Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Physical model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Physical model (most commonly referred to simply as a model but in this context distinguished from a conceptual model) is a smaller or larger physical copy of an object. The object being modelled may be small (for example, an atom) or large (for example, the Solar System).

Testing system for ring-digital and physical mixed real-time power simulation and test method thereof

The invention discloses a testing system for ring-digital and physical mixed real-time power simulation. A digital simulation work station is connected with an RTDS digital simulator through the Ethernet, the RTDS digital simulator is connected with an analog output interface card through fibers, and the analog output interface card is connected with a controller through hard wiring. The controller is connected with a four-quadrant linear power amplifier through hard wiring, and the four-quadrant linear power amplifier is connected with a power type physical model through a cable conductor to output voltage analog of the RTDS digital simulator to the power type physical model. The power type physical model is connected with a current measurement sensor, the current measurement sensor is connected with the analog input interface card through hard wiring, and the analog input interface card is connected with the RTDS digital simulator through fibers to return the current of the power type physical model to the RTDS digital simulator.

Owner:POWER GRID TECH RES CENT CHINA SOUTHERN POWER GRID +2

Dynamic reconstruction method of time-shift logging curve

ActiveCN106019378AHigh precisionSeismic signal processingSeismology for water-loggingLongitudinal waveFluid replacement

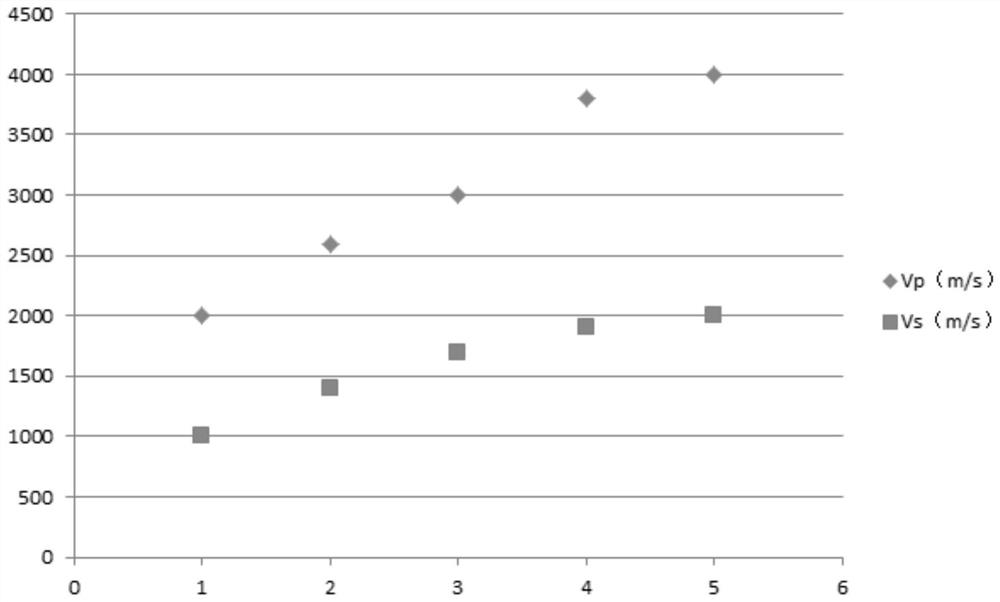

The invention relates to a dynamic reconstruction method of a time-shift logging curve. The method comprises the following steps: determining basic data of a target work area; directly measuring pressure change of a production well shaft along the vertical thickness of a destination layer; determining a water penetration mode of a production well at a destination layer position; determining pressure change of a shaft position in a longitudinal direction; obtaining oil-containing saturation of a destination layer position at different time points by performing fluid replacement simulation on the production well at the destination layer position according to time; obtaining oil-containing saturation of a logging curve after reconstruction by screening the oil-containing saturation of the simulated destination layer position at the different time points; calibrating a rock physical model; calculating longitudinal wave speed, a transverse wave speed and density of the logging curve after dynamic reconstruction; obtaining synthetic seismic data through forwarding synthesis; comparing the synthetic seismic data with an actual well bypass, and if the dynamic reconstruction satisfying correlation requirements, ending the method; and otherwise, modifying a most influential parameter in the rock physical model, and returning to the previous step.

Owner:CHINA NAT OFFSHORE OIL CORP +1

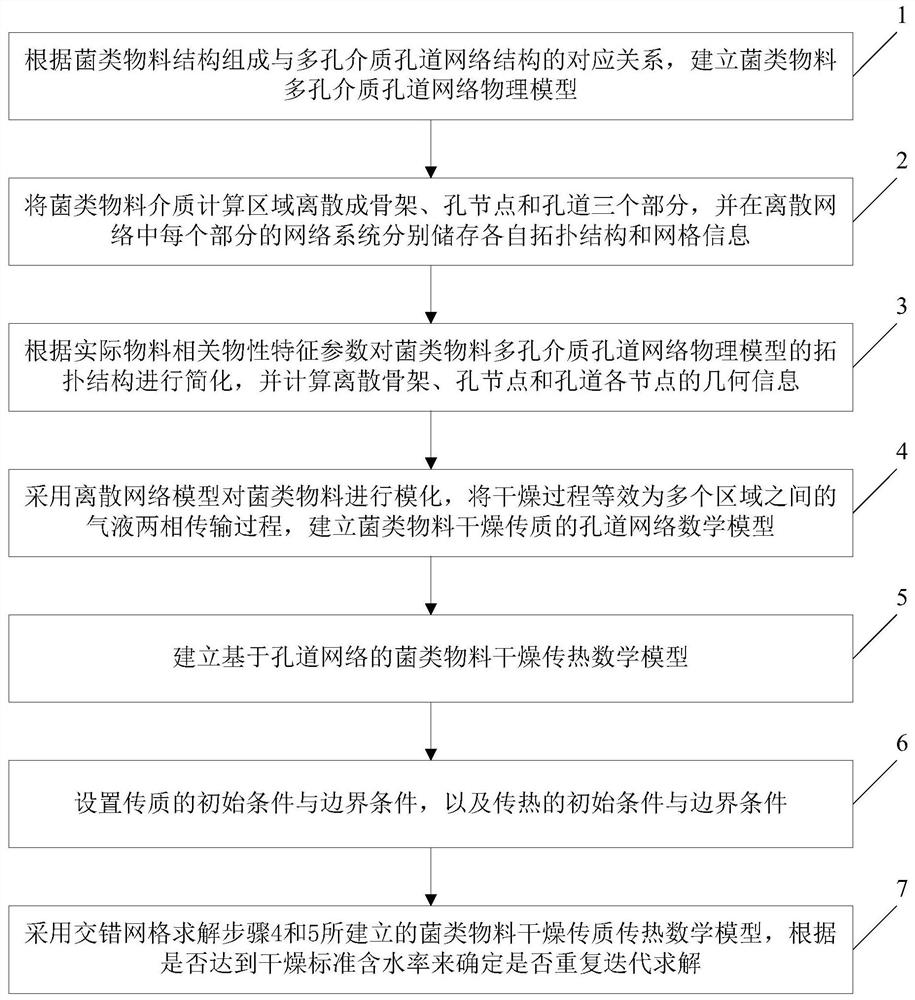

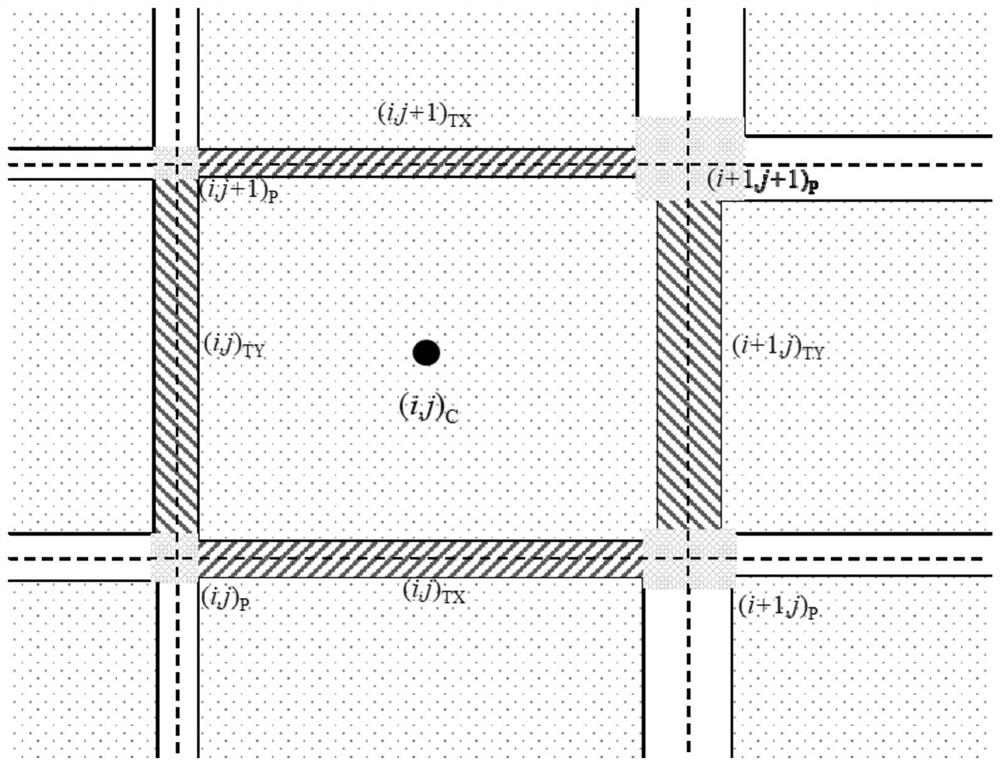

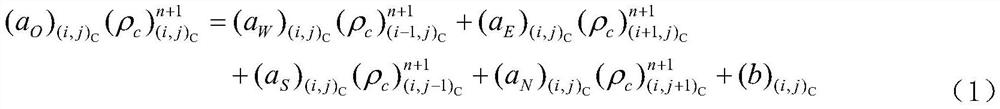

Simulation method for hot air drying process of fungus material

ActiveCN112507589ADesign optimisation/simulationSpecial data processing applicationsPorous mediumMathematical model

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

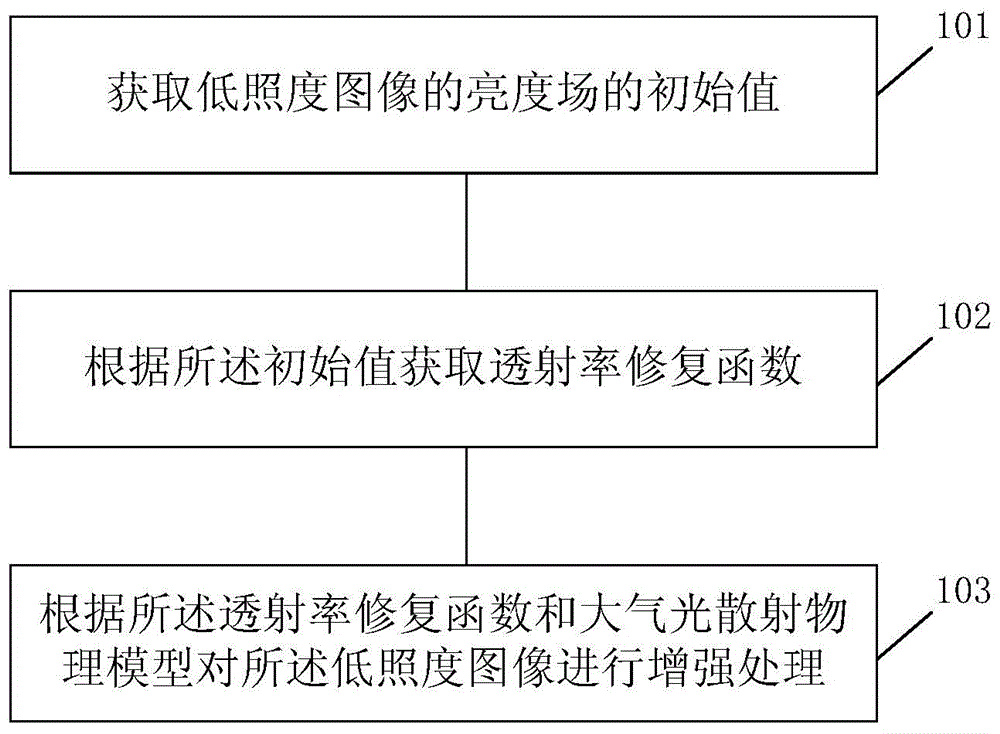

Method and device for enhancing night vision image in self-adaption mode

Owner:NINGXIA UNIVERSITY

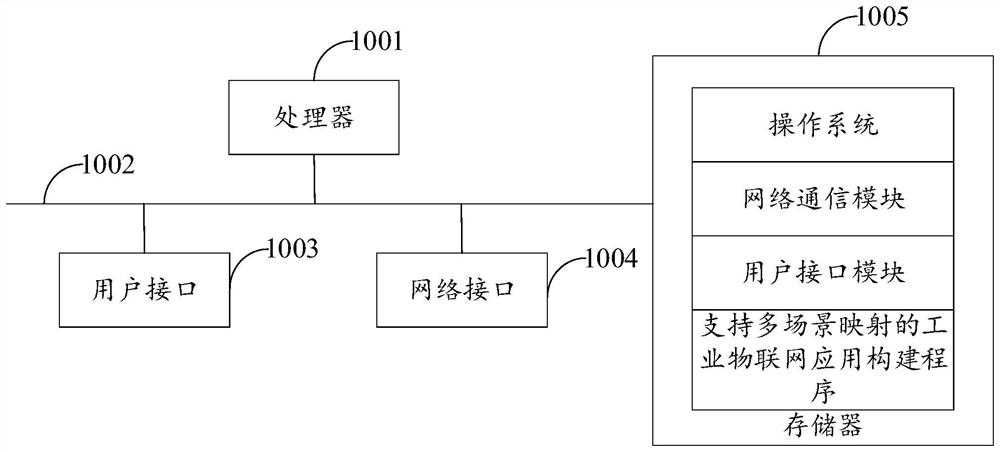

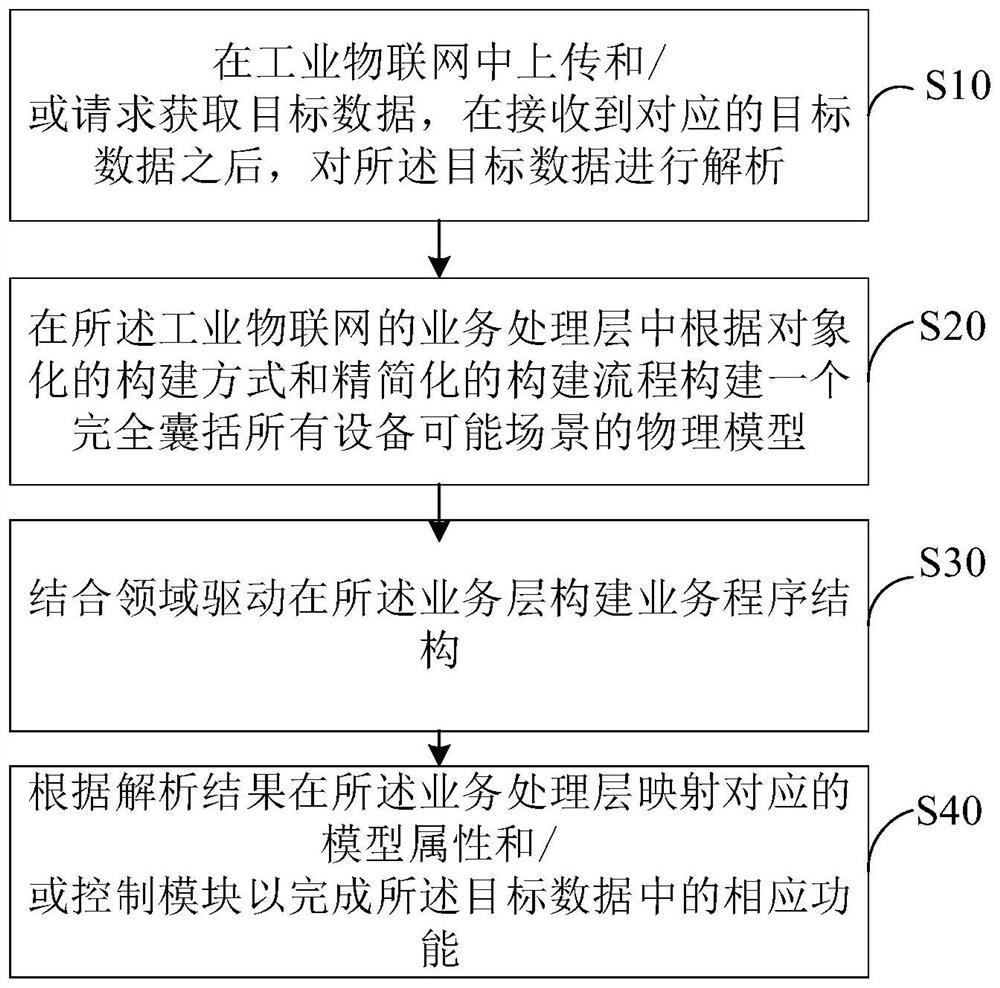

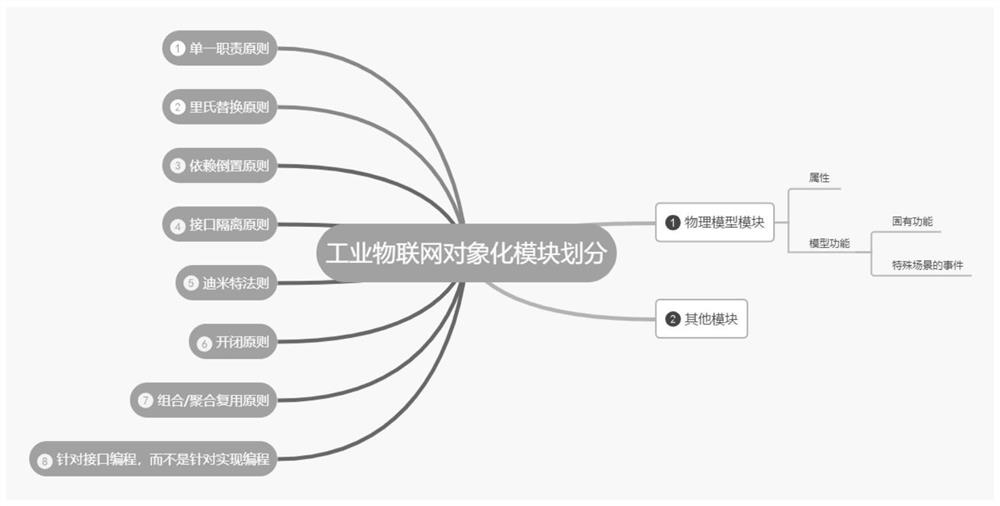

Industrial Internet of Things application construction method supporting multi-scene mapping

PendingCN114398794AImprove acceleration performanceImprove portabilityGeometric CADDesign optimisation/simulationSoftware engineeringPhysical model

Owner:中电望辰科技有限公司

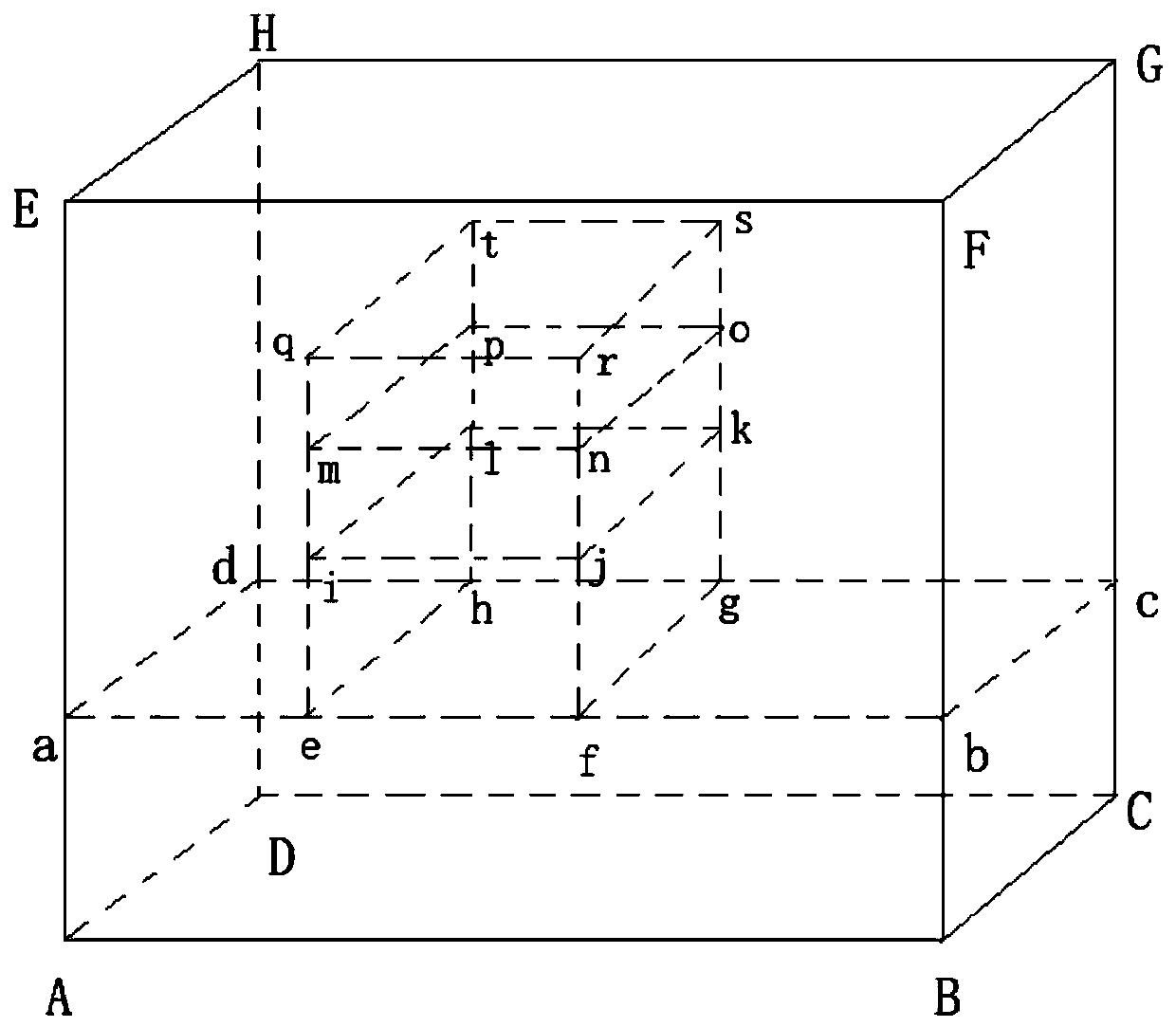

Rock stratum micro-disturbance continuous excavation method related to similar physical model

ActiveCN111537299AReduce disturbanceReduce production quantityPreparing sample for investigationModel buildingPhysical model

Owner:XIANGTAN UNIV

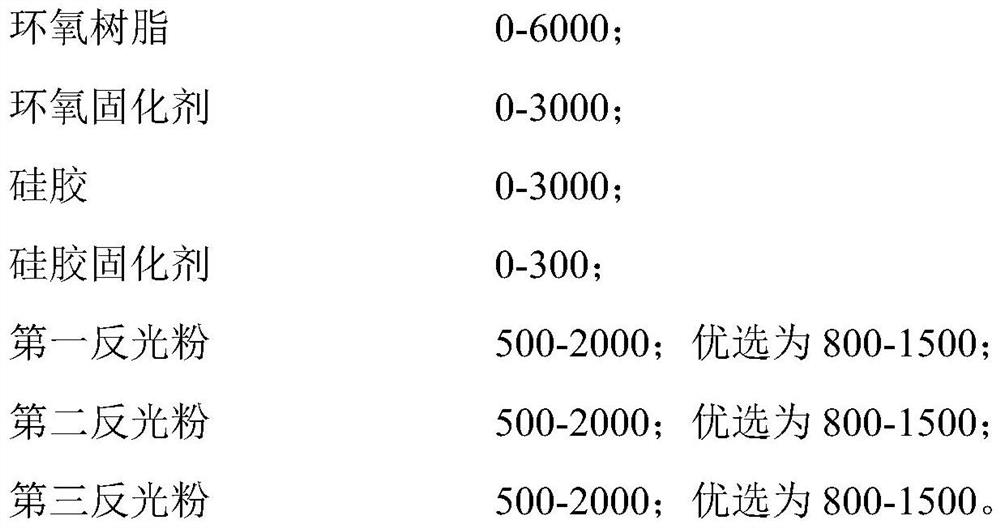

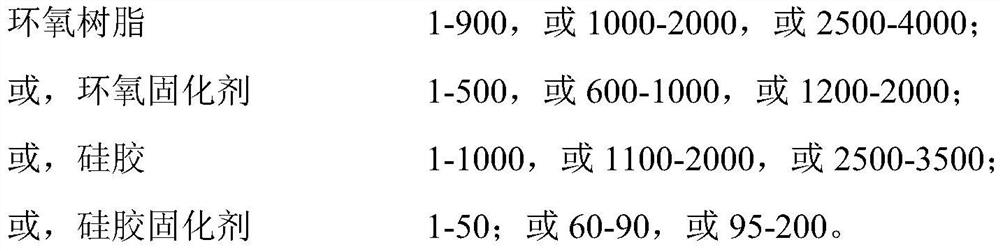

Composition for preparing earthquake physical model, earthquake physical model and preparation and construction method

Owner:CHINA PETROLEUM & CHEM CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap