Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition - What does Impact Resistance mean? Impact resistance is a material's ability to withstand intense force or shock applied to it over a short period of time.

Long-fiber enhanced thermoplastic composite material vane used for wind energy generator

InactiveCN102675740ALow shrinkageLow temperature impact resistanceFinal product manufactureMachines/enginesGlass fiberPhoto aging

Owner:BEIJING NASHENGTONG ADVANCED MATERIAL & TECH CO LTD

Cutting elements, methods for manufacturing such cutting elements, and tools incorporating such cutting elements

The present disclosure relates to cutting elements incorporating polycrystalline diamond bodies used for subterranean drilling applications, and more particularly, to polycrystalline diamond bodies having a high diamond content which are configured to provide improved properties of thermal stability and wear resistance, while maintaining a desired degree of impact resistance, when compared to prior polycrystalline diamond bodies, hi various embodiments disclosed herein, a cutting element with high diamond content includes a modified PCD structure and / or a modified interface (between the PCD body and a substrate), to provide superior performance.

Owner:SMITH INT INC

Functional composite coating and preparing method thereof

ActiveCN105623341AOn-site construction is simpleImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyFluoropolymer

Owner:CHANGCHUN A&Z SCI CO LTD

Thermal stabilizer-free thermoplastic resin composition and method of preparing the same

Owner:LG CHEM LTD

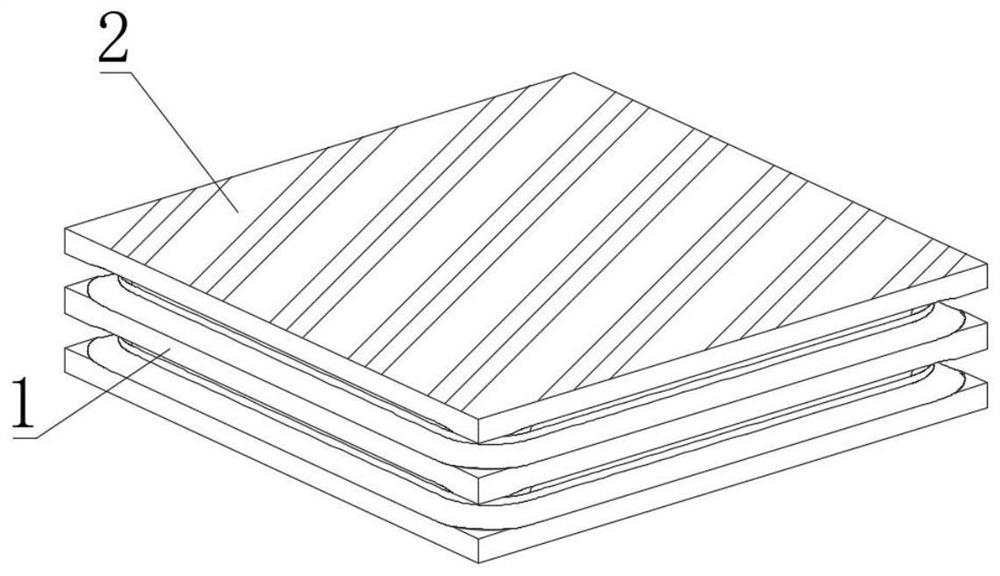

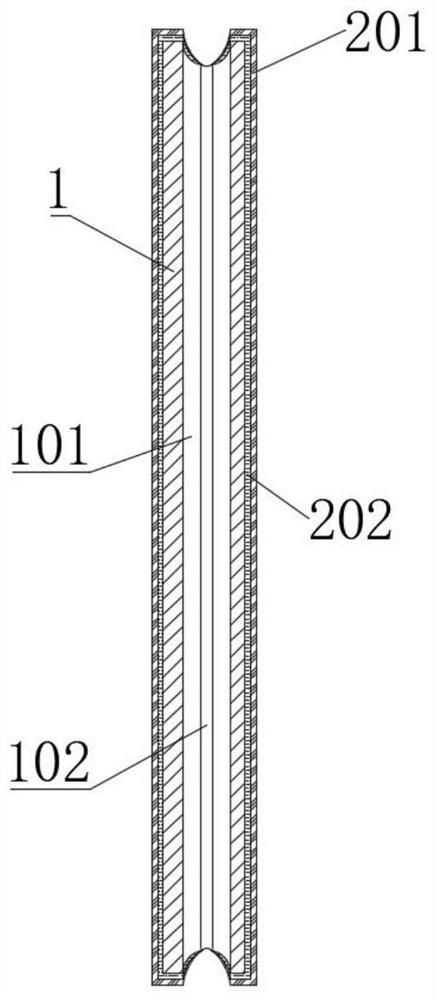

High-strength environment-friendly composite board and preparation method thereof

InactiveCN104690805AHigh strengthImprove toughnessNon-macromolecular adhesive additivesProtein adhesivesEnvironmental resistanceFiber

Owner:安徽忠盛新型装饰材料有限公司

Superhard non-stick silicon cooker coating prepared by sol-gel hybridization technique

InactiveCN102002268ALower sintering temperatureIncreased durabilityCoatingsSilicic acidCeramic coating

The invention discloses a superhard non-stick silicon cooker coating prepared by a sol-gel hybridization technique. The coating comprises the following components: 30-50% of nanometer silica, 20-40% of silicic acid compound, 5-10% of magnesium-calcium compound, 3-5% of ammonium chloride, 0.5-2.0% of catalyst, 1-4% of accessory ingredient, 0.5-2.0% of silane coupling agent, 15-25% of multielement organosilicon material, 5-10% of absolute ethyl alcohol and 10-20% of distilled water. The preparation method of the coating comprises the following steps: using a sol-gel method to synthesize nano CaO-SiO2 power; replacing Ca by Mg to develop a (Ca, Mg)SiO3 nano power material; introducing low-temperature sintered assistant precursors into sol to reduce the sintering temperature of ceramics; and adding a defined amount of organosilicon material to adjust the hardening temperature of the ceramics to obtain the low-temperature sintering nano ceramic coating at the temperature below 250 DEG C. The superhard non-stick silicon cooker coating has strong adhesive force, high hardness, small possibility of scratch, and impact resistance, is non-toxic and environment-friendly, and can completely replace Teflon non-stick coatings.

Owner:DONGGUAN EONTEC CO LTD

Polylactic acid/polyester alloy and preparation method thereof

The invention relates to a polylactic acid / polyester alloy and a preparation method thereof. The polylactic acid / polyester alloy comprises the following components in percentage by weight: polylactic acid, polyester, a compatilizer, a flexibilizer, an antioxidant and a lubricant. The preparation method comprises the following steps: firstly, proportioning the raw materials and mixing at a room temperature; and respectively carrying out melting extrusion, carrying out ultrasonic treatment at the first late stage, extruding at the second stage and pelletizing, so as to obtain degradable, high-impact-resistant and high-heat-resistant polylactic acid / polyester alloy. Compared with an existing method, the controllable ultrasonic treatment is utilized; and a similar polylactic acid-g-polyester structure is formed by in-situ reaction, so that the heat resistance of the polyester and the biodegradability of the polylactic acid are reserved; and meanwhile, a toughening system with a core-shell structure is formed in an alloy system through interface interaction of a special toughening compatilizer, so that the alloy product with high impact resistance, high heat resistance and high biodegradability can be obtained.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

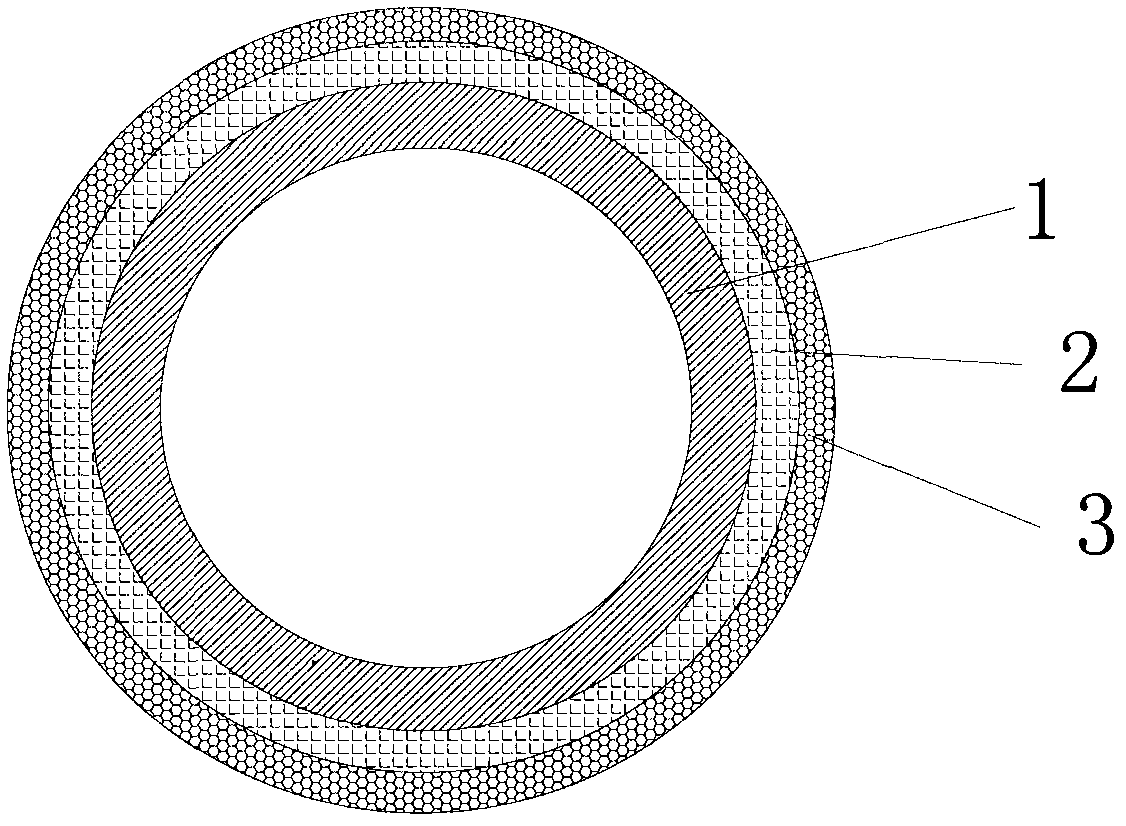

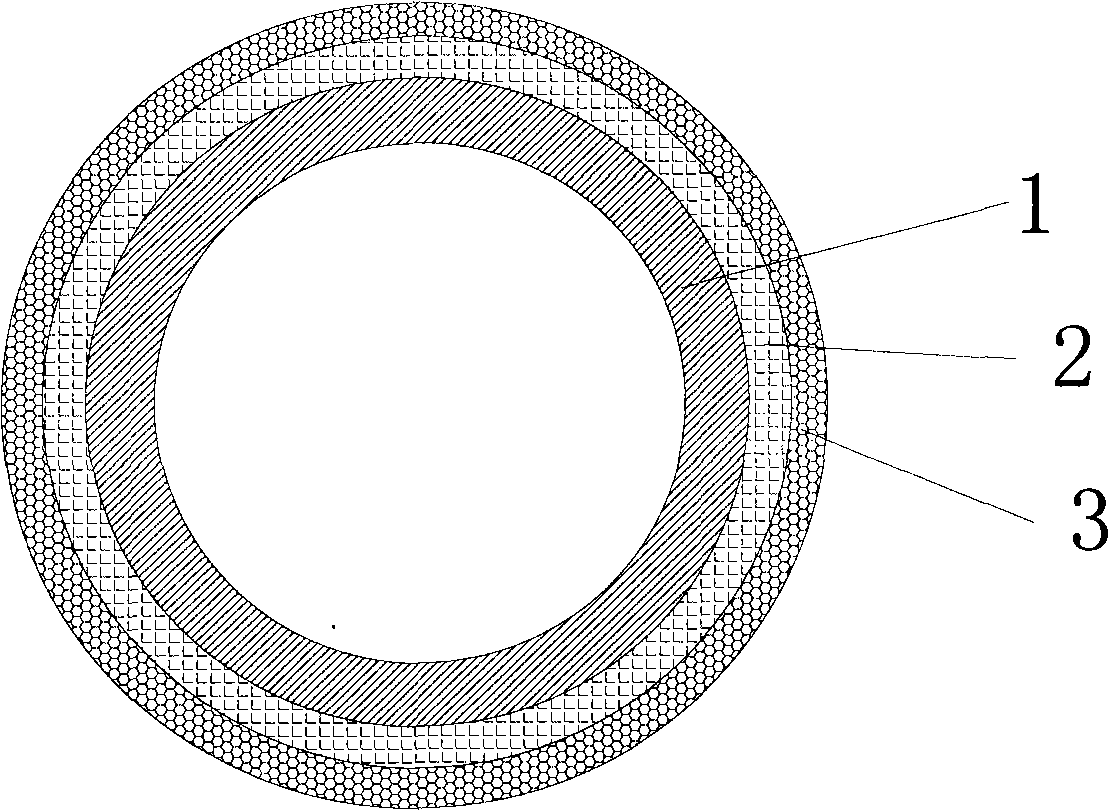

Camera and double-ring glass component thereof

InactiveCN102148925AImprove seismic performanceImprove performanceTelevision system detailsColor television detailsCore componentShock resistance

The invention discloses a camera and a double-ring glass component thereof. The camera comprises a front cylinder component, a rear cylinder component and a machine core component. The front cylinder component comprises a front cylinder and the double-ring glass component; the front cylinder has a cylindrical structure with two open ends; one end of the front cylinder is closed by the double-ring glass component, and the other end of the front cylinder is connected with the rear cylinder component; the double-ring glass component comprises a light-transmitting ring, a light-transmitting sheet and a ray isolation ring; and the light-transmitting ring is sleeved outside the ray isolation ring, while the light-transmitting sheet is arranged inside the ray isolation ring, and the light-transmitting ring is made of acrylics. When the camera of the double-ring glass component based on the technical scheme adopted by the invention is adopted, because the light-transmitting ring is made of acrylics, the impact resistance of the acrylic light-transmitting ring is 200 times that of a glass light-transmitting ring, so the light-transmitting ring is not broken by shock, and the shock resistance of the camera can be improved; moreover, the thermal stability is better than that of the glass light-transmitting ring, so the glass light-transmitting ring is not ruptured by thermal shock, and the performance of the camera can be greatly improved.

Owner:SHENZHEN FSAN INTELLIGENT TECH

High stiffness high impact propylene impact copolymers field of the invention

ActiveUS20110306731A1Impact resistanceZiegler–Natta catalystHigh stiffness

Owner:WR GRACE & CO CONN

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

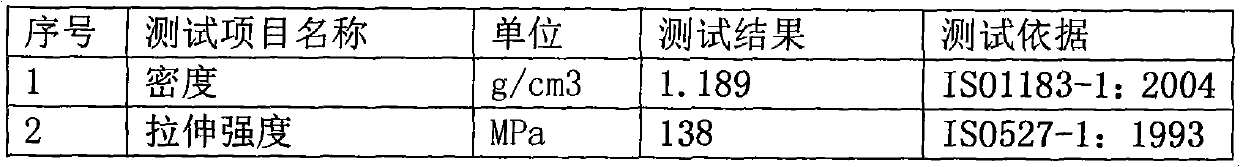

High-rigidity and high-toughness resin material for clothing buttons

Owner:HEBEI JIASHICHENG ENERGY TECH CO LTD

Continuous dry-type transformer winding with free arrangement in radial direction and processing method thereof

PendingCN110459388AIncrease productivityLow turn-to-turn voltageTransformers/inductances coils/windings/connectionsCoils manufactureOccupancy rateInter layer

Owner:ZHEJIANG JIANGSHAN TRANSFORMER CO LTD

Eyelet light pole with high stagnation

Owner:中华人民共和国天津海事局天津航标处 +1

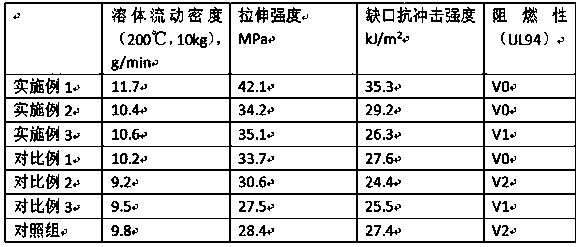

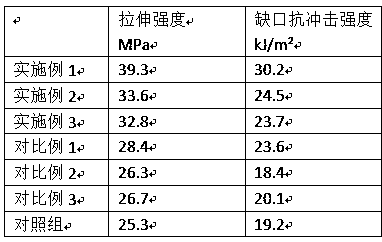

High-impact flame-retardant reinforced PC/ABS alloy material and preparation method thereof

Owner:四川鑫达企业集团有限公司

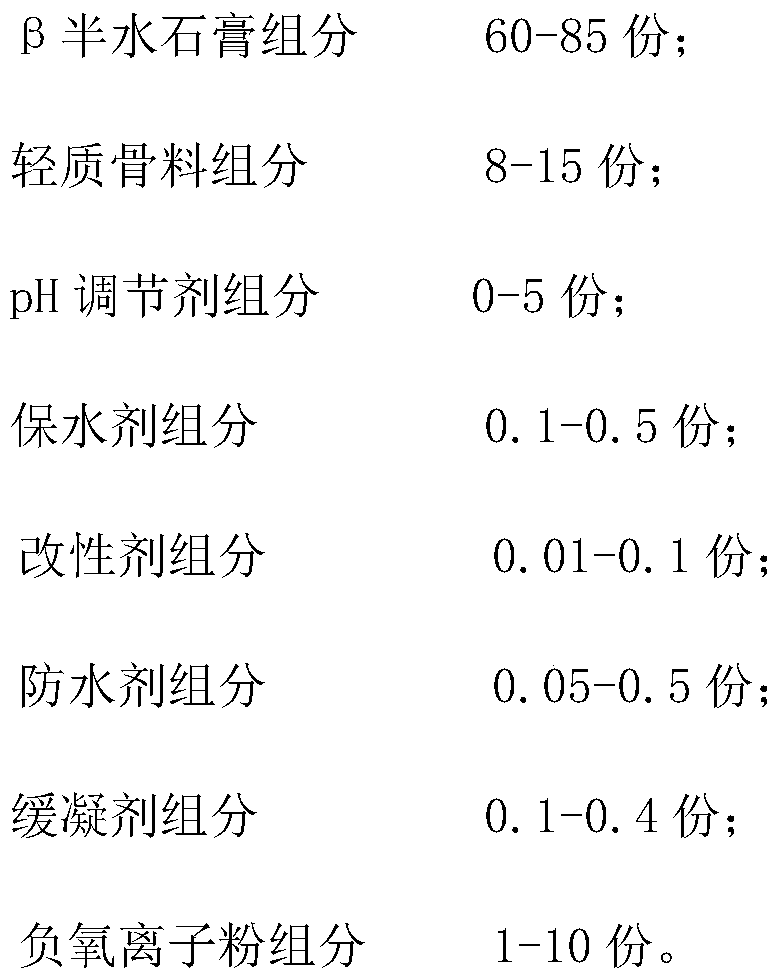

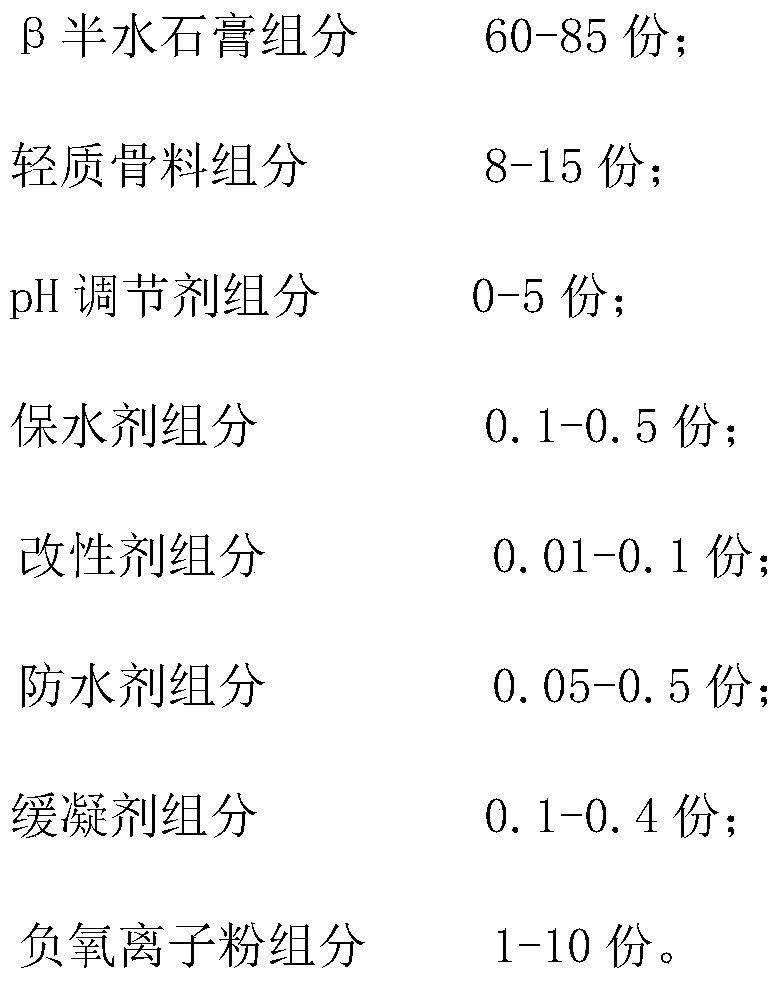

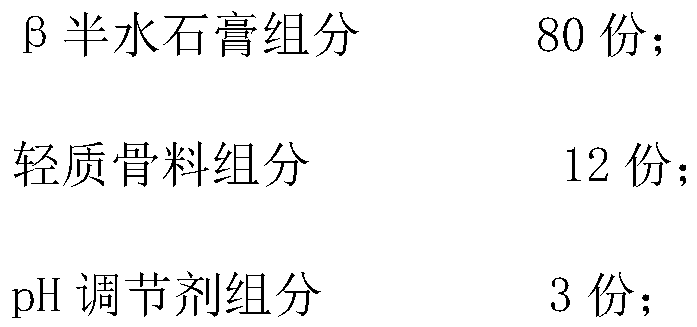

Damp-proof light plastering gypsum capable of releasing negative oxygen ions, and preparation method of plastering gypsum

PendingCN110790558AStrengthen and activate physical activityImprove flame retardant performancePhysical chemistryOxygen ions

Owner:贵州蓝图磷石膏环保科技有限公司

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

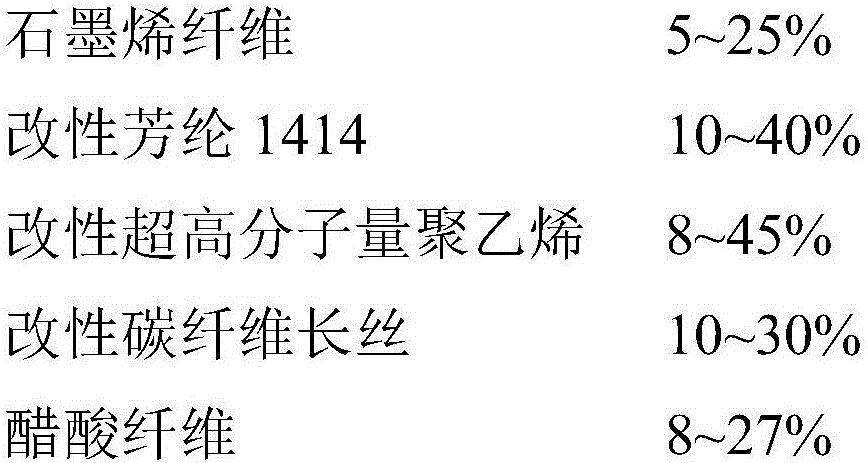

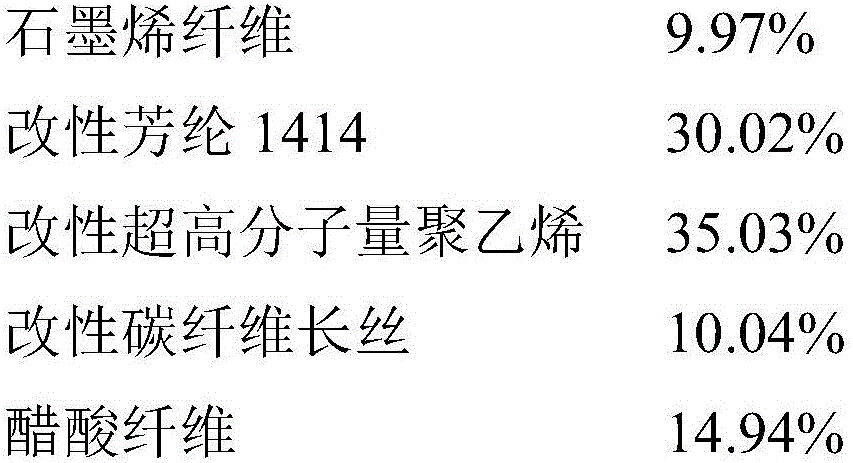

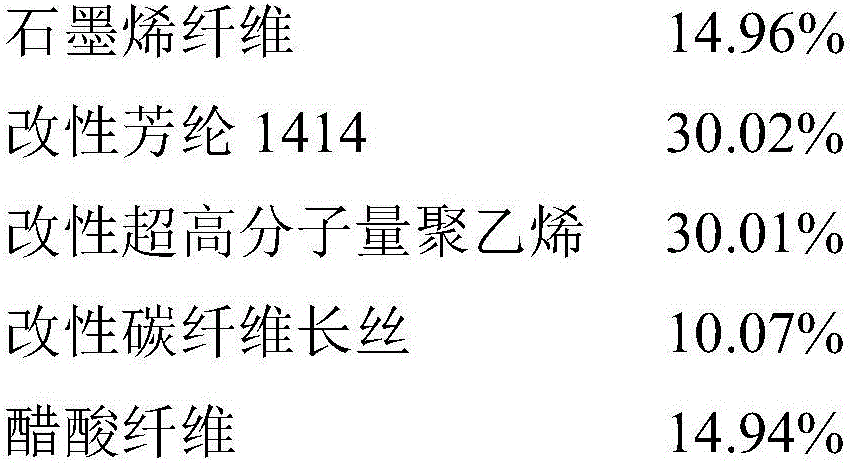

Ultralight bulletproof cloth and manufacture method thereof

Owner:广东军铠防护科技有限公司

Wave-absorbing breathable environment-friendly molding and preparation method thereof

InactiveCN107324688AImprove the performance of anti-electromagnetic radiationEffective absorptionSolid waste managementBuilding constructionsFiberPolyester

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Organic silicon electronic potting adhesive for PCB circuit board with stable dielectric insulation performance

InactiveCN106634810AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricAdhesive

The invention discloses an organic silicon electronic potting adhesive for a PCB circuit board with stable dielectric insulation performance. The organic silicon electronic potting adhesive is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12% of a platinum catalyst, 0.02 to 0.04 part of acetenyl cyclohexanol, 25 to 30 parts of vinyl silicon resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-epoxypropane, 23 to 25 parts of 1,3,5,7-tetramethyl cyclotetrasiloxane, 2.7 to 3.6 parts of a silane coupling agent A171, an appropriate amount of silicon-containing silicon oil, 2.6 to 3 parts of mica powder, 1.8 to 3 parts of porcelain powder, 0.2 to 0.3 part of dimethyl silicone polymer, 4.6 to 5 parts of carboxylated latex, 1.1 to 1.6 parts of polyvinyl alcohol and an appropriate amount of deionized water. The potting adhesive disclosed by the invention has high heat conduction, dielectric insulation, impact resistance and adhesive performance, is high in fluidity, and is extremely suitable for potting electronic products.

Owner:TONGLING ONBOLE PCB CO LTD

High-weatherability anti-corrosive paint and iron tower assembly

InactiveCN102070986ANot easy to ageNot easy to corrodeLighting support devicesAnti-corrosive paintsUltravioletEngineering

Owner:CHANGSHU FENGFAN POWER EQUIP

Food packaging bag and preparation method thereof

Owner:安徽明诚塑业有限公司

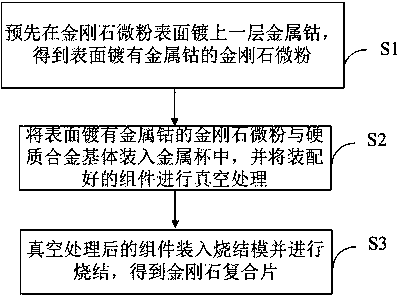

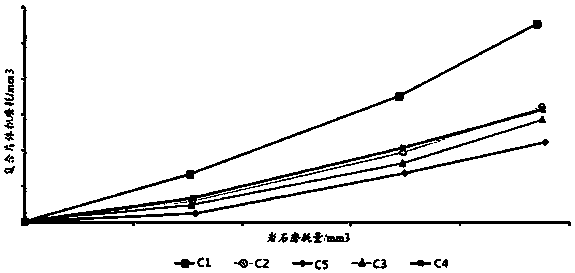

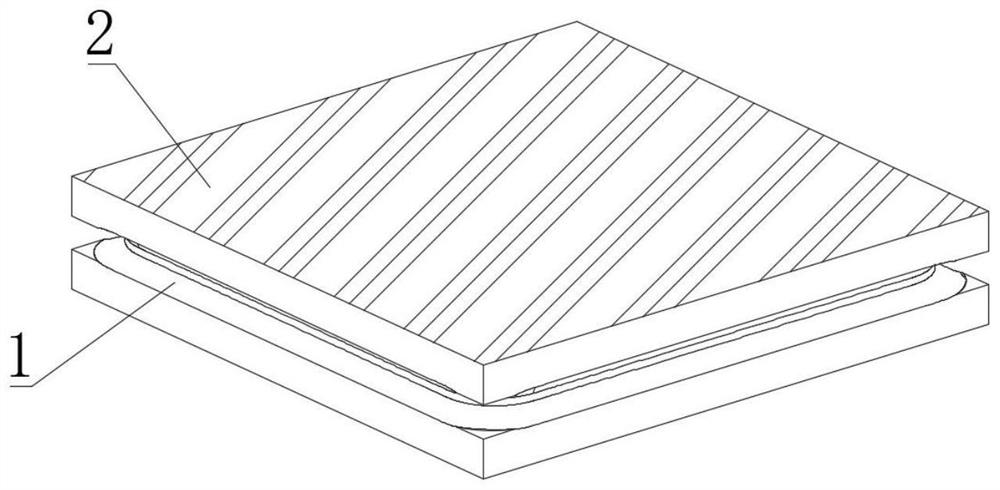

Diamond composite sheet and preparation method thereof

ActiveCN107790710AImprove wear resistanceAvoid abrasionDrill bitsTransportation and packagingAlloy substrateCemented carbide

Owner:SHENZHEN HAIMINGRUN SUPERHARD MATERIALS

Impact-resistant conductive polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of high polymer materials, and relates to an impact-resistant conductive polyphenylene sulfide material and a preparation method thereof. The impact resistant conductive polyphenylene sulfide material is prepared from the following components in parts by weight: 60-75 parts of PPS, 0.5-1 part of a lubricant, 0.5-0.8 part of epoxy resin, 8-15 parts of a toughening agent, 17-25 parts of carbon black and 0.5-2 parts of a coupling agent. The impact-resistant conductive polyphenylene sulfide material is prepared by using a high-speed pre-mixing dispersion one-step extrusion process. The impact-resistant conductive polyphenylene sulfide material provided by the invention has the characteristics of being good in mechanical property, good in flame retardancy, good in stability, easy to process, good in impact resistance and the like, and is applicable to packages of precise and advanced products of the electronic industry, the war industry and the like.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

High-impact-resistance high-flowability ABS resin and preparation method thereof

InactiveCN108329646ASolve the problem of low impact strengthLiquidPolymer scienceBulk polymerization

The invention specifically relates to a preparation method for a high-impact-resistance high-flowability ABS resin, belonging to the technical field of high-molecular materials. The preparation methodcomprises the following steps: preparing ABS resin with high impact strength by using a DOW continuous bulk polymerization process, adding bulk ABS resin, SAN resin, a plasticizer, a lubricant and acompatibilizer in a certain mass ratio into a mixer for thorough mixing so as to obtain a mixed material; and then feeding the obtained mixed material into a twin-screw extruder for mixing, extruding,drawing, cooling and pelletizing so as to obtain the high-impact-resistance high-flowability ABS resin. The ABS resin prepared in the invention has superior impact performance; at the same time, thecompatibilizer is added during blending, so the compatibility between the ABS resin and the SAN resin is improved, the adhesion between the two polymers is increased, and a more stable structure is formed.

Owner:NORTH HUAJIN CHEM IND CO LTD

Attractive, elegant and high-impact-resistance automobile trim material

InactiveCN105543999AImprove interface compatibilityImprove wear resistancePhysical treatmentSpinning head liquid feederFiberPolyvinyl alcohol

Owner:芜湖跃飞新型吸音材料股份有限公司

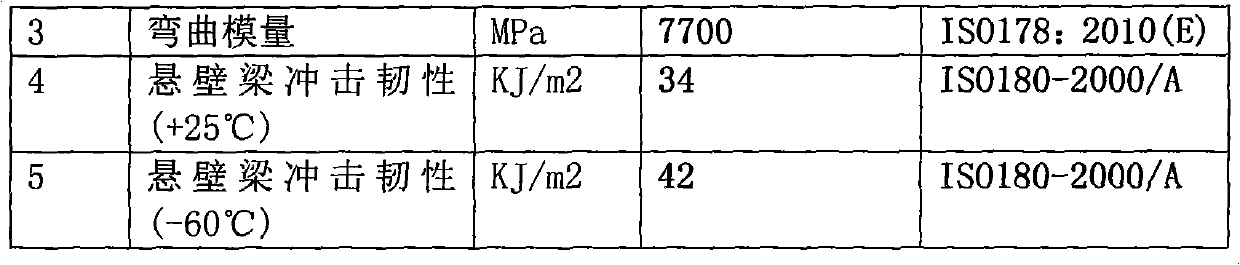

PC/ABS composite with low-temperature impact resistance and product thereof

The invention specifically relates to a PC / ABS composite with low-temperature impact resistance and a product thereof, belonging to the technical field of high polymer materials. The PC / ABS compositewith low-temperature impact resistance comprises organosilicon-copolymerized PC resin, ABS resin, a flexibilizer, a fire retardant and an inorganic filling material. The product is prepared by moldingthe PC / ABS composite with low-temperature impact resistance. According to the invention, the organosilicon-copolymerized PC resin and the compound flexibilizer with low-temperature impact resistanceare used for the PC / ABS composite, so the PC / ABS composite has excellent notch impact strength at a low temperature after addition of the inorganic filling material.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Medical full-protection intelligent voice helmet

InactiveCN113729345AImprove comfortReduce shoulder and neck burdenHelmetsHelmet coversPhysical medicine and rehabilitationInfection risk

The invention discloses a medical full-protection intelligent voice helmet, which comprises a device main body, the device main body comprises a face protection cover, a supporting strip, a head protection cover, a first supporting leg and a second supporting leg. First connecting sheets are fixedly connected to two sides of the face protection cover, and connecting blocks are attached to the outer sides of the first connecting sheets; bolts penetrate through the interiors of the connecting blocks, and one sides of the outer walls of the bolts penetrate into the interiors of the first connecting pieces; and one sides of the connecting blocks are movably connected with the first supporting leg and the second supporting leg correspondingly. The invention relates to the technical field ofmedical instruments. The intelligence and protection of the device main body are greatly improved; the face protection cover and the head protection cover are both made of PET materials and have high permeability, fog resistance and high impact resistance, so that droplet is effectively prevented from splashing when a medical staff wear the mask, the safety of the medical staff is protected to the maximum extent, and the infection risk of the medical staff is reduced.

Owner:SECOND AFFILIATED HOSPITAL OF XIAN MEDICAL UNIV

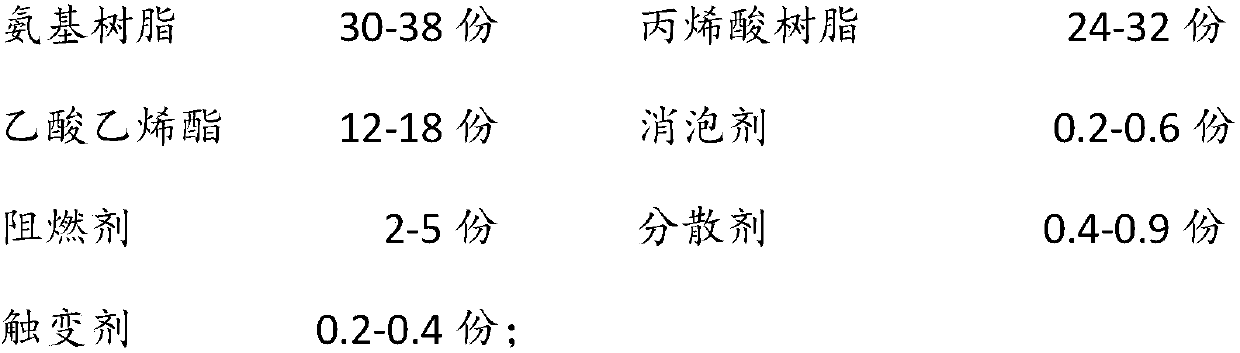

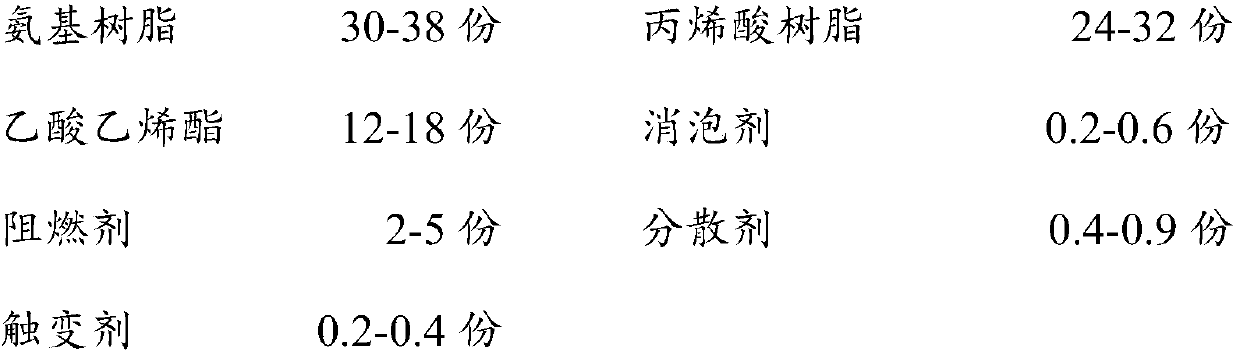

Flame-retardant finish paint for furniture

InactiveCN107629661AImprove flame retardant performanceStrong impact resistanceFireproof paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

Owner:佛山市三水区白坭镇巨财红木厂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap