Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about "Woven fabrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

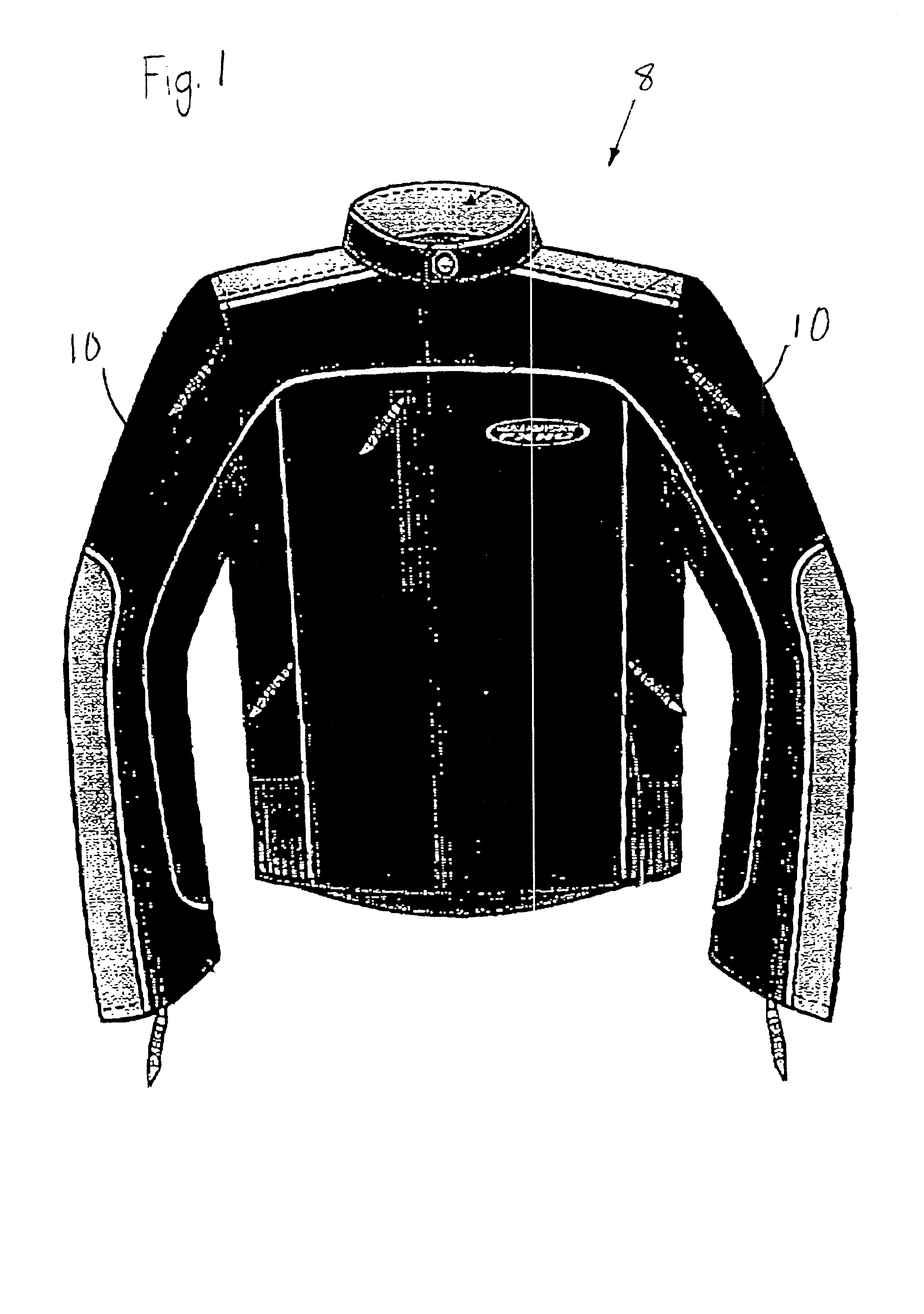

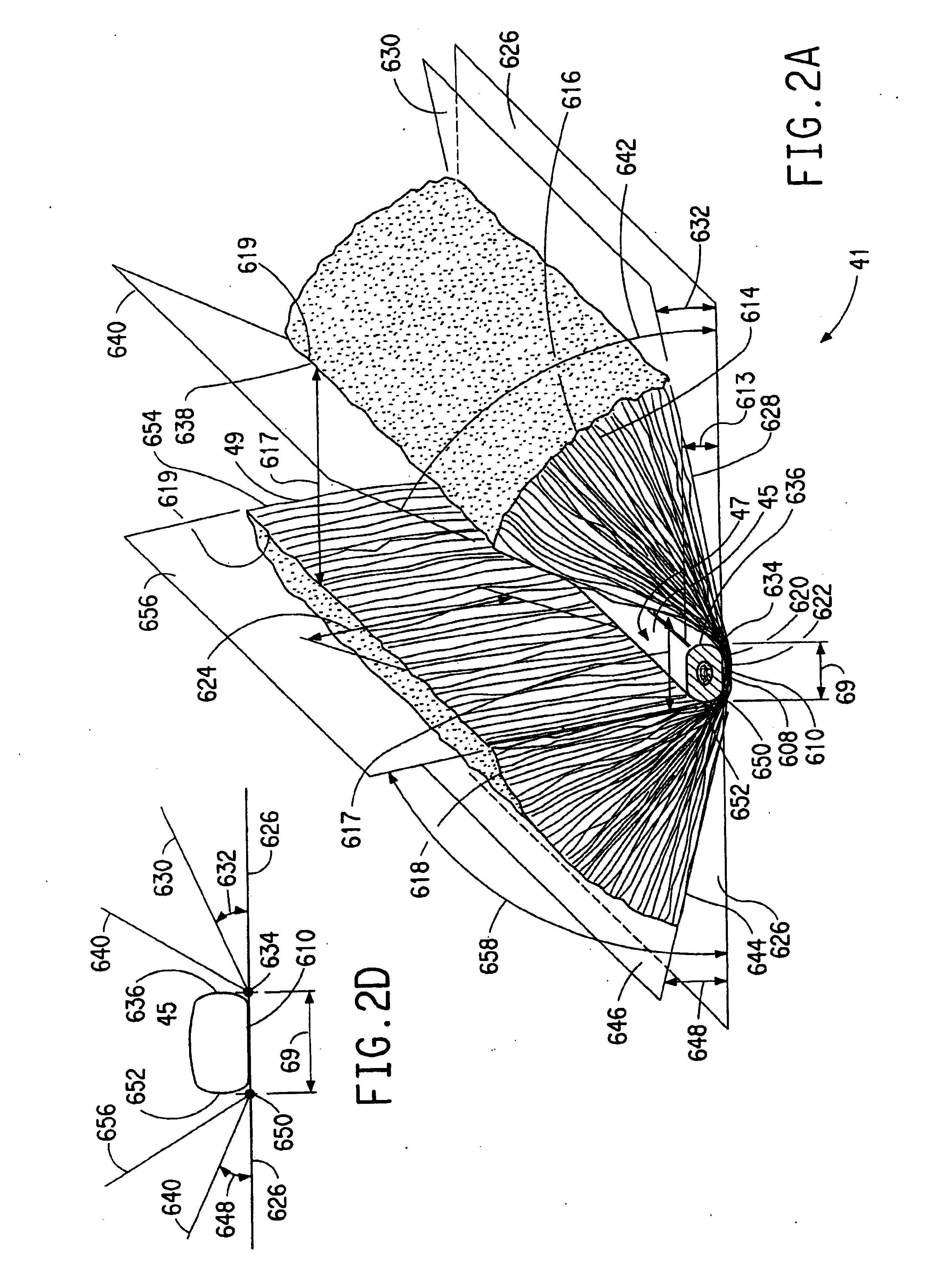

Garment ventilation system

InactiveUS6792621B2Synthetic resin layered productsCellulosic plastic layered productsEngineeringWater resistant

Owner:HARLEY DAVIDSON MOTOR COMPANY GROUP INC

Ecological bacteriostatic breathable smooth tatting fabric

Owner:FUJIAN BAIKAI WARP KNITTING INDUSTRY CO LTD

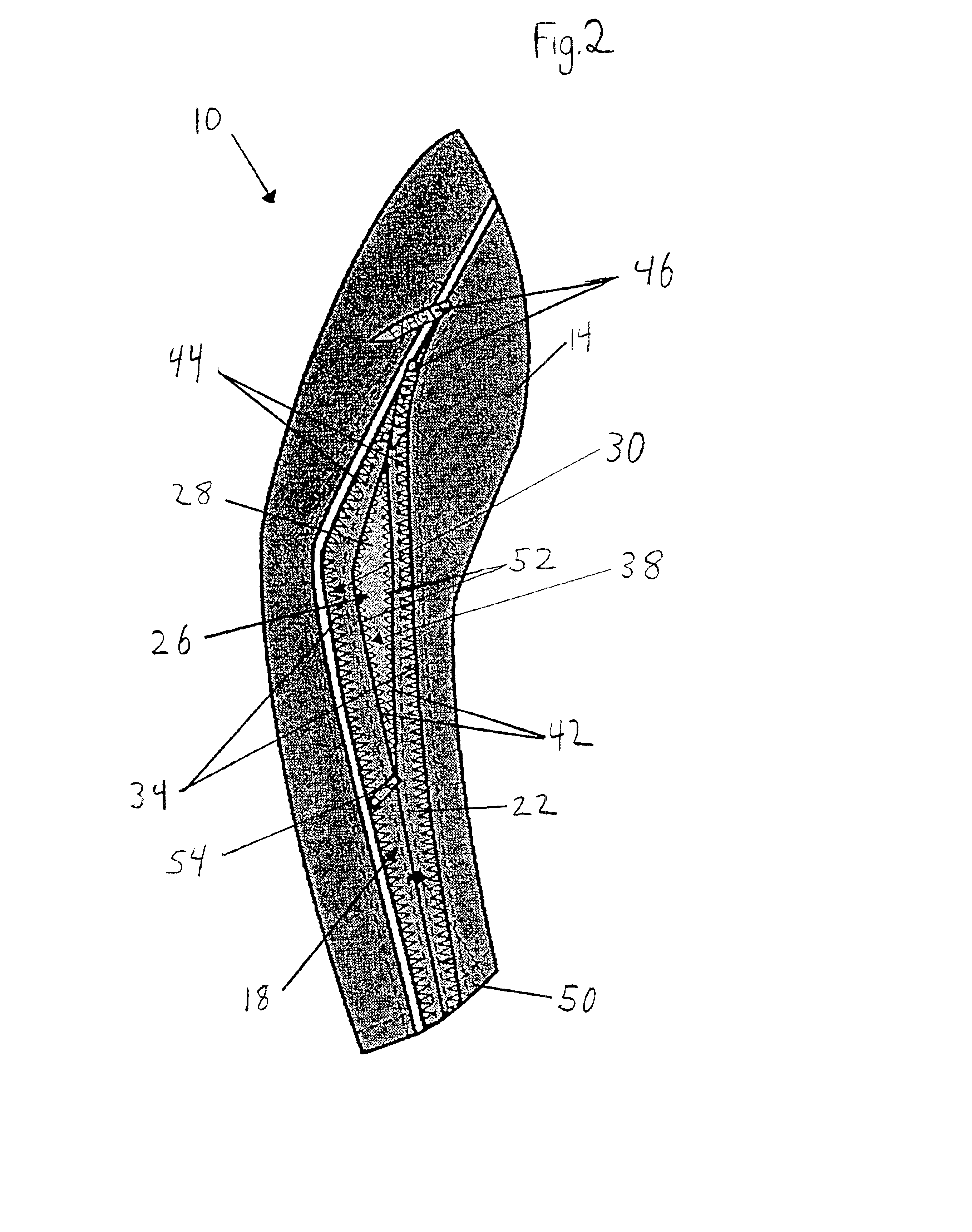

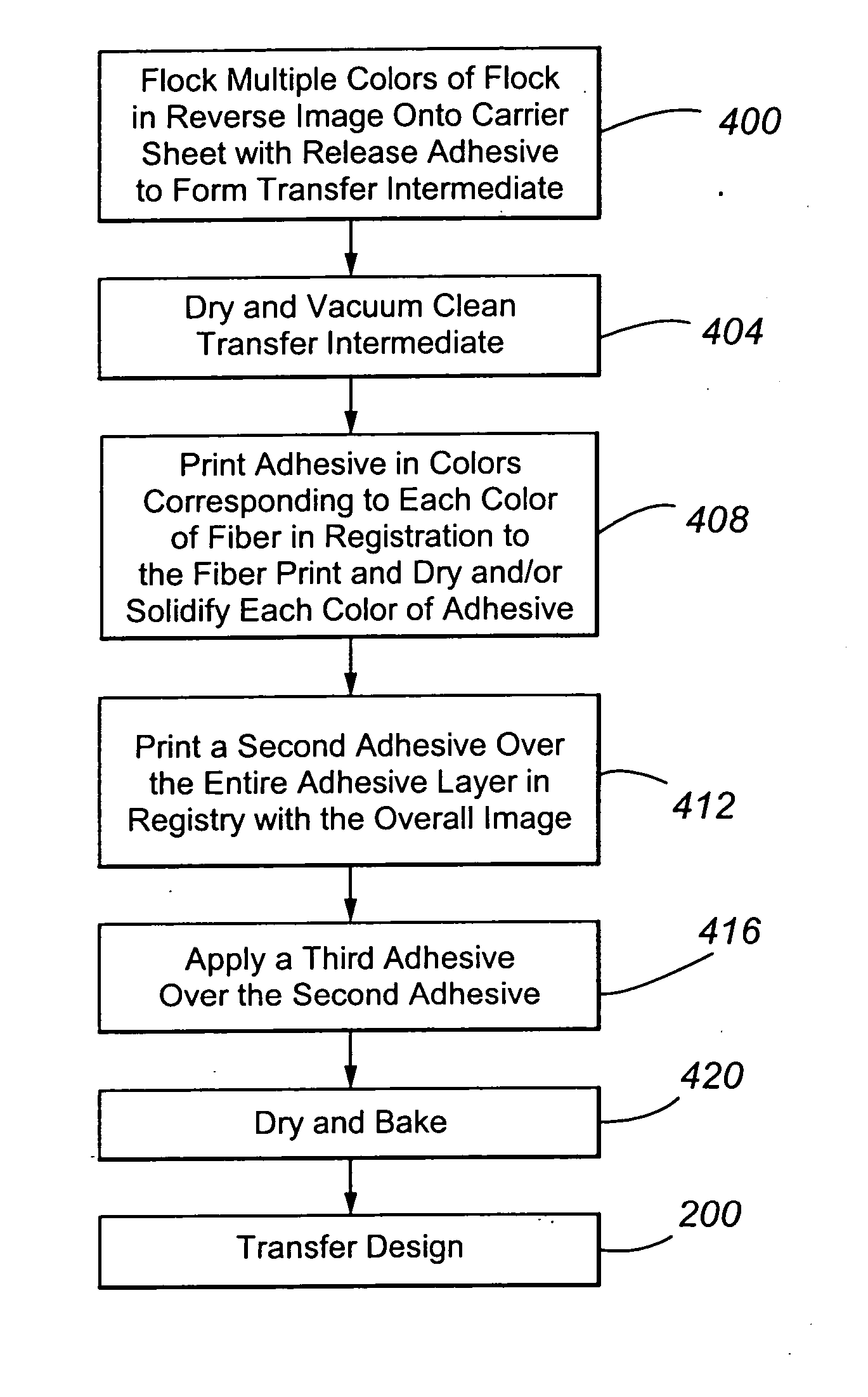

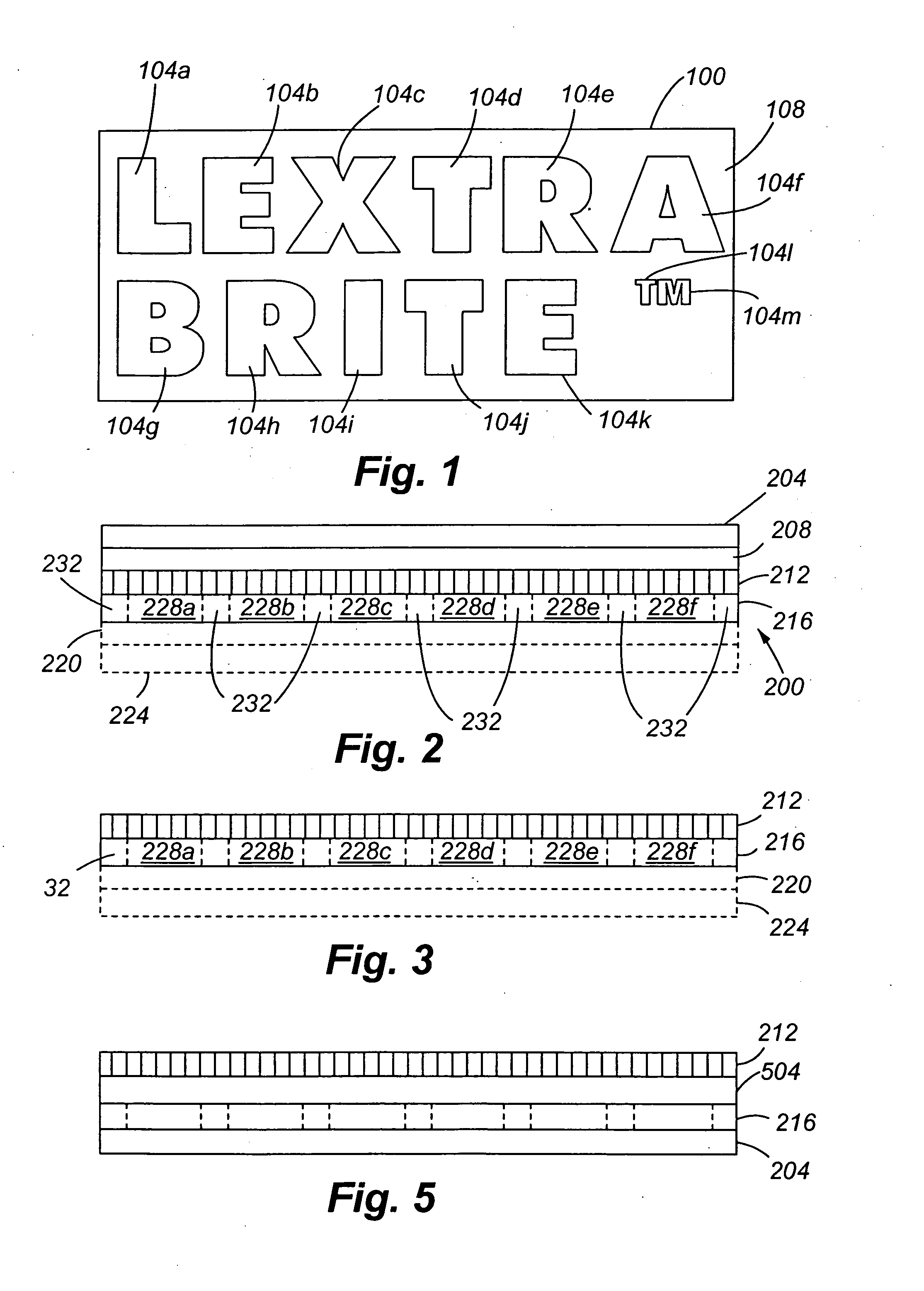

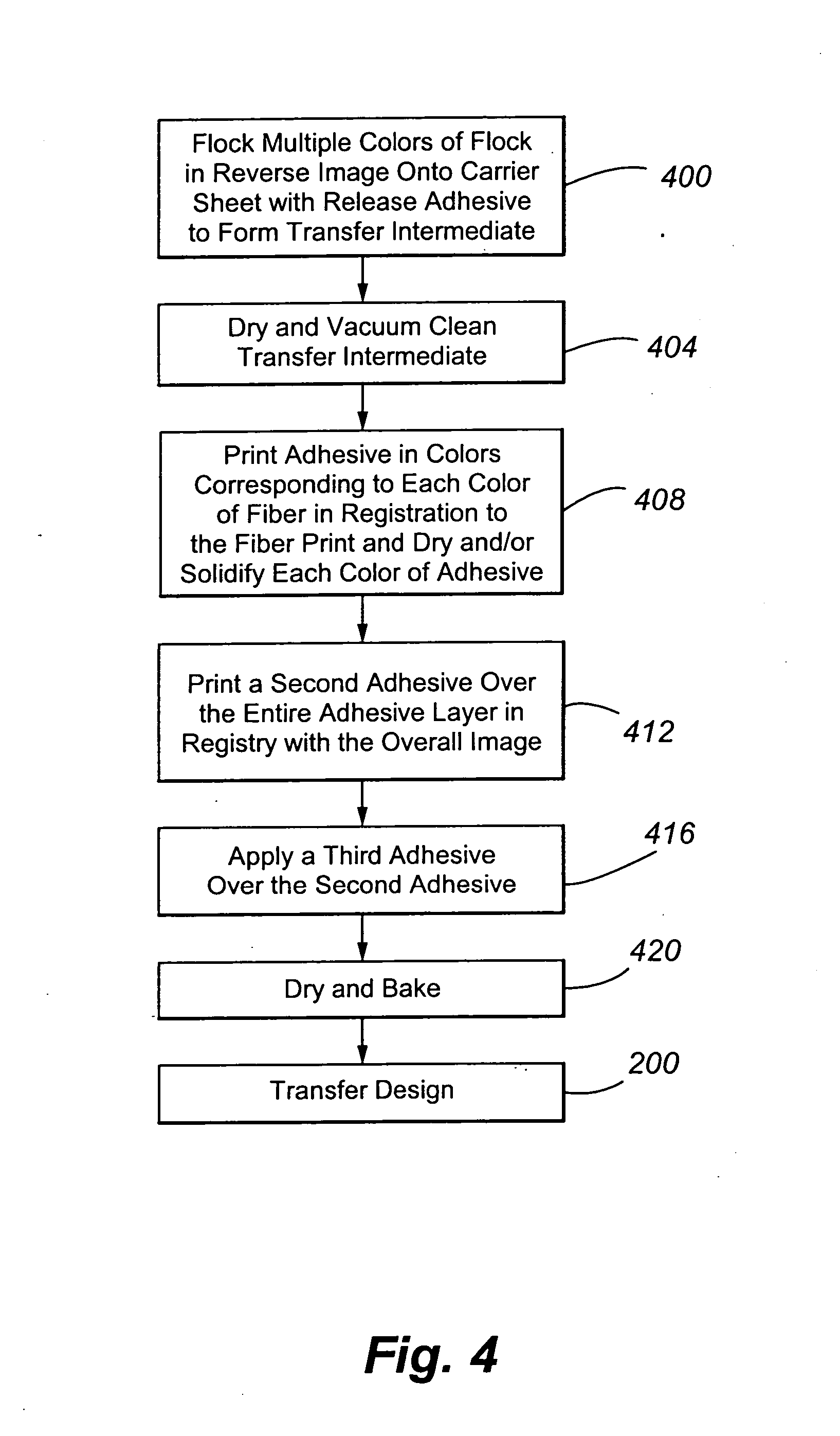

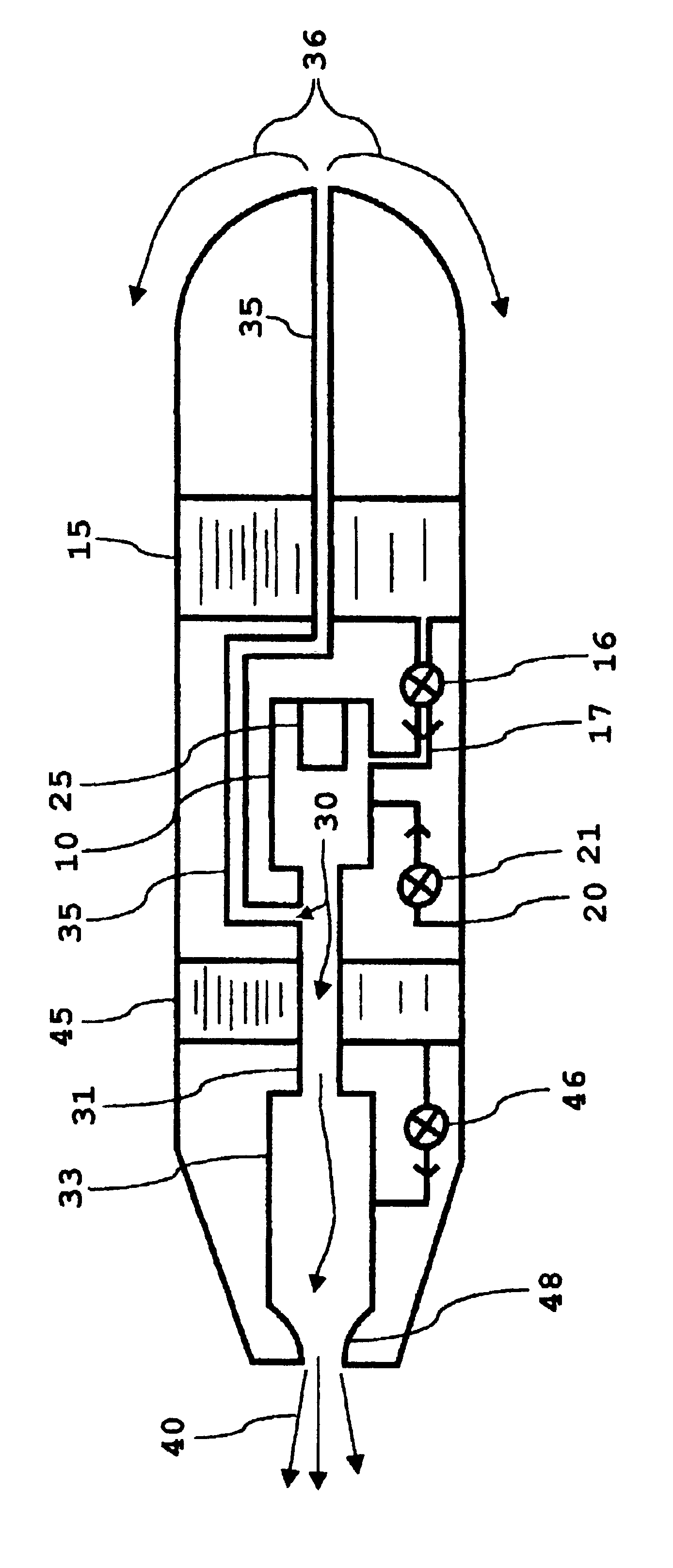

Flocked multi-colored adhesive article with bright lustered flock and methods for making the same

InactiveUS20060251852A1Reduce shadowing effectFlock densityLayered productsOrnamental structuresFiberEngineering

Owner:HIGH VOLTAGE GRAPHICS

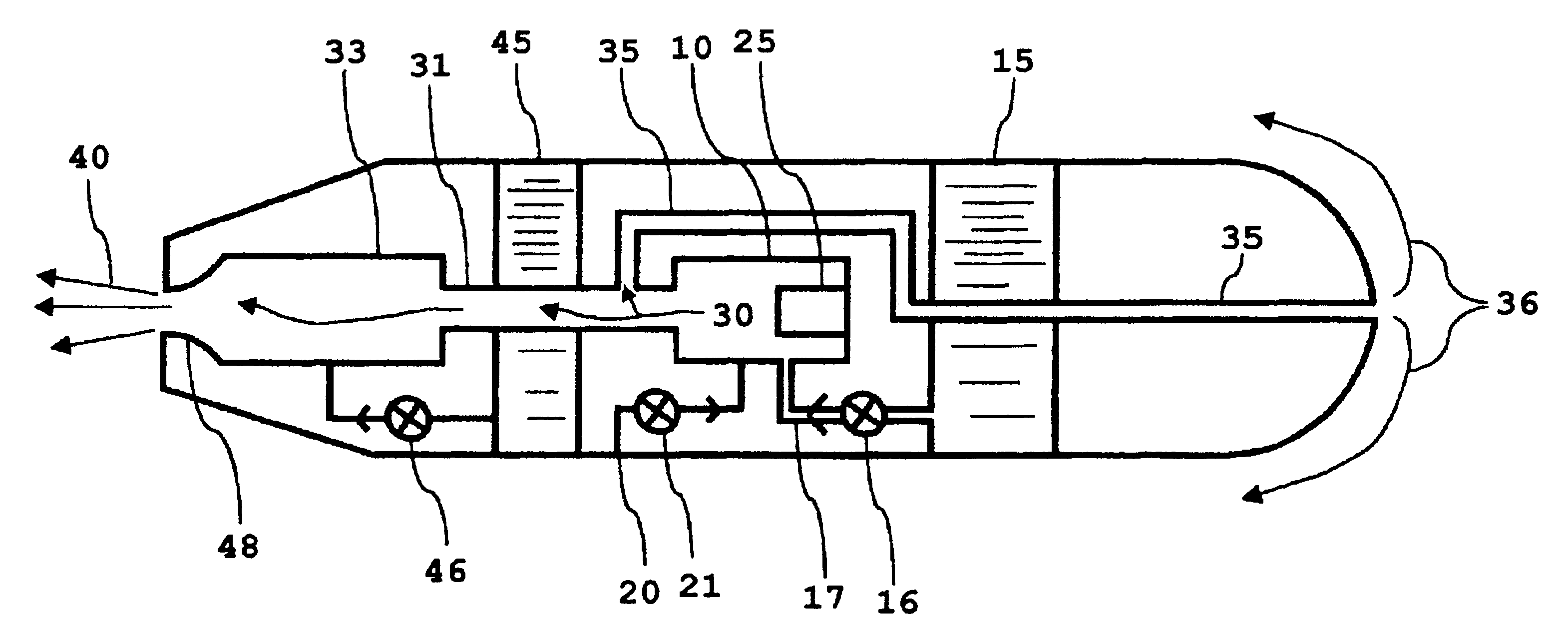

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

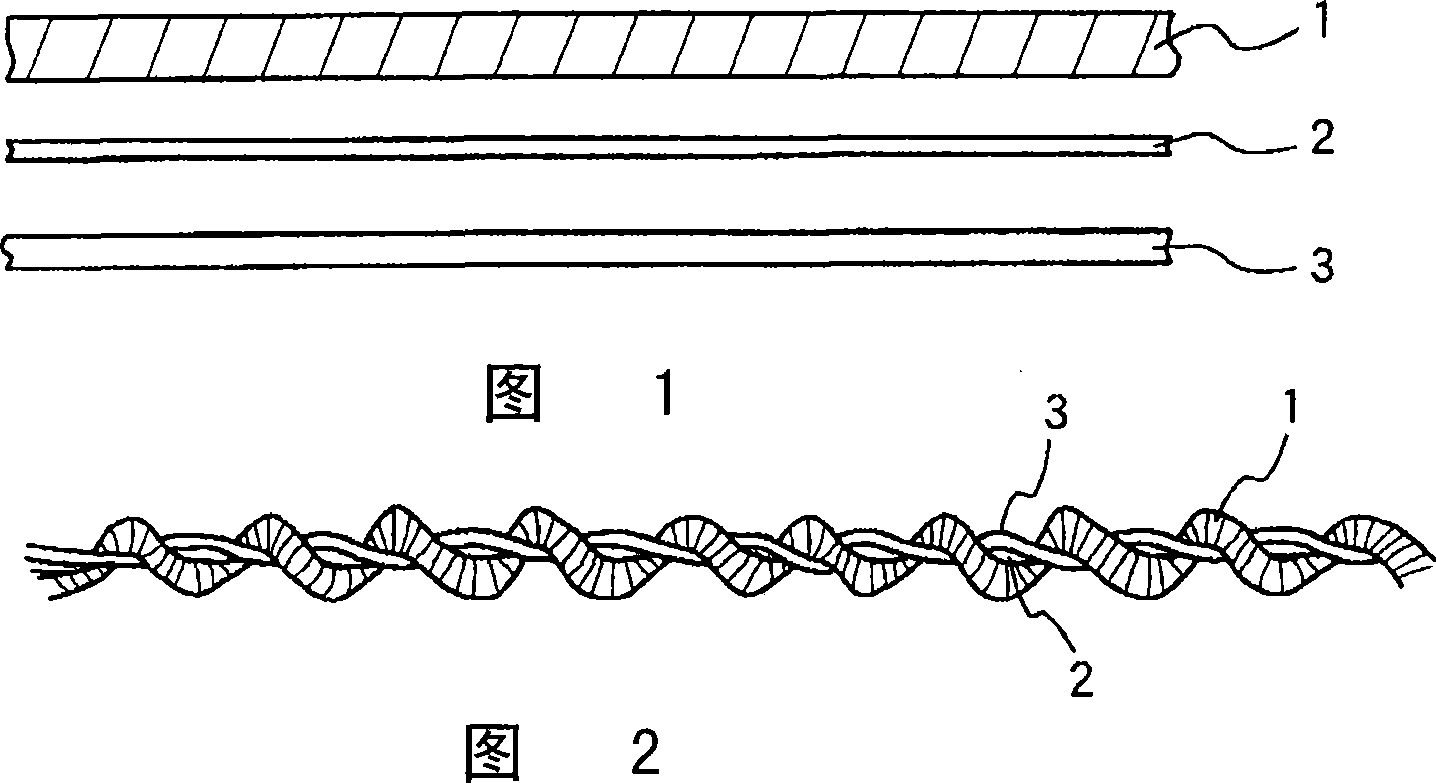

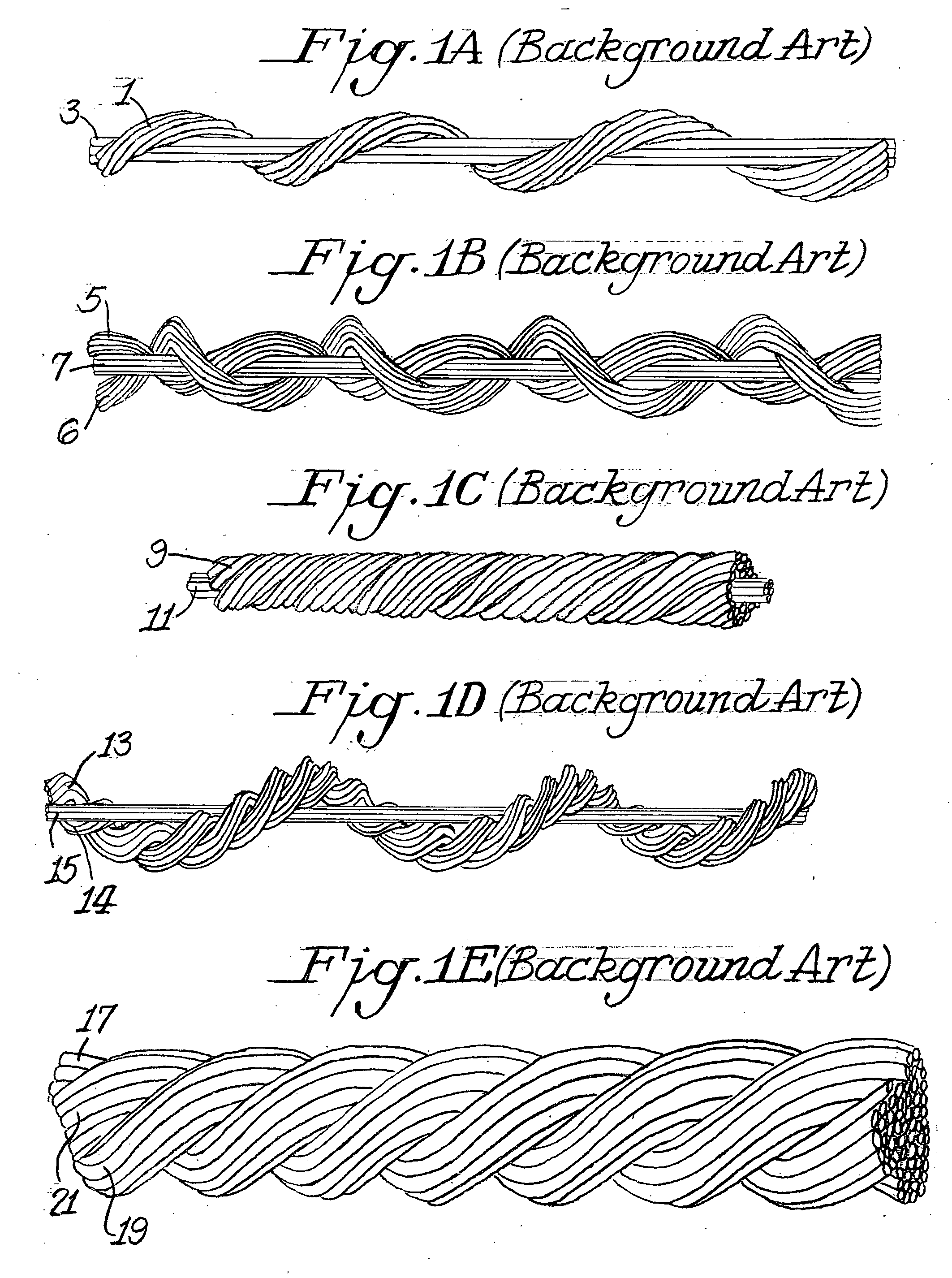

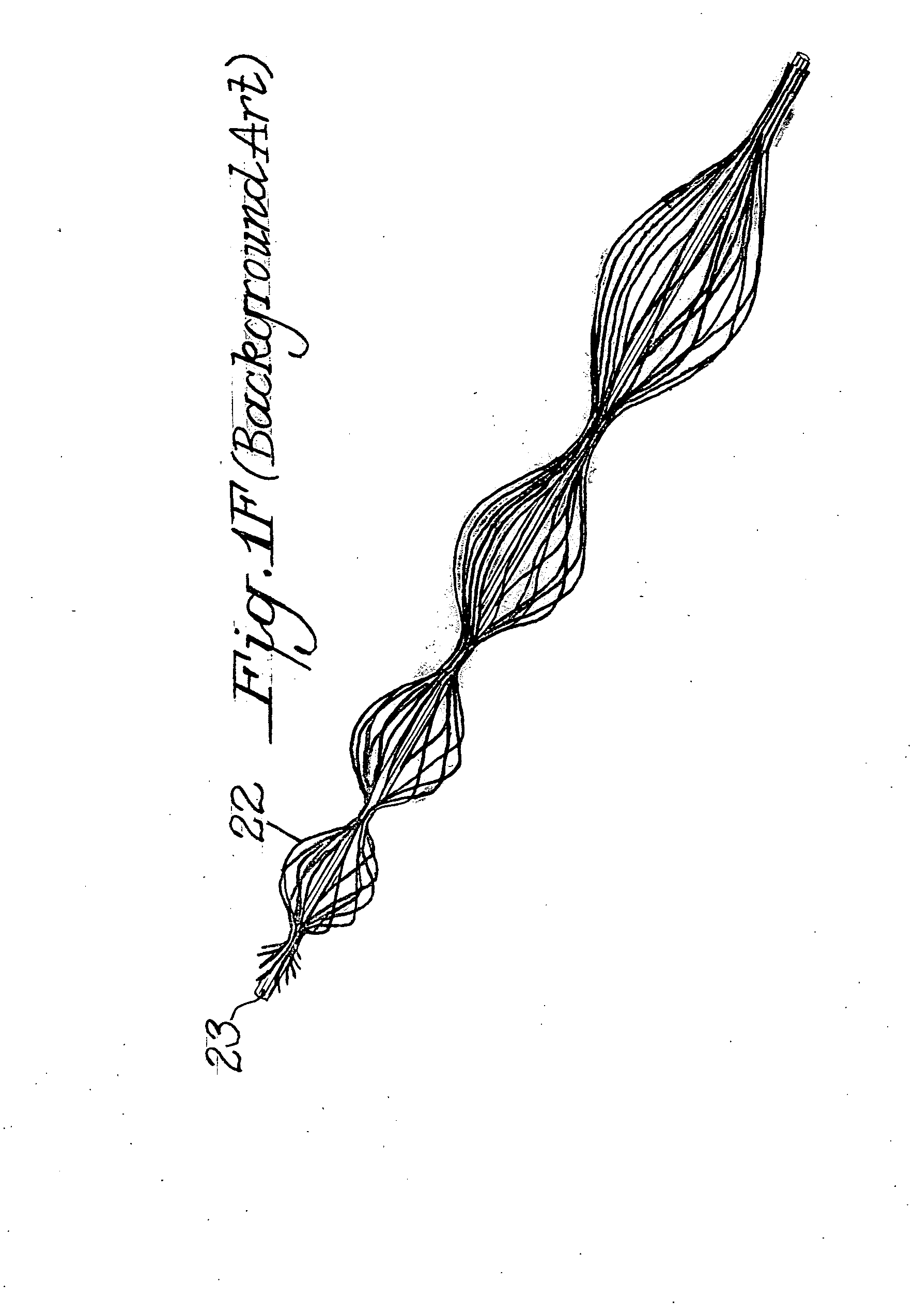

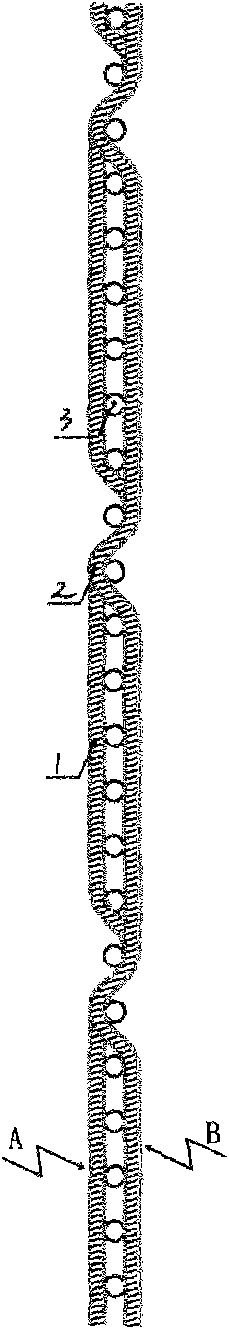

Composite twist yarn

Owner:KURARAY TRADING CO LTD +1

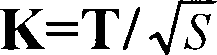

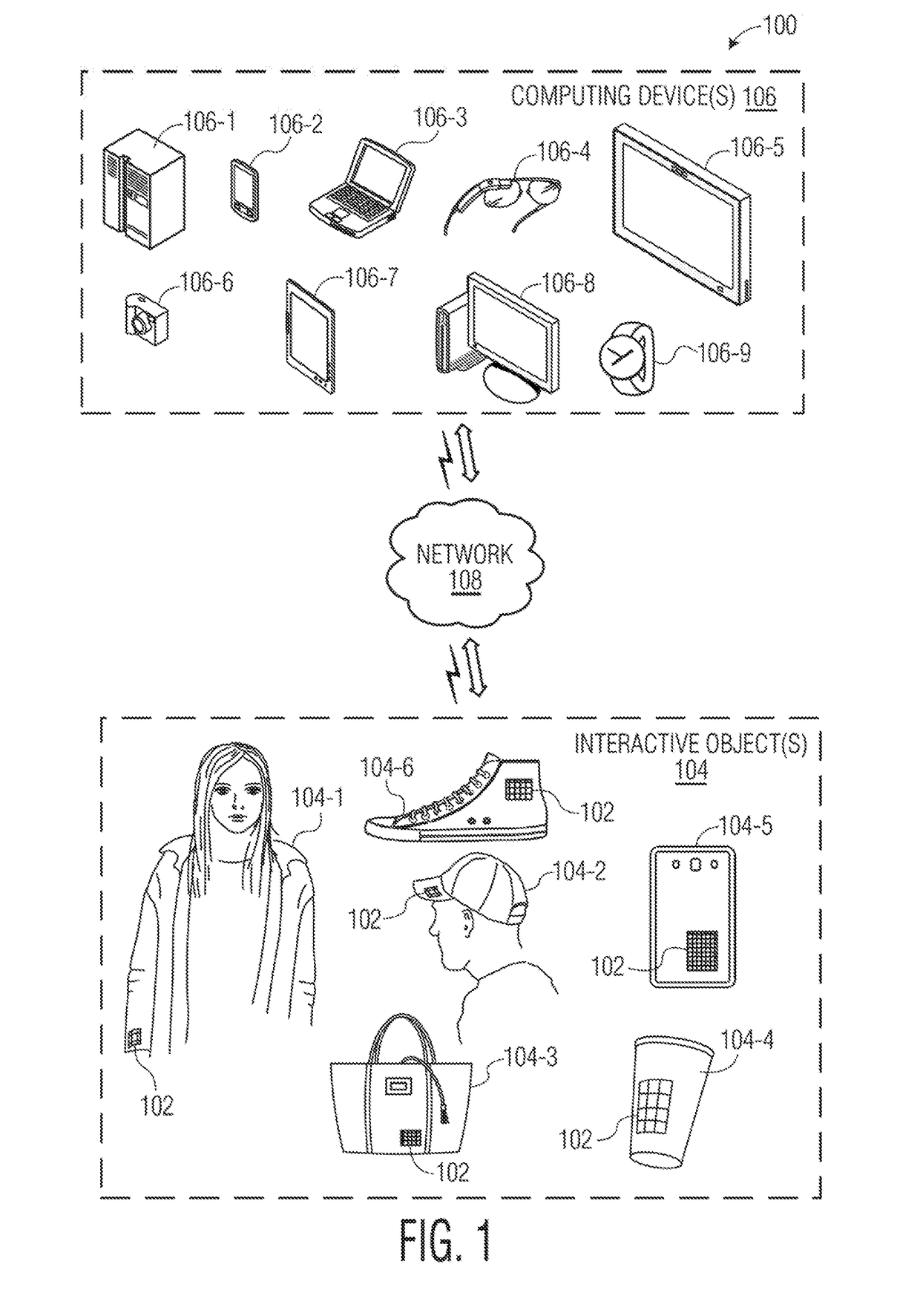

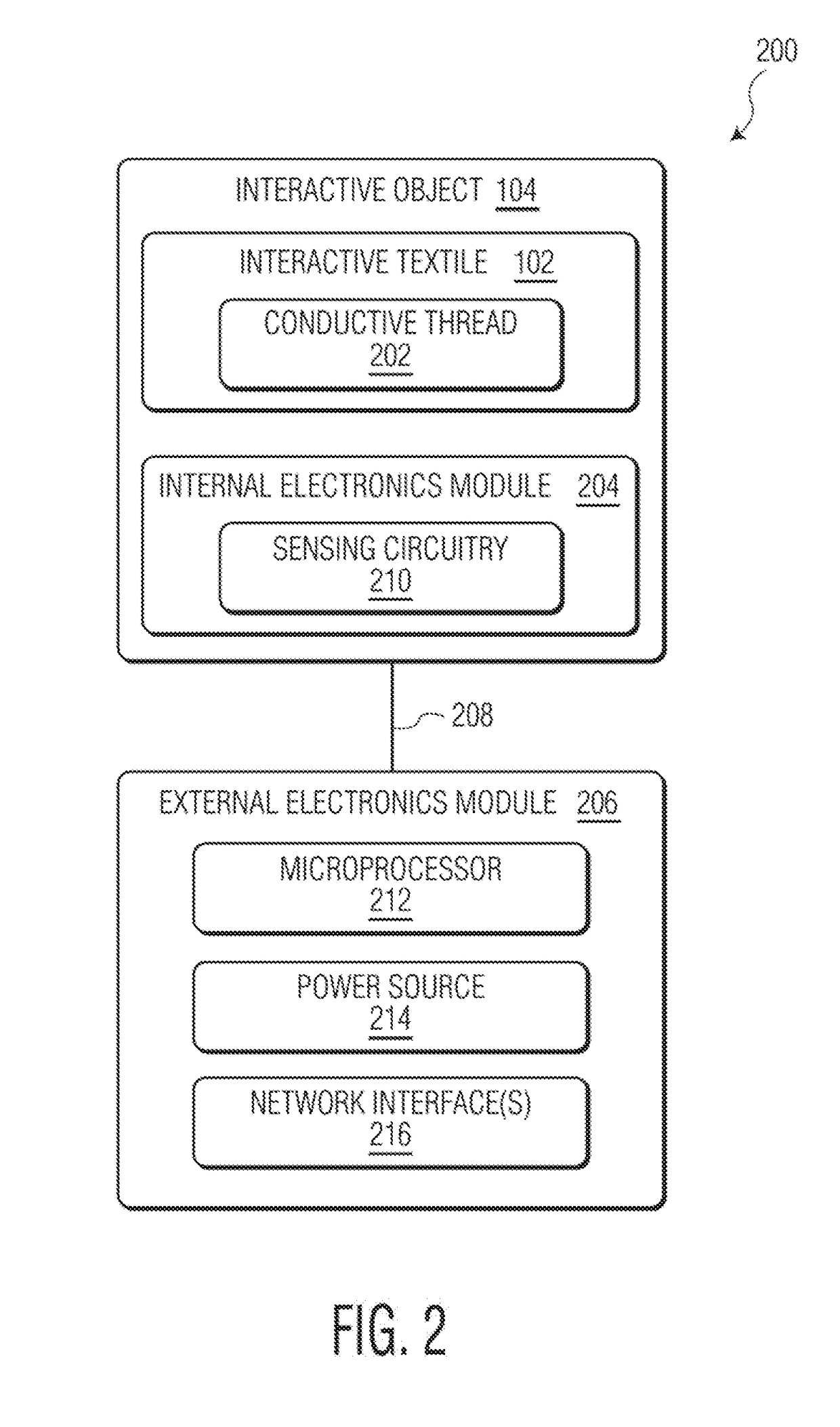

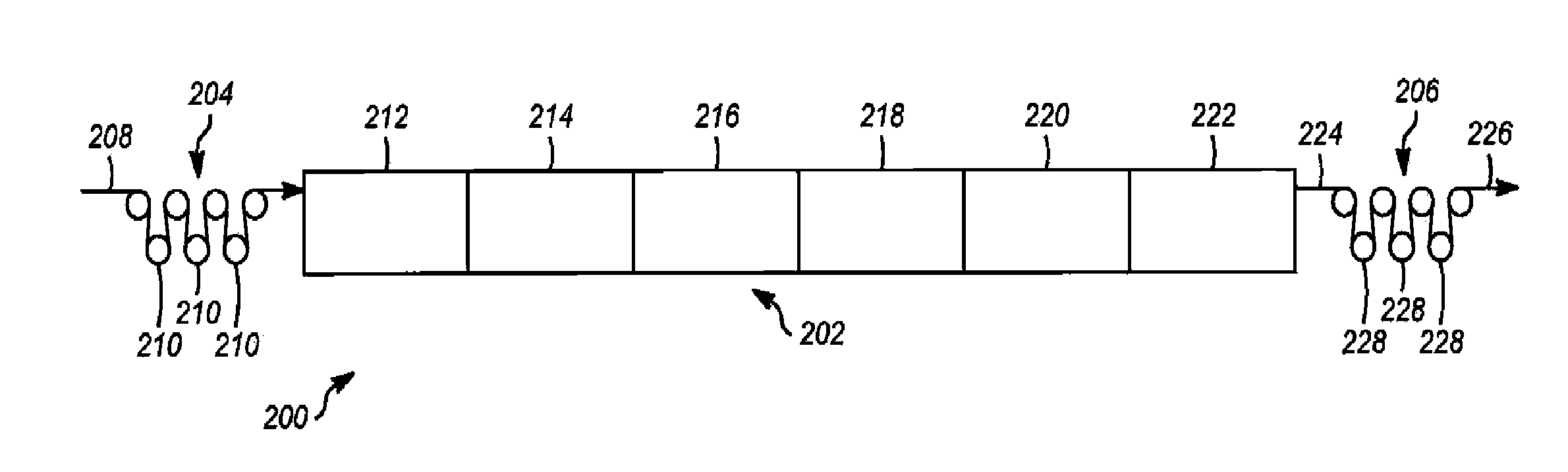

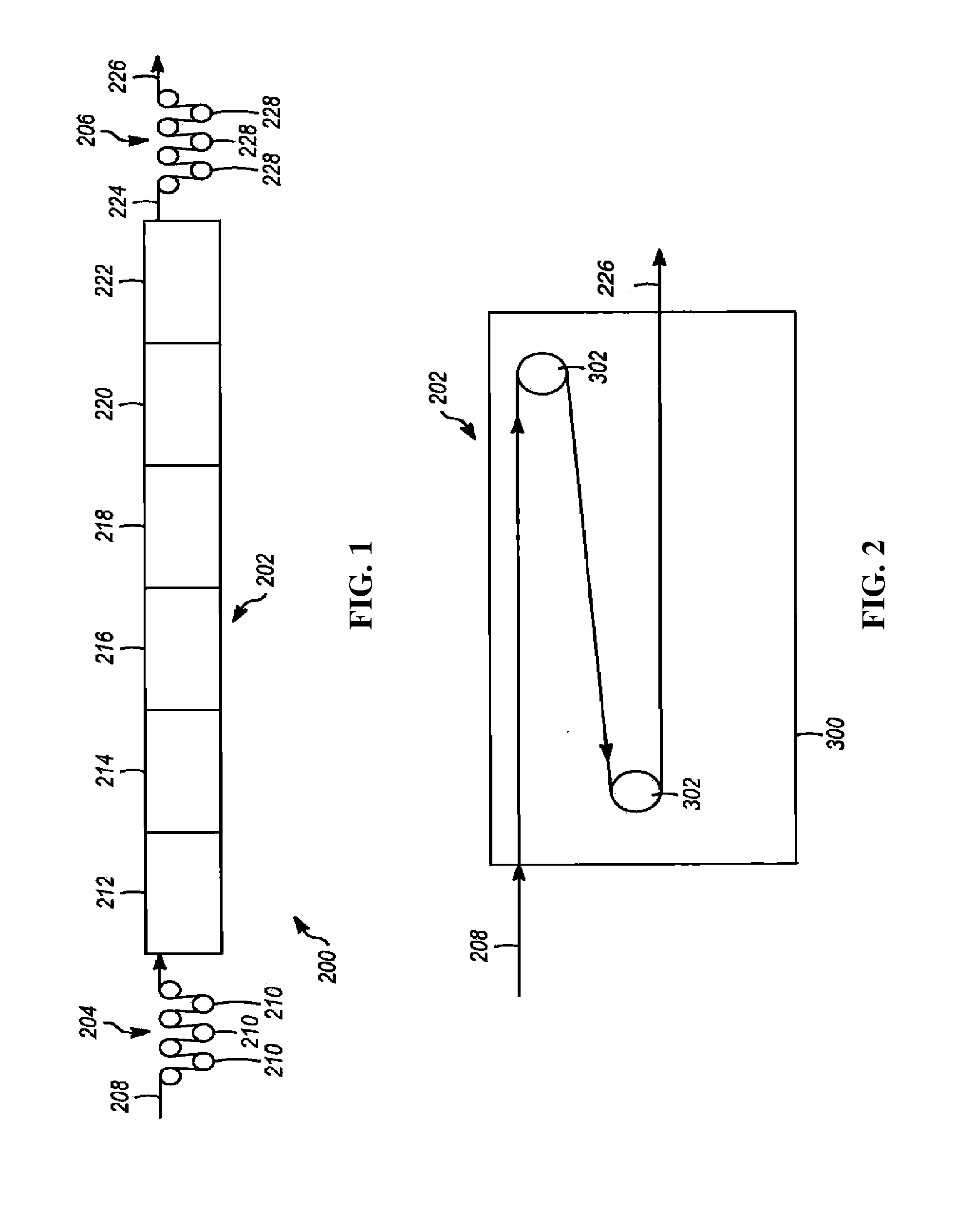

Connector Integration for Smart Clothing

ActiveUS20180260052A1Provide strain reliefPrinted circuit aspectsOvergarmentsCommunication interfaceComputer module

Owner:GOOGLE LLC

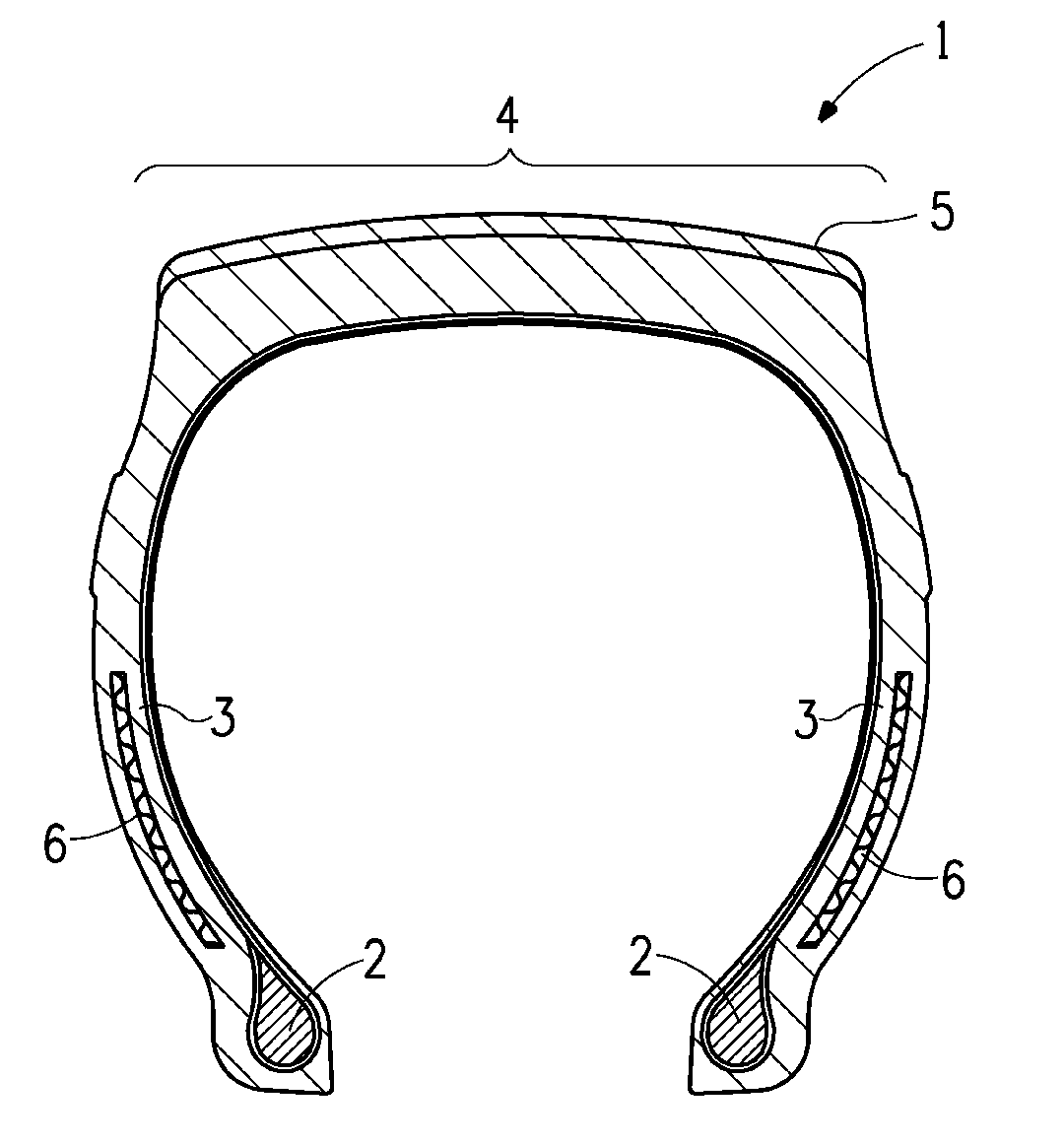

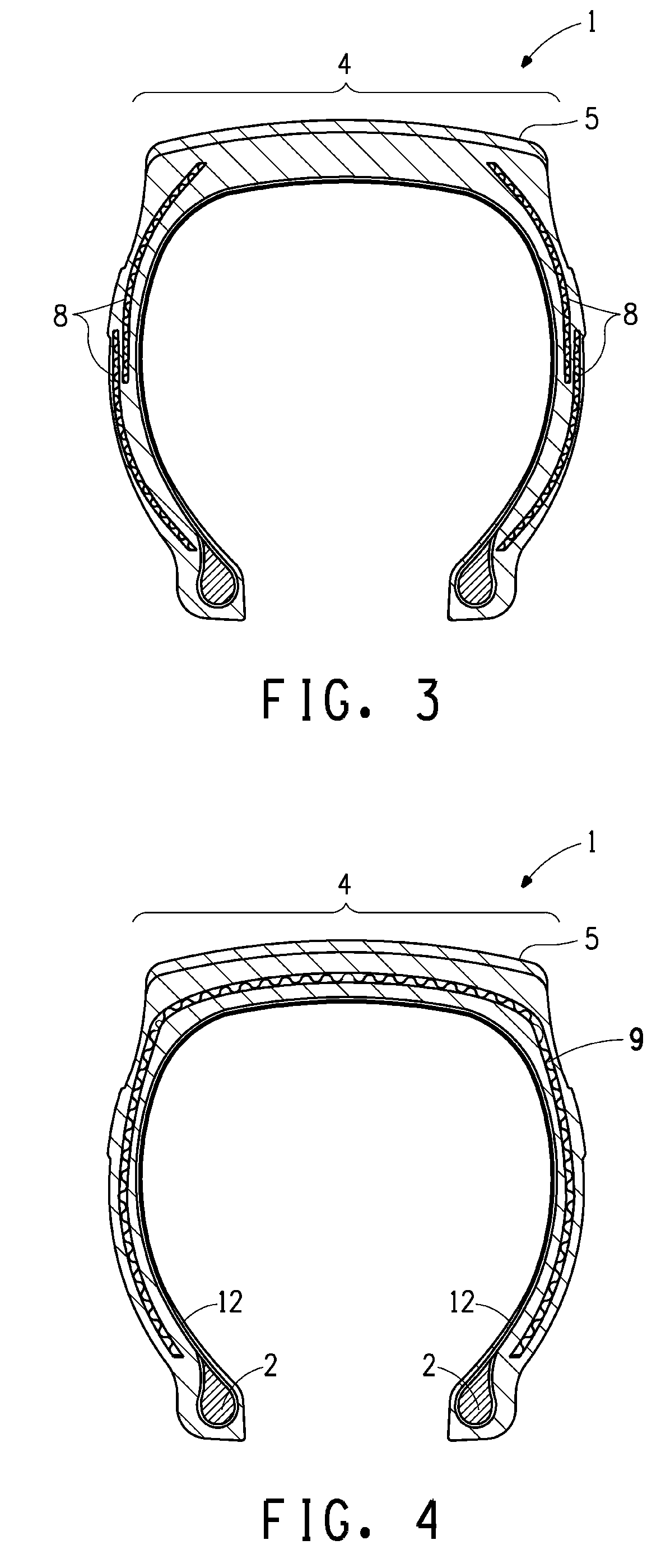

Extensible non-load bearing cut resistant tire side-wall component cotaining elastomeric filament, tire containing said component, and processes for making same

InactiveUS20100108218A1Improved adhesion of fabricLayered productsPneumatic tyre reinforcementsYarnFiber

Owner:EI DU PONT DE NEMOURS & CO +1

Novel uhmwpe fiber and method to produce

Owner:HONEYWELL INT INC

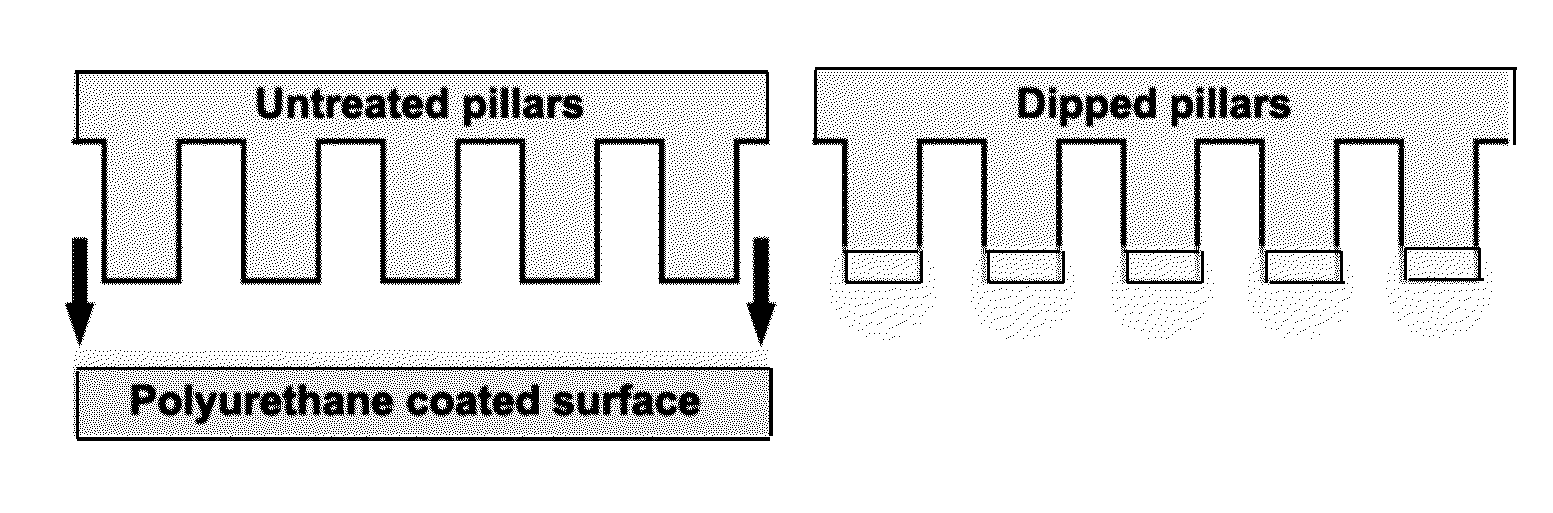

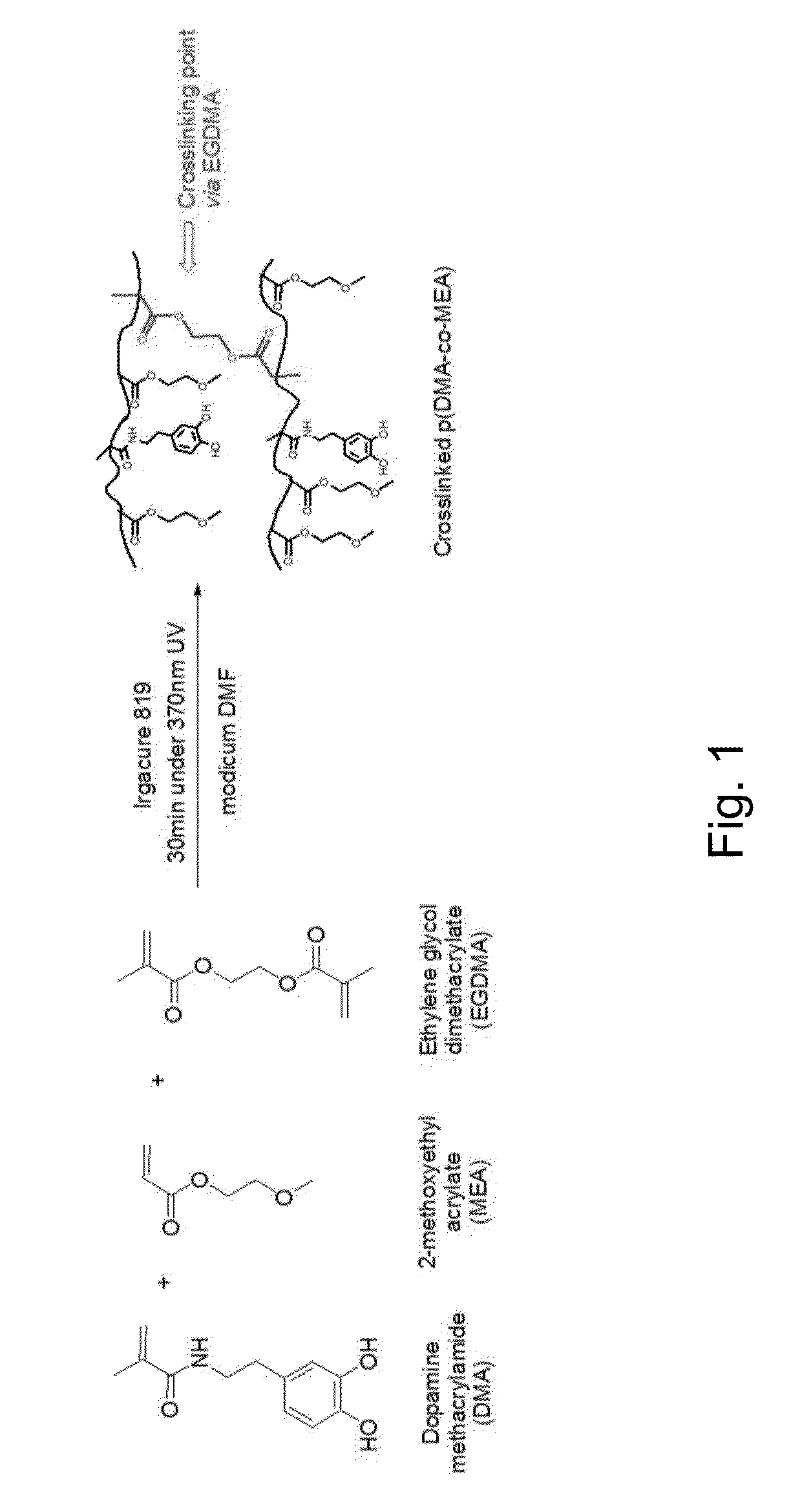

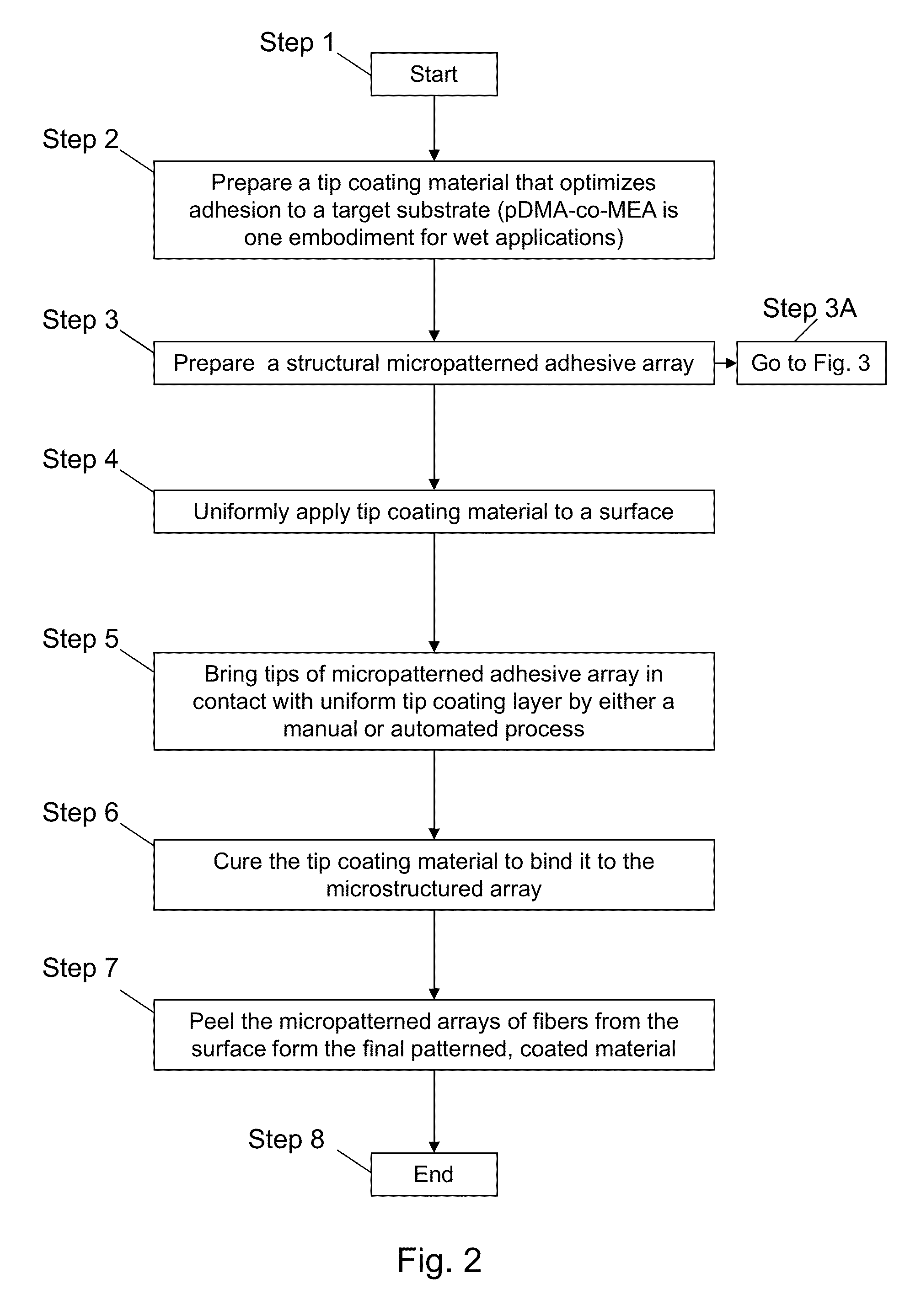

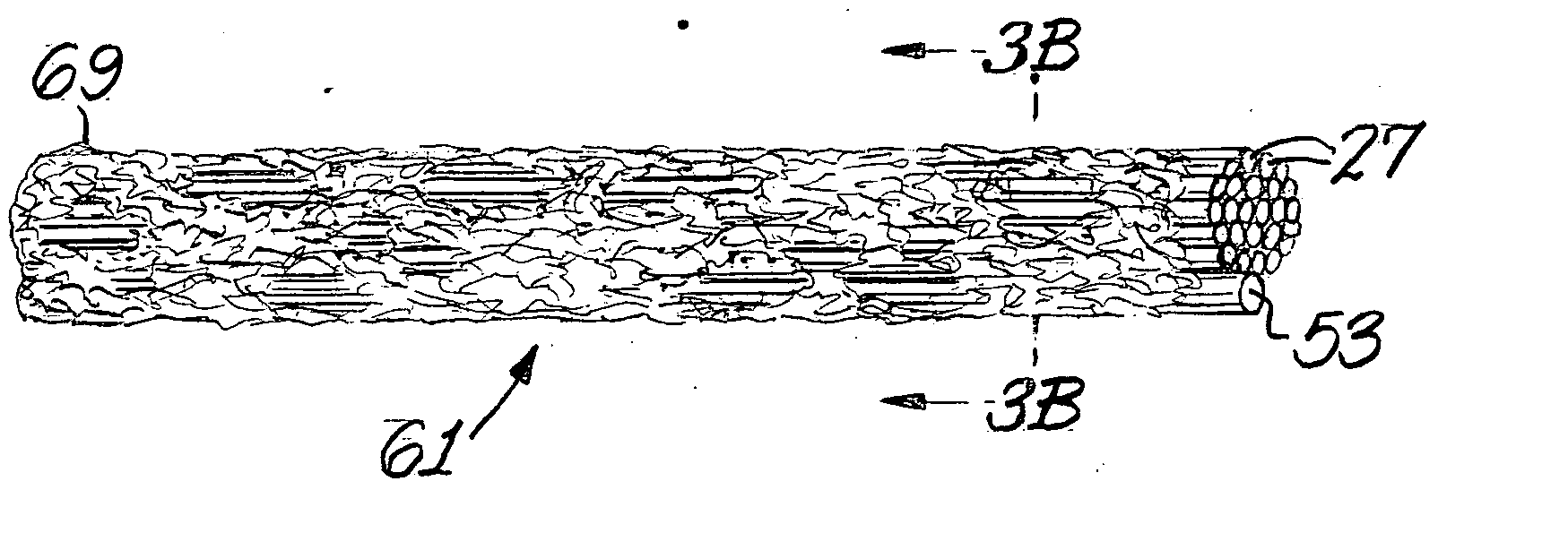

Micro-fiber arrays with tip coating and transfer method for preparing same

ActiveUS20130183481A1Performance deteriorationLayered productsPretreated surfacesMicron scaleElastomer

Owner:CARNEGIE MELLON UNIV CENT FOR TECH TRANSFER & ENTERPRISE CREATION

Size-covered composite yarns and method for making same

InactiveUS20050124245A1Appealing tactile propertyIncrease speedWarp knittingSynthetic resin layered productsYarnFiber

Owner:INVISTA NORTH AMERICA R L

Fiber mat and process for making same

InactiveUS20060292952A1Improved tensileHigh tear strengthNatural cellulose pulp/paperSpecial paperFiberEngineering

Owner:BUILDING MATERIALS INVESTMENT

Waterproofing Membrane

InactiveUS20100196648A1Improve adhesionGood anti-sag performanceAdhesive articlesCoatingsLow-density polyethylenePolymer science

Owner:GCP APPL TECH INC

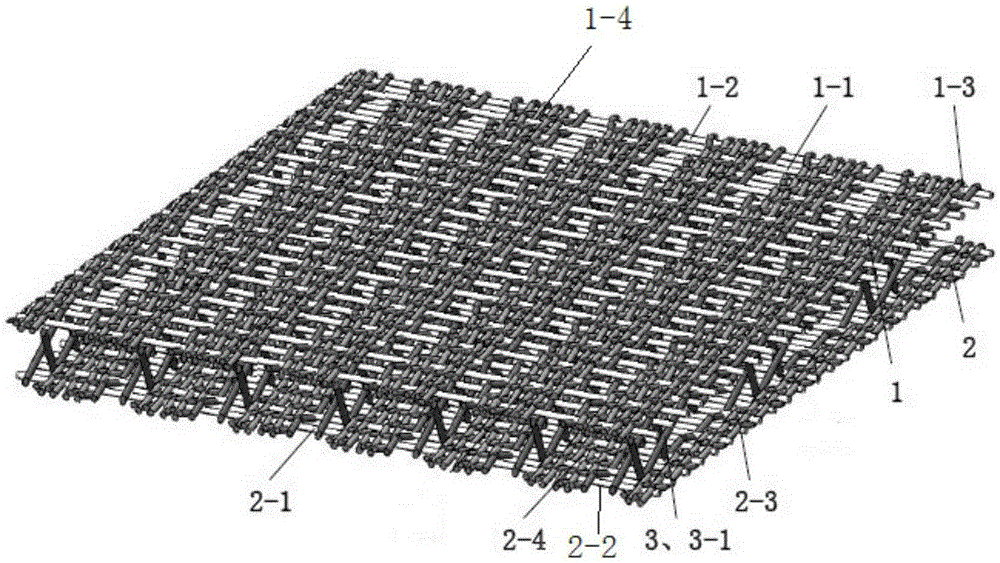

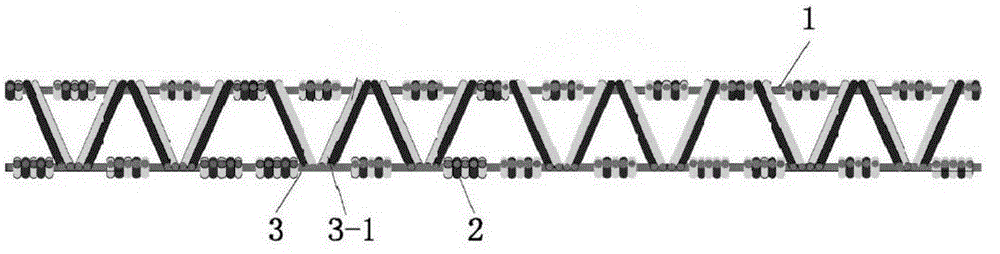

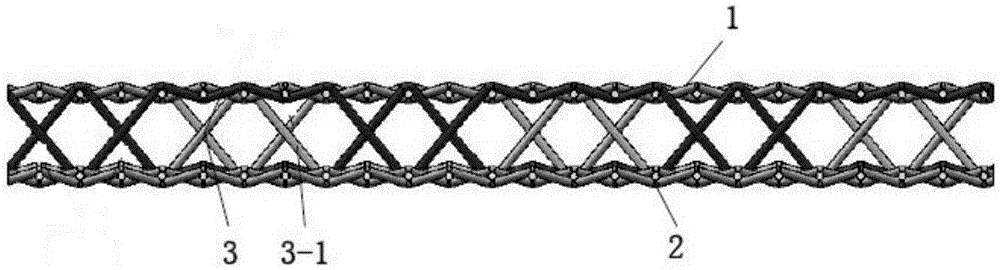

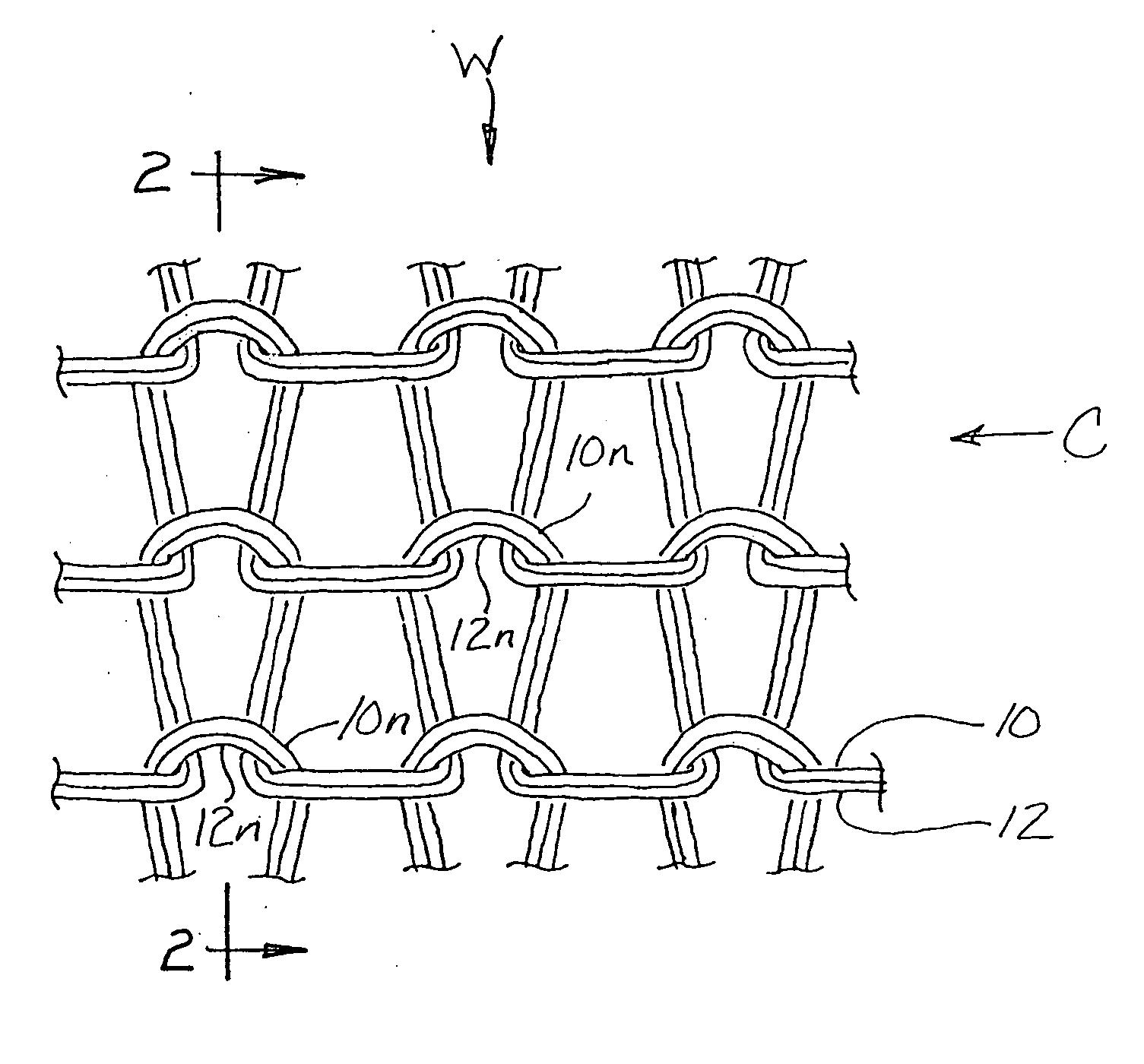

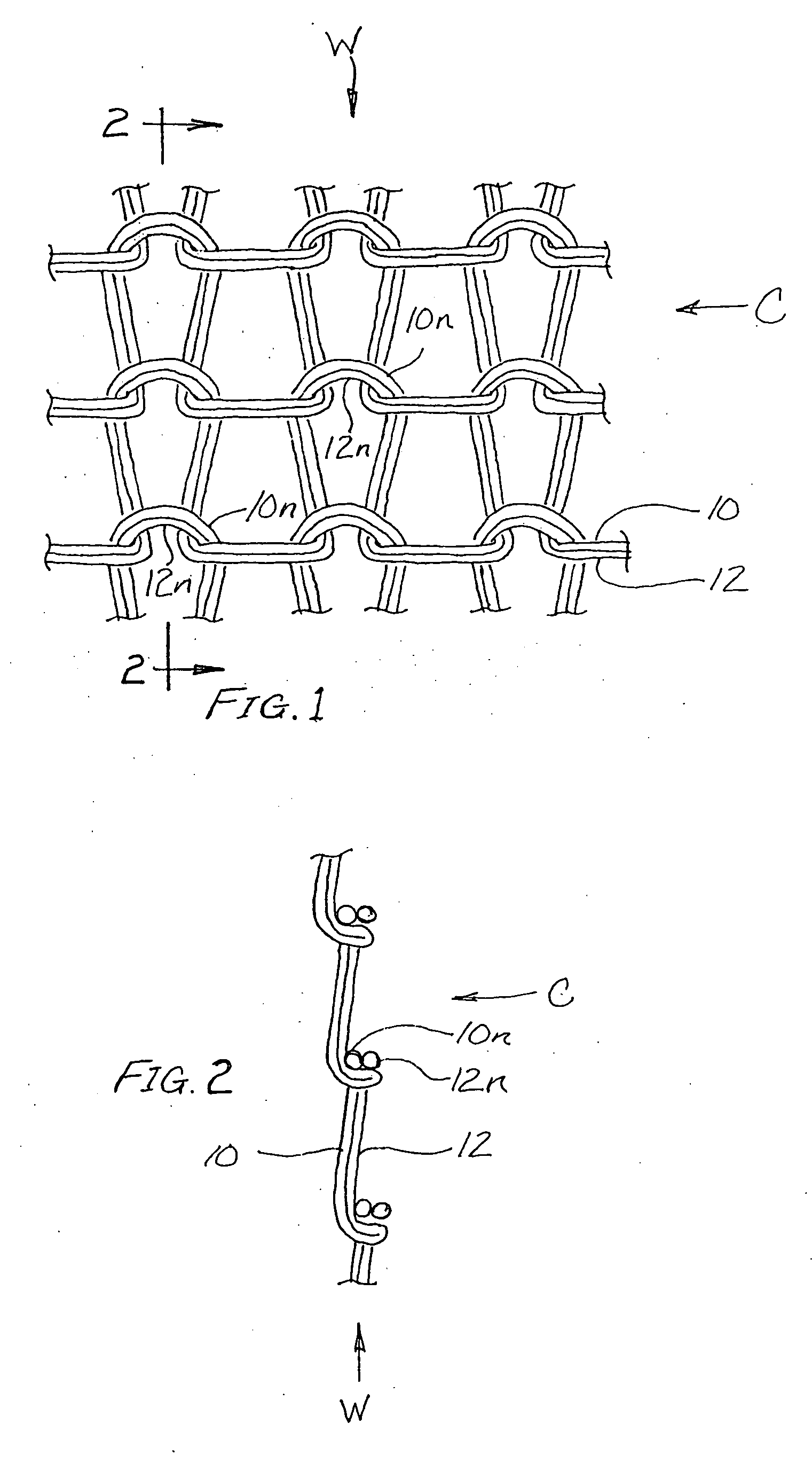

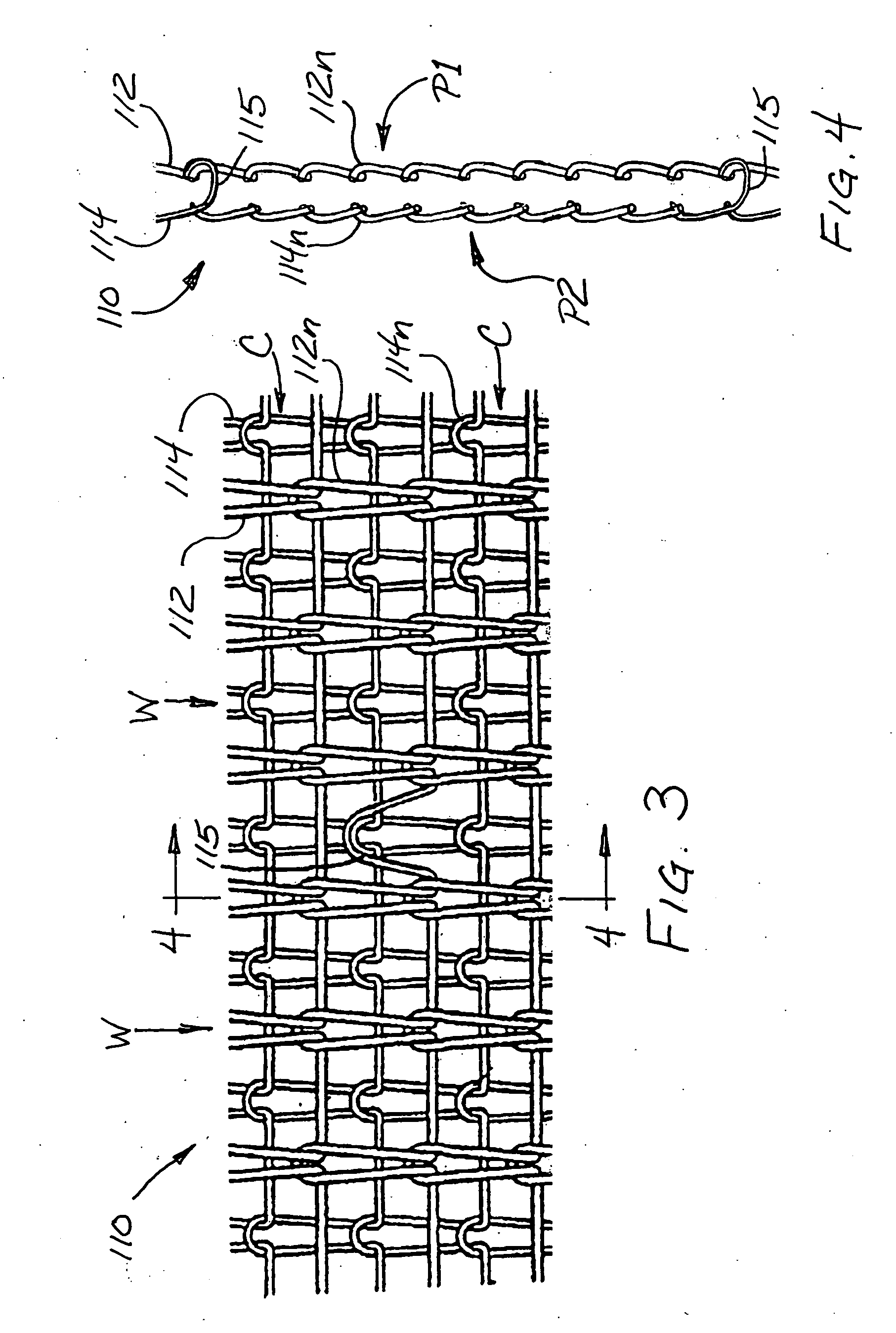

Plastic resin-impregnated three-dimensional hollow platelike woven fabric

Owner:CHANGZHOU YUECHENG NEW MATERIAL

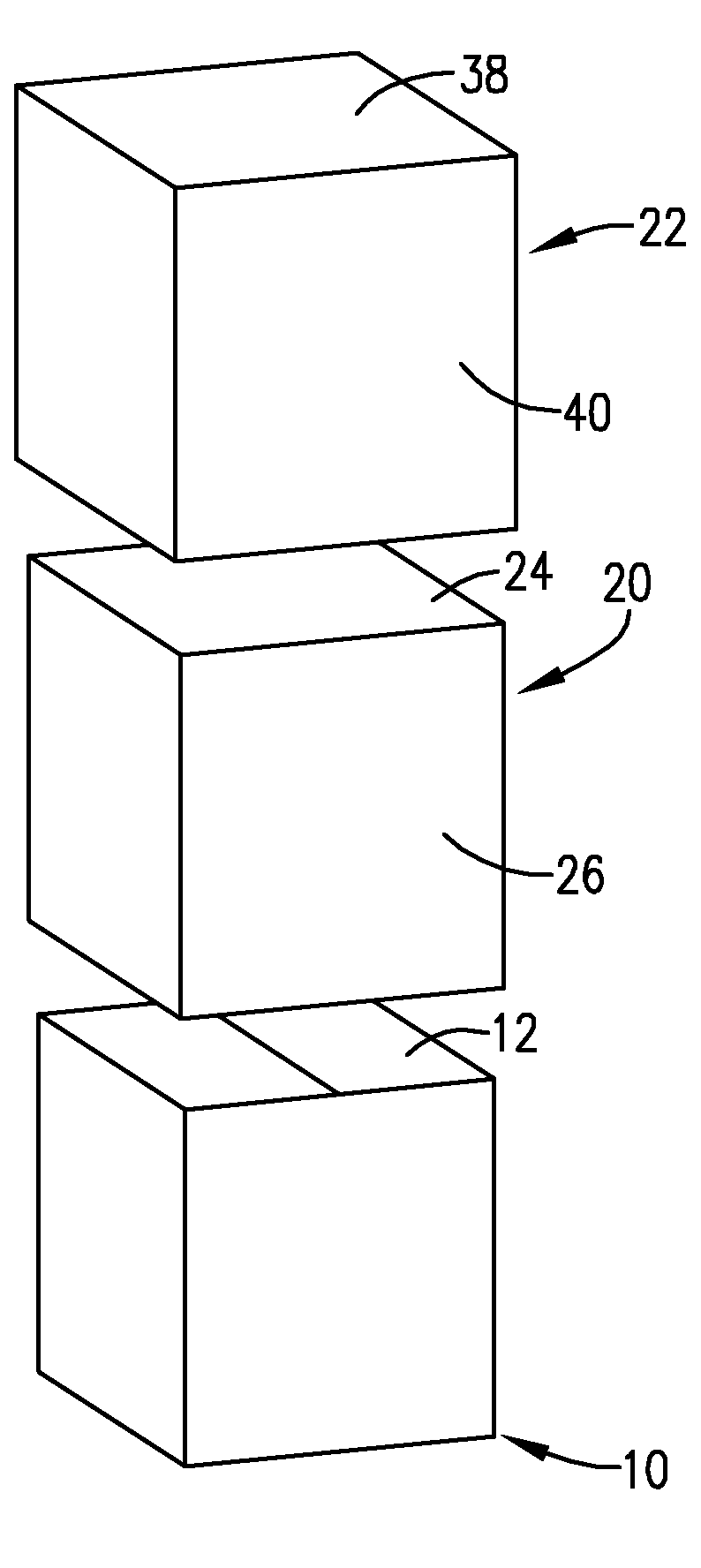

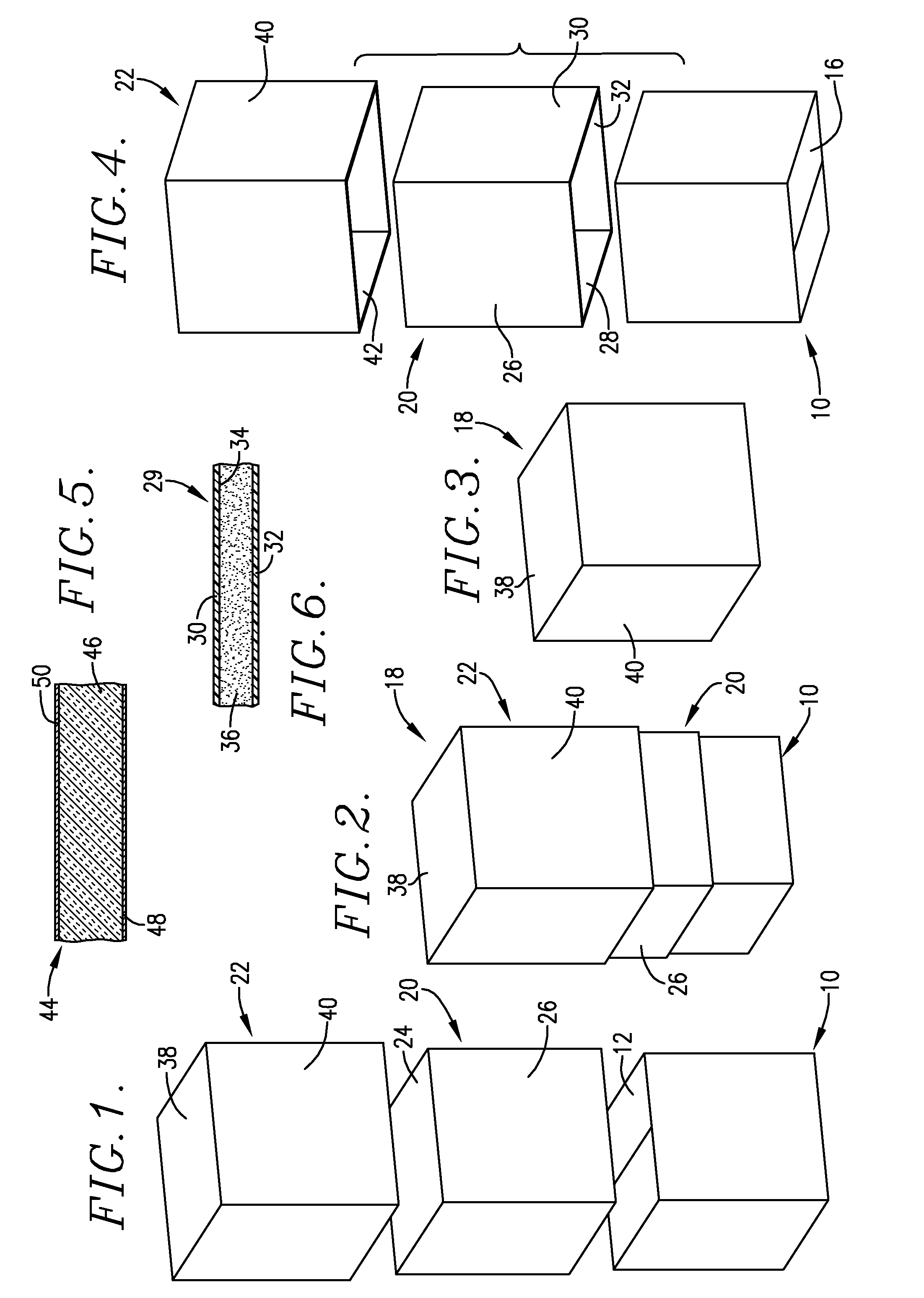

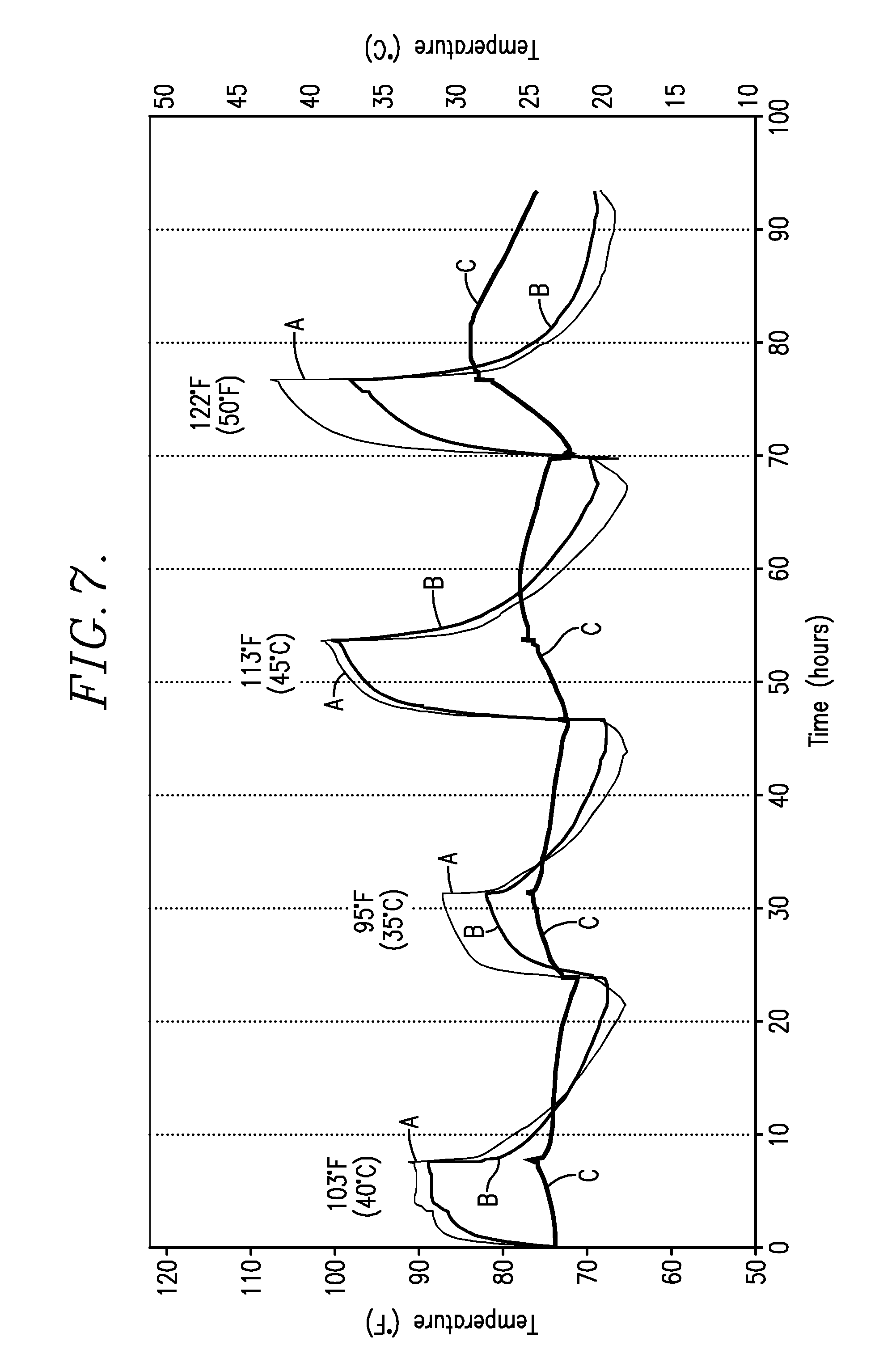

Cover assembly for temperature-sensitive cartons or articles

Owner:GRAND DESIGN

Fabric with water absorption and air permeability and production method thereof

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

Pure mulberry silk fabric comprising double sided warp patterns

Owner:DALI SILK ZHEJIANG

Cured In Place Pipe Liner With Styrene Barrier

InactiveUS20100243154A1Promote migrationHigh hardnessPipe elementsRecord information storageEngineeringCured-in-place pipe

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on fibrous mat of non-woven fabric. The TPU coating contains a barrier layer to retard the migration of styrene from the liner to the media used to force the liner against the damaged pipe and to activate the thermoset resin. The thermoset resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe.

Owner:LUBRIZOL ADVANCED MATERIALS INC

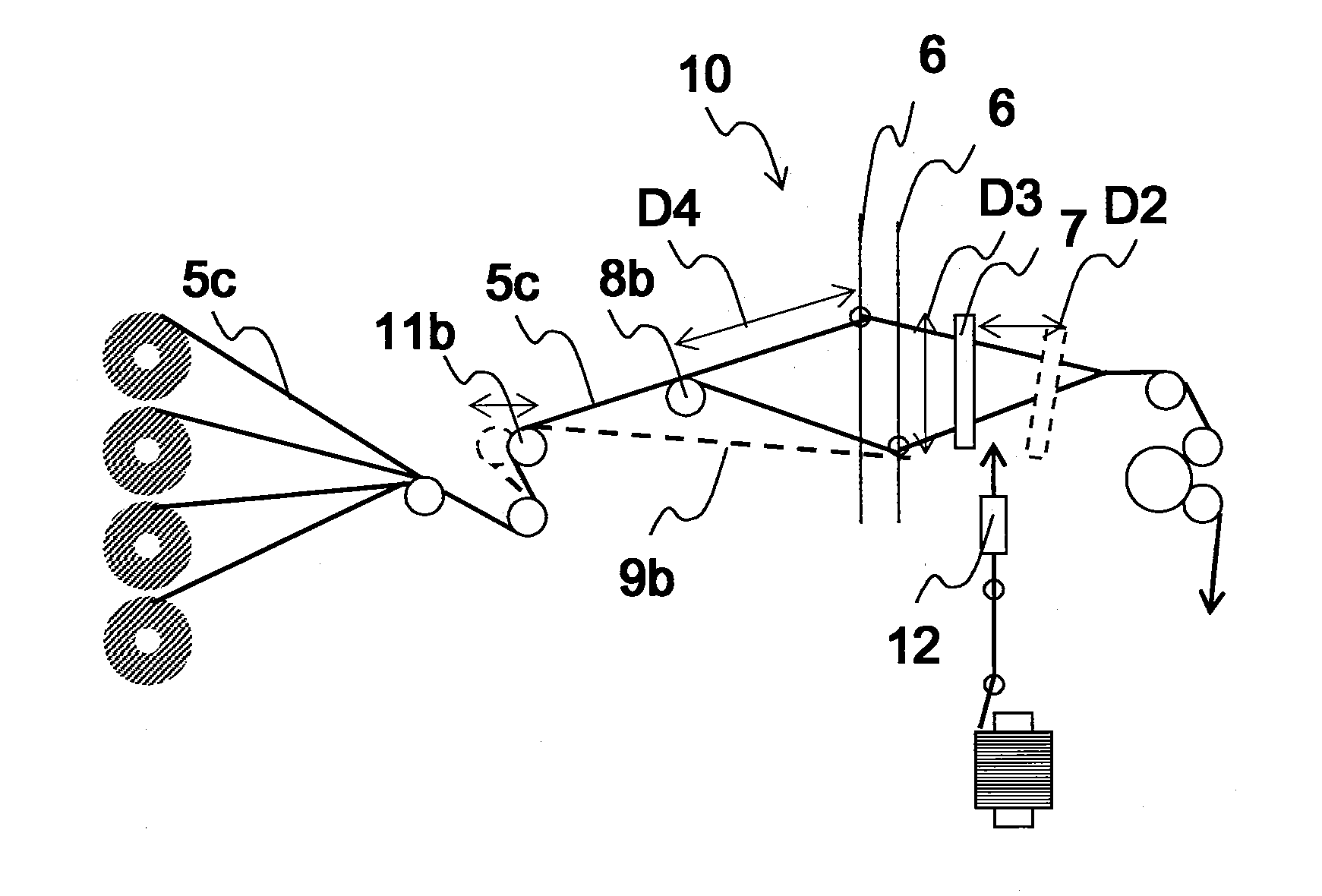

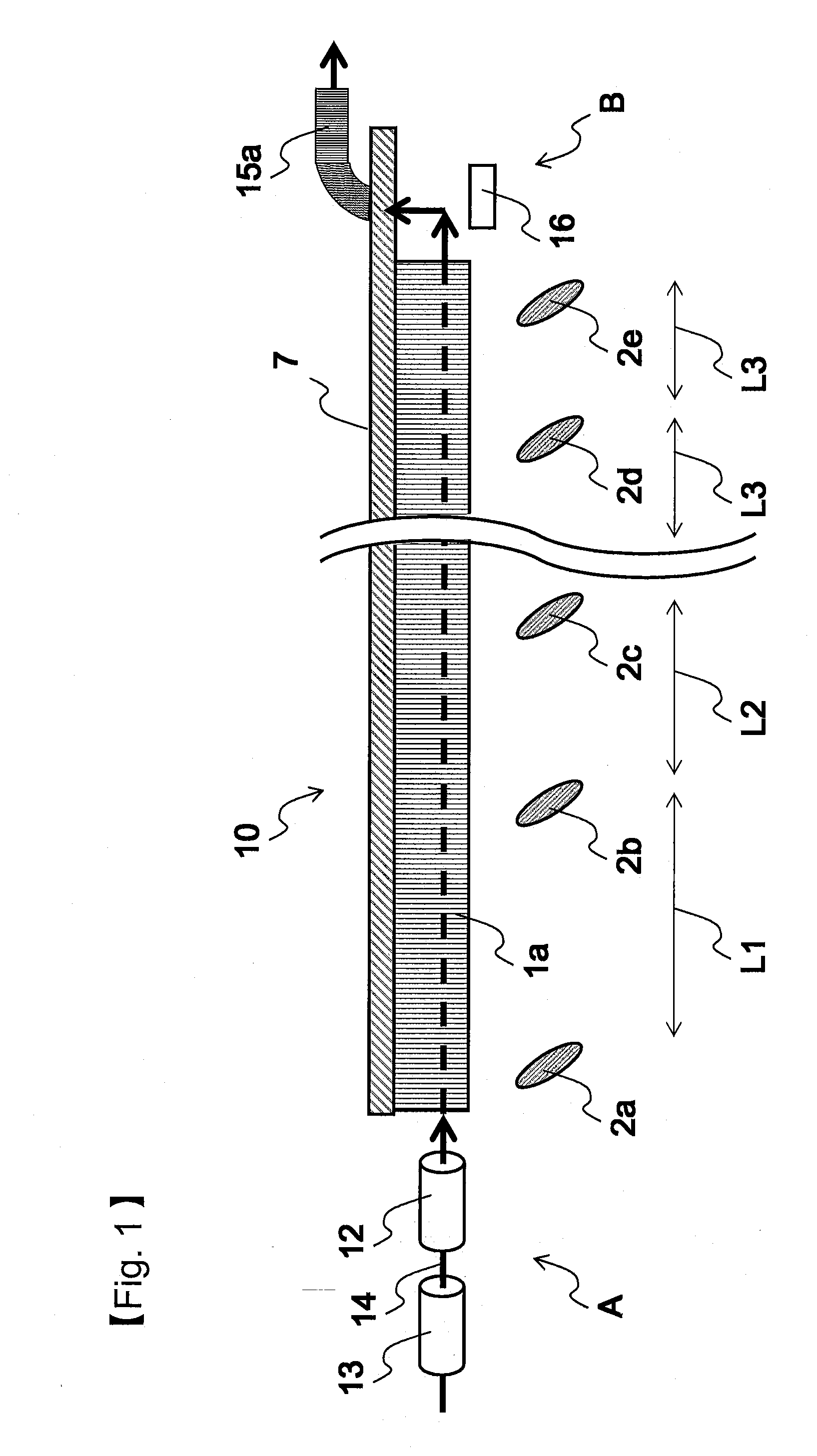

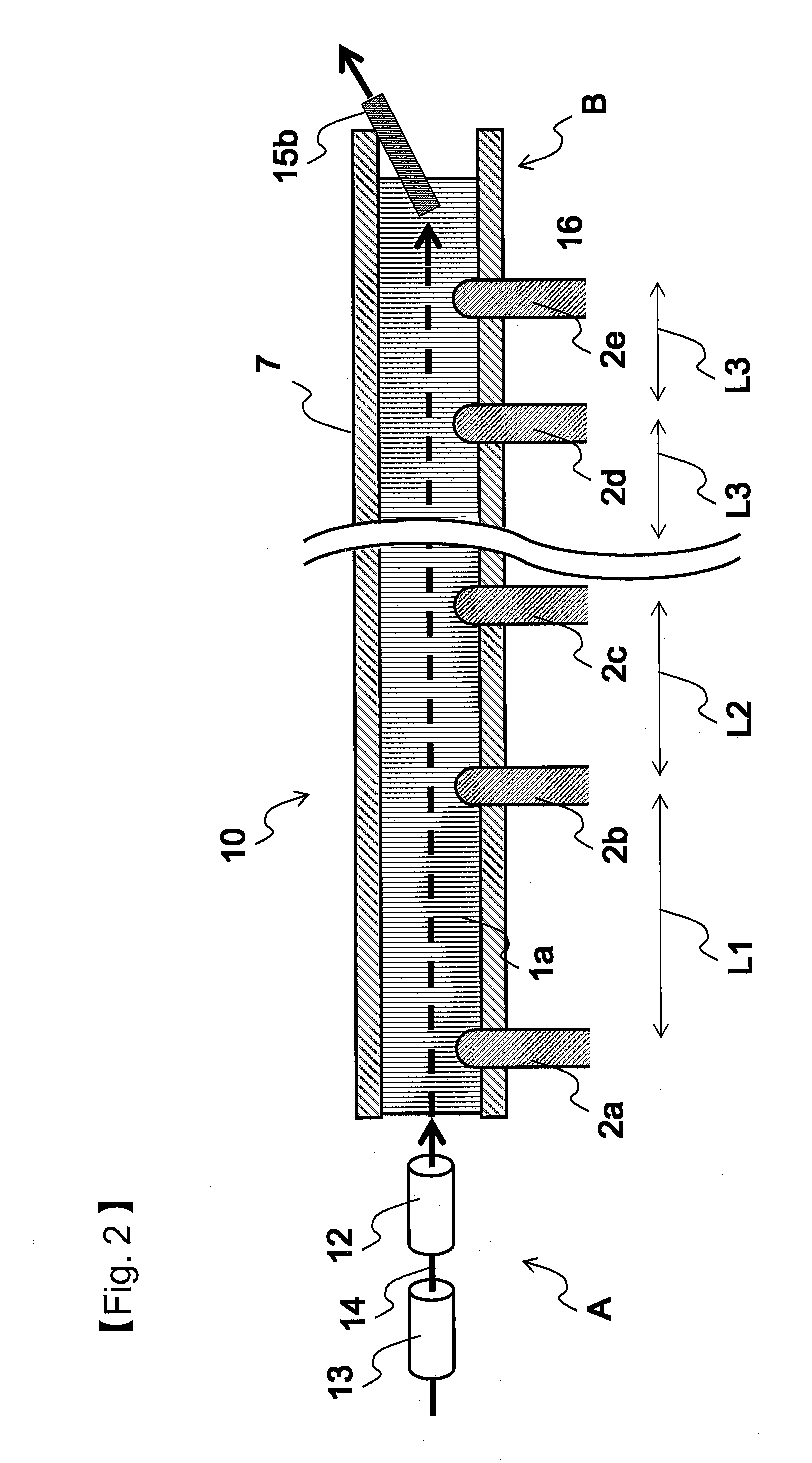

Method for producing carbon fiber woven fabric

ActiveUS20100032049A1Quality improvementImprove productivityLoomsWoven fabricsProduction rateCarbon fibers

Owner:TORAY IND INC

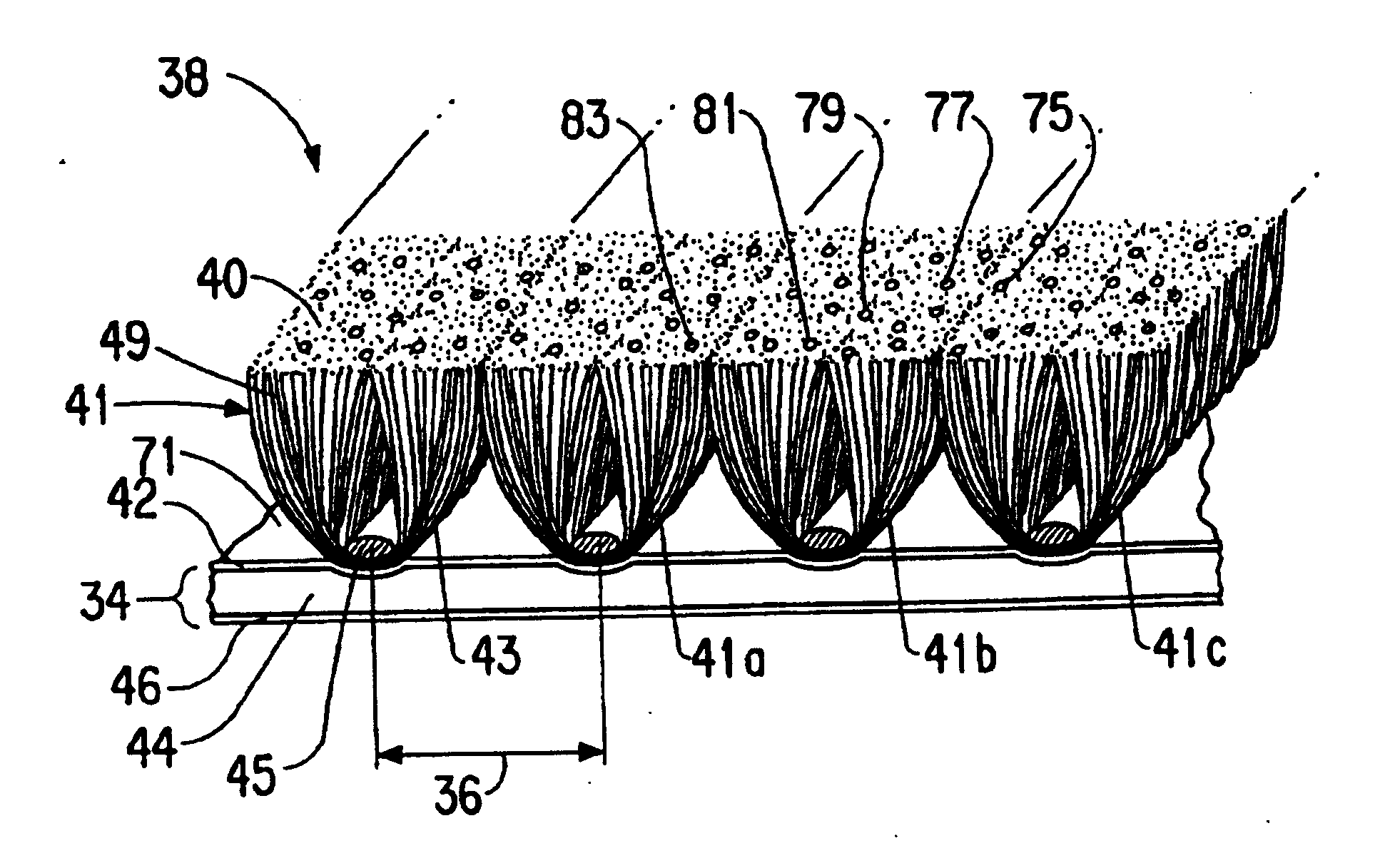

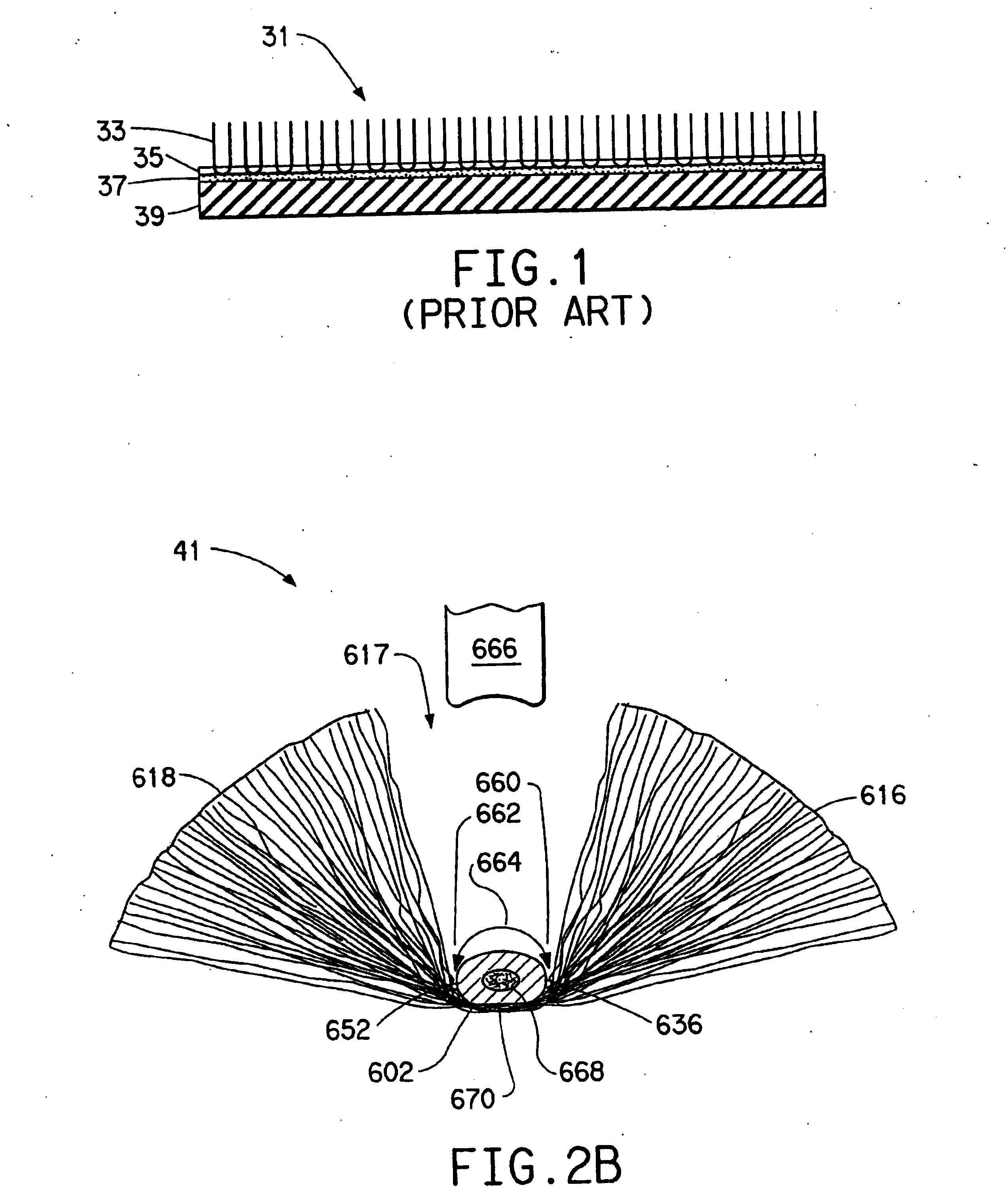

Velour-like pile articles and pile surface structures and methods of making

InactiveUS20050129905A1Convenient guidanceLittle torsional stabilityVehicle arrangementsSynthetic resin layered productsYarnStructural engineering

Owner:INVISTA NORTH AMERICA R L

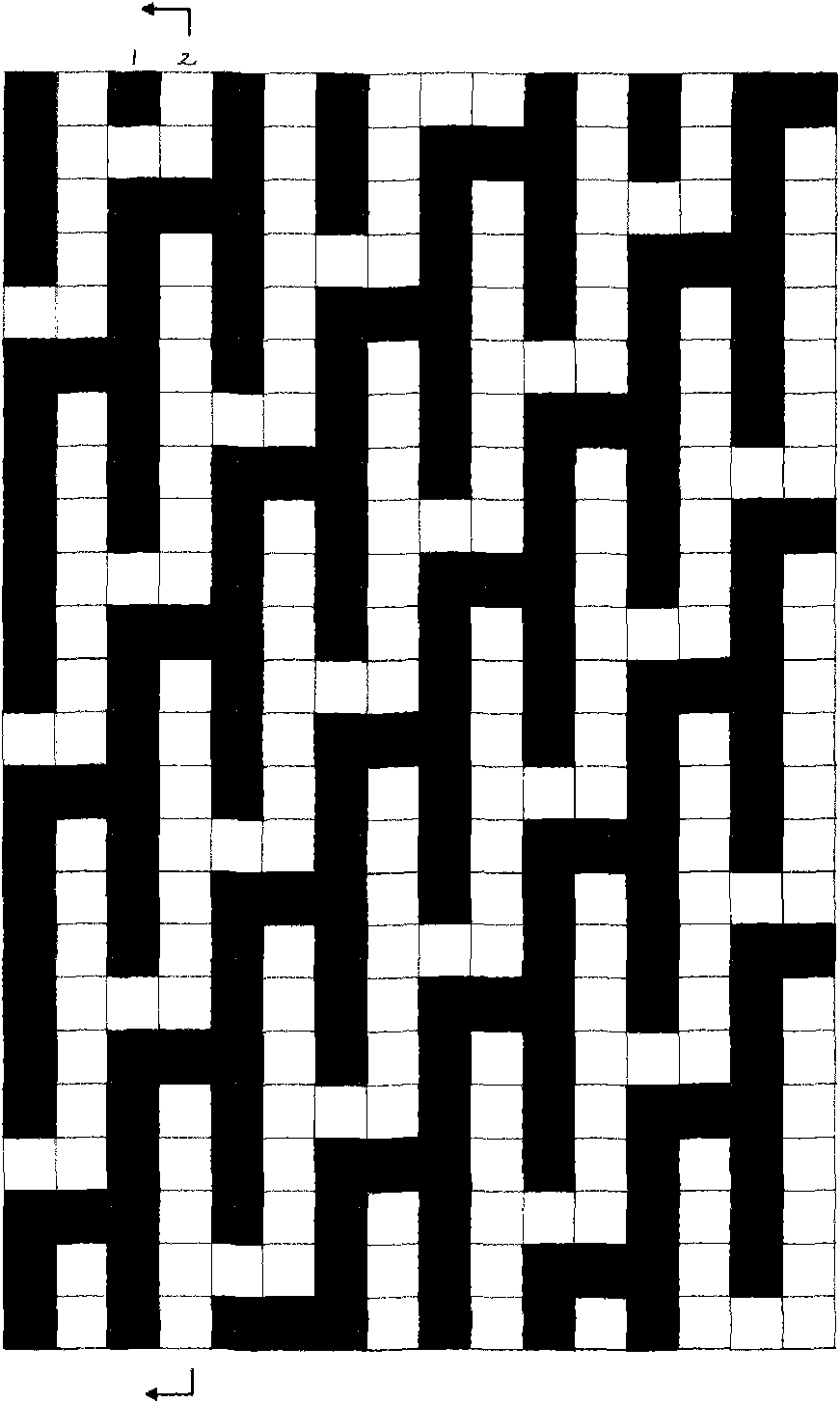

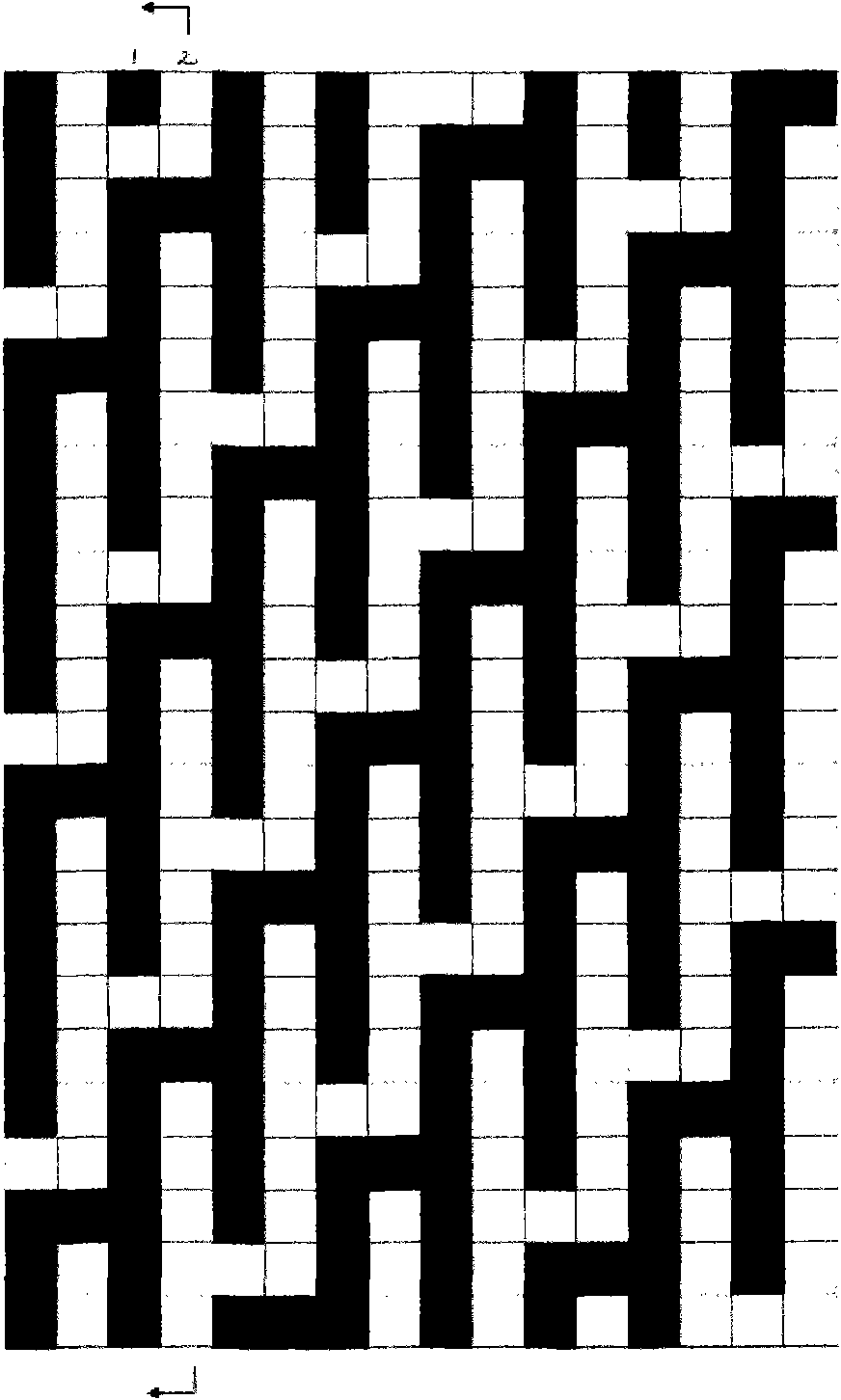

Six-layer jacquard satin towel and quilt type product and weaving method thereof

ActiveCN102973067ASoft touchImprove breathabilityWoven fabricsBed-coversMoisture absorptionBiomedical engineering

Owner:SUNVIM GROUP

Outdoor sport fabric

InactiveCN102477641ASimple structureReasonable structureWoven fabricsPolyethylene terephthalatePolytrimethylene terephthalate

The invention discloses an outdoor sport fabric. The outdoor sport fabric is interwoven by warp yarns and weft yarns. The outdoor sport fabric is characterized in that the warp yarns are 75D / 72F polyester low-stretch moisture-absorption sweat-discharging fibers; two weft yarns are available in the fabric; weft yarns A are 150D / 64F PET / PTT (Polyethylene Terephthalate / Polytrimethylene Terephthalate) composite elastic fibers; the weft yarns B are 32S / 1 tencel fibers; the weft face is adopted as the fabric of the front face of the fabric; weft yarns float at the front face of the fabric; and warp yarns float at the back face of the fabric. The outdoor sport fabric has the advantages of simple and reasonable structure, good cloth surface color uniformity, clear lines, full particles, strong three-dimensional sense, good moisture absorption, softness, comfort, smooth tencel fibers, good drapability and antistatic performances and is an ideal outdoor sport fabric.

Owner:WUJIANG HUAHUANG PRINTING PROD

Ironing-free fabric and manufacturing method thereof

The invention aims to provide an ironing-free fabric and a manufacturing method thereof. On the premise that a resin finishing agent is not used for finishing, the ironing-free fabric still has good anti-wrinkle effect, and the problems of wrinkling, deformation, difficult finishing and the like when the traditional fabrics are washed are solved. The ironing-free fabric is woven by using warps and wefts, wherein the warps are luster polyester filament yarns, and the wefts are cotton yarns. The manufacturing method is characterized in that: a jacquard process is used for weaving; and luster polyester fibers, polyurethane fibers and cotton yarns are dyed at different temperatures during later dyeing respectively. The luster polyester filament yarns are used as the yarns of the ironing-free fabric, so the cloth cover effect is more finished; and the cotton yarns with elastic fibers are used as the wefts, so the ironing-free fabric achieves the handfeel of cotton fabrics and has rebound capability at the same time. Therefore, the fabric has good shape memory function and special ironing-free effect.

Owner:WUJIANG MINGSHIDA TEXTILE

Wool and rabbit fur coat

The invention discloses a wool and rabbit fur coat. Warps of the wool and rabbit fur coat are pure cashmere yarns smaller than 1.0% in roving ratio, while wefts are composite wool yarns formed by blending wool fiber and milk protein fiber according to a mass ratio of 10:1-10:3. The wool fiber is 18-22 micrometers in fineness and 22-25mm in length. The milk protein fiber is 25-32 micrometers in fineness and 33-38mm in length. The wool and rabbit fur coat is fine in quality, light and soft with no hair slip, and antistatic.

Owner:KUNSHAN CITY ZHOUSHI FEIHUANG GARMENT FACTORY

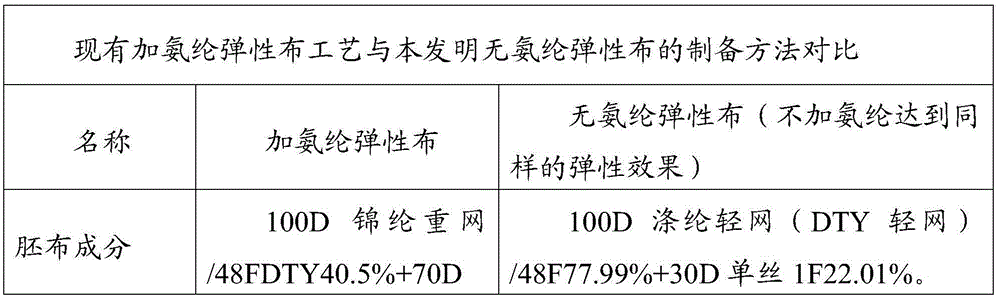

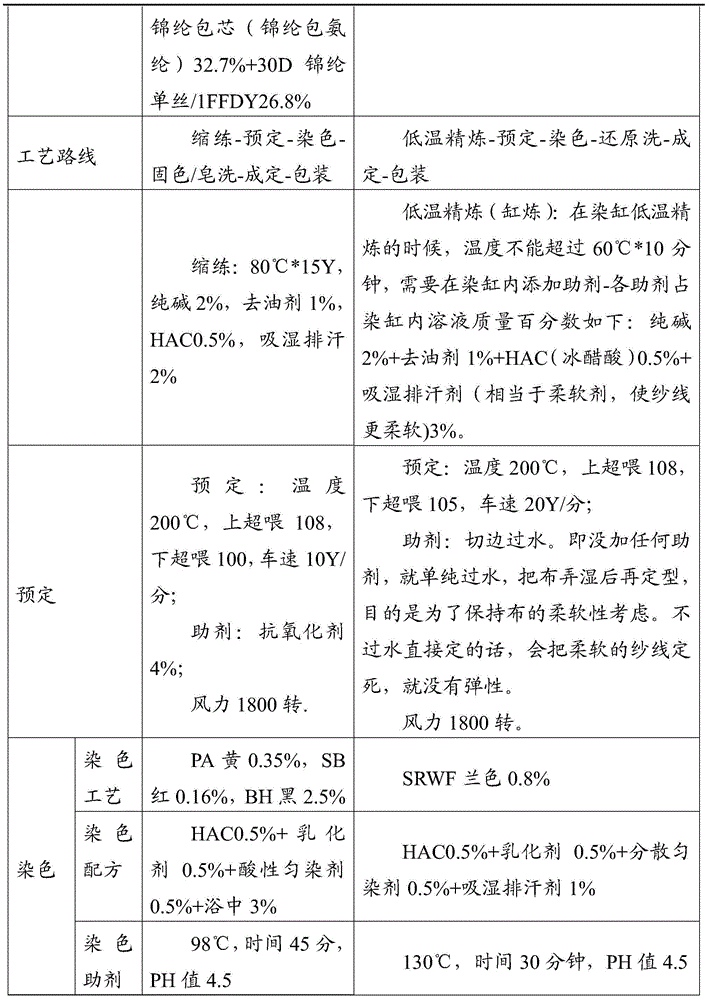

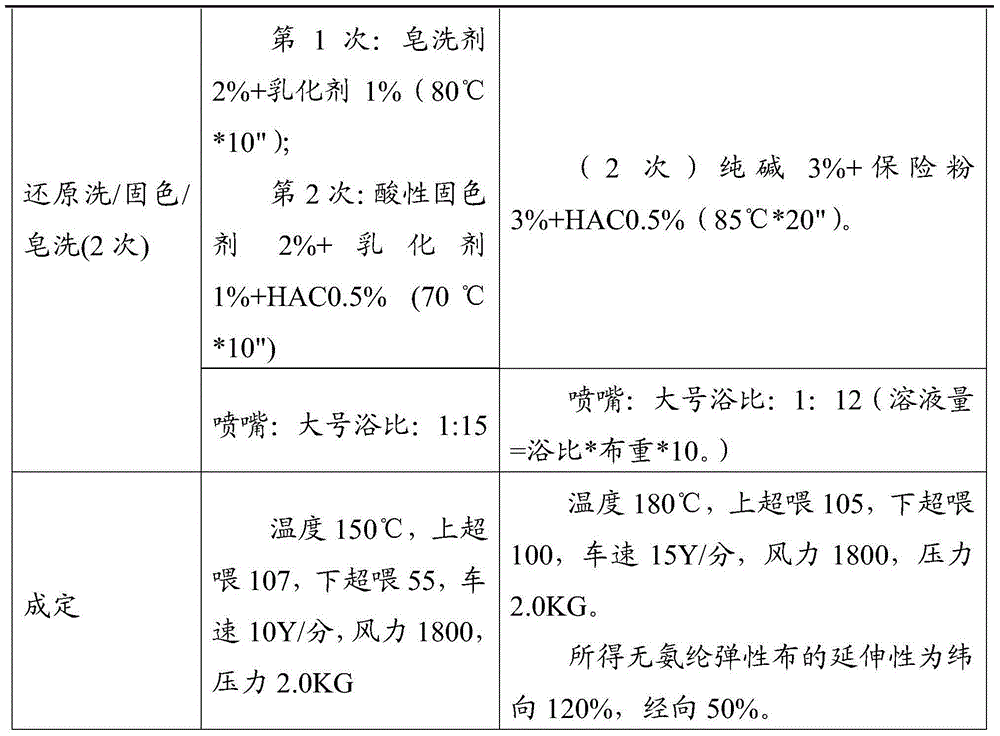

Preparation method of spandex-free elastic cloth

InactiveCN105274878APrevent color spillBleeding does not occurFibre typesHeating/cooling textile fabricsPolyesterYarn

Owner:PUTIAN HUAFENG IND & TRADE CO LTD

Production method of suede elastic fabric

Owner:JIANGSU SUNSHINE GRP CO LTD

Flame-resistant high visibility textile fabric for use in safety apparel

ActiveUS20100003880A1Improve visibilityFlame resistanceWeft knittingOrnamental textile articlesVisibilityYarn

Owner:INNOVATIVE TEXTILES LLC

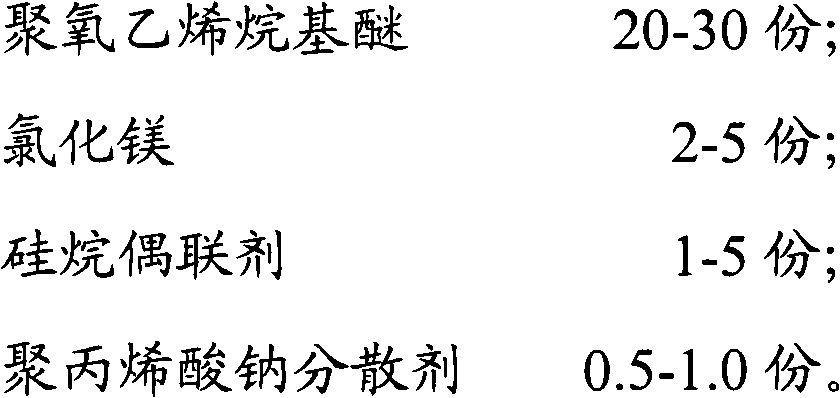

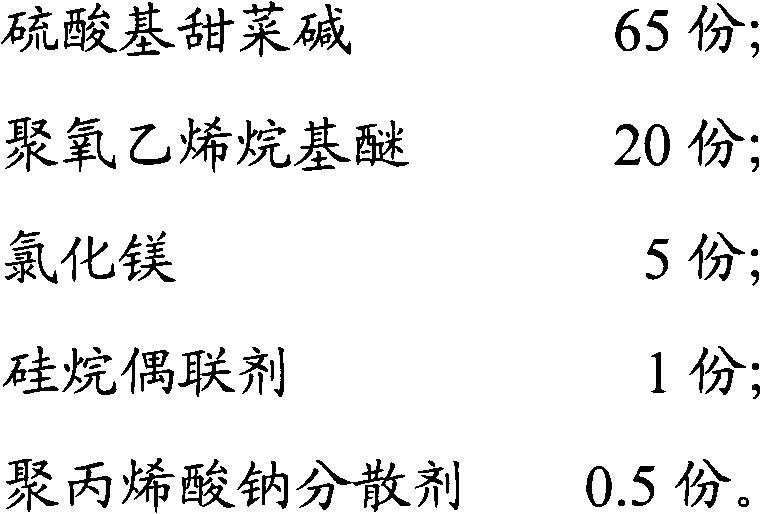

Antibacterial finishing agent, antibacterial yarn and preparation method and application of antibacterial yarn

InactiveCN107217481AHas antibacterial propertiesPrevent mildewBiochemical fibre treatmentGrip property fibresYarnWater based

Owner:湖南莎丽袜业股份有限公司 +1

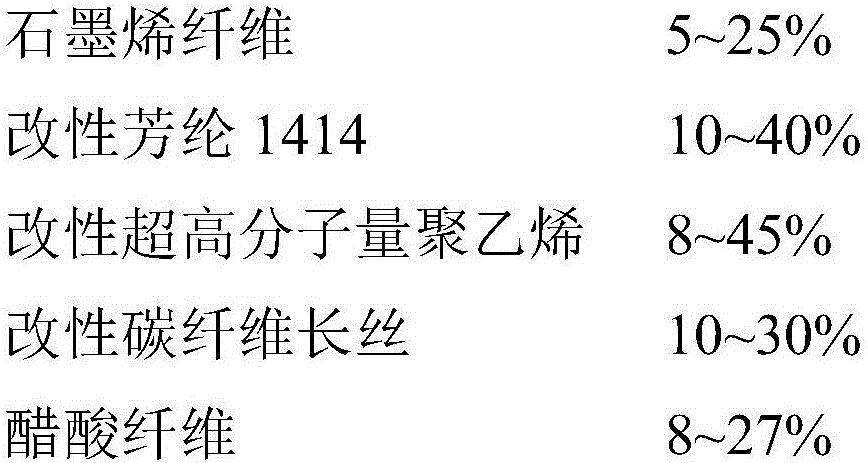

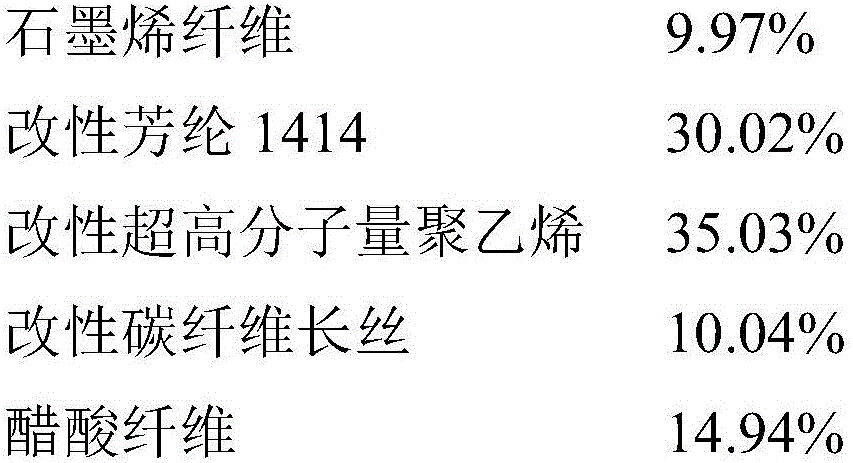

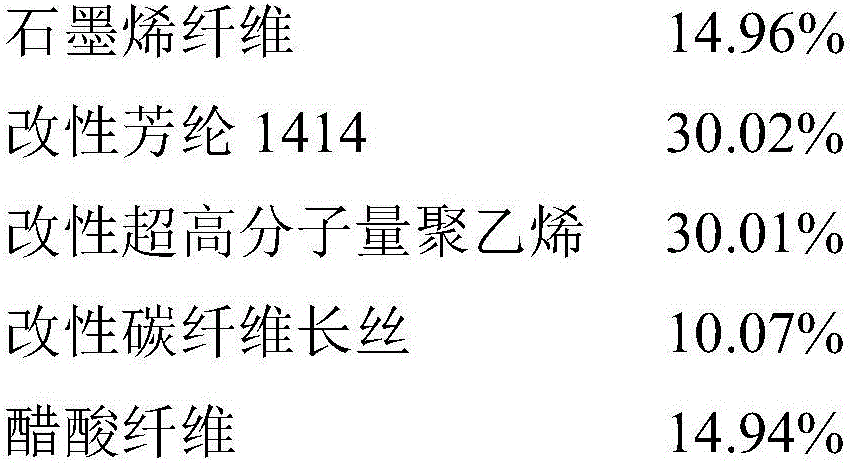

Ultralight bulletproof cloth and manufacture method thereof

Owner:广东军铠防护科技有限公司

Method for manufacturing viscose fiber/wool/polyester fiber blended fabric

InactiveCN104674433AImprove performanceWith adjustment functionWoven fabricsLiquid/gas/vapor textile treatmentPolyesterPolymer science

The invention discloses a method for manufacturing a viscose fiber / wool / polyester fiber blended fabric. Selected warps and wefts comprise the following components in parts by mass: 30 to 60 parts of wool, 10 to 15 parts of polyester fibers, 3 to 8 parts of mulberry silk, 40 to 90 parts of viscose fibers, 20 to 40 parts of combed cotton and 8 to 18 parts of super fine denier polyester. Warps are 92 / 2, and wefts are 48 / 1. The preparation process of the blended fabric comprises the following operations of scotching, cotton carding, sliver mixing, knitting for the first time, knitting for the second time, knitting for the third time, knitting for the fourth time, roving, spinning and weaving, wherein the weaving process also comprises the operations of warping, doubling, double-twisting, vacuum shaping, sizing and air injection, and in the operations of drawing, knitting for the first time, knitting for the second time, knitting for the third time, knitting for the fourth time, roving and spinning, the relative humidity is controlled to be 70 to 75 percent, and the temperature is controlled to be 26 to 30 DEG C. The blending quality of the blended fabric can be improved, and meanwhile, guarantee for the subsequent dyeing quality is provided.

Owner:SUZHOU CHENHENG WEAVING

Polyester viscose blended fabric

Owner:QINGDAO TOPLINK INFORMATION TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap