Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "Pre treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The purpose of the pre-treatment is to remove most of the non-soluble solids physically in order to reduce the pollutant loads and to protect all the subsequent steps in the treatment plant. Providing a reliable, high-quality supply of treated water is critical to many processes.

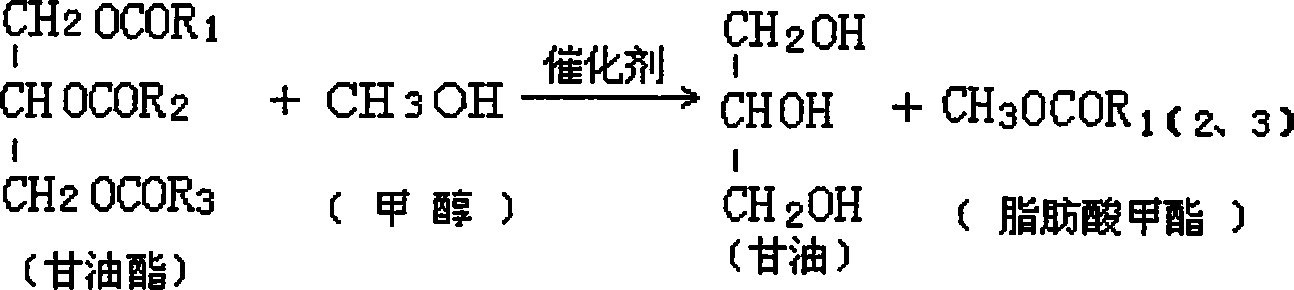

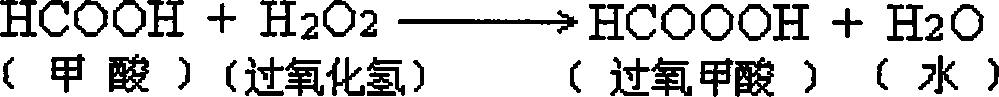

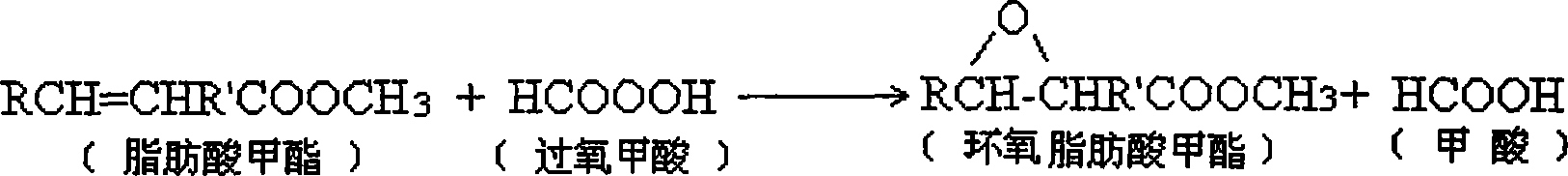

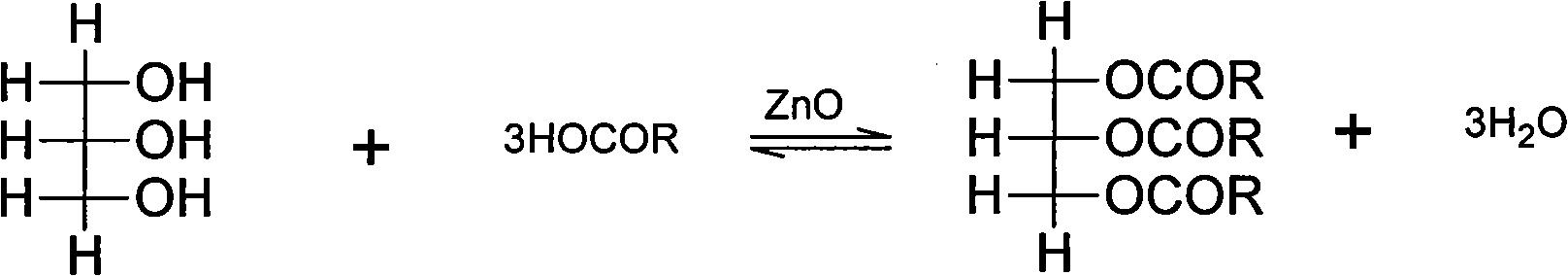

Method for producing epoxy plasticizer using waste grease

InactiveCN101070510AHarm reductionReduce dosageFatty oils/acids recovery from wasteFatty acid esterificationEpoxyDistillation

Owner:江苏向阳科技有限公司

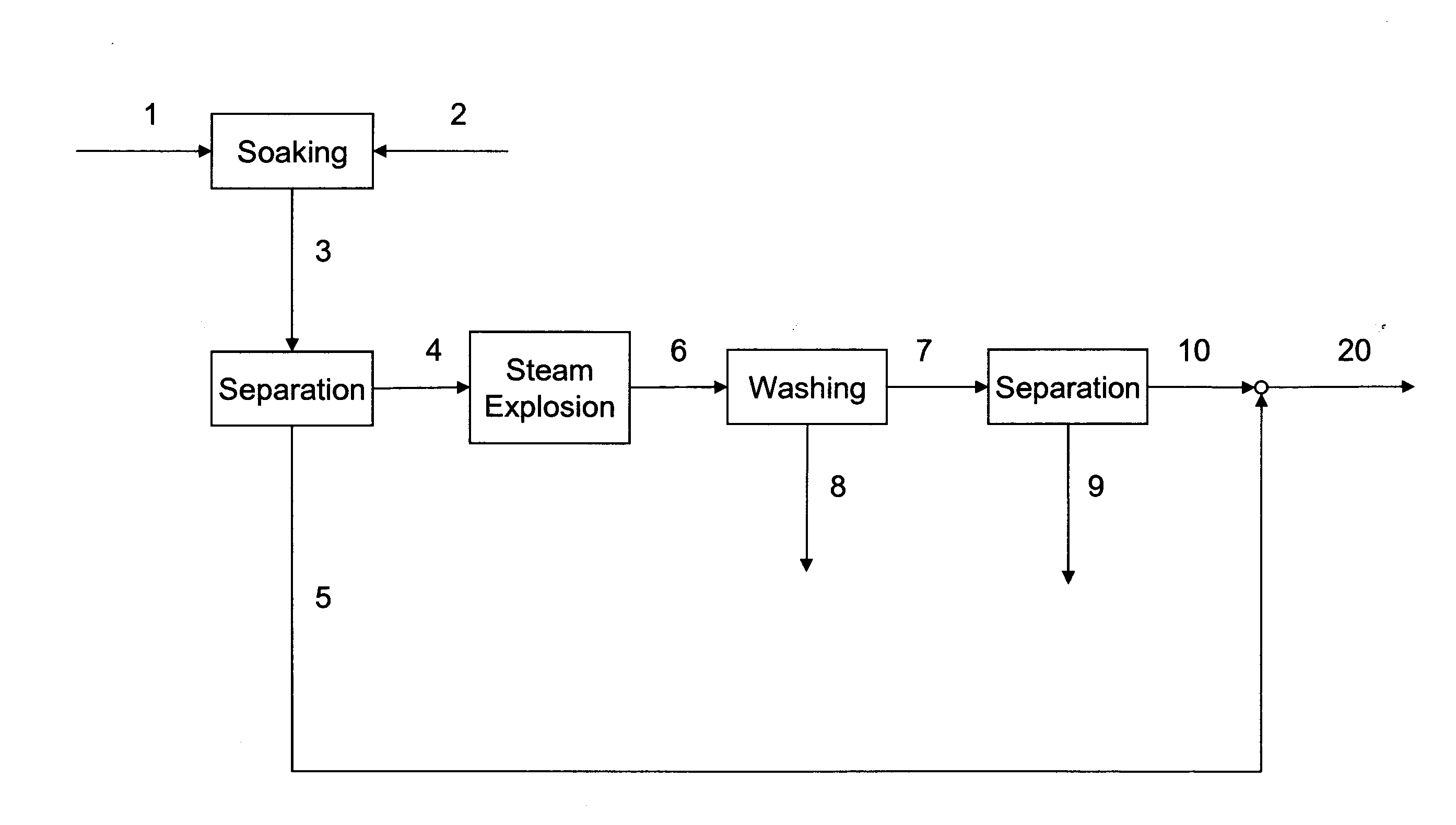

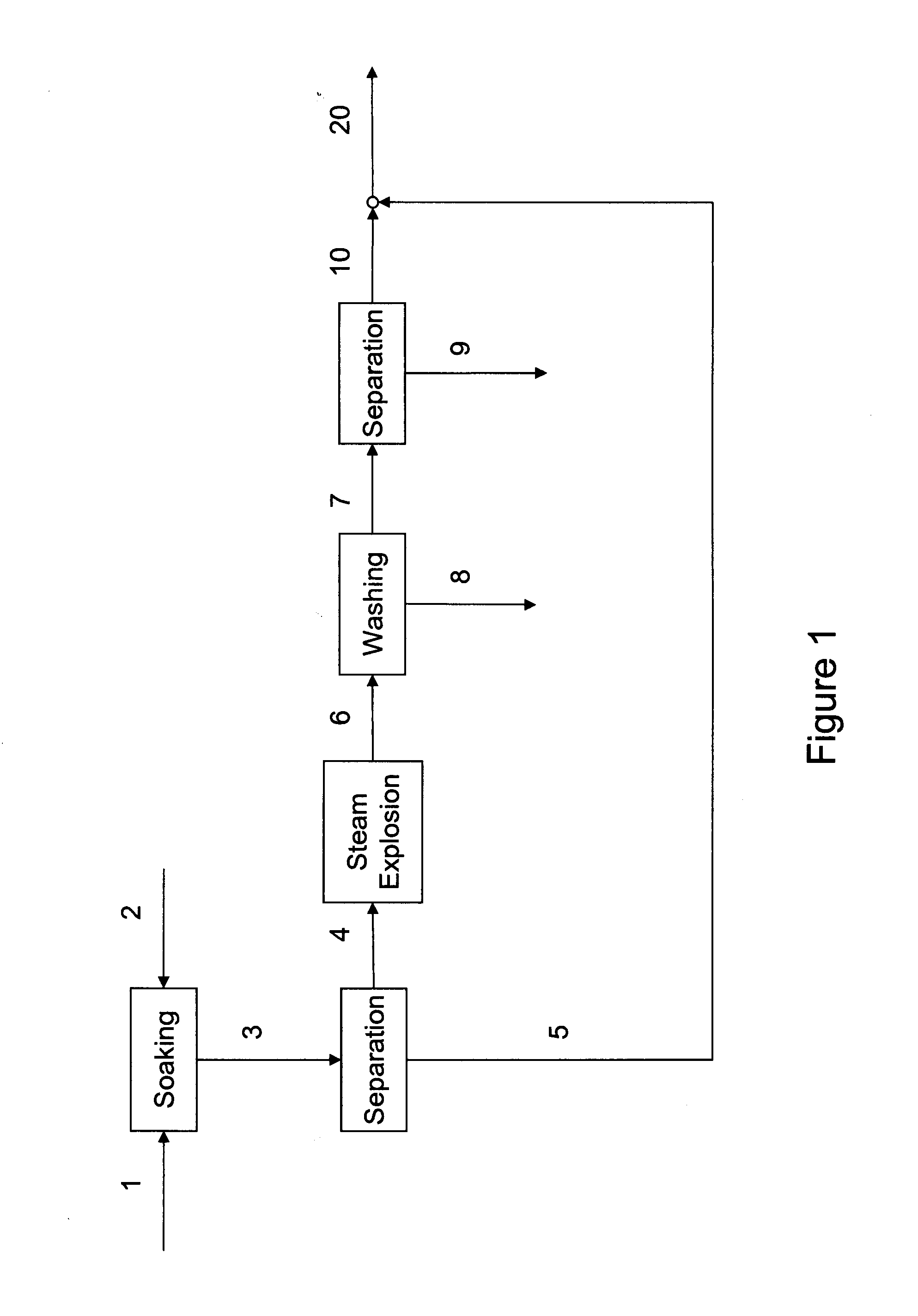

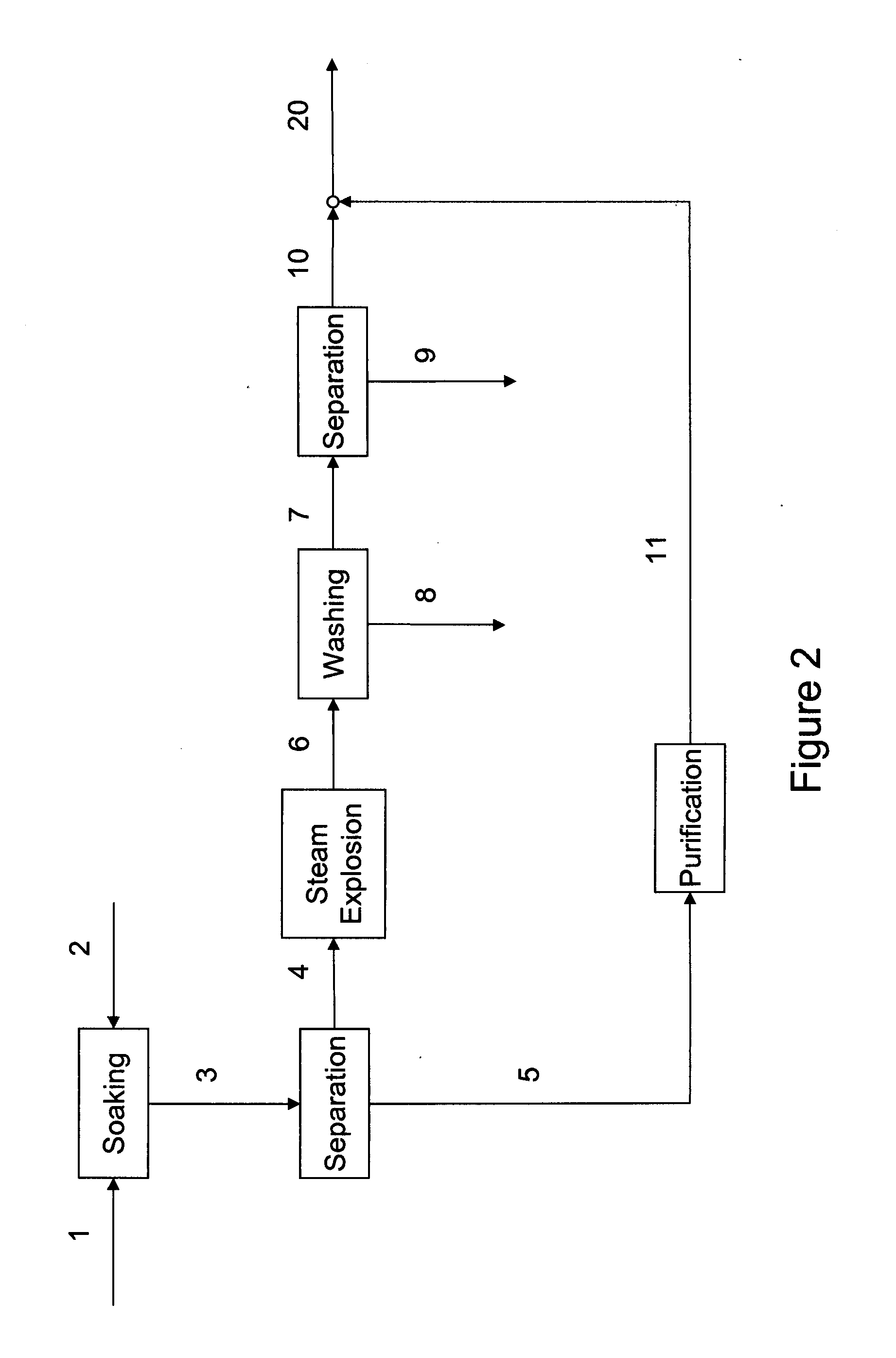

Biomass pretreatment process

Owner:CHEMTEX ITAL +1

Method for processing instant foods of high-moisture oyster

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

High-acid value rice bran oil esterification depickling process

Owner:HEFEI UNIV OF TECH

Conductive composite fiber and preparation method thereof

The invention relates to a conductive composite fiber and a preparation method thereof. The conductive composite fiber comprises a skin core structure including conductive particles and organic fibers, wherein the mass percentage composition of the conductive particles is 0.5-10%, and the mass percentage composition of the organic fibers is 90-99.5%. The preparation method comprises the following steps: (1) pre-treating the organic fibers in pretreatment liquid, and blowing; (2) soaking the fibers into water dispersion liquid of the conductive particles, ultrasonically assisting the conductive particles to outer layers of the fibers in ice water bath, soaking, drying, and soaking, cleaning and drying through hydrochloric acid solution to obtain the conductive composite fiber. According to the invention, the conductive composite fiber has the advantages of no organic solvent in preparation, greenness and environmental friendliness, simple process, low cost, continuous large-scale production, high conductivity of a product, difficulty in falling conductive components, durable conductive performance, soft hand feel and capability of being knitted; and the conductive composite fiber is used as an antistatic and electromagnetic shield material and an energy storage electrode material.

Owner:DONGHUA UNIV

Method for producing ethanol from crop straw

ActiveCN101186943AEasy to separateTake advantage ofBiofuelsMicroorganism based processesSolid componentFiltration

The invention provides a process for producing ethanol with raw materials of straws. The process comprises preliminary treatment to crops straws, solid-liquid separation, hydrolyzed solid components and fermentation with yeasts after hyperfiltration and filtration enrichment by RO combination. The invention can simultaneously conduct evaporating concentration to liquid components, and produce corresponding by-product of lignosulfonate by adding sulfonating agent. The ethanol producing process of the invention greatly decreases the cost of industrial production which ferments straws to produce ethanol, and efficiently utilizes all the ingredients of crops straws.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

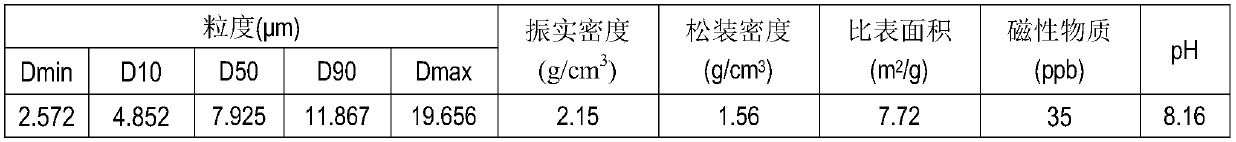

Device technology configuration method for treating house refuses by using rotary cement kiln

The invention provides a device technology configuration method for treating house refuses by using a rotary cement kiln, comprising a pre-treatment device technology configuration method and an incineration device technology configuration method, wherein the whole process of the crushing treatment of the house refuses is implemented by using the pre-treatment device technology configuration method, and a whole incineration process is carried out on the crushed house refuses by using the incineration device technology configuration method; the incineration device technology configuration comprises a double-layer power-driven flap valve, an L-shaped incinerator, a double-layer heavy punch flap valve, a vibrating conveyor and a bucket elevator; and partial tertiary air captured from a tertiary air tube of a rotary kiln enters into the L-shaped incinerator through an air intake tube and high temperature incineration is carried out on the house refuses in the incinerator, smoke generated when incineration passes through an air discharging tube and then is converged with the tertiary air tube, a loop formed by the air intake tube and the air discharging tube of the L-shaped incinerator is provided with a second high-temperature electric butterfly valve and a third high-temperature electric butterfly valve, and a first high-temperature electric butterfly valve is arranged on the tertiary air tube. Harmful gases such as dioxin can be inhibited by high-temperature environment which is generated by using the rotary cement kiln.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Dephosphorizing agent and application thereof

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

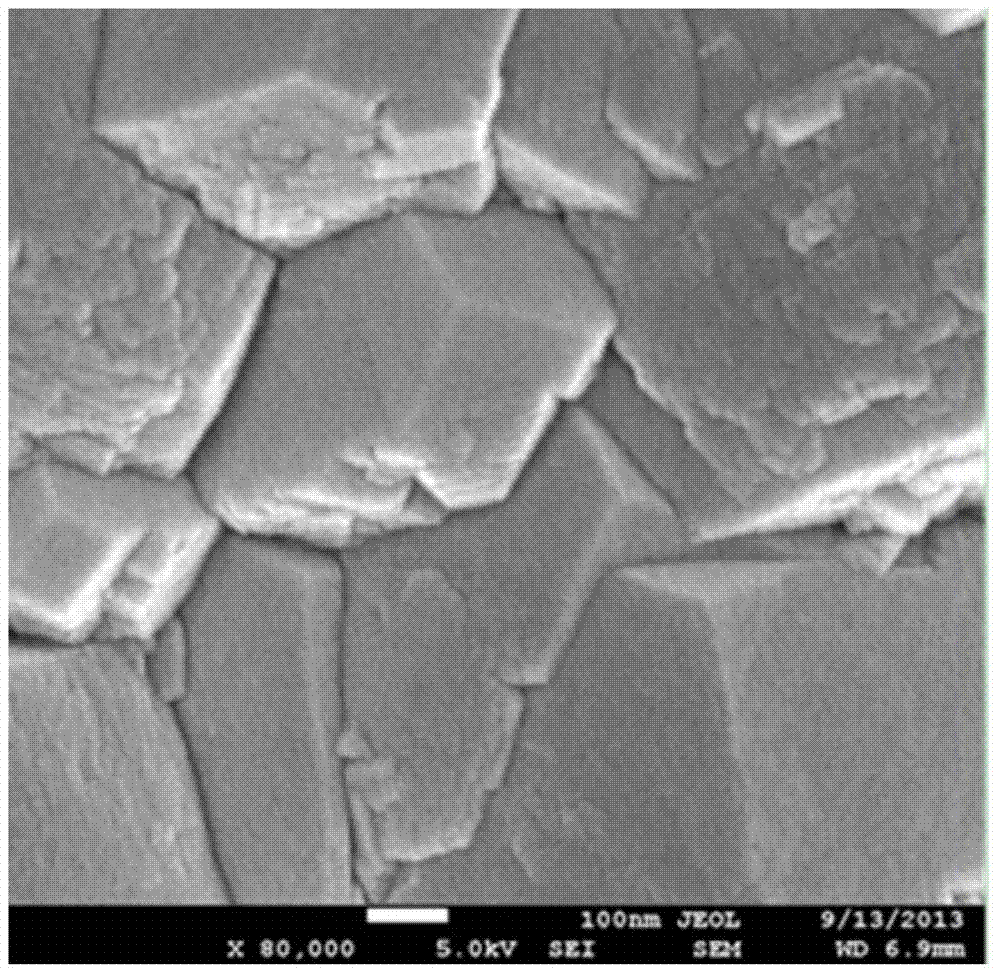

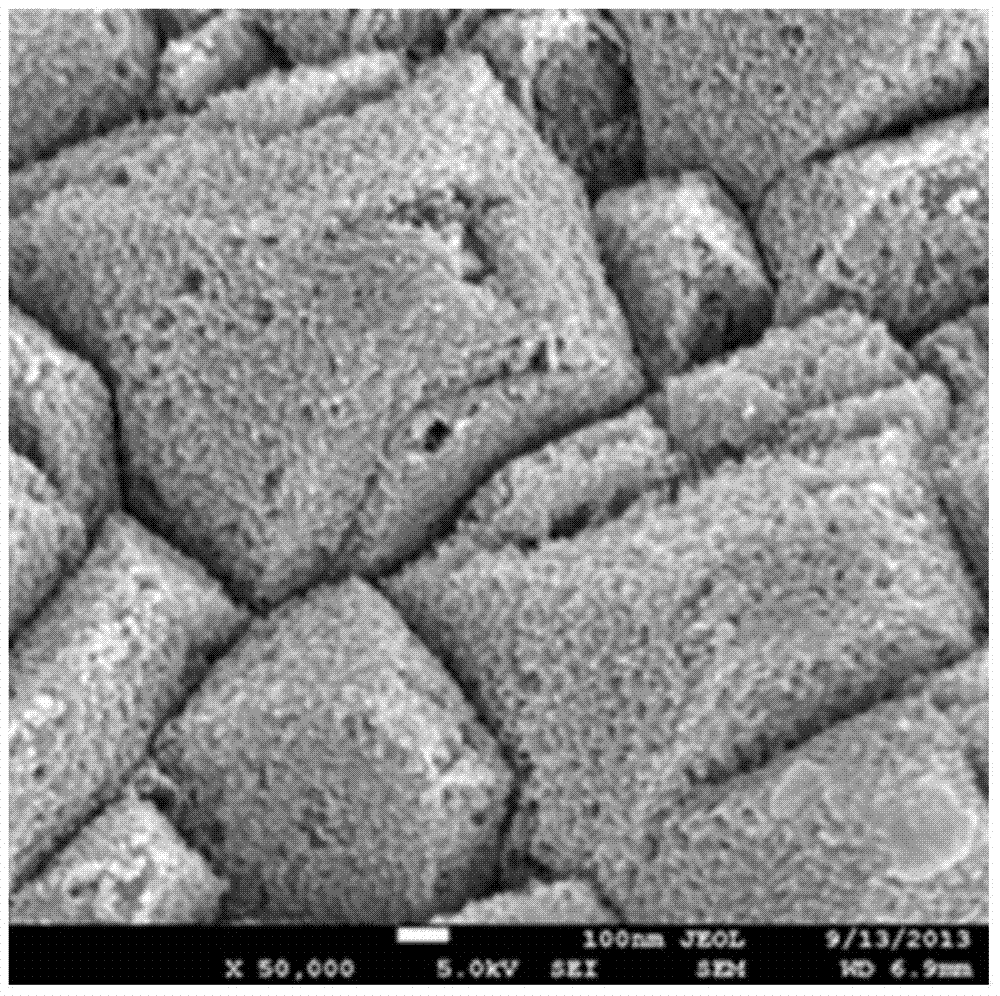

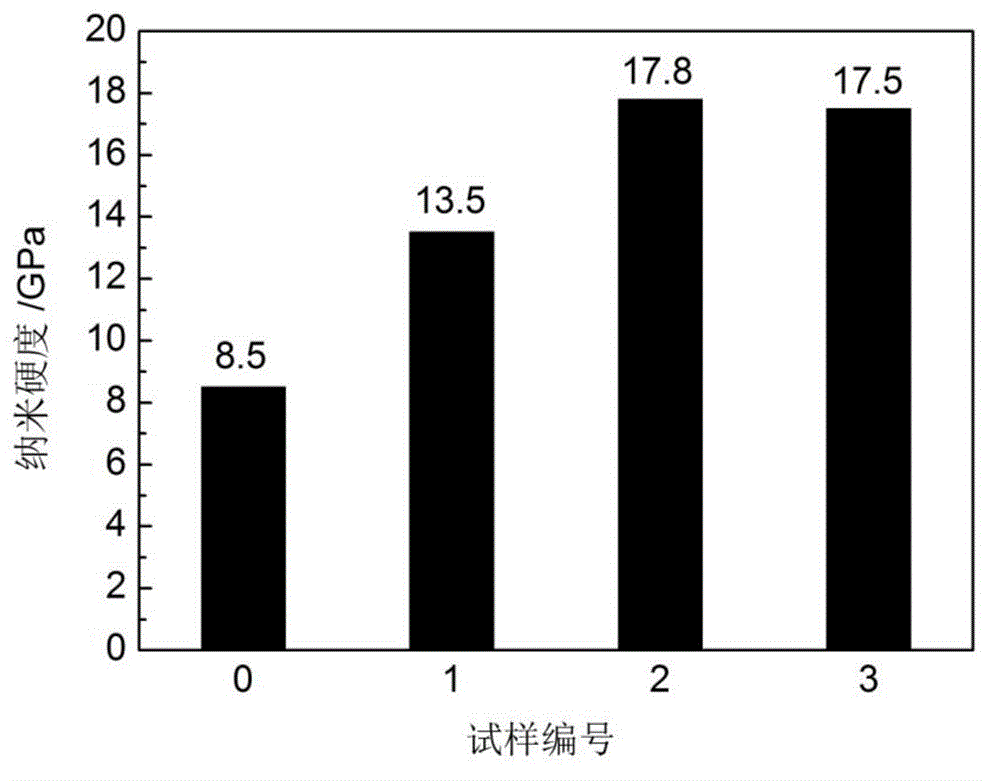

Preparation method of porous diamond film

ActiveCN104498894AImprove hydrophilicityIncrease contentChemical vapor deposition coatingAir atmosphereMicrowave

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

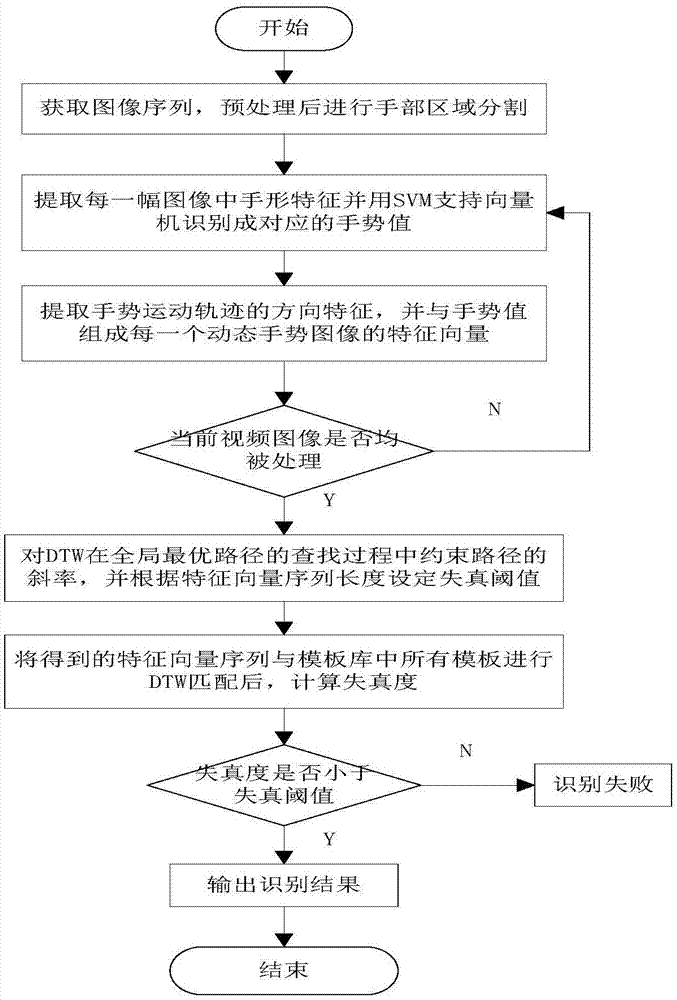

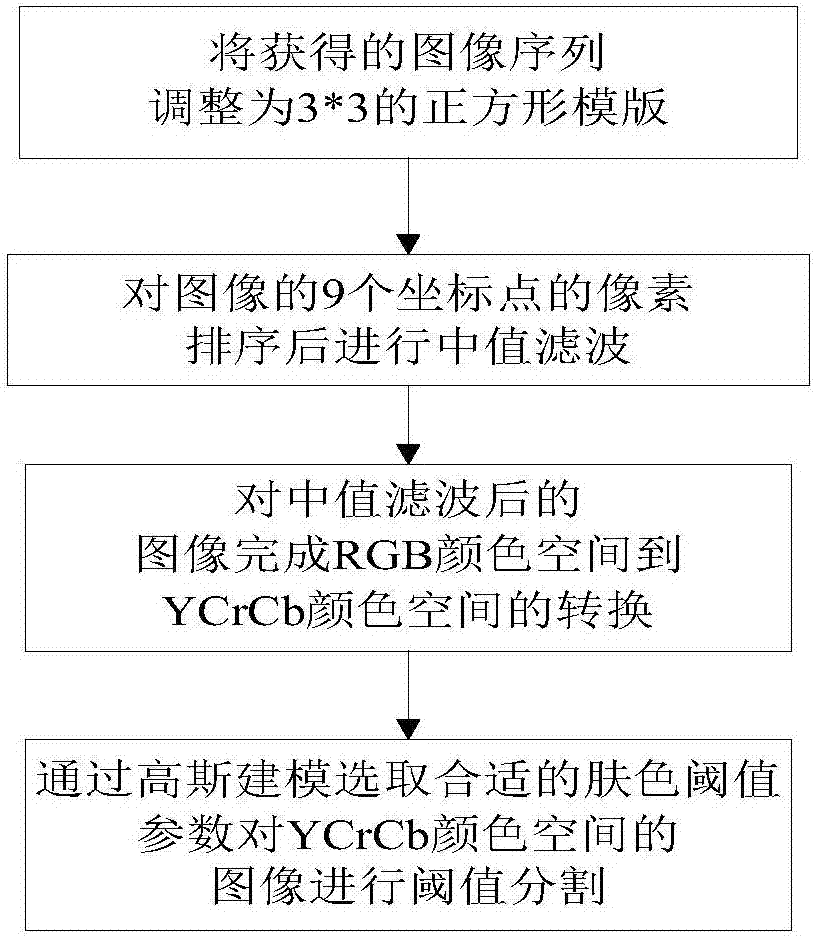

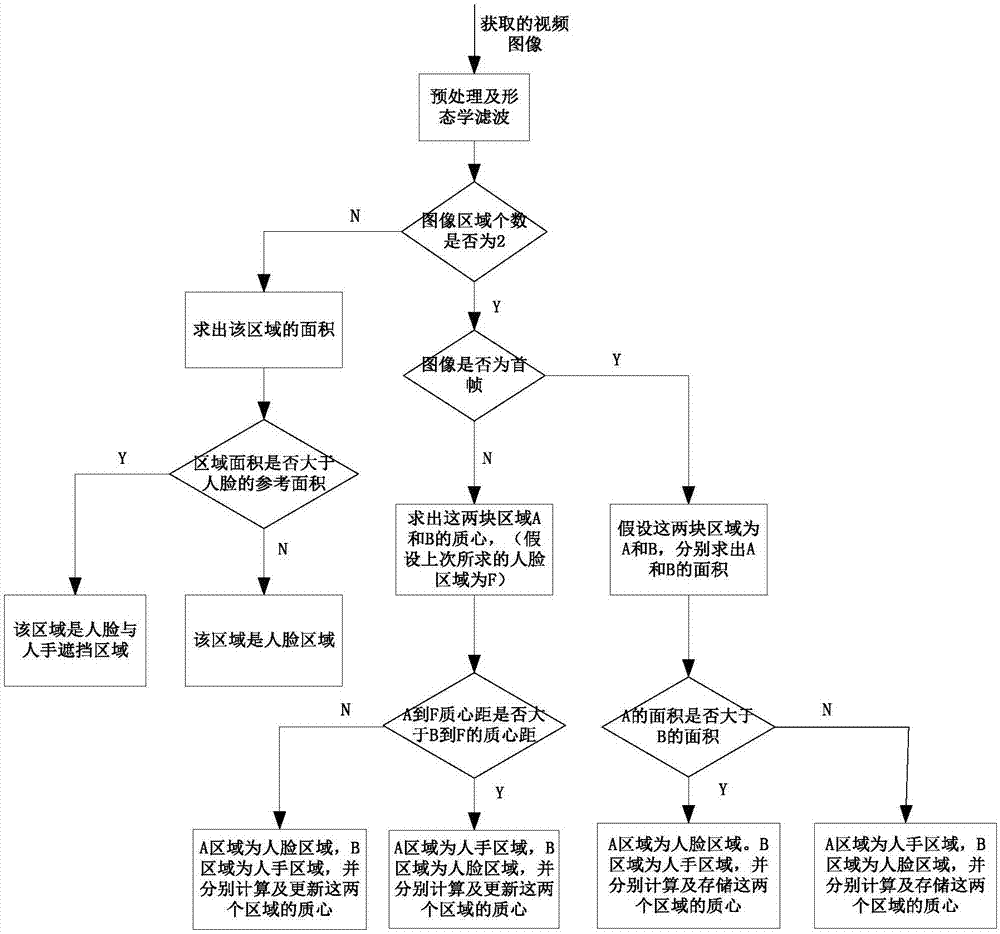

Real-time gesture recognition method

InactiveCN107958218AImprove dynamic gesture recognition rateImprove recognition rateInput/output for user-computer interactionCharacter and pattern recognitionSupport vector machineFeature vector

Owner:NANJING UNIV OF POSTS & TELECOMM

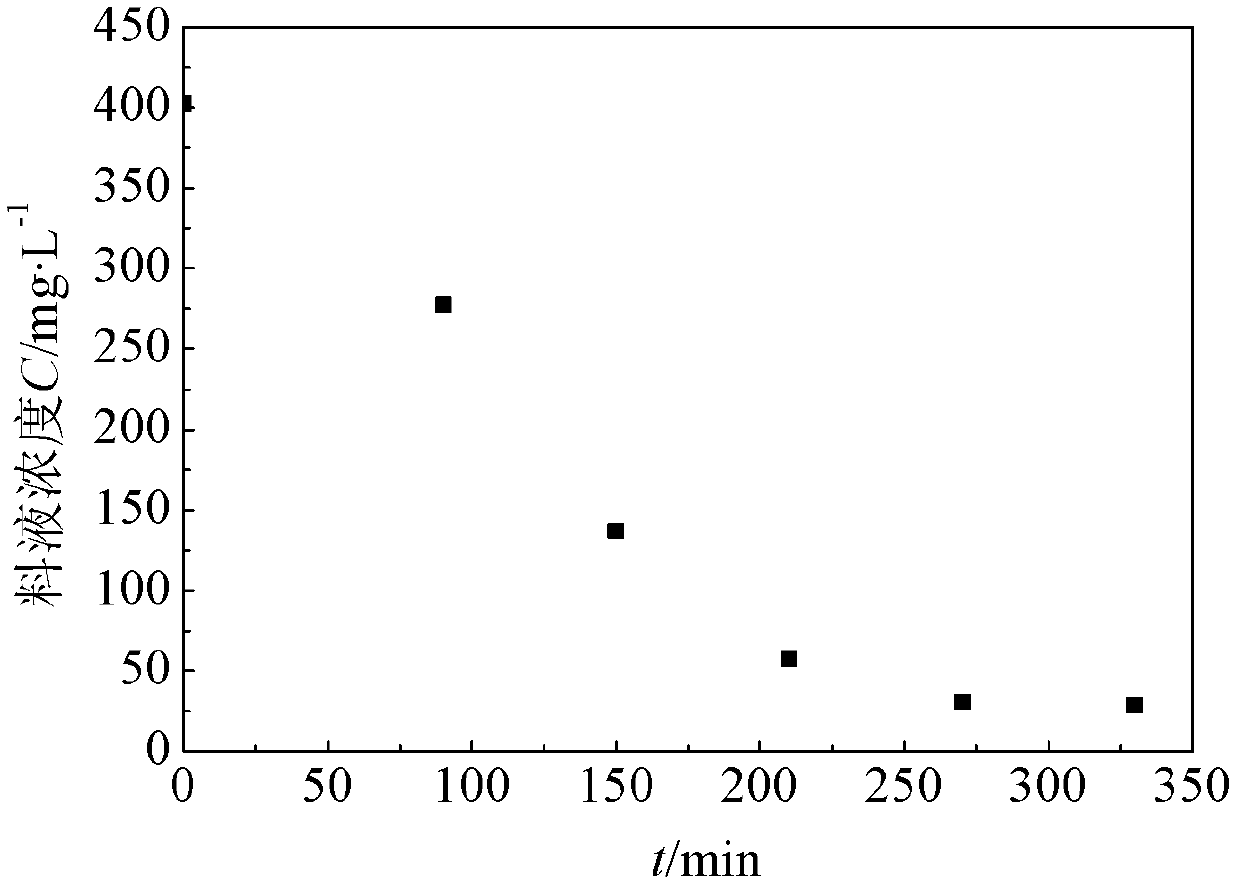

Method for removing phenol in phenol contained wastewater by using hollow fiber membrane

InactiveCN103304005AImprove stabilityImprove mass transfer efficiencyWater contaminantsWater/sewage treatment bu osmosis/dialysisHollow fibre membraneBenzene

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing sodium antimonate from antimony oxide ore via alkaline approach

ActiveCN103866121AHigh recovery rateImprove qualityProcess efficiency improvementWastewaterPre treatment

The invention discloses a method for preparing sodium antimonate from an antimony oxide ore via an alkaline approach. The method comprises the following steps: (1) leaching the antimony oxide ore, (2) purifying filtrate, and (3) oxidizing the purified filtrate. The method is high in recovery rate, the leaching rate of antimony is 95-99%, the direct recovery rate of sodium antimonate is 90-95%, the whole process is performed under an alkaline environment, the requirement on corrosion resistance of equipment is not high, no complicated pretreatment is required in the process, the needed raw materials are nontoxic and harmless, the alkaline liquid is recyclable, neither waste water nor waste gas is generated in the process, and waste residues are nontoxic and harmless.

Owner:XIKUANG SHANXING ANTIMONY CO LTD

Bright etched frosted glass and preparation method thereof

Owner:YIWU HUAHONG CULTURE CREATIVE CO LTD

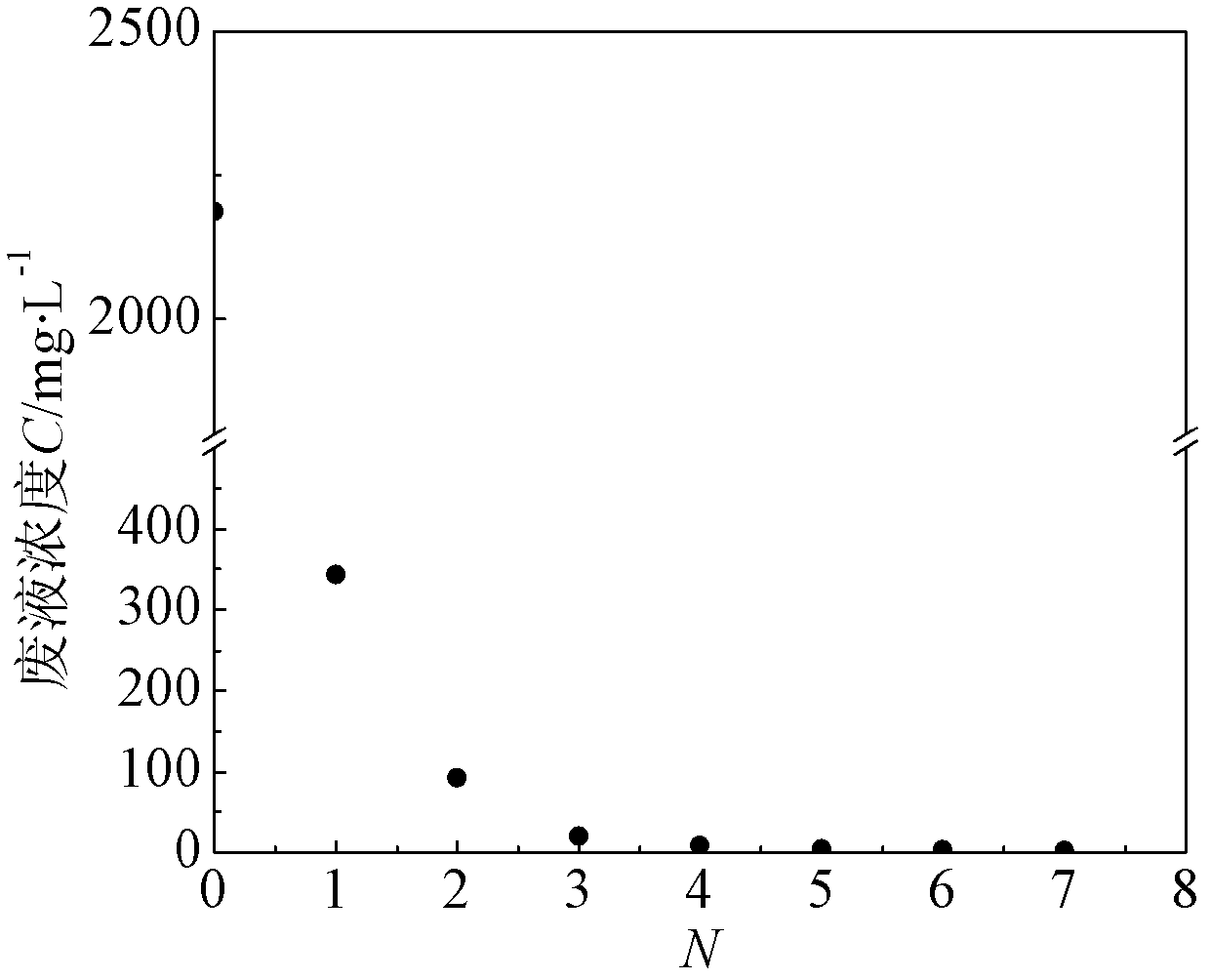

Method for removing phenol-based substances from water by using iron-sulfur supported multi-walled carbon nano-tube reinforced persulfate

InactiveCN107487832ALow costEasy to operateWater contaminantsWater/sewage treatment by sorptionPersulfateSulfur

Owner:SICHUAN UNIV

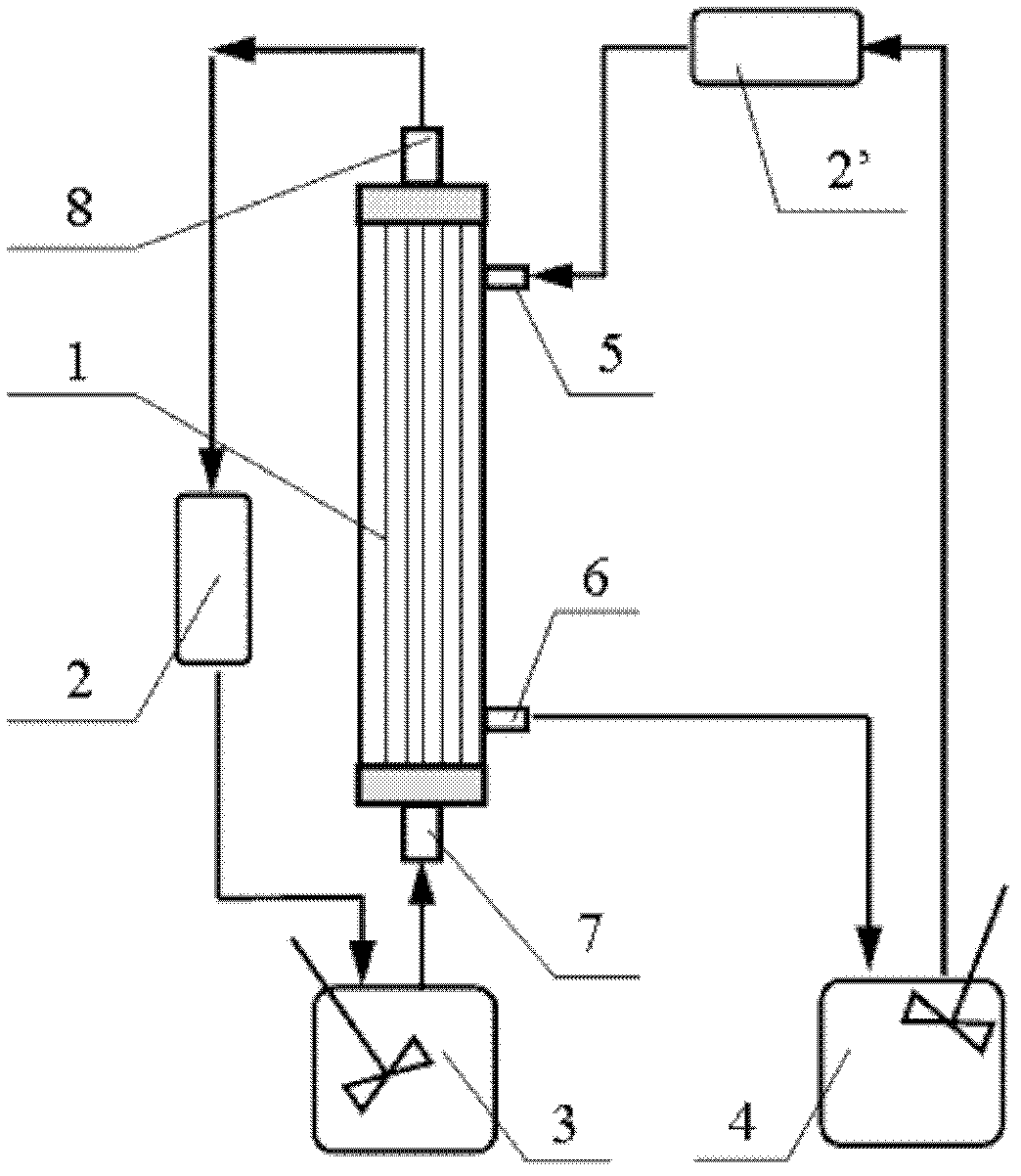

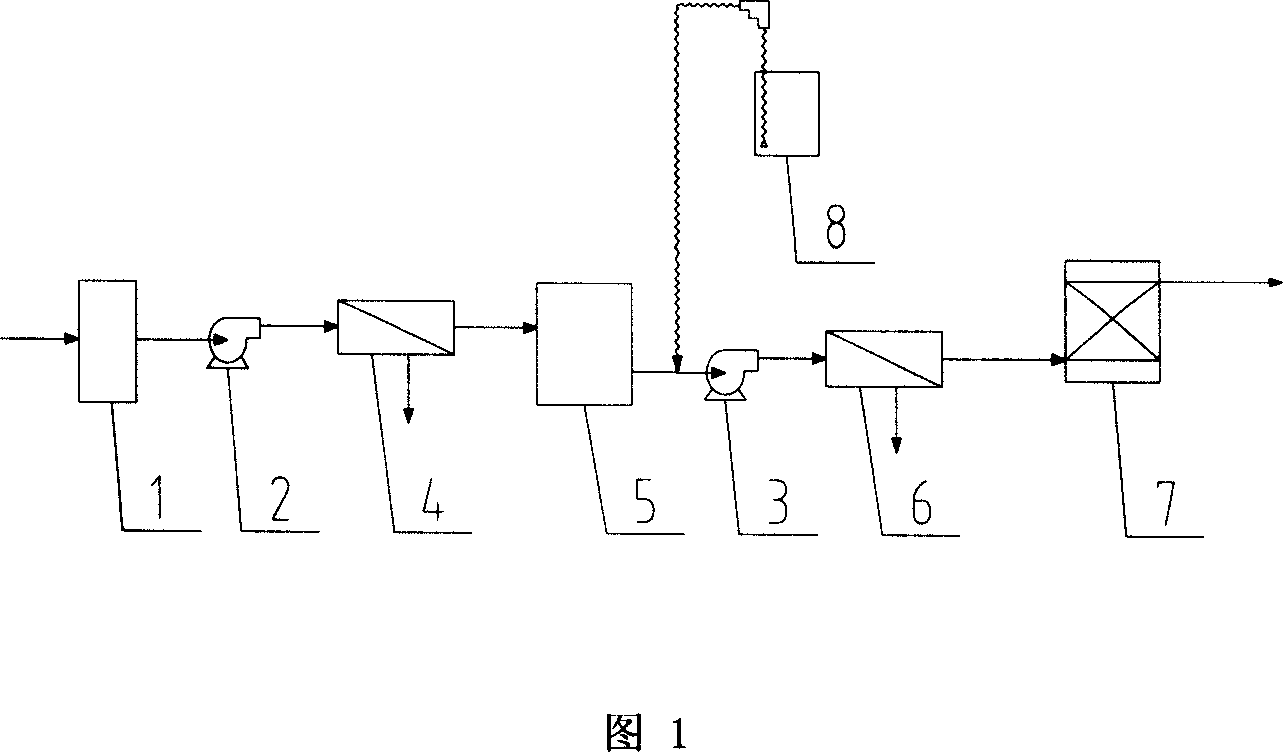

System and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy

The invention discloses a system and method for producing hydrogen by directly electrolyzing urea-containing wastewater with renewable energy. The system comprises a renewable energy generation module, a power conditioning module, a urea-containing wastewater pretreatment module, an alkaline urea electrolytic hydrogen production module, a gas / liquid separation, drying and purifying module, an alkaline liquor circulating pump, a hydrogen storage tank and an anode product storage module, wherein an output end of the renewable energy generation module is connected with an input end of the power conditioning module, and an output end of the power conditioning module is connected with the alkaline urea electrolytic hydrogen production module. By means of the system, nearby in-time consumption of renewable energy power is facilitated, the hydrogen production cost is r educed, the tolerance of the hydrogen production system to the volatility and intermittence of a power supply is improved, a hydrogen production technology is combined with a water treatment technology, and while the hydrogen production energy consumption is reduced, environmental pollution is avoided; the applicability of the system is wide, the stability is high, the hydrogen produced by the system is high in purity, the process is simple, and industrial production is facilitated.

Owner:闫巍

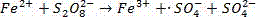

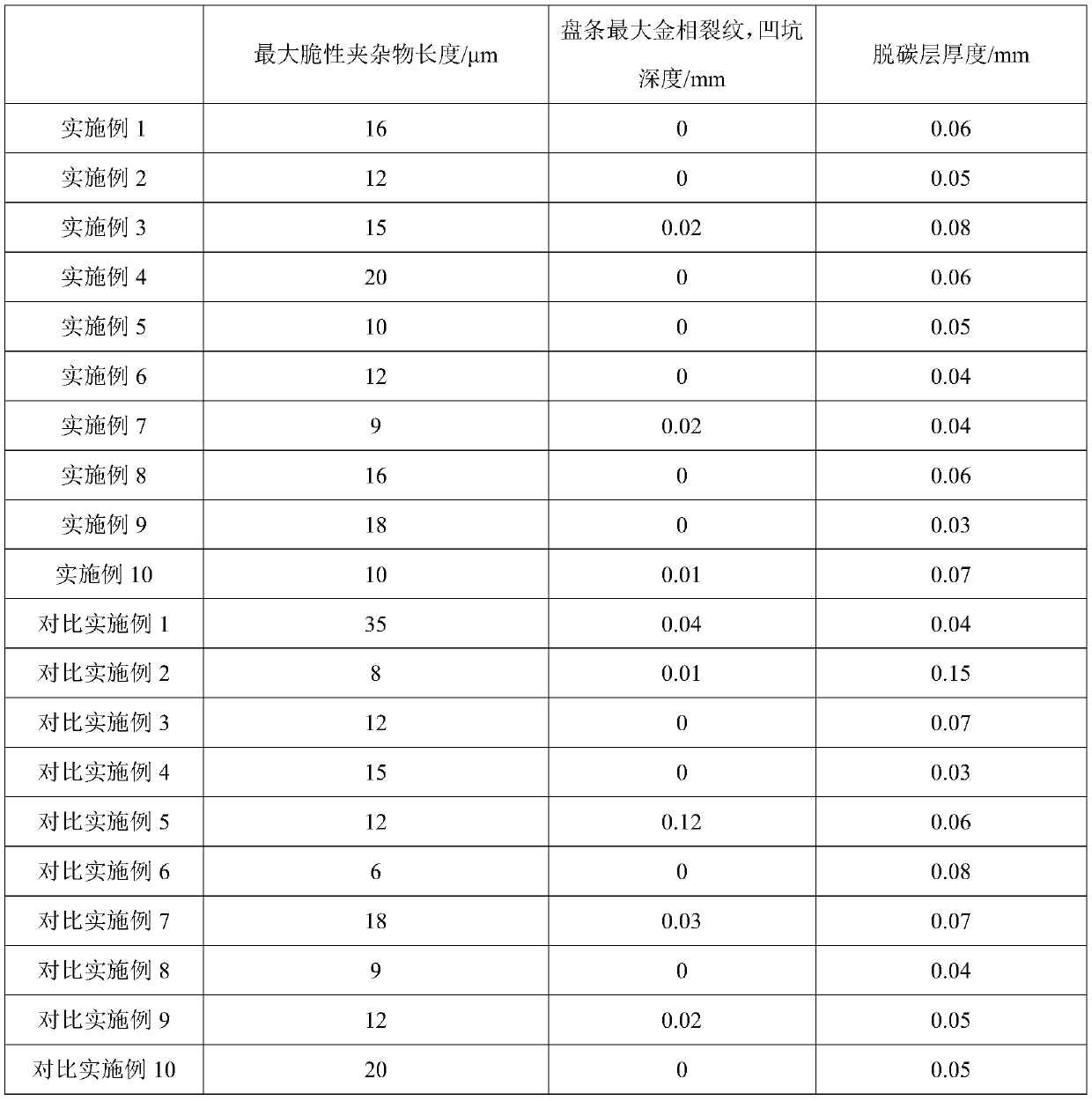

2000 MPa-grade bridge cable galvanized steel wire and preparation method thereof

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Heat-insulating plastering gypsum for building interior wall and preparation method thereof

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Process for preparing industrial high purity water

InactiveCN101085681AHigh resistivityEnsure water qualityGeneral water supply conservationWater/sewage treatment by electrochemical methodsFiltrationWater quality

Owner:上海三邦水处理技术有限公司

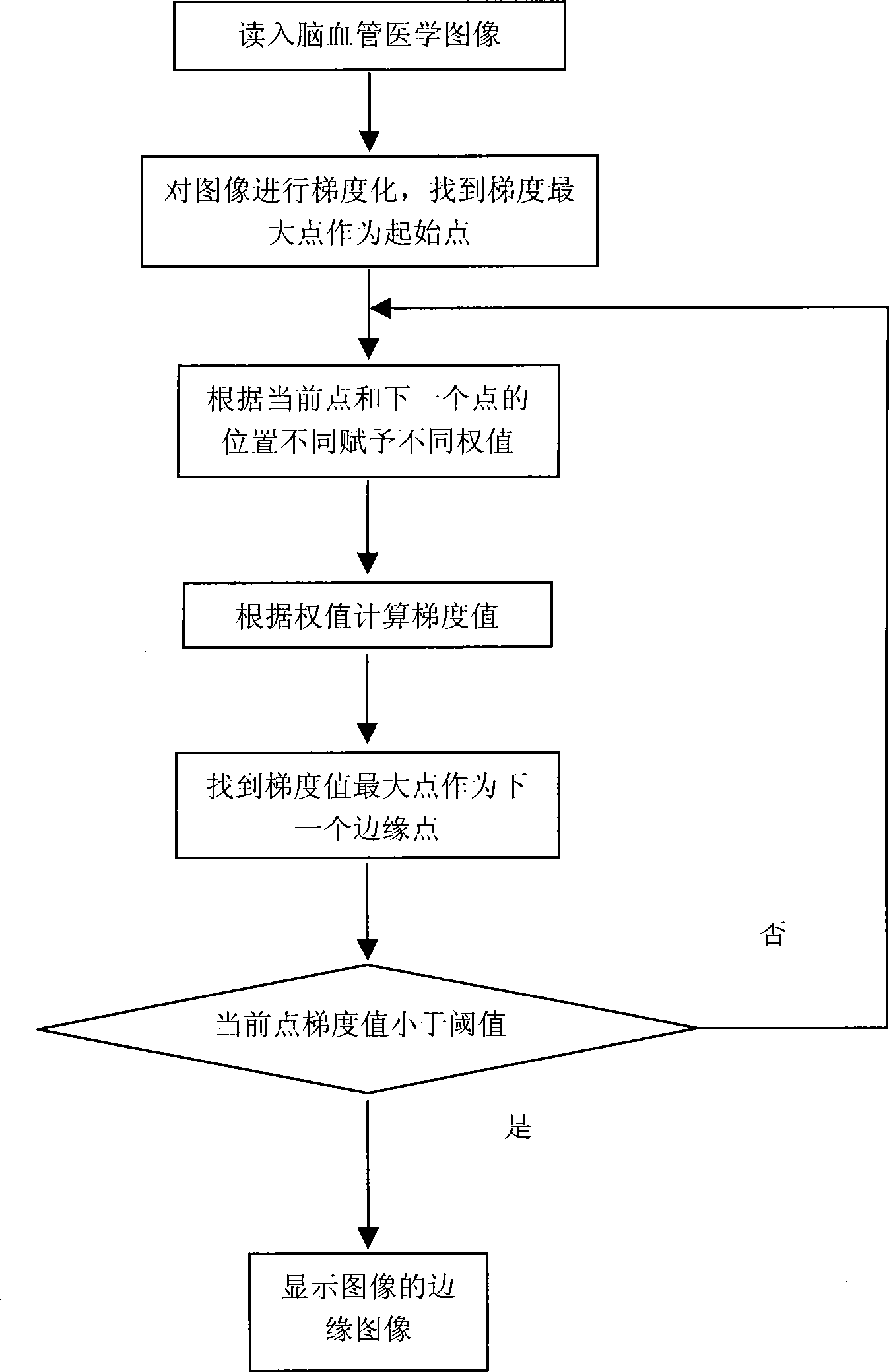

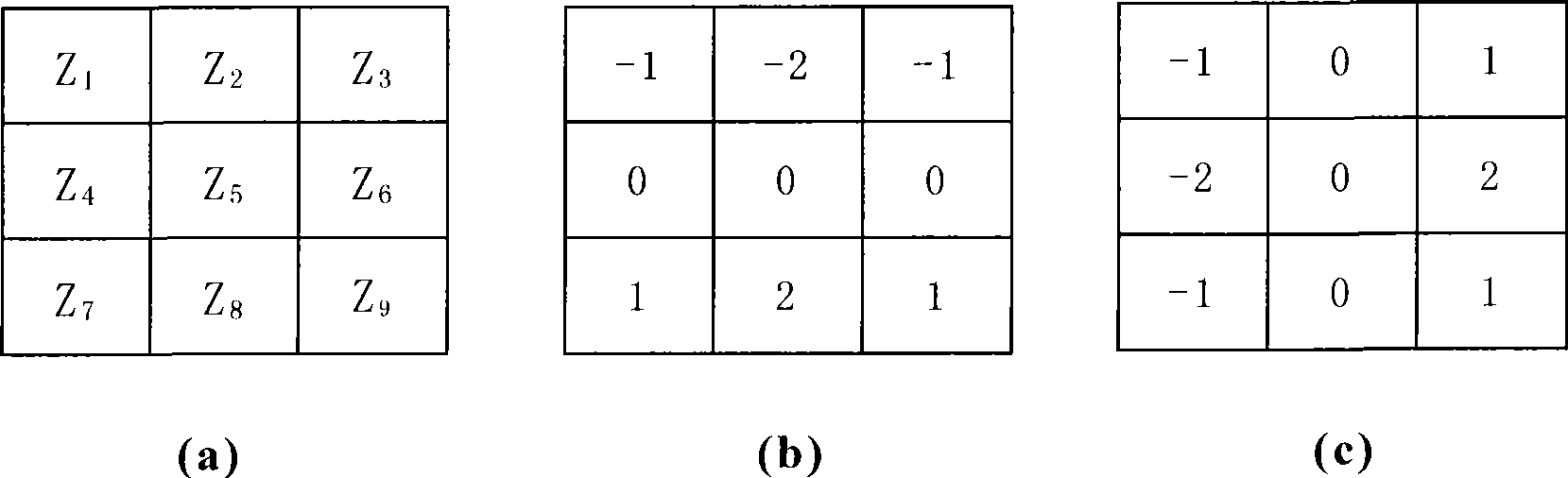

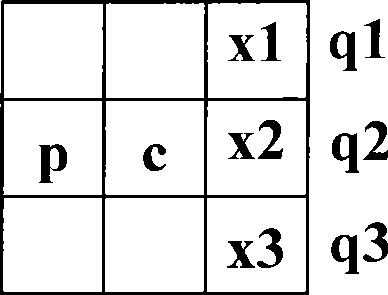

Method for implementing cerebrovascular image recognition by using fast boundary tracking

Owner:SUZHOU SOUKE INFORMATION TECH

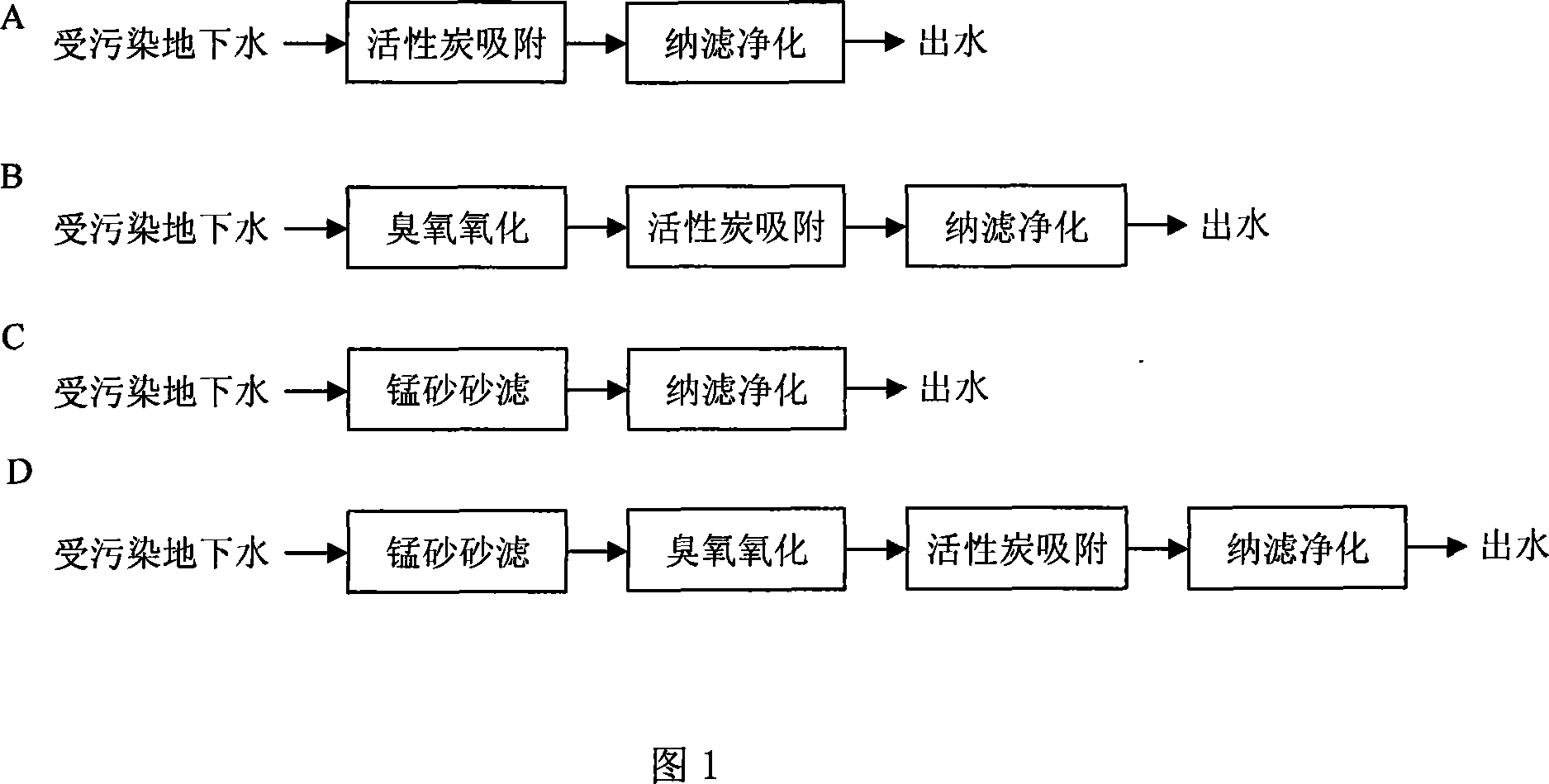

Underground water pollutant eliminating combined nanofiltering membrane process

InactiveCN101066813APollution controlControl degradationUltrafiltrationMultistage water/sewage treatmentWater qualityPre treatment

Owner:DONGHUA UNIV

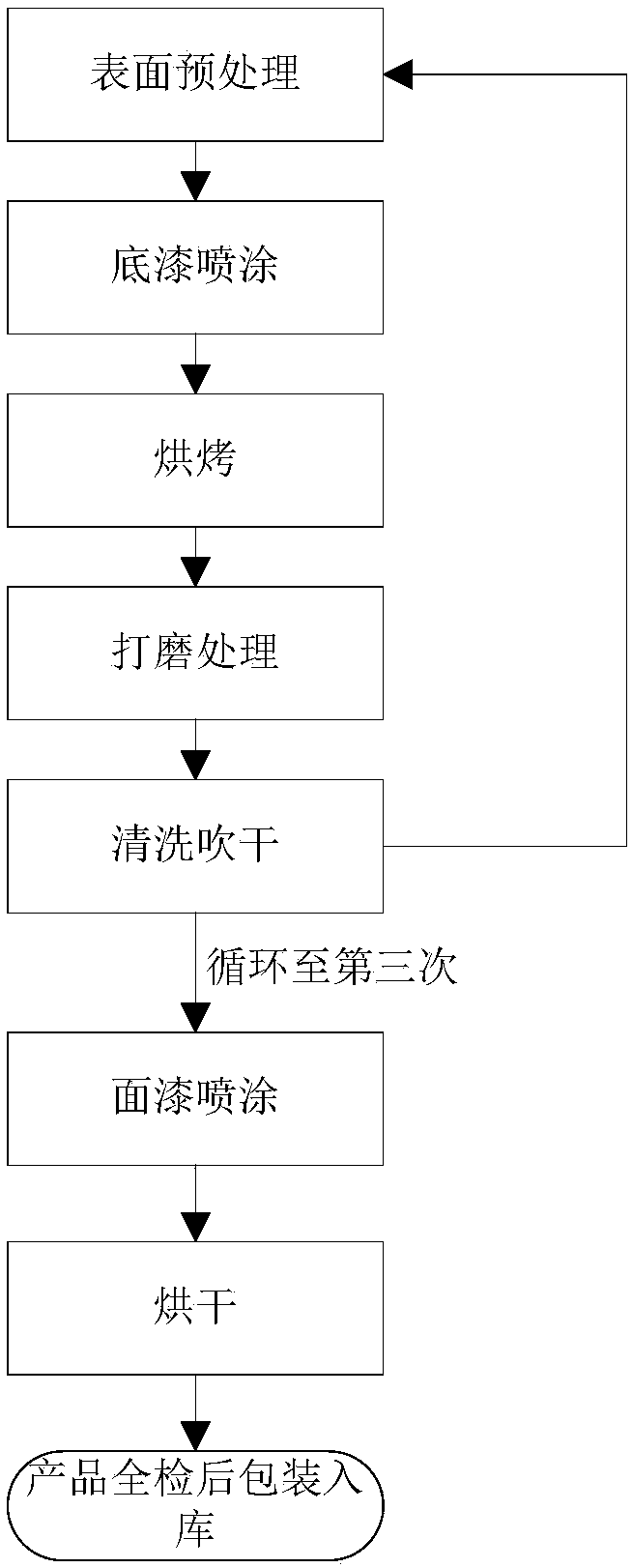

Hardware surface coating process

Owner:深圳市旺鑫精密工业有限公司

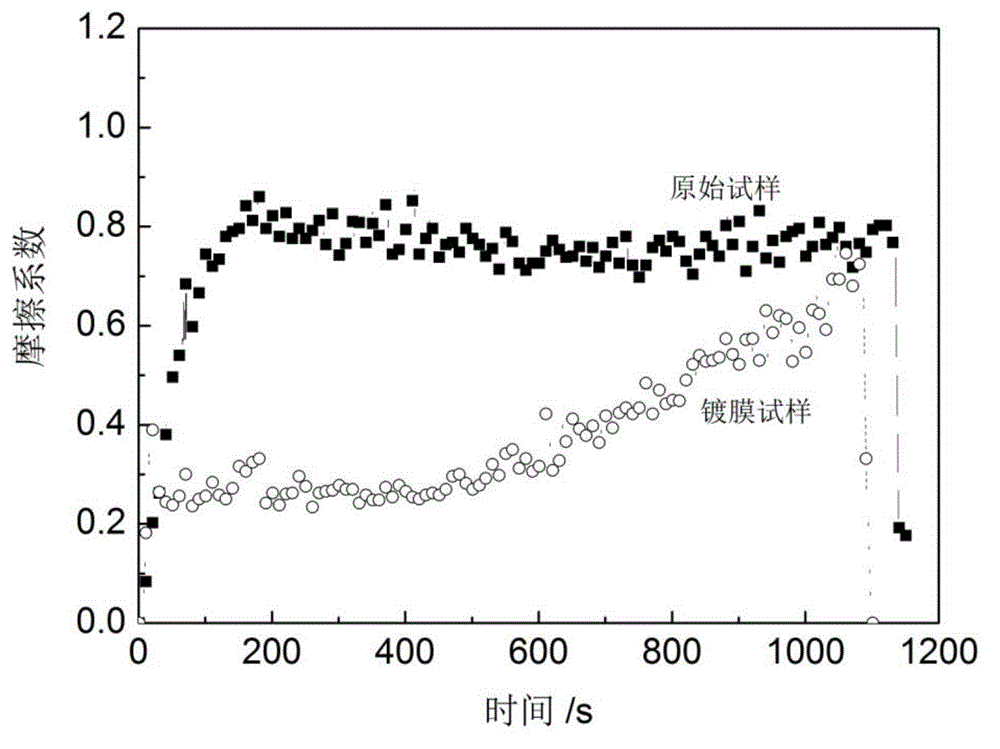

Preparation method of Ta (Tantalum) film on bearing steel surface

Owner:SHANGHAI UNIV OF ENG SCI

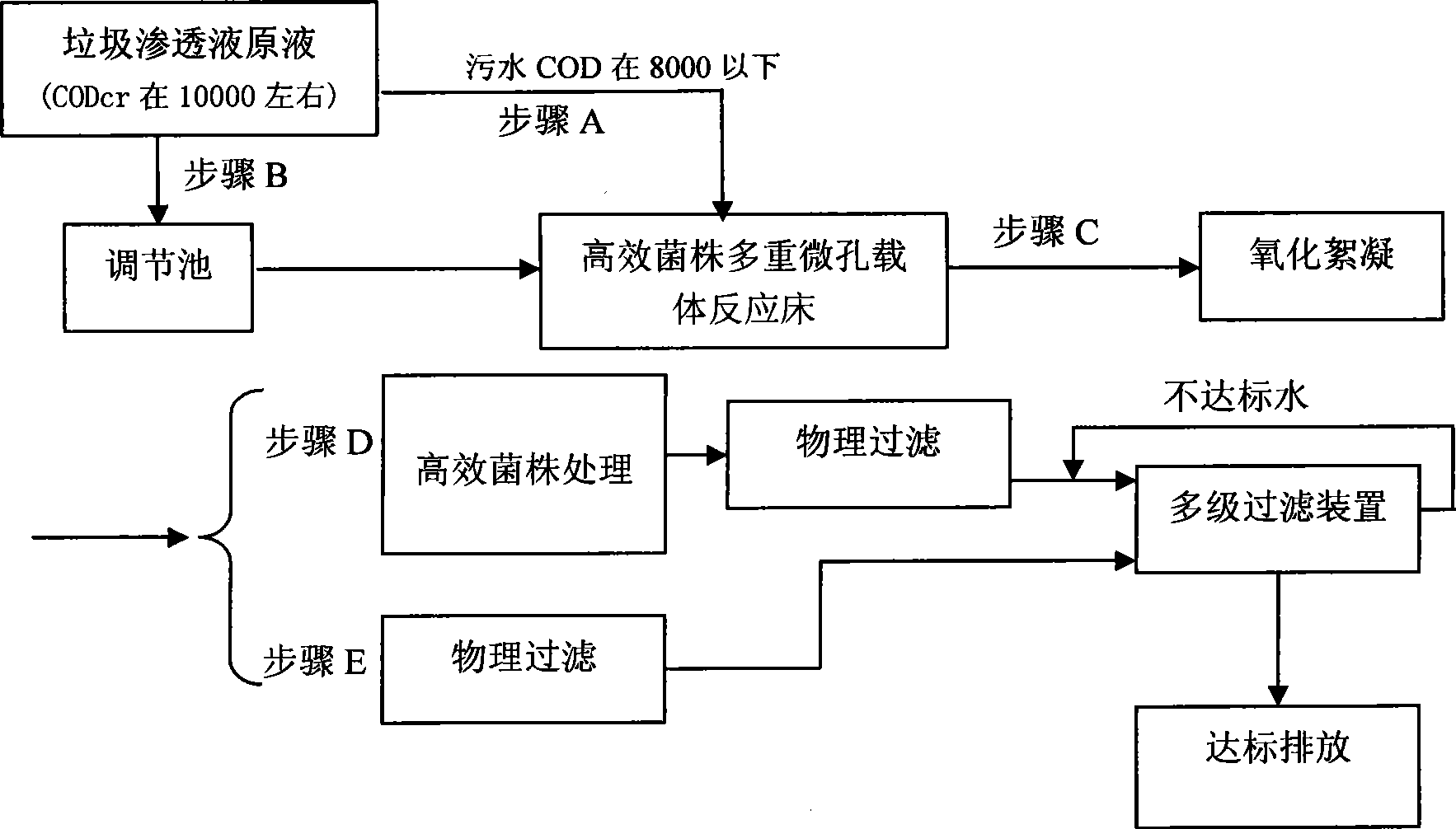

Combined process for treatment and qualified discharge of garbage leachate

InactiveCN101428927ALow costSimple processTreatment with anaerobic digestion processesWater/sewage treatment bu osmosis/dialysisFlocculationMetabolite

Owner:上海环境工程技术有限公司

Cellulosic fiber fabric ink jet transfer printing method

ActiveCN107780264APrevent seepageImprove bindingTransfer printing processDyeing processColour fastnessPolyethylene terephthalate

Owner:CHANGZHOU UNIV

Method for preparing organic carbon fertilizer from agricultural wastes as raw materials

The invention discloses a method for preparing organic carbon fertilizer from agricultural wastes as raw materials. The method comprises, 1, raw material pretreatment: crushing agricultural wastes, adding water into the agricultural wastes and carrying out blending, 2, acid addition and digestion reaction, and 3, centrifugal separation or settling separation and supernatant collection. The agricultural wastes comprise straws. The straws comprise corn stalks, wheat straws, paddy rice straws, sugar cane stalks, cotton stalks or the rest part of crops treated by seed collection. The acid comprises more or more of sulfuric acid, nitric acid, perchloric acid, hypochlorous acid and hydrogen peroxide. The digestion reaction temperature is in a range of 80-180 DEG C and digestion reaction time is in a range of 1-30min. A mass ratio of the agricultural wastes to the acid is 100: (1-9). The method has simple and fast processes and small energy consumption. The obtained organic carbon fertilizer comprises micromolecule organic carbon and can be absorbed easily by crops.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

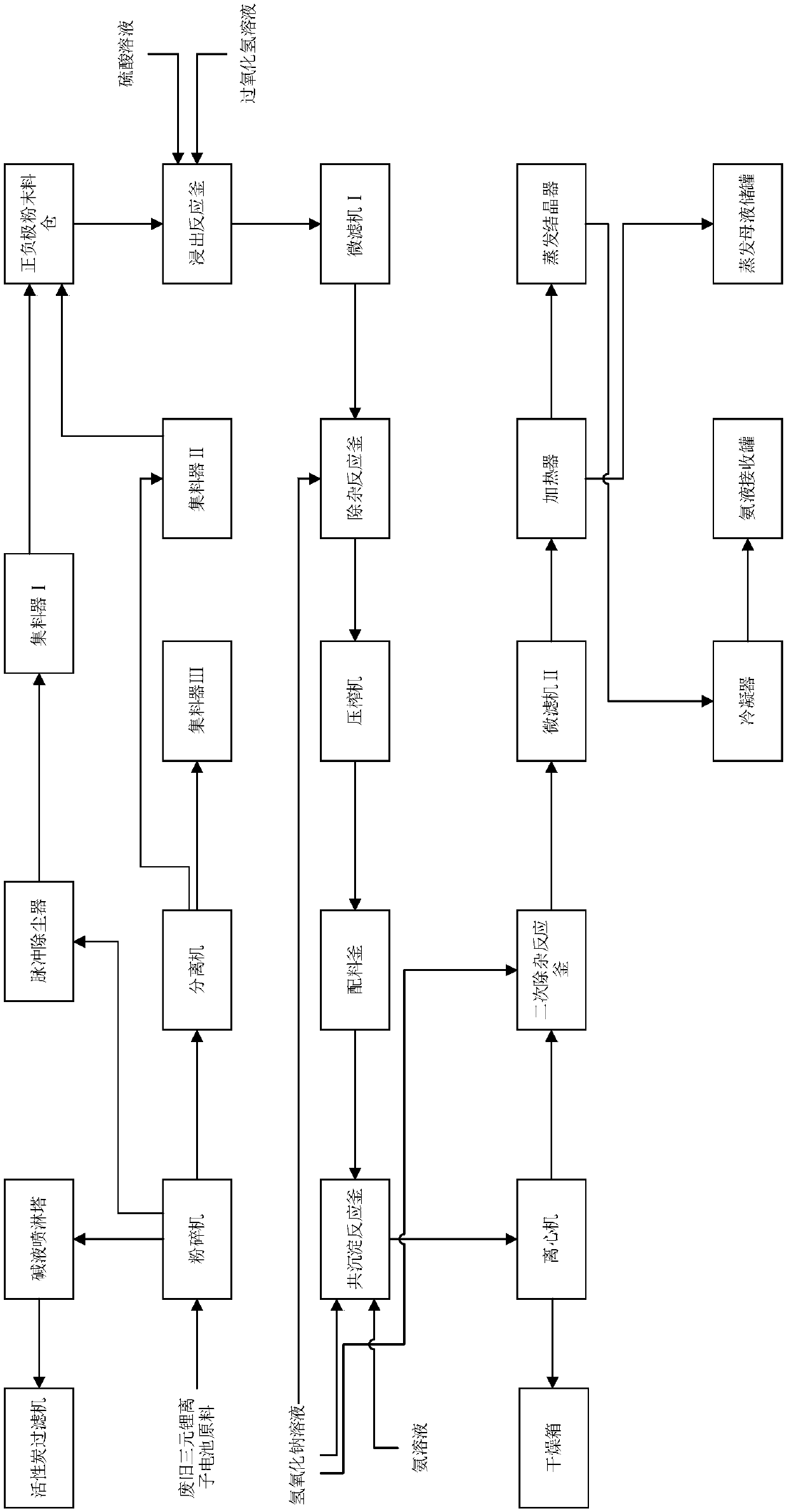

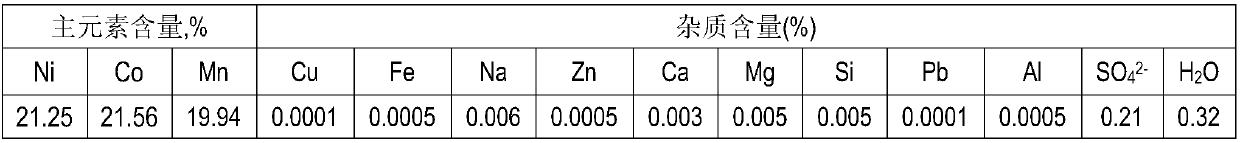

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

System for monitoring transforming plant DC

InactiveCN101414763AReduce the burden onWide adaptabilityNon-electrical signal transmission systemsComputer controlData simulationTransformer

The present invention discloses a transformer DC monitoring system, which consists of a far-end measurement control unit, an optical fiber channel input unit, an optical fiber channel, a server, a workstation and a client. A prepositive computer is arranged between the optical fiber channel input unit and the optical fiber channel; the prepositive computer consists of a main prepositive computer, a deputy prepositive computer and a dual-computer switching device; the dual-computer switching device is connected with the optical fiber channel input unit; the main prepositive computer and the deputy prepositive computer are both connected with the dual-computer switching device; the communication mode between the main prepositive computer and the deputy prepositive computer adopts GPS wireless mode; data monitoring, parameter setting, data analog, data pre-treatment and data transmission computer programs are arranged in the main prepositive computer and the deputy prepositive computer in advance. The transformer DC monitoring system makes full use of existing equipment to establish a long-distance centralized DC monitoring system which is applicable to various substations and improve the comprehensive monitoring level, openness and expandability of the system and the stability and reliability of the monitoring. The transformer DC monitoring system is used for power systems.

Owner:HEBI POWER SUPPLY OF HENAN ELECTRIC POWERCORP

Rolling-cut type bilateral scissors and manufacturing method thereof

ActiveCN104233101AMeet normal cutting needsFurnace typesHeat treatment furnacesThick plateIngot casting

Owner:TAIER HEAVY IND

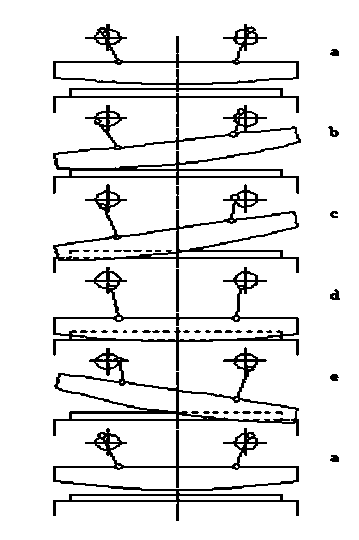

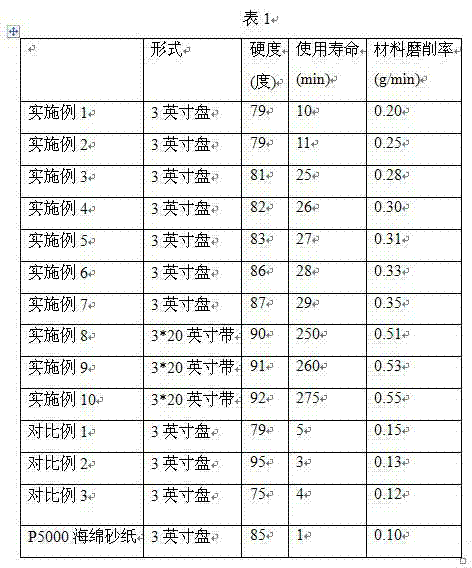

Foam coating grinding tool and preparing method thereof

Owner:ZIBO RIKEN MT COATED ABRASIVES

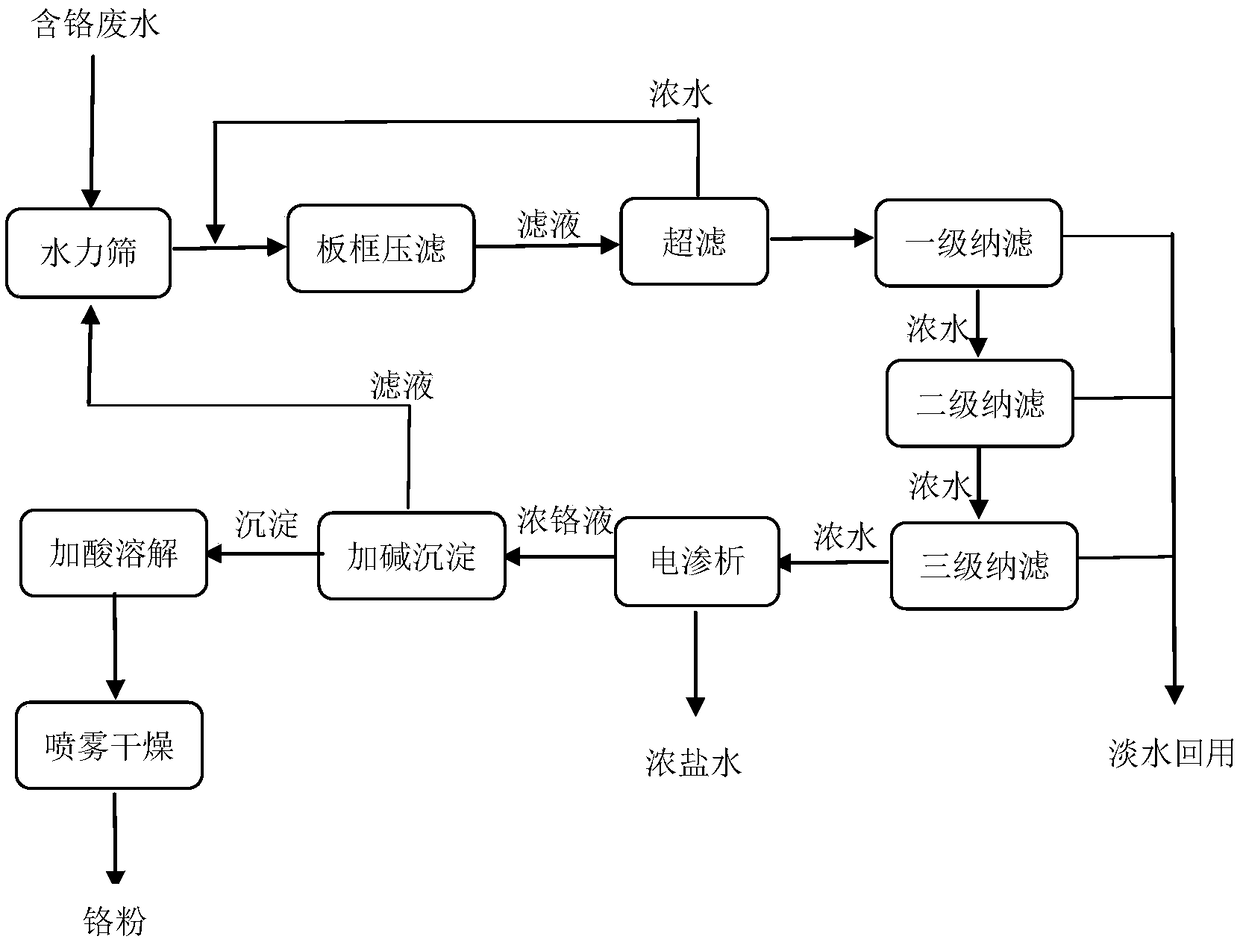

Leather industry chromium-containing wastewater recycling treatment process system

InactiveCN108164051ALong-term continuous and stable operationEffective height separationWater contaminantsTreatment involving filtrationLeather industryProcess systems

Owner:QUANZHOU NORMAL UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap