Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Wear resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of wear-resistant in English: wear-resistant. adjective. (of a surface or material) not easily damaged by friction or use. ‘a layer of wear-resistant rubber matting’. ‘wear-resistant carbide blades’.

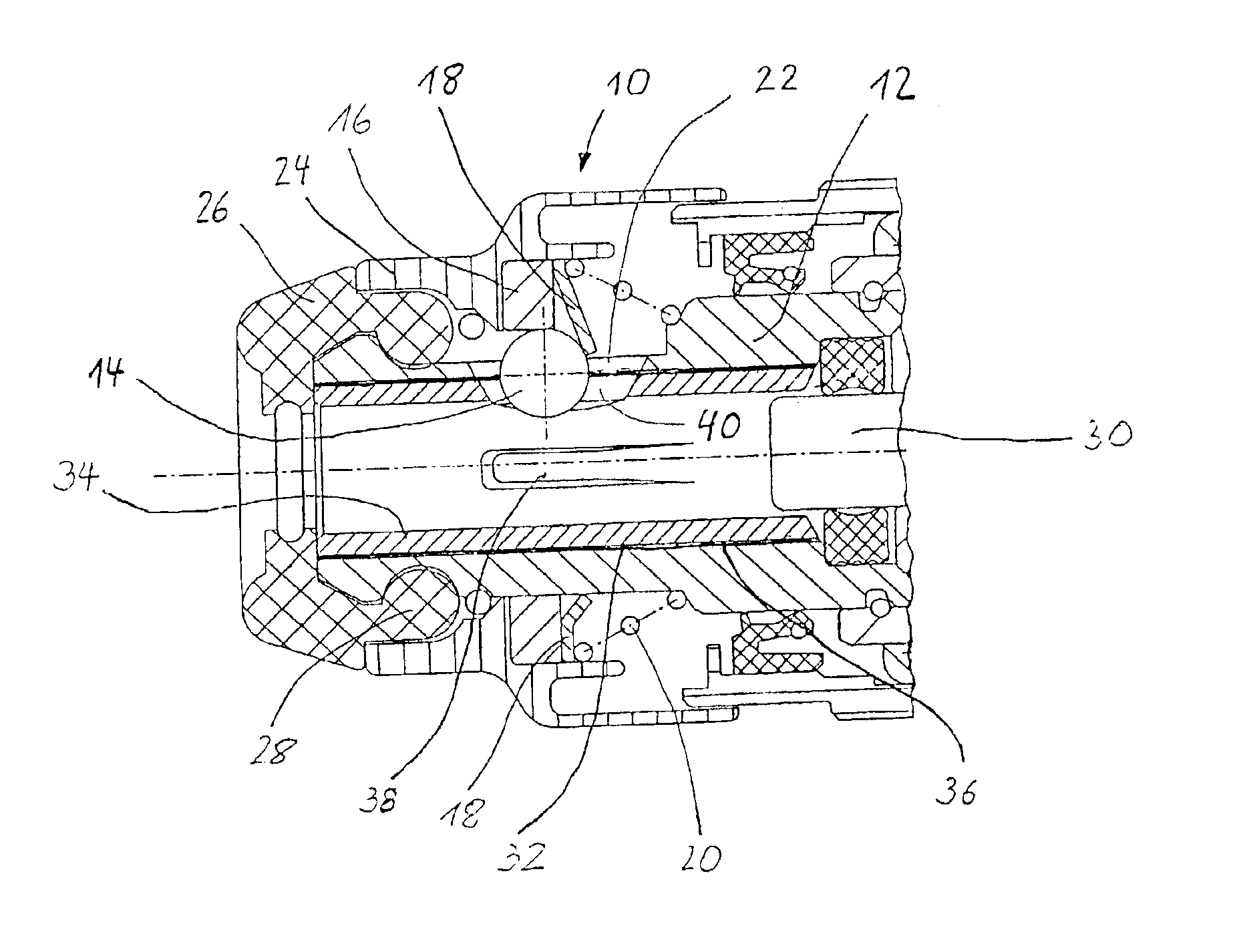

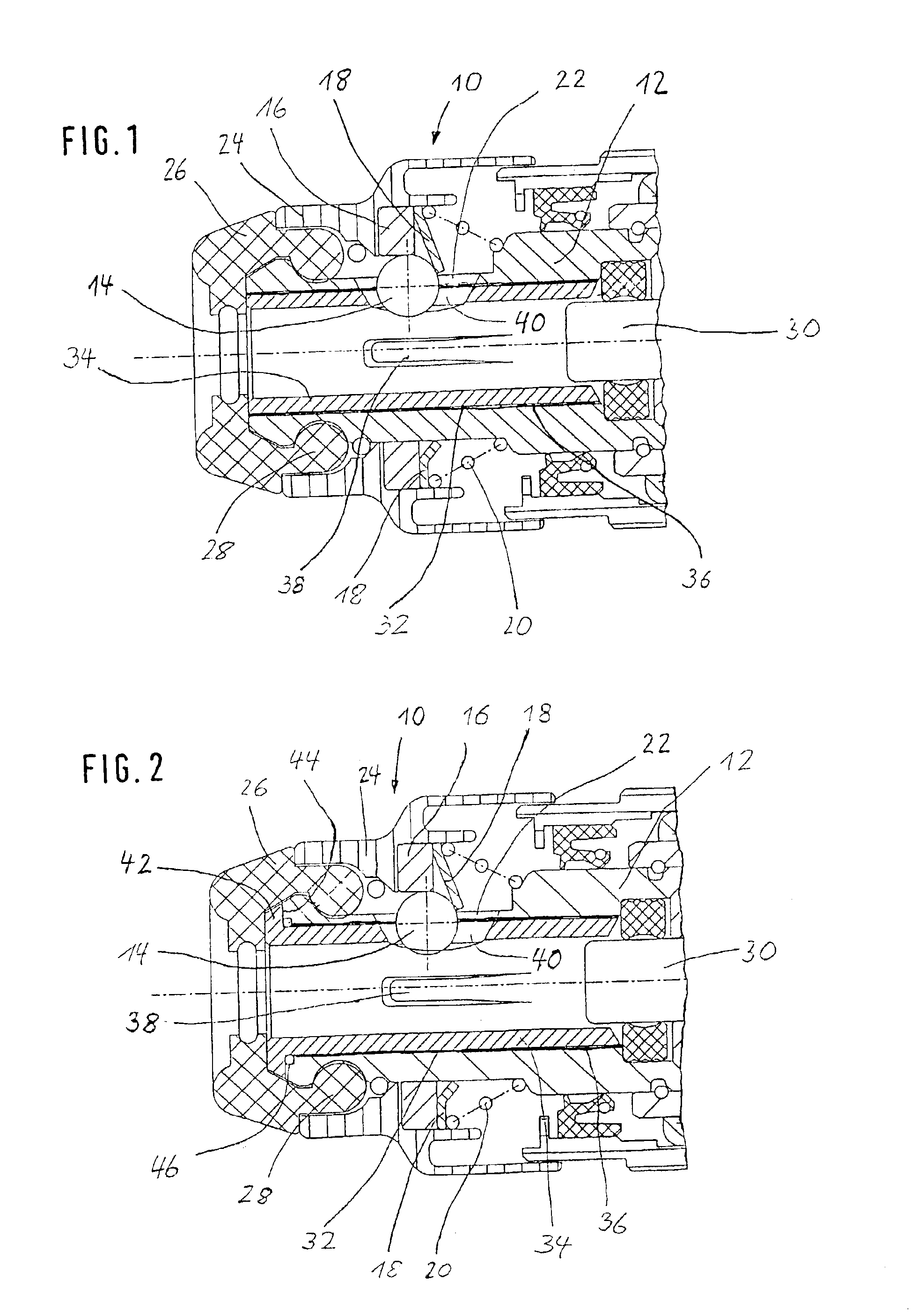

Tool mounting for a hand machine tool

Owner:ROBERT BOSCH GMBH

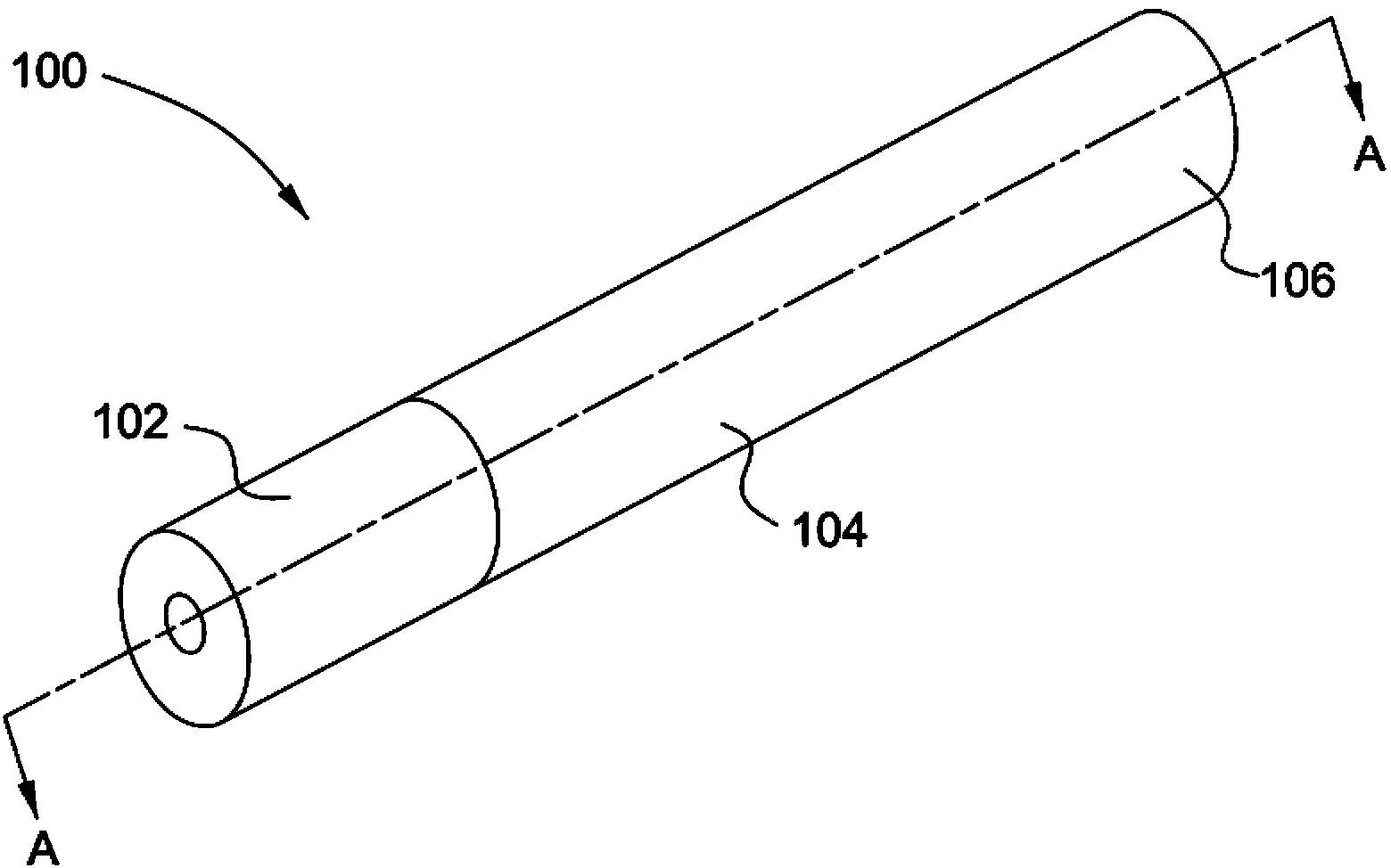

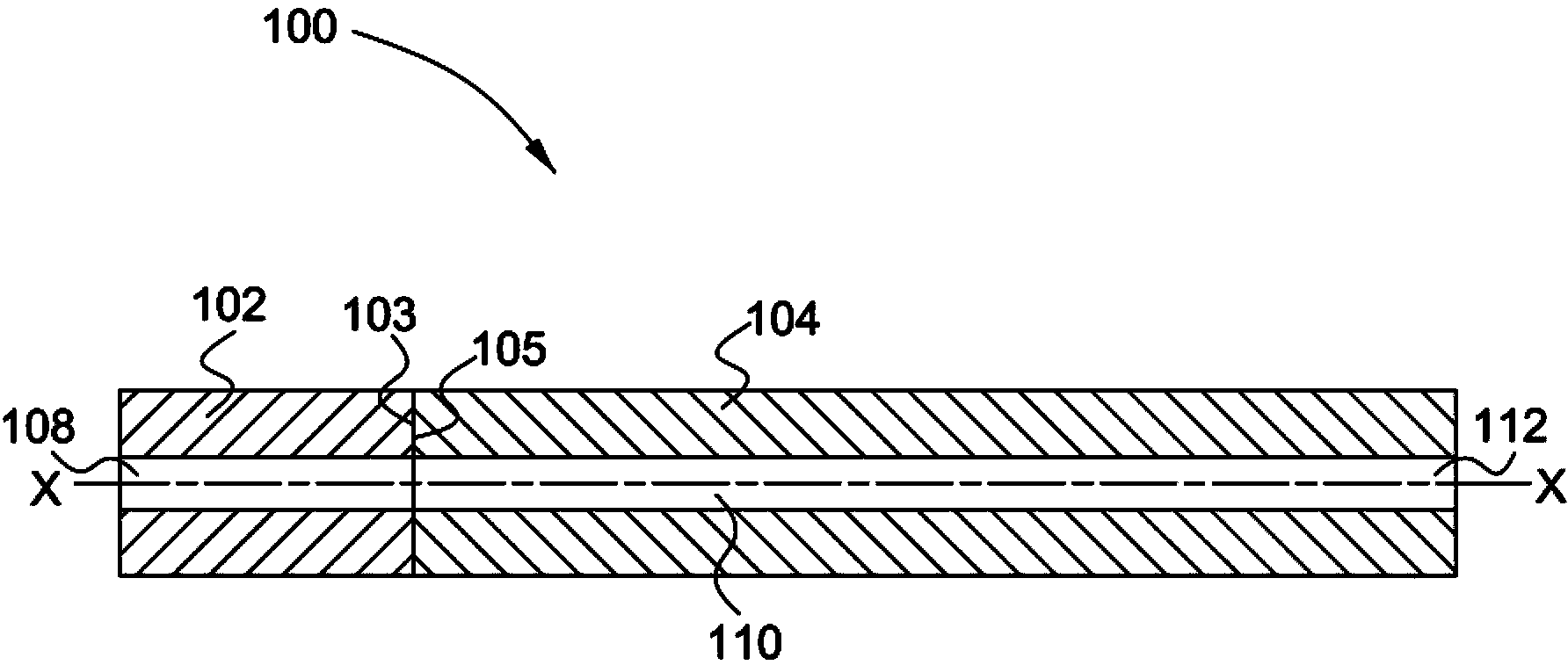

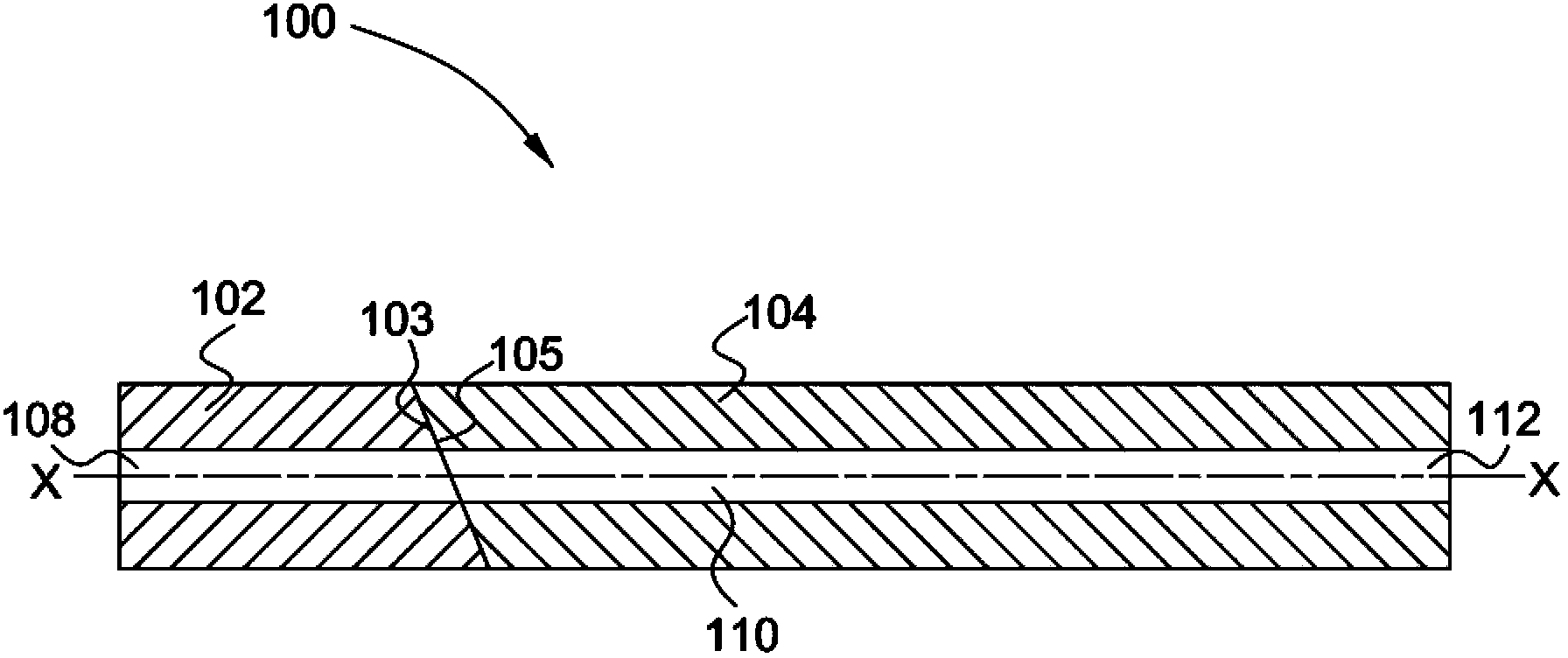

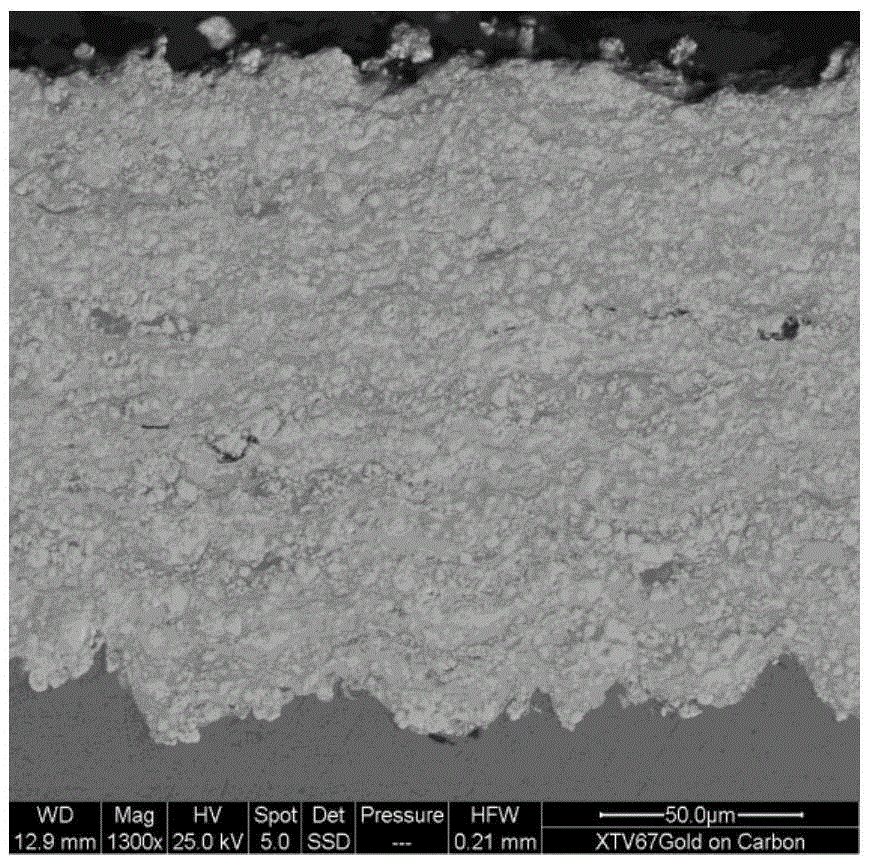

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

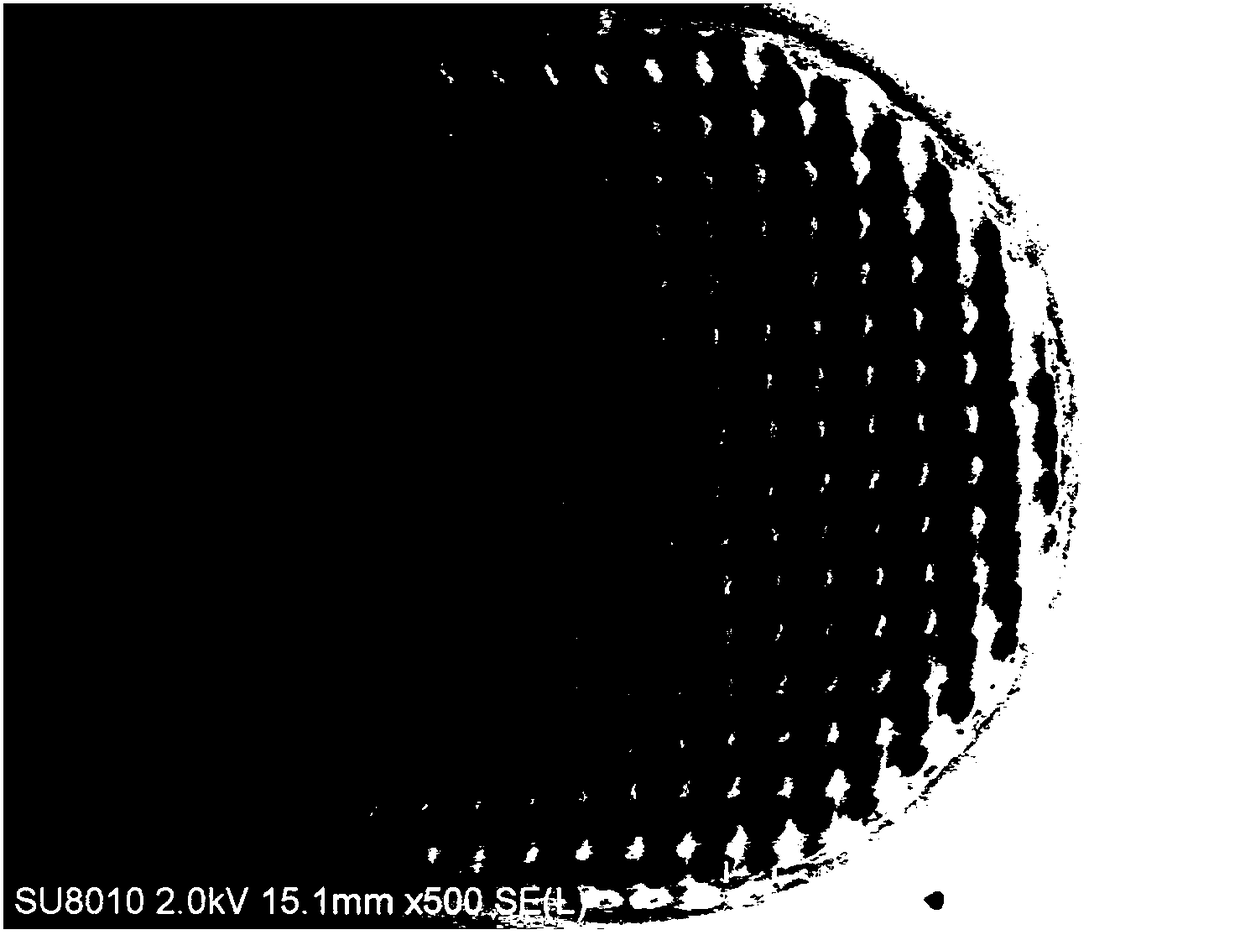

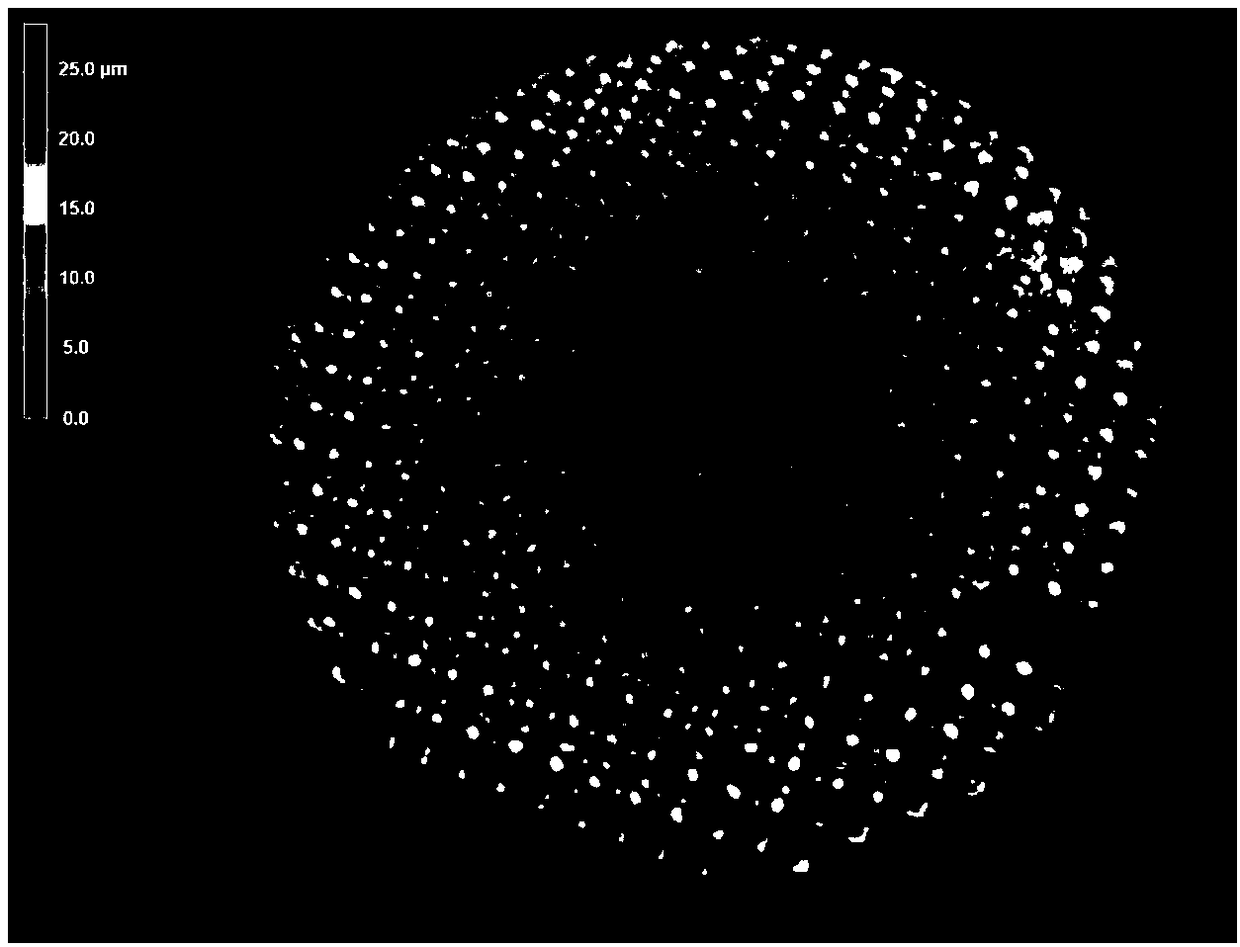

Chopper for improving bonding strength of lead

ActiveCN108389806AImprove bonding performanceImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingWear resistantEngineering

The invention discloses a chopper for improving bonding strength of a lead. The chopper is a welding ceramic chopper and comprises a body, a welding nozzle and a hole, wherein the welding nozzle is arranged at one end of the body, the hole extends along a longitudinal axis of the body and the welding nozzle, and a tip surface of the welding nozzle comprises convex parts and concave parts which arealternatively distributed. By the design of a chopper surface structure, the wear-resistant region of the surface can be expanded, the hardness of the tip surface is improved, the roughness of the surface is improved, and the service lifetime is prolonged; compared with a traditional polishing and thermal processing chopper, the chopper has the advantages of better bonding effect and higher stability; on one hand, the gold reservation degree of a tip is effectively reduced by the design; and on the other hand, the wear-resistant degree of a porcelain nozzle is improved, and thus, the servicelifetime of the porcelain nozzle is prolonged.

Owner:CHAOZHOU THREE CIRCLE GRP

Wear resistant sole material

InactiveCN103483677ADoes not affect elasticityDoes not affect resilienceSolesEnvironmental resistanceFoaming agent

The invention relates to a wear resistant sole material. The wear resistant sole material comprises, by weight, 35-45 parts of EVA, 4-8 parts of styrene butadiene rubber, 1-8 parts of butadiene rubber, 1-4 parts of a vulcanizing agent, 2-5 parts of a reinforcing agent, 1-4 parts of an activator, 1-4 parts of an accelerant and 0.5-3 parts of a foaming agent. The wear resistant material greatly improves the wear resistance of a sole without influencing the elasticity, the resilience, the portability or the like of the sole, and also has the advantages of non-toxicity, no pollution, safety and environmental protection.

Owner:KUNSHAN CHUNBAI PRECISE HARDWARE CO LTD

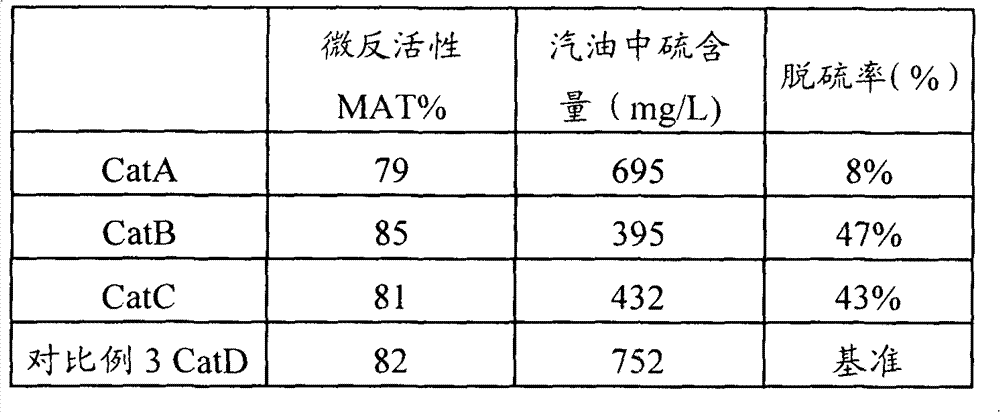

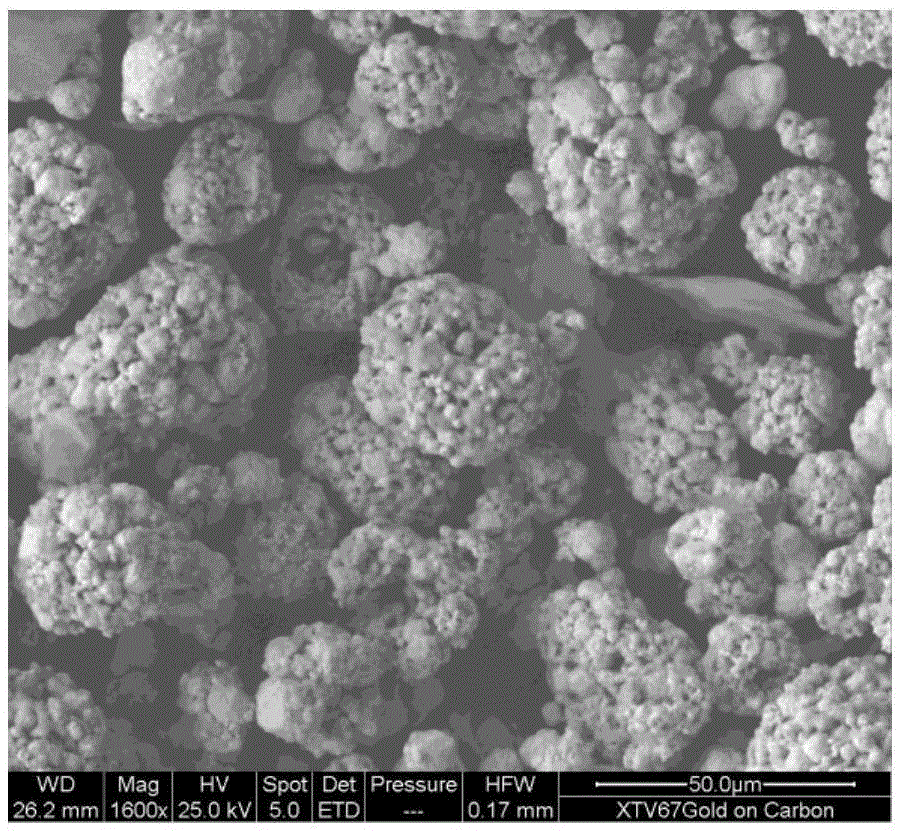

Wear-resistant heavy oil catalytic cracking catalyst capable of reducing sulfur content of gasoline and preparation method thereof

ActiveCN103028432AImprove wear resistanceHigh activityCatalytic crackingMolecular sieve catalystsMicrosphereWear resistant

Owner:EAST CHINA UNIV OF SCI & TECH +1

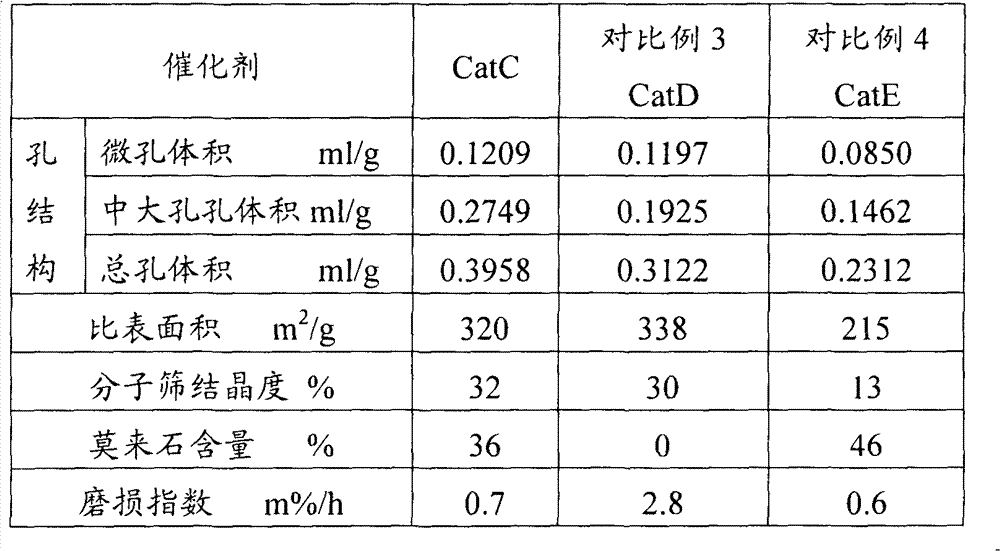

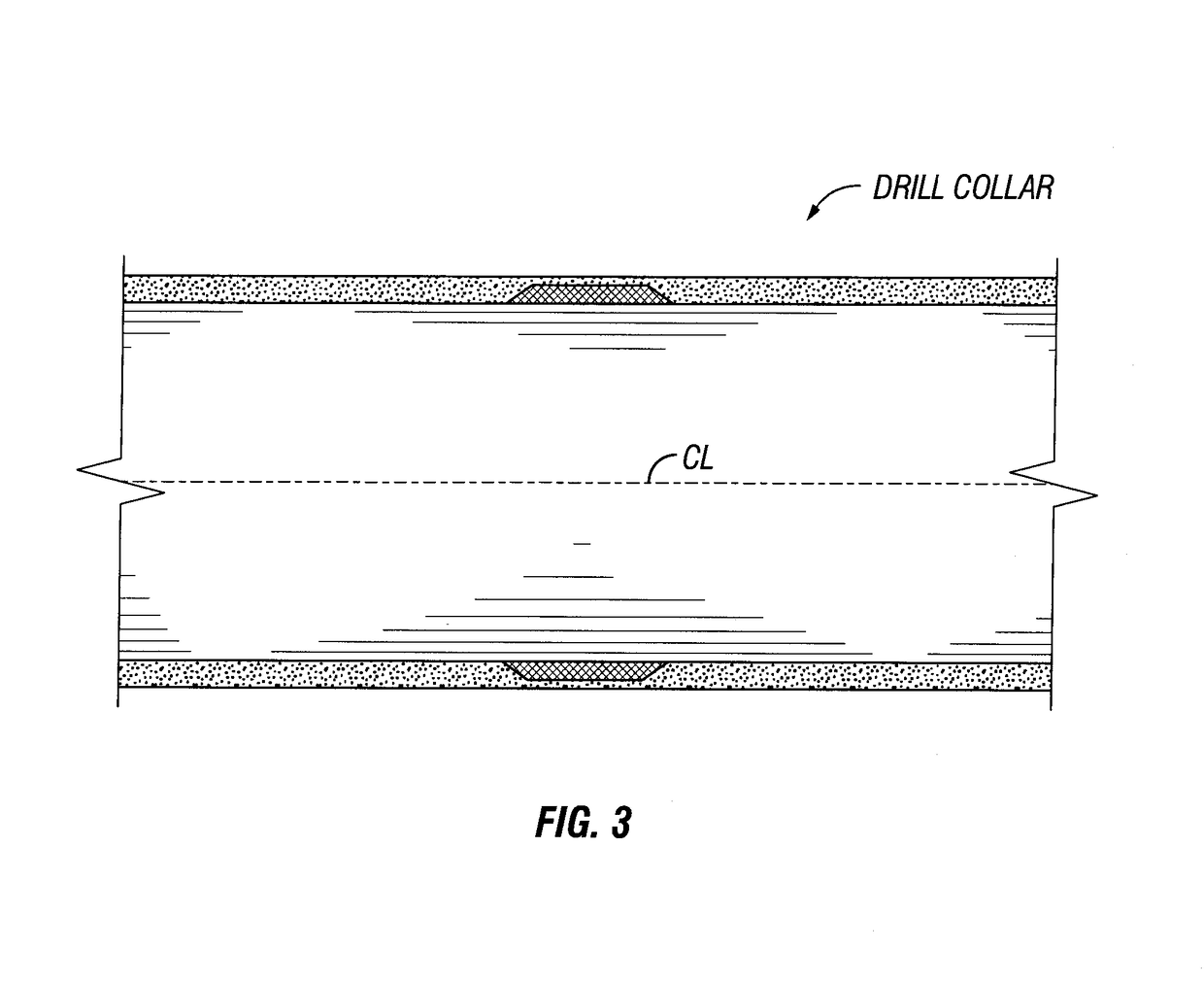

Drill bit of hollow drill and manufacturing method thereof

InactiveCN103752907AAnti-corrosionWith cleanTransportation and packagingTool adaptersWear resistantDrill bit

Owner:宁波神钻工具有限公司

Compound electrode, and machining device and machining method

Owner:GENERAL ELECTRIC CO

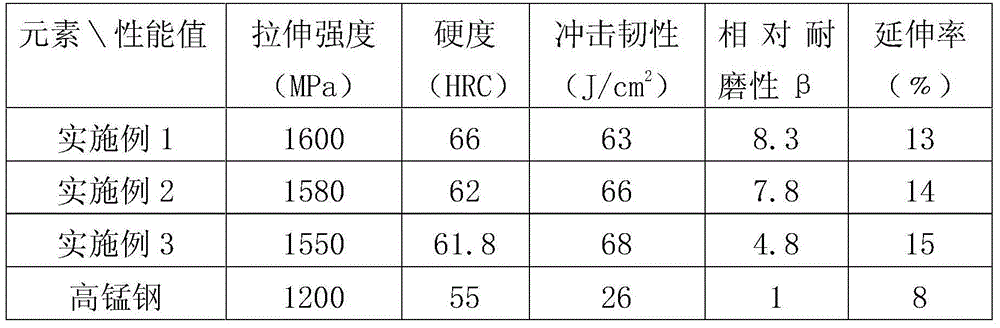

Boron-bearing chromium molybdenum nickel wear-resistant alloy and preparation method thereof

Owner:GUANGXI UNIV

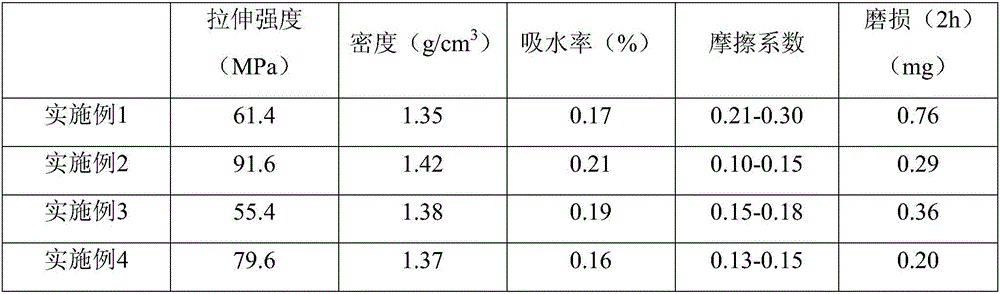

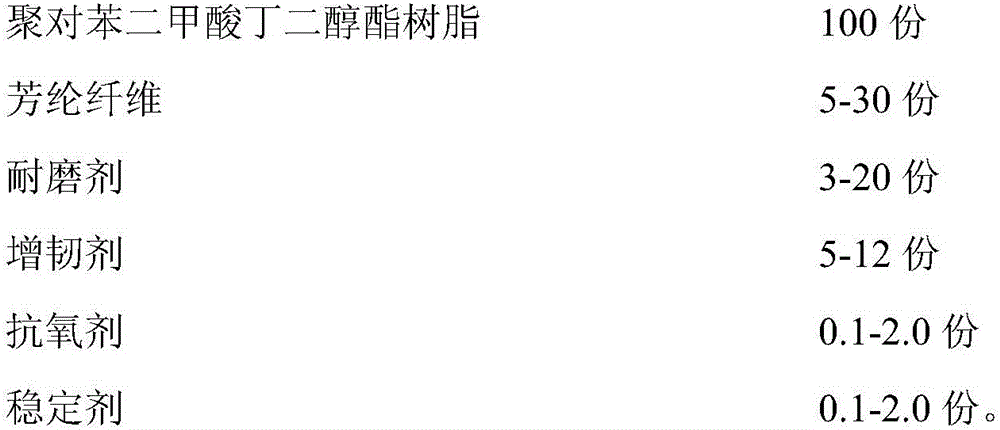

High-molecular self-lubricating material, preparation method of high-molecular self-lubricating material, and plate spring flanged bushing made of high-molecular self-lubricating material

InactiveCN106633695AWith wear resistanceGood dimensional stabilityResilient suspensionsVehicle springsPolytetramethylene terephthalateAntioxidant

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for preparing cobalt-based wear-resistant and corrosion-resistant coating layer by adopting ultra-high speed laser cladding

InactiveCN108118334ASmall amount of deformationNot easily oxidizedMetallic material coating processesUltra high speedWear resistant

The invention relates to a method for preparing cobalt-based wear-resistant and corrosion-resistant coating layer by adopting ultra-high speed laser cladding and belongs to the technical field of surface treatment. Through methods of selecting appropriate cobalt-based alloy powder, adjusting the positions of a powder convergence point and a laser focus, adjusting process parameters and the like, the cobalt-based wear-resistant and corrosion-resistant coating layer with good surface evenness and small thickness and without defect can be quickly and accurately produced, so that the ultra-high speed laser cladding is realized, and the purposes of improving the production efficiency and reducing the production cost are achieved.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

Surface layer abrasion-proof paper

ActiveCN101148849AHighly transparentExtended service lifeSpecial paperPaper/cardboardSurface layerWear resistant

The surface wear resistant paper for making decorating thermosetting laminated sheet contains stuffing and assistant. It has high transparency, high wear resistance, long service life, environment friendship and other advantages. It is applied widely for the surface of furniture, vehicle, ship, airplane, floor, instrument, etc.

Owner:SHANDONG QIFENG SPECIAL PAPER

Crease-resistant wear-resistant fabric

InactiveCN109532130AGood warmth retentionImprove breathabilitySynthetic resin layered productsClothingsYarnWear resistant

The invention provides a crease-resistant wear-resistant fabric, which comprises a fabric body, wherein the fabric body is of an double-rib composite double-layer tissue structure compounded by changeplain stitch and tuck stitch; an inner layer fabric of the fabric body is woven by spandex composite yarns; an outer layer fabric of the fabric body is woven by chinlon composite yarns; the inner layer fabric and the outer layer fabric are connected in series through the tuck stitch. The fabric uses a double-rib air layer structure; the spandex composite yarns are used as the inner layer fabric;the chinlon composite yarns are used as the outer layer fabric; the problems of poor wear resistant performance, poor durability and easy crease occurrence of the existing fabric are solved.

Owner:SWOTO PROTECTION & TECH CO LTD +1

Rubber composition used for treads of middle-large-size automobile tires

ActiveCN107759860AIncrease elasticityImprove wear resistanceSpecial tyresVulcanizationPolymer science

Owner:ZHAOQING JUNHONG CO LTD

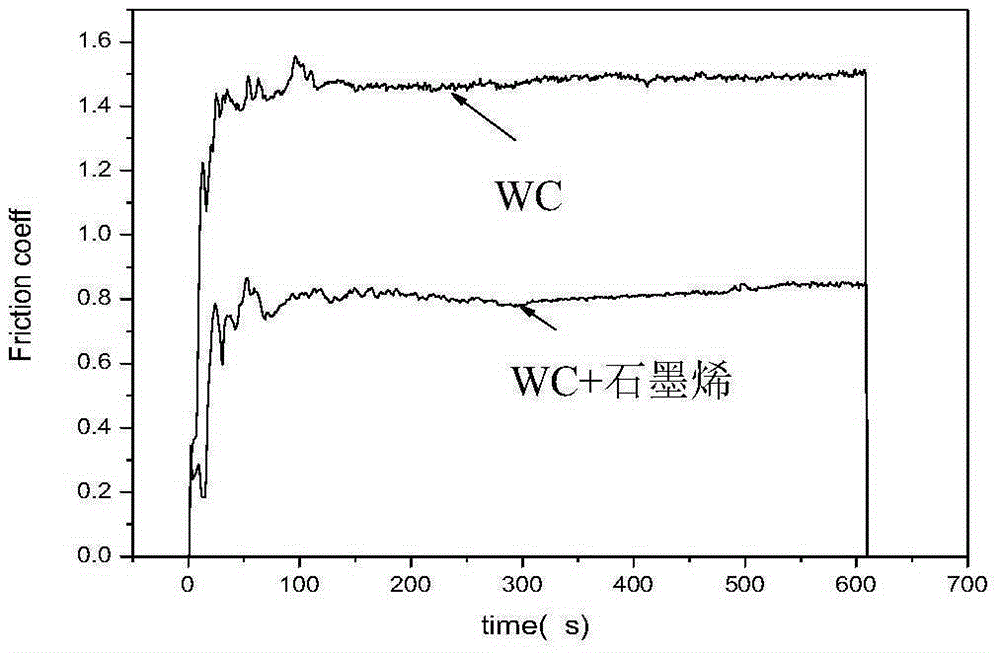

Graphene modified self-lubricating wear-resistant coating

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Graphene-containing wear-resistant composite material and preparation method thereof

Disclosed are a graphene-containing wear-resistant composite material and a preparation method thereof. The composite material is in a sheet-layer shape, and by weight, 500 g of latex correspondinglycontains 3-5 g of calcium chloride, 10-20 g of zinc oxide, 15-25 g of analytically-pure magnesium oxide, 2-6 g of stearic acid, 1-3 g of an accelerator NA-22 and 20-30 g of large-radial-size graphenemicrochips, wherein calcium chloride, zinc oxide, analytically-pure magnesium oxide, stearic acid, the accelerator NA-22 and the large-radial-size graphene microchips are uniformly dispersed in the latex. The preparation method comprises the steps of preparation of the graphene microchips, preparation, preparation of rubber masterbatches and preparation of the sheet-layer composite material.

Owner:GUOHONG ZHONGJING GRP CO LTD

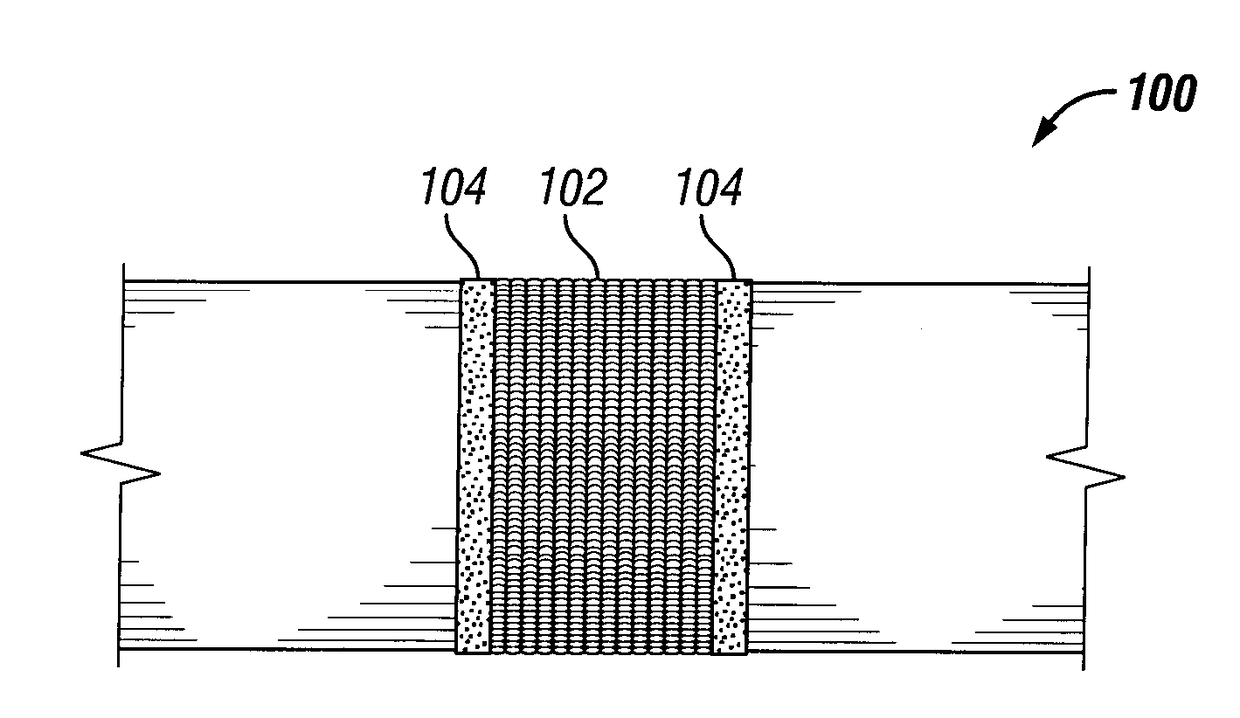

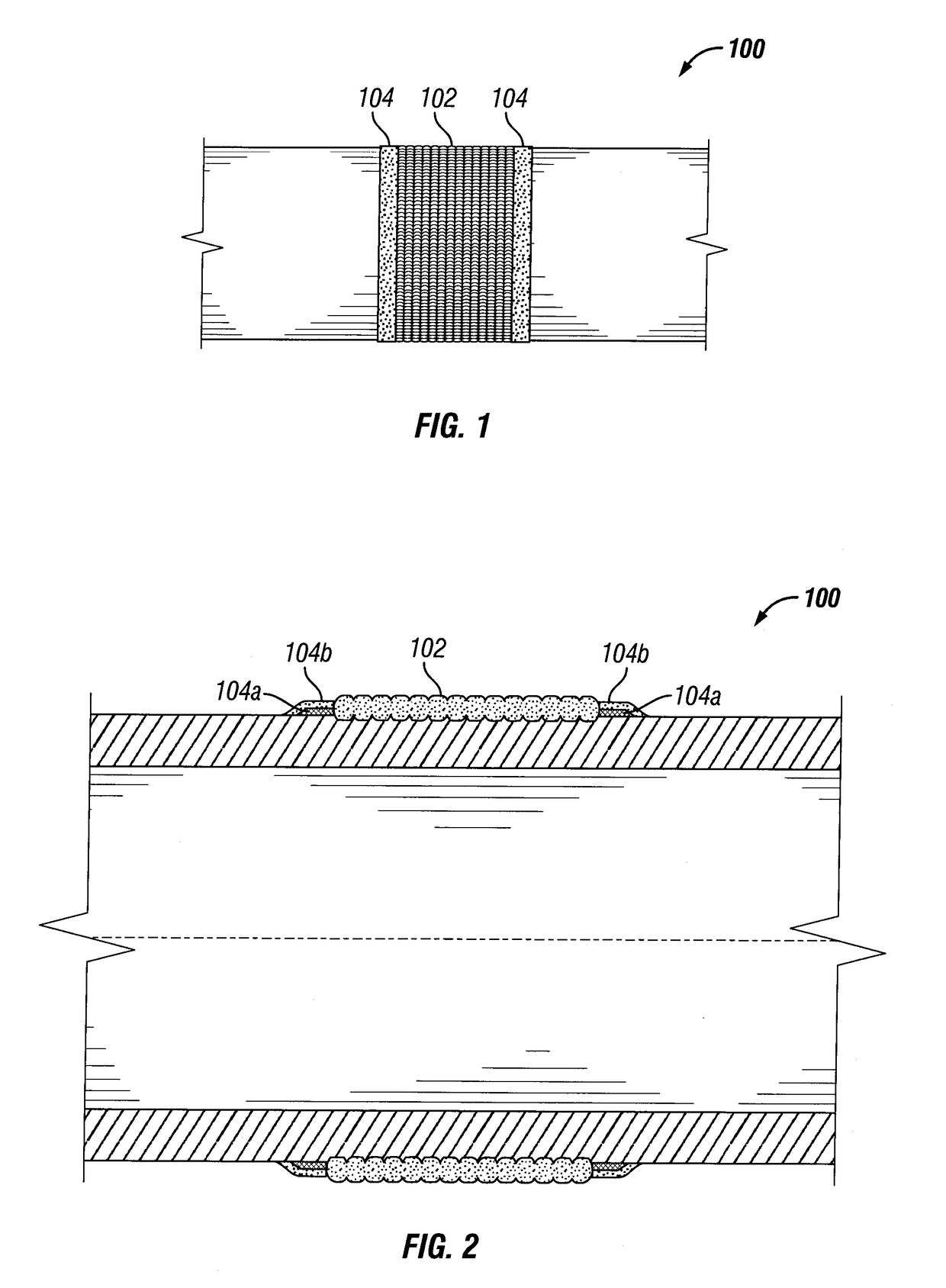

Multi-layer coating and related methods of application

Owner:SUPERIOR SHOT PEENING

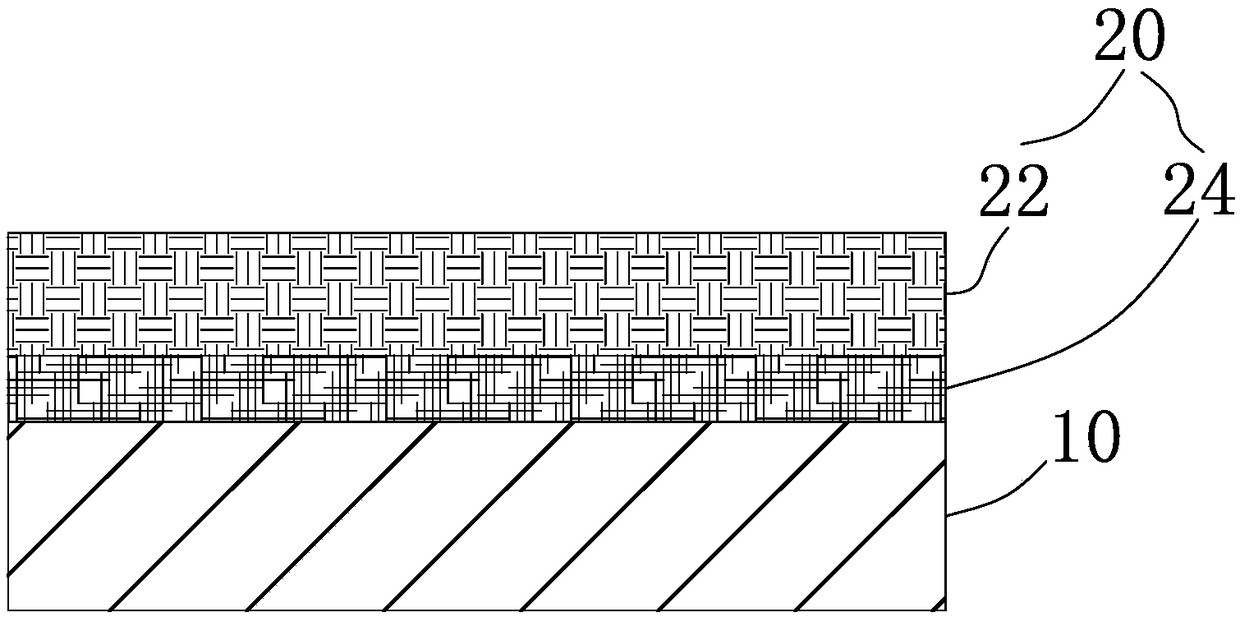

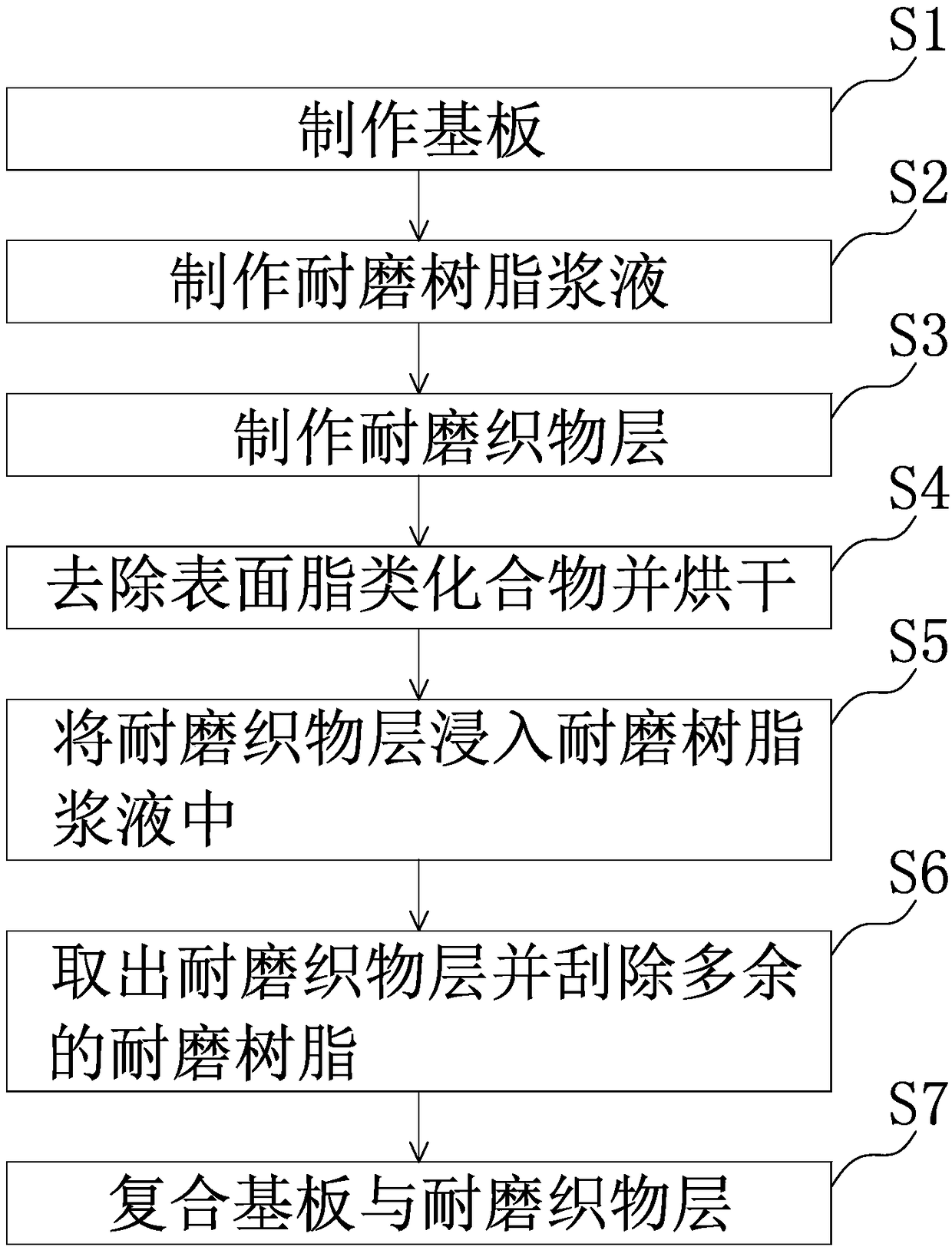

Wear-resistant non-metal composite board and production method thereof

ActiveCN108437585AReduced carrying capacityExtended service lifeLamination ancillary operationsSynthetic resin layered productsPolyesterEpoxy

Owner:JIASHAN CSB PLASTIC BEARING TECH CO LTD

Waterborne polyurethane super wear-resistant finish paint and preparation process thereof

ActiveCN109456690ASmall particle diameterGood dispersionPolyurea/polyurethane coatingsWear resistantWear resistance

The invention discloses waterborne polyurethane super wear-resistant finish paint and a preparation process thereof, and relates to the technical field of preparation of finish paint, aiming at solving the problem that the finish paint is poorer in wear resistance, so that local damage is easily caused in a using process. The finish paint is prepared from a component A and a component B, wherein the component A is prepared from the following raw materials: 50-60 parts of waterborne polyurethane resin AH-1618, 12-18 parts of polyurethane color paste, 0.8-1.2 parts of a leveling agent BYK346, 0.3-0.5 part of an aqueous leveling agent BYK333, 0.3-0.6 part of a polyurethane rheological agent SN612NC, 0.3-0.5 part of a defoaming agent BYK024, 0.08-0.1 part of a defoaming agent Tego901W, 0.8-1.5parts of rutile titanium dioxide, 8-10 parts of wear-resistant ball powder, 0.8-1.5 parts of an aqueous scratch-resistant agent, 1.2-1.6 parts of propylene glycol methyl ether and 12-18 parts of deionized water; the component B is prepared from 95-100 parts of a polyurethane curing agent; the ratio of parts by weight of the component A to parts by weight of the components B is equal to (4-6) to 1. The waterborne polyurethane super wear-resistant finish paint has good wear resistance after being cured.

Owner:SHANGHAI BOGE BUILDING MATERIALS CO LTD

Wear-resistant composite microcrystalline sheet material

Owner:HENAN JINGXIANG ABRASION PROOF MATERIAL

High-temperature burden guiding device between pre-reducing furnace and final-reducing furnace

Owner:MCC CAPITAL ENGINEERING & RESEARCH

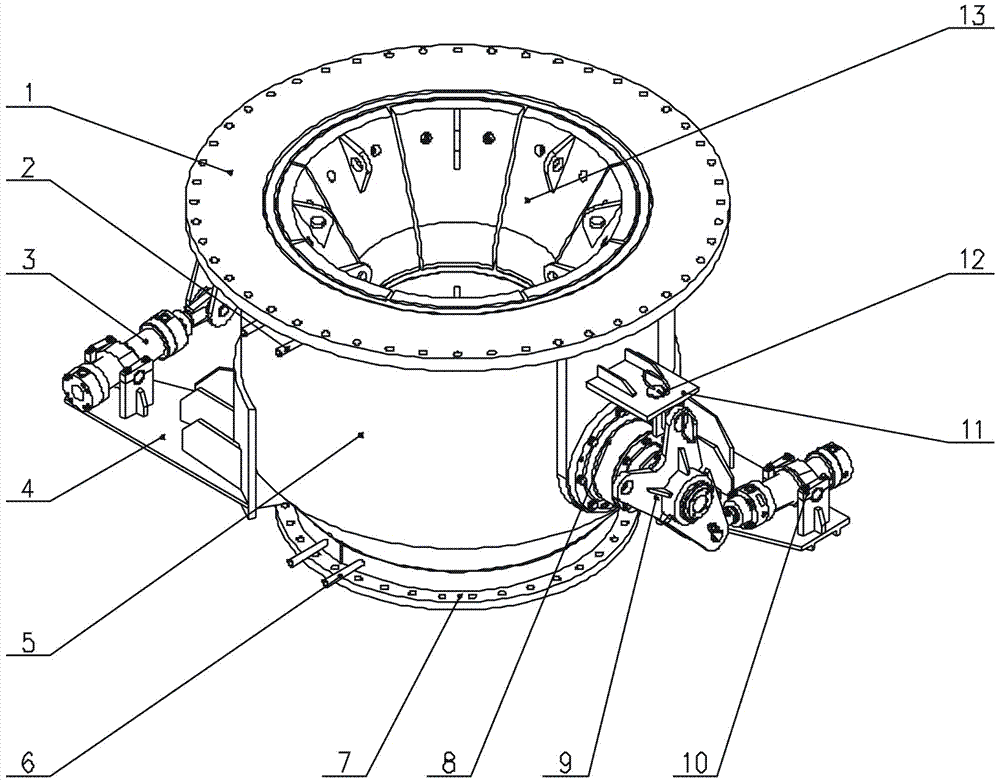

Ore pulp slide damper device

InactiveCN106151561ASimple and reasonable structureFlexible valve switchOperating means/releasing devices for valvesSlide valveWear resistantEngineering

The invention is mainly applied to the field of ore pulp delivery and particularly relates to an ore pulp slide damper. The ore pulp slide damper comprises a support and a valve port, wherein a valve plate is arranged in the valve port, sliding grooves are arranged in the inner sides of the two side edges of the support, the valve plate is mounted in the sliding grooves, the top of the valve plate is provided with a pull rope, the pull rope is wound on a reel, the reel is connected with a driving device, the driving device is mounted at the top of the support, the top of the support is provided with a through hole corresponding to the pull rope, a locating hole is formed in the side wall of the valve plate, a partition plate is arranged between a top plate of the valve port and the top of the support, holes for threading the pull rope are distributed in the partition plate, a locating rod is arranged below the partition plate, the locating rod is connected with a cylinder, the cylinder is mounted on the side edge of the support, and marking lines are arranged at the two sides of the valve port. The ore pulp slide damper is simple and reasonable in structure, convenient to open and close, easy to realize, safe and convenient to locate and easy to control and operate. The valve plate is wear-resistant and is longer in service life than a rubber valve or a gate valve, so that change times is reduced.

Owner:SHANDONG HUALIAN MINING

High-strength wear-resistant environmental-friendly plastic and preparing method thereof

Owner:ANHUI GUANGYUAN TECH DEV

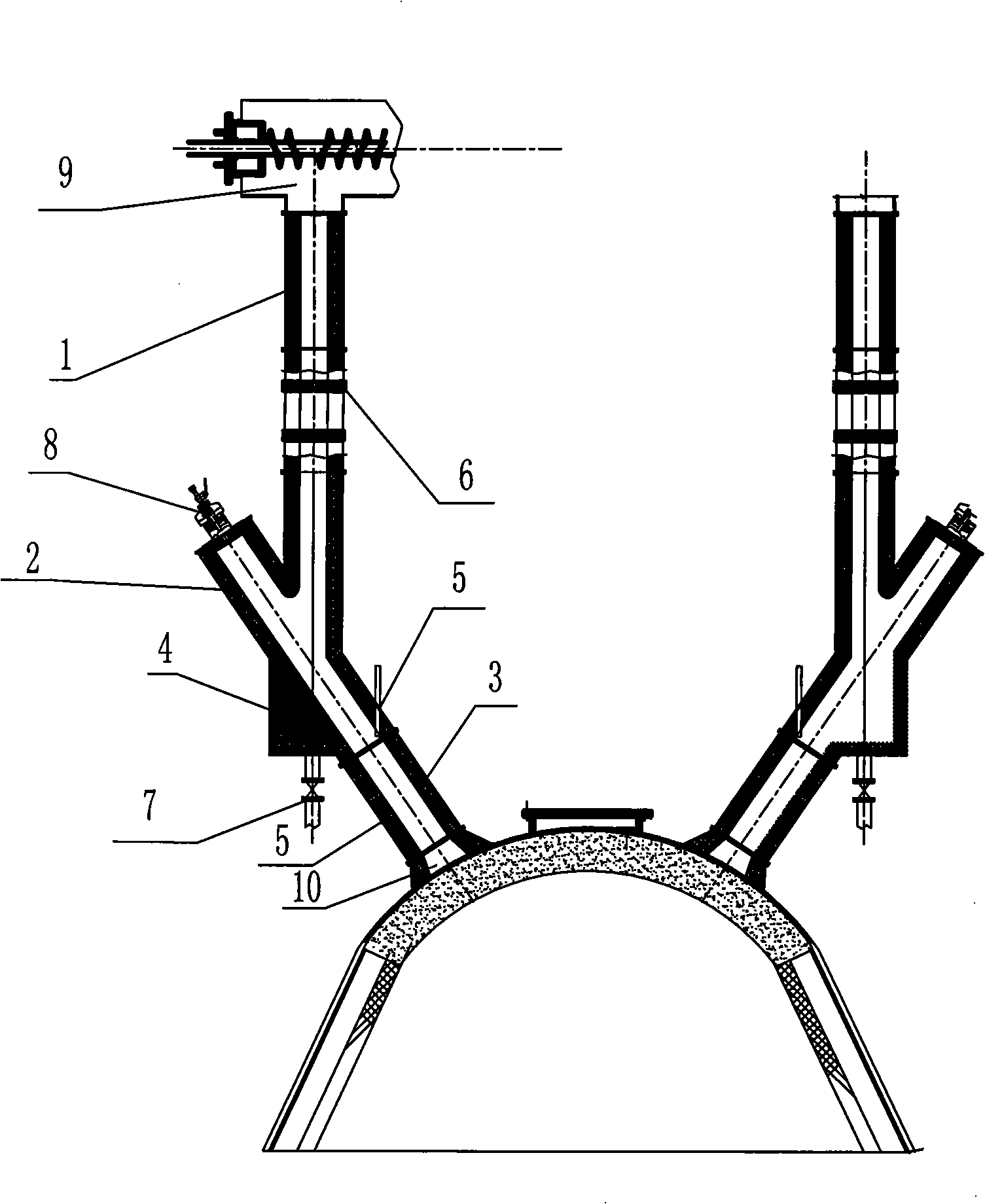

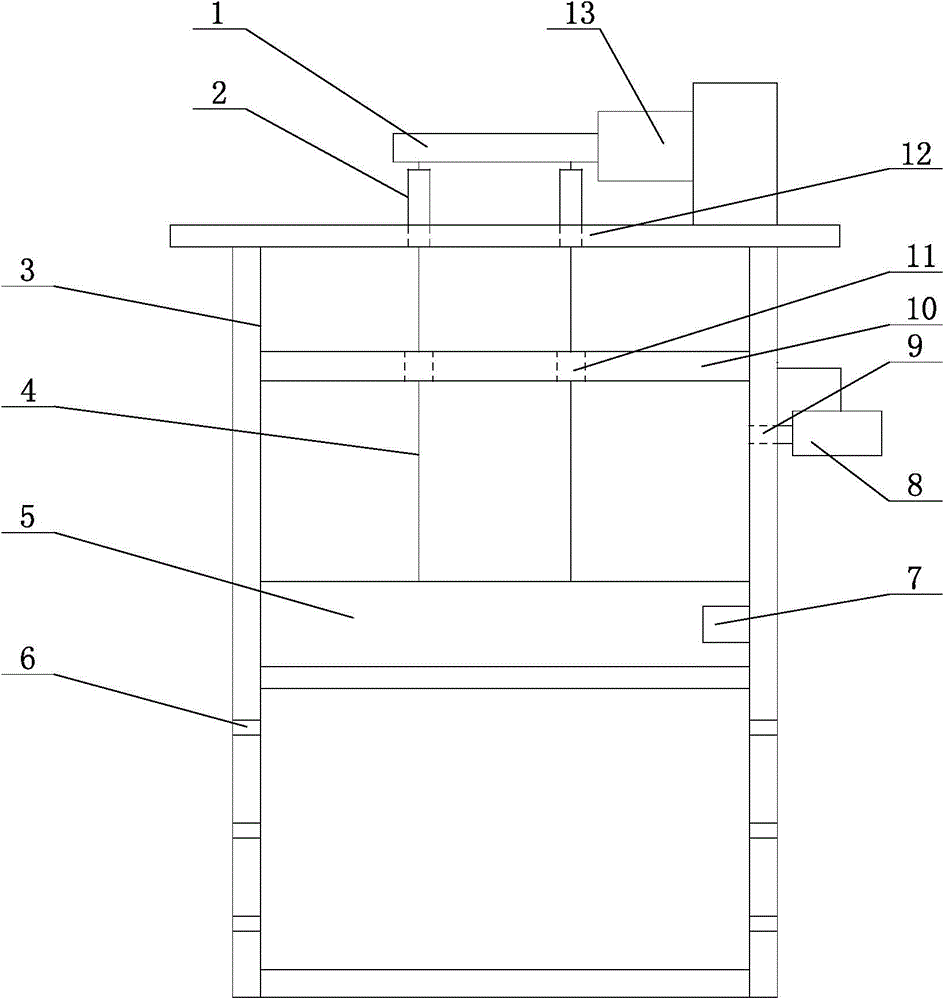

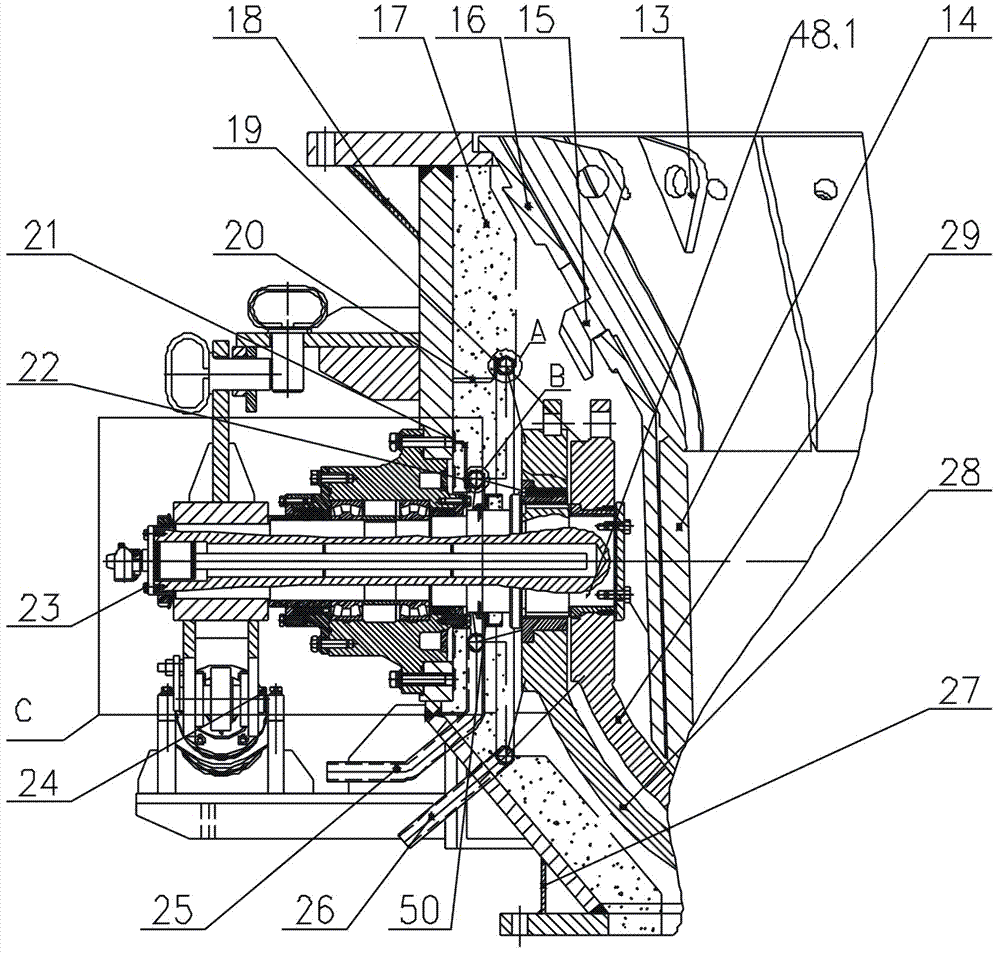

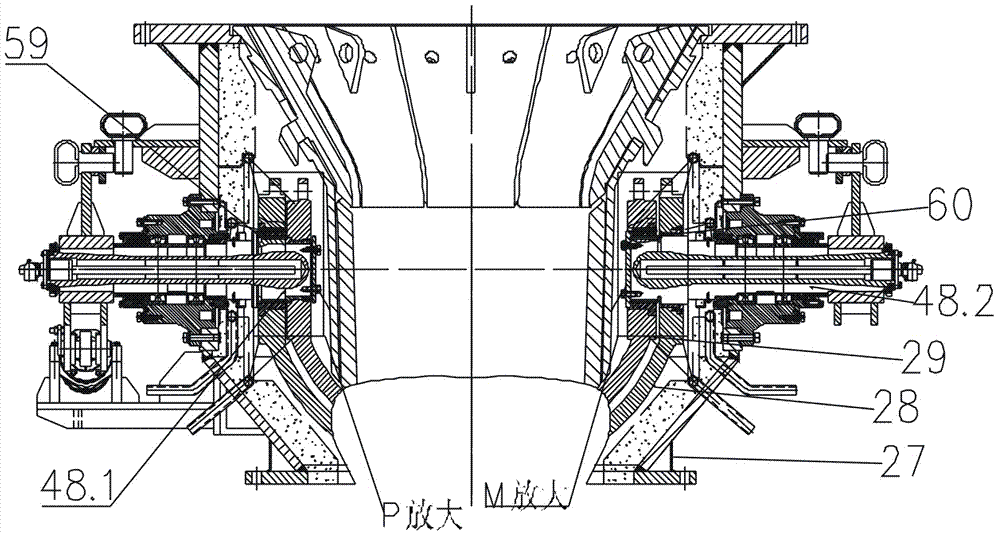

Blast furnace charge-flow adjusting valve device suitable for high-temperature furnace charge

ActiveCN102925604AAchieve design functionReduce local temperatureBell-and-hopper arrangementWear resistantDrive shaft

Owner:WISDRI ENG & RES INC LTD

Heat processing technology method of austenitic ductile iron wear-resistant casting

Owner:NINGGUO HUAFENG WEAR RESISTANT MATERIAL

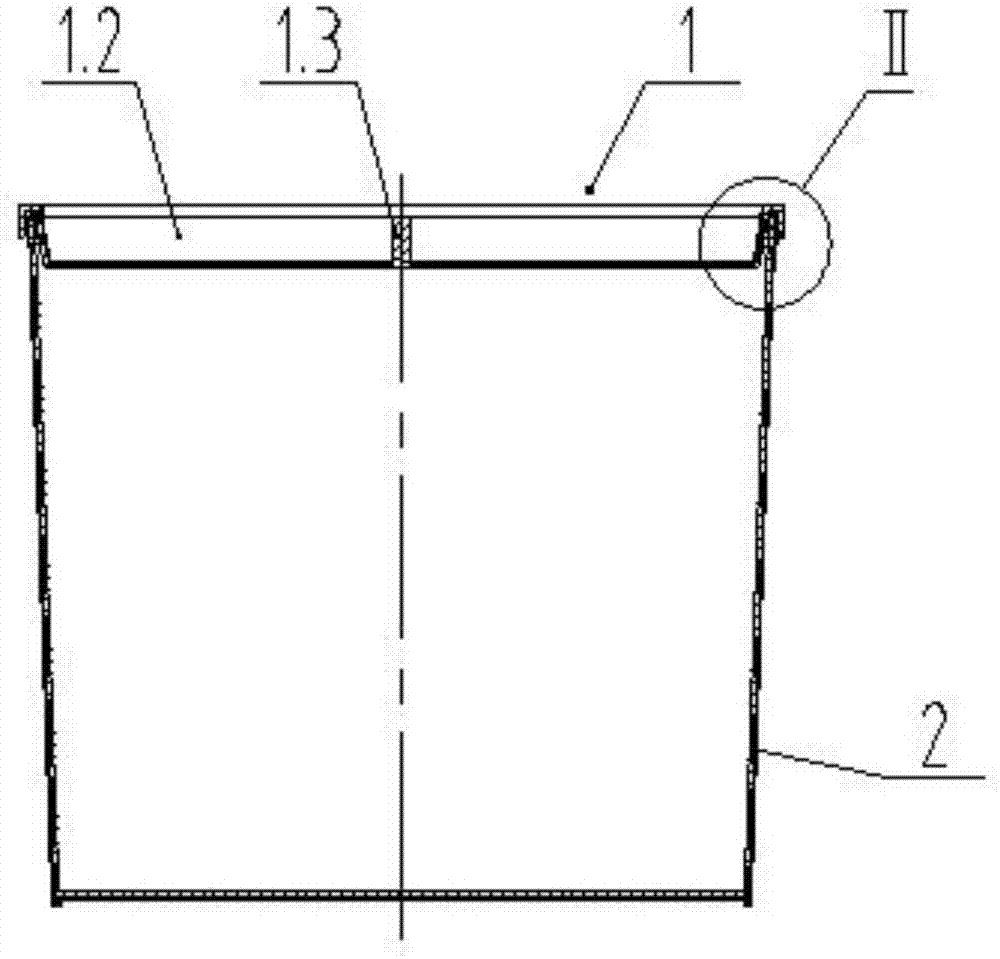

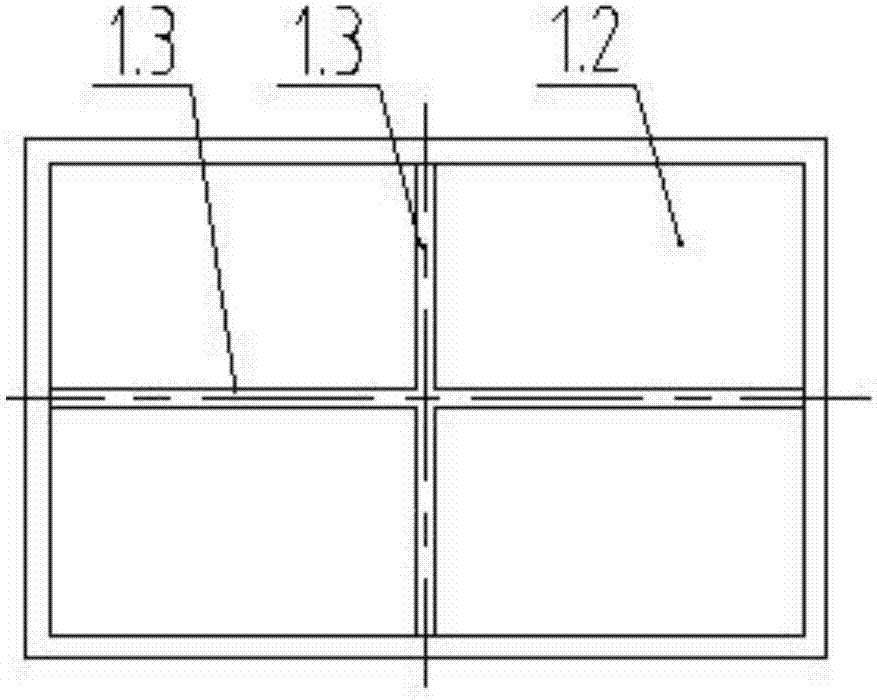

High-performance wood plastic composite packing case

InactiveCN107399484AImprove wear resistanceExtended service lifeSynthetic resin layered productsRemovable lids/coversMulti materialWear resistant

Owner:QIHANG PLASTIC JIANGSU

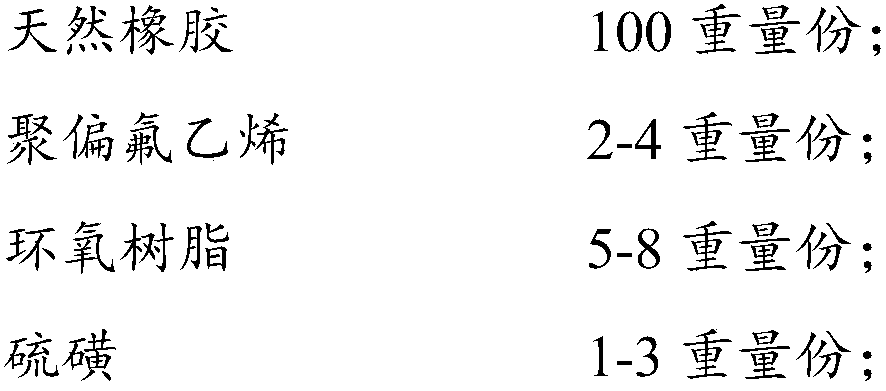

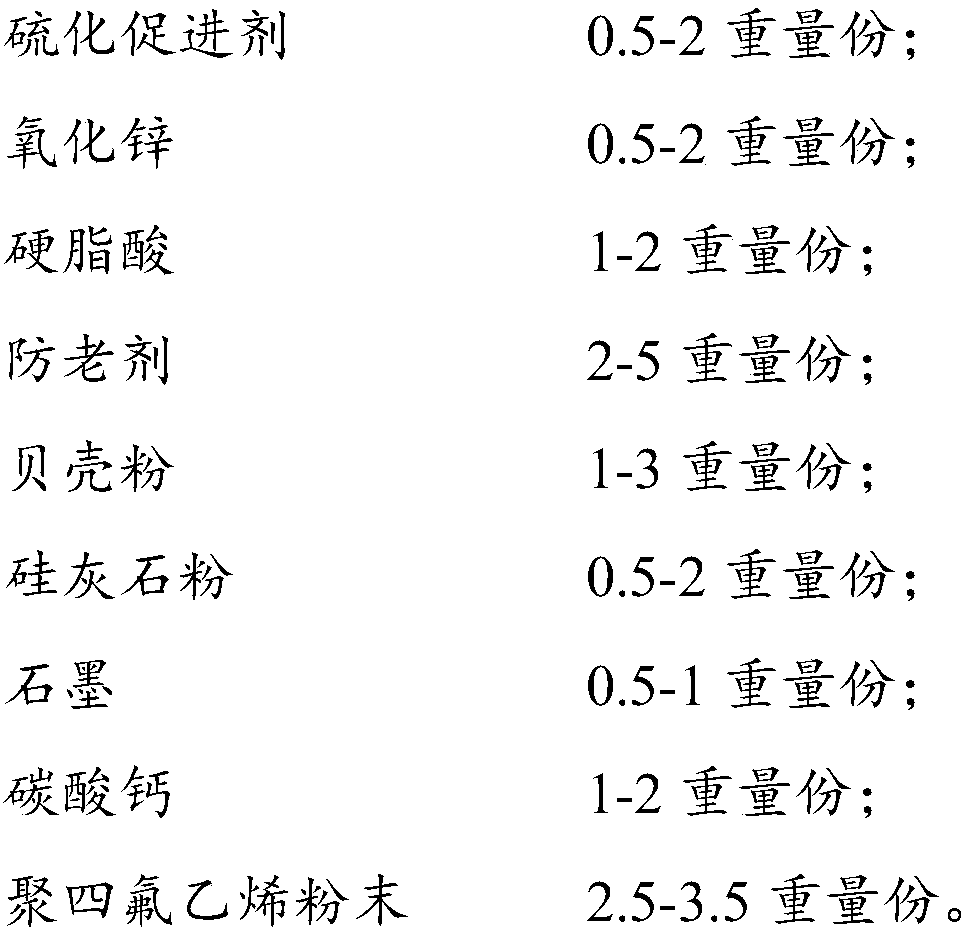

Heat-resistant and wear-resistance natural rubber composite material and preparation method thereof

Owner:长春智享优创科技咨询有限公司

Alloy powder for plasma cladding

PendingCN109735842AImprove performanceGood workmanshipMetallic material coating processesWear resistantAlloy

Owner:WEIFANG UNIVERSITY

Method for preparing coarse granularity chromium carbide powder

ActiveCN108046259AMeet wear resistanceCorrosiveCarbon compoundsChemical industryAdhesiveWear resistant

Owner:锦州市金属材料研究所

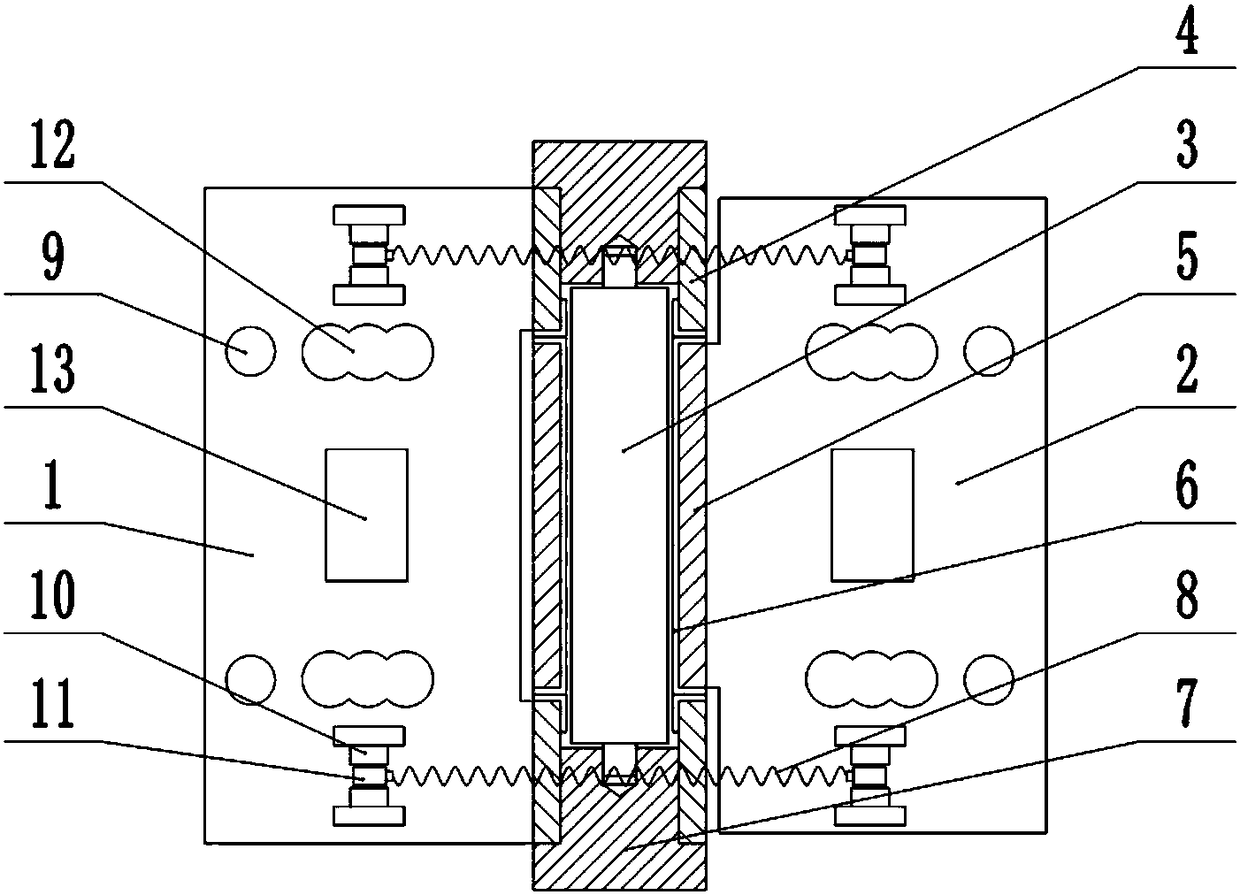

Hinge with spring-back function

InactiveCN108086833AImprove wear resistanceFunction increasePin hingesWing openersWear resistantEngineering

Owner:TIANJIN GUTE METAL PROD

Nylon enhanced rubber conveyer belt

InactiveCN101879979AExtended service lifeOptimize the process routeConveyorsProduction lineNylon material

Owner:XIANGFAN ABSB AUTOMOBILE ABSORBER

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap