Method for preparing high-hardness antireflection film on basis of hollow silicon dioxide

A silicon oxide, high hardness technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as harsh environmental conditions, film damage, film peeling, etc., and achieve the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

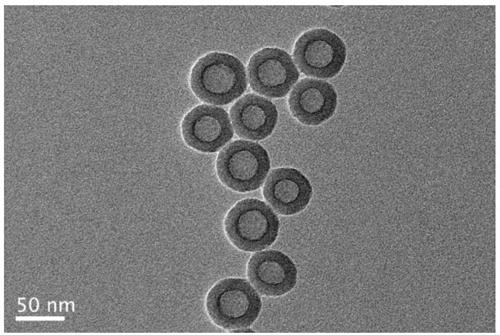

Embodiment 1

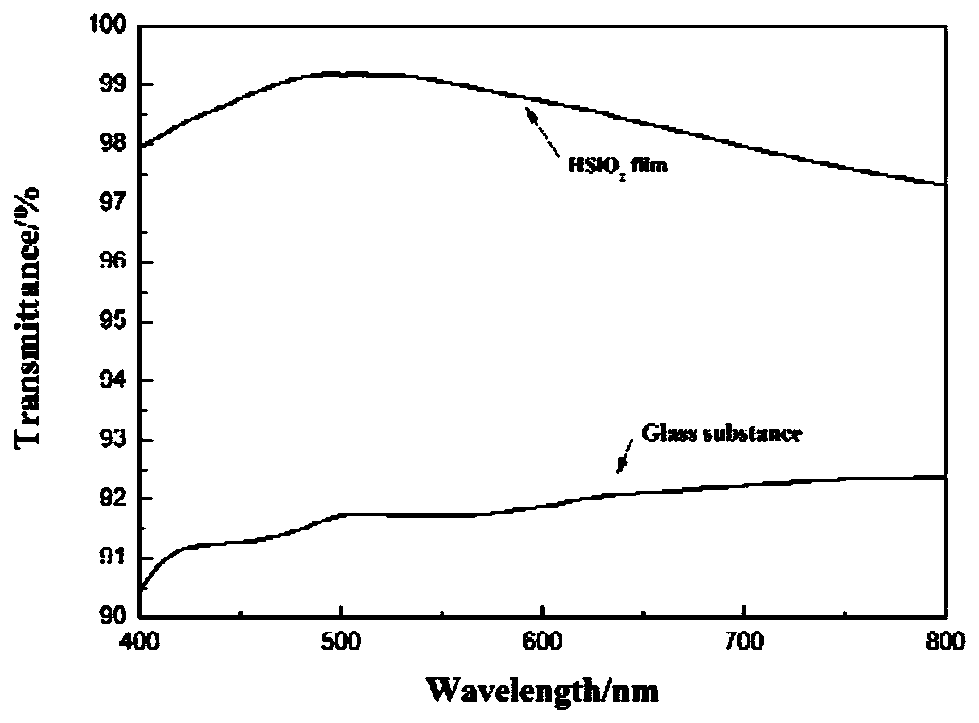

[0030] At room temperature, dissolve 0.12g of polyacrylic acid in 6ml of ammonia water, mix well and add to the rotor, slowly add a mixed solution of 84ml of 2-isopropoxyethanol and 36ml of methanol under stirring, and place it in a water bath at 30°C after the addition is complete After vigorously stirring for 10 minutes, 2ml tetraethyl orthosilicate was added dropwise in 5 times (0.4ml each time), the time interval was 10min, and the mixed solution was sealed and vigorously stirred for 10h to obtain a 60nm hollow SiO 2 Nanoparticle sol. Stir the above sol in a fume hood, and stop stirring when the pH of the solution drops to 7. After the weight percentage of the sol was adjusted to 1.5 wt%, it was recorded as the sol to be coated.

[0031] Put 2 × 10cm glass substrates (light transmittance 92%) in the sequence of 10% hydrochloric acid and 10% NaOH solution for ultrasonic treatment for 70min, the ultrasonic power is 60W, and then use Ultrasonic washing with water ethanol and d

Embodiment 2

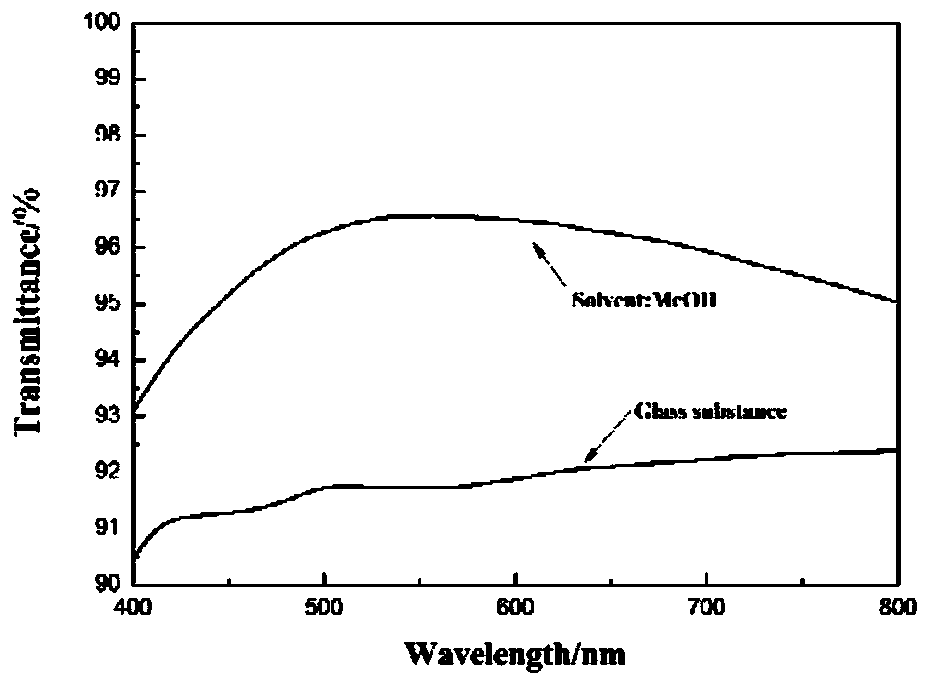

[0033] At room temperature, dissolve 0.12g of polyacrylic acid in 6ml of ammonia water, mix well and add to the rotor, slowly add a mixed solution of 84ml of 2-isopropoxyethanol and 36ml of methanol under stirring, and place it in a water bath at 30°C after the addition is complete After stirring vigorously for 10 minutes, 0.2ml tetraethyl orthosilicate was added dropwise in 5 times with a time interval of 10 minutes. After the mixed solution was sealed and stirred vigorously for 10 hours, a hollow SiO with a thickness of 54.5nm was obtained. 2 Nanoparticle sol. Stir the above sol in a fume hood, and stop stirring when the pH of the solution drops to 7. After the weight percentage of the sol was adjusted to 1.5 wt%, it was recorded as the sol to be coated.

[0034] Put 2 × 10cm glass substrates (light transmittance 92%) in the sequence of 10% hydrochloric acid and 10% NaOH solution for ultrasonic treatment for 70min, the ultrasonic power is 60W, and then use Ultrasonic washing

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap