High-molecular self-lubricating material, preparation method of high-molecular self-lubricating material, and plate spring flanged bushing made of high-molecular self-lubricating material

A technology of self-lubricating materials and polymers, applied in vehicle springs, elastic suspensions, transportation and packaging, etc., can solve the problems of increasing the use of non-standard parts of the whole vehicle, complex bushing structure, and affecting service life, etc., to achieve dimensional stability Excellent performance, good wear resistance, and the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

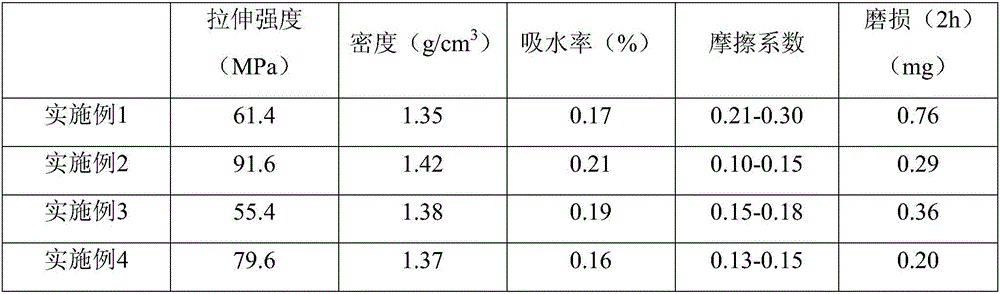

Embodiment 1

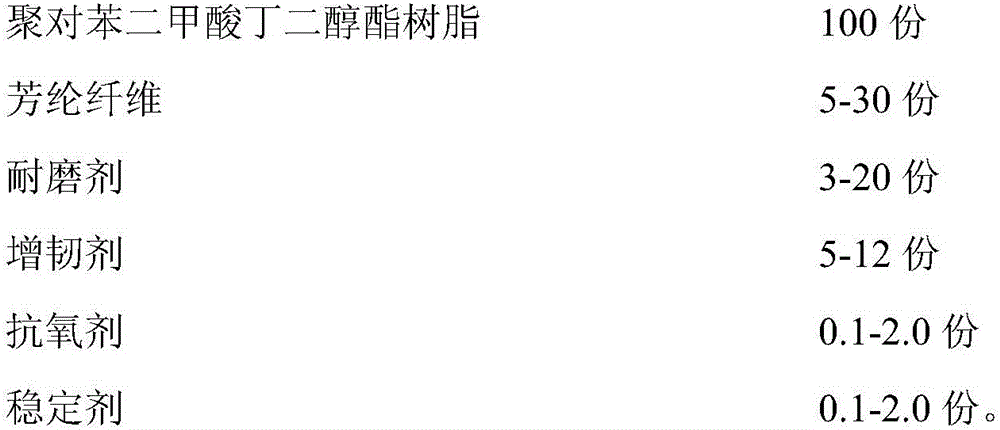

[0028] An embodiment of the polymer self-lubricating material and its preparation method, and the leaf spring lug bush made of the polymer self-lubricating material of the present invention, the polymer self-lubricating material includes the following components in parts by weight: 100 Parts of polybutylene terephthalate resin, 5 parts of aramid long fiber, 3 parts of polytetrafluoroethylene (PTFE, wear-resistant agent), 5 parts of EPDM rubber (EPDM, toughening agent), 0.1 part Antioxidant and 0.1 part stabilizer.

[0029] The polymer self-lubricating material is prepared by the following method:

[0030] (1) Put the polybutylene terephthalate resin in an oven and dry it at 120°C for 4 hours, then take 100kg of dried polybutylene terephthalate resin, 3kg of polytetrafluoroethylene, 5kg of three Yuan ethylene propylene rubber, 0.1kg antioxidant and 0.1kg stabilizer are placed in a high-speed mixer for mixing for 15 minutes;

[0031] (2) Add the material after the mixing in step

Embodiment 2

[0035] An embodiment of the polymer self-lubricating material and its preparation method, and the leaf spring lug bush made of the polymer self-lubricating material of the present invention, the polymer self-lubricating material includes the following components in parts by weight: 100 Parts of polybutylene terephthalate resin, 30 parts of aramid staple fiber, 10 parts of polytetrafluoroethylene, 10 parts of graphite, 12 parts of ABS resin, 2.0 parts of antioxidant and 2.0 parts of stabilizer.

[0036]The polymer self-lubricating material is prepared by the following method:

[0037] (1) Put the polybutylene terephthalate resin in an oven and dry it at 110°C for 6 hours, then take 100kg of dried polybutylene terephthalate resin, 10kg of polytetrafluoroethylene, and 10kg of graphite 12kgABS resin (acrylonitrile-butadiene-styrene copolymer), 2.0kg antioxidant and 2.0kg stabilizer are placed in a high-speed mixer and mixed for 10min;

[0038] (2) Add the material after the mixing i

Embodiment 3

[0042] An embodiment of the polymer self-lubricating material and its preparation method, and the leaf spring lug bush made of the polymer self-lubricating material of the present invention, the polymer self-lubricating material includes the following components in parts by weight: 100 Parts of polybutylene terephthalate resin, 20 parts of aramid fiber powder, 10 parts of polytetrafluoroethylene, 5 parts of molybdenum disulfide, 8 parts of EPDM rubber, 1 part of antioxidant and 1 part of stabilizer.

[0043] The polymer self-lubricating material is prepared by the following method:

[0044] (1) Put polybutylene terephthalate resin in an oven and dry at 110°C for 6 hours, then take 100kg of dried polybutylene terephthalate resin, 10kg of polytetrafluoroethylene, 5kg of Molybdenum sulfide, 8kg EPDM rubber, 1kg antioxidant and 1kg stabilizer were placed in a high-speed mixer and mixed for 10 minutes;

[0045] (2) Add the material after the mixing in step (1) to the twin-screw extru

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap