Method for removing phenol in phenol contained wastewater by using hollow fiber membrane

A fiber membrane, phenol wastewater technology, applied in chemical instruments and methods, water pollutants, extraction water/sewage treatment, etc., can solve the problems of unsatisfactory phenol technology in water, loss of separation effect, and difficulty in large-scale promotion, etc. Simple post-processing procedures, great flexibility in operation, and significant environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

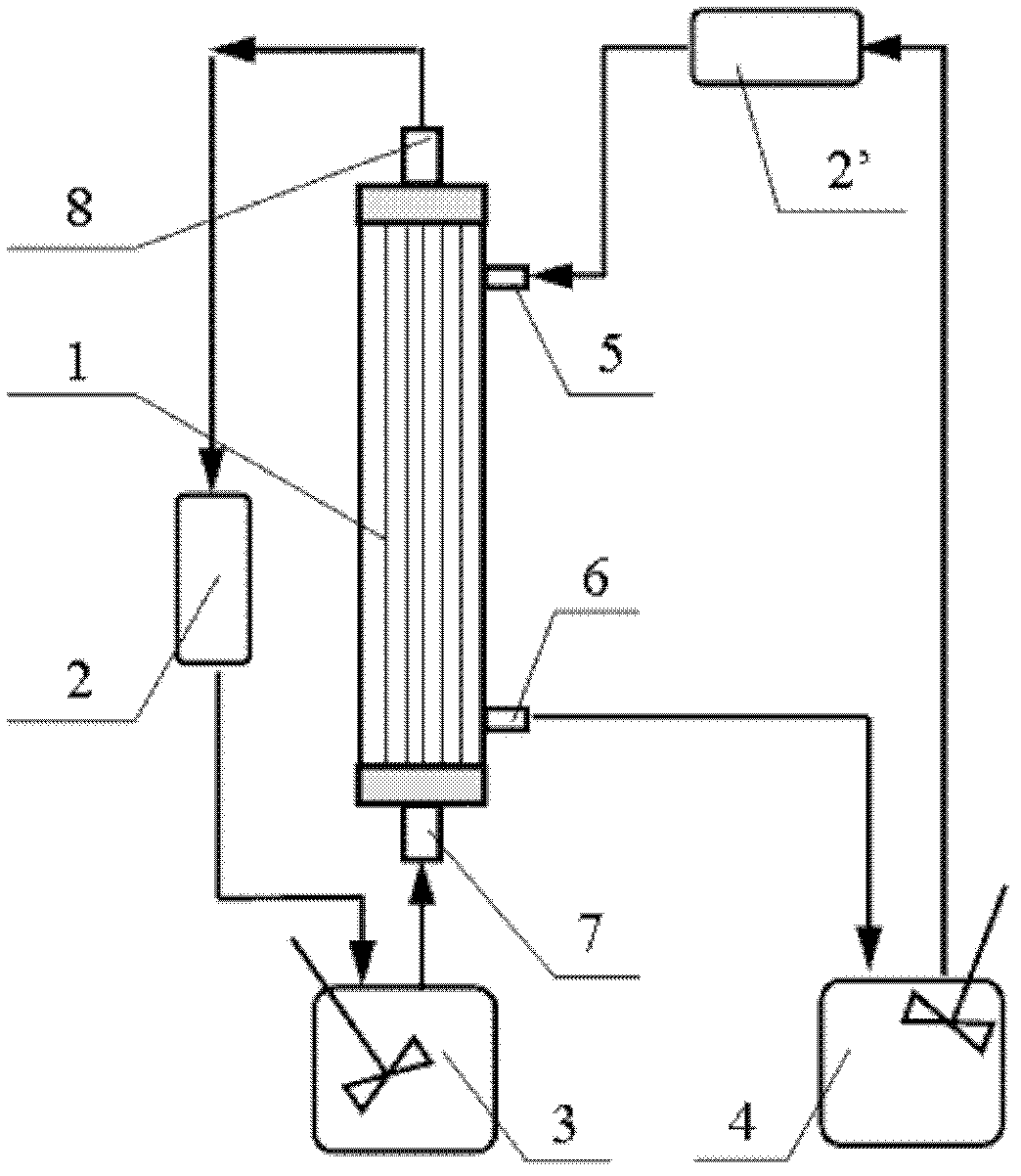

[0028] use figure 1In the device shown, the effective length of the membrane contactor used is 300mm, the inner diameter is 10mm, the hollow fiber membrane material is PP, the inner and outer diameters are 0.35mm and 0.45mm respectively, and the filling capacity is 100.

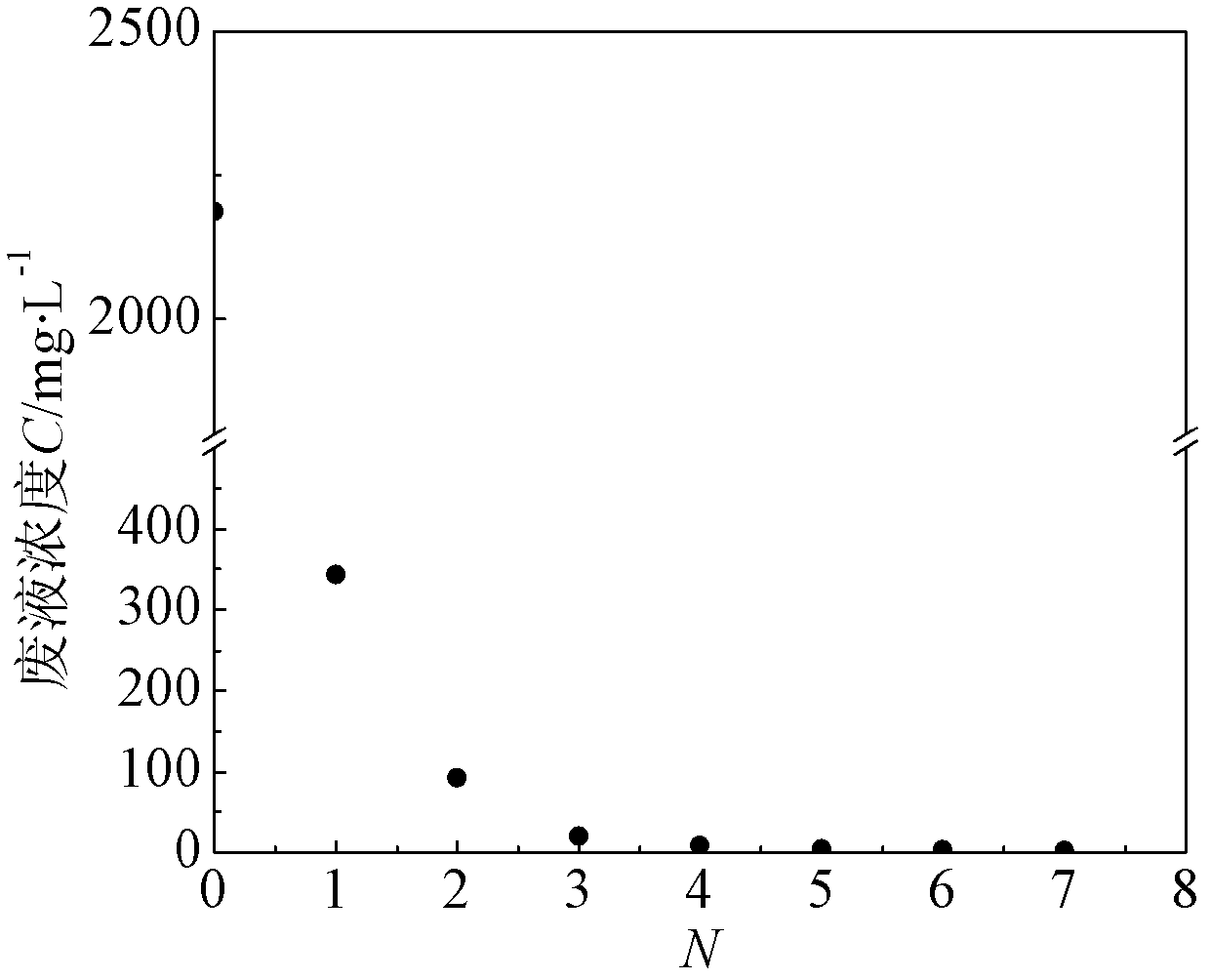

[0029] A. Take tributyl phosphate as the carrier and kerosene as the diluent to mix and prepare the extractant, wherein the volume fraction of the carrier is 10%; 400ml of NaOH solution with a concentration of 1mol / L is the stripping agent, and the extractant in the treatment liquid is The volume ratio of the extraction agent and the stripping agent is 1:20, and the two phases of the extraction agent and the stripping agent are stirred evenly.

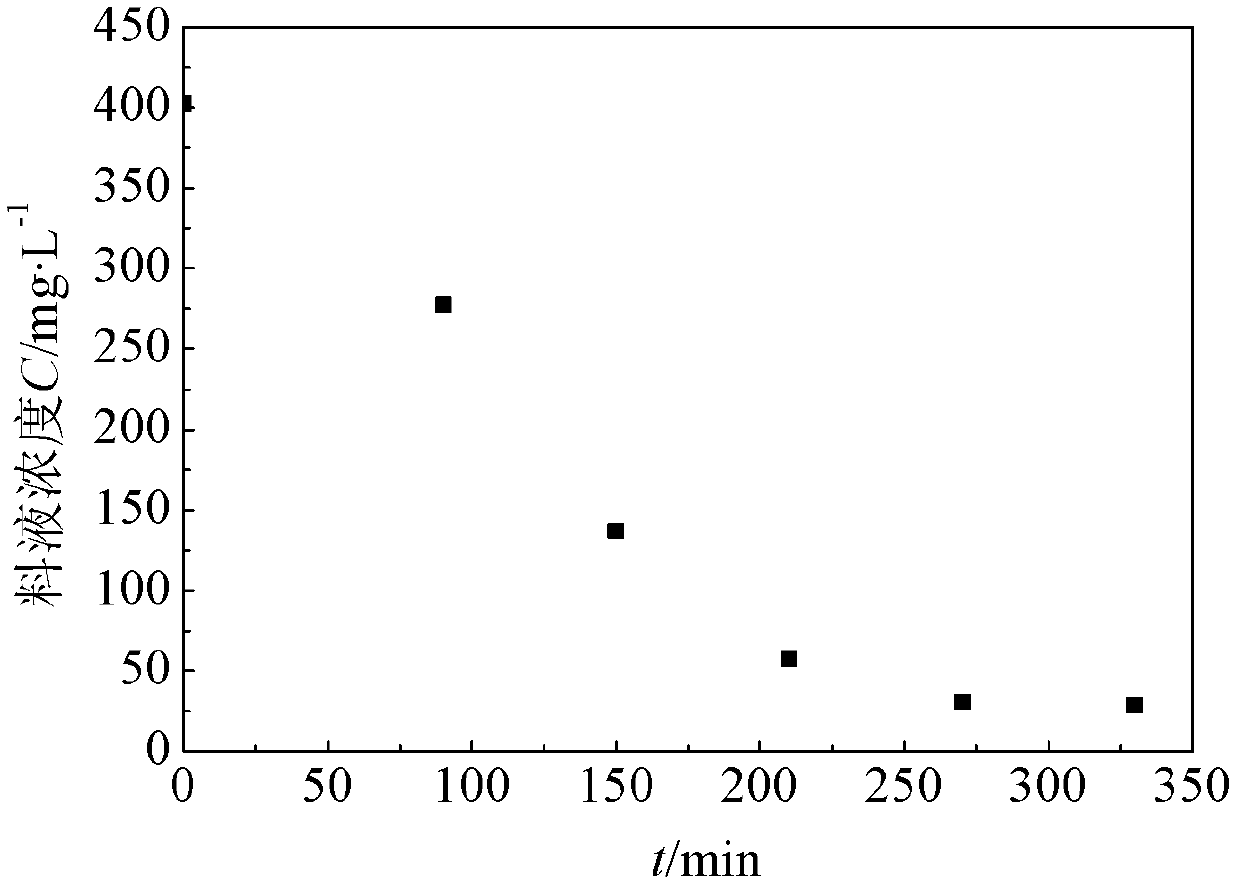

[0030] B. Input the treatment liquid into the membrane module from the tube side, and the flow rate at the inlet is 50ml / min. Use about 400mg / L phenol-containing wastewater 970mL to simulate phenol-containing wastewater, and use H 2 SO 4 The solution adjusts the

Embodiment 2

[0033] Using the conditions in Example 1, the two streams are operated in parallel.

[0034] Use about 500mg / L phenol-containing wastewater 1000mL to simulate phenol-containing wastewater, and use H 2 SO 4 The solution adjusts the acidity of wastewater to about pH4.5. After the treatment time is about 300min, the removal rate reaches over 90%, and the average mass transfer flux of the whole treatment process is 1443mg / m 2 h.

Embodiment 3

[0036] Adopt the device in embodiment 1, material condition is constant, with the phenolic waste water 1000mL simulation phenolic waste water of about 400mg / L, use H 2 SO 4 The solution adjusts the acidity of wastewater to about pH4.5. Change the material flow in the tube side and the shell side, wherein the treatment liquid is input into the membrane module from the tube side, and the flow rate at the inlet is 50ml / min; the phenol-containing wastewater is input into the membrane module from the shell side, and the flow rate is 100ml / min. The two streams operate countercurrently.

[0037] After about 300 minutes of treatment time, the removal rate is 94%, and the average mass transfer flux of the whole treatment process is 1898mg / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap