Preparation method of composite filler for improving impact resistance of plastic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

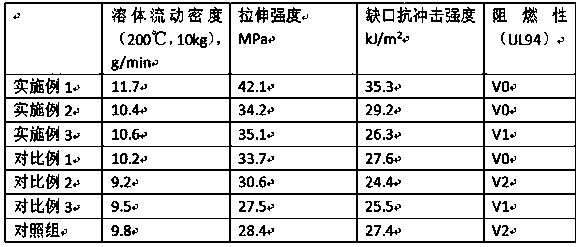

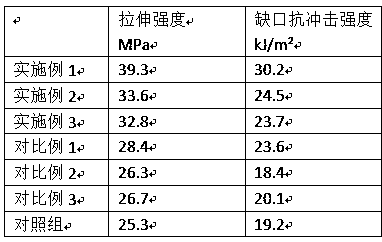

Examples

Embodiment 1

[0026] A method for preparing a composite filler for improving the impact resistance of plastics, which is prepared by the following method:

[0027] (1) Soak the attapulgite in a nitric acid solution with a mass fraction of 8% for 20 minutes, then wash it with deionized water, wash it three times with deionized water, and then dry it at 400°C;

[0028] (2) Soak the montmorillonite in an oxalic acid solution with a mass fraction of 3% for 35 minutes, use ultrasonic vibration treatment during the soaking process, and then dry it;

[0029] (3) Take 5 parts of polyethylene glycol, 3 parts of polyvinyl alcohol, 0.2 parts of expanded graphite, 1.2 parts of glass fiber, and 12 parts of water by weight, and stir at 35-40 ° C for 1-2 hours to obtain a mixed solution ;

[0030] (4) Mix the attapulgite prepared in step (1), the montmorillonite prepared in step (2), and the mixed solution obtained in step (3) in a weight ratio of 6:1:12, and mix them at 550r / min Stir at a rotating speed

Embodiment 2

[0041] Compared with Example 1, the carbonization treatment directly raises the temperature to 720° C. for carbonization without performing temperature swing treatment.

Embodiment 3

[0043] Compared with Example 1, the glass fiber is not modified.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap