Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Rare earth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare Earth is an American rock band affiliated with Motown's Rare Earth record label (named after the band), which prospered from 1970–1972. Although not the first white band signed to Motown, Rare Earth was the first big hit-making act signed by Motown that consisted only of white members. (None of the previously signed all-white acts - The Rustix, The Dalton Boys, or The Underdogs - had ...

Method of risisting high-temp. oxidation and heat corrosion for high-temp. alloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Deformed Al-Mn series alloy and preparing process thereof

Owner:ZHENGZHOU UNIV

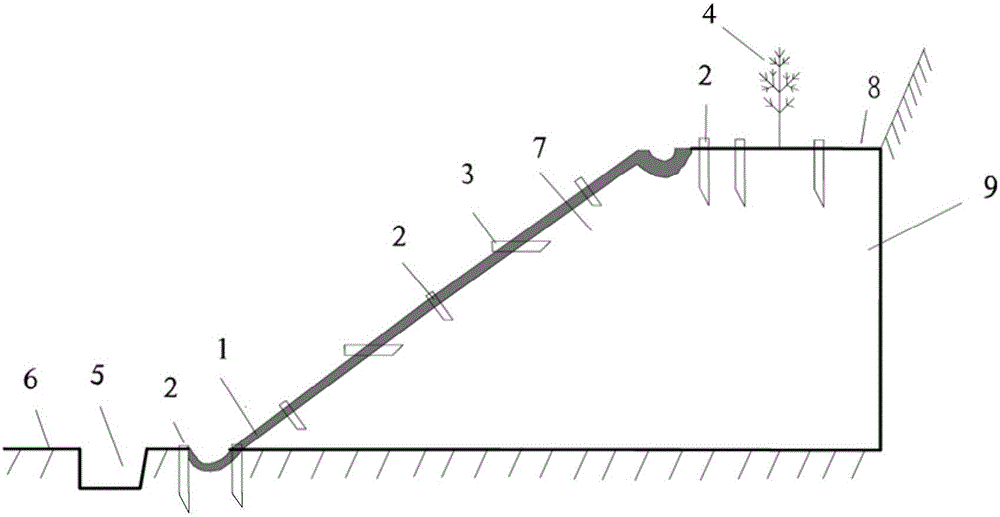

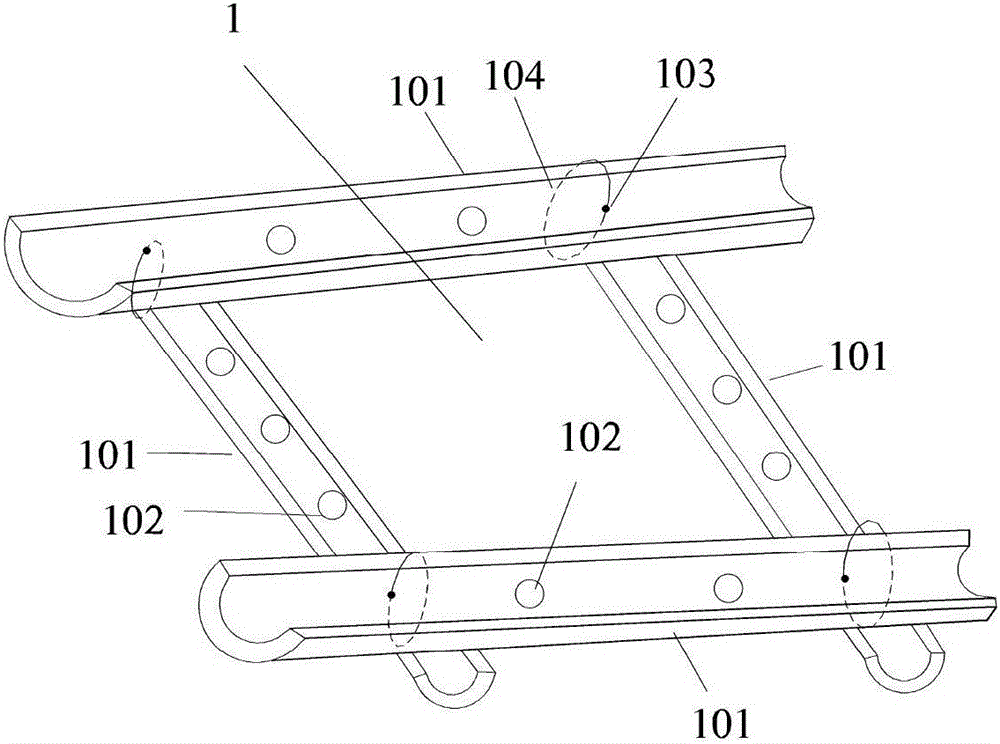

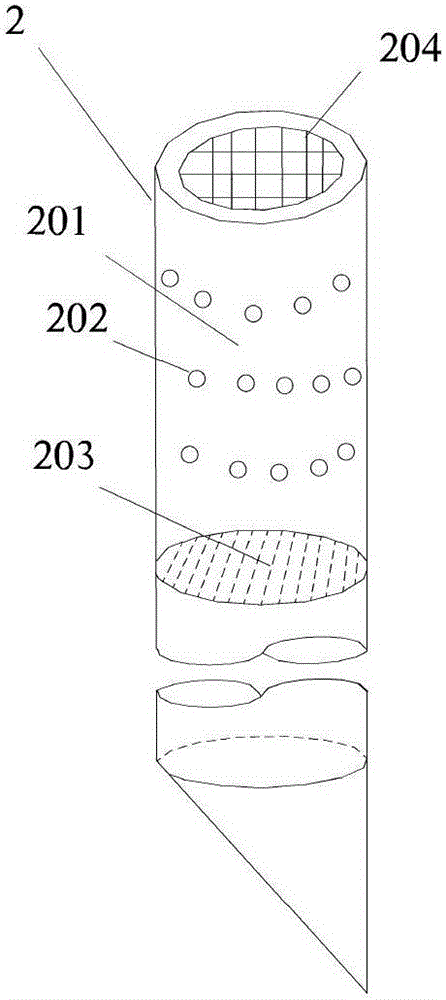

Ecological slope protection structure for ion rare earth mine

Owner:JIANGXI UNIV OF SCI & TECH

Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

ActiveCN103627906AShort processReduce recycling costsProcess efficiency improvementLiquid wasteEconomic benefits

The invention discloses a comprehensive recycling treatment method of a waste rare-earth fluorescent lamp, which comprises the steps that S1, waste fluorescent powder, a waste glass tube and mercury-containing waste liquid are separated and recycled from the waste rare-earth fluorescent lamp; S2, the waste fluorescent powder is roasted; an obtained roasted ore is leached; a leaching solution and a leaching residue are obtained; S3, the leaching solution is subjected to extraction, reverse extraction and separation; alumina and rare-earth oxide are obtained; and S4, the leaching residue is subjected to digestion, extraction and purification; and a strontium-containing product is obtained. The waste rare-earth fluorescent lamp is separated, the obtained waste fluorescent powder and the obtained mercury-containing waste liquid are comprehensively recycled respectively by technologies of roasting, leaching, extraction, reverse extraction and the like, and then secondary valuable resources such as alumina, various rare-earth oxide and the strontium-containing product are comprehensively recycled from the waste fluorescent powder. The method is short in technological process and low in recycling cost, solves the problems of stockpiling, environmental pollution and the like caused by the industrial waste rare-earth fluorescent lamp, and has certain economic benefits and industrial significance.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

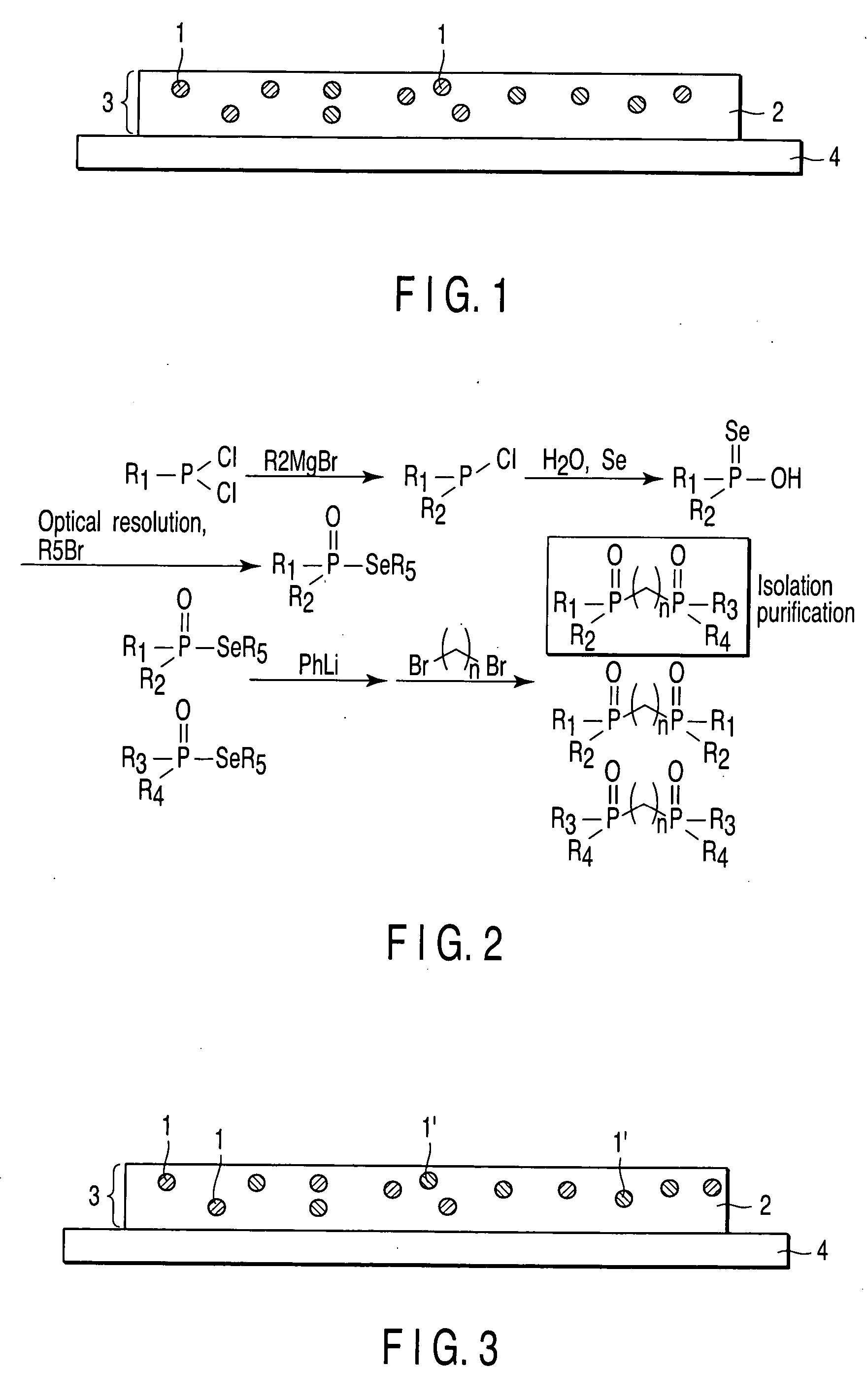

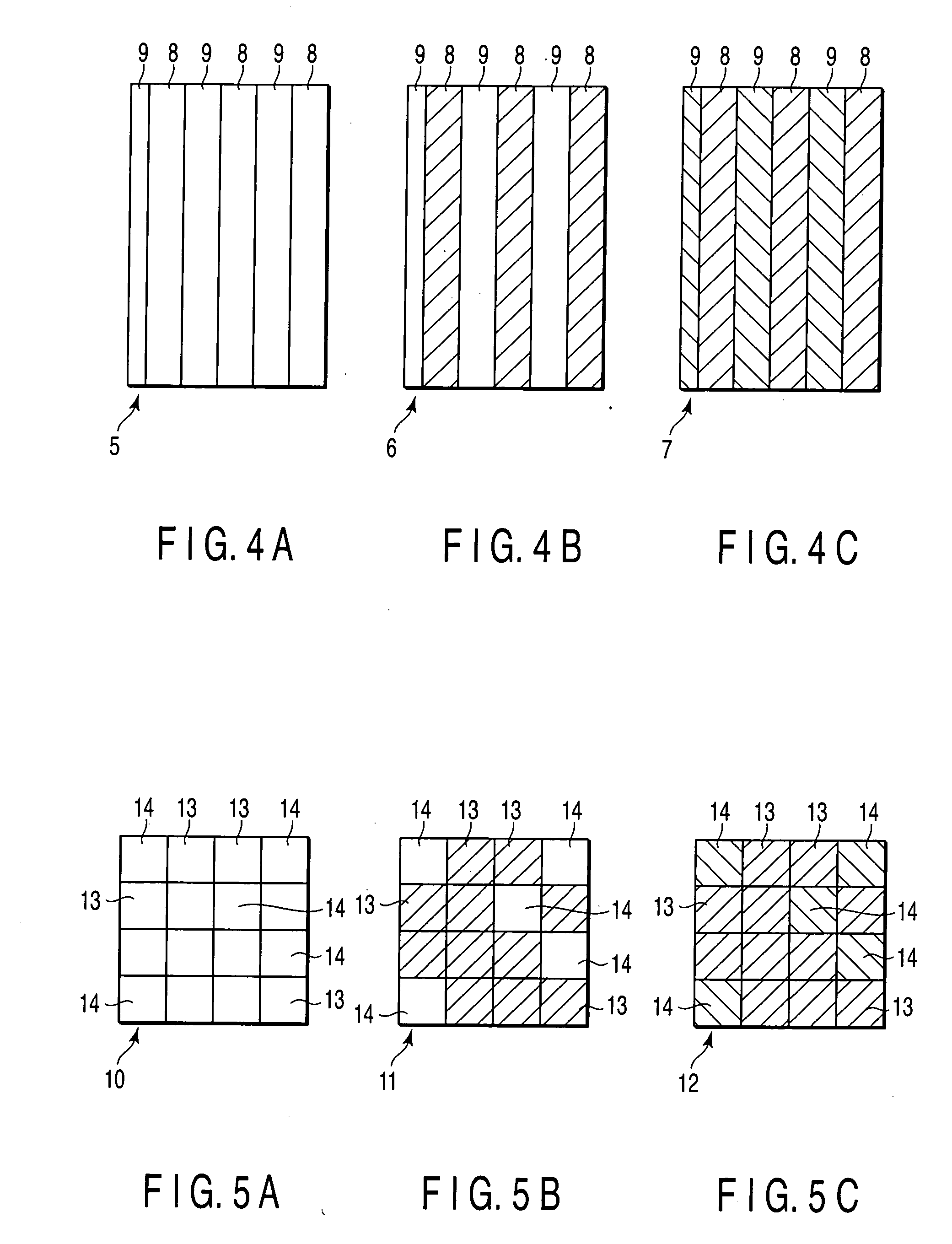

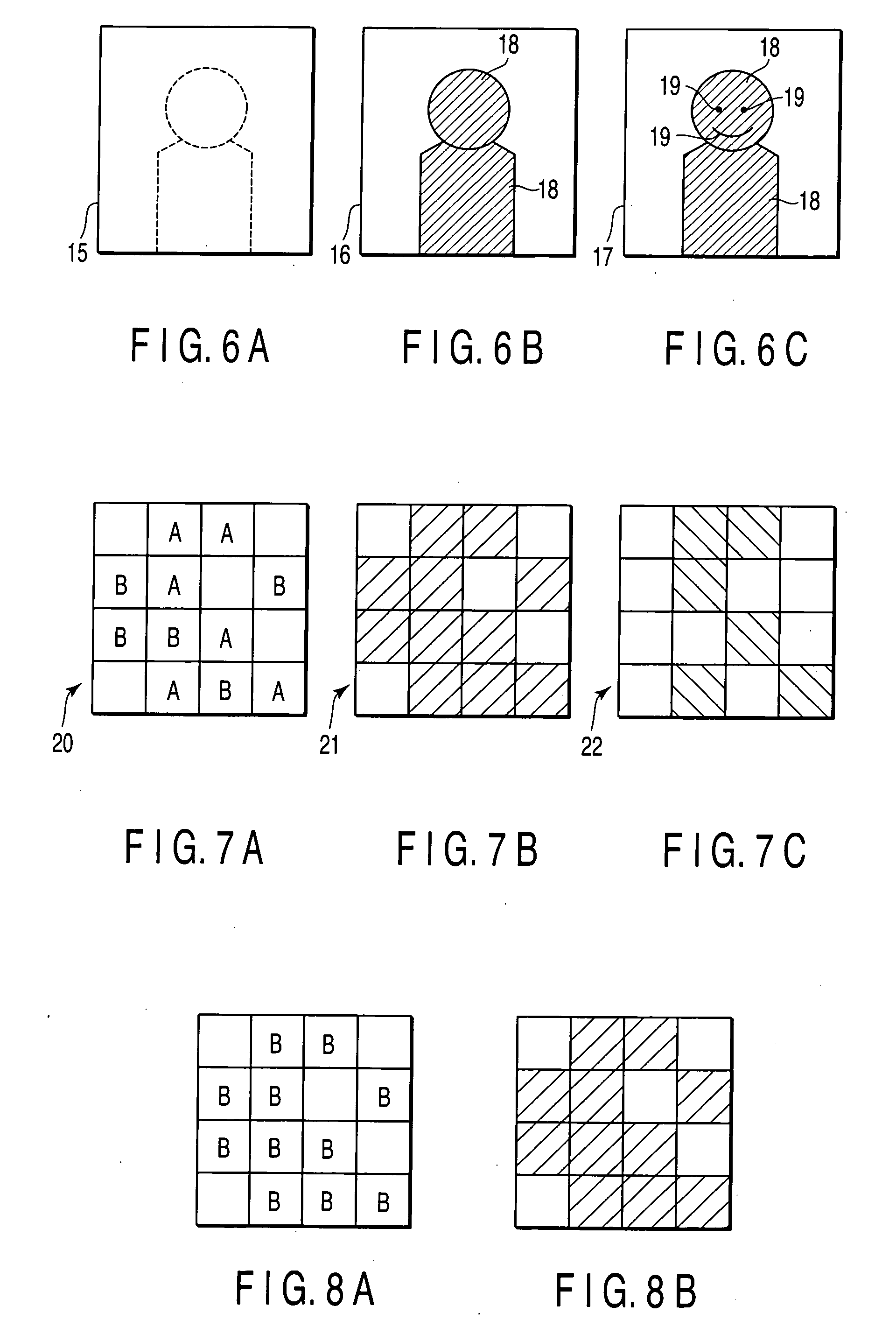

Fluorescent image-printed article and fluorescent ink

ActiveUS20060063036A1Improve security levelOther printing matterDuplicating/marking methodsFluorescenceRare earth

Owner:KK TOSHIBA

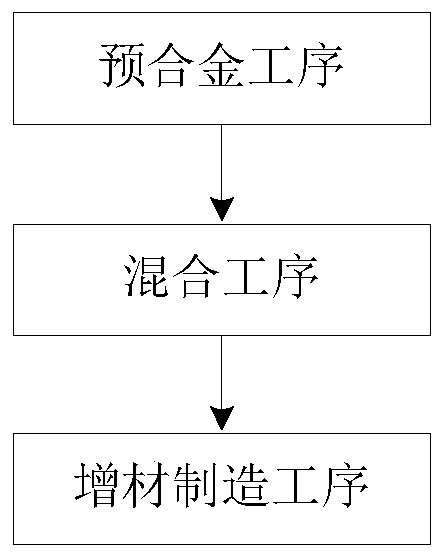

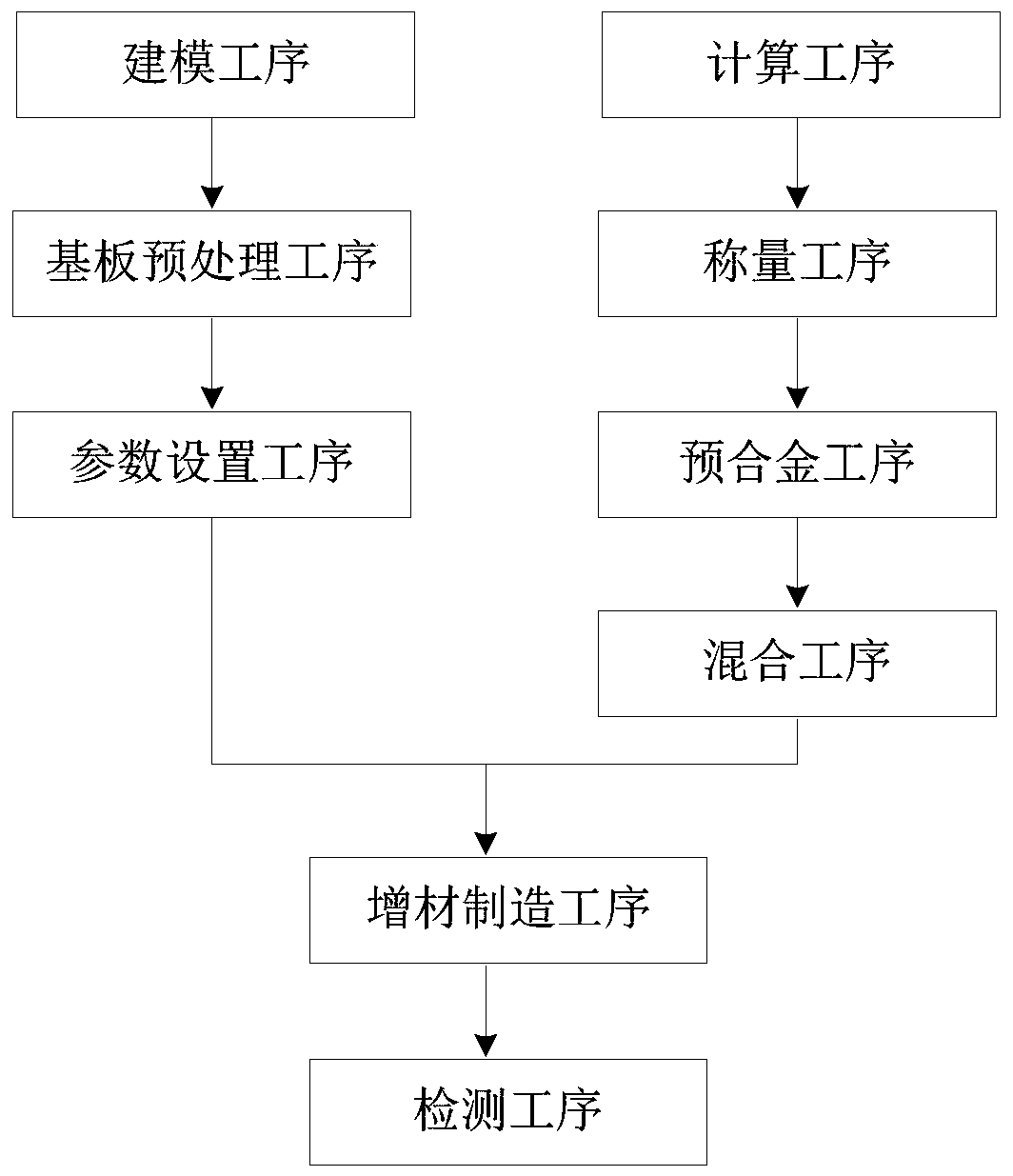

Alloying component and preparation method thereof

ActiveCN110592411AImprove distributionFull play formAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysCarbon nanotube

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

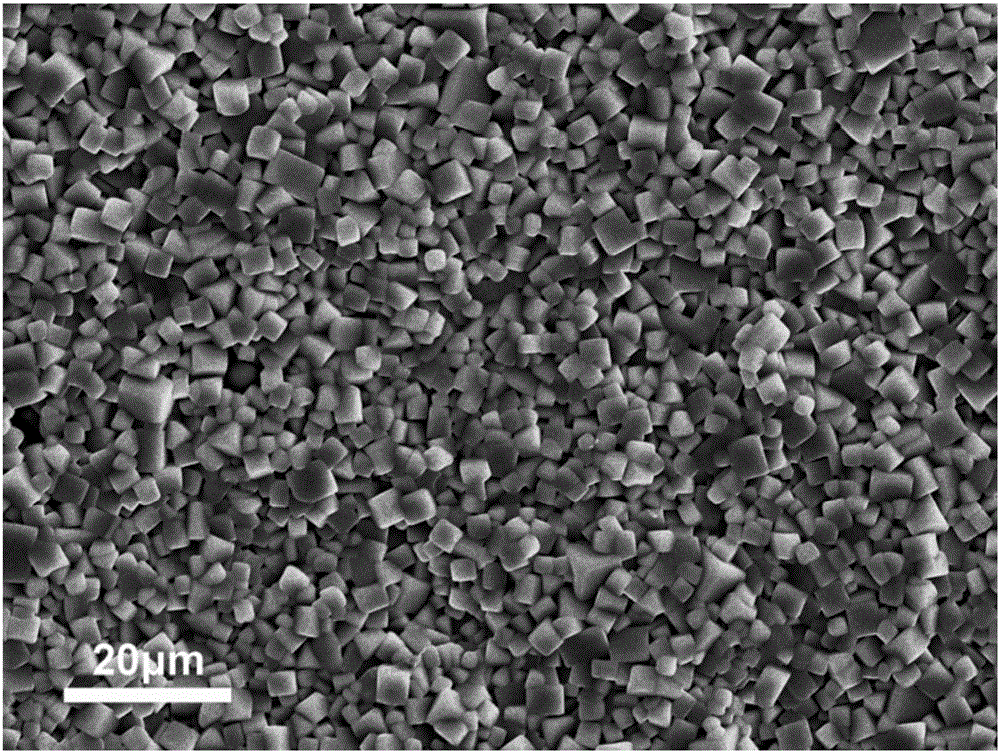

Low-temperature photo-irradiation preparation method for rare earth doped bismuth titanate ferro-electricity membrane

InactiveCN101269957APromoting solidification and densificationImprove ferroelectric propertiesElectricityPhoto irradiation

Owner:HARBIN INST OF TECH

Silicon-calcium-barium-magnesium desoxidant for steelmaking and/or electroslag

The invention relates to a silicon-calcium-barium-magnesium desoxidant for steelmaking and / or electroslag. The desoxidant is composed of the following chemical components in mass percent: 20-50% of Si, 10-40% of Ca, 5-20% of Ba, 2-10% of Mg, 0-10% of RE, not larger than 0.030% of P, not larger than 0.040% of S, 0-2% of C and the balance of Fe. The preparation method comprises the following steps: firstly smelting iron and silicon in a melting furnace to an intermediate alloy, adding barium, calcium, magnesium and / or rare earth, melting and casting to an alloy block, and controlling the specific gravity of the silicon-calcium-barium-magnesium desoxidant to 3-5 g / cm<3>. When in use, the silicon-calcium-barium-magnesium desoxidant is directly thrown into a steel furnace and / or an electroslag remelting crystallizer slag bath, the specific gravity of the desoxidant is increased, the vapor pressure is reduced, the desoxidant is deposited at a slag-steel interface to generate a CaO-BaO-SiO2 type impurity, and the CaO-BaO-SiO2 type impurity is larger in granule, lower in melting point, easy to be captured by the slag and easy to float to be removed, so that the cleanness of molten steel is improved.

Owner:ZHONGYUAN SPECIAL STEEL

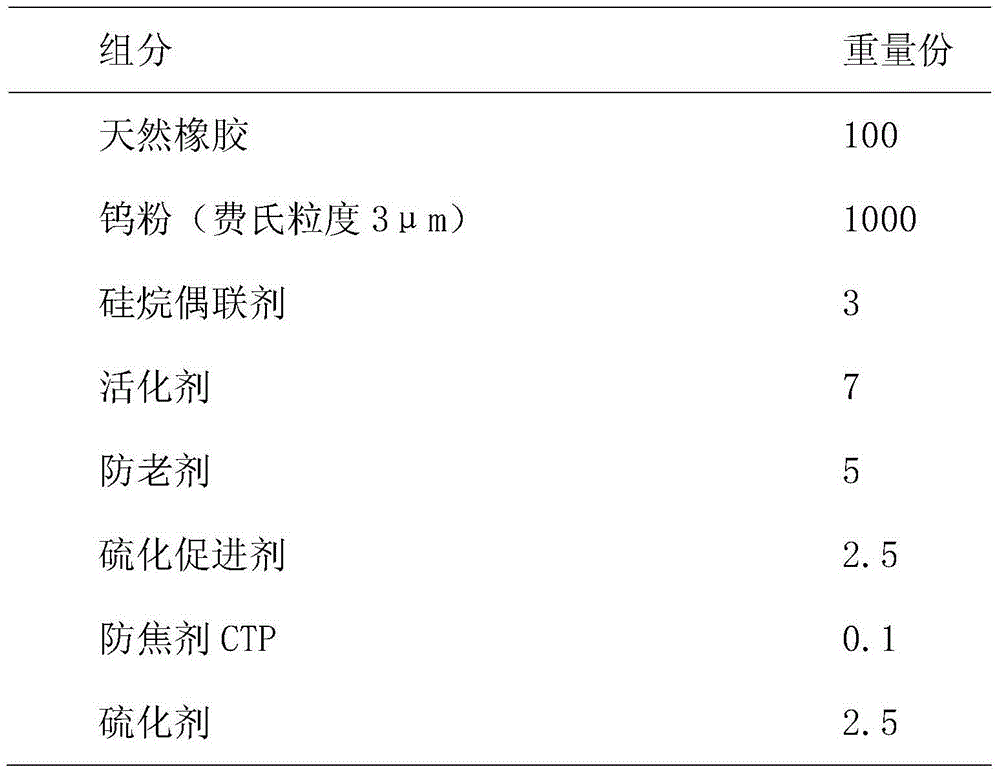

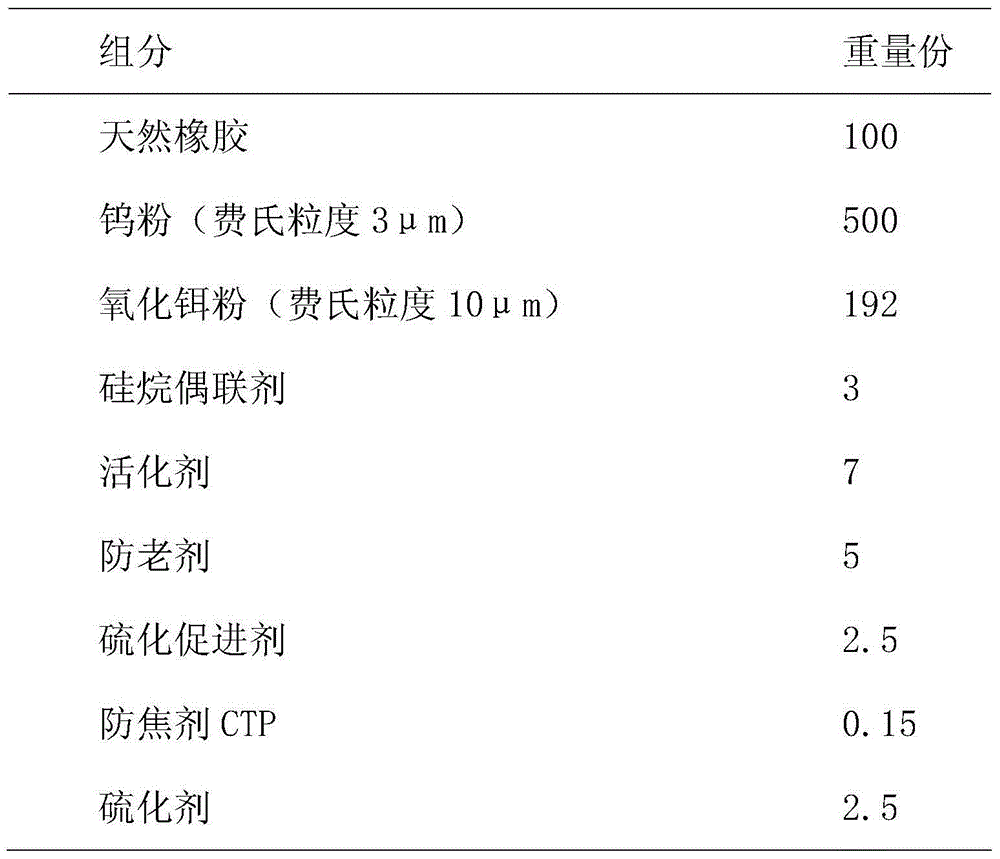

Tungsten-base composite material applied to ray shielding and preparation method thereof

Owner:XIAMEN HONGLU TUNGSTEN MOLYBDENUM IND CO LTD

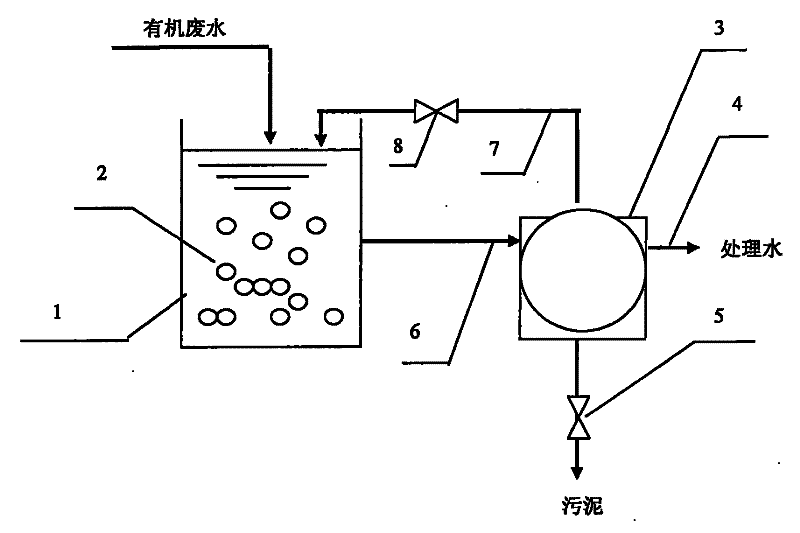

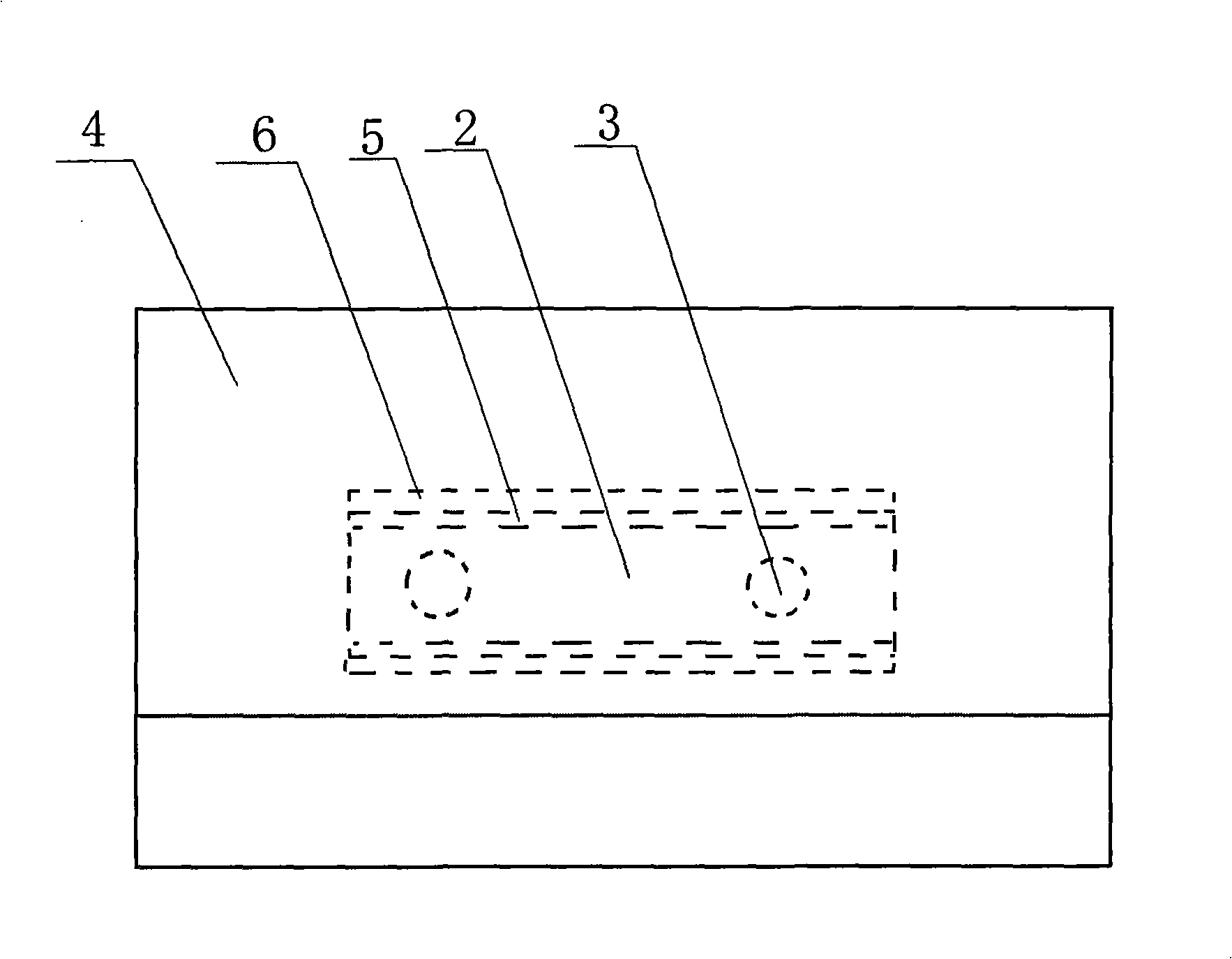

Magnetic bioreaction separation device for treating organic wastewater

InactiveCN101746883ANotable featuresSignificant positive effectWater contaminantsWater/sewage treatment bu osmosis/dialysisHigh concentrationRare earth

Owner:四川环美能科技有限公司

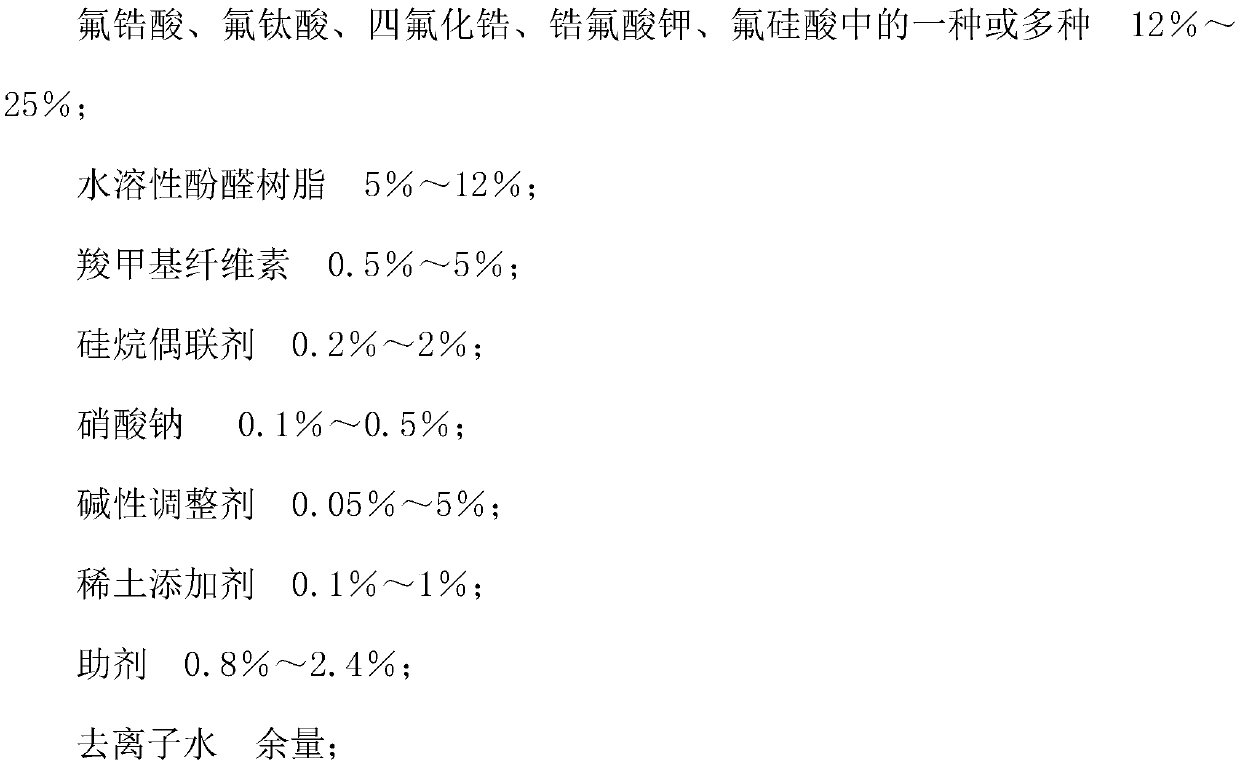

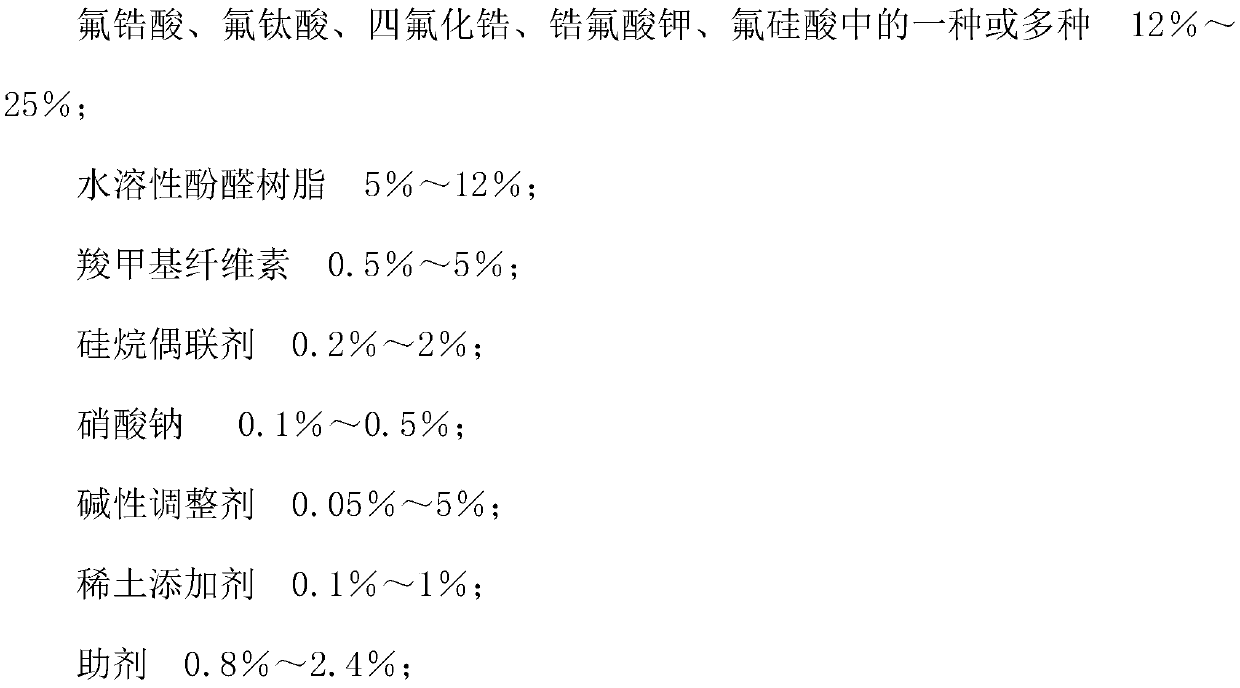

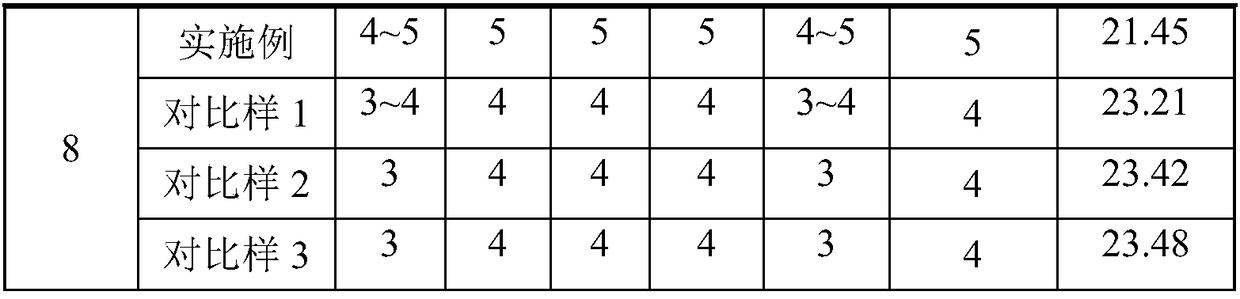

Aluminum profile chromate-free passivation agent

PendingCN110257809AImprove rust resistanceLow costMetallic material coating processesAntioxidantRare earth

Owner:浙江九合环保科技有限公司

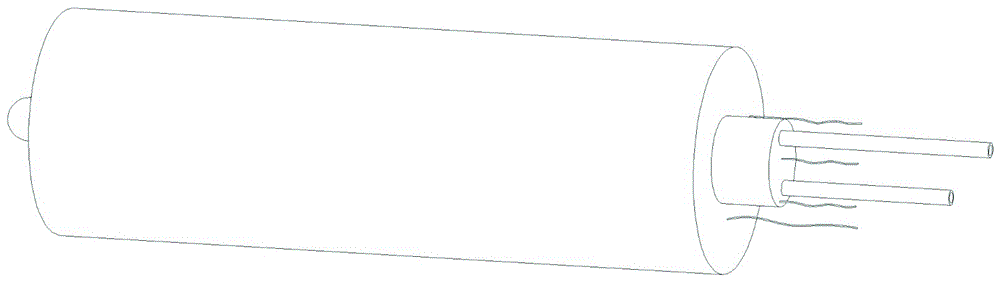

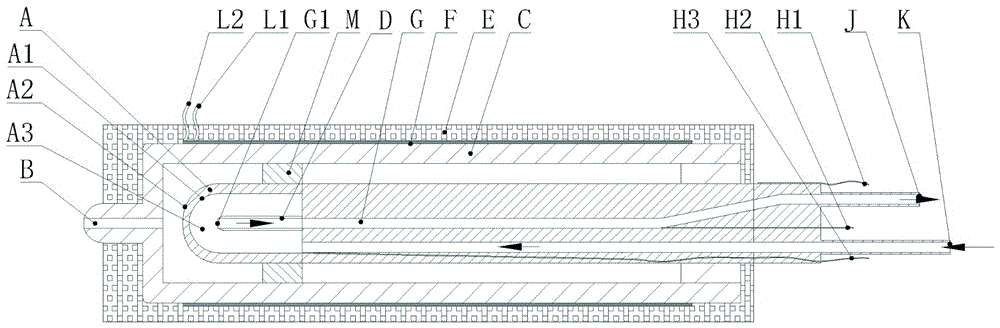

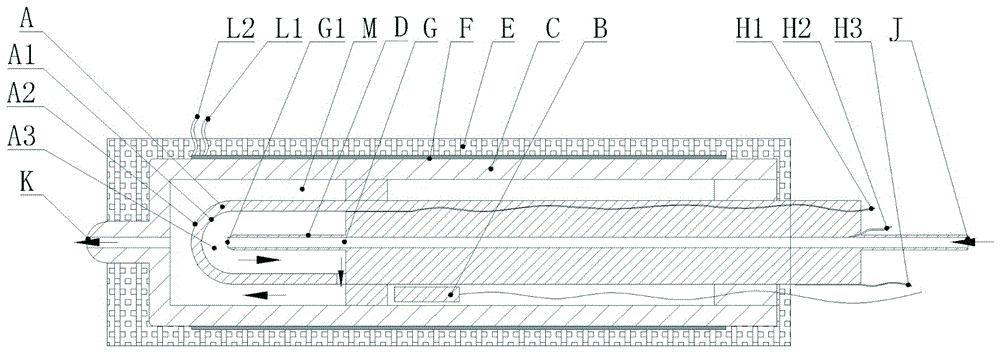

Rare-earth alloy permanent magnet material preparation device and technique

InactiveCN104308160ASolve segregationImprove coercive forceMagnetic materialsMaterials preparationRare earth

A rare-earth alloy permanent magnet material preparation device comprises a raw material treatment portion, a precipitation tank, an electrolytic furnace, a grinding mechanism, a stamping mechanism and a vacuum sintering furnace. The raw material treatment portion comprises a rare-earth metal treatment tank and a blending tank, a delivery pipe connected with the blending tank is arranged on the rear-earth metal treatment tank, the blending tank is connected with the precipitation tank through a complexing solution delivery pipe, the precipitation tank is connected with the electrolytic furnace, a feed inlet is arranged on one side of the electrolytic furnace, a casting chamber is arranged at the tail end of the electrolytic furnace and connected with a cooling chamber, the cooling chamber is connected with the grinding mechanism through a discharge pipe, and the grinding mechanism is connected with the stamping mechanism which is connected with the vacuum sintering furnace. The problem of segregation of alloy ingots is solved effectively, high temperature strength, structural stability, welding performance and corrosion resistance of the alloy ingots are improved beneficially due to addition of Sc, and the common electrolytic furnace can be used for smelting the alloy ingots by adopting mixture after Nd, Pr, Dy and Sc complexing.

Owner:NANJING SABER IND DESIGN & RES INST CO LTD

Preparation method of thiourea dioxide low-temperature reduction clearing catalyst for disperse dyes and reduction clearing method

Owner:HENAN INST OF ENG

Hot dip galvanizing Al Bi rare earth alloy for steel and iron member hot dip galvanizing and its ingot type and method

PendingCN101086048AAvoid uneven compositionAvoid burnsHot-dipping/immersion processesSymmetrical earsRare earth

Owner:ZHUZHOU SMELTER GRP

Cut application used after operation

InactiveCN101310776APromote growthPromote healingAdhesive dressingsAbsorbent padsWound healingSurface layer

Owner:徐茂山

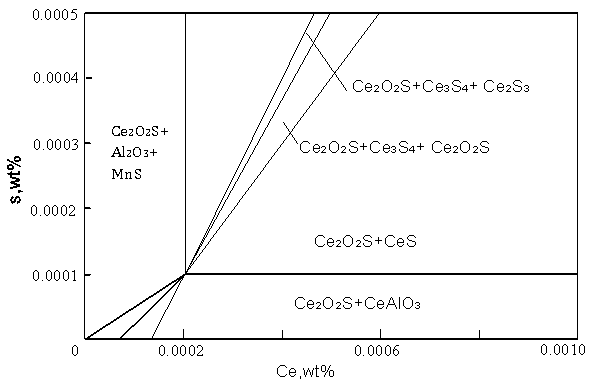

Smelting method for rare-earth microalloyed steel

Owner:内蒙古中天宏远稀土新材料股份公司

Degradable capacitor plastic shell and preparation method thereof

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Composite material for enhancing photoluminescence of rare earth Er ions and preparation method thereof

Owner:NANJING UNIV

Chemical pump inner cavity insulated oil paint and preparation method thereof

InactiveCN106046954AUniform textureGuaranteed to workRubber insulatorsRubber derivative coatingsRare earthPyrophosphate

Owner:安徽天富泵阀有限公司

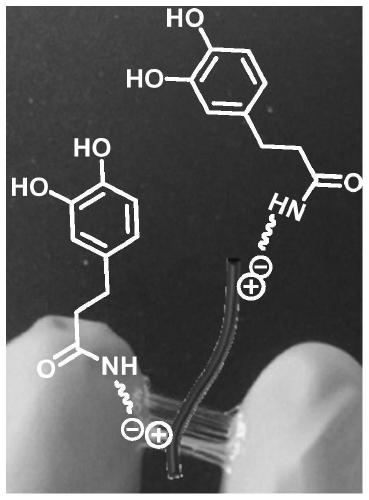

High-strength rare-earth protein adhesive and preparation method thereof

ActiveCN110373152AExcellent adhesionImprove adhesionNon-macromolecular adhesive additivesProtein adhesivesCuticleAdhesive

Owner:北京镧系生物科技有限公司

Cold-proof double swing and processing process thereof

InactiveCN107854842AReduce porosityReduce tensionSwingsConjugated diene hydrocarbon coatingsMetallurgyRare earth

Owner:苏州胤宗智能科技有限公司

Electrostatic spraying slushing oil

InactiveCN104611109AImprove adhesionImprove thermal stabilityLubricant compositionPolyesterPhosphate

The invention discloses electrostatic spraying slushing oil. The electrostatic spraying slushing oil is composed of the following raw materials in parts by weight: 0.4-1 part of p-nitrophenyl phosphate sodium, 60-70 parts of #25 transformer oil, 1-2 parts of polyisobutene, 3-5 parts of microcrystalline wax, 2-3 parts of hosho oil, 2-4 parts of phthalate polyester, 4-6 parts of petroleum sodium sulfonate, 2-3 parts of fumed silica, 1-3 parts of triethanolamine oleic soap, 1-2 parts of diphenyl silandiol, 0.5-1 part of monopotassium phosphate, 0.4-1 part of inositol hexaphosphoric acid, 0.3-0.5 part of zinc acetylacetonate, 2-3 parts of oleic acid and 3-5 parts of wear resistant machine oil. A molecular directional adsorption film can be formed on the surface of the metal by adding the wear resistant machine oil into the slushing oil, so that the friction can be reduced; the modified terpene resin has a good cohesive property and strong thermal stability so that the compatibility between the materials can be promoted and the adhesive force of the film can be enhanced; the zinc dihydrogen phosphate is used as a common metal surfactant which has a good rust removal preservative effect; the rare earth lanthanum ion and the OH<-> generated on the surface of the metal material during the oxygen absorption corrosion process can generate an insoluble complex which can slow down the corrosion of the electrode reaction and has a good slow-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

Fire ion detector

PendingCN106841445AAvoid safety hazardsSolve the big problem of difficult monitoringComponent separationChemical industryNitrogen gas

Owner:成都凯圣捷科技有限公司

Nodular cast iron valve and casting process thereof

InactiveCN107841677AImprove atomic activityImprove hardenabilityFoundry mouldsProcess efficiency improvementLanthanideRare earth

Owner:曹安飞

High-temperature-resistant wear-resistant compound resin material table surface

InactiveCN105217999AImprove high temperature resistanceHigh temperature resistanceWear resistantRare earth

Owner:SUZHOU FAST INFORMATION TECH CO LTD

Dairy cow feed capable of effectively inhibiting rumen protozoa growth

ActiveCN109864184AGrowth inhibitionInhibition of reproductionInorganic active ingredientsFood processingProtozoaMilk cow's

The invention discloses a dairy cow feed capable of effectively inhibiting rumen protozoa growth. The feed comprises a basic ration, and 0.5 g of hop and 0.2 g of a rare earth compound are also addedinto each kilogram of the basic ration. The dairy cow feed can effectively inhibit growth and reproduction of the protozoa in the rumen, so that the conversion of nitrogen elements in the feed by dairy cows is improved, the feeding cost is reduced, and the environment is effectively protected.

Owner:HEBEI AGRICULTURAL UNIV.

High-efficient composite filter material prepared by blending melt-blown polypropylene with modified pseudo-boehmite and used for sewage treatment and preparation method thereof

InactiveCN104759266AImproved purification and adsorption capacityStable and efficient structureOther chemical processesAlkali metal oxides/hydroxidesRare earthLanthanum

Owner:BENGBU DEMO FILTRATION TECH

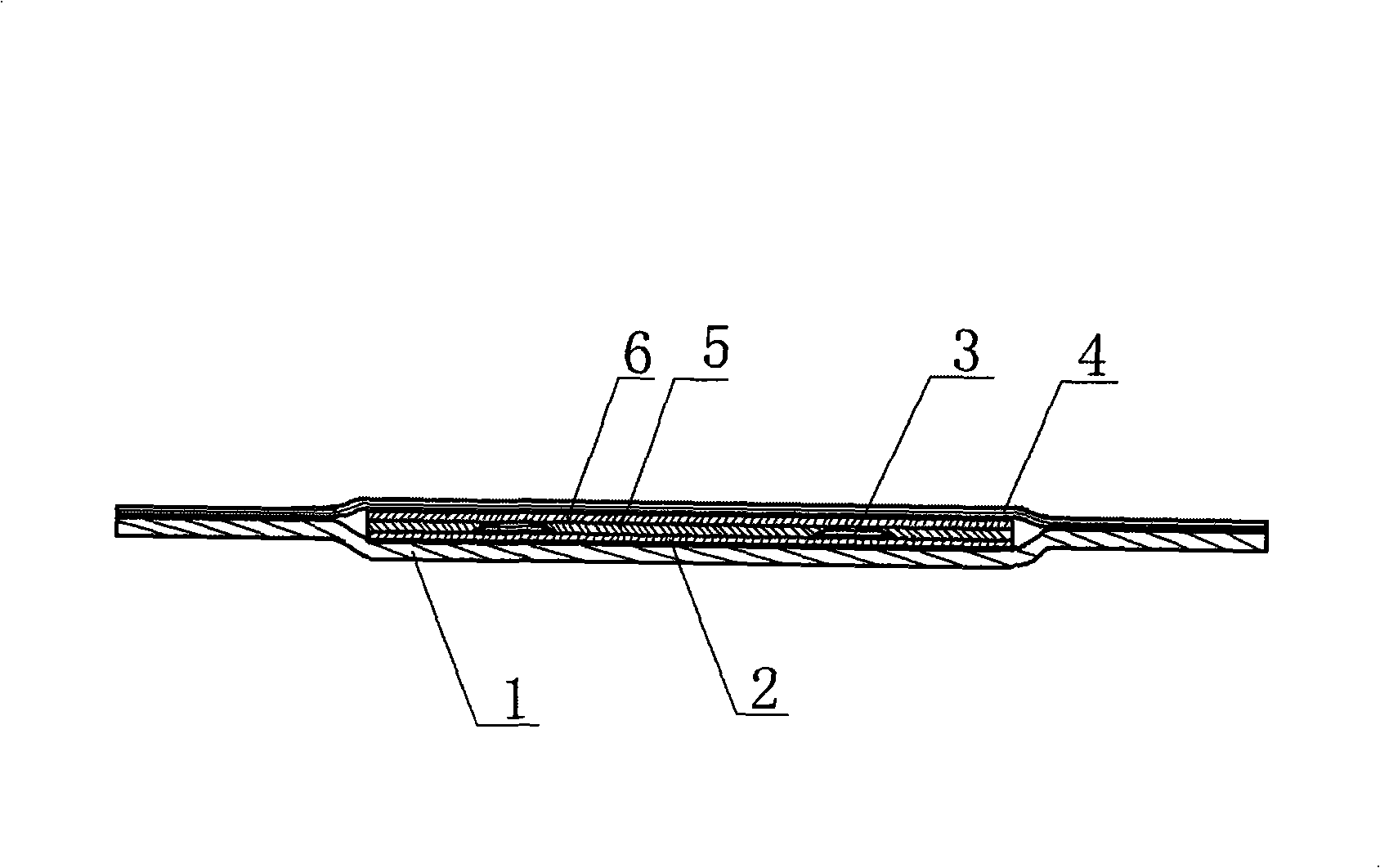

High toughness cable for aviation and preparation method thereof

The invention discloses a high toughness cable for aviation and a preparation method thereof. The preparation method comprises 1) stirring to mix fibers, nano-calcium carbonate, tetrahydrofuran and ethanol in a nitrogen protective atmosphere at a temperature of 120-140 DEG C and collecting precipitates M1, 2) mixing neoprene and butadiene rubber to obtain mixed rubber M2, 3) mixing the precipitates M1, the mixed glue M2, a phosphate, a rare earth oxide and an antioxidant and pressing the mixture to obtain rubber sheet blanks M3, 4) mixing the rubber sheet blanks M3 and a vulcanizing agent and carrying out vulcanization to obtain rubber sheets M4, and 5) coating the rubber sheets M4 with metal wires to obtain the high toughness cable for aviation. The high toughness cable has high toughness, greatly-prolonged service life, improved use performances, and widened cable application field.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

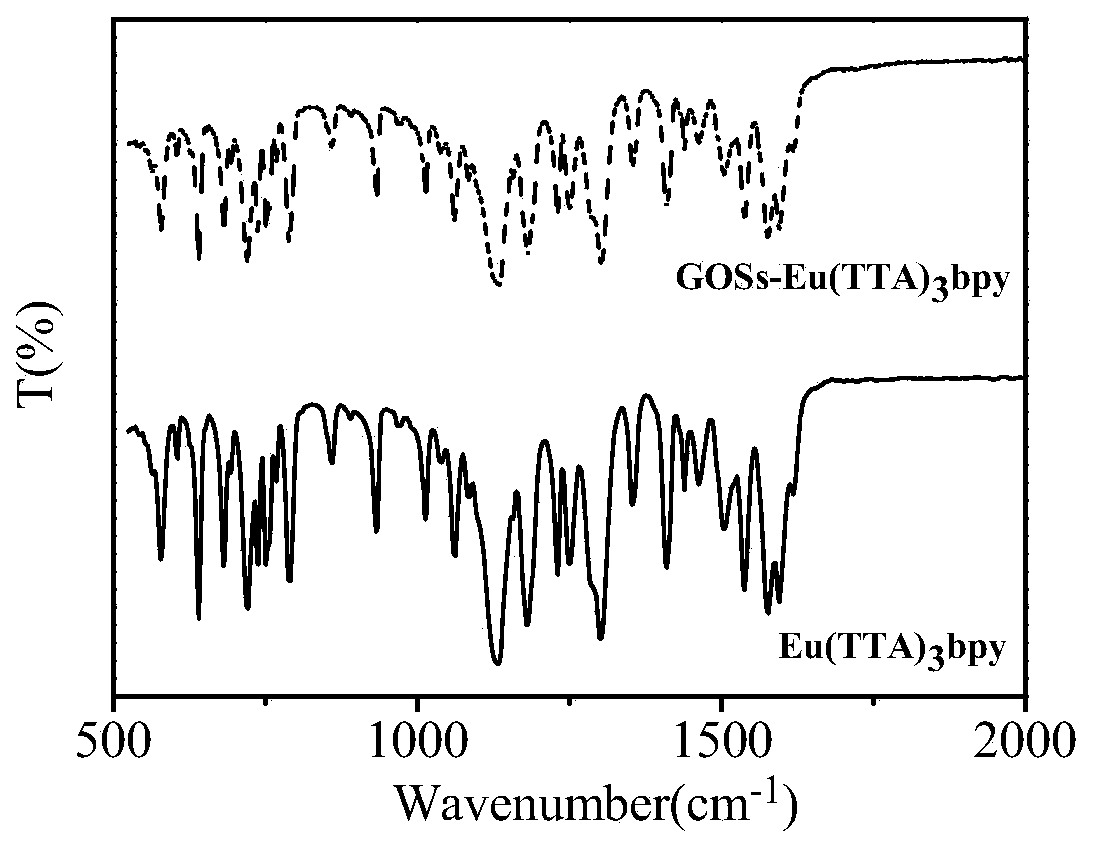

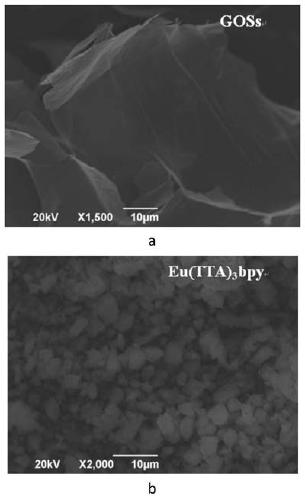

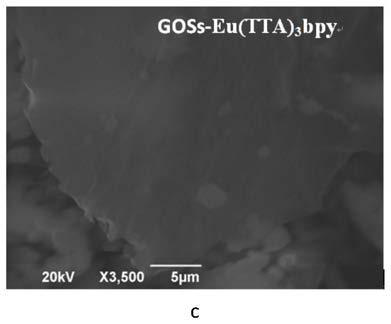

Preparation method of graphene oxide and rare earth complex composite ultraviolet enhancement film

ActiveCN109796710AEfficient UV enhancementMaterials are readily availableLuminescent compositionsRare earthUltraviolet

Owner:HEFEI UNIV OF TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap