Pure mulberry silk fabric comprising double sided warp patterns

A technology of silk fabrics and mulberry silk, which is applied in fabrics, textiles, textiles and papermaking, etc. It can solve the problems of not being able to meet the double-sided pattern function and the pattern pattern is not clear, so as to achieve good market reflection, reduce variegated colors, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Double-sided printed warp fabric for curtains

[0030] 1. Specification design

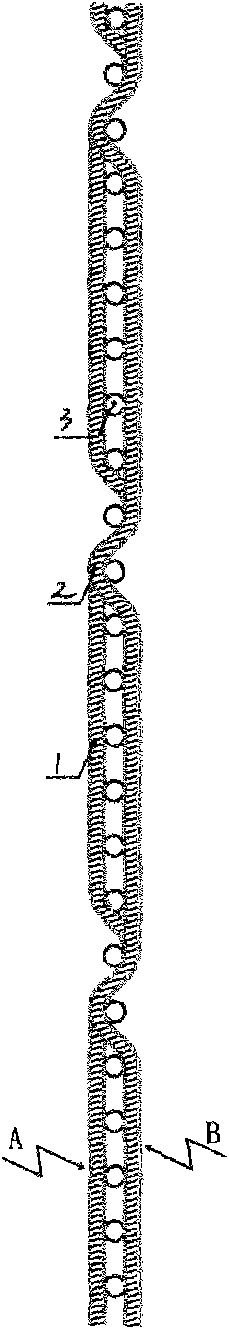

[0031] The upper warp 1 is 4 / 20 / 22D mulberry silk (cooked silk beige), the lower warp 2 is 4 / 20 / 22D mulberry silk (cooked beige), and the weft 3 is 4 / 20 / 22D mulberry silk (raw silk light coffee); The width of the finished product is 140cm, the warp density of the finished product is 140 threads / cm, the weft density of the finished product is 54 threads / cm, and the thickness of the finished product is 34 mm.

[0032] According to the characteristics of the curtain fabric, the hand feeling of the fabric is required to be slightly stiff and skinny, and the weft 3 should be selected from non-degummed mulberry silk that produces color.

[0033] 2. Organizational structure design

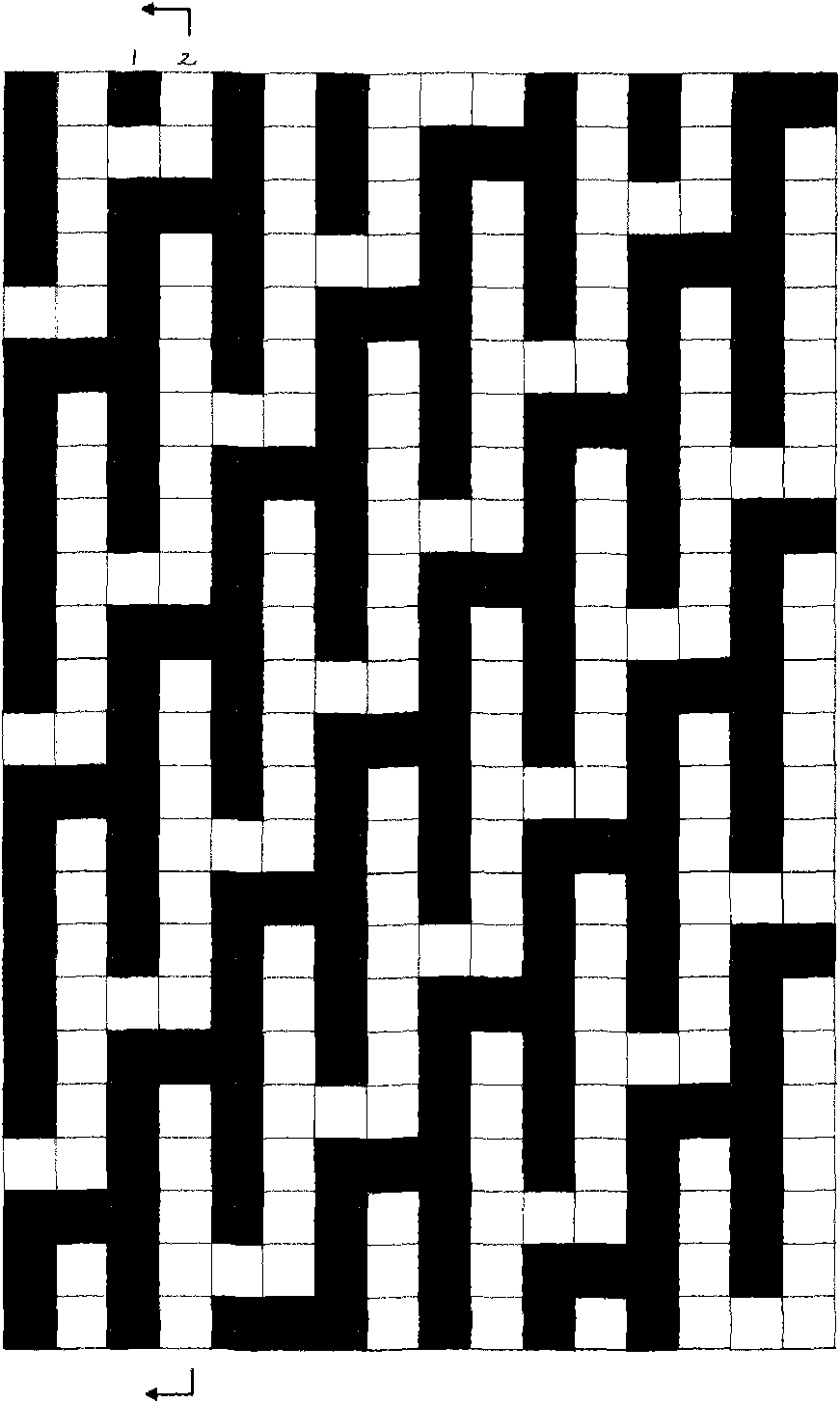

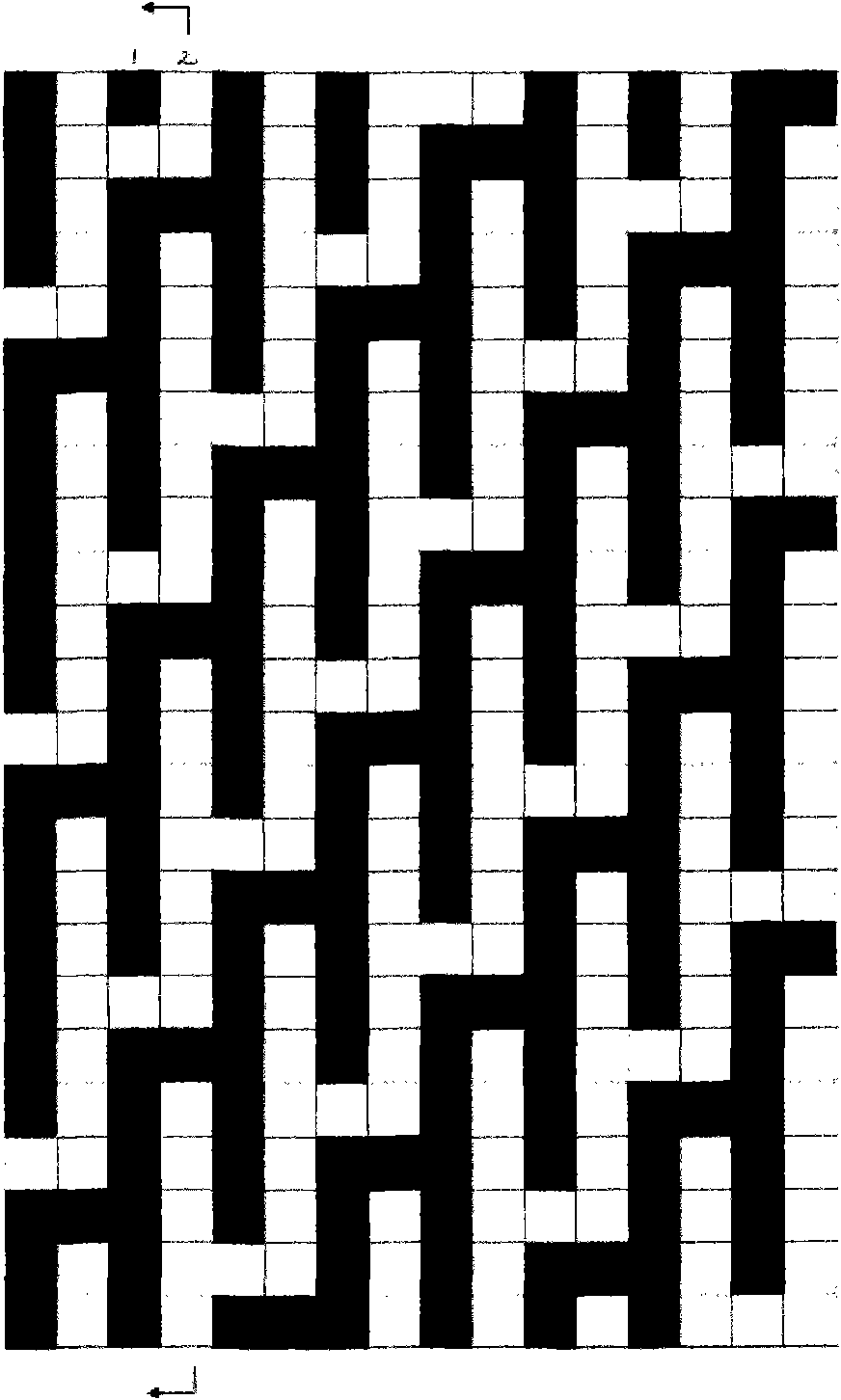

[0034] The upper satin weave layer A and the bottom satin weave fabric B layer of the double-layer satin weave fabric adopt eight pieces of satin weave combination organization.

[0035] 3. W

Embodiment 2

[0052] Example 2: double-sided warp-printed fabric for screens

[0053] 1. Specification design

[0054] The upper warp 1 is 3 / 20 / 22D mulberry silk (cooked silk beige), the lower warp 2 is 3 / 20 / 22D mulberry silk (cooked beige), and the weft 3 is 3 / 20 / 22D mulberry silk (raw silk light coffee); The width of the finished product is 140cm, the warp density of the finished product is 150 threads / cm, the weft density of the finished product is 52 threads / cm, and the thickness of the finished product is 30 mm.

[0055] According to the characteristics of the screen fabric, the fabric needs to feel slightly stiff and skinny, and the weft thread should choose colored and undegummed mulberry silk.

[0056] 2. Organizational structure design

[0057] The upper satin weave layer and the bottom satin weave layer of the double-layer satin weave fabric adopt eight pieces of satin weave combination organization.

[0058] 3. Warping

[0059] Two warp beams with a door width of

Embodiment 3

[0075] Embodiment 3: two-sided printed warp fabric for fashion

[0076] 1. Specification design

[0077] Upper warp 1 is 2 / 20 / 22D mulberry silk (cooked silk beige), lower warp 2 is 2 / 20 / 22D mulberry silk (cooked beige), weft 3 is 2 / 20 / 22D mulberry silk (cooked light coffee) ; The finished product has a door width of 140cm, a finished product warp density of 190 threads / cm, a finished weft density of 48 threads / cm, and a finished product thickness of 22.5 mm.

[0078] According to the characteristics of clothing fabrics, if the fabric is required to feel soft, smooth and easy to bend, cooked silk should be selected for the weft.

[0079] 2. Organizational structure design

[0080] The upper satin weave layer and the bottom satin weave layer of the double-layer satin weave fabric adopt four pieces of satin weave combination organization.

[0081] 3. Warping

[0082] Two warp beams with a door width of 143cm are respectively processed by the section warping machi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap