Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Manganese" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese is a chemical element with the symbol Mn and atomic number 25. It is not found as a free element in nature; it is often found in minerals in combination with iron. Manganese is a transition metal with important industrial alloy uses, particularly in stainless steels.

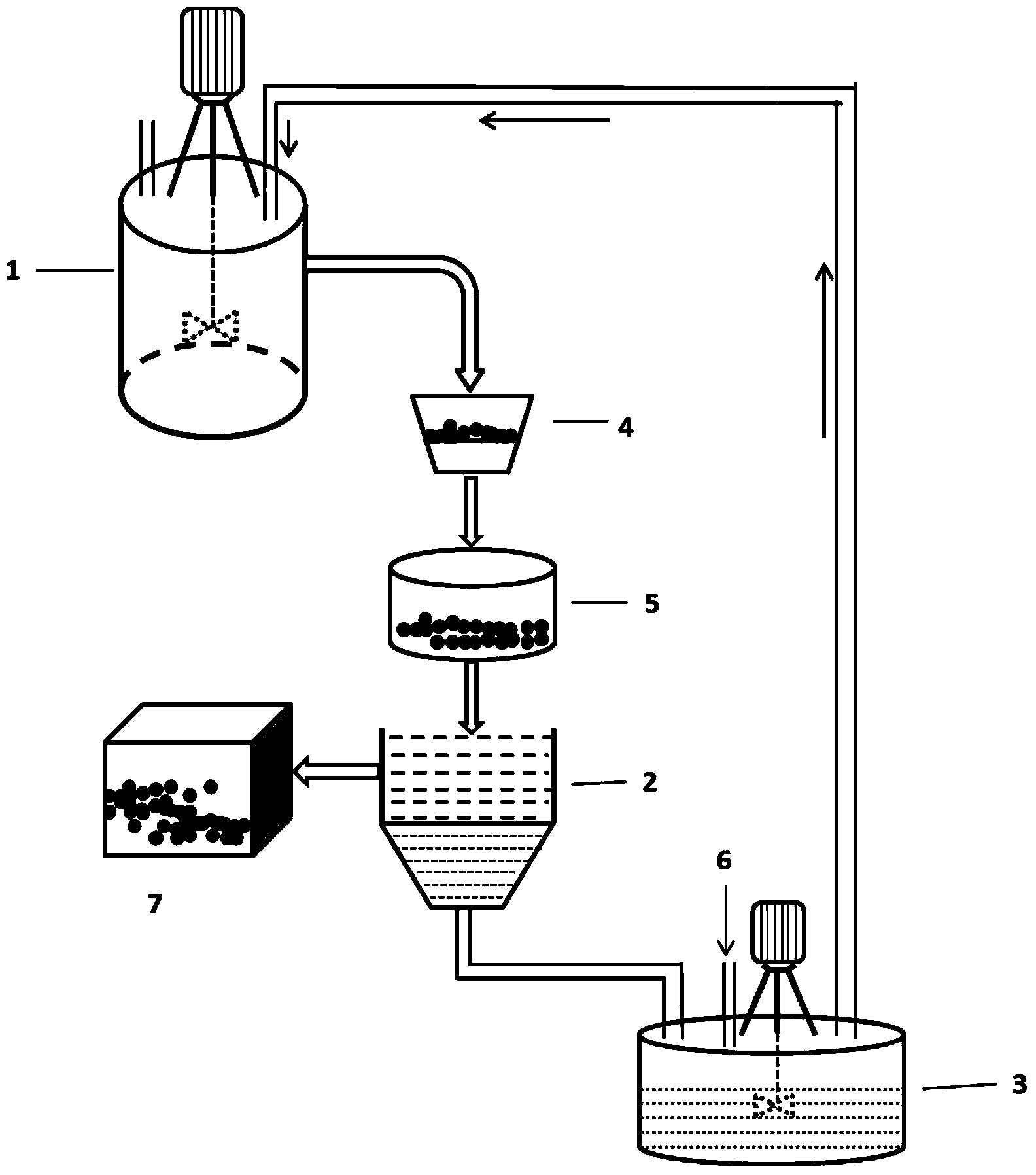

Method for preparing nickel-cobalt-manganese ternary material precursor

ActiveCN103943847ARealize comprehensive utilizationIncrease profitCell electrodesSecondary cellsManganeseCobalt

Owner:北京盟固利新材料科技有限公司

Positive active material and nonaqueous electrolyte secondary battery

ActiveUS20060093914A1Large capacityStable structureActive material electrodesCobalt compoundsManganeseLithium manganese oxide

A positive active material including a compound expressed by a general formula LimMxM′yM″zO2 (here, M designates at least one kind of element selected from Co, Ni and Mn, M′ designates at least one kind of element selected from Al, Cr, V, Fe, Cu, Zn, Sn, Ti, Mg, Sr, B, Ga, In, Si and Ge, and M″ designates at least one kind of element selected from Mg, Ca, B and Ga. Further, x is designated by an expression of 0.9≦x<1, y is indicated by an expression of 0.001≦y≦0.5, z is indicated by an expression of 0≦z≦0.5, and m is indicated by an expression of 0.5≦m) and lithium manganese oxide expressed by a general formula LisMn2-tMatO4 (here, the value of s is expressed by 0.9≦s, the value of t is located within a range expressed by 0.01≦t≦0.5, and Ma indicates one or a plurality of elements between Fe, Co, Ni, Cu, Zn, Al, Sn, Cr, V, Ti, Mg, Ca, Sr, B, Ga, In, Si and Ge) are included, so that both a large capacity and the suppression of the rise of temperature of a battery upon overcharging operation are achieved.

Owner:MURATA MFG CO LTD

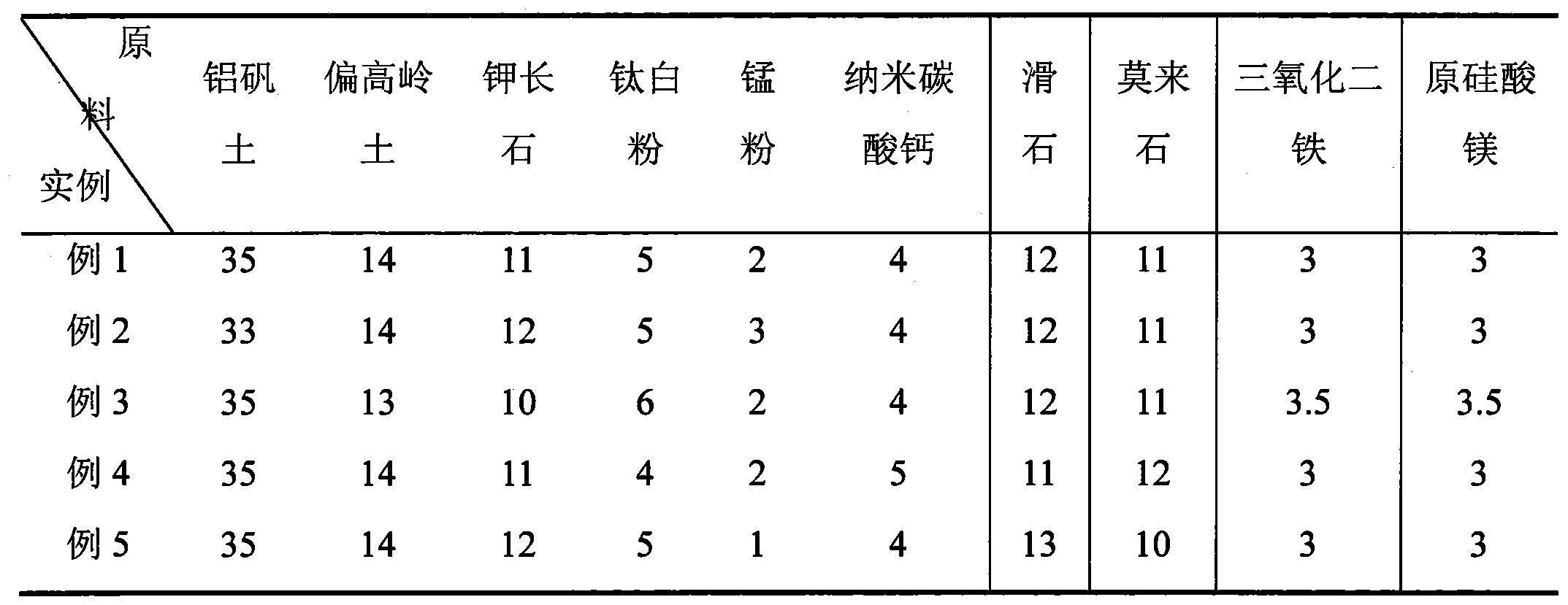

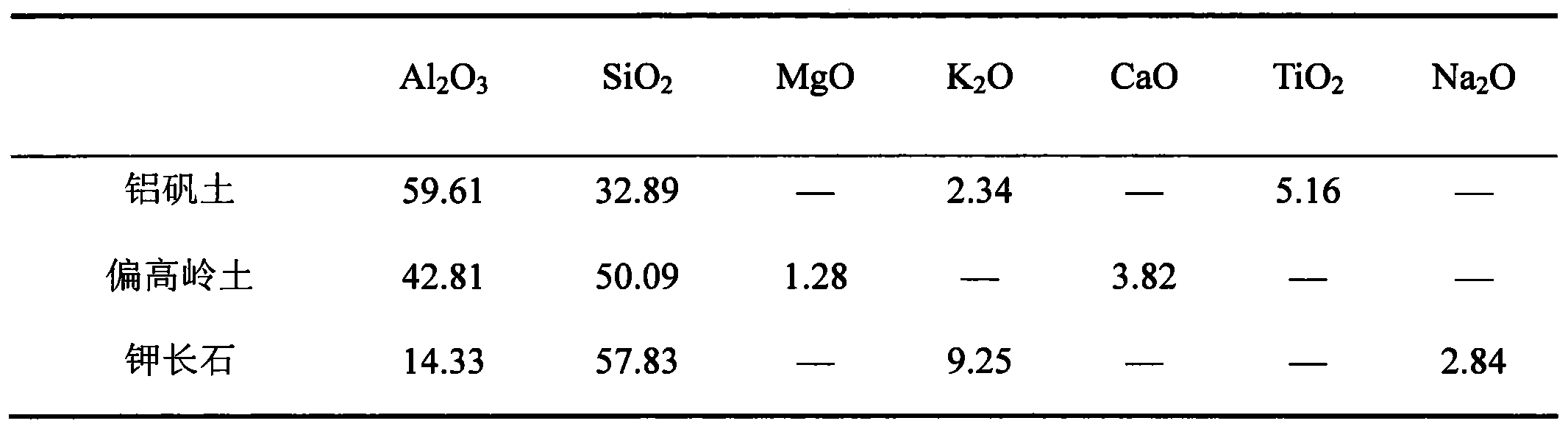

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

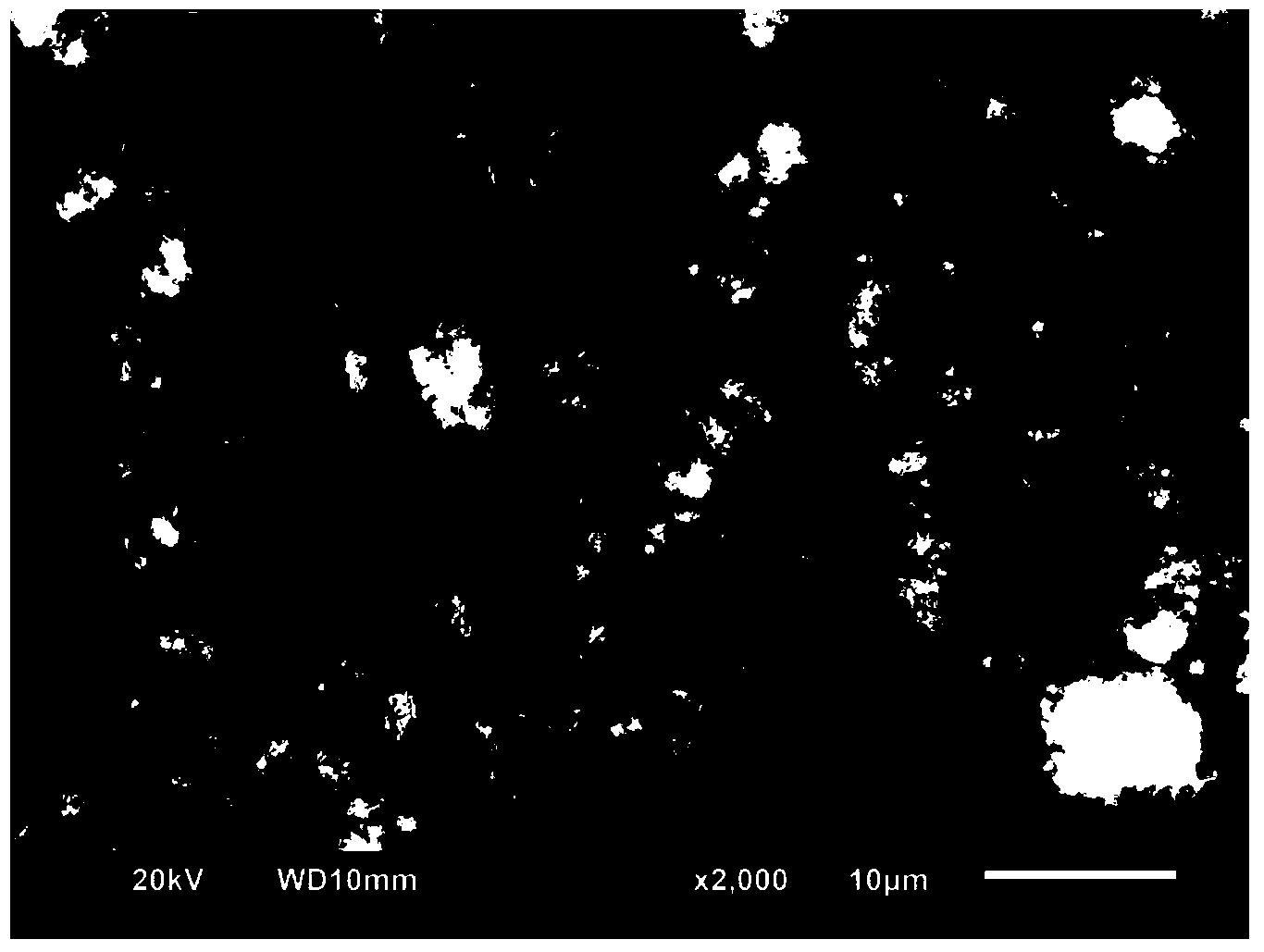

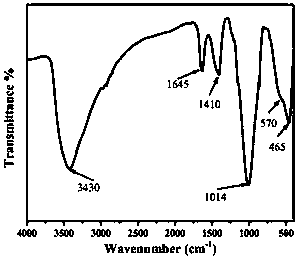

Preparation method of manganese-based composite metal oxide ozonolysis catalyst

InactiveCN109833868AHigh activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOzonolysis

The invention provides a preparation method of a manganese-based composite metal oxide ozonolysis catalyst, and belongs to the fields of catalysis and environmental protection. The method uses a redoxprecipitation process to synthesize the nano-fibrous manganese-based composite transition metal oxide catalyst. The preparation method of the catalyst has the advantages of simple process, mild conditions, and realization of high stability of catalytic ozonolysis. The catalyst prepared by the method disclosed in the invention has a high ozone removal catalysis activity, and can realize complete removal of ozone at normal temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

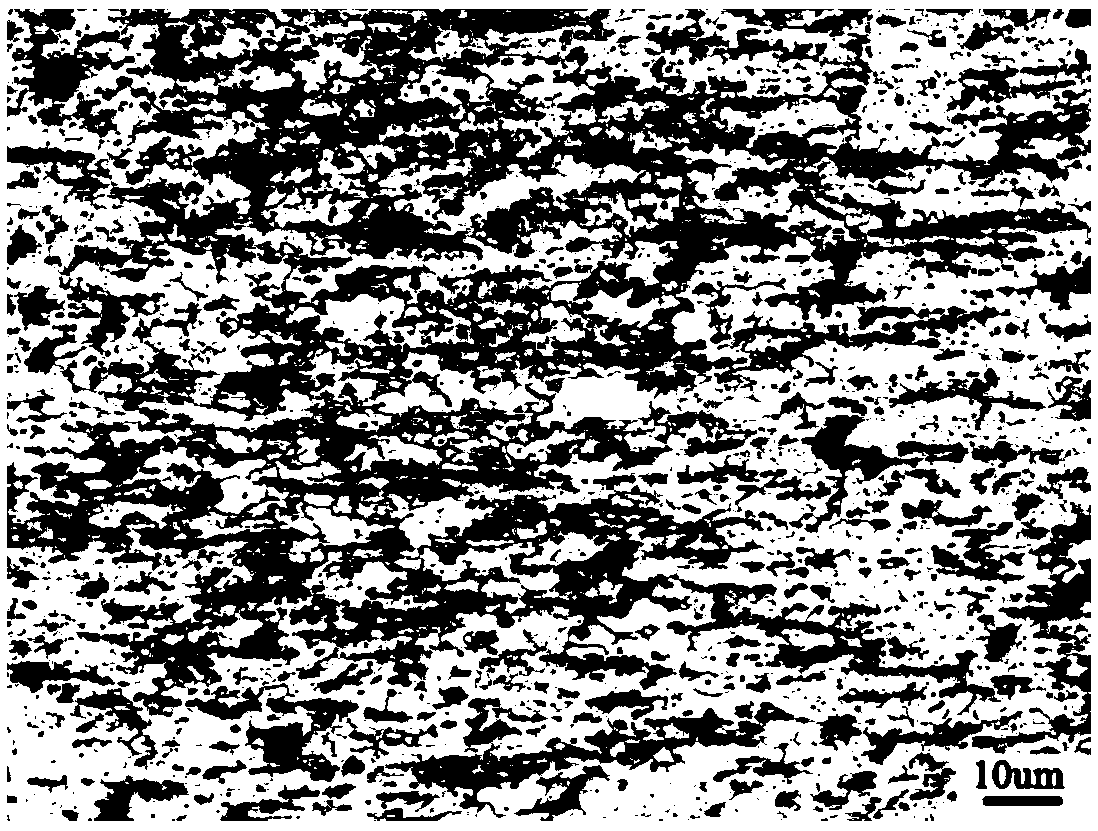

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

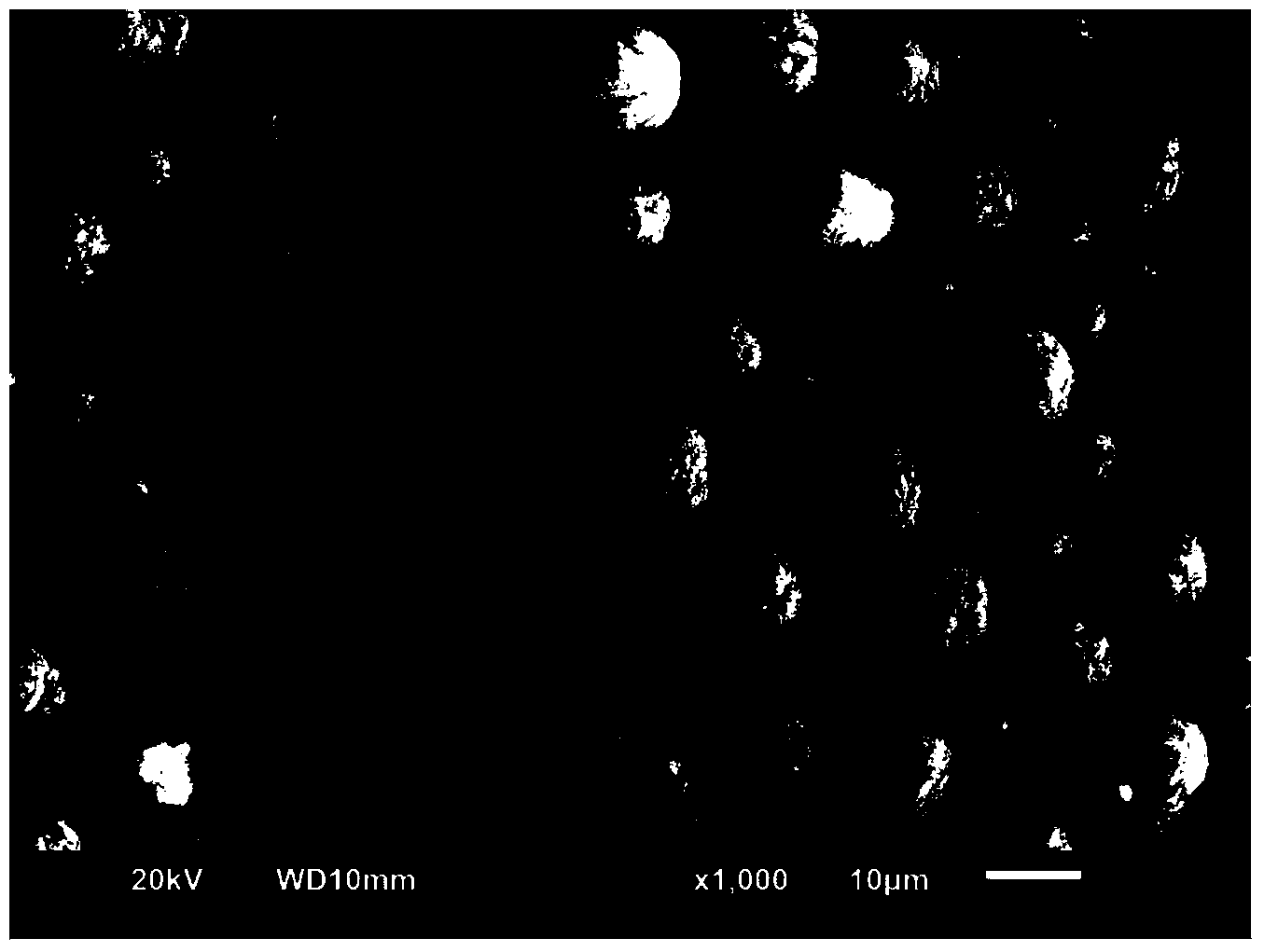

Method for extracting lithium from brine to prepare battery-grade lithium carbonate by ion exchange method

ActiveCN106629789AHigh recovery rateLarge particle sizeHydrotalciteLithium carbonates/bicarbonatesDesorptionManganese

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Flux for removing iron from Mg alloy and its preparing process

Owner:SHANGHAI JIAO TONG UNIV

Modified lithium-rich manganese-based cathode material for lithium ion battery

ActiveCN103682290AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesManganeseStrontium

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

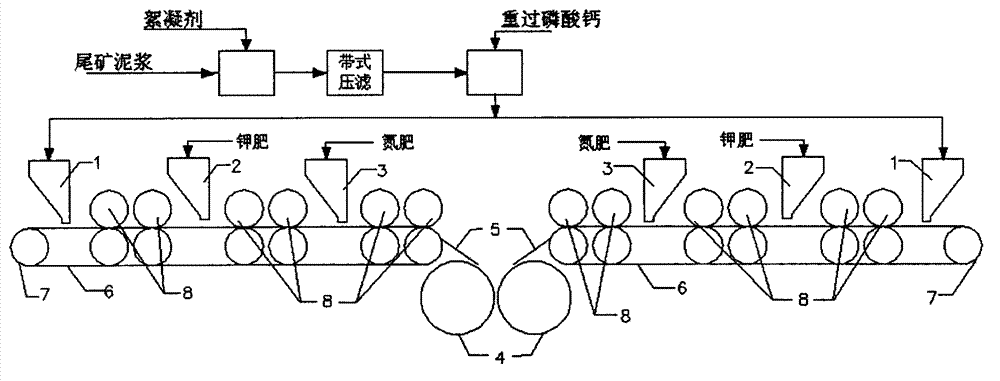

Method and equipment for producing slow-release compound fertilizer from manganese ore tailings

InactiveCN103204743AReduce processing costsSolving Stacking Handling IssuesFertiliser formsFertilizer mixturesElectrolysisManganese

Owner:赵阳臣

Lithium air battery catalyst based on metal organic frameworks (MOFs), and method for preparing lithium air battery catalyst

InactiveCN103170366AHigh catalytic activityImprove catalytic stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesLithium–air batteryCobalt salt

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

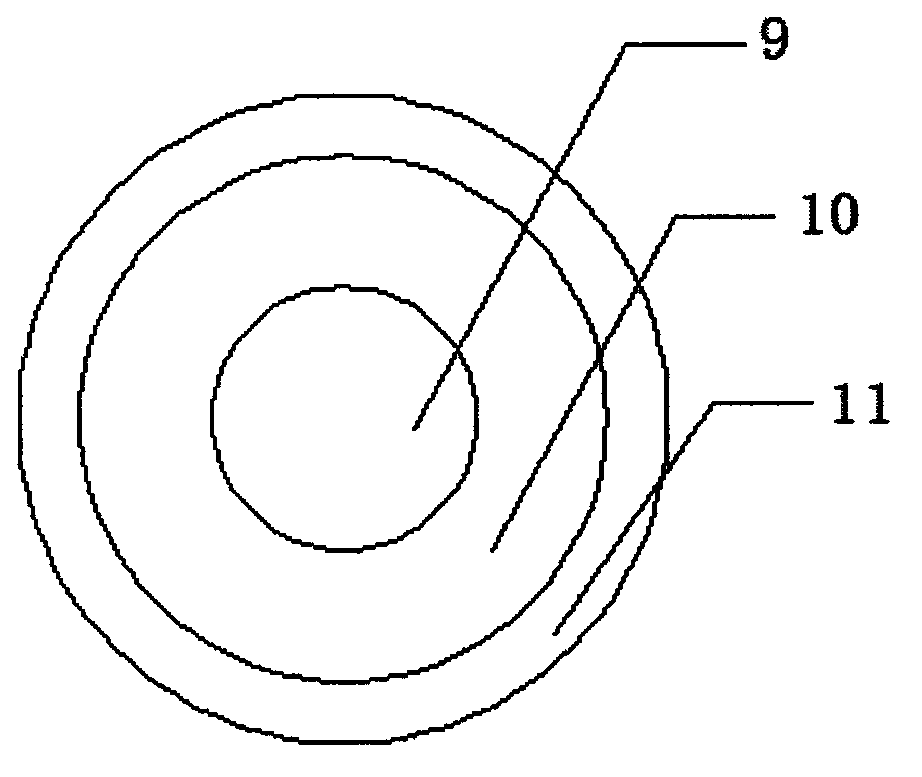

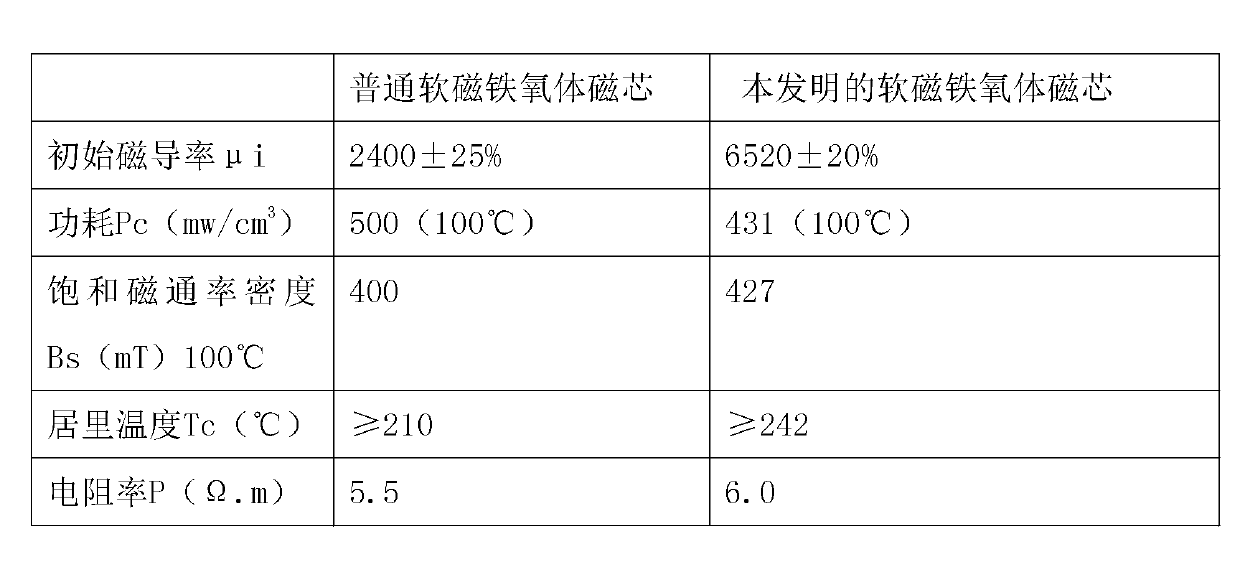

Preparation method of MnZn (Manganese-Zinc) soft magnetic ferrite material containing modified nanoscale titanium dioxide

Owner:浙江大通磁业科技有限公司

Humic acid-containing complete-element water soluble fertilizer, and preparation method and application thereof

InactiveCN105669297AIncrease profitPromote growthMagnesium fertilisersAlkali orthophosphate fertiliserSolubilityPhosphate

Owner:HUNAN TAIGU BIOTECH

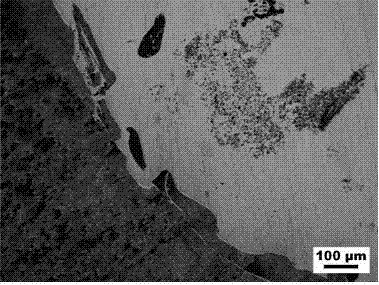

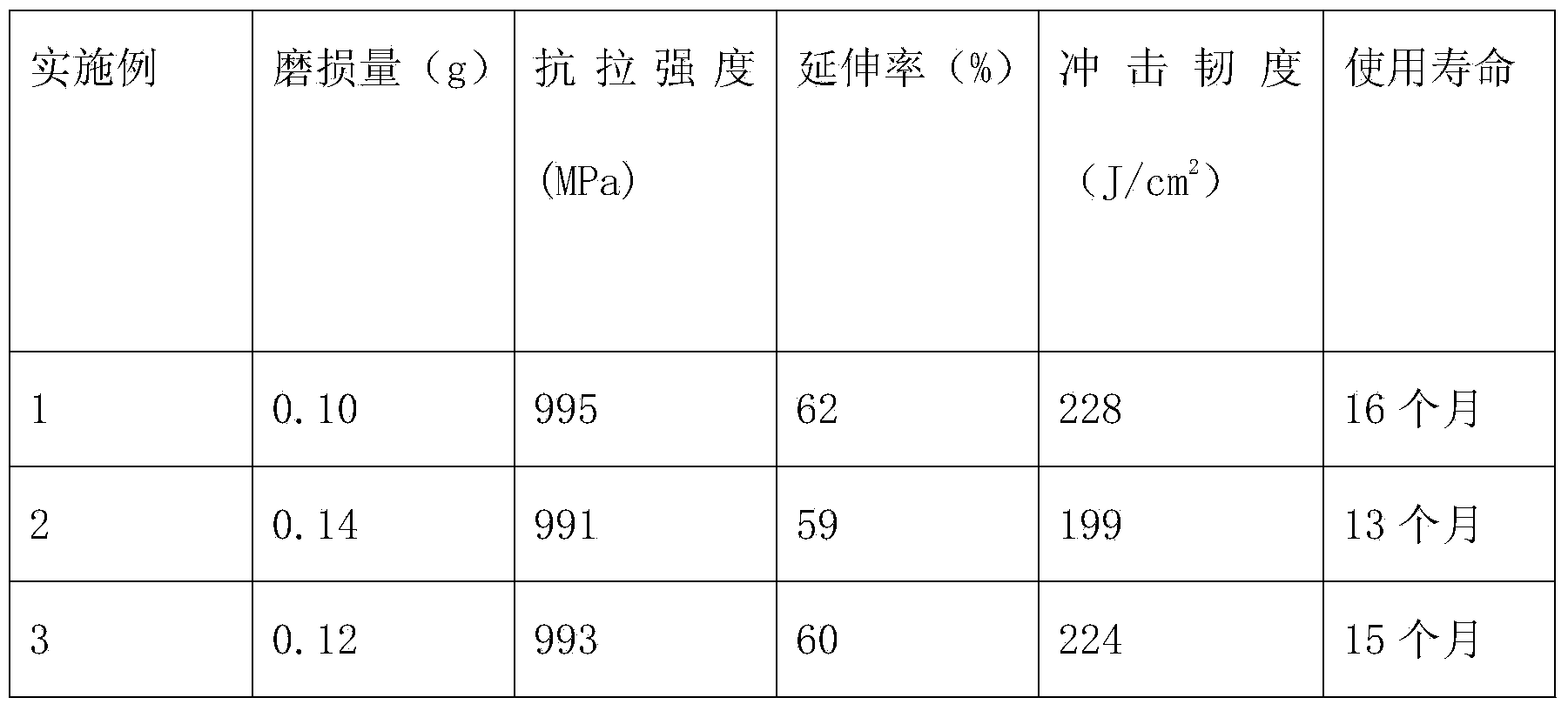

Double metal alloy barrel material and producing technology thereof

InactiveCN107312962AModerate hardnessImprove high temperature performanceChromium carbideMetal alloy

The invention discloses a double metal alloy barrel material. Raw material powder of the double metal alloy barrel material comprises, by mass, 25-50% of molybdenum, 2-10% of boron, 5-15% of chromium, 2-10% of nickel, 1-5 %of manganese, 0.1-1% of carbon, 0.8-3% of chromium carbide and the balance ferrum. The producing technology of the double metal alloy barrel material comprises the following steps of 1), raw powder ball-milling, 2), powder mixing and drying, 3), powder pressing for forming a green body, 4) green body machining and shaping, 5), vacuum degreasing and sintering, 6) semi-finished product shaping and machining, 7) green body heat covering treatment, and 8), inner hole machining treatment. A double metal alloy barrel produced by the above materials is moderate in rigidity, excellent in high temperature performance, good in bending strength, close to density of steel substrate, high in breaking tenacity, excellent in wear-resisting property and excellent in decay resistance, plastic molding can be more stable by using the producing technology, and the service life of the alloy barrel is greatly improved.

Owner:DONGGUAN JIEYU MASCH CO

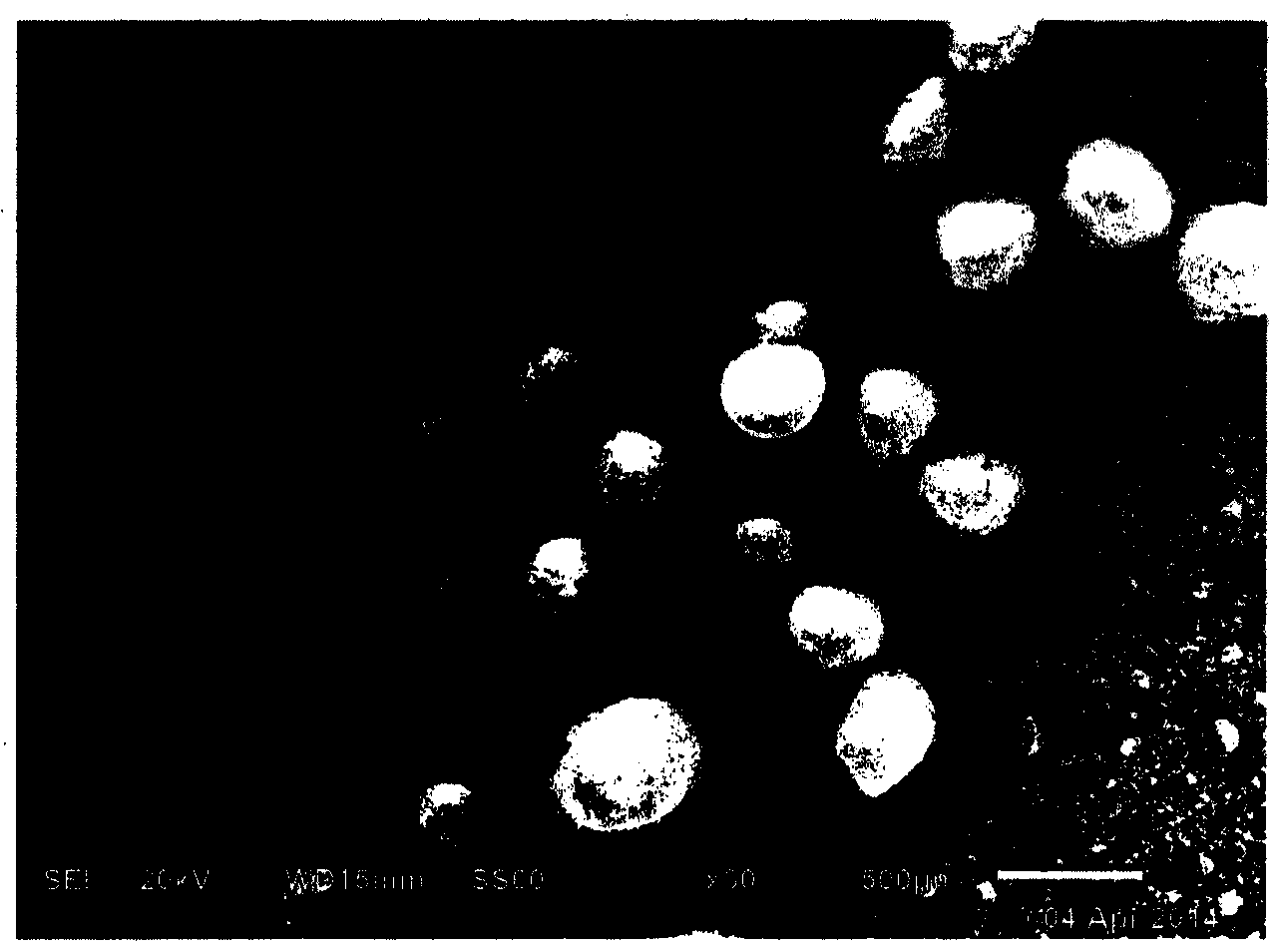

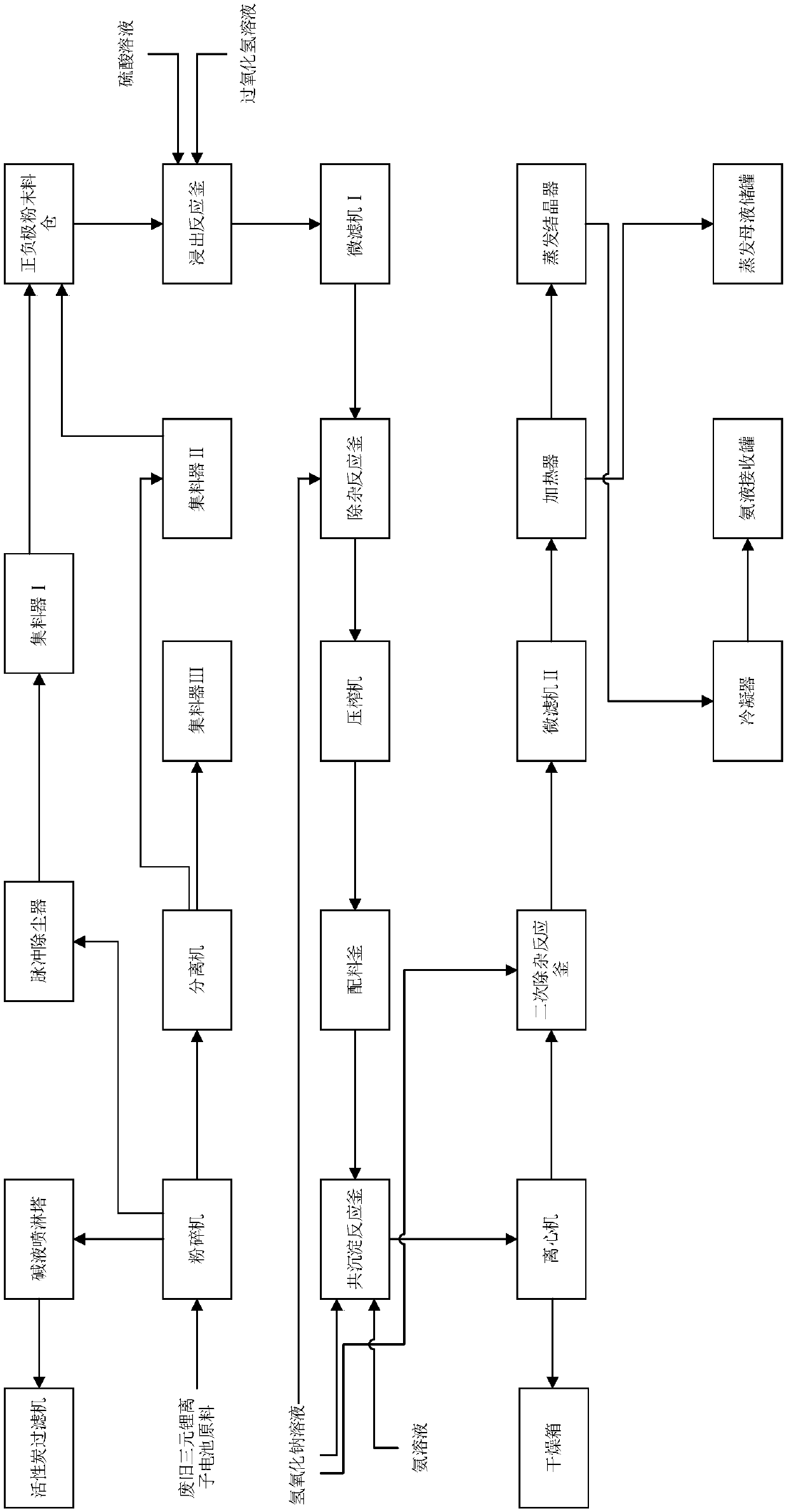

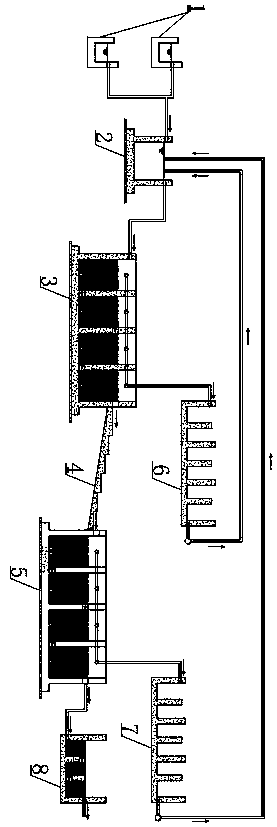

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

Positive Electrode Active Material for Lithium Secondary Battery

Provided is a novel positive electrode active material which can effectively suppress the quantity of gas generated by the reaction with an electrolytic solution. Proposed is a positive electrode active material for a lithium secondary battery including positive electrode active material particles obtained by equipping the entire surface or a part of a surface of lithium manganese-containing composite oxide particles (also referred to as the “core particles”) operating at a charging voltage in a region exceeding 4.3 V in a metal Li reference potential with a layer A containing at least titanium (Ti), aluminum (Al), zirconium (Zr), or two or more kinds of these.

Owner:MITSUI MINING & SMELTING CO LTD

Preparation method for manganese dioxide@silica nano composite particles with core-shell structures

Owner:UNIV OF SCI & TECH OF CHINA

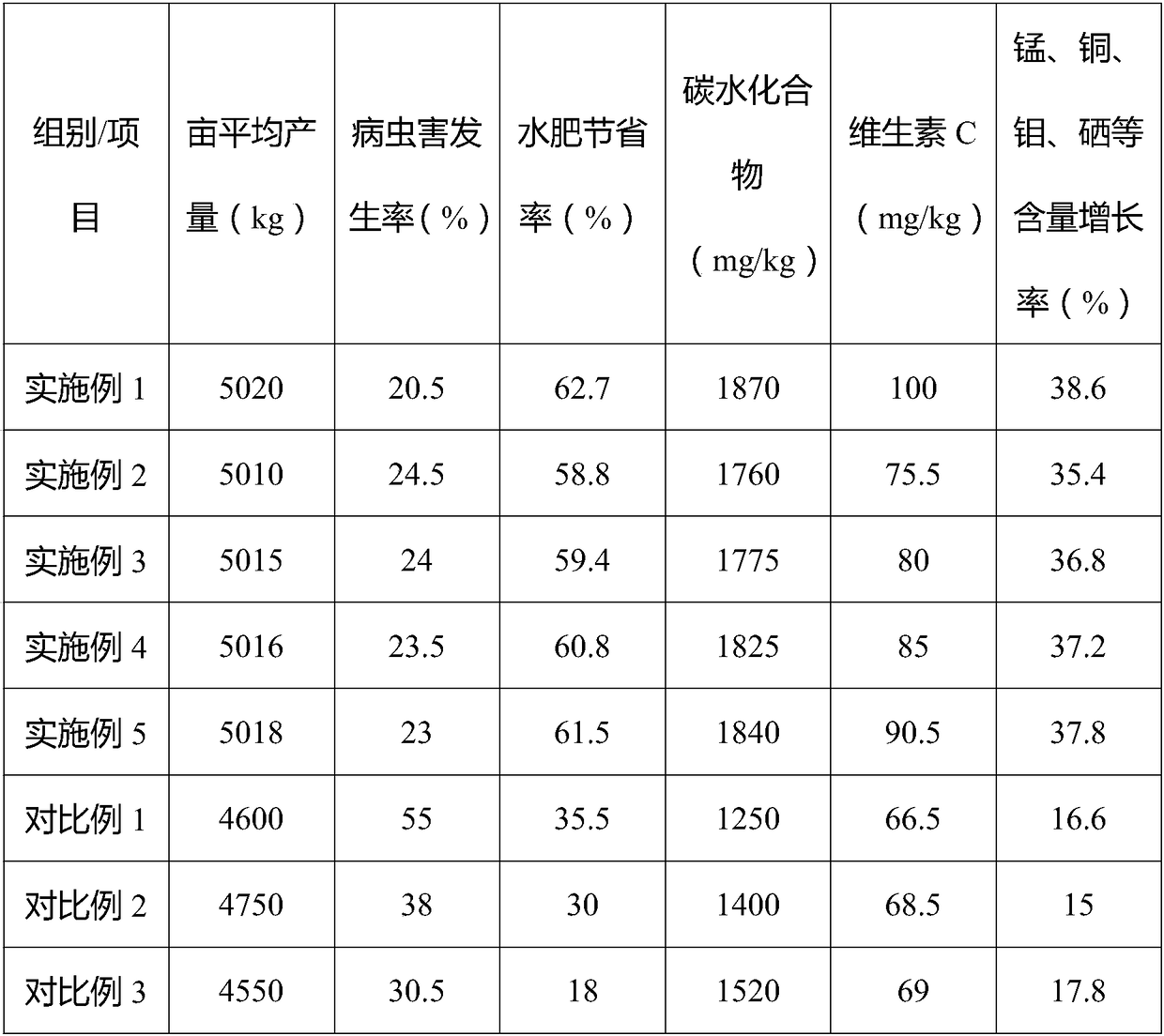

Foliar fertilizer for improving crisp pear quality and application method thereof

InactiveCN109053258AIncrease the sugar contentHigh in vitaminsNitrogenous fertilisersFertilizer mixturesArginineManganese

The invention discloses foliar fertilizer for improving crisp pear quality and an application method thereof. The pear foliar fertilizer is prepared from arginine, proline, lysine, glycine, glutamic acid, leucine, zinc, manganese, copper, iron, threonine, asparaginic acid, alanine and phenylalanine, wherein arginine and proline have a promoting effect on pear growth development; lysine, glycine, glutamic acid, leucine, the zinc, the manganese, the copper and the iron have a promoting effect on pear photosynthesis; threonine, asparaginic acid, alanine and phenylalanine have a promoting effect on pear stress resistance. The application method of the pear foliar fertilizer comprises the steps: mixing with water to dilute the pear foliar fertilizer spraying 2 to 4 times in a fruit expanding period, spraying to the front and back sides of leaves when no wind, no rain and no burning sun and spraying until the leaves are wet in each spraying. When the fertilizer disclosed by the invention isused, pear photosynthesis and metabolism are promoted, the sugar content and the vitamin content of crisp pears are better improved, and pear quality is improved.

Owner:HEFEI LVNONG FERTILIZER IND +1

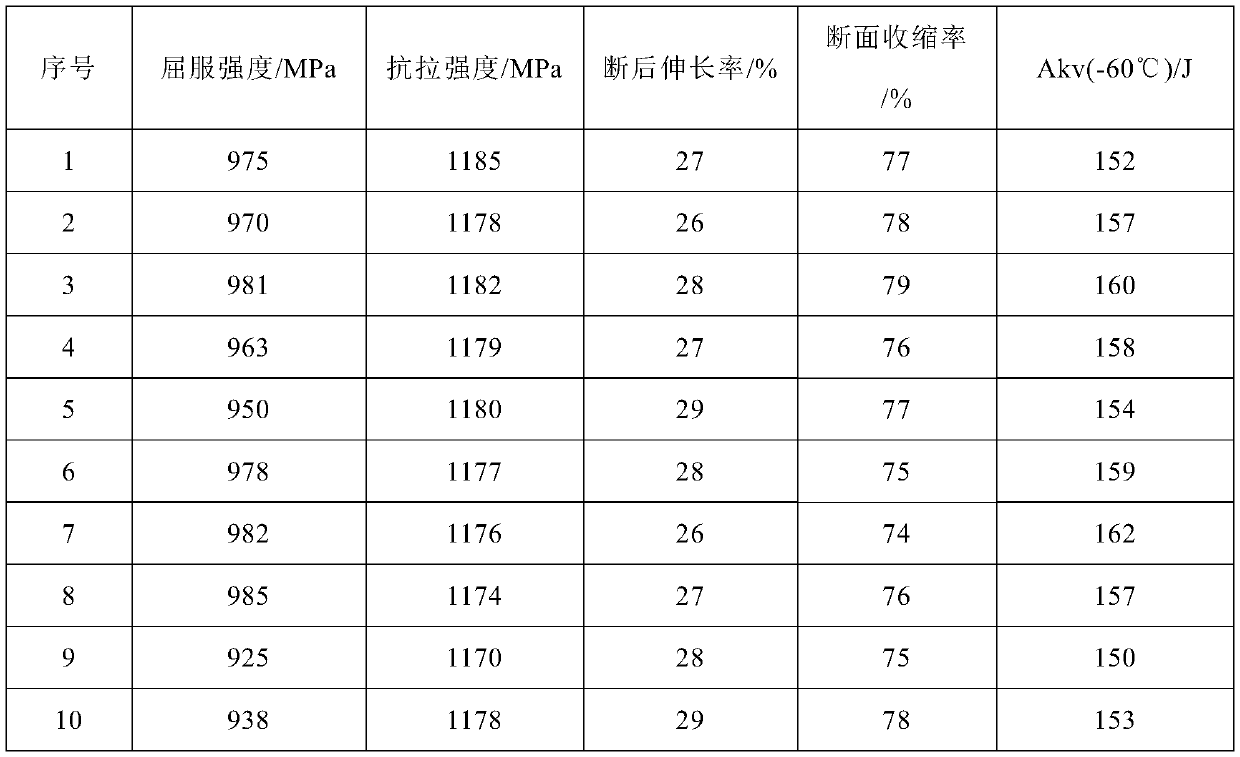

High-strength 23Mn2CrNiMnVERA steel for railway train connection and preparation method thereof

Owner:SHANDONG XIWANG SPECIAL STEEL

Acer truncatum transplanting planting method

The invention discloses an acer truncatum transplanting planting method which comprises the following steps: 1) performing preparation before transplanting; 2) performing balance twig cutting treatment on acer truncatum; 3) performing root cutting and root ball reduction treatment; 4) packaging and transporting root balls; 5) performing planting; and 6) performing maintenance management after transplanting. By adopting the acer truncatum transplanting planting method disclosed by the invention, in the transplanting process, distillers' grains, cattle dung, trace elements (iron, sulfur, copper, manganese and selenium) are mixed with water to obtain paste, gauze or cotton cloth is coated by the paste, cut parts are wrapped by the gauze or the cotton cloth, an organic penetration tube which is prepared in advance is placed around roots annually, then relatively effective and direct absorption of air, moisture, fertilizers and essential growth medicines by trees is promoted, and furthermore the purposes of rapid survival and growth after tree transplanting are achieved.

Owner:CHONGQING LVFENGSHUN AGRI TECH DEV CO LTD

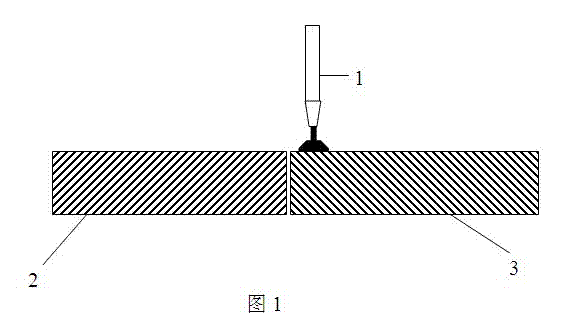

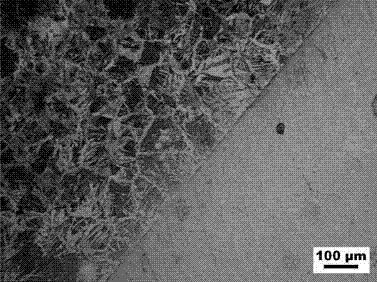

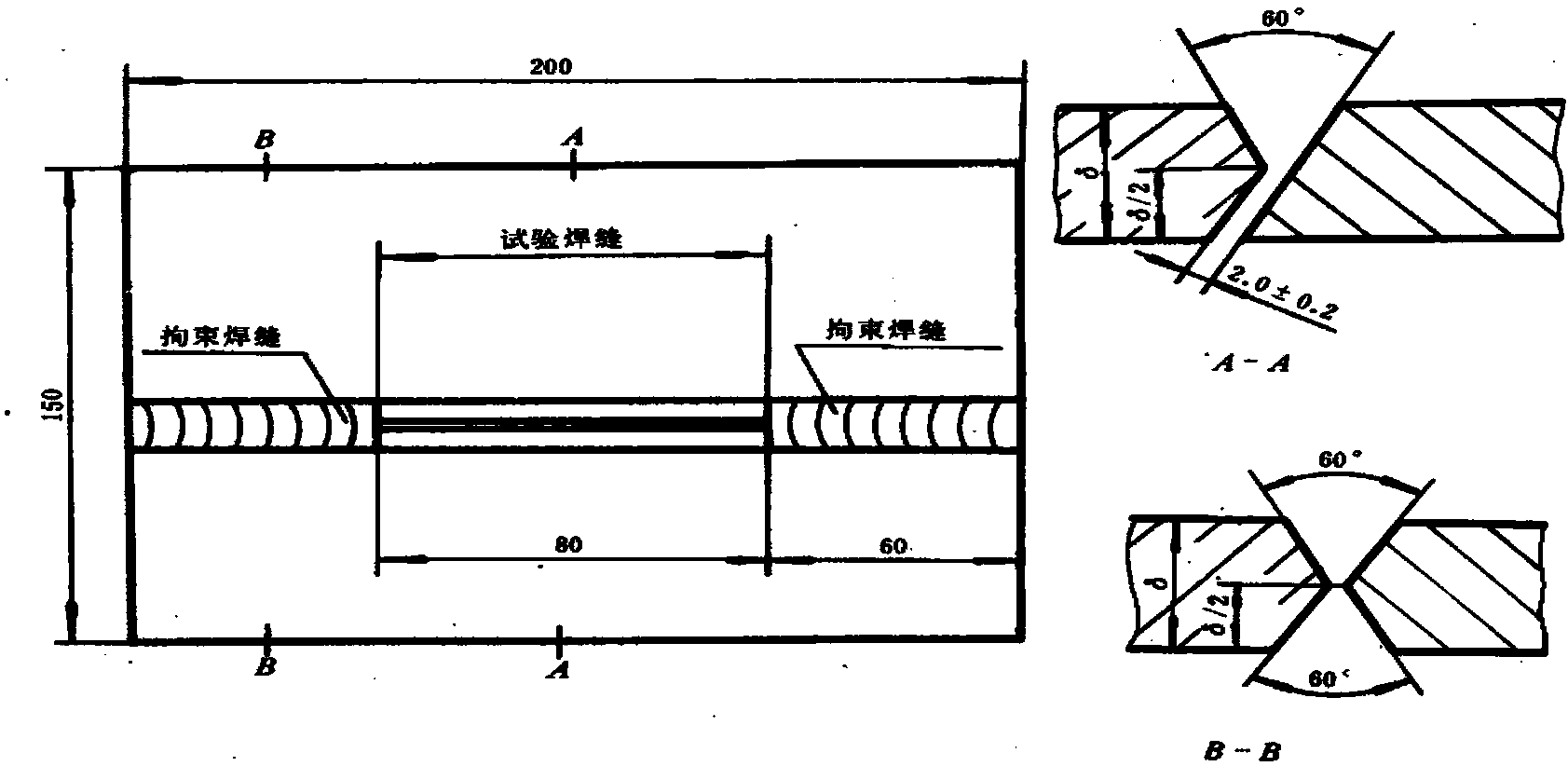

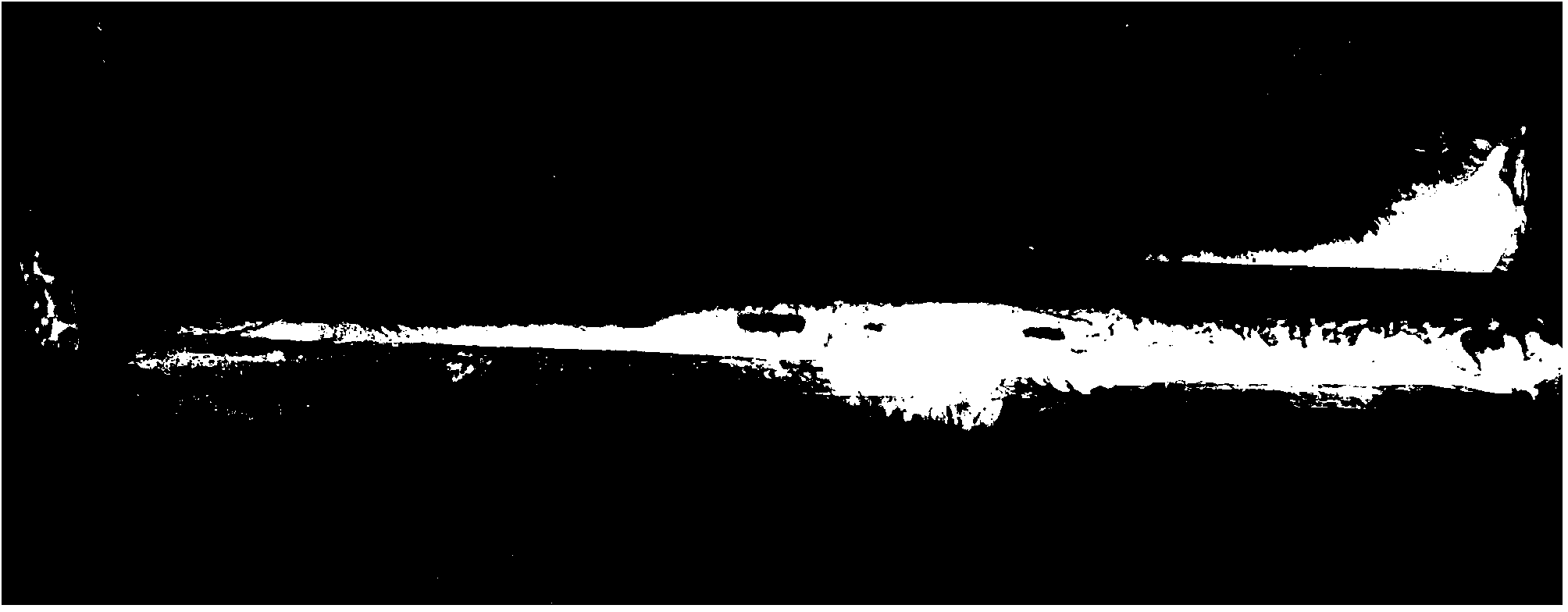

Welding wire of steel-copper dissimilar metal submerged-arc welding and welding method of welding wirethereof

InactiveCN102873467AImprove mechanical propertiesBeautiful shapeArc welding apparatusWelding/cutting media/materialsManganeseSpot welding

Owner:SHENYANG POLYTECHNIC UNIV +1

Anti-corrosion and anti-wear high manganese steel and preparation method thereof

Owner:江苏久华环保科技股份有限公司

Novel thermoforming reinforcer and processing method thereof

Owner:JINGJIANG XINCHENG VEHICLE PARTS

Low-aluminum and low-silicon welding wire steel low-sulfur-control smelting method

ActiveCN111979374AReduce sulfur contentPrevent slagSteelmakingSlag (welding)

Owner:NANJING IRON & STEEL CO LTD

Planting method for beet rich in various trace elements

InactiveCN108739144AReduce volatilityReduce churnBio-organic fraction processingExcrement fertilisersPlant cellManganese

Owner:FOSHAN RIKEWEI FOOD TECH RES INST GENERAL PARTNER

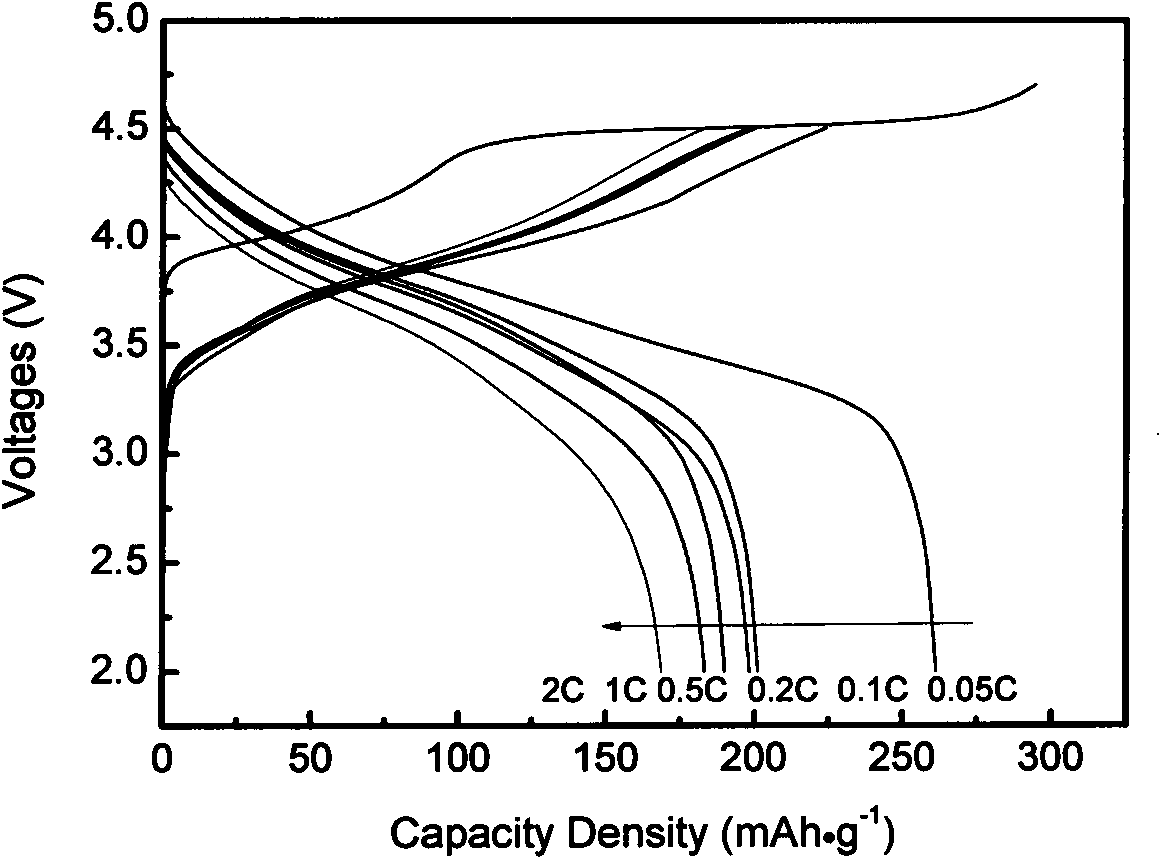

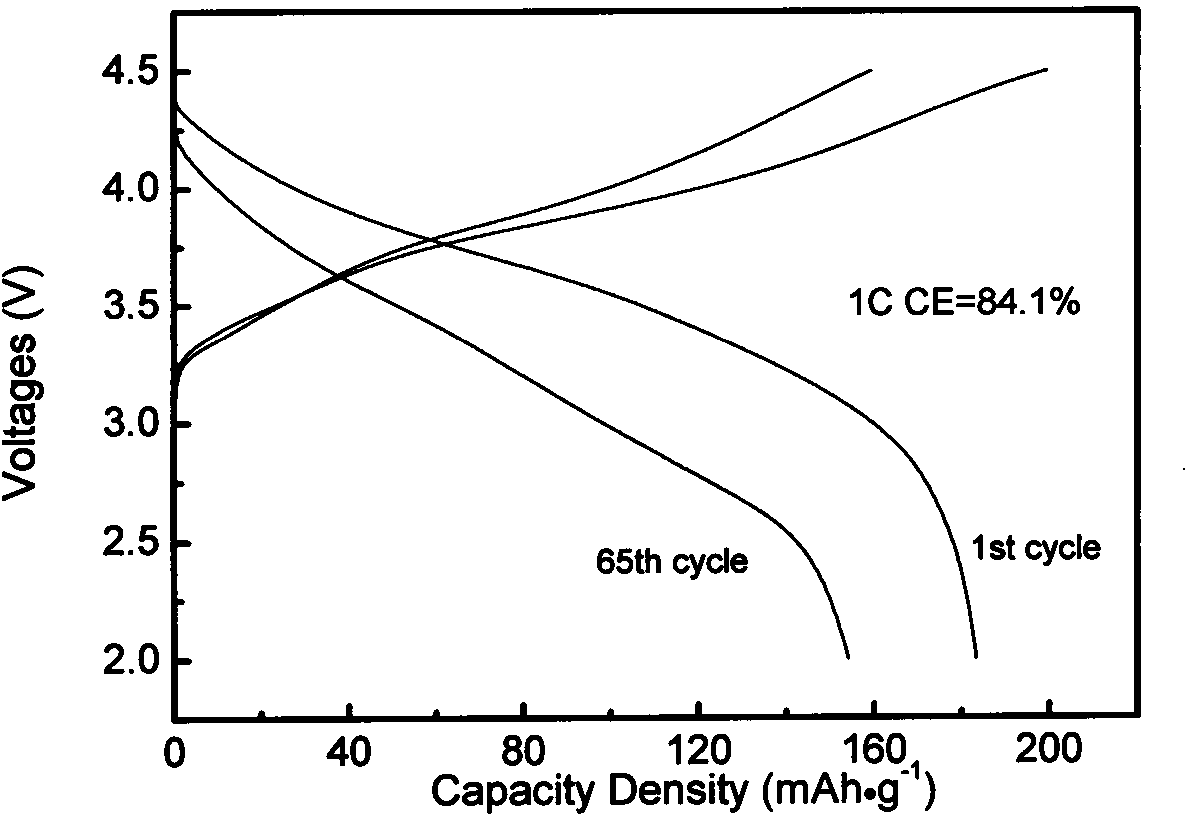

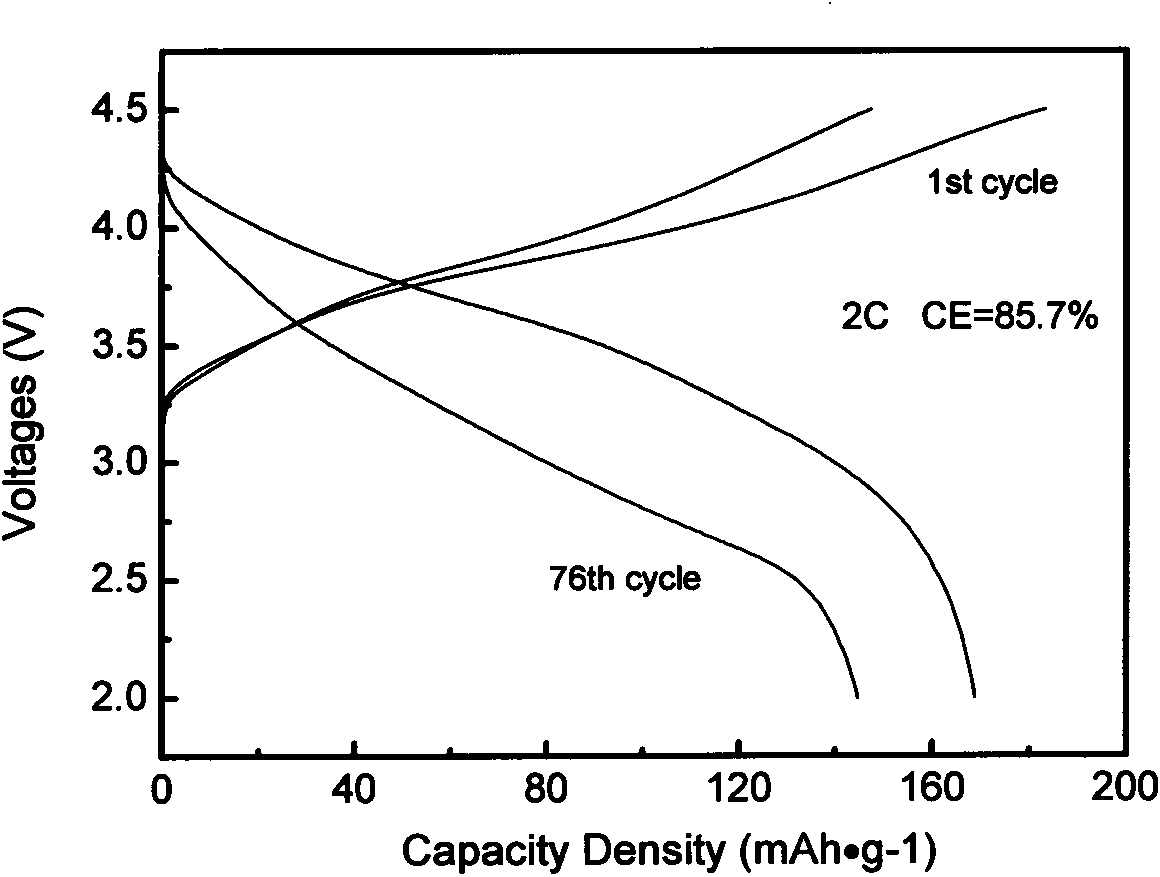

Stable lithium ion battery with high capacitance

InactiveCN103606666AImproved high-magnification performanceImprove power densityCell electrodesSecondary cellsCapacitanceManganese

The invention discloses a stable lithium ion battery with high capacitance. Two poles are respectively prepared from a composite carbon cathode material and a ternary composite anode material. By adopting the stable lithium ion battery, the high magnification performance and the power density of the lithium ion battery can be effectively improved. The stable lithium ion battery has high-magnification charge and discharge properties. Three transition metals such as nickel, manganese and cobalt are evenly mixed, so that a layered structure of the material is stabilized by synergistic effects of the nickel, manganese and cobalt, and the charge and discharge capacities, the cycle performance and the overcharging tolerance of the material are improved.

Owner:JIANGSU TENPOWER LITHIUM

High-efficiency environment-friendly composite fertilizer specially used for lotus drought plantation

Owner:太仓市林港农场专业合作社

Cold-rolling high-strength hot-galvanized steel plate and preparation method

ActiveCN108914014AHigh strengthReduce manufacturing costHot-dipping/immersion processesManganeseSteel plates

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +2

Titanium type gas-shielded flux-cored wire

ActiveCN103521949AGood workmanshipImprove crack resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceManganese

Owner:TIANJIN YONGCHANG WELDING WIRES

Mine acidic iron-containing wastewater treatment method and system

PendingCN110950464AReduce dosageLess investmentWaste water treatment from quariesSpecific water treatment objectivesSludgeCatalytic oxidation

Owner:SICHUAN INST OF GEOLOGICAL ENG INVESTIGATION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap