Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Improve thermal conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-supporting nickel phosphide catalyst and preparation method and application thereof

ActiveCN107694584AImprove thermal conductivityGood choiceOrganic compound preparationCarboxylic acid esters preparationOxalateNickel oxide hydroxide

The invention discloses a self-supporting nickel phosphide catalyst and a preparation method and application thereof. The self-supporting nickel phosphide catalyst is a nickel phosphide catalyst obtained by in-situ growing of a nickel oxalate or nickel hydroxide crystal layer on a framework matrix through a hydrothermal method and performing phosphating while secondary forming is not needed, and the nickel phosphide catalyst is composed of the framework matrix and a nickel-phosphorus compound, wherein the nickel-phosphorus compound is at least one of Ni3P, Ni12P5, Ni2P and Ni5P4, total mass ratio of the nickel-phosphorus compound is 0.1-50%, and the balance is the framework matrix. Experiments show that the self-supporting nickel phosphide catalyst is high in stability and thermal conductivity, easy to form and fill, high in flux and low in pressure drop, especially has the advantages of high low-temperature activity, high dimethyl oxalate conversion rate and high methyl glycolate selectivity and can be used as a reaction catalyst for hydrogenating dimethyl oxalate to prepare methyl glycolate.

Owner:EAST CHINA NORMAL UNIV

Shoulder wedge composite material and manufacturing method thereof

The invention discloses a shoulder wedge composite material and a manufacturing method thereof. The shoulder wedge composite material consists of the following raw materials in part by weight: 100 parts of natural rubber, 10 to 50 parts of carbon series nano thermal conducting filler, 10 to 35 parts of coarse particle size carbon black, 2 to 6 parts of octyl phenolic resin, 2 to 4 parts of surfactant, 1 to 8 parts of silane coupling agent, 1.5 to 9 parts of vulcanizing agent and the balance of other common aids. The preparation method comprises the following steps of: plasticating the rubber in an internal mixer, adding the coarse particle size carbon black, the carbon series nano thermal conducting filler, the octyl phenolic resin, the surfactant and the other aids into the internal mixer, mixing and controlling the temperature to be between 80 and 120 DEG C; adding the silane coupling agent into the mixture, controlling the temperature to be between 120 and 160 DEG C, and discharging the sizing material; adding a master batch and the vulcanizing agent into the internal mixer and discharging products until the temperature is 80 to 120 DEG C, wherein if the other aids contain scorch retarder, the scorch retarder and the vulcanizing agent are added together. The shoulder wedge composite material provided by the invention meets the requirements of mechanical properties, and is low in themogenesis, high in thermal conductivity, and excellent in machinability.

Owner:BEIJING UNIV OF CHEM TECH +1

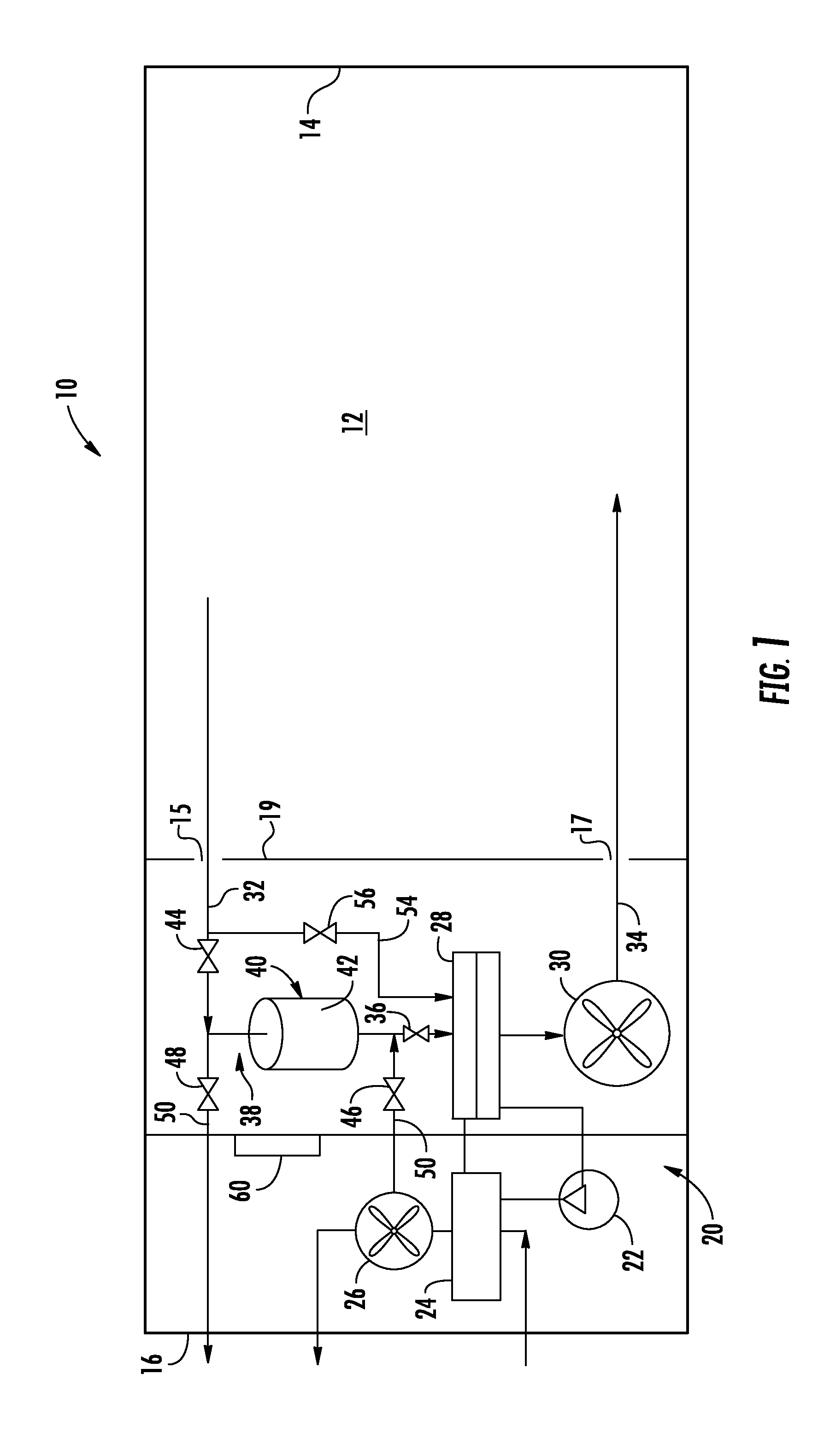

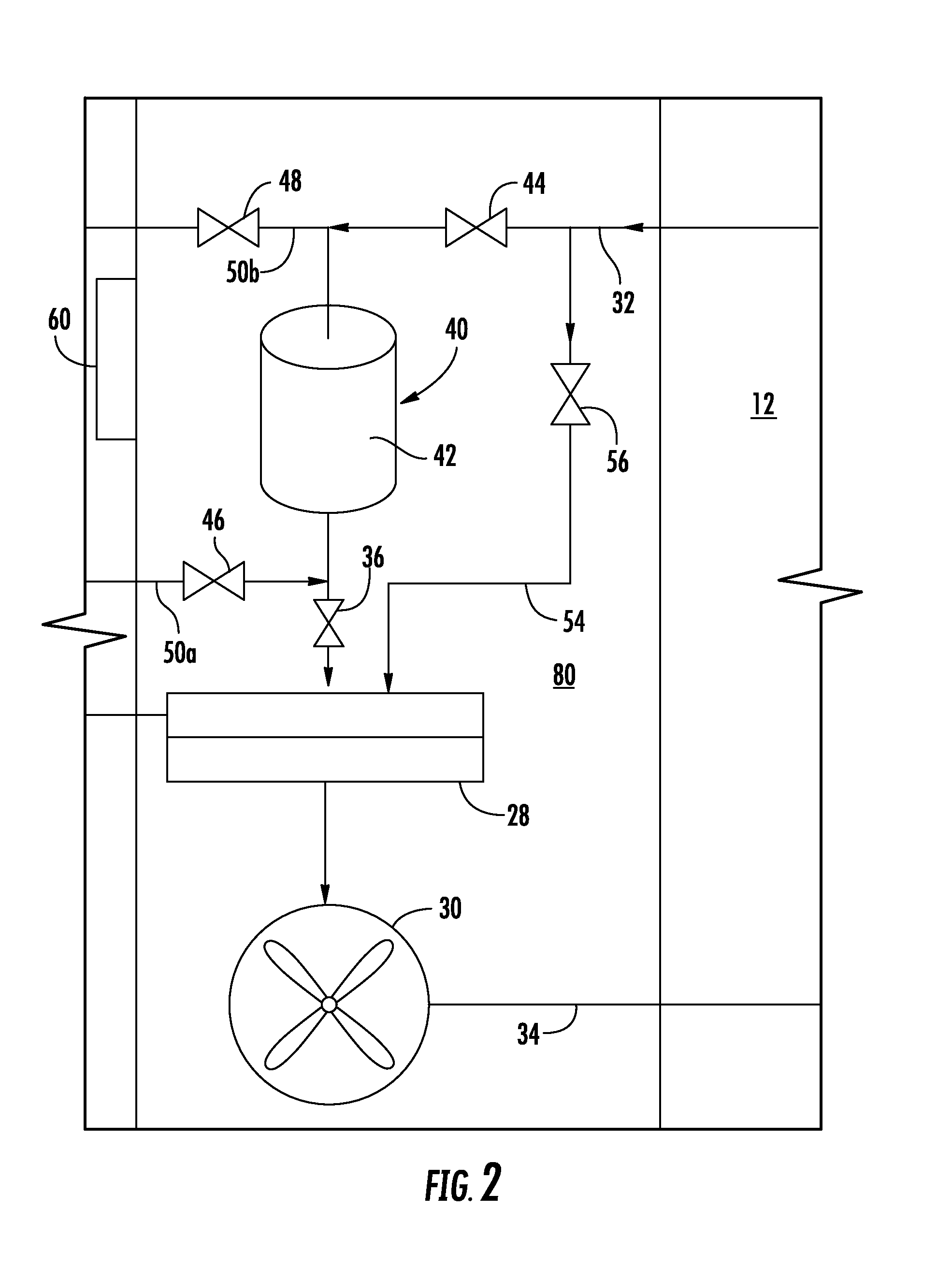

Control Of Atmosphere Within A Closed Environment

ActiveUS20140202183A1Improve thermal conductivityFruit and vegetables preservationLighting and heating apparatusGaseous atmosphereScrubber

Owner:CARRIER CORP

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Diamond micro-channel Cu-based CVD diamond heat sink sheet and preparation method thereof

ActiveCN110557936AThermal limitationsHigh densityModifications by conduction heat transferHeat sinkNucleation

The invention discloses a diamond micro-channel Cu-based CVD diamond heat sink sheet and a preparation method thereof. The diamond micro-channel Cu-based CVD diamond heat sink sheet sequentially comprises a Cu substrate, a micro-through-hole template and a CVD diamond film from bottom to top, wherein the Cu substrate and the micro-through-hole template are provided with nano-diamond particles therebetween, the Cu substrate is embedded with a diamond micro-channel array, the diameter of each diamond micro-channel ranges from 0.3mm to 0.5mm, and the distance between every two micro-channels ranges from 2mm to 3mm. The heat dissipation effect of the heat sink sheet is superior to that of traditional heat sink sheets such as Ag, Cu and Al; the heat dissipation performance of the micro-channelCu-based diamond heat sink sheet is better; the nucleation density and the growth rate of diamond in the micro-through-hole are greatly improved; and the CVD selective growth of the diamond film is realized in the micro-through holes.

Owner:SHAANXI UNIV OF SCI & TECH

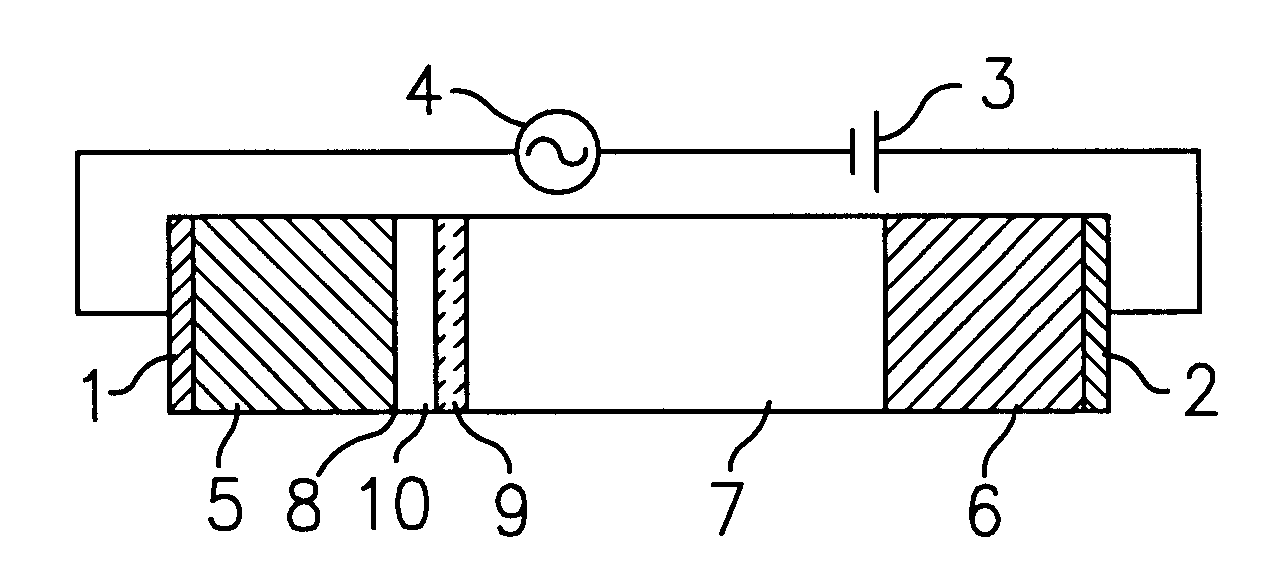

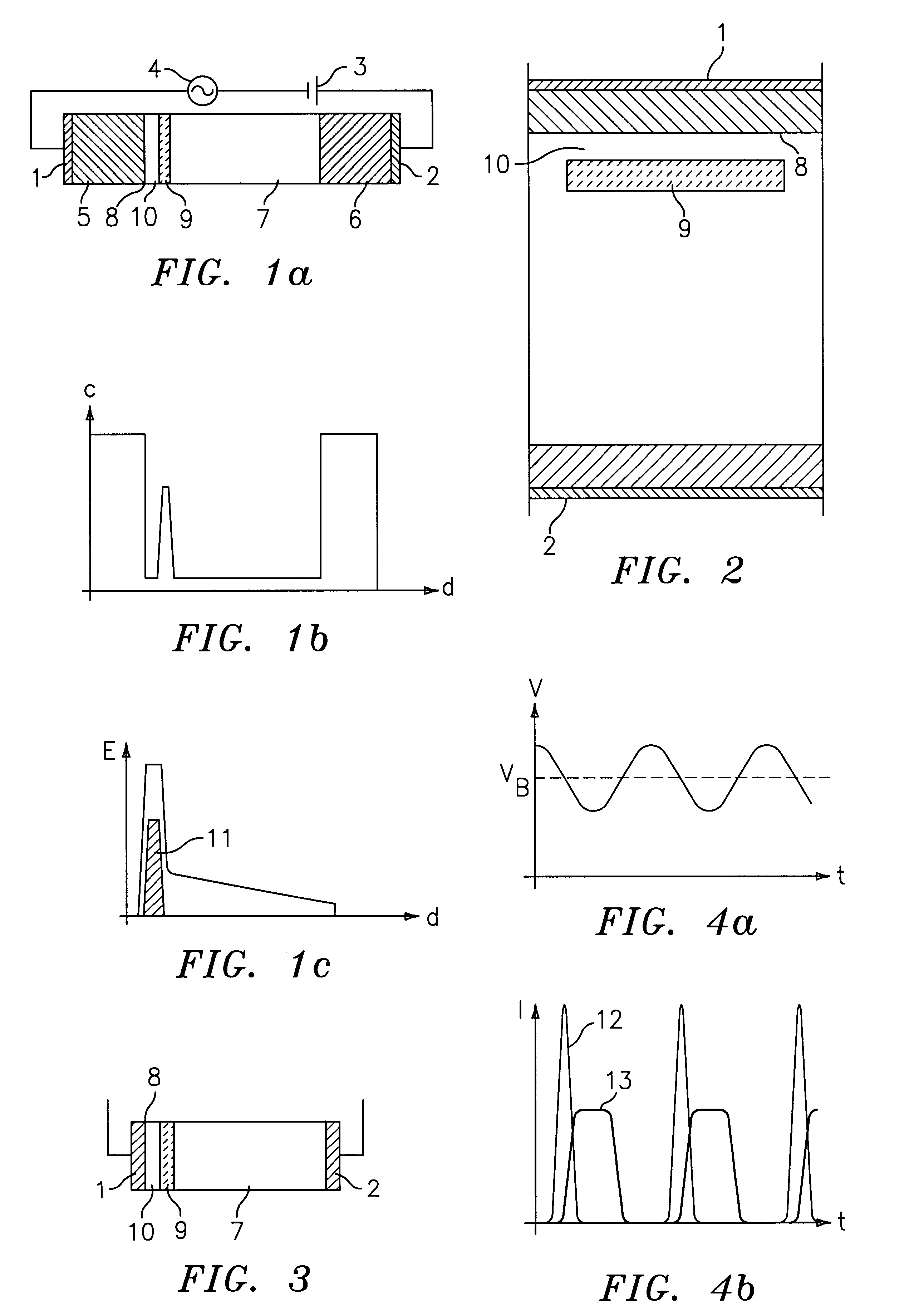

High power impatt diode

InactiveUS6252250B1Lower breakdown voltageIncrease concentrationSemiconductor devicesAvalanche breakdownTransit time

In a high power IMPATT ( Impact Avalanche Transit Time) diode for generating high frequency signals two electrodes, anode (2) and cathode (1), are arranged with a semiconductor layer therebetween. Said semiconductor layer comprises a drift layer (7) for transport of charge carriers between the electrodes. The semiconductor layer is made of crystalline SiC and it is provided with means (9) adapted to locally increase the electric field in the drift layer substantially with respect to the average electric field therein for generating an avalanche breakdown at a considerably lower voltage across the electrodes than would the electric field be substantially constant across the entire drift layer.

Owner:CREE SWEDEN

Breeding Nuclear Fuel Mixture Using Metallic Thorium

InactiveUS20110299645A1Improve economyImprove thermal conductivityFuel elementsConversion outside reactor/acceleratorsNuclear plantNuclear power

Disclosed is a breeding nuclear fuel mixture including metallic thorium useable in a nuclear power plant, prepared by mixing uranium dioxide (UO2) or plutonium dioxide (PuO2) having ceramic properties with metallic thorium (Th), in order to enable thorium breeding by neutrons released during nuclear fission of U or Pu and conversion of the bred thorium into a novel nuclear fissile material, i.e., U-233, thereby ensuring continuous nuclear fission. The foregoing nuclear fuel mixture may be burned at a reactor core of a nuclear power plant through thorium breeding over a long period of time. Therefore, when the inventive breeding nuclear fuel mixture is employed in a nuclear power plant, utilization of the nuclear power plant may be increased while maximizing conservation of limited uranium resources.

Owner:KOREA ATOMIC ENERGY RES INST +1

Reinforcement part for speaker diaphragm, diaphragm and speaker

ActiveCN109451400AHeat dissipation fastImprove thermal conductivityDiaphragm extensionsLoudspeakersComposite structureEngineering

Owner:GOERTEK INC

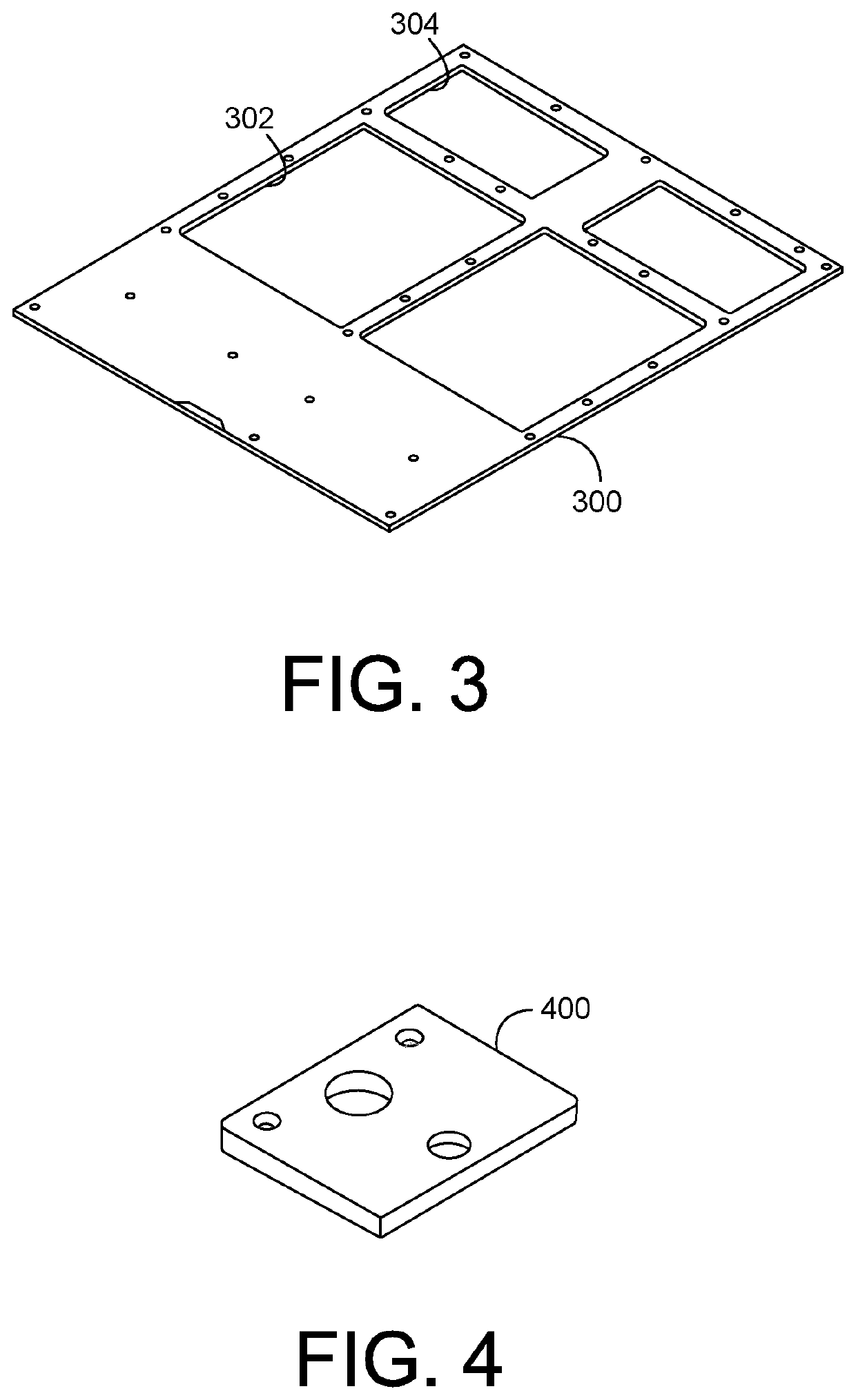

Printed circuit board and method for manufacturing thereof

InactiveUS20080121414A1Improve thermal conductivityPrinted circuit aspectsConductive pattern formationInter layerEngineering

A printed circuit board and a method of manufacturing thereof are disclosed. With a printed circuit board comprising an insulating layer; a circuit pattern formed on one side of the insulating layer; an inter-layer conductive part joining with the insulating layer by passing through the insulating layer, and electrically connected to the circuit pattern; a heat dissipating layer laminated on the other side of the insulating layer; and a heat dissipating coating layer interposed between the insulating layer and the heat dissipating layer, and connected with the inter-layer conductive part, the heat contained in the insulating layer may be delivered to the heat dissipating layer effectively and the efficiency of heat dissipation may be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for manufacturing thermoelectric module having high-insulation thermal coupling surface, low thermal resistance and no brazing layer

ActiveCN101783386ASolve electrical connection problemsReduce work stepsThermoelectric device manufacture/treatmentThermoelectric device detailsMetal coatingThermoelectric element

The invention relates to a method for manufacturing a thermoelectric module having a high-insulation thermal coupling surface, low thermal resistance and no brazing layer. The method comprises the following steps: manufacturing an insulated frame which is embedded with at least two metal electric-connection terminals by an injection molding method; preparing thermoelectric elements; placing the thermoelectric elements in through holes of the insulated frame; respectively spraying metal coating on the upper ends and the lower ends of the thermoelectric elements; grinding the sprayed surfaces; and covering an alumina film layer on the grounded surfaces respectively, wherein the insulated frame is provided with a plurality of through holes in which thermoelectric elements are placed; grooves of which the number corresponds to that of the metal electric-connection terminals are formed in side frames of the insulated frame and are communicated with different through holes; the first end parts of the metal electric-connection terminals are respectively arranged in the grooves, while the second end parts are positioned outside the side frames of the insulated frame. The thermoelectric module manufactured by the manufacturing method has the high-insulation thermal coupling surface, the low resistance and no brazing layer, and has the characteristics of improvement on the reliability of the electric connection between the thermoelectric elements and an external system, simplification of operation steps, reduction of material cost, excellent performance, and suitability for large-scale generalization and application.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD +1

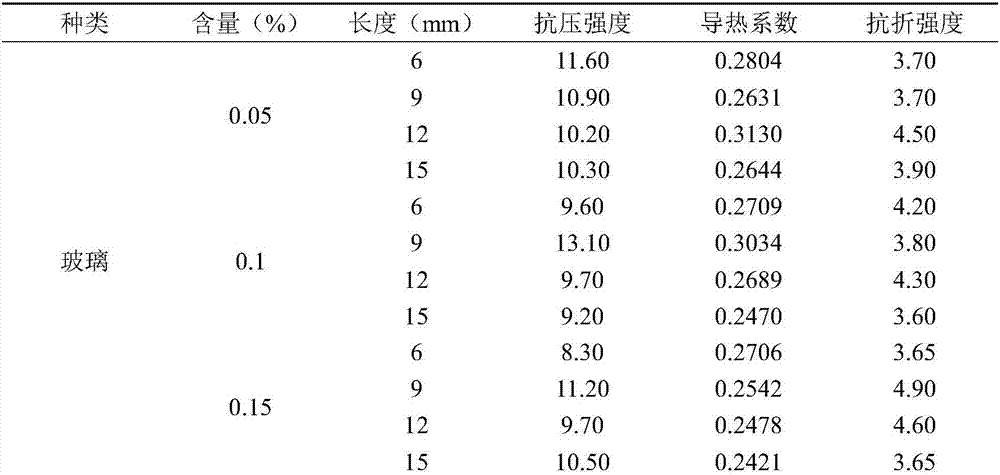

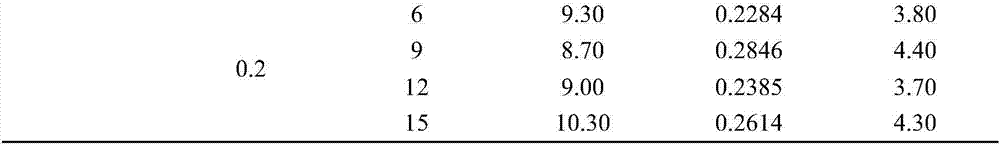

Fiber foamed concrete and preparation method thereof

ActiveCN106866177AIncrease the degree of mixingHigh compressive strengthCeramicwareThermal insulationSubgrade

The invention discloses a fiber foamed concrete and a preparation method thereof. The fiber foamed concrete comprises the following raw materials in parts by weight: 5290 parts of cement, 4965 parts of water, 1.361 part of foaming solution, 1.2964 part of fly ash and 10 parts of fiber. The preparation method comprises the following steps: proportionally weighing the components; sequentially adding the cement and fly ash into a stirrer, proportionally weighing the water, uniformly stirring the mixture by the stirrer, and adding the fiber; preparing and adding the foaming solution; gradually adding the foam into the mixture, and continuously stirring until all the components are uniformly mixed; pouring the mixture into a mold on which lubricating oil is brushed, and curing in a curing chamber; after 24 hours, removing the mold; and respectively curing for 3 days, 7 days and 28 days for experimental detection. The fiber foamed concrete has the advantages of favorable thermal insulation property, favorable compression resistance and favorable bending resistance, and is applicable to a railway bed strengthening layer.

Owner:SHIJIAZHUANG TIEDAO UNIV

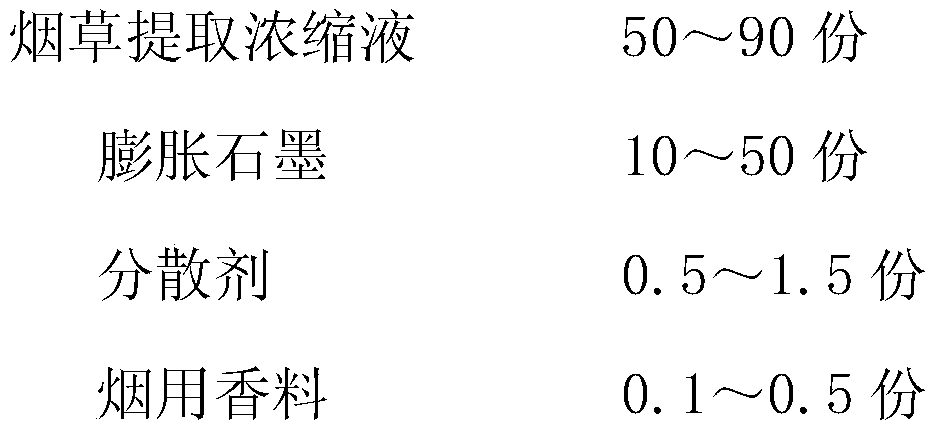

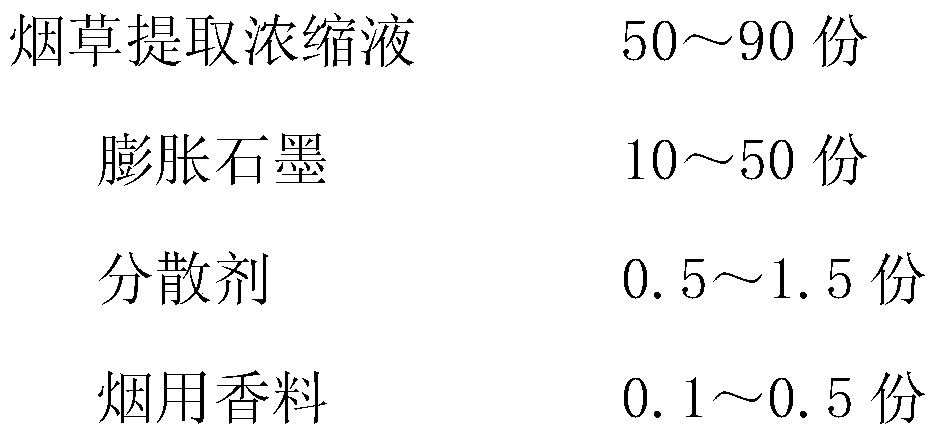

Coating liquid for heating incombustible tobacco product cigarette paper and preparation method and application of coating liquid

ActiveCN109763378AImprove protectionNo pollution in the processNon-fibrous pulp additionCoatings with pigmentsFlavorTobacco product

The invention provides coating liquid for heating incombustible tobacco product cigarette paper and a preparation method and application of the coating liquid. The coating liquid is prepared from thestep that tobacco extracting concentrated solution, expanded graphite particles, a dispersing agent and tobacco flavor are evenly mixed and subjected to ultrasonic dispersion for 7-15 minutes. The expanded graphite particles are prepared from the steps that expanded graphite particles with the particle diameters of 5-15[mu]m are placed in an atomizing agent solution, fully stirred under a negativepressure condition and absorb the atomizing agent solution, and drying at a low temperature of 70-100 DEG C is carried out. The tobacco extracting concentrated solution is prepared from the step thata tobacco extracting concentrated solution is subjected to vacuum concentration to the relative concentration of 1.21-1.28g / cm<3>. One surface of cigarette paper substrate paper is coated with the coating liquid evenly and subjected to drying slicing under the condition of 50-65 DEG C to obtain the cigarette paper, the cigarette paper can resist high temperature (about 300 DEG C), and the smoke releasing quantity during smoking can be improved.

Owner:HUBEI CHINA TOBACCO IND

PCB

InactiveCN107734839AImprove cooling effectHigh working reliabilityPrinted circuit aspectsCircuit thermal arrangementsEngineeringMetal

The invention relates to the technical field of PCB structures, discloses a PCB. The PCB includes a substrate, a metal block, and a heat dissipating hole; the substrate has a stepped groove; the metalblock is arranged in the stepped groove and same as the stepped groove in shape, and a heat conduction medium is arranged between the top surface of the metal block and a component; the heat dissipating hole is formed in the substrate, and the heat dissipating hole and the metal block can be used for heat conduction. By forming a groove in the PCB, embedding the metal block making direct contactwith the component and forming the heat dissipating hole which can be used for heat conduction with the metal block, heat generated by the component and heat in a metal layer in the PCB can be timelyand rapidly dissipated, the heat dissipation performance of the PCB is improved, and the service life of the PCB and the component is prolonged.

Owner:DONGGUAN SHENGYI ELECTRONICS

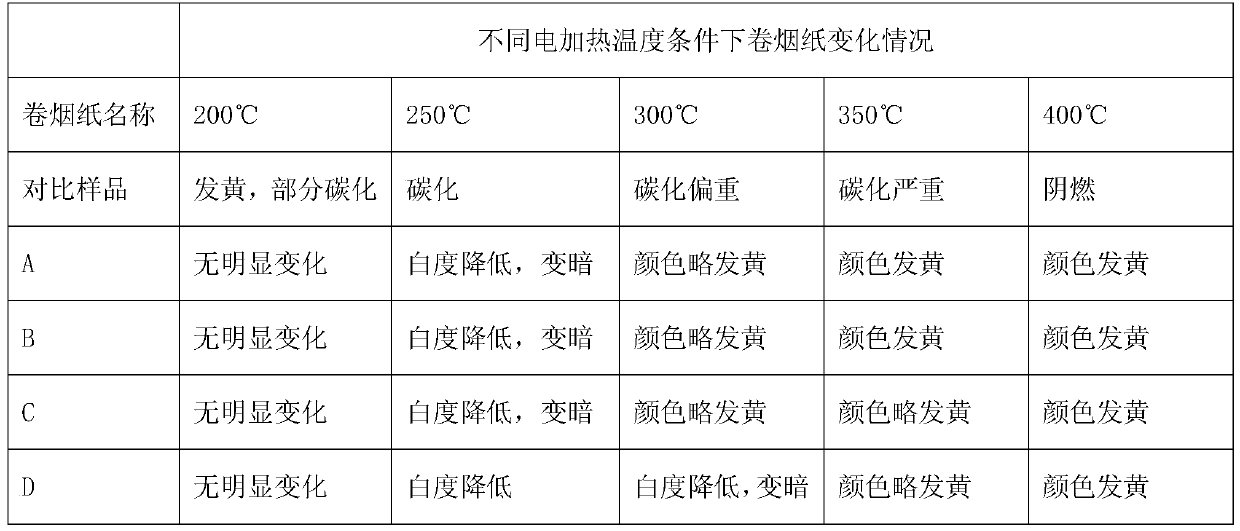

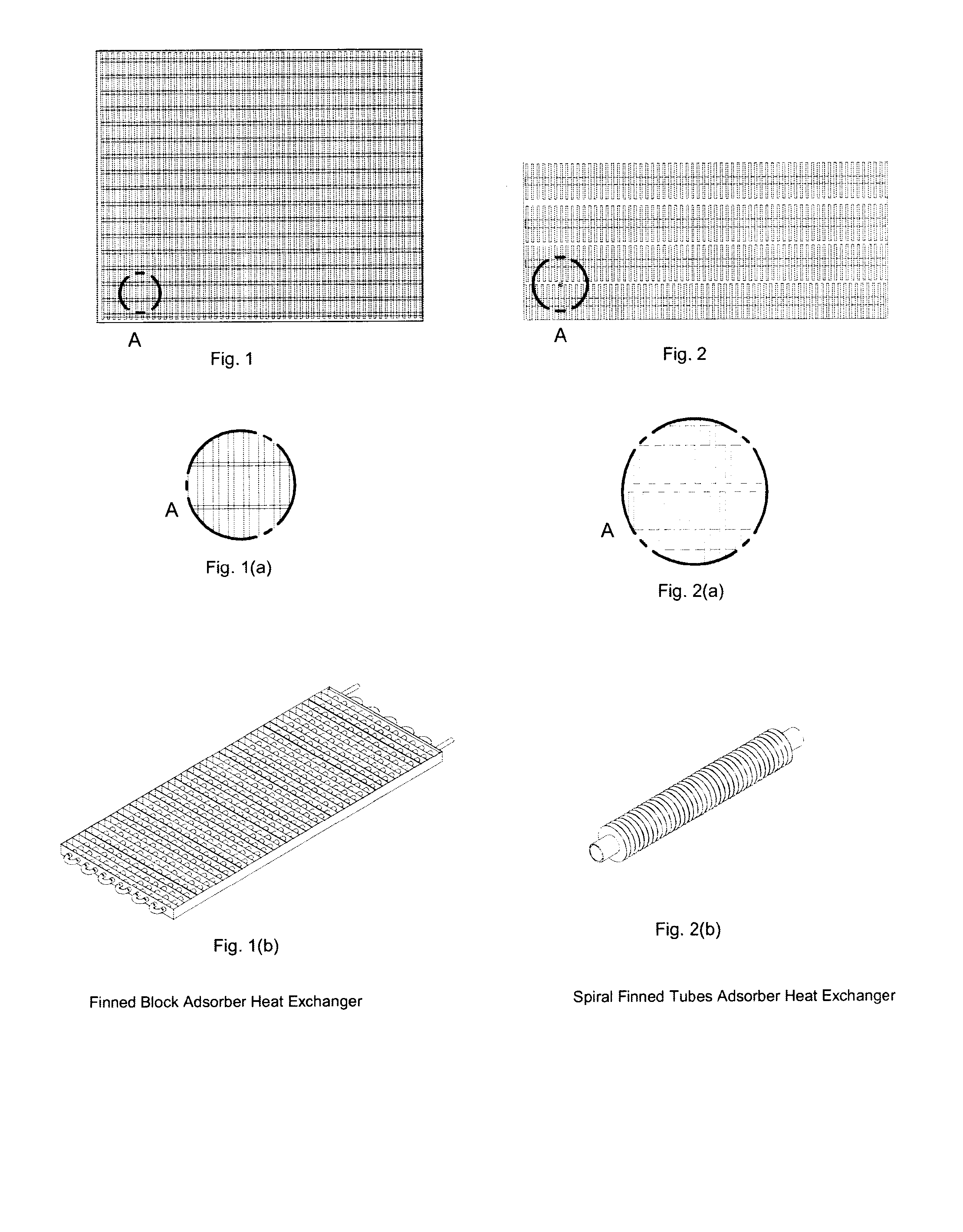

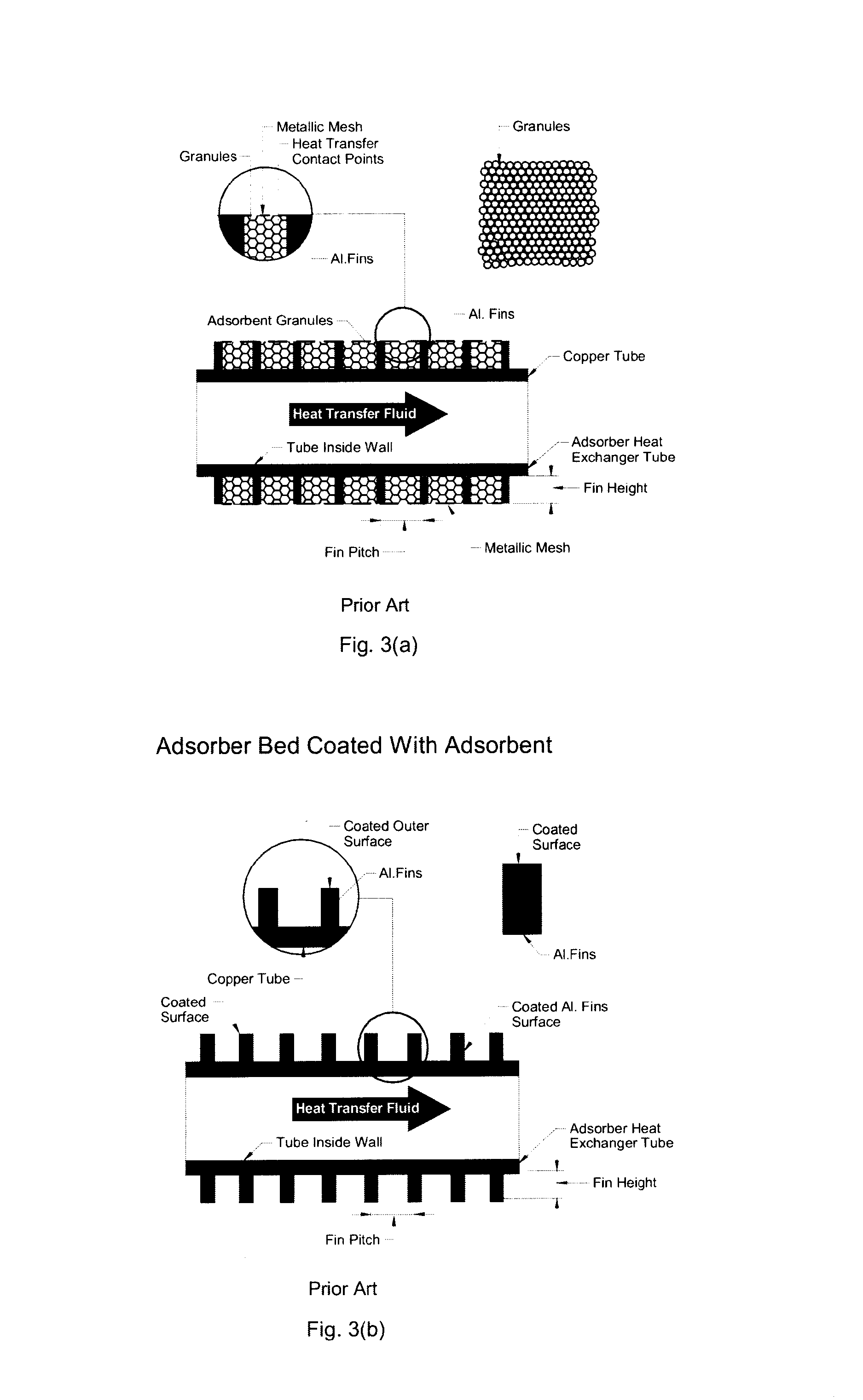

Hybrid adsorber heat exchanging device and method of manufacture

PendingUS20160334145A1Improve thermal conductivityBoiler absorbersClimate change adaptationHeat transfer fluidBiomedical engineering

Owner:BRY AIR ASIA PVT

LED lamp with water-circulating heat dissipation function

ActiveCN105221970AEven heat absorptionImprove heat absorption efficiencyPoint-like light sourceLighting heating/cooling arrangementsWater flowEngineering

The invention discloses an LED lamp with a water-circulating heat dissipation function. The LED lamp comprises an LED wafer (1), a connecting wire (2), a lens (3), an LED wafer substrate (5), a system circuit board (6) and a heat dissipation fin (7), wherein a heat dissipation device (8) used for heat dissipation is arranged below the heat dissipation fin (7); the water inlet (9) of the heat dissipation device (8) is positioned under the heat dissipation device (8); and two or more water outlets (10) are arranged the heat dissipation device (8) and uniformly distributed on the side surface of the heat dissipation device (8). The LED lamp has the beneficial effects that the water inlet is arranged under the heat dissipation device and the water outlets are arranged on the side surface of the heat dissipation device, and water flows in from below and flows out from the surroundings, so that water flow of relative low temperature is formed from the middle to both sides of the heat dissipation fin, heat on the heat dissipation fin is brought away, uniform heat absorption of the water flow is achieved, heat absorption efficiency of the water flow is improved, and all regions of the heat dissipation fin can keep the same and stable temperature.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

Antistatic geothermal floor

InactiveCN104234374AFast heat conductionImprove the status quo of performance defectsFlooring insulationsWater-setting substance layered productMagnesiumAntistatic agent

The invention relates to an antistatic geothermal floor. The antistatic geothermal floor is characterized by comprising a decorative layer on an upper surface, an antistatic layer on a lower surface, and a core layer sandwiched between the upper surface layer and the lower surface layer, wherein the core layer is a sheet material made of magnesium oxysulfate cement and bamboo fibers. The antistatic geothermal floor has the beneficial benefits that 1, the magnesium oxysulfate cement which has high combination degree with the bamboo fibers and does not corrode the bamboo fibers covers the bamboo fibers to form a floor core layer which meets a fire resistance requirement, the antistatic layer is compounded on the lower surface of the core layer to meet the requirement of a geothermal floor, and the present situation that the existing geothermal floor has defective performance is improved; 2, the sheet material for manufacturing the core layer is made of a mixture in a semi-dry state, and is formed by pressing, maintaining pressure and curing, so that the requirement of high strength of the antistatic geothermal floor is met; 3, the antistatic layer made of a composite material meets an antistatic requirement, and meanwhile, has high heat conductivity, so that the heat conductivity of the floor is improved, the utilization rate of heat is improved, and energy conservation and emission reduction are facilitated.

Owner:NG TERASUN AIR DUCT

Method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions

ActiveCN106316397AHigh purityQuality improvementLayered productsCooling/ventilation/heating modificationsHeat conductingGranularity

The invention discloses a method of preparing high-strength heat conducting graphite flakes with flow guiding and heat conducting functions. The method includes the steps of raw material preparing, pre-crushing, pre-screening, deironing, secondary crushing, secondary screening, mixing, profiling and heating, graphitizing at high temperature, back film preparing, heat conducting tank pressing and cutting. The machining process is scientific and reasonable in step, the machining process in the prior art is improved, the raw material is processed in a refined mode, the granularity of the graphite flakes is more uniform, the qualification rate of the finished product is increased, and electrical conductivity and heat conductivity of the heat conducting graphite flakes are improved; by means of the process, the chemical stability of the graphite flakes can be improved, thermal expansion is reduced, and the graphite flakes are easy to machine and shape.

Owner:DONGGUAN KAIDI CARBON CO LTD

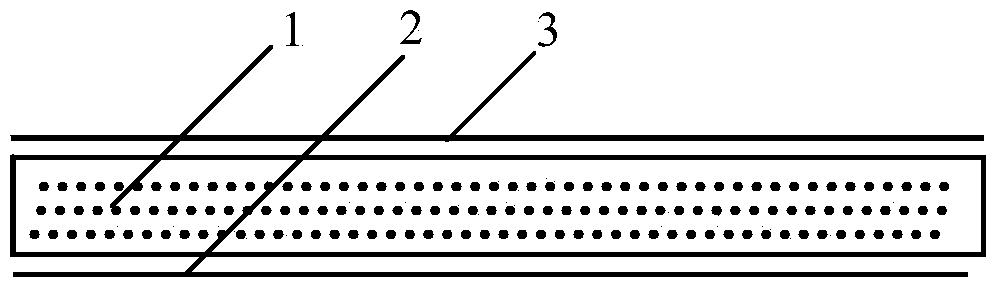

Paraffin type thermostat

InactiveCN106150659AImprove thermal conductivityCoolant flow controlMachines/enginesInductorParaffin oils

The invention relates to a paraffin type thermostat. The paraffin type thermostat comprises a main valve 1, a cover and seal gasket assembly 2, an upper support 3, a rubber pipe 4, a valve seat 5, a vent hole 6, a lower support 7, paraffin 8, an inductor 9, a bypass valve 10, a central rod 11 and a spring 12. The upper support, the lower support and the valve seat of the thermostat are riveted into a whole. The upper end of the central rod is fixed to the center of the upper support. The lower portion of the central rod is inserted into a central hole of the rubber pipe. The lower end of the central rod is conical. A cavity between the rubber pipe and a shell of the inductor contains the paraffin. The upper portion and the lower portion of the shell of the inductor are provided with the main valve and the bypass valve which are in linkage. The vent hole is formed in the main valve. The paraffin type thermostat is high in heat conductivity and guarantees that an engine cannot be excessively cold.

Owner:天津纳尚科技发展有限公司

Organic silicon electronic potting adhesive for PCB circuit board with stable dielectric insulation performance

InactiveCN106634810AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricAdhesive

The invention discloses an organic silicon electronic potting adhesive for a PCB circuit board with stable dielectric insulation performance. The organic silicon electronic potting adhesive is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12% of a platinum catalyst, 0.02 to 0.04 part of acetenyl cyclohexanol, 25 to 30 parts of vinyl silicon resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-epoxypropane, 23 to 25 parts of 1,3,5,7-tetramethyl cyclotetrasiloxane, 2.7 to 3.6 parts of a silane coupling agent A171, an appropriate amount of silicon-containing silicon oil, 2.6 to 3 parts of mica powder, 1.8 to 3 parts of porcelain powder, 0.2 to 0.3 part of dimethyl silicone polymer, 4.6 to 5 parts of carboxylated latex, 1.1 to 1.6 parts of polyvinyl alcohol and an appropriate amount of deionized water. The potting adhesive disclosed by the invention has high heat conduction, dielectric insulation, impact resistance and adhesive performance, is high in fluidity, and is extremely suitable for potting electronic products.

Owner:TONGLING ONBOLE PCB CO LTD

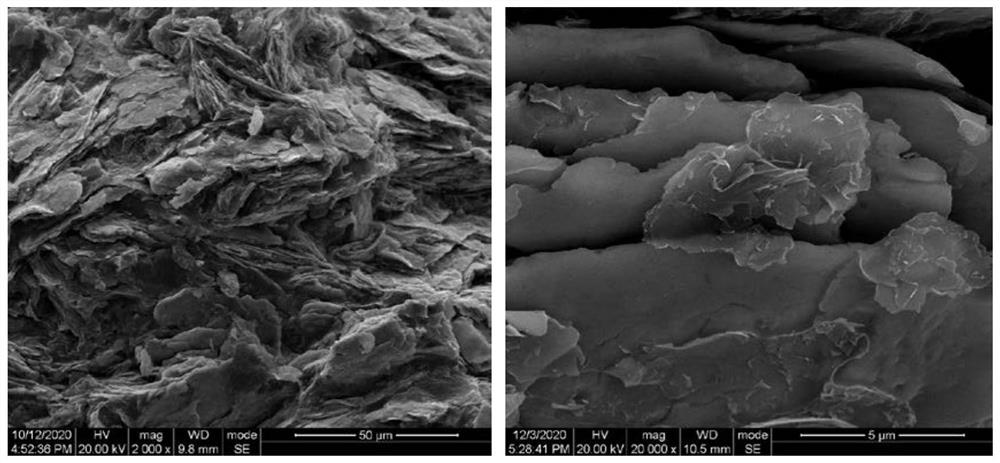

Resin graphene composite material, preparation method and application thereof

InactiveCN108329520AImprove conductivityImprove thermal conductivityElectroconductive/antistatic filament manufactureAnti-corrosive paintsSlurryCvd graphene

The invention provides a resin graphene composite material, a preparation method and an application thereof, which belong to the technical field of the graphene composite material. The preparation method comprises the following steps: 1) mixing a metal auxiliary agent, a graphene material and water and stirring a mixture to obtain a slurry; 2) drying the slurry to obtain metal graphene; and 3) heating the metal graphene and thermoplastic resin and heating the materials under inert gas atmosphere to the temperature of 50-300 DEG C for a reaction. The preparation method composites the graphene material and the thermoplastic resin, through a Pi bond electron cloud of the graphene material, free electron transmission is carried out, the obtained resin graphene composite material has good conductivity and thermal conductivity, and can be used as a novel electric conduction and heat conduction composite material.

Owner:BEIJING NORTH GUONENG TECH CO LTD

Method for Preparing Graphene-Containing Inorganic Coating Composition for Coating Non-Ferrous Metal Objects and Graphene-Containing Inorganic Coating Composition Prepared Thereby

ActiveUS20190055415A1Increased durabilityImprove thermal conductivityMaterial nanotechnologyLuminescent paintsSolventCvd graphene

Owner:YOON WOONG TAE +1

Die-casting piston

A die-casting piston having a receiving unit attachable to a piston rod, which includes a cooling device and a connecting device for the piston rod. A hollow cylindrical carrier body of a cup-shaped design has a melt-side end face, on whose lateral surface at least one hollow cylindrical sliding body is mountable. An end ring is disposed between the end face of the carrier body and an end face of the sliding body, which is used as a front-end first holding element for the at least one hollow cylindrical sliding body. The carrier body is axially mountable on the receiving unit, extending over the cooling device, and may be locked to the receiving unit and released again with the aid of a connecting device, the connecting device being disposed axially downstream from the sliding body on the side facing away from the end face of the carrier body, and the connecting device being a bayonet joint.

Owner:WIELAND WERKE AG

Multipurpose photon cold-set gel and preparation method thereof

ActiveCN110279887AExpected fill effectAvoid burnsEnergy modified materialsPharmaceutical delivery mechanismAdditive ingredientPolyethylene glycol

The invention relates to a multipurpose photon cold-set gel and a preparation method thereof, and belongs to the technical fields of medical cosmetology and biomedical treatment. The multipurpose photon cold-set gel provided by the invention mainly comprises the following ingredients in parts by weight on the basis of 100 parts of the ingredients: 2-50 parts of PLGA (poly(lactic-co-glycolic acid)), 0.1-5 parts of carbomer, 1-10 parts of polyethylene glycol, 1-10 parts of an osmotic pressure regulator, 0.1-2 parts of a pH regulator, 0.05-0.5 parts of a bacteriostatic agent and the balance of water for injection. The multipurpose photon cold-set gel prepared in the invention can be used as a coating agent for laser cosmetology, can also be used for injection cosmetology, is good in biocompatibility and does not have cytotoxicity, skin irritation, sensitization and the like; in addition, the preparation method is easy in operation, so that industrial production is conveniently realized.

Owner:王月玲 +1

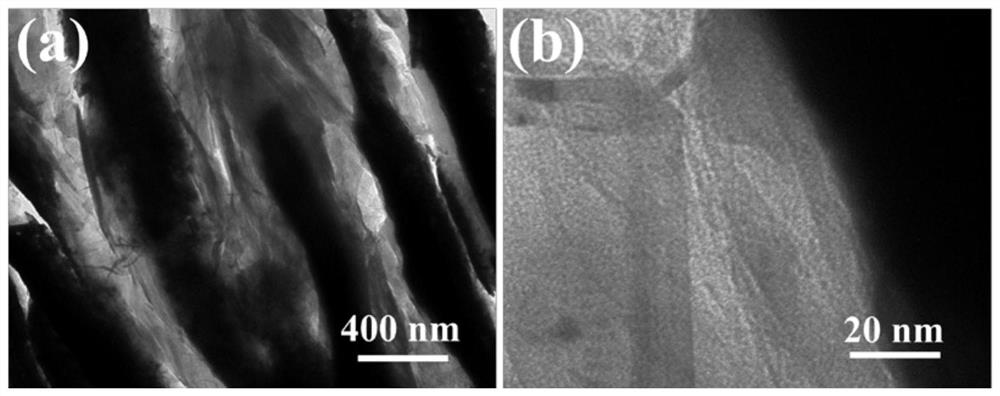

Ultrahigh-isotropy heat-conducting material of epoxy two-dimensional flaky metal nanofiller and preparation method of heat-conducting material

ActiveCN113416389AImprove thermal conductivityEfficient synergyHeat-exchange elementsLap jointResin matrix

The invention provides an ultrahigh-isotropy heat-conducting material of an epoxy two-dimensional flaky metal nanofiller and a preparation method of the heat-conducting material. The material mainly comprises the following components: epoxy resin, a two-dimensional sheet metal nanofiller, a two-dimensional sheet carbon series heat conduction filler and a diluent. The method comprises the following steps: uniformly mixing the components, removing the diluent, and preparing the heat-conducting material or a workpiece through a hot press molding process. The two kinds of two-dimensional sheet-shaped heat-conducting fillers are in lap joint in an epoxy resin matrix to form a three-dimensional heat-conducting network, efficient lap joint and efficient synergistic effect of the two-dimensional sheet-shaped metal nanofiller are achieved, the heat-conducting property of the obtained heat-conducting material or the workpiece is greatly improved, and the isotropic heat-conducting characteristic is achieved.

Owner:SICHUAN UNIV

Preparation method of fiber mesh-compounded diatom ooze coating

InactiveCN112266631AGuaranteed flatnessImprove structural strengthCovering/liningsAntifouling/underwater paintsBenzeneFiber

The invention relates to the technical field of diatom ooze coatings, and discloses a preparation method of a fiber mesh-compounded diatom ooze coating. The preparation method comprises the followingstep: S1, preparing raw materials including a fiber mesh, 25-35 parts of deionized water, 15-25 parts of diatomite, 2-8 parts of a humectant, 15-25 parts of an odor-free pure benzene emulsion, 10-18 parts of a filler, 2-6 parts of quartz powder and 0.5-1 part of a dispersant. The invention further provides a construction method of the fiber mesh-compounded diatom ooze coating. The construction method comprises the following steps: S1, cleaning a wall surface, namely cleaning the wall surface to be constructed by using a tool; and S2, fixing the fiber mesh. According to the invention, the overall structural strength of a diatom ooze coating composite layer is improved, and the diatom ooze coating is distributed in meshes of the fiber mesh and bonded and compounded to the fiber mesh and a wall surface base layer, so the flexibility of the diatom ooze coating composite layer is improved, construction is convenient, formaldehyde, benzene and other organic matters can be effectively decomposed, and a good air purification effect is achieved.

Owner:佘丽辉

Stimulated X-ray emission source with crystalline resonance cavity

ActiveUS10998693B1Improve thermal conductivityLow angular divergenceLaser using scattering effectsX-ray apparatusStimulated emissionParticle physics

An X-ray laser has a target anode of a crystalline material that emits X-ray radiation in response to excitation and that is located on a thermally conductive substrate. An X-ray source provides an input X-ray beam that illuminates a predetermined volume of the target anode at a predefined angle relative to a surface of the anode so as to induce a Borrmann mode standing wave in the predetermined volume. An electron source outputs an electron beam that is incident on the Borrmann mode region so as to cause electron impact ionization of the crystalline material and thereby induce stimulated emission of a coherent output X-ray beam.

Owner:BRUKER AXS

Semiconductor Metrology And Inspection Based On An X-Ray Source With An Electron Emitter Array

PendingUS20210239629A1Improve thermal conductivityMinimize risk of damageDischarge tube/lamp detailsMaterial analysis using wave/particle radiationAnodeAtomic physics

Owner:KLA TENCOR CORP

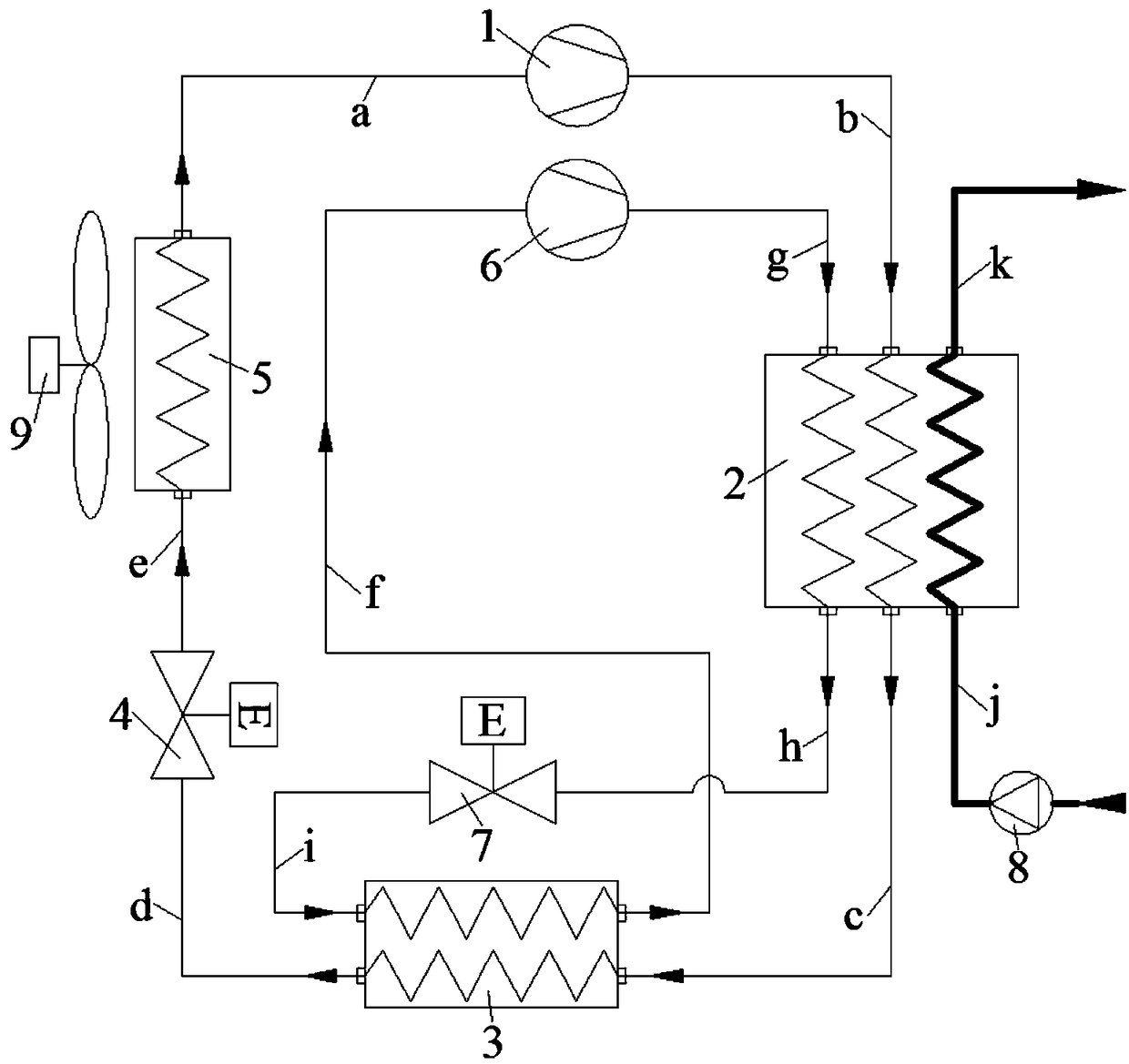

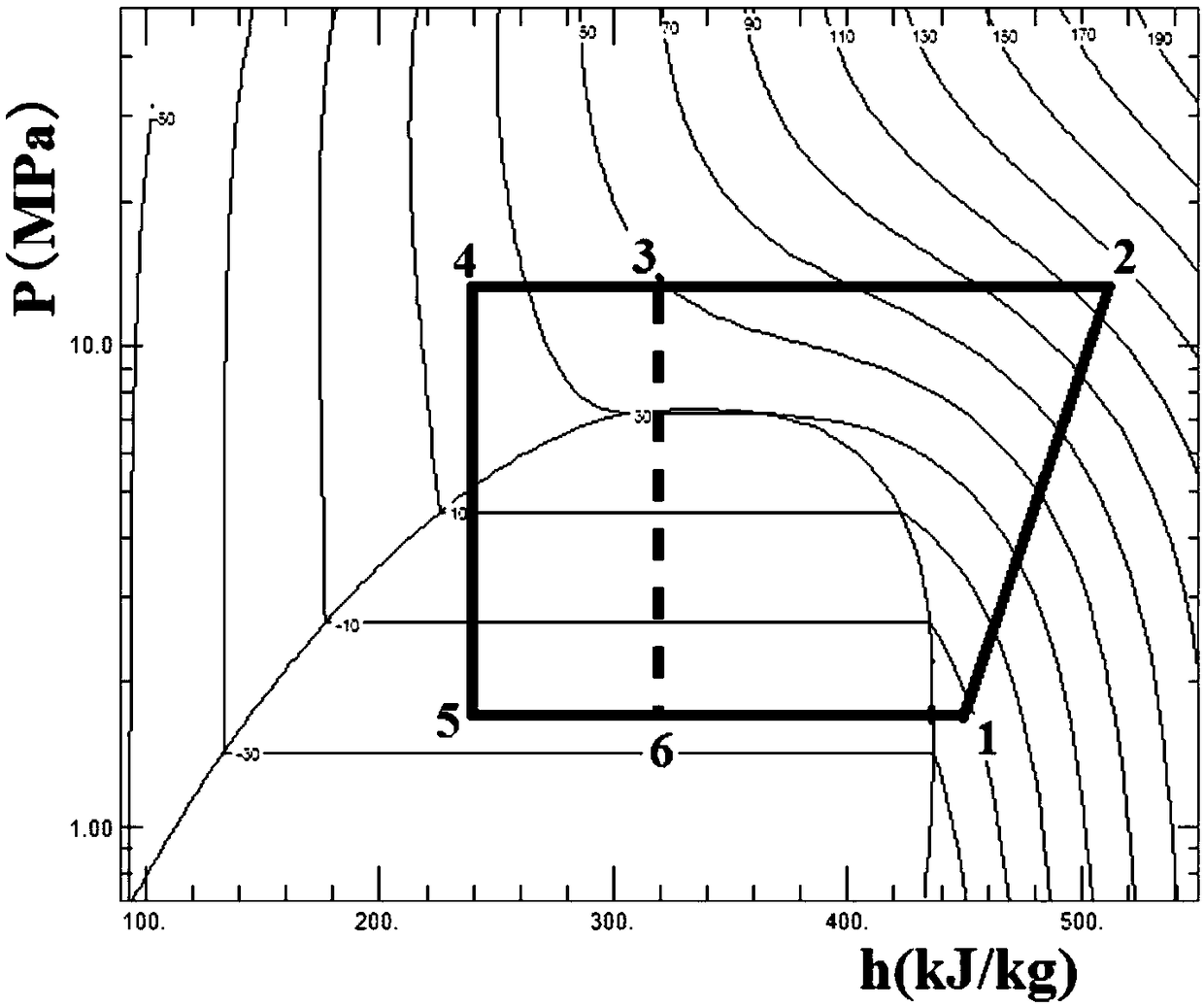

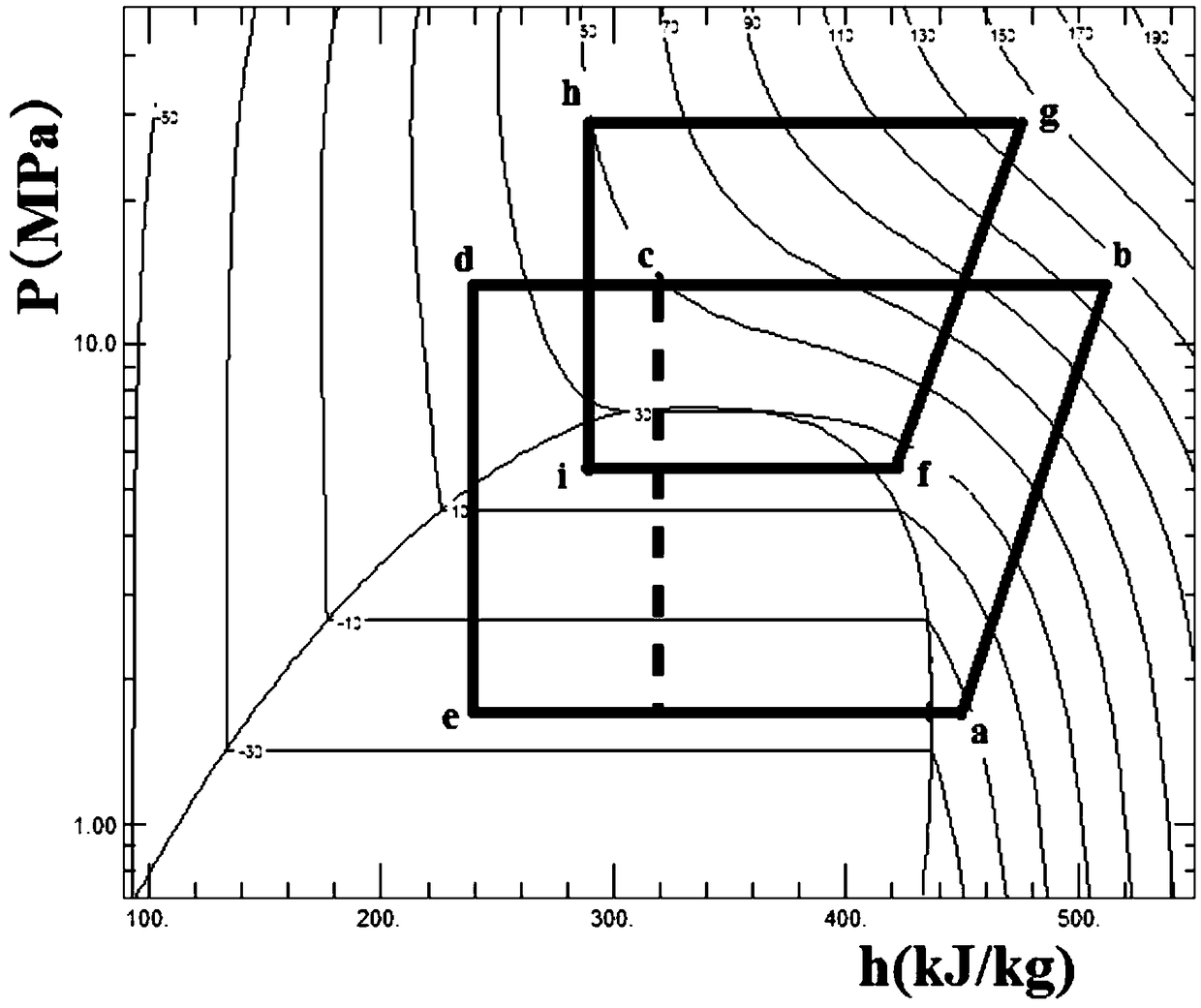

Cross-critical CO2 parallel compression system and capacity ratio method thereof

ActiveCN109186115AImprove efficiencyReduce energy consumptionMechanical apparatusCompression machinesProcess engineeringParallel compression

The invention discloses a cross-critical CO2 parallel compression system and a capacity ratio method thereof. The system comprises a main loop and an auxiliary loop, and the temperature of the outletof a main loop of a gas cooler is reduced to the temperature of the outlet of a main loop of a supercooling-evaporator through the evaporation effect of the auxiliary loop in the supercooling-evaporator. The system comprises three working modes, the environment temperature is minus 20 DEG C to zero DEG C in a normal operation mode, and the frequency of the auxiliary loop compressor is adjusted toensure the efficient operation of the system; the environment temperature is 0-15 DEG C in a low-frequency operation mode, when the environment temperature is high and the heating amount is large, theenergy is saved by reducing the frequency; the environment temperature is lower than minus 20 DEG C in an ultra-frequency operation mode, so that the heating amount and the running stability of the system under an extremely low environment temperature are guaranteed; and the water return temperature in the three modes ranges from 35 DEG C to 50 DEG C, and the water outlet temperature ranges from50 DEG C to 70 DEG C. In the starting process, a low-frequency starting mode of the auxiliary loop compressor is carried out when the pressure of the auxiliary loop is less than 5 MPa, and the stability of the starting operation process of the auxiliary loop is ensured.

Owner:XI AN JIAOTONG UNIV

Special copper alloy and manufacturing method thereof

InactiveCN100523236CConductiveImprove thermal conductivityMetal/alloy conductorsRare-earth elementElectric power

The invention relates to a novel high-strength high-conductivity copper-based alloy and preparation method thereof, which belongs to copper-based electrical material. The chemical compositions of the weight percentage of the copper-based electrical alloy are 0.01-5.0Eu, 0.01-5.0Gd, 0.01-5.0Er, 0.01-3.0C and Cu which holds the weight percentage. The process for preparing the copper-based alloy is to allocate Cu, Eu, Gd, and Er (mixed rare earth element) according to the composition proportion of the alloy design, melt the mixture in the vacuum medium-frequency and fuse the mixture in the powder-making device, fast solidify the inert gas to atomize, and then CuEuGdEr alloy powder is produced. The powder is mixed with C powder by mechanical alloying, and then the mixed powder is processed by the processing technique of isostatic cool pressing formation, sinter, extrusion and the like to achieve the production of pipe, rod or sheet. The alloy material is characterized by good heat and electrical conductivity, large strength of room temperature, high resoftening temperature and high conductive rate, which can be used as conducting bar, resistance welding electrode, blasting fuse frame, conducting bridge, commutator and the like in the industries of electric power, electrotechnology, electronics and electromechannics.

Owner:KUNMING INST OF PRECIOUS METALS

Multi-Stack Cooling Structure for Radiofrequency Component

ActiveUS20210259092A1Improve thermal conductivityImprove rigidityHigh frequency circuit adaptationsPrinted circuit aspectsHeat carrierRadio frequency

Owner:COMET

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap