Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "High tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable tissue retractor

InactiveUS6936005B2High tensile strengthEasily grasped and moved and stabilizedSuture equipmentsSurgical needlesLess invasive surgeryForceps

This invention describes novel methods and devices for stabilizing and retracting tissue during surgery, in particular internal tissue. Patches of material, preferably biodegradable, are adhered to tissue surfaces. By manipulation of the patches, for example directly with forceps, or via sutures attached to the patches, tissues can be retracted or otherwise manipulated with minimal trauma to the tissues. The method is especially useful in minimally-invasive surgery.

Owner:FOCAL INC

Method for casting rotary axis casts of aerogenerators

ActiveCN101618425AImprove yieldReduce manufacturing costFoundry mouldsFoundry coresMetallurgyBlock effect

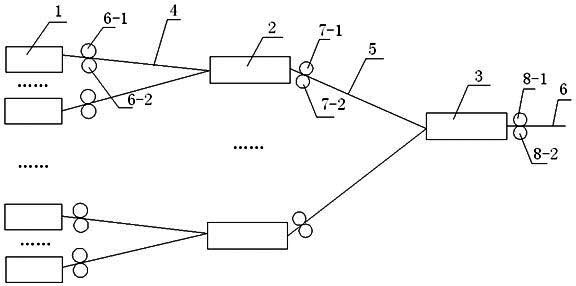

The invention discloses a method for casting rotary axis casts of aerogenerators, which comprises the steps of mould manufacture, the manufacture of sand moulds and moulding by casting. In the step b of the manufacture of sand moulds, a top sprue (1) is used as an inlet of iron liquor, and is alternately communicated with runners; a bottom runner is communicated with an ingate communicated with a cast mould cavity; the runners are designed into a first runner (3), a second runner (4) and a circular runner (5); the ingate is designed into a plurality of radial runners (6) for communicating the circular runner (5) and the cast mould cavity; filtering apparatuses are arranged on the first runner (3) and the second runner (4), and are also arranged between each radial runner (6) and the circular runner (5); and in the step c of moulding by casting, the casting temperature is controlled from 1310 DEG C to 1350DEG C; and finally, a cast (2) is obtained. The method for casting rotary axis cast of aerogenerator has the advantages of good residue blocking effect and low production cost.

Owner:RIYUE HEAVY IND

Annular super-hard abrasive wire and method for manufacturing same

ActiveCN102873401AUniform particle distributionHigh tensile strengthMetal sawing tool makingElectrical conductorHigh intensity

The invention discloses an annular super-hard abrasive wire and a method for manufacturing the same. The annular super-hard abrasive wire comprises a rope, super-hard abrasive particles and a coating, wherein the size of the rope ranges from 0.1mm to 6mm, the super-hard abrasive particles are solidified on the surface of the rope, and the coating is used for solidifying the super-hard abrasive particles. The method for manufacturing the annular super-hard abrasive wire includes braiding the thin rope to form a ring with an optional perimeter; and then solidifying the super-hard abrasive particles on the surface of the annular rope by means of coating to form the high-strength annular super-hard abrasive wire with the uniform outer diameter and a long service life. The annular super-hard abrasive wire is low in cost, high in fatigue strength, long in service life, good in cutting quality and high in cutting efficiency, and a cutting machine with the annular wire can be used for cutting conductors, semiconductors and non-conductor materials.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

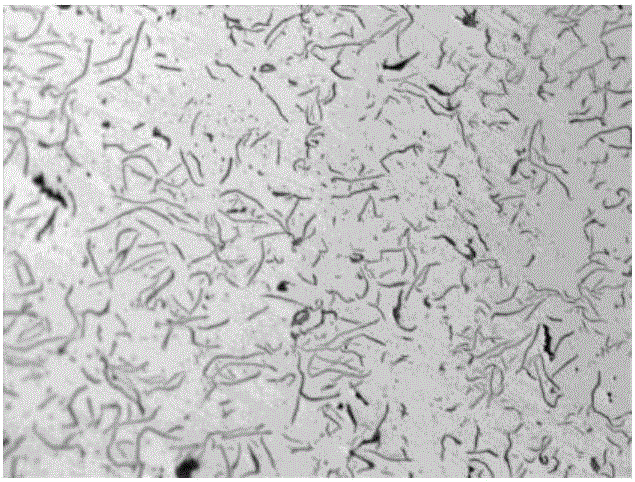

Preparation method of sheepskin collagen casing

The invention discloses a preparation method of a sheepskin collagen casing. The preparation method comprises raw sheepskin immersion in water and washing, liming hair removal, hydrogen peroxide treatment, primary pickling, mincing and beating, compounding, secondary pickling, homogenization and filtration, extrusion and curing, water washing and plastification, UV crosslinking, drying and humidification. The preparation method realizes the comprehensive utilization of bur sheepskin, prevents the waste of resources and the pollution of the environment and can produce huge economic and social benefits.

Owner:INNER MONGOLIA QIUSHI BIOLOGICAL CO LTD

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

High-toughness and corrosion-resistant aluminum alloy profile for aerospace and preparation method thereof

Owner:NORTHEAST LIGHT ALLOY CO LTD

Ultra-low carbon martensitic stainless steel seamless tube and manufacturing method thereof

InactiveCN108277438AHigh tensile strengthHigh yield strengthFurnace typesHeat treatment furnacesMartensitic stainless steelHigh pressure

The invention discloses an ultra-low carbon martensitic stainless steel seamless tube. The ultra-low carbon martensitic stainless steel seamless tube is prepared from ultra-low carbon martensitic stainless steel. The ultra-low carbon martensitic stainless steel is prepared from the following components in percentage by mass: less than or equal to 0.03% of C, 0.1-0.5% of Si, 0.2-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 12.2-13.2% of Cr, 5.2-5.7% of Ni, 1.9-2.1% of Mo, 0.1-1.6% of Cu and the balance of Fe and other impurities. The seamless tube can be suitable for oil and gas fields. The invention also provides a manufacturing method of the seamless tube. The manufacturing method comprises the following steps: smelting; tube blank thermal processing;steel tube thermal processing; and thermal treatment, wherein the heating temperature of tube blank thermal processing is 1200-1280 DEG C, the heating temperature of tube manufacturing by means of anextruding method is 1150-1250 DEG C, the heating temperature of tube manufacturing by means of a perforating cold rolling method is 1200-1280 DEG C, and the temperatures for thermal treatment are as follows: quenching at 900-1050 DEG C and tempering at 550-680 DEG C. The seamless tube provided by the invention has excellent strength and corrosion resistance in a CO2 and Cl<-> coexisting corrosionenvironment and in high-temperature and high pressure conditions.

Owner:TAIYUAN IRON & STEEL (GRP) CO LTD

Method for preparing temperature-resistant high-molecular elastic leakproof rubber capable of enhancing safety property of automobile tyre

InactiveCN103834359AEasy to operateHigh tensile strengthAdhesivesOther chemical processesAntioxidantHot Temperature

Owner:LUOYANG JUNTENG ENERGY TECH +1

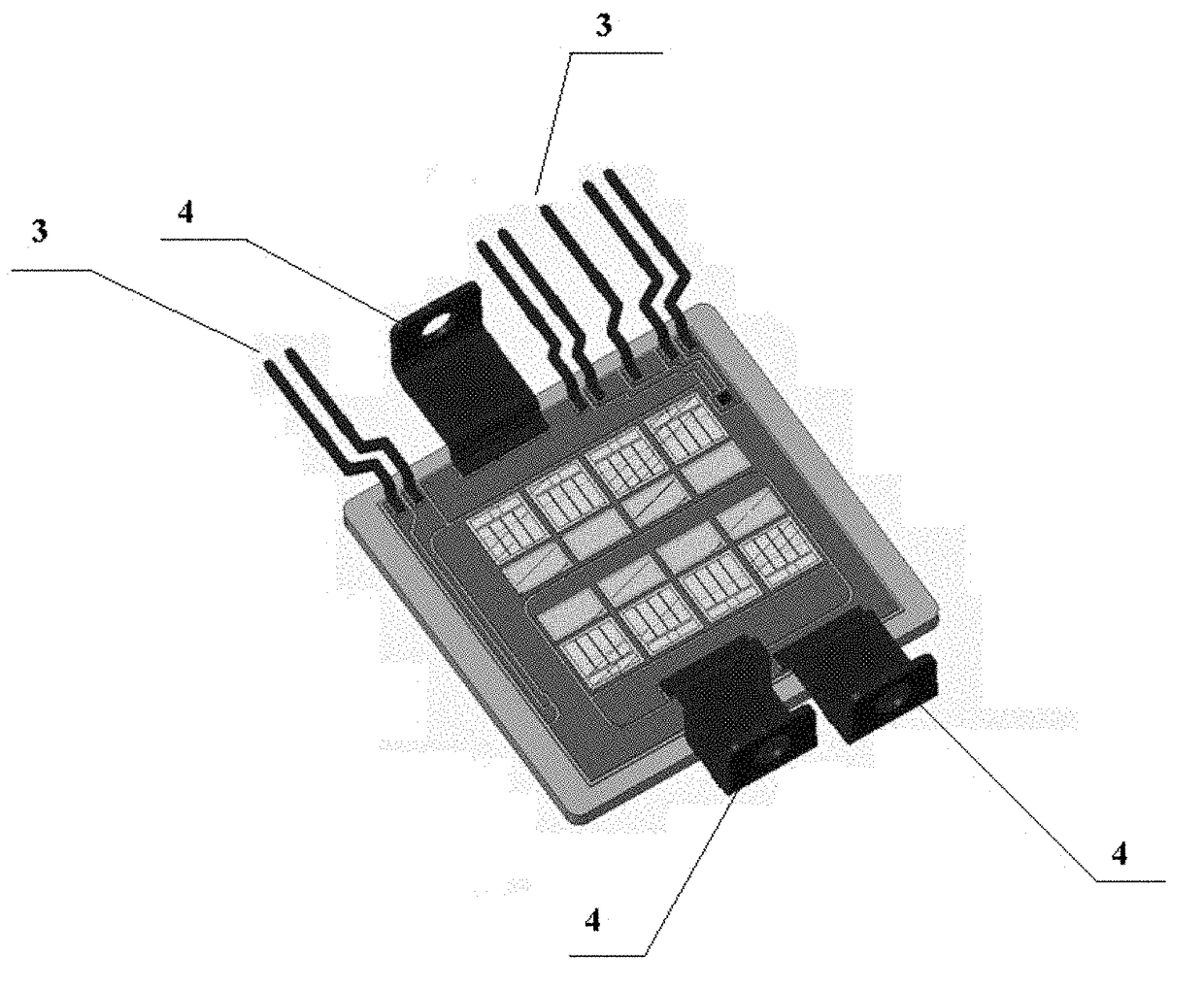

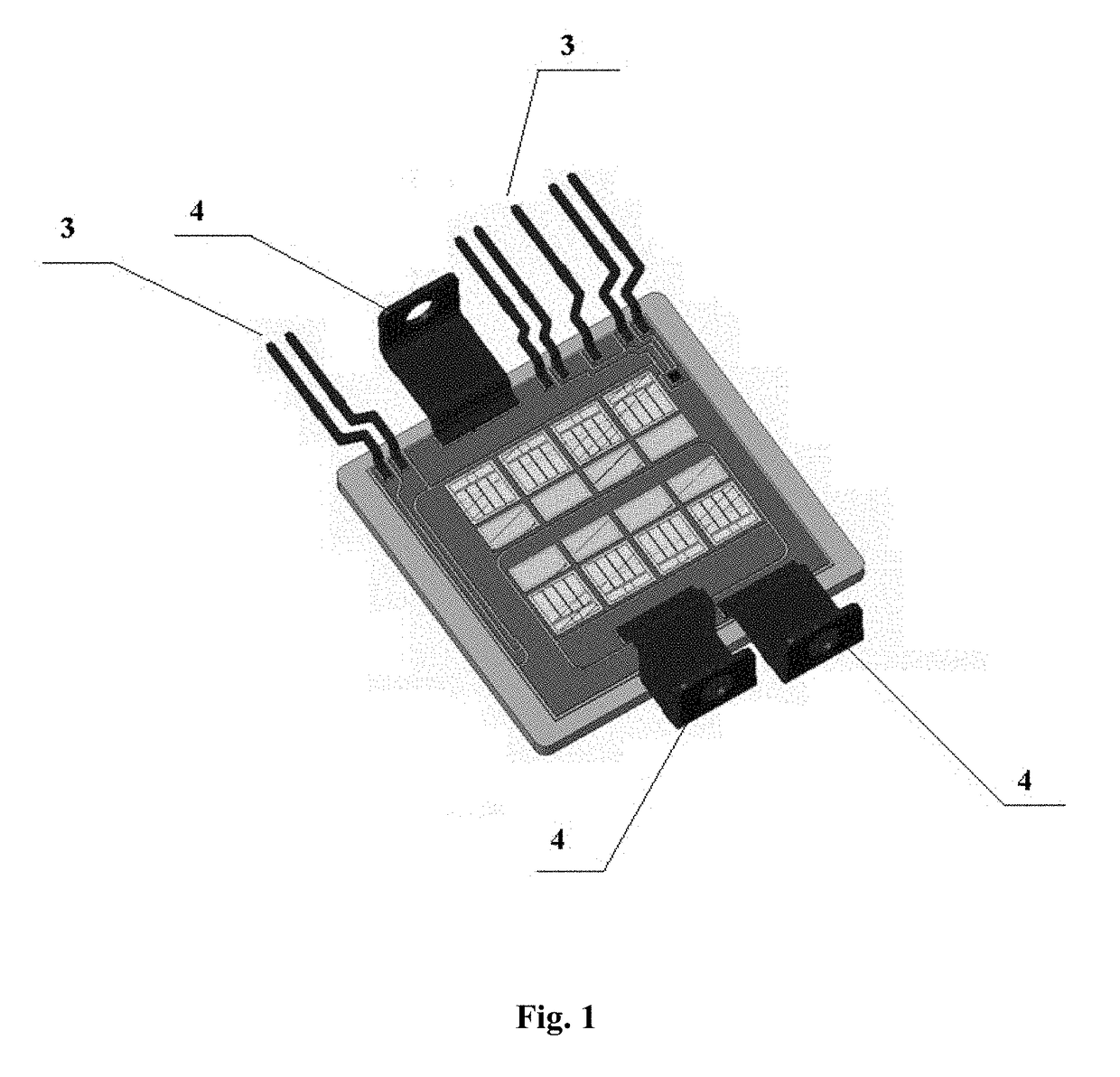

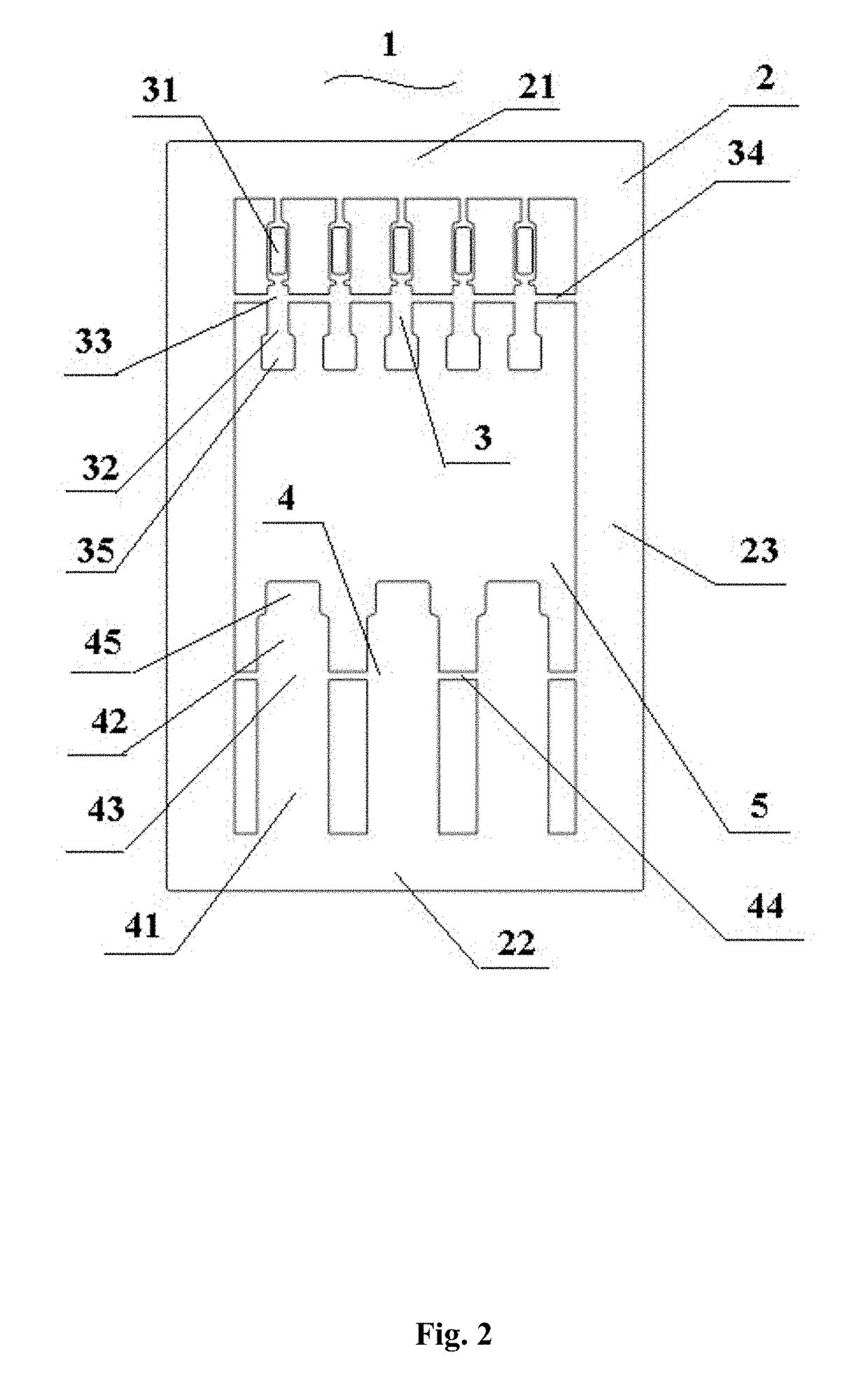

Lead frame and method of fabricating the same

ActiveUS20180012828A1High tensile strengthGood electrical conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringCopper

Owner:DANFOSS SILICON POWER

Special high-strength modified phenolic resin adhesive for precoated sand and preparation method of special high-strength modified phenolic resin adhesive

InactiveCN105348461AImprove pass rateImprove toughnessFoundry mouldsFoundry coresPolymer sciencePtru catalyst

The invention provides a special high-strength modified phenolic resin adhesive for precoated sand and a preparation method of the special high-strength modified phenolic resin adhesive. The adhesive comprises phenol, formaldehyde, a catalyst, a modifier 1, a modifier 2 and silane, wherein the mole ratio of phenol to formaldehyde is 1:(0.7-0.8), the adding quantity of the modifier 1 accounts for 3%-30% of the mass of phenol, the adding quantity of the modifier 2 accounts for 0.5%-10% of the mass of phenol, and the adding quantity of silane accounts for 0.3%-0.8% of the mass of phenol. The preparation method is simple and convenient to operate, and reduction of the enterprise cost and promotion of energy saving and emission reduction are facilitated. The adhesive and the preparation method can be applied to the field of adhesives.

Owner:ZHUHAI DOUMEN FULIAN MOLDING MATERIALS IND CO LTD

Preparation technique of complex fungicide repairing amino acid fermenting wastewater

ActiveCN104891677ALarge specific surface areaHigh tensile strengthBiological water/sewage treatmentFungicideEngineering

Owner:内蒙古阜丰生物科技有限公司

Stretch-proof and easily-degradable plastic bag and preparation method thereof

ActiveCN112457615AHigh tensile strengthImprove stretch mildly lowBio-packagingBall millCITRATE ESTER

Owner:深圳市正旺环保新材料有限公司

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

Antistatic polypropylene fiber and nylon composite superfine fiber and production method thereof

ActiveCN103320892AGood drawing performanceHigh tensile strengthArtifical filament manufactureConjugated synthetic polymer artificial filamentsCerium oxideCoating

Owner:桐乡市来得宝家纺股份有限公司

Modified graphene reinforced magnesium matrix metal material and preparation method thereof

The invention discloses a modified graphene reinforced magnesium matrix metal material and a preparation method thereof. The modified graphene reinforced magnesium matrix metal material comprises the following components in percentages by mass: 0.02-0.5wt% of modified graphene, 5.9-11.2wt% of copper, 1.2-4.6wt% of silicon dioxide, 1.4-5.6wt% of aluminum oxide, 1.3-7.8wt% of carbon nanotubes, 4.5-7.9wt% of nickel, 1.3-3.8wt% of titanium dioxide, 1.3-4.6wt% of lanthanum oxide and the balance of magnesium. The mechanical property of the modified graphene reinforced magnesium matrix metal material can still be good at the temperature of minus 20 DEG C; and the performance parameters such as the tensile strength and the elongation of the magnesium matrix metal material are increased, and are higher than the performance parameters of commercial alloy by 7-11%.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Preparation method for degradable polysaccharide-based hemicellulose composite biomembrane

InactiveCN104262658AHigh tensile strengthReduce water vapor permeabilityBiodegradationComposite membrane

Owner:GUANGXI UNIV

High-strength silver-free copper-based brazing filler metal

InactiveCN104889598ALow melting pointHigh tensile strengthWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalCopper

The invention discloses a high-strength silver-free copper-based brazing filler metal which is composed of P, Sn, Ni and Cu. The high-strength silver-free copper-based brazing filler metal is low in cost, safe, environmentally friendly and good in welding effect; through the adding of Sn and Ni, the melting point of brazing filler metal alloy is reduced, and the tensile strength and wettability of the brazing filler metal alloy are enhanced.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Suspending swing arm assembly

InactiveCN102745033AGood securityHigh tensile strengthPivoted suspension armsMagnesium alloyRoad condition

Owner:SHAOXING UNIVERSITY

Fixed-size production equipment of steel rope

InactiveCN102002874AHigh tensile strengthImprove efficiencyRope making machinesProgrammable logic controllerEngineering

Owner:JIANGSU JULI WIRE ROPE

PC/PMMA composite material and preparation method thereof

InactiveCN110607063AImprove physical performanceHigh tensile strengthHeat deflection temperatureThermal deformation

Owner:SICHUAN LONGHUA FILM CO LTD

Environment-friendly plastic material and preparation method thereof

The invention discloses an environment-friendly plastic material and a preparation method thereof. The preparation method comprises the following steps that 1, ball milling is performed on calcium sulfate and magnesium oxide through a ball mill, the ball milling time is 3-5 h, and the ratio of grinding media to the materials is 20:1-30:1; 2, 12-20 parts of polyamide-1010, 5-10 parts of polycarbonate, 4-9 parts of alkyd resin, 4-8 parts of polyvinyl alcohol, 3-8 parts of calcium sulfate, 4-10 parts of magnesium oxide, 2-6 parts of polytrimethylene terephthalate, 3-8 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 2-6 parts of polybutyl methacrylate and 4-10 parts of polyparahydroxybenzoic acid are weighed by weight, all the components are extruded inside a double-screw extruder, and the extruded components are the environment-friendly plastic material. The obtained plastic material effectively overcomes the defects that the tensile strength and the elongation at break of the conventional plastic material are low, and the mechanical performance of the plastic material is improved.

Owner:SUZHOU SHURUI ENVIRONMENTAL PROTECTION TECH CO LTD

Organic silicon electronic potting adhesive for PCB circuit board with stable dielectric insulation performance

InactiveCN106634810AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricAdhesive

The invention discloses an organic silicon electronic potting adhesive for a PCB circuit board with stable dielectric insulation performance. The organic silicon electronic potting adhesive is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12% of a platinum catalyst, 0.02 to 0.04 part of acetenyl cyclohexanol, 25 to 30 parts of vinyl silicon resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-epoxypropane, 23 to 25 parts of 1,3,5,7-tetramethyl cyclotetrasiloxane, 2.7 to 3.6 parts of a silane coupling agent A171, an appropriate amount of silicon-containing silicon oil, 2.6 to 3 parts of mica powder, 1.8 to 3 parts of porcelain powder, 0.2 to 0.3 part of dimethyl silicone polymer, 4.6 to 5 parts of carboxylated latex, 1.1 to 1.6 parts of polyvinyl alcohol and an appropriate amount of deionized water. The potting adhesive disclosed by the invention has high heat conduction, dielectric insulation, impact resistance and adhesive performance, is high in fluidity, and is extremely suitable for potting electronic products.

Owner:TONGLING ONBOLE PCB CO LTD

Moisture-proof lead-free soldering nylon 46 composite material and preparation method thereof

InactiveCN102942785AImprove high temperature resistanceHigh tensile strengthGlass fiberMixed materials

The invention relates to a moisture-proof lead-free soldering nylon 46 composite material and a preparation method thereof. The nylon 46 composite material comprises the following components by weight: 40.4-89.2% of PA46 resin, 5-15% of PPO resin, 0-5% of a compatibilizer, 0-45% of glass fiber and 1-2% of other assistants. The preparation method of the composite material is as follows: weighing each component according to the above weight, and drying the components; adding the dried PA46 resin, PPO resin, compatibilizer and assistants into a high-speed mixer for mixing; and adding the mixed materials into a double-screw extruder, adding glass fiber for reinforcement, and extruding for granulation. The composite material provided by the invention has excellent wet proof lead-free soldering performance and good mechanical properties, and can be applied to the preparation of connector of electronic and electrical products requiring lead-free soldering and preparation of high-temperature resistant automotive plastic parts, etc.

Owner:HUIZHOU HUAJU PLASTIC TECH CO LTD +1

Production method of DMC composite material

Owner:句容市久诺复合材料有限公司

Plant fiber recycled concrete block and preparation method thereof

InactiveCN105601185AHigh flexural strengthHigh tensile strengthSolid waste managementCementCompressive strength

Owner:HARBIN INST OF TECH

Bionic flexible grabbing device integrating adhesion and claw mixing contact

ActiveCN108501015AHigh tensile strengthImprove surface adaptabilityGripping headsAir pressure effectsBionics

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

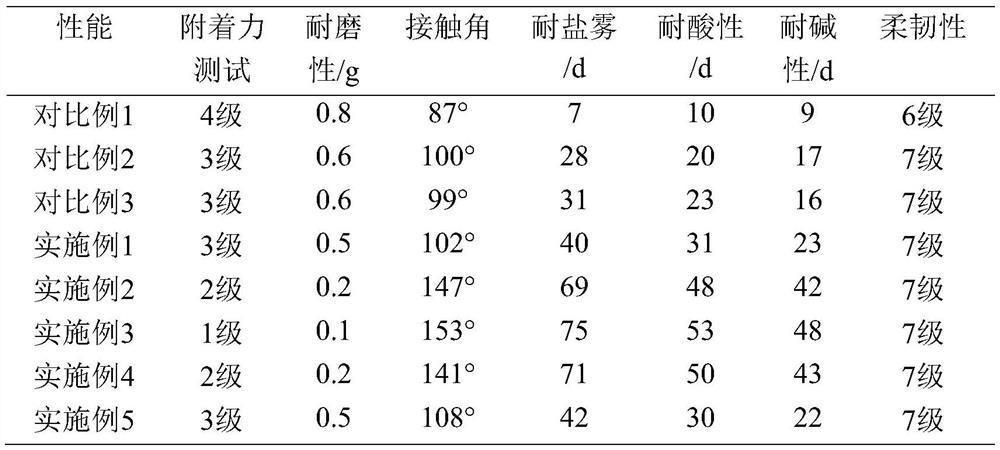

High-performance anti-corrosion composite coating material and preparation method thereof

ActiveCN113337212AHigh temperature control accuracyIncreased durabilityAnti-corrosive paintsAlkaline activationPolythylene glycol

The invention relates to a high-performance anti-corrosion composite coating material, which is prepared from the following components in parts by weight: 30 to 45 parts of a fluororesin monomer, 30 to 45 parts of a styrene monomer, 10 to 40 parts of a hexamethylcyclotrisiloxane monomer, 4 to 8 parts of polyethylene glycol octylphenol ether, 4 to 6 parts of polyethylene glycol, 3 to 8 parts of polyethylene glycol stearate, 20 to 30 parts of water glass 100 to 150 parts of fly ash, 2 to 4 parts of an initiator, 100 to 200 parts of water, 1 to 3 parts of defoaming powder, 5 to 10 parts of sericite powder, 0.2 to 0.5 part of a water reducing agent, 5 to 8 parts of a dispersing agent and 3 to 7 parts of a flatting agent. The invention further discloses a preparation method of the high-performance and high-corrosion-resistance composite coating material. According to the invention, a durability-improved modified fluororesin emulsion is synthesized and prepared in an efficient and environment-friendly mode, and the composite coating obtained after the modified fluororesin and the alkali-activated fly ash are fully mixed and stirred can effectively improve the compressive strength, tensile strength, low permeability, alkali resistance and good corrosion resistance of concrete.

Owner:HUBEI UNIV OF TECH

Wear-resistant flame-retardant TPU material and preparation method thereof

The invention relates to the technical field of TPU materials, and particularly discloses a wear-resistant flame-retardant TPU material and a preparation method thereof. The TPU material is prepared from the following raw materials in parts by weight: 60 to 100 parts of polyurethane, 15 to 30 parts of epoxy resin, 3 to 10 parts of di-o-chlorodiphenylamine methane, 20 to 50 parts of polyethylene, 10 to 28 parts of modified calcium sulfate dihydrate whisker, 10 to 28 parts of composite flame retardant and 2 to 6 parts of silicone oil. The preparation method comprises the following steps: uniformly mixing the silicone oil and the modified calcium sulfate dihydrate whisker to obtain a mixture A; uniformly mixing polyurethane, epoxy resin, di-o-chlorodiphenylamine methane and polyethylene to obtain a mixture B; then adding the composite flame retardant into the mixture B, and uniformly stirring to obtain a mixture C; finally, uniformly mixing the mixture A and the mixture C to prepare the wear-resistant and flame-retardant TPU material. The wear-resistant flame-retardant TPU material disclosed by the invention has the advantages of high wear resistance and high flame retardance.

Owner:RONGWEIDA OPTOELECTRONICS (DONGGUAN) CO LTD

Modified PVC (Polyvinyl Chloride) composite material and preparation method thereof

InactiveCN107474428AImprove creep resistanceImprove low temperature impact performancePlastic/resin/waxes insulatorsActive agentPolyvinyl chloride

The invention discloses a PVC (Polyvinyl Chloride) composite modified material and a preparation method thereof, relates to a PVC modified material and a preparation method thereof, and aims to solve the problems that a product surface is rough and lusterless as a conventional PVC modified material has a certain amount of unsaturated double bonds on a molecular chain, an active center can be formed and thus the ductility is low and a melt is easily crushed. The PVC composite modified material is prepared from the following components in parts by weight: a PVC resin, a low-temperature flexibilizer, an impact modifier, processing aids, a surfactant, a composite stabilizer, a covering agent, an initiator and a cross-linking agent. The preparation method comprises the following steps: I, weighing; II, premixing so as to obtain a premix; III, mixing at different steps so as to obtain mixtures of different steps; IV, performing final mixing so as to obtain a final mixture; and V, performing extrusion pelletizing, thereby obtaining the PVC composite modified material. The invention aims to prepare the PVC composite modified material.

Owner:WUHU PILOT NEW MATERIAL TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap