Hardware surface coating process

A technology of surface coating and hardware, applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., can solve the problems of wasting manpower and time, poor appearance effect, long processing cycle, etc., to reduce the number of processing , The effect of saving raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

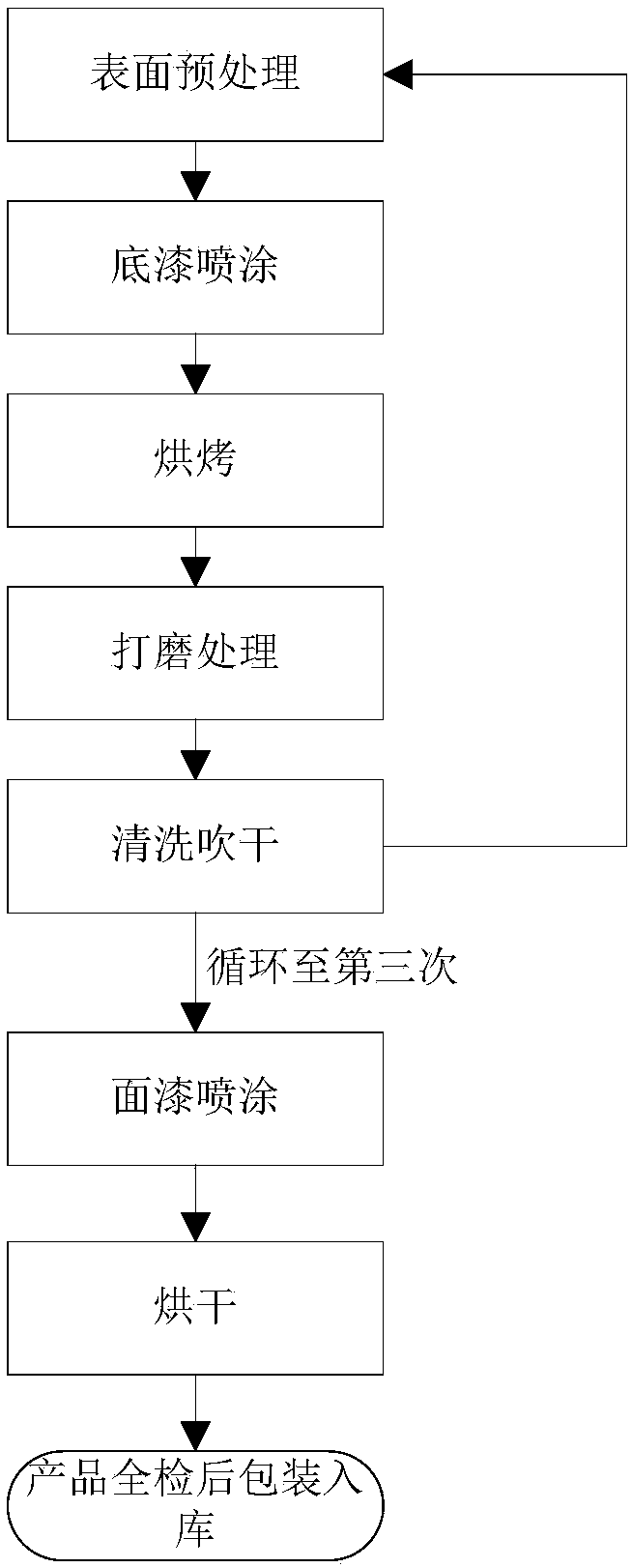

[0036] A hardware surface coating process, the process steps are as follows:

[0037] Step 1: Pre-treat the surface of the hardware. Make the surface of the product meet the standards required by spraying;

[0038] Step 2: Place the hardware after surface pretreatment on the spraying line and pass it through the automatic electrostatic precipitator. The dust removal efficiency of the automatic electrostatic precipitator is high, so that the hardware can completely reach the state of dust removal;

[0039] Step 3: Adjust the coating, and use a spray gun to spray primer on the hardware that has passed the automatic electrostatic precipitator. Spray the hardware evenly with a spray gun;

[0040] Step 4: After the primer spraying process is completed, remove the hardware fr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap