first collimating lens, a 45-degree cylindrical reflecting mirror, a reference objective, a reference reflecting mirror, a two-dimensional scanning galvanometer, a sample objective and a part to be detected; a detection arm part comprises a second collimating lens, a transmission grating, a focusing lens, a photoelectric detector and a computer. The method comprises the steps that light of a reference arm and light of a sample arm return back to the single-mode optical fiber circulator in the same way, light beams of the two arms encounter, and interference is caused; interfered light beams are subjected to light splitting through the transmission grating and then focused on different pixel elements of the photoelectric detector through the focusing lens, the photoelectric detector inputs collected signals into the computer, the signals are processed, and faultage images of different positions are obtained. According to the sub-micron scale glass subsurface defect detection device and method, the ultra-wide band light source, the high-power aperture imaging objectives and the common light path imaging structure are adopted, and the three-dimensional structure of sub-micron scale glass subsurface cracks is obtained.

Owner:NANJING UNIV OF SCI & TECH

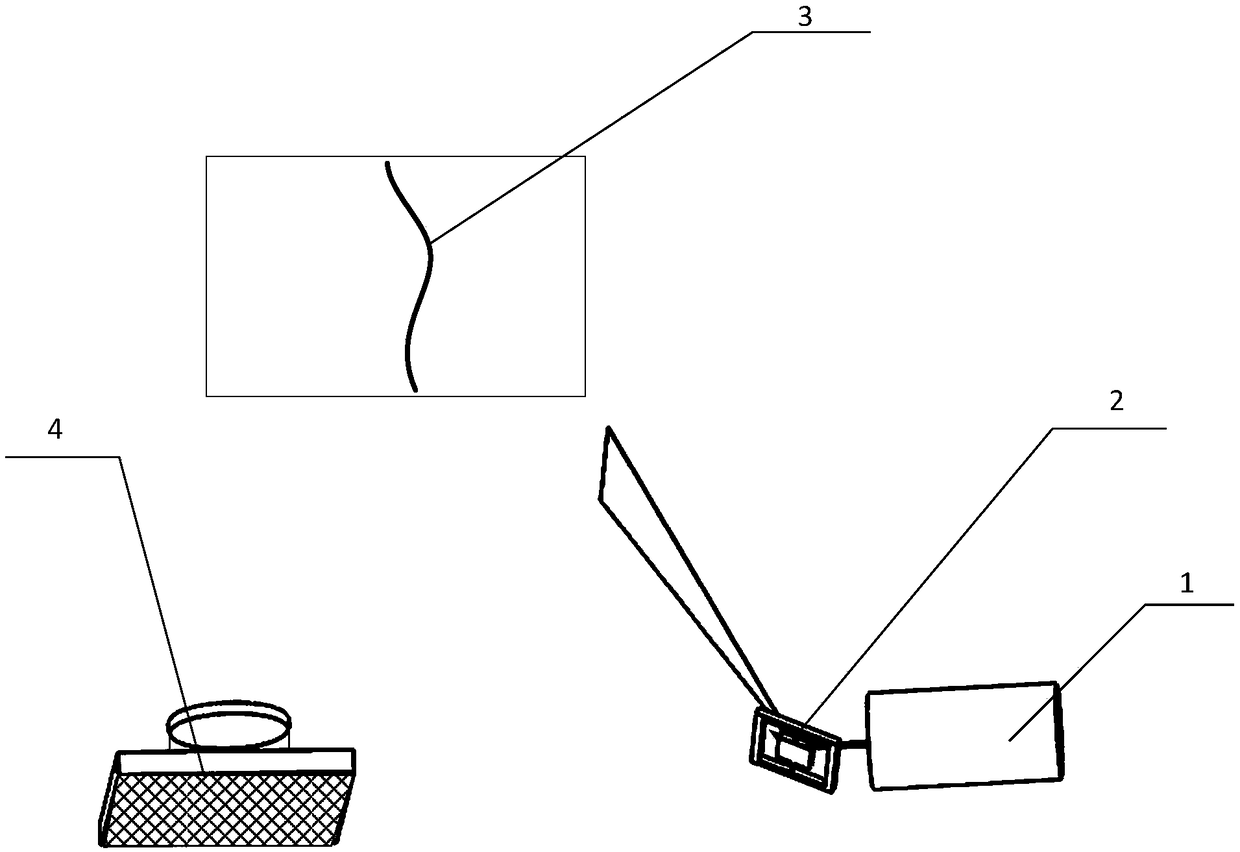

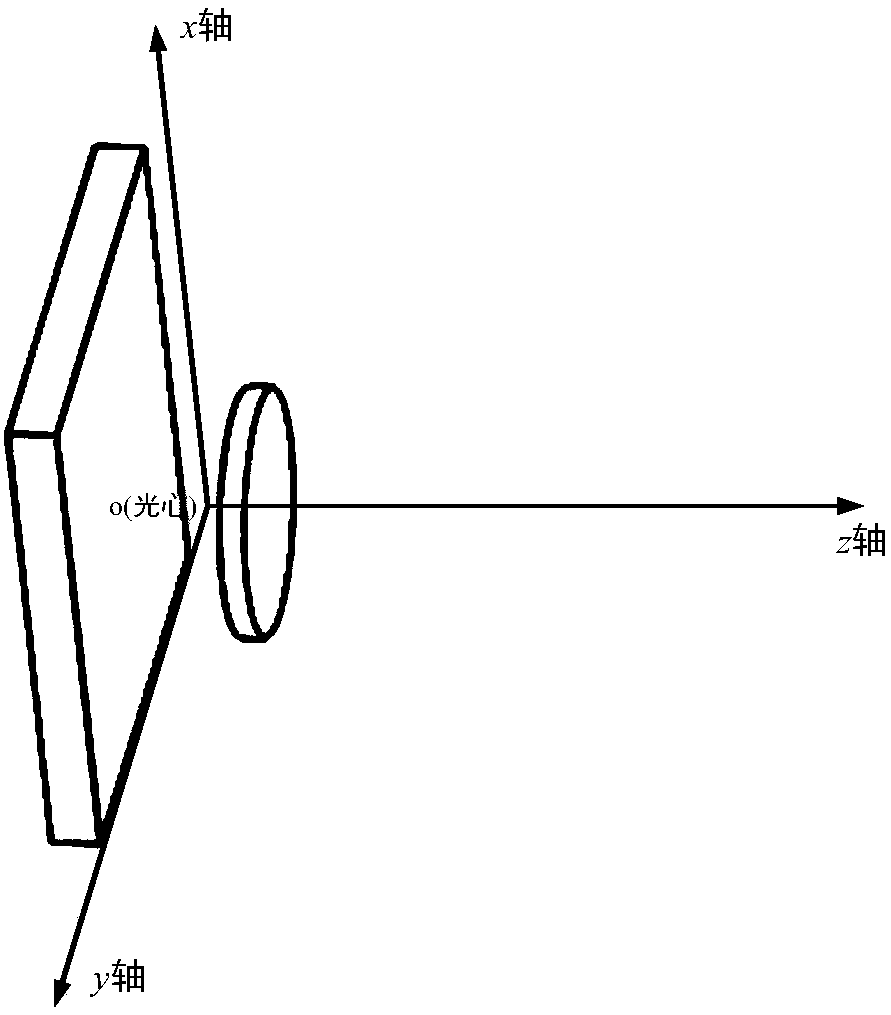

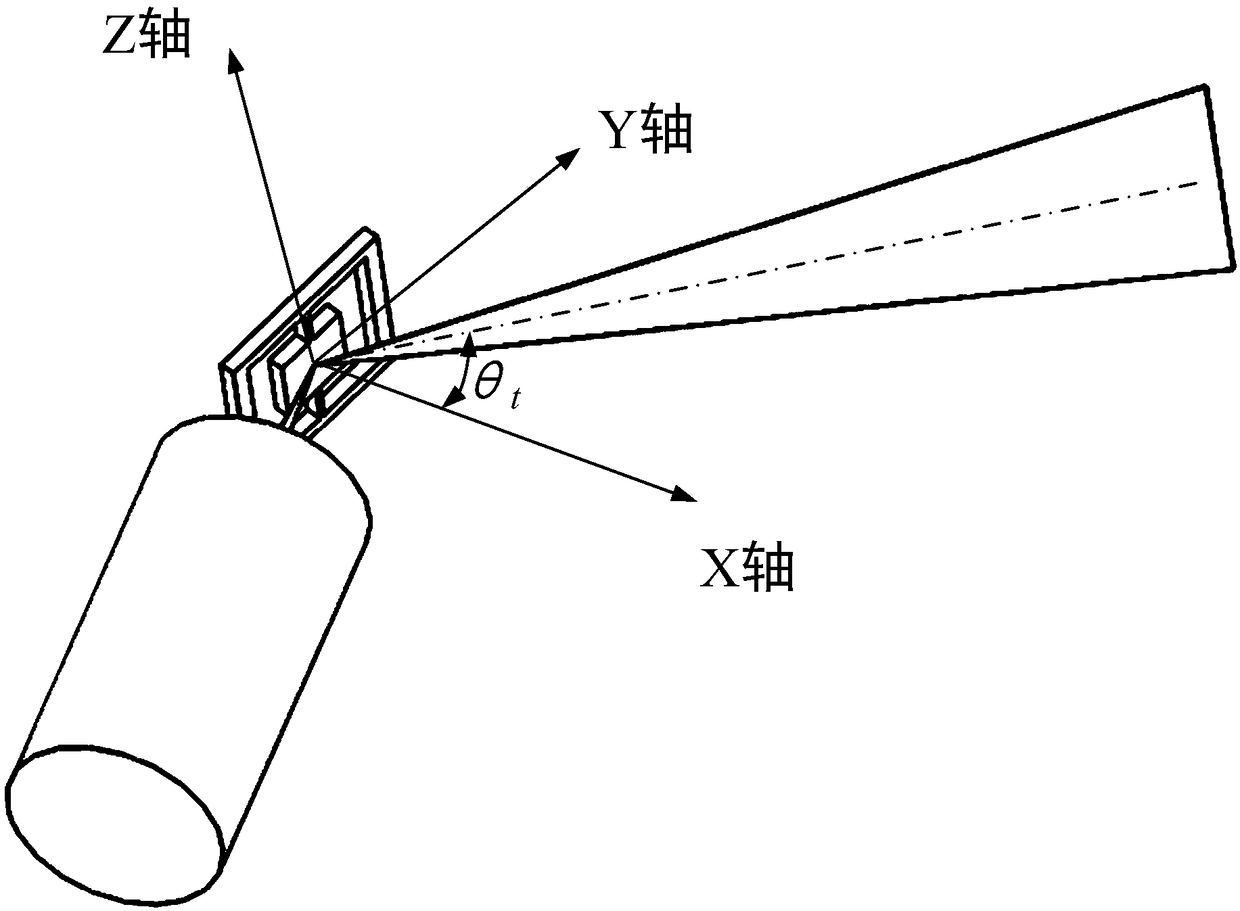

Laser line scanning 3D detection method and system based on scanning galvanometer and event camera

ActiveCN109458928ASimple algorithmSmall amount of calculationUsing optical meansGalvanometerLaser scanning

The invention belongs to the field of 3D detection and measurement, and particularly relates to a laser line scanning 3D detection method and system based on a scanning galvanometer and an event camera. The method comprises the following steps: the laser line is reflected to an object to be detected by the scanning galvanometer, so that laser line scanning is achieved; the event camera is adoptedto collect laser line signal information reflected from the object to be measured, and pixel points with changed brightness on the object to be measured and corresponding time points are stored and output; the position coordinate of the space point of the object to be detected scanned by the laser line at the moment is calculated through the relative position between the scanning galvanometer andthe event camera, the pixel point output in the step 2 and the scanning galvanometer rotation angle corresponding to the moment point corresponding to the pixel point; the steps are repeated to complete all space point coordinates of the object to be measured so as to obtain 3D point cloud data of the object to be measured, thereby solving the limitations of frame rate, resolution and illuminationresistance in the current 3D scheme.

Owner:XI AN ZHISENSOR TECH CO LTD

Device and method for pattern processing on surface of ceramic ball by using femtosecond laser

Owner:JILIN UNIV

A filter for decomposing galvanometer and servo positions

PendingCN111049500AReduce shockImprove acceleration and decelerationDigital technique networkLaser beam welding apparatusLaser processingGalvanometer

Owner:XIAN MICROMACH TECH CO LTD

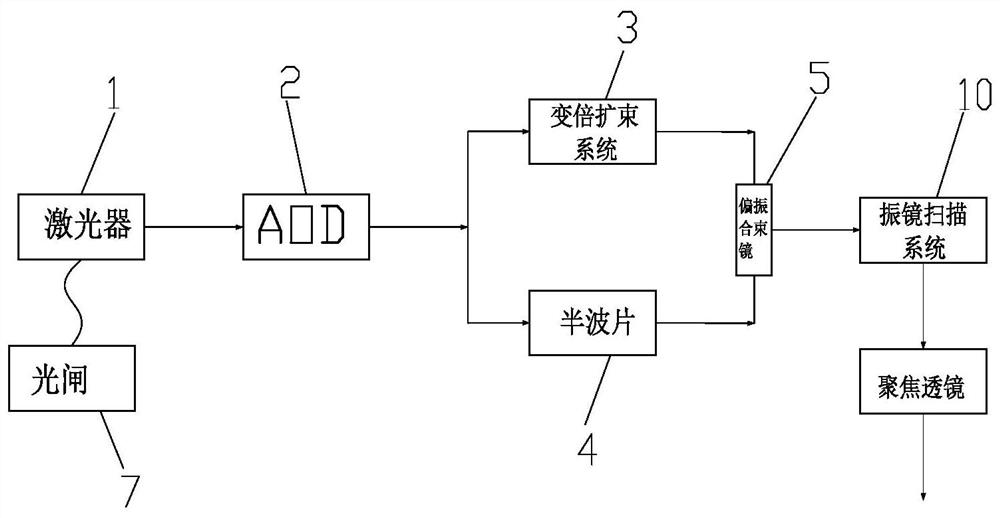

Laser light path system and method for processing flexible circuit board by using laser light path system

PendingCN112589296AShorten the processing pathImprove processing efficiencyPrinted circuit manufactureMetal working apparatusBeam expanderAcousto optic deflector

Owner:珠海市镭通激光科技有限公司

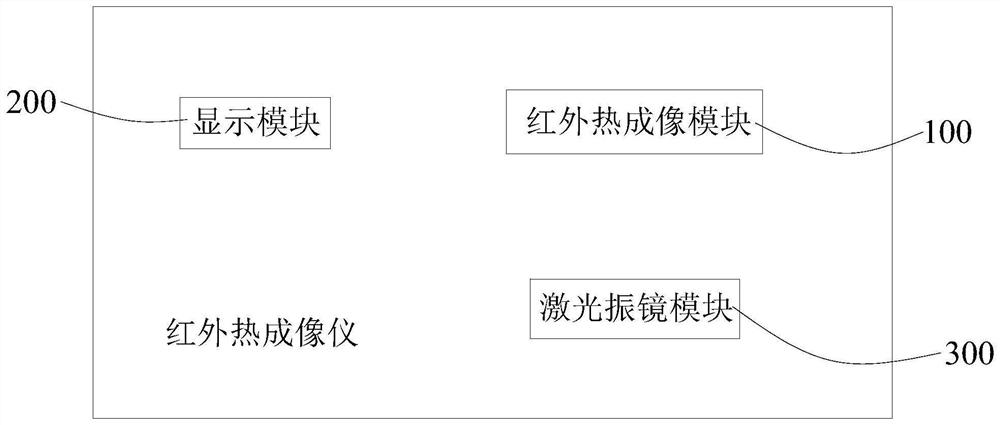

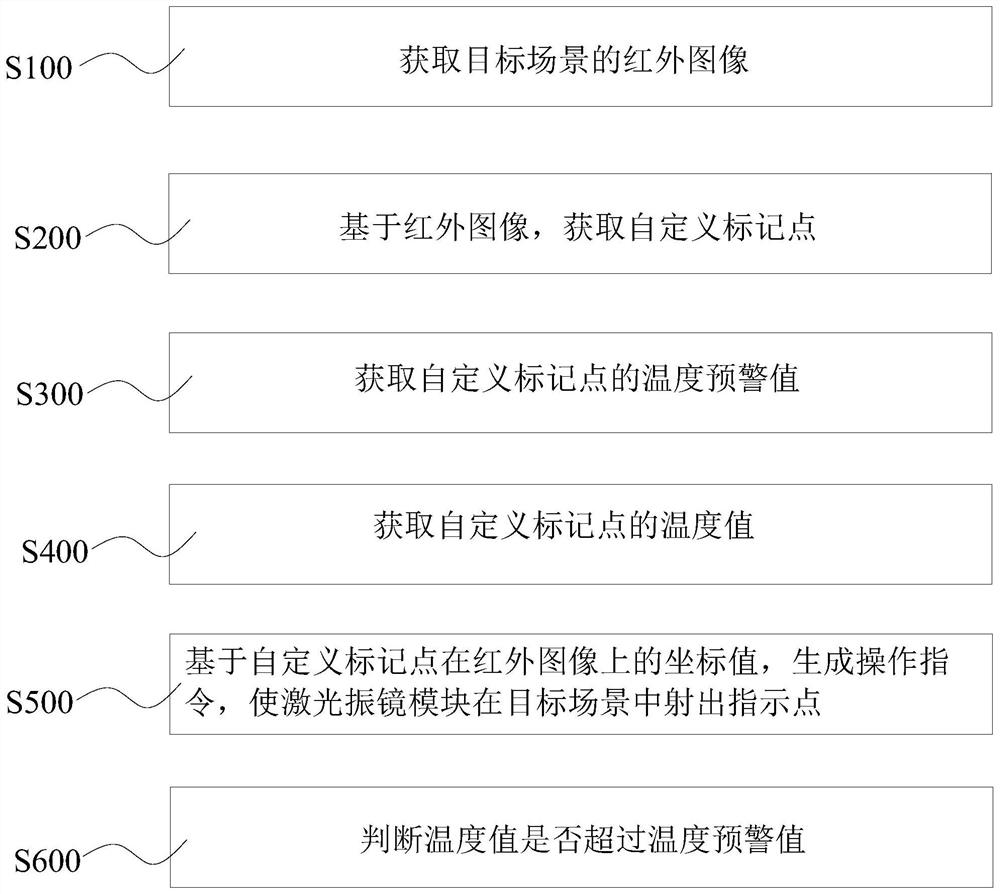

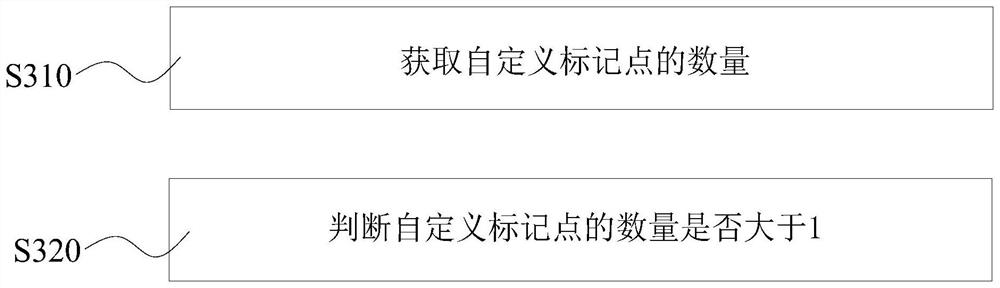

Dynamic marking method and device, computer equipment, medium and infrared thermal imager

PendingCN114323300ARealize patrol monitoringEasy to operateRadiation thermographyGalvanometerThermographic camera

Owner:UNI TREND TECH (CHINA) CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap