Mine acidic iron-containing wastewater treatment method and system

A wastewater treatment system and wastewater treatment technology, which is applied in the fields of mining wastewater treatment, water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of traffic, inconvenience of electricity consumption, large investment in construction of sewage treatment plants, and high power consumption High cost and other issues, to achieve the effect of good promotion value, low transportation cost, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

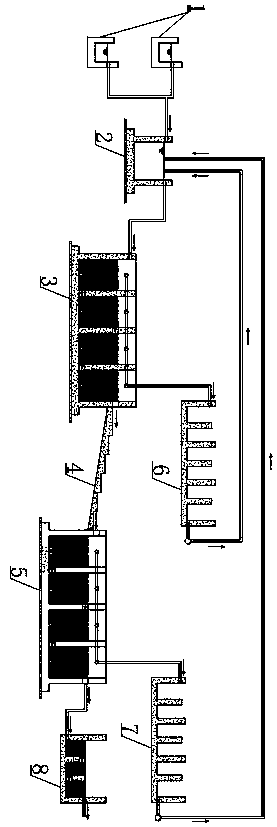

Image

Examples

Embodiment Construction

[0045] The following examples are used to illustrate a mine acidic iron-containing wastewater treatment method and system thereof of the present invention, but are not intended to limit the protection scope of the present invention.

[0046] A method for treating acidic iron-containing wastewater from a mine. The treatment steps are as follows: after the mine wastewater is collected, the pH value is pre-adjusted by using limestone gravel, and then the pH value is adjusted to above 6 through the fly ash filter material; Drop water for aeration, make the wastewater fully contact with the air, and increase the dissolved oxygen content in the wastewater; then use manganese sand filter material to remove iron in the water through contact oxidation method; use quartz sand to filter the supernatant to further reduce the concentration of suspended solids Wastewater treatment is then completed.

[0047] The fly ash filter material and the manganese sand filter material can be backwashed w

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap