Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Polyacrylic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Poly(acrylic acid) (PAA; trade name Carbomer) is a synthetic high-molecular weight polymer of acrylic acid. The IUPAC name is poly(1-carboxyethylene). They may be homopolymers of acrylic acid, or crosslinked with an allyl ether of pentaerythritol, allyl ether of sucrose, or allyl ether of propylene. In a water solution at neutral pH, PAA is an anionic polymer, i.e. many of the side chains of PAA will lose their protons and acquire a negative charge. This makes PAAs polyelectrolytes, with the ability to absorb and retain water and swell to many times their original volume.

Green total organic carbon steel scale and corrosion inhibitor for circulating cooling water system

InactiveCN102351328AEasy to makeEasy to useScale removal and water softeningEutrophicationCarboxylic acid

The invention discloses a green total organic carbon steel scale and corrosion inhibitor for a circulating cooling water system, which comprises a scale inhibitor and a corrosion inhibitor, wherein the scale inhibitor comprises one or more of hydrolyzed polymaleic anhydride, polyacrylic acid, polymethacrylic acid, acrylic acid / hydroxypropyl acrylate copolymer, acrylic acid / hydroxypropyl acrylate / methyl acrylate terpolymer and acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid copolymer; and the corrosion inhibitor comprises oxalic acid or oxalate, alpha-hydroxycarboxylic acid or salt thereof and silicate. The scale and corrosion inhibitor has excellent scale inhibition and corrosion inhibition performance, and belongs to a completely phosphorus-free metal-free environment-friendly total organic composition. Discharged waste water treated by the composition can not cause eutrophication pollution to the environment.

Owner:TIANJIN HEGUANG ELECTRICAL & MECHANICAL EQUIP CO LTD

Building method of molecularly imprinted fluorescent probe, and application thereof in benzimidazole detection

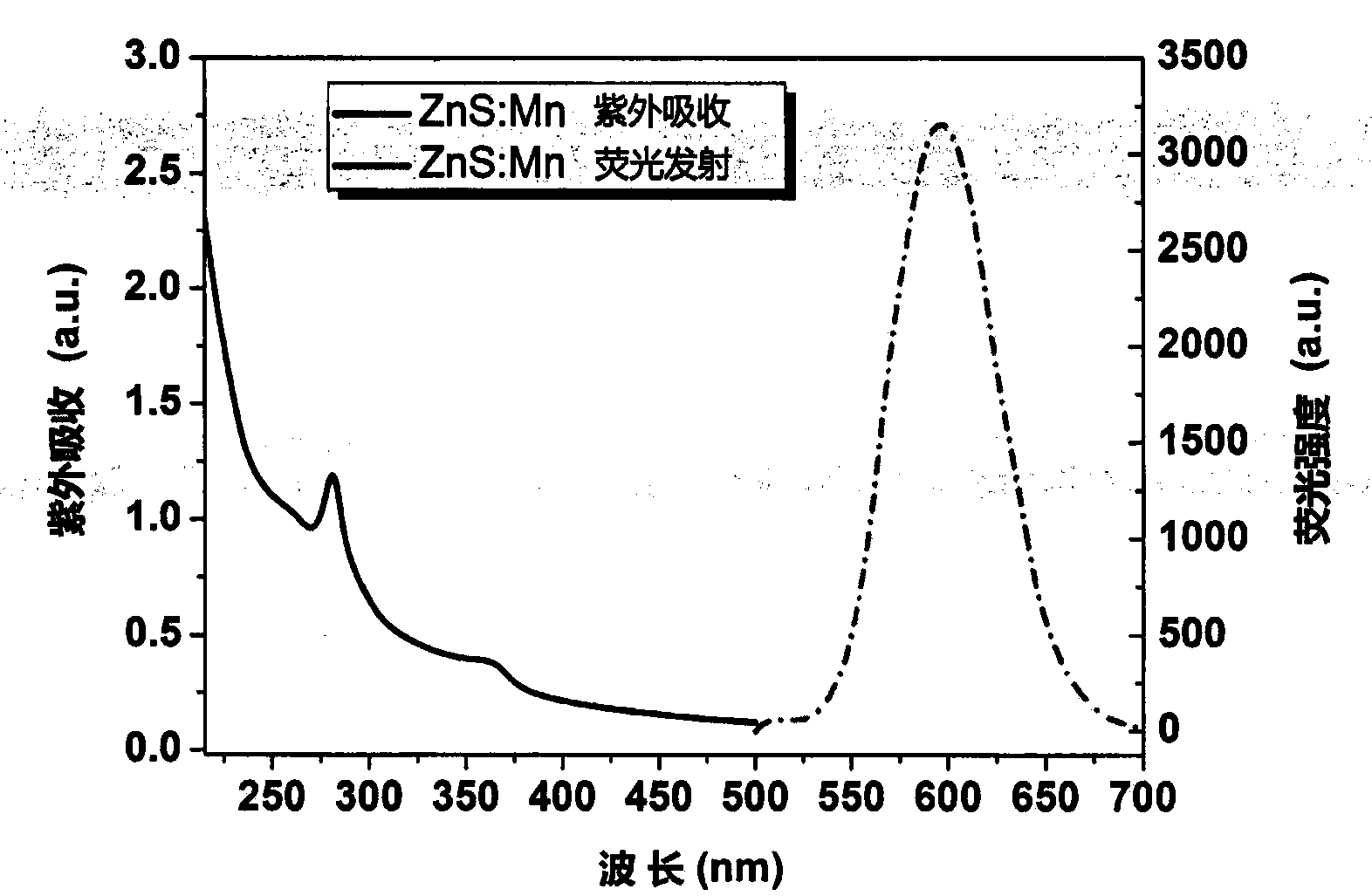

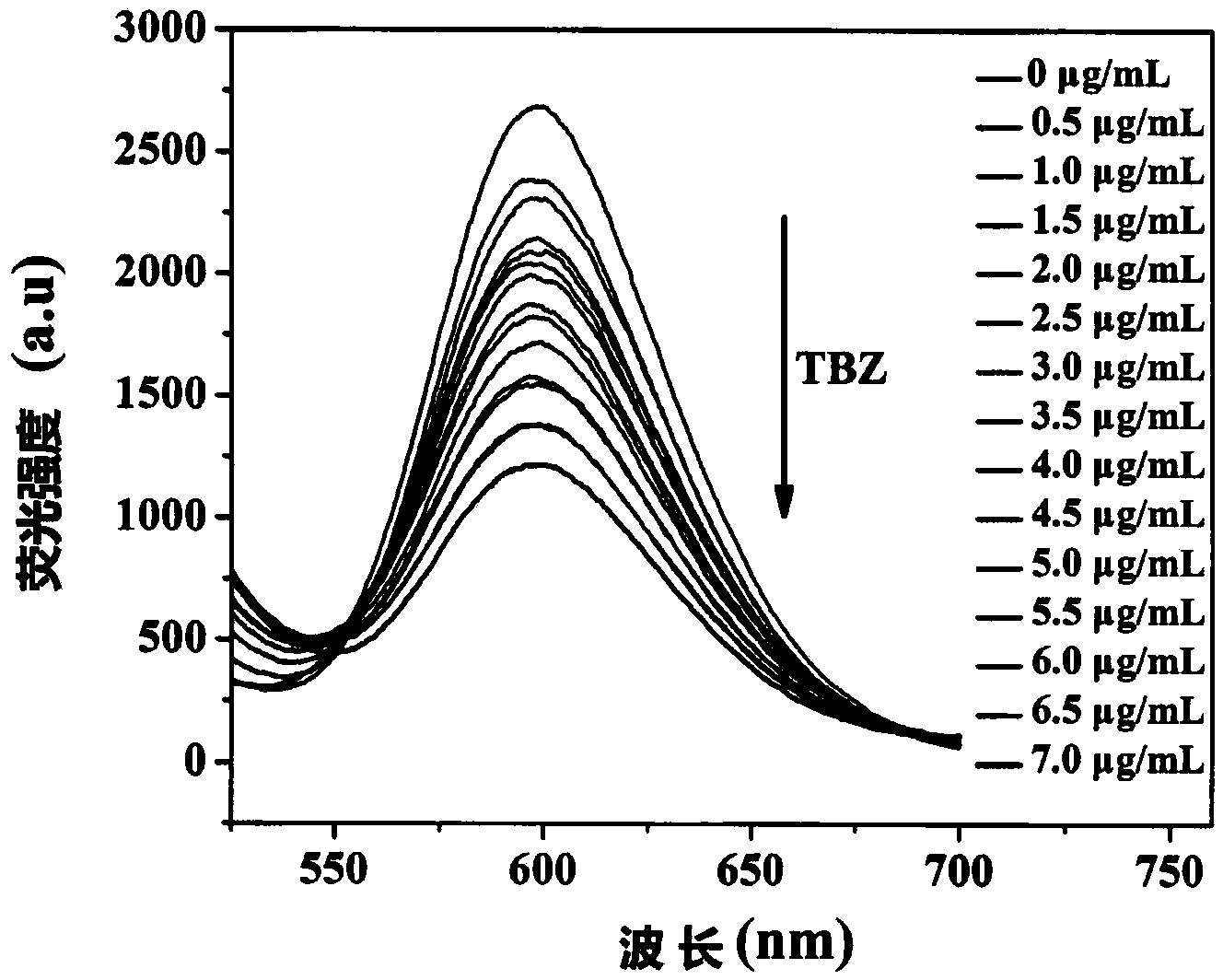

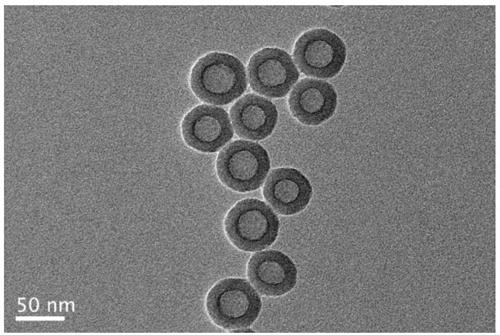

InactiveCN103709433AHigh sensitivityImprove featuresFluorescence/phosphorescenceMicrosphereQuenching

Owner:TIANJIN POLYTECHNIC UNIV

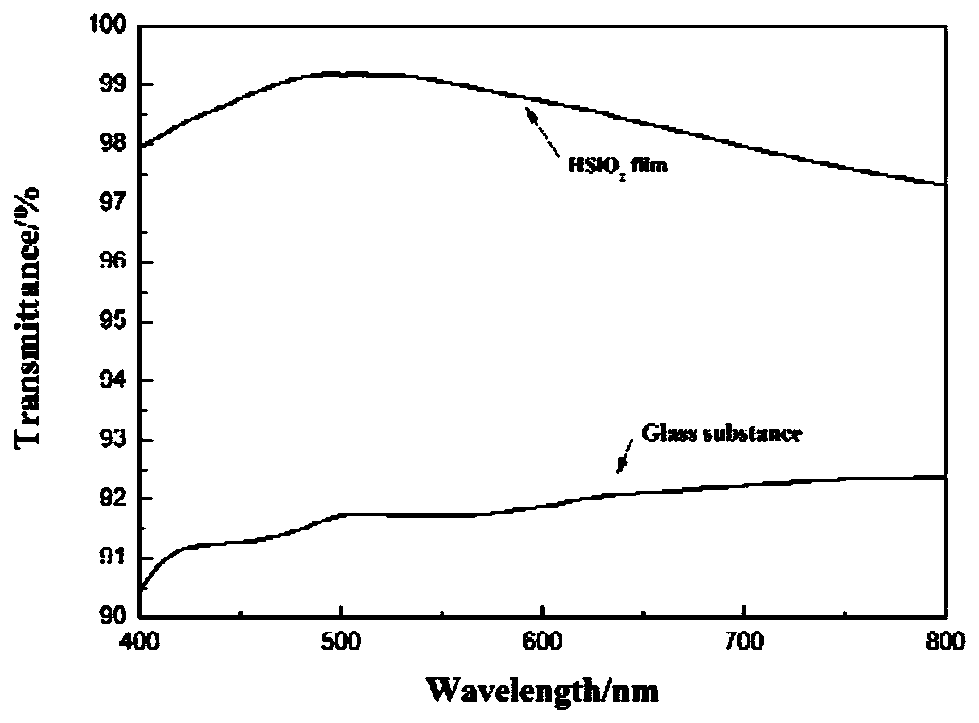

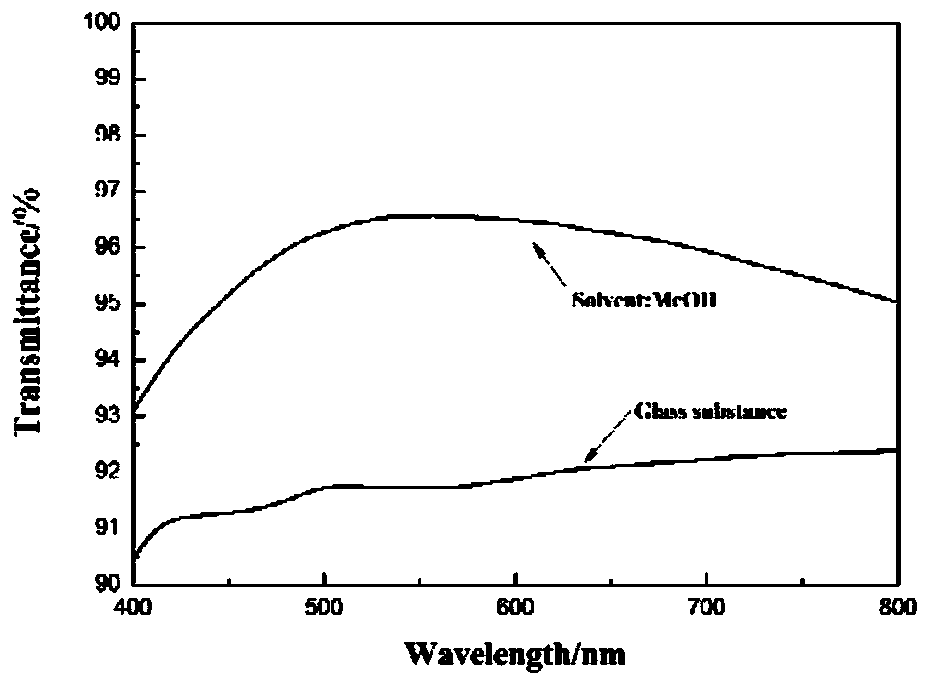

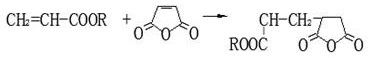

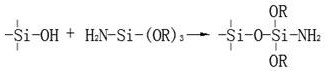

Method for preparing high-hardness antireflection film on basis of hollow silicon dioxide

ActiveCN109502987AUniform sizeHigh light transmittanceCoatingsSilicon compoundsOptical thin filmSolvent

Owner:CHANGZHOU UNIV

Waterproof reinforced composite and preparation method thereof

The invention discloses a waterproof reinforced composite and a preparation method thereof. The waterproof reinforced composite is prepared from the following raw materials in parts by weight: 60-90 parts of epoxy resin modified polyurethane emulsion, 15-30 parts of organic silicon styrene-acrylic emulsion, 10-30 parts of methyl methacrylate, 10-20 parts of polyacrylate, 2-4 parts of N-hydroxymethyl acrylamide, 6-12 parts of oxide-coated titanium dioxide, 10-30 parts of composite filler, 3-8 parts of silane coupling agent, 3-6 parts of propanediol butyl ether, 3-6 parts of diethylene glycol monobutyl ether, 5-10 parts of sodium polyphosphate, 4-8 parts of polyvinyl butyral, 2-5 parts of urea-isobutyraldehyde-formaldehyde resin, 0.3-0.6 part of sodium perfluorous nonenoxybenzene sulfonate,0.4-0.9 part of polypropylene wax emulsion, 0.3-0.7 part of polyether modified polysiloxane, 0.5-1 part of hydroxypropyl methyl cellulose, 1-3 parts of epoxy phosphate ester, 1-5 parts of compound antiaging agent and 10-20 parts of water.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

General fodder quality modifier for common aquatic products and preparation method thereof

Owner:江苏神力特生物科技股份有限公司

Preparation method of PET release film

ActiveCN113999625AImprove scratch resistanceImprove wear resistanceCoatingsFilm/foil adhesive release linersSilica nanoparticlesPolyvinyl alcohol

Owner:潍坊胜达科技股份有限公司

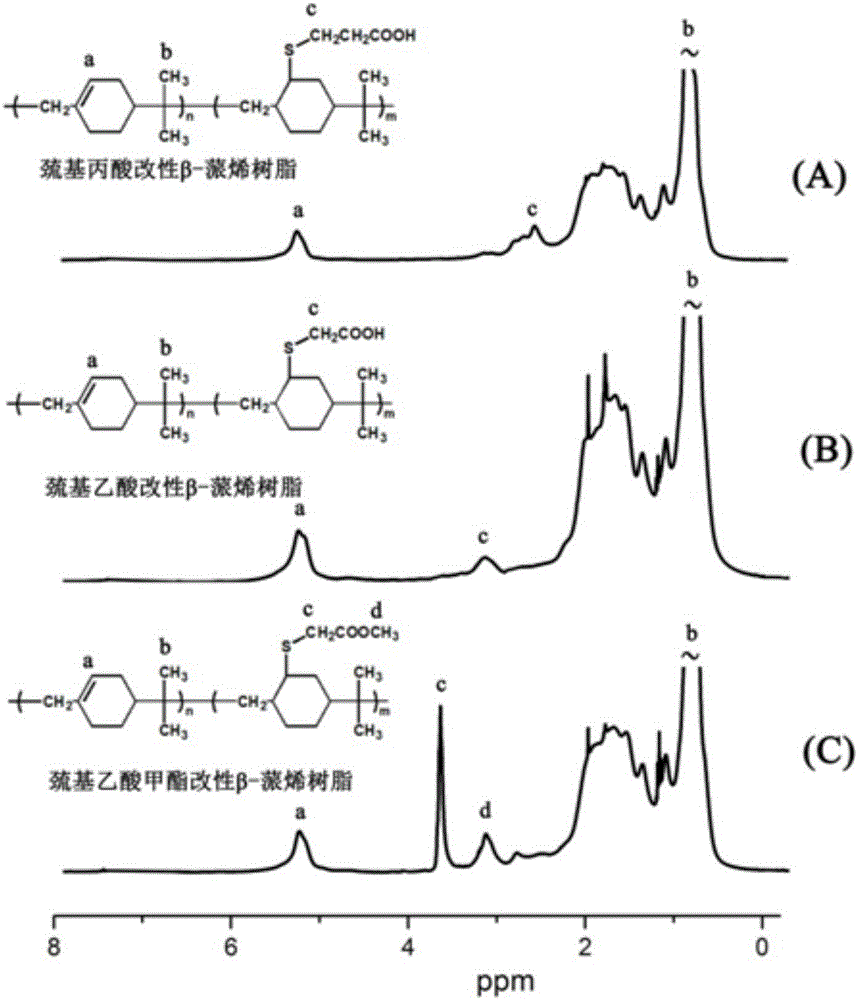

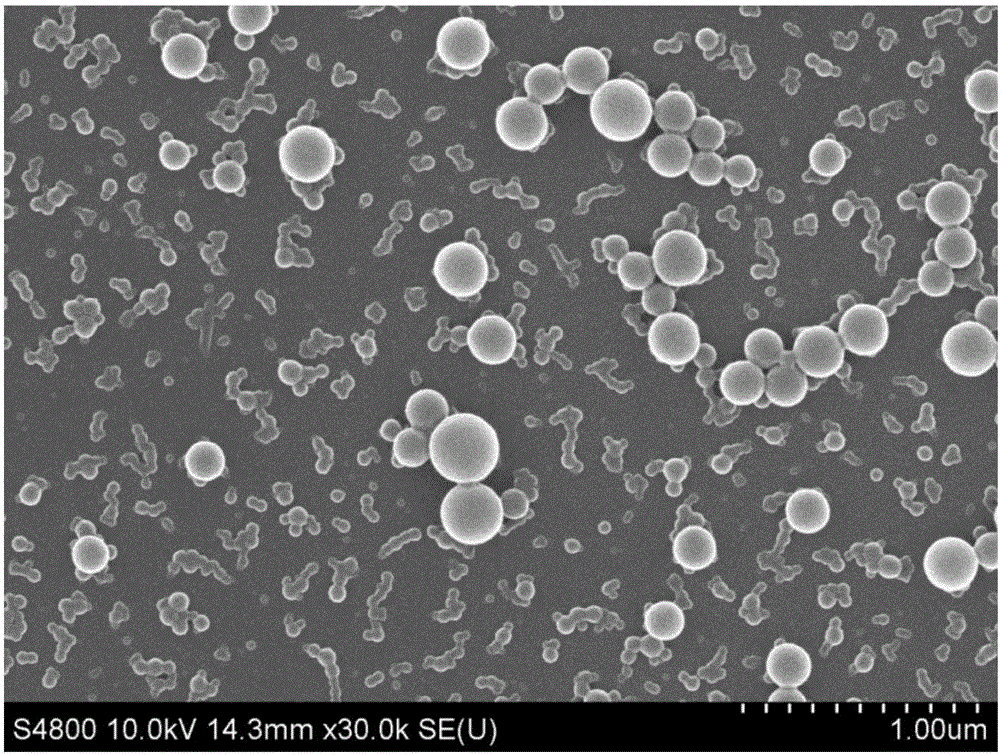

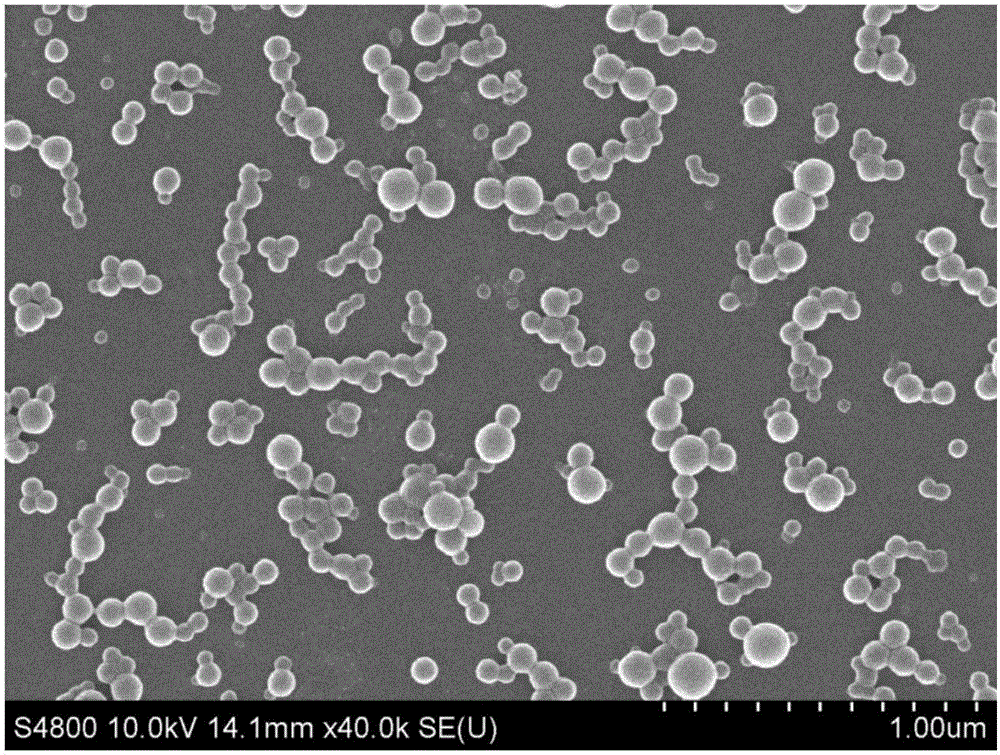

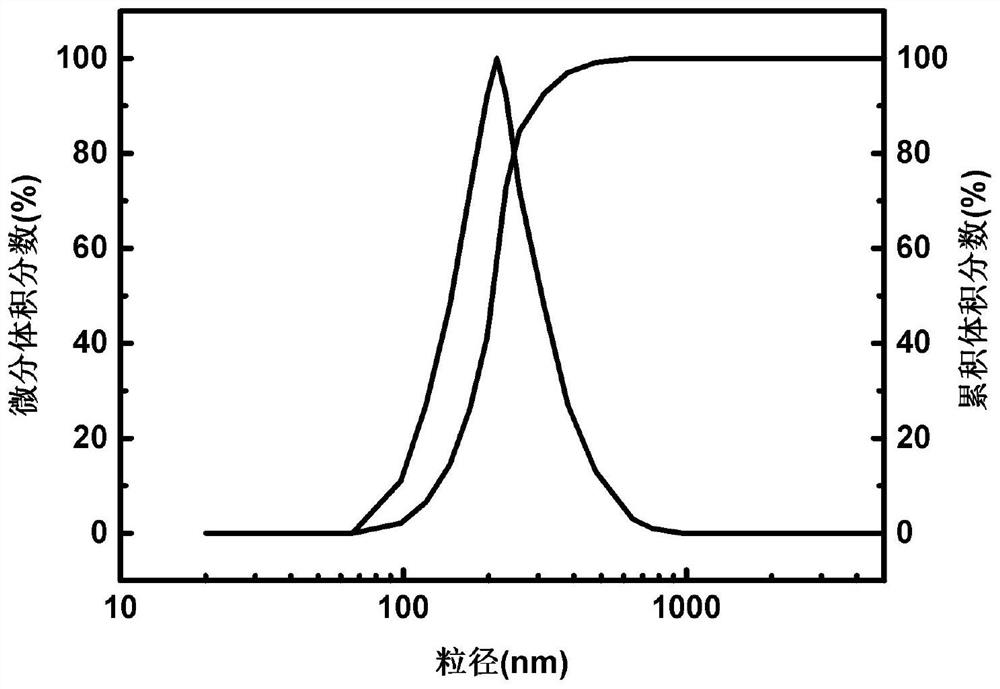

New method for functional modification of poly(beta-pinene) resin

Owner:SUN YAT SEN UNIV +1

Polyacrylate grafted graphene oxide plugging agent and oil-based drilling fluid

InactiveCN114752365AImprove rheologyGood sealability and other aspects of performanceNanotechnologyDrilling compositionSilane compoundsPhysical chemistry

Owner:SOUTHWEST PETROLEUM UNIV

Novel moisture-curing flame-retardant polyurethane hot melt adhesive and preparation method thereof

InactiveCN109679562AImprove performanceImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterMethacrylate

Owner:SHUNDE POLYTECHNIC

Diacetyl tartaric acid ester of mono(di)glyceride fried bread stick bulking agents

InactiveCN103891813ARaw materials are easy to getLow costDough treatmentBakery productsSodium bicarbonatePhosphate

Owner:韦谷林

Nanometer titanium dioxide dispersion emulsion and preparation process thereof

PendingCN110856820AImprove permeabilityGood dispersionOrganic-compounds/hydrides/coordination-complexes catalystsSODIUM METAPHOSPHATESodium phosphates

Owner:倍肯(浙江)科技发展有限公司

High-thermal-conductive composite material and preparation method thereof

InactiveCN110283430AImprove heat transfer efficiencyHeat-exchange elementsVacuum assistedFreeze-drying

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Anti-yellowing leather finishing emulsion

InactiveCN111004556AEfficient captureAvoid oxidation reactionsCoatingsPolymer sciencePolypropylene glycol

The invention discloses an anti-yellowing leather finishing emulsion, which is prepared from the following raw materials in parts by weight: 65 to 80 parts of a modified polyacrylate resin, 1 to 3 parts of polydimethylsiloxane, 0.5 to 1.5 parts of an antifoaming agent, 0.5 to 1.5 parts of a leveling agent, 1.5 to 3 parts of silicon dioxide, 5 to 8 parts of polypropylene glycol and 10 to 20 parts of deionized water. According to the invention, the polyacrylate resin is modified, and the anti-yellowing modifier is prepared, is introduced into the polyacrylate resin in a cross-linking manner, andis firmly connected into the resin in a chemical bond manner, so that the polymers in a leather coating are effectively protected from an oxidation reaction, the good scrubbing resistance is achieved, and leather can resist yellowing for a long time.

Owner:王磊

Ceramic coating with corrosion resistance

InactiveCN109207016AImprove corrosion resistanceNot easy to corrodeAnti-corrosive paintsEpoxy resin coatingsFiberEpoxy

Owner:佛山市高明区生产力促进中心

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap