Preparation method of graphene oxide and rare earth complex composite ultraviolet enhancement film

A technology of rare earth complexes and graphene, applied in chemical instruments and methods, luminescent materials, etc., can solve problems affecting the range of use of devices, poor stability of coating materials, etc., and achieve low cost, easy-to-obtain materials, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

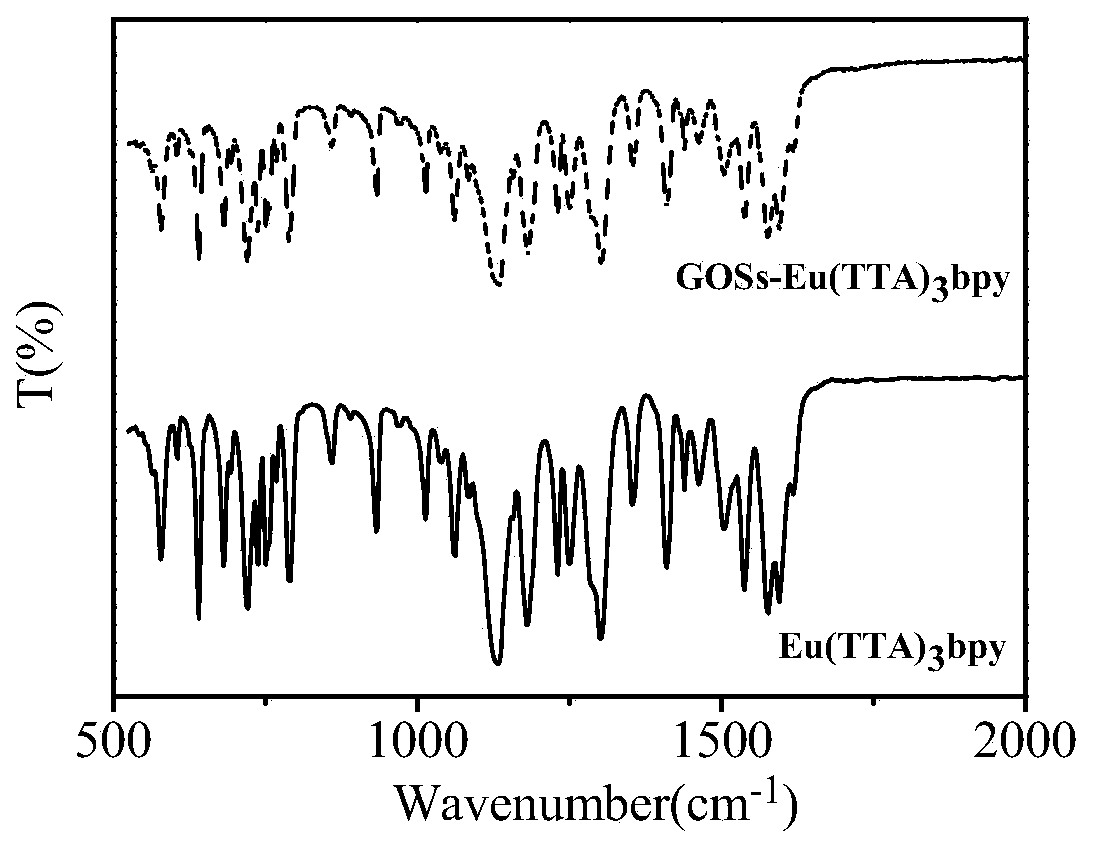

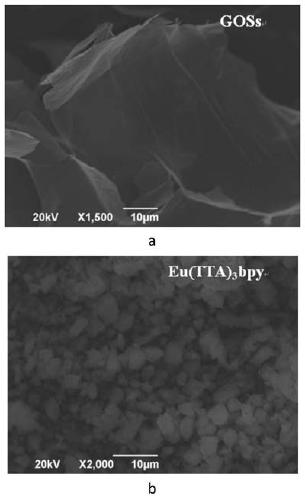

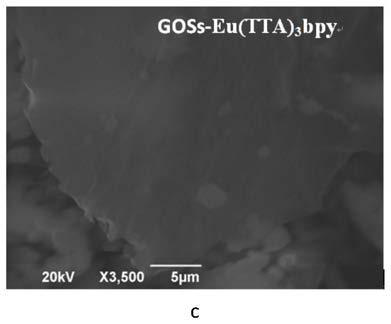

Method used

Image

Examples

Embodiment 1

[0028] Preparation of GOSs-rare earth complex fluorescent materials:

[0029] (1) Weigh the reaction raw materials according to the mass corresponding to the molar ratio of EuCl3·6H2O:2'2-bipyridyl:thienoyltrifluoroacetone=1:1:3;

[0030] (2) Put EuCl3·6H2O and GOSs in ethanol, mix and sonicate to obtain suspension A;

[0031] (3) Dissolving 2'2-bipyridine and thienoyltrifluoroacetone in ethanol to obtain solution B;

[0032] (4) Add suspension A and solution B into a 250ml single-necked bottle;

[0033] (5) Add an appropriate amount of NaOH aqueous solution to adjust the pH to 6-7;

[0034] (6) Heat at 60°C, stir, and react for 3 hours;

[0035] (7) Turn off the power, stand at room temperature for 12 hours, then filter with suction, wash with ethanol several times, and collect the product;

[0036] (8) Dry in an oven at 70°C (normal pressure), and collect the product.

Embodiment 2

[0038] Preparation of composite reinforced film:

[0039] (1) Weigh PVA124 into a glass bottle, add distilled water, and let stand for 2 hours (to make PVA swell);

[0040] (2) Add a stirrer, heat and stir at 85°C until completely dissolved;

[0041] (3) Add absolute ethanol, heat and stir at 65°C until completely dissolved;

[0042] (4) Weigh an appropriate amount of complex and add it to the above PVA solution;

[0043] (5) Heat and stir at 40°C for 24 hours to form a mixed luminescent glue;

[0044] (6) Spin-coating or casting to form a film as required;

[0045] (7) Oven drying at 40°C (normal pressure) to form a film.

Embodiment 3

[0047] Preparation of UV-enhanced linear array CCD:

[0048] (1) Cast the prepared luminescent mixture into the photosensitive tank of the linear array CCD;

[0049] (2) Place the CCD poured into the luminescent compound flatly in a drying oven;

[0050] (3) Drying in a 40°C oven under normal pressure;

[0051] (4) Device packaging.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap