Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Composite coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite coating is the combination of two or more substances that offer protection against corrosion. This special type of coating is chiefly based on epoxy and polyurethane as well as resin. It is produced through state-of-the-art resin technology in order to meet the requirements of various industries.

Method for preparing diamond-like composite coating on surface of piston ring

InactiveCN101665940AImprove wear resistanceImprove the lubrication effectVacuum evaporation coatingSputtering coatingLow temperature plasmaMagnetic filtration

The invention relates to a method for preparing a diamond-like composite coating with high hardness and good abrasion proof and self lubricating properties on the surface of a piston ring. In the method, a nitriding layer with high bonding strength, high hardness and good abrasion resistance is formed on the surface of the piston ring by the low-temperature plasma nitriding treatment, a non-hydrogen diamond-like surface layer with solid lubricating property is deposited by the combination of magnetic filtration cathode arc and magnetic control sputtering, and finally the nitriding / diamond-likecomposite coating, which is dense and smooth and possesses excellent abrasion proof and self-lubricating properties, is obtained on the surface of the piston ring. Compared with the durionising piston ring or CrN plating piston ring, the coating of the piston ring of the invention has higher comprehensive performance.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

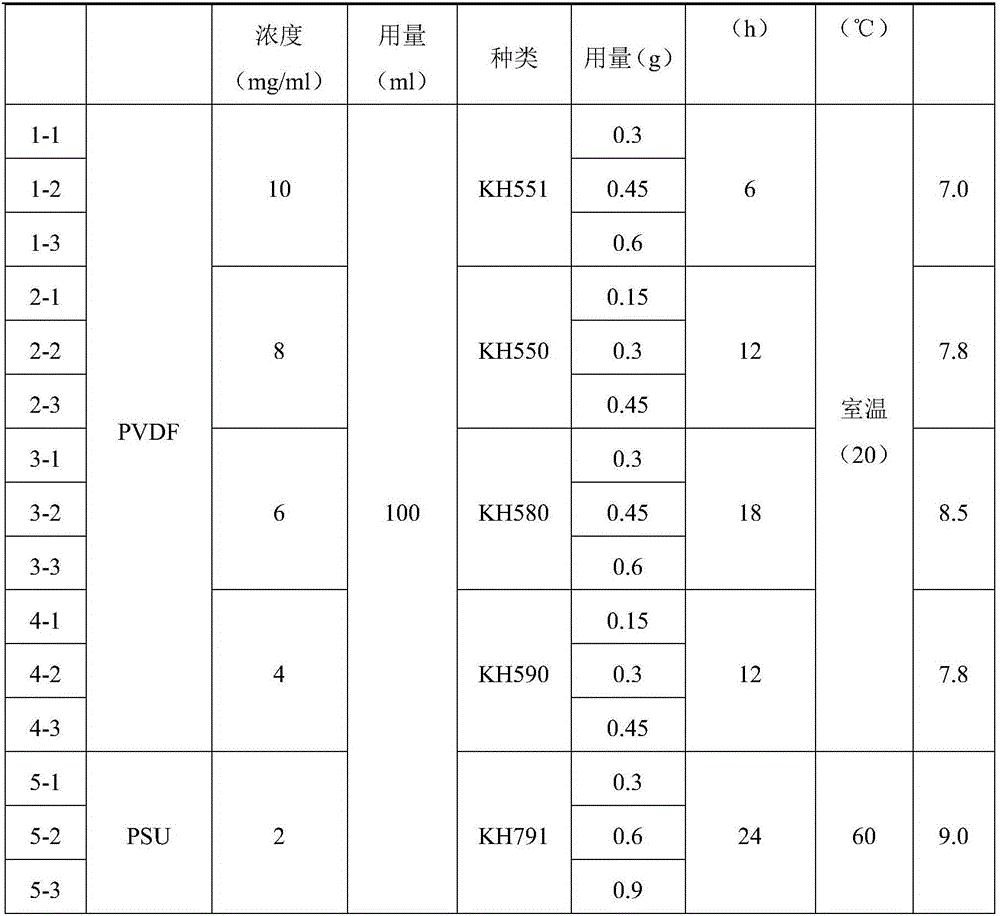

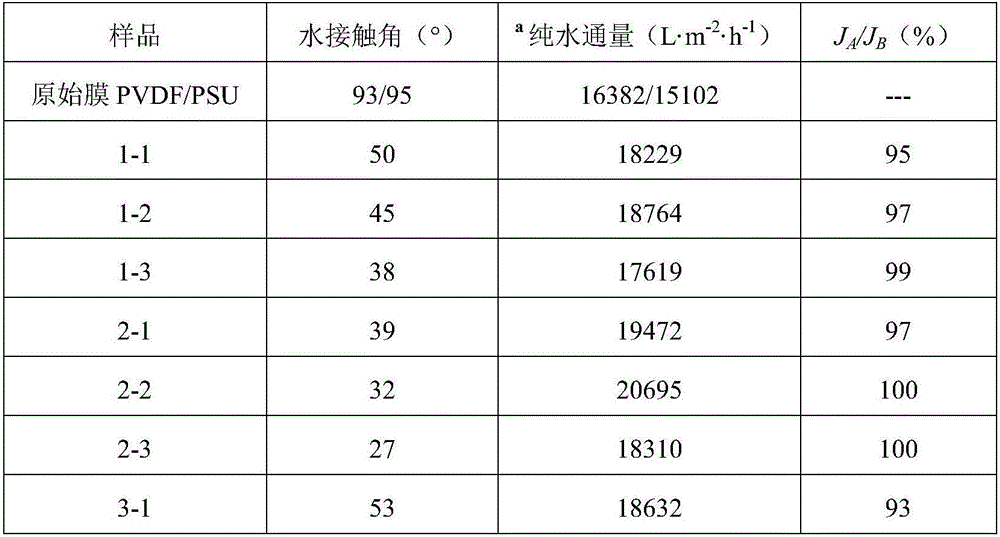

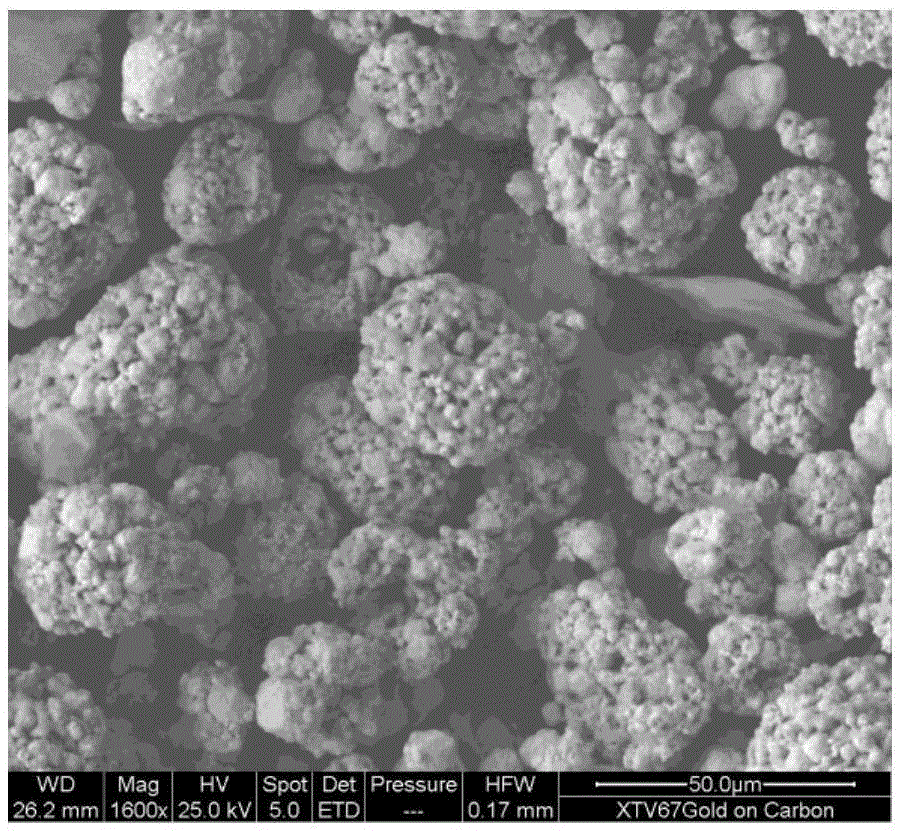

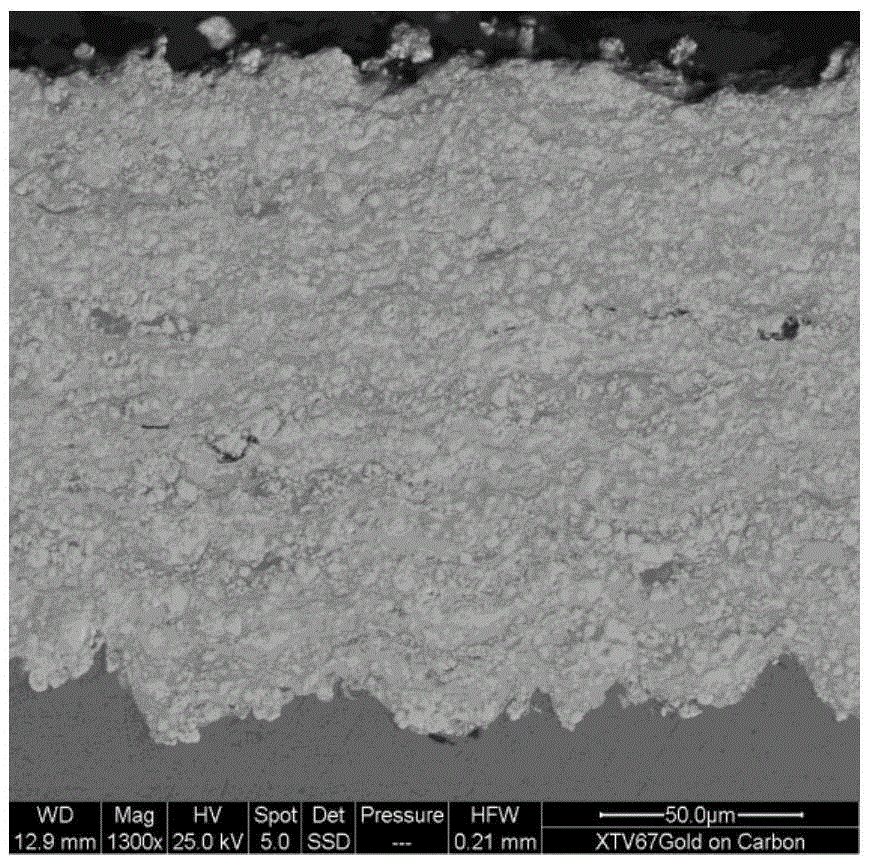

Hydrophobic polymer film composite coating hydrophiling modification method

ActiveCN106310958AImprove hydrophilicityImprove stabilityMembranesSemi-permeable membranesPolymer scienceHydrophobic polymer

Owner:WUHAN UNIV OF TECH

Preparation method for durable aluminum and aluminum alloy superhydrophobic surface coating

InactiveCN102527619AExtended service lifeGood antifoulingSpecial surfacesCoatingsSuperhydrophobic coatingPolypropylene

Owner:HUNAN UNIV OF TECH

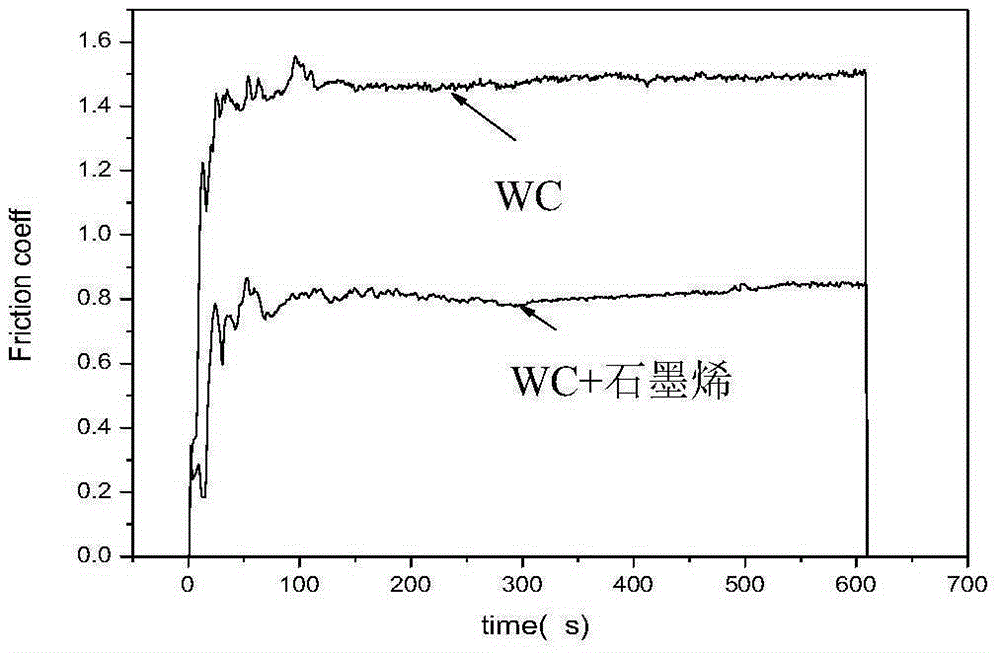

Graphene modified self-lubricating wear-resistant coating

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

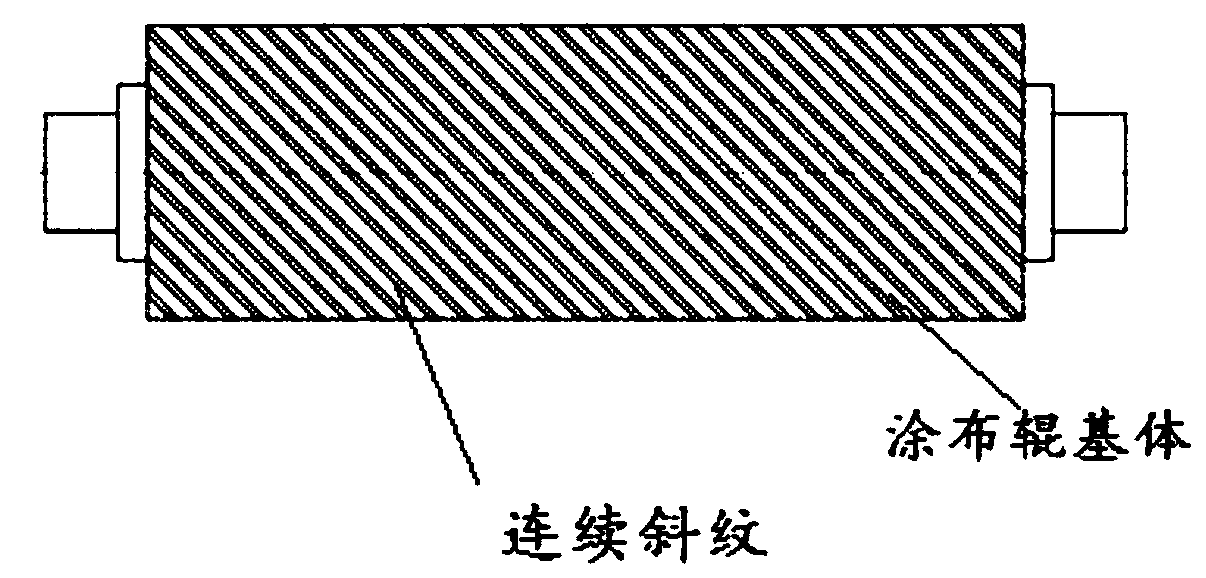

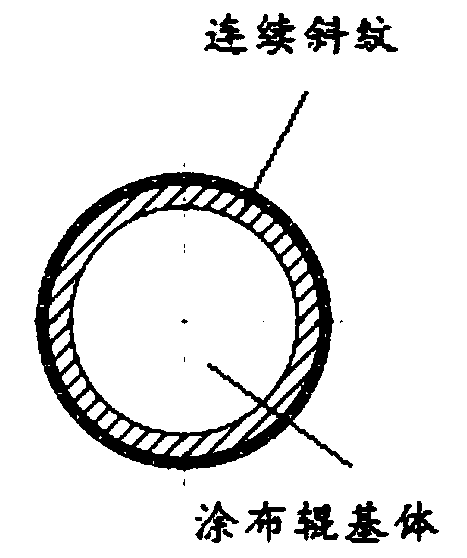

Coating roller, and application and preparation method thereof

PendingCN110280439AHigh hardnessImprove wear resistanceSpecial surfacesCoatingsHardnessWear resistance

Owner:GUANGDONG INST OF NEW MATERIALS +1

FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

InactiveCN112442187ARegulatory loadModulation of crosslink densityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceWater methanol

The invention belongs to the technical field of anticorrosive materials in a marine environment, and particularly relates to an FG-coated MOF composite material, a coating containing the composite material, and preparation methods and application of the composite material and coating. The preparation method of the coating comprises the following steps: dispersing FG in absolute methanol, carryingout ultrasonic oscillation, adding a metal salt and an imidazole ligand into an FG methanol dispersion liquid, conducting stirring to obtain a turbid liquid, carrying out centrifugal separation to obtain a solid, alternately conducting washing with methanol and deionized water, and carrying out vacuum drying to obtain an FG-coated MOF composite material; and mixing epoxy resin, the FG-coated MOF composite material and a diluent, carrying out ball-milling stirring, adding a curing agent, and conducting uniform mixing to obtain a composite coating. A composite coating layer is obtained by coating the surface of a pretreated metal matrix with the composite coating, and conducting drying and curing. The epoxy resin is modified by the FG-coated MOF composite material, so that an imidazole ringin the composite material is chemically bonded with the epoxy resin, the problem of interfacial compatibility between the FG and the epoxy resin is solved, and the corrosion resistance and the mechanical property of an epoxy resin coating are improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

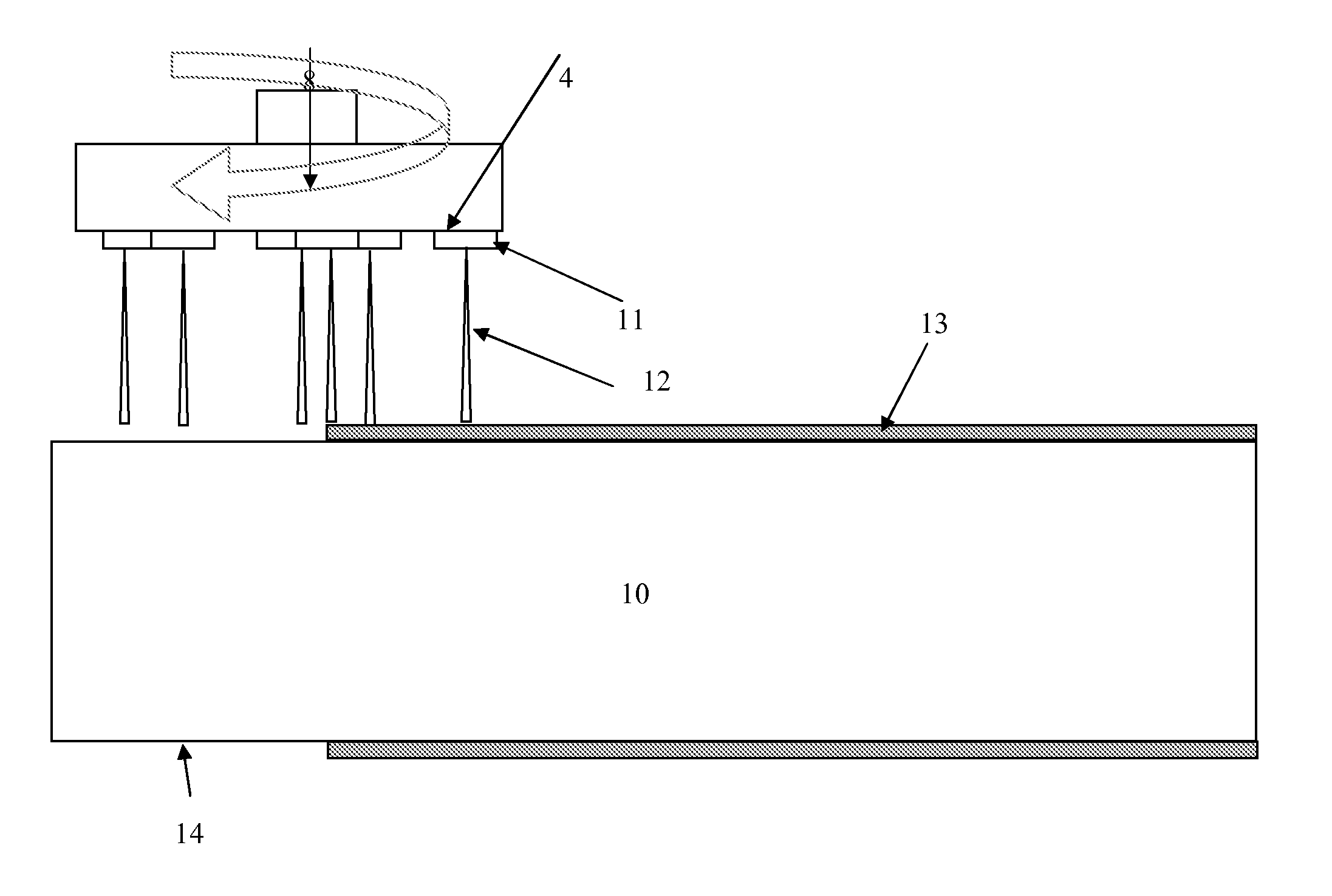

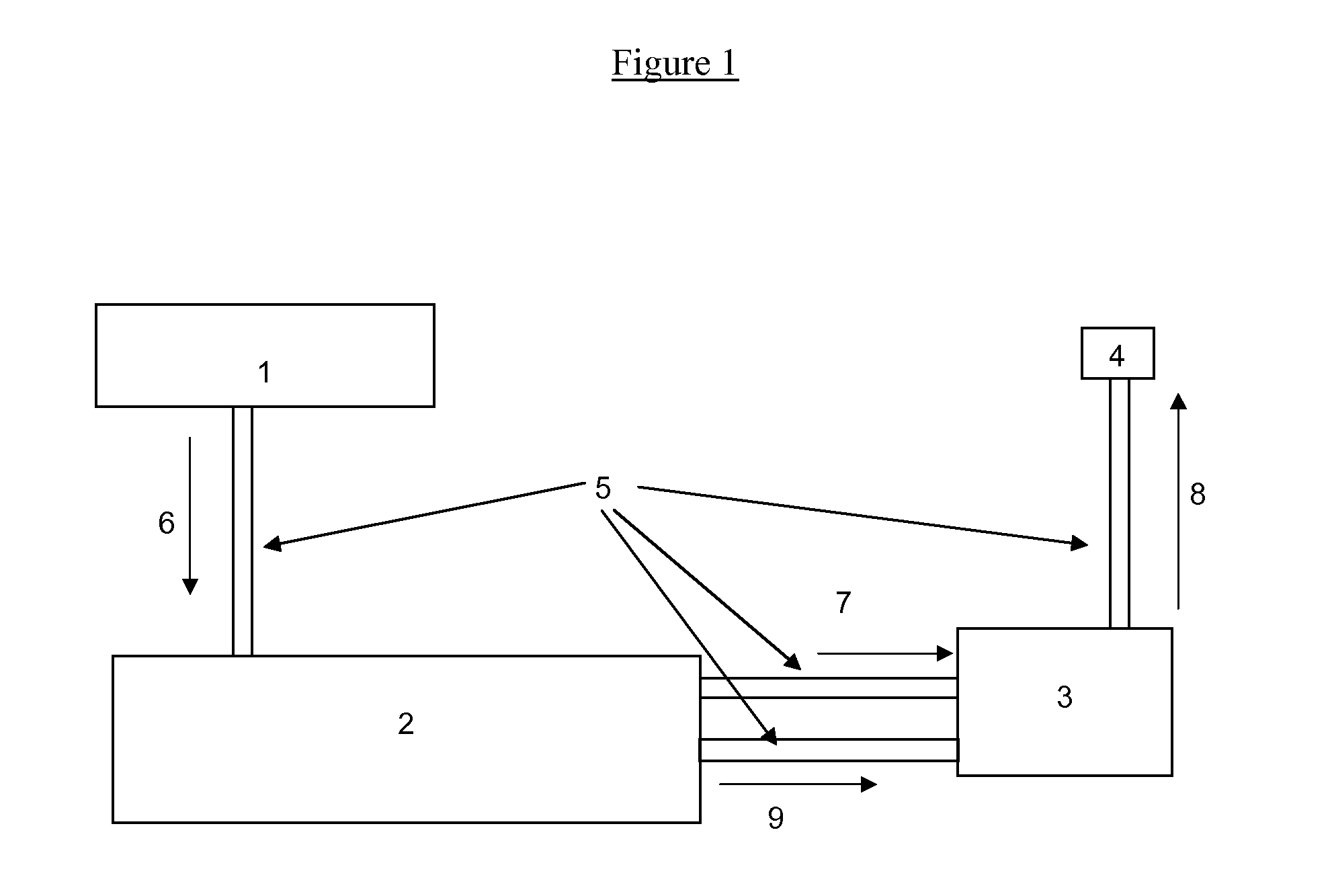

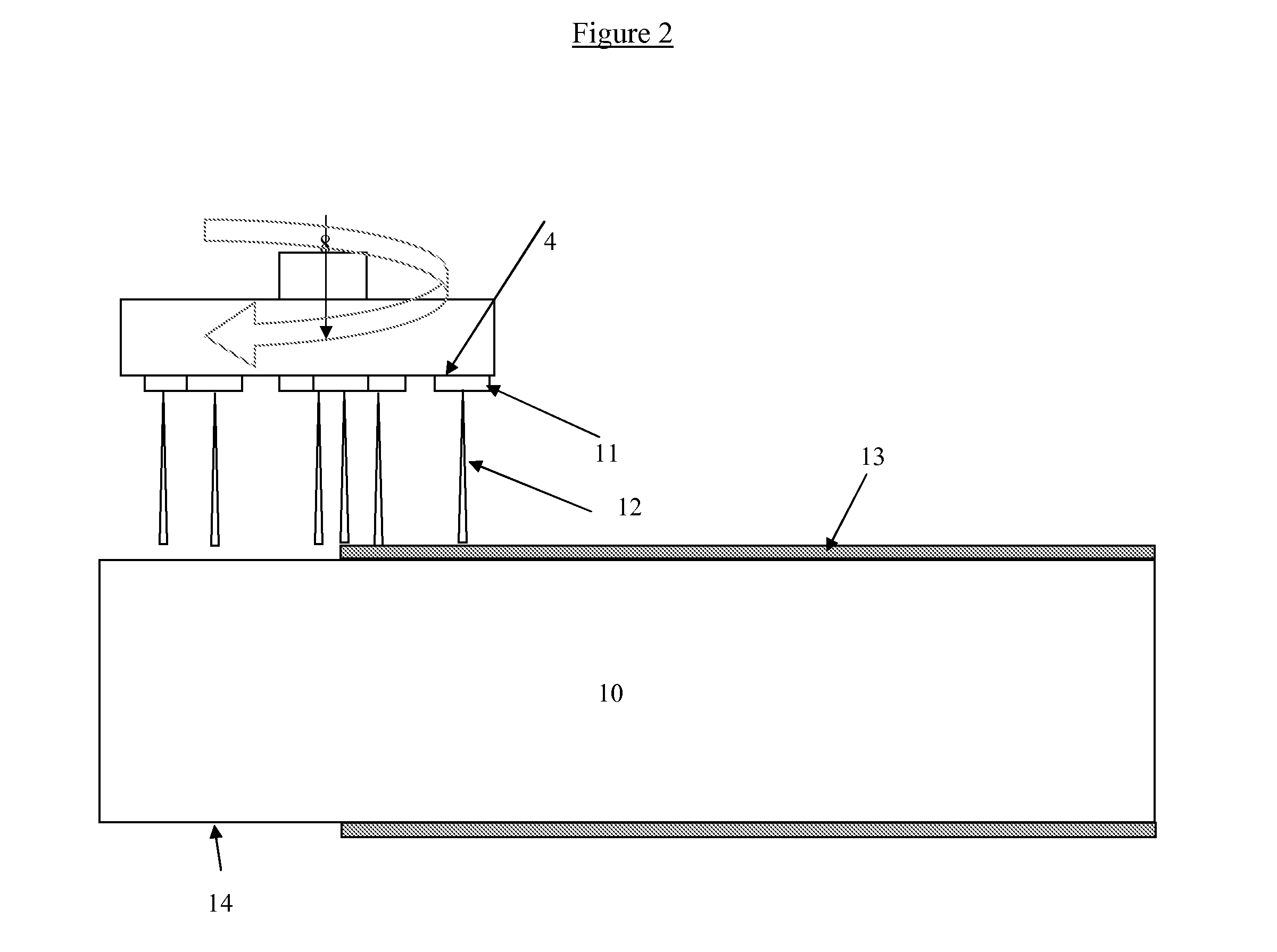

Process for removing a composite coating present on the surface of a gas cartridge

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap