Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about "Material nanotechnology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

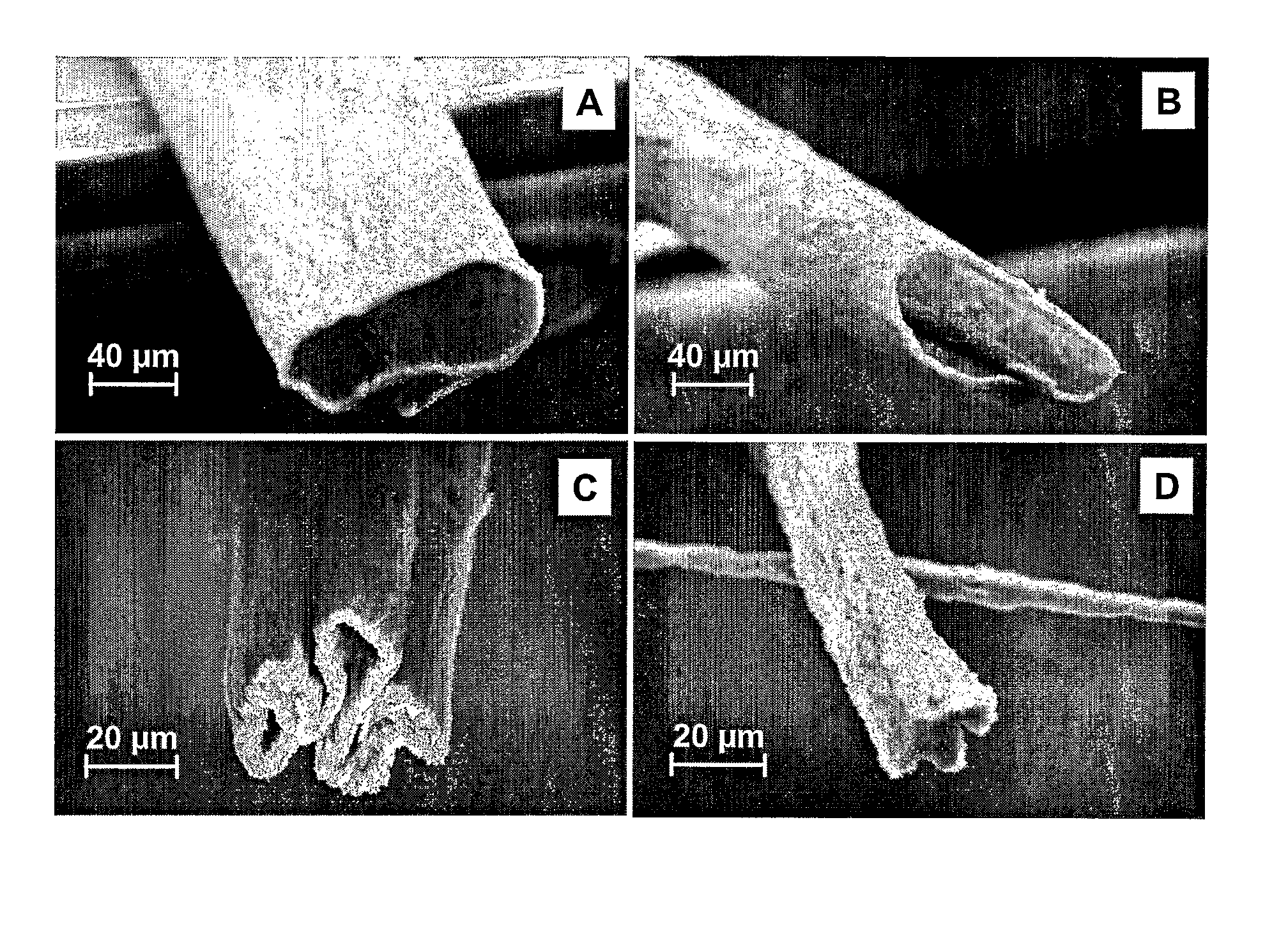

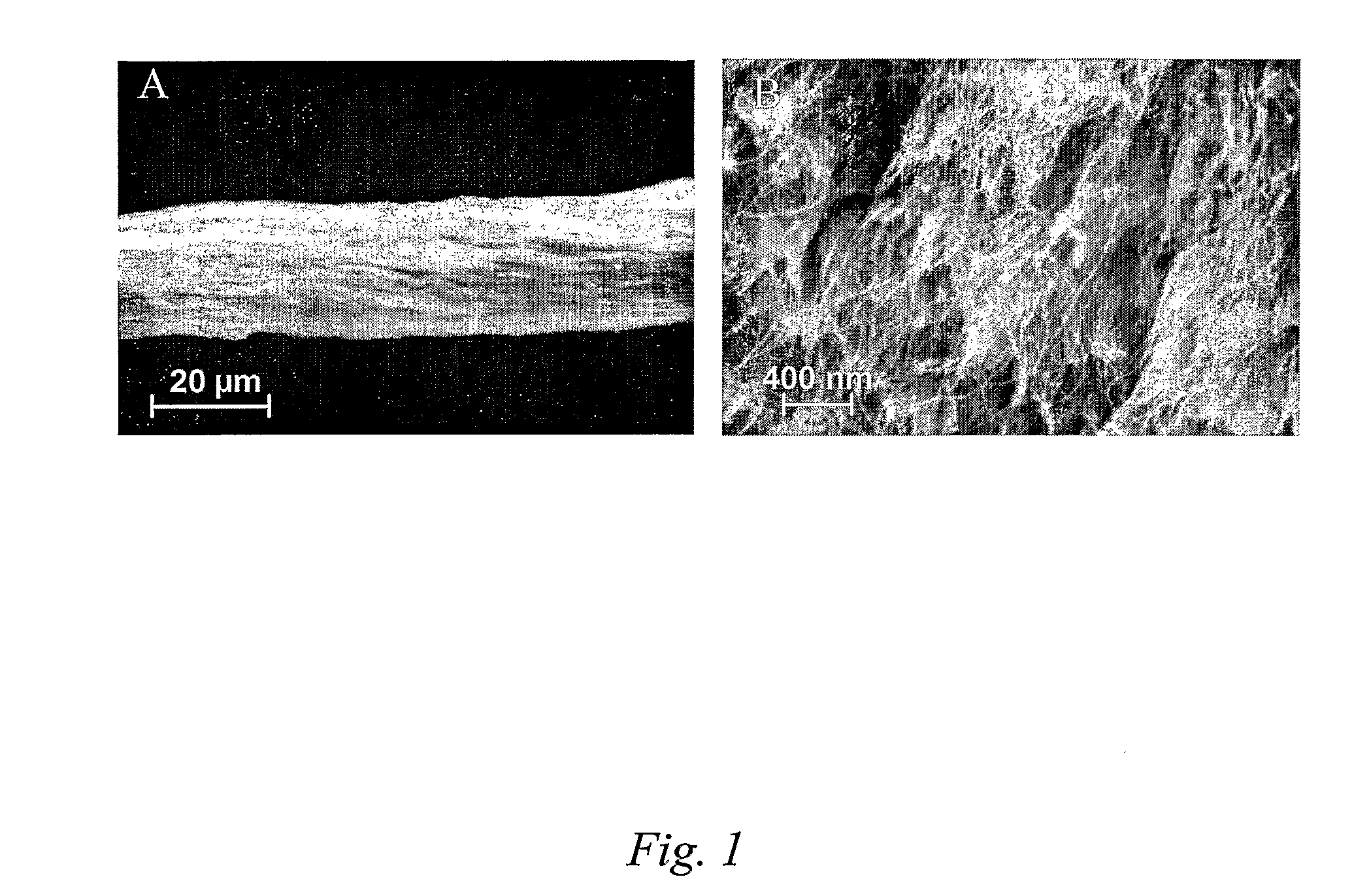

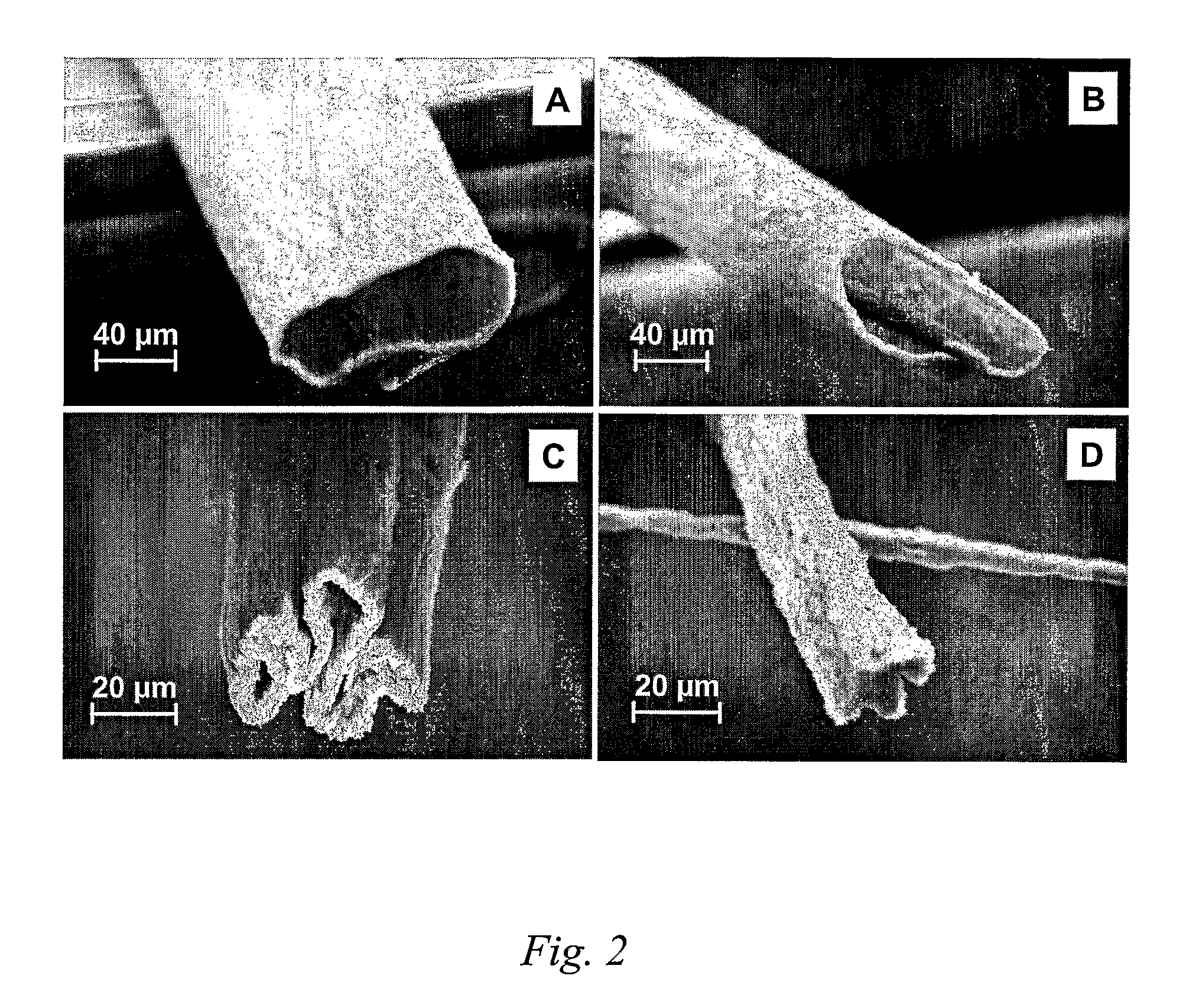

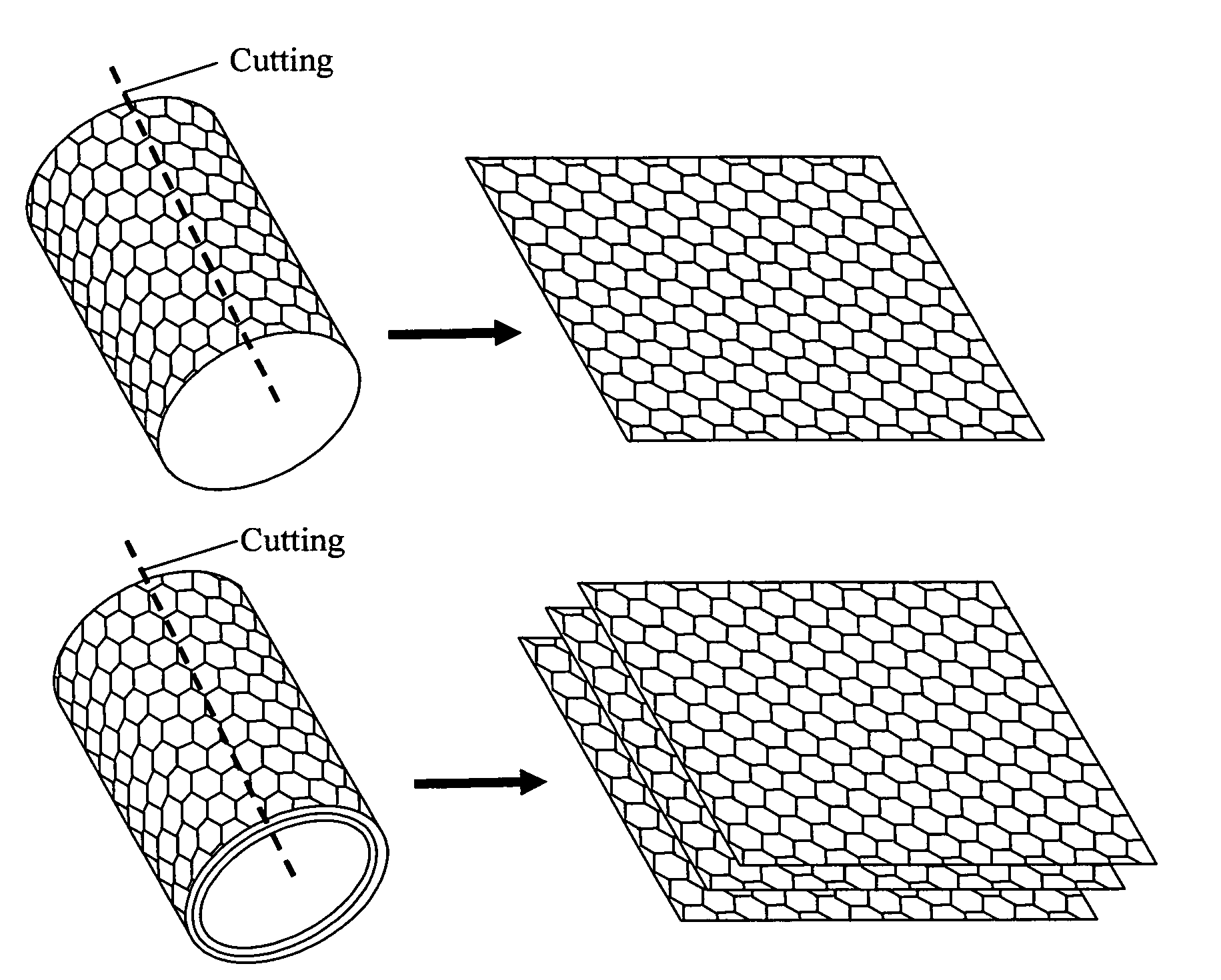

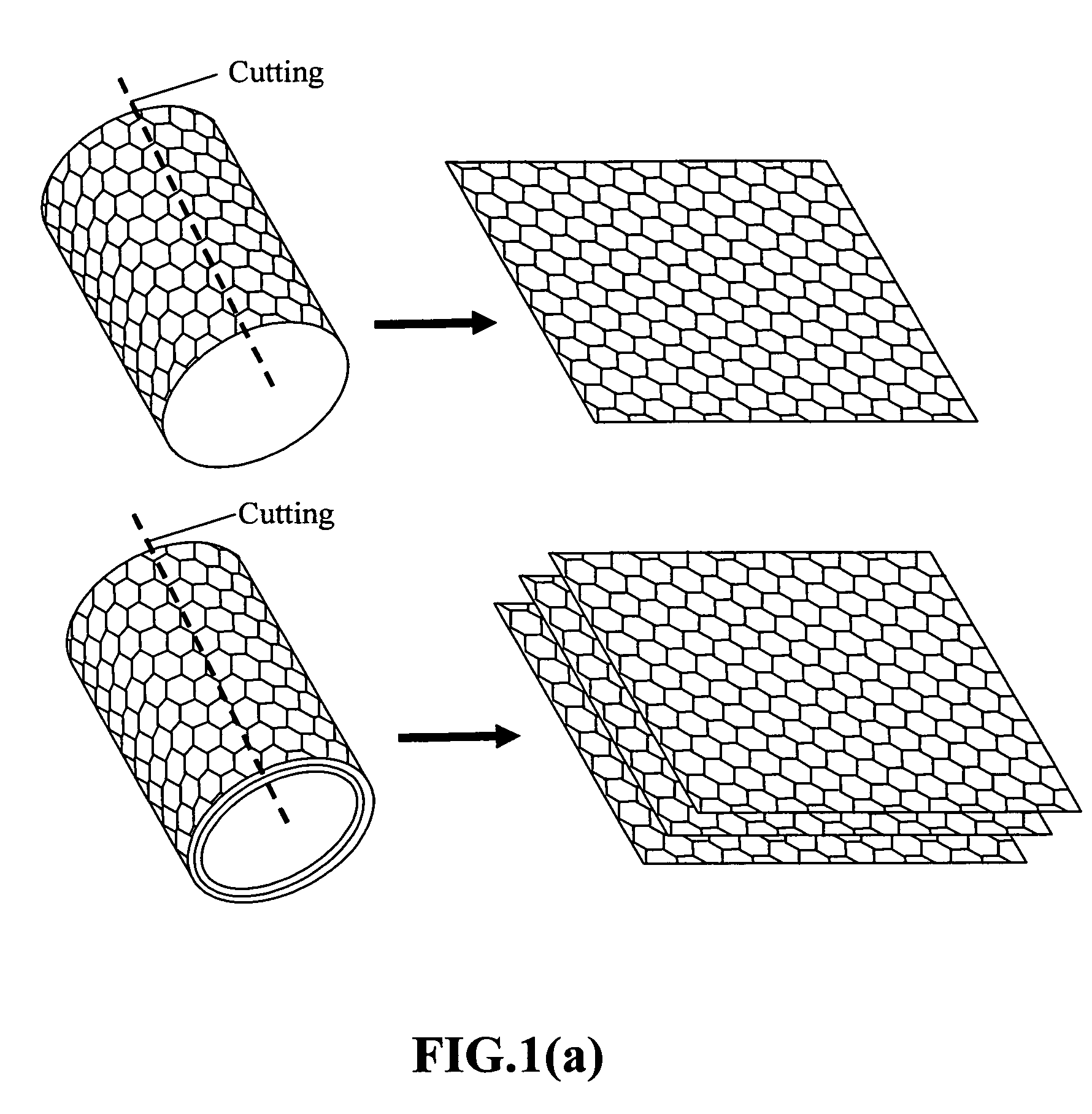

Polymer-Free Carbon Nanotube Assemblies (Fibers, Ropes, Ribbons, Films)

InactiveUS20070243124A1Pigmenting treatmentMaterial nanotechnologyCarbon nanotubeElectromechanical actuator

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Highly conductive nano-scaled graphene plate nanocomposites and products

ActiveUS20070158618A1Improve conductivityImprove bulk conductivityMaterial nanotechnologyConductive materialElectrically conductiveNanometre

Owner:GLOBAL GRAPHENE GRP INC

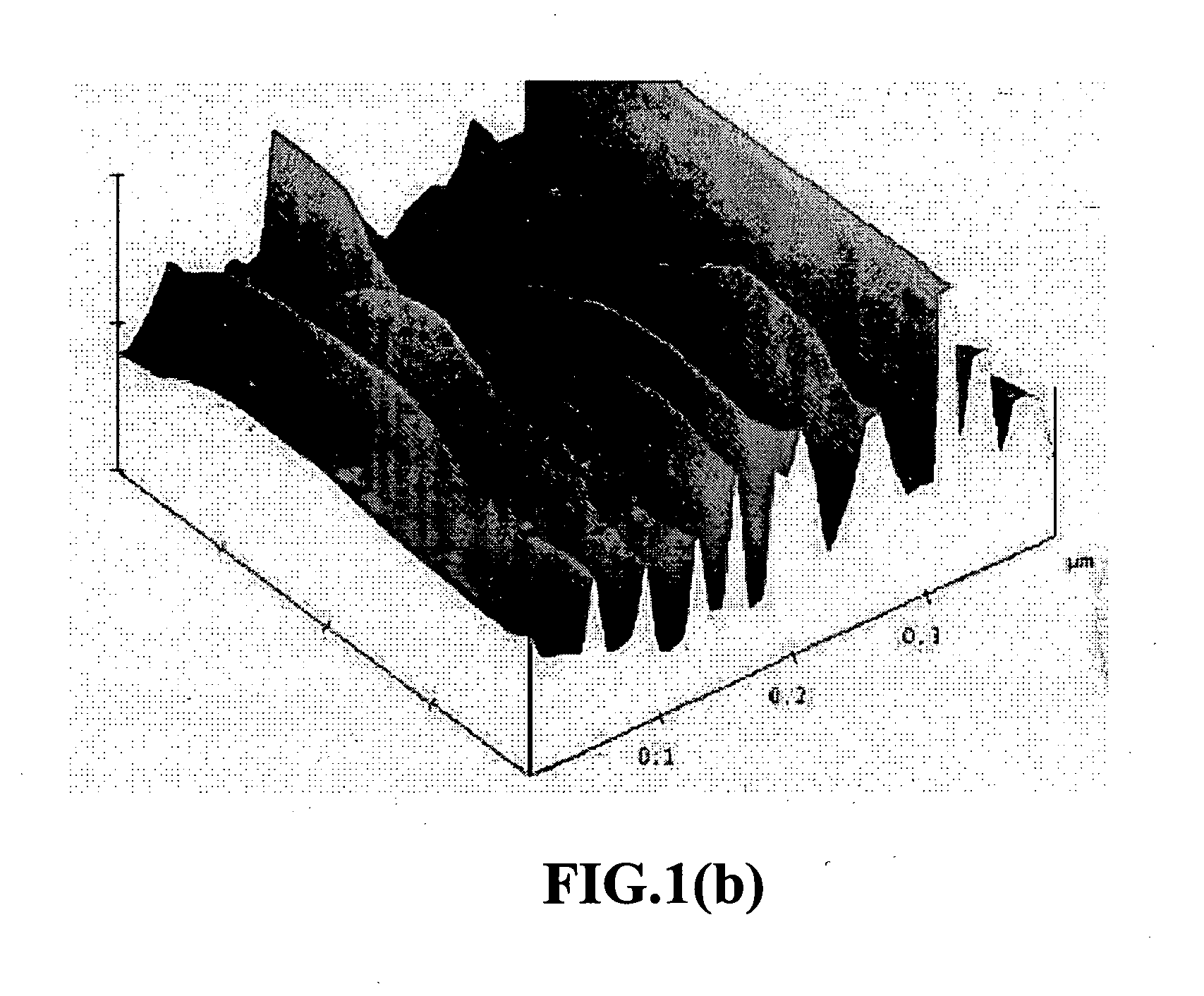

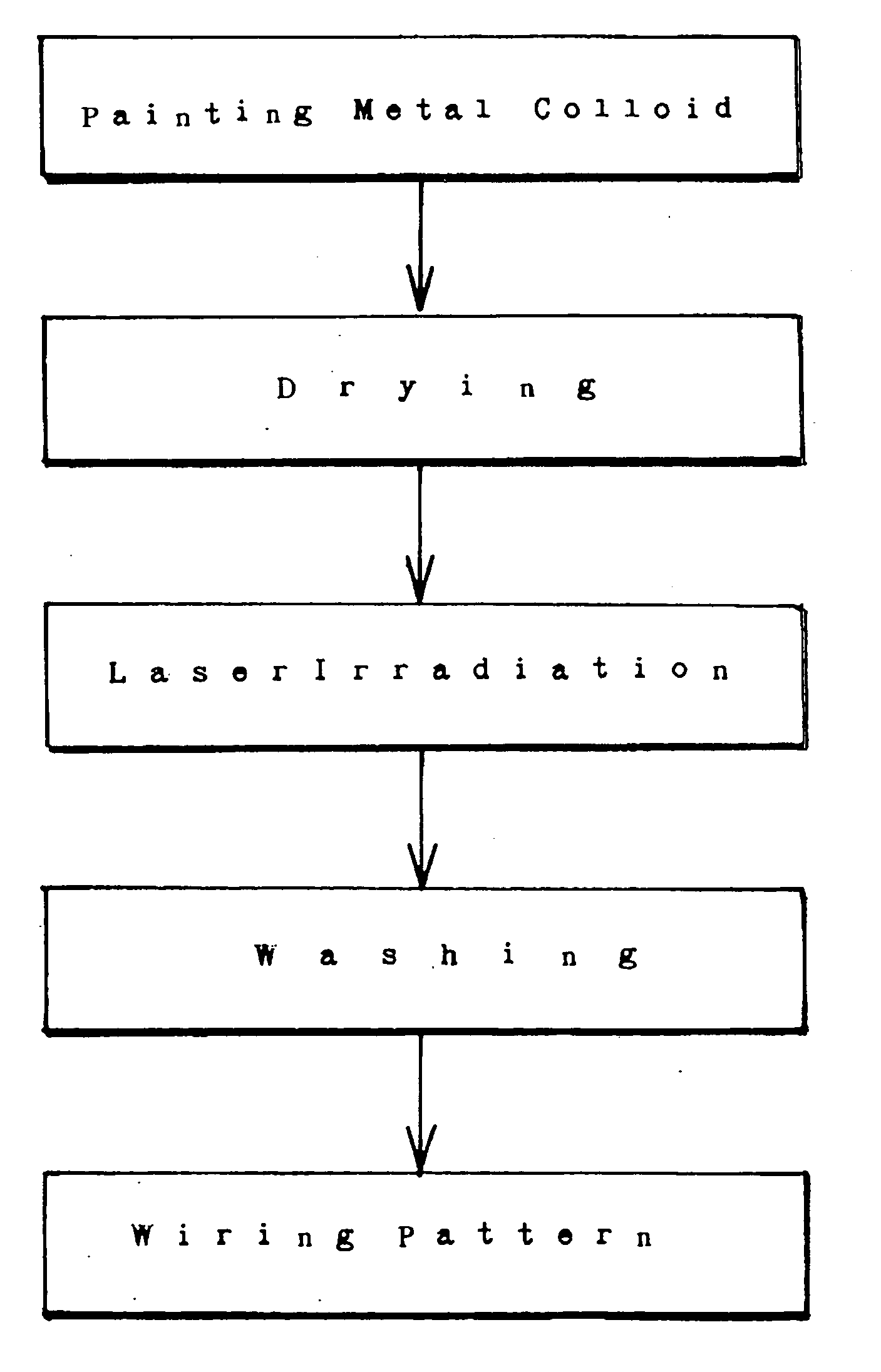

Method of forming a conductive wiring pattern by laser irradiation and a conductive wiring pattern

InactiveUS20060057502A1Poor adhesionEasy to eliminateMaterial nanotechnologyPhotomechanical apparatusResistCompound (substance)

Owner:SUMITOMO ELECTRIC IND LTD

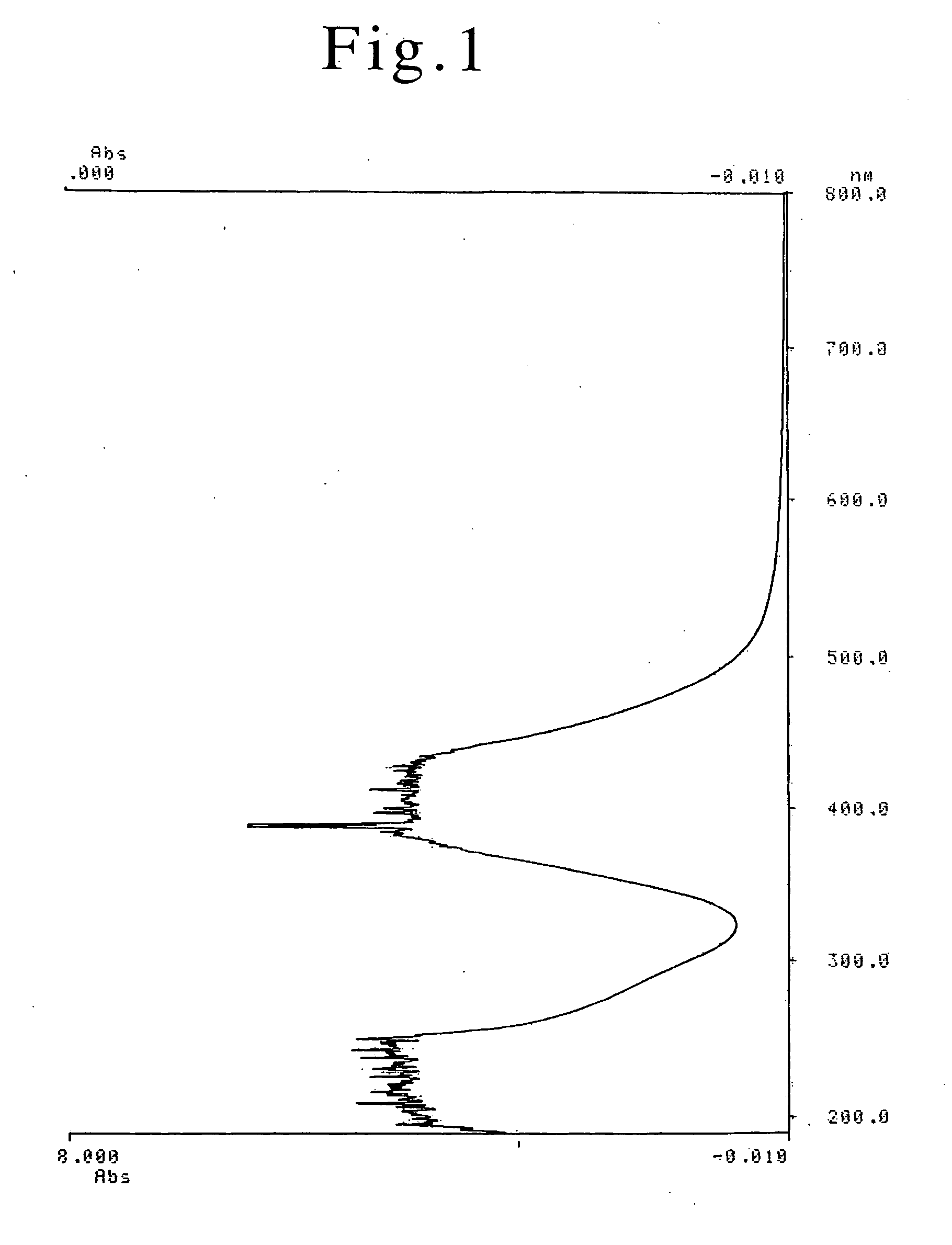

Metal Nanoparticle, Metal Nanoparticle Colloid, Method for Storing Metal Nanoparticle Colloid, and Metal Coating Film

InactiveUS20090029148A1Highly conductiveHighly stableMaterial nanotechnologyMetal-working apparatusConductive coatingOrganic acid

Owner:NIPPON SHOKUBAI CO LTD

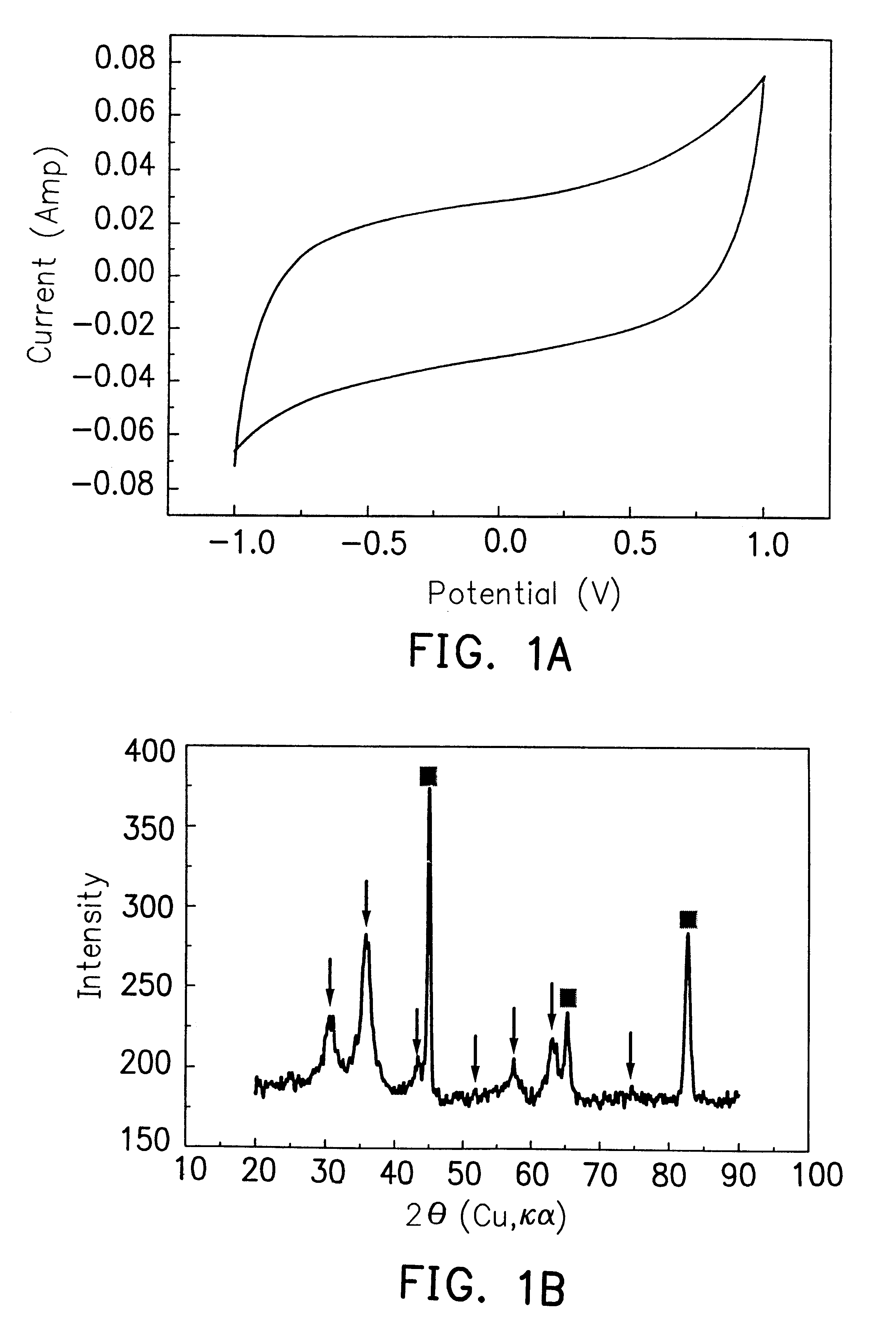

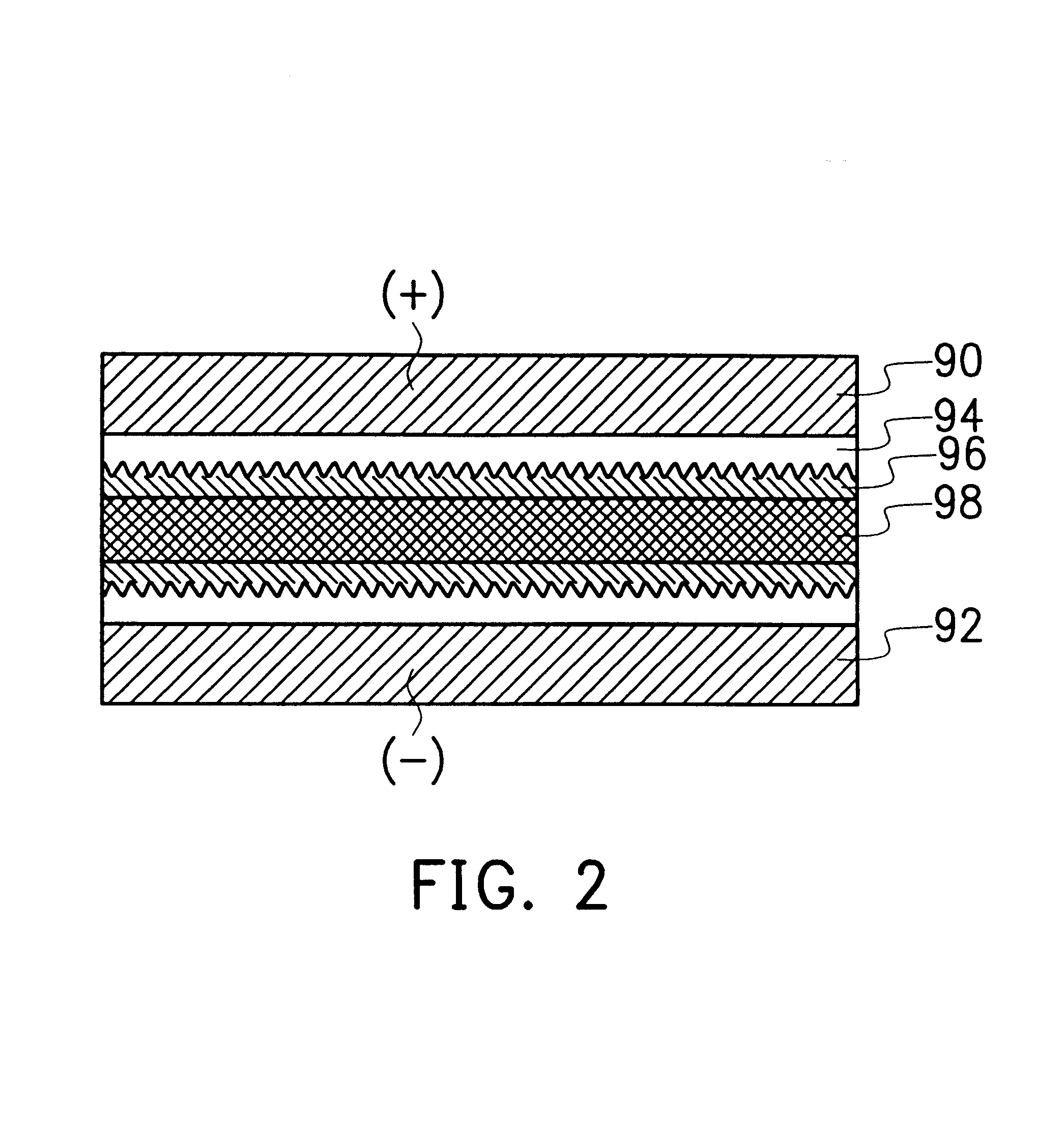

Ionic solvents used in ionic polymer transducers, sensors and actuators

InactiveUS20050103706A1Stable responseSolve the stability is not highMaterial nanotechnologySemi-permeable membranesIonomerTransducer

Ionic liquids are incorporated into transducers, actuators or sensors which employ the ionic polymer membranes. The ionic liquids have superior electrochemical stability, low viscosity and low vapor pressure. The transducers, actuators and sensors which utilize ionic polymer membranes solvated with ionic liquids have long term air stability. Superior results are achieved when a conductive powder and ionomer mixture is applied to the ionic polymer membrane to form the electrodes during or after the ionic liquid is imbibed into the ionic polymer membrane.

Owner:VIRGINIA TECH INTPROP INC +1

Anti-stiction technique for thin film and wafer-bonded encapsulated microelectromechanical systems

ActiveUS20050095833A1Material nanotechnologyAcceleration measurement using interia forcesDamp environmentOperating environment

Owner:ROBERT BOSCH GMBH

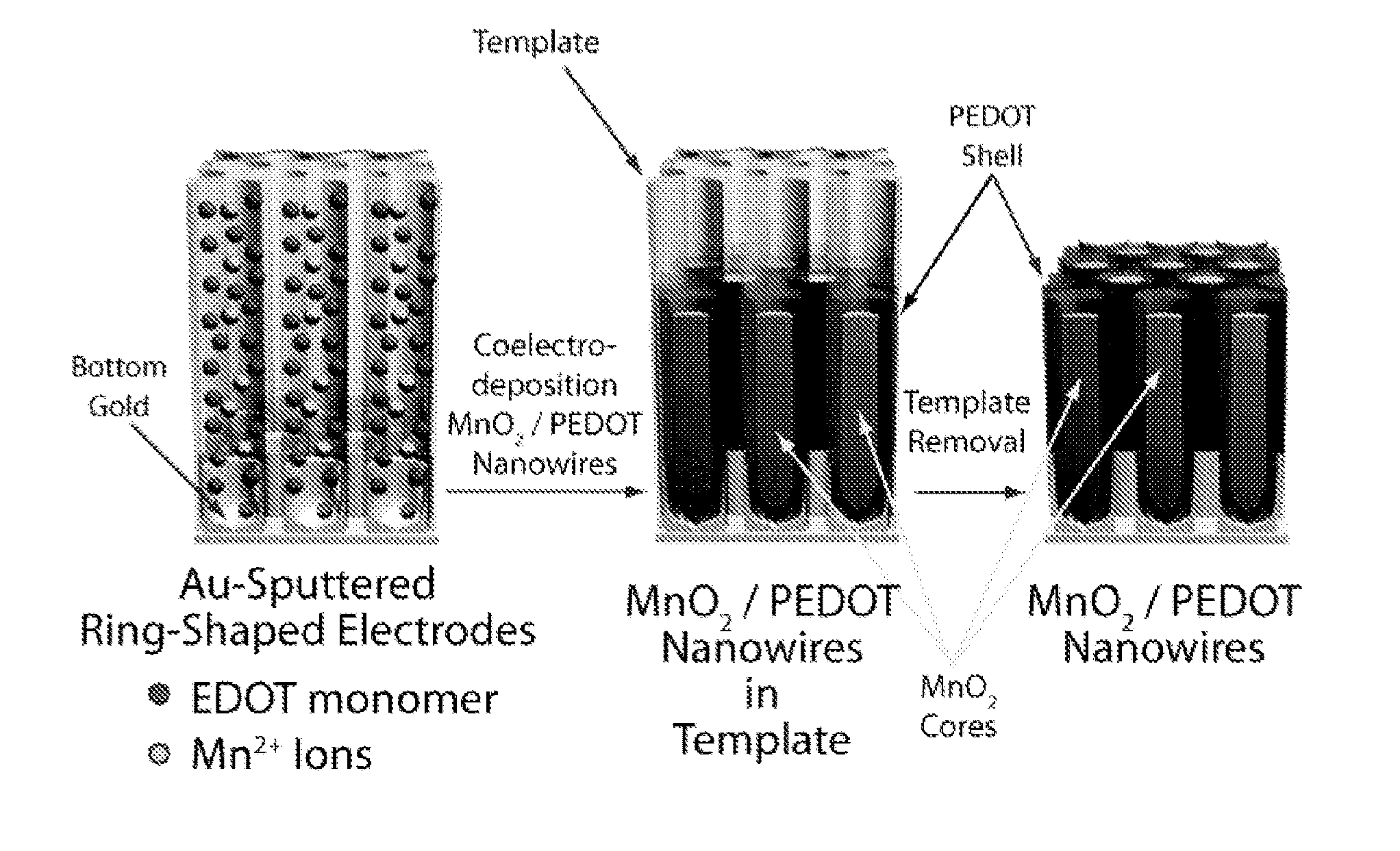

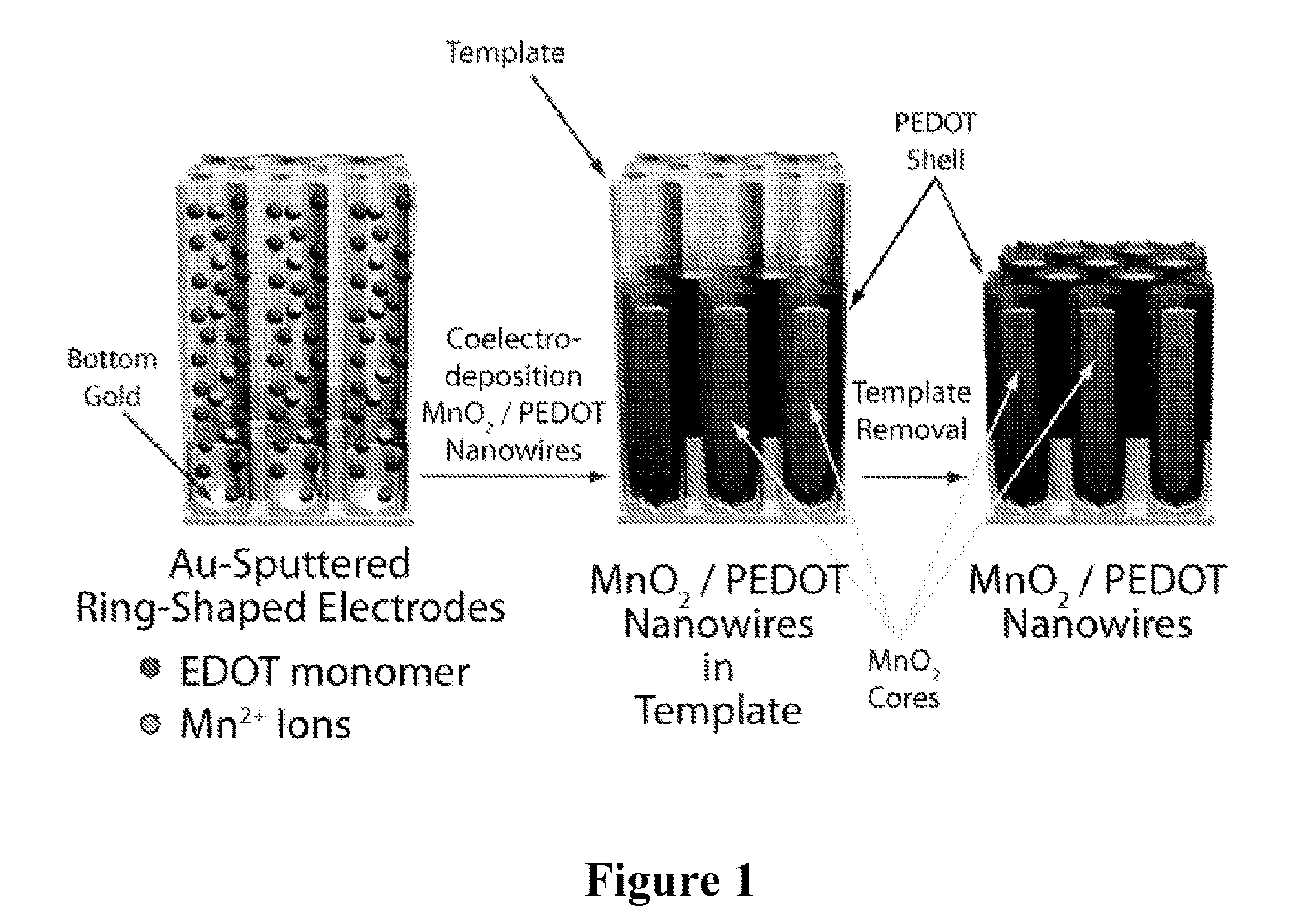

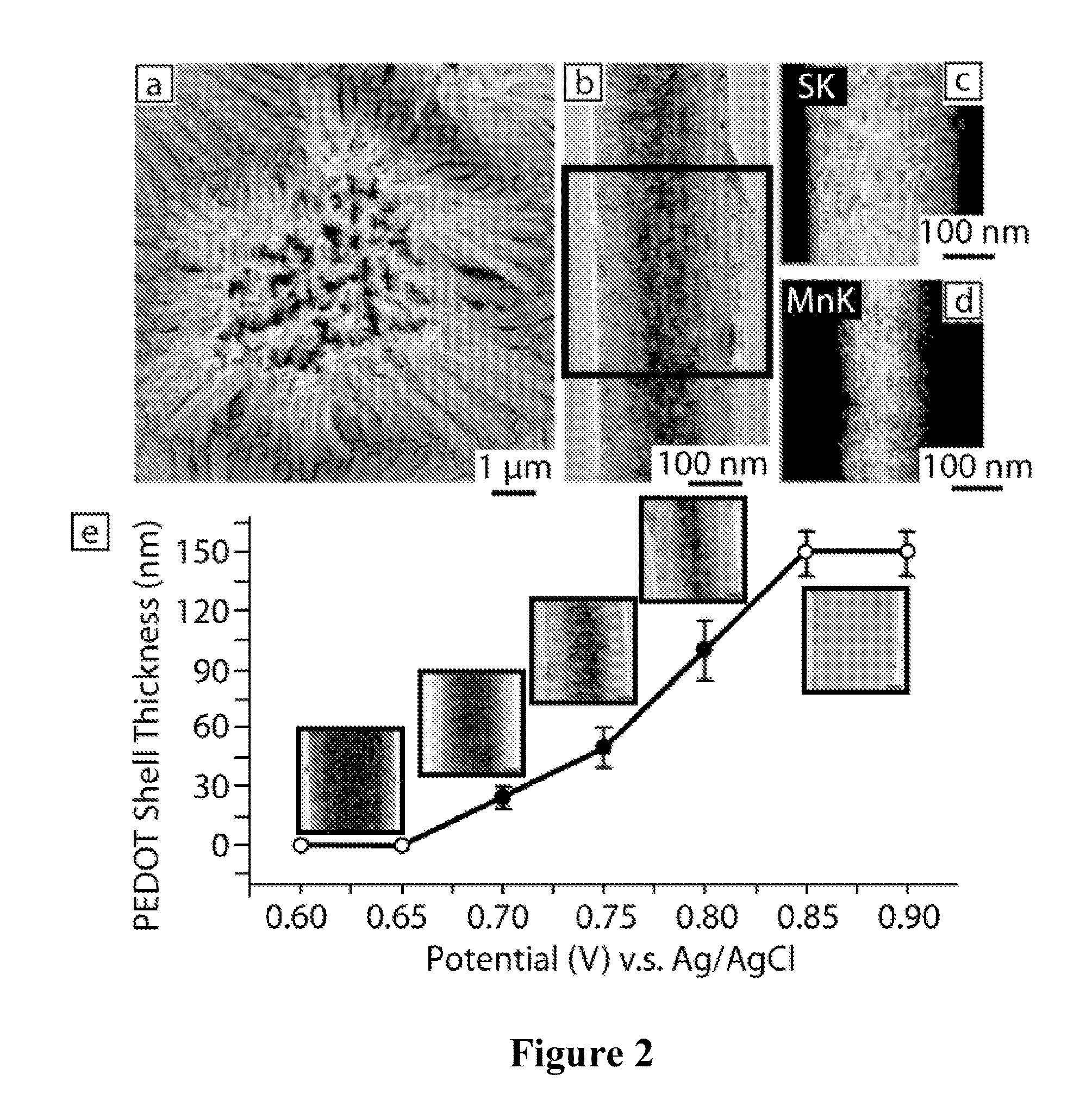

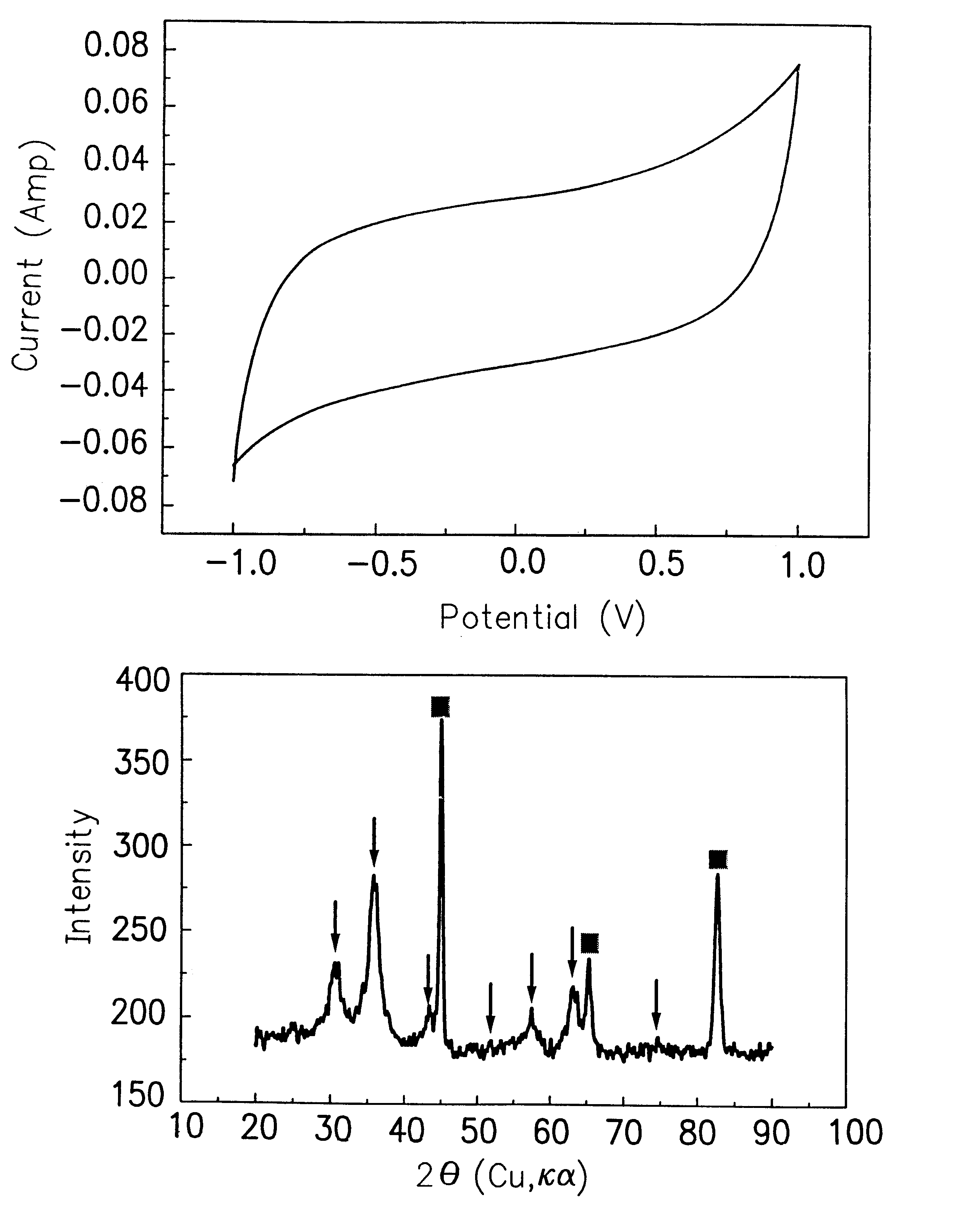

High-Powered Electrochemical Energy Storage Devices and Methods for Their Fabrication

ActiveUS20100266897A1Silver accumulatorsMaterial nanotechnologySelf-assemblyElectrochemical energy storage

Owner:UNIV OF MARYLAND

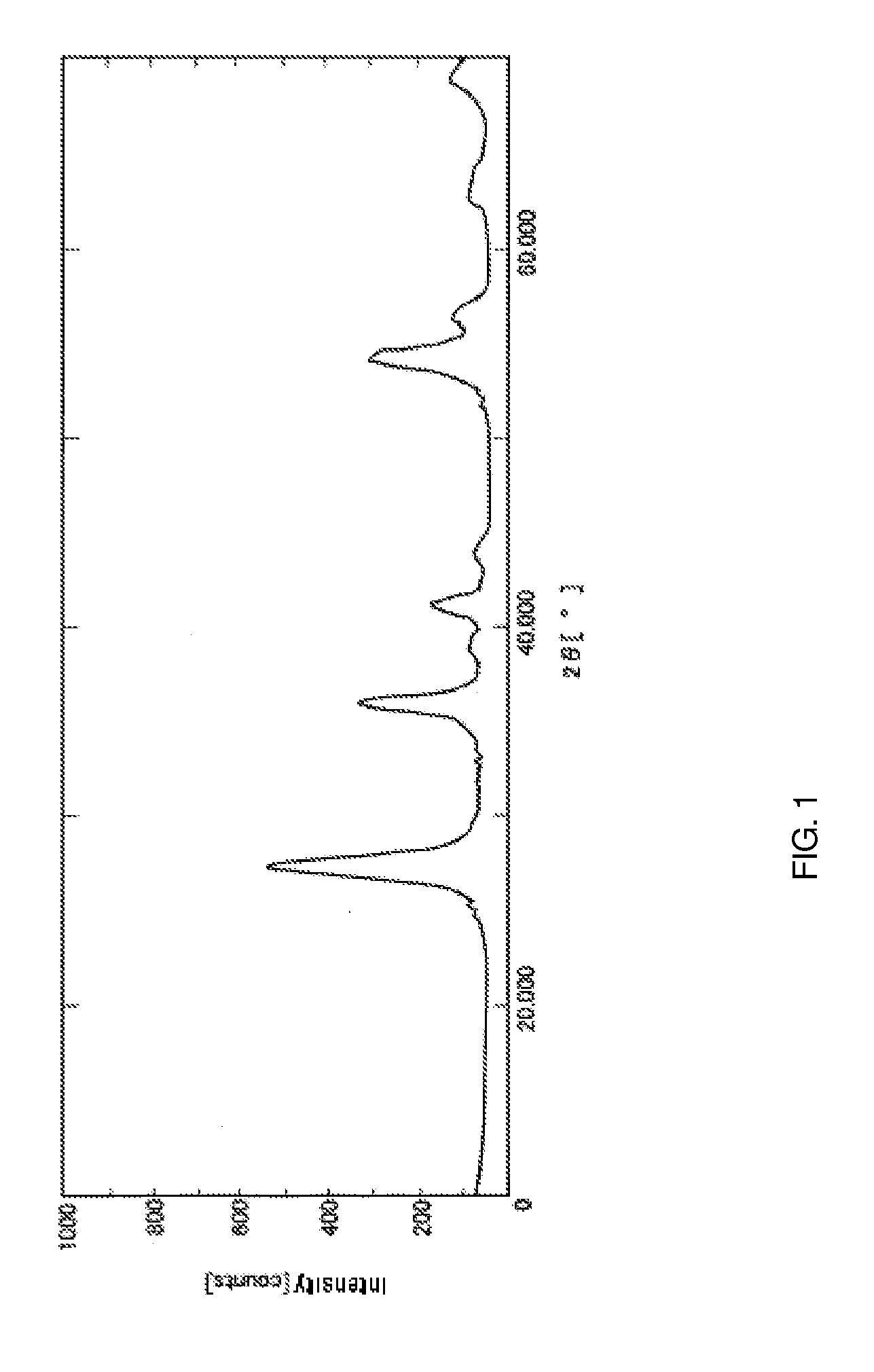

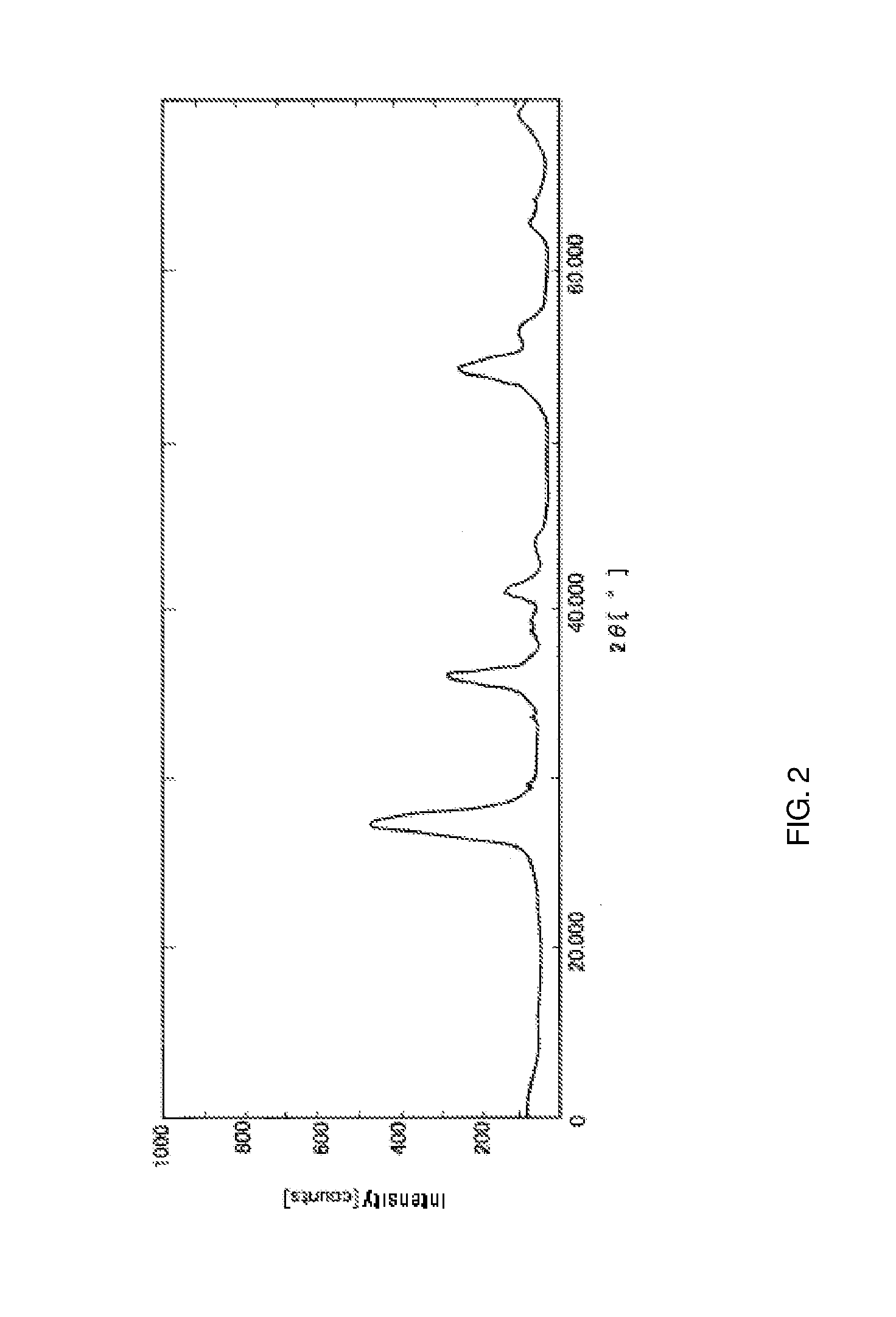

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

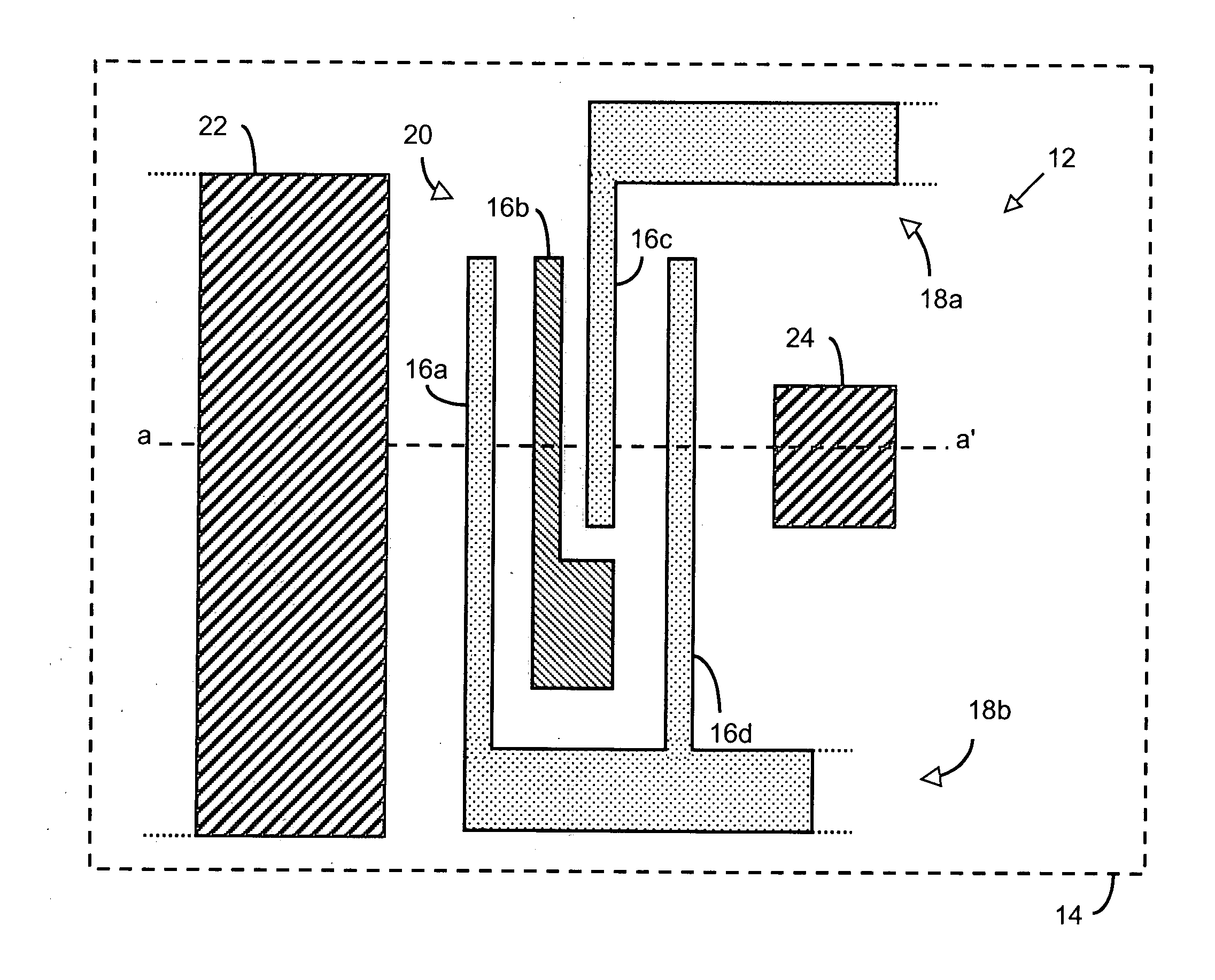

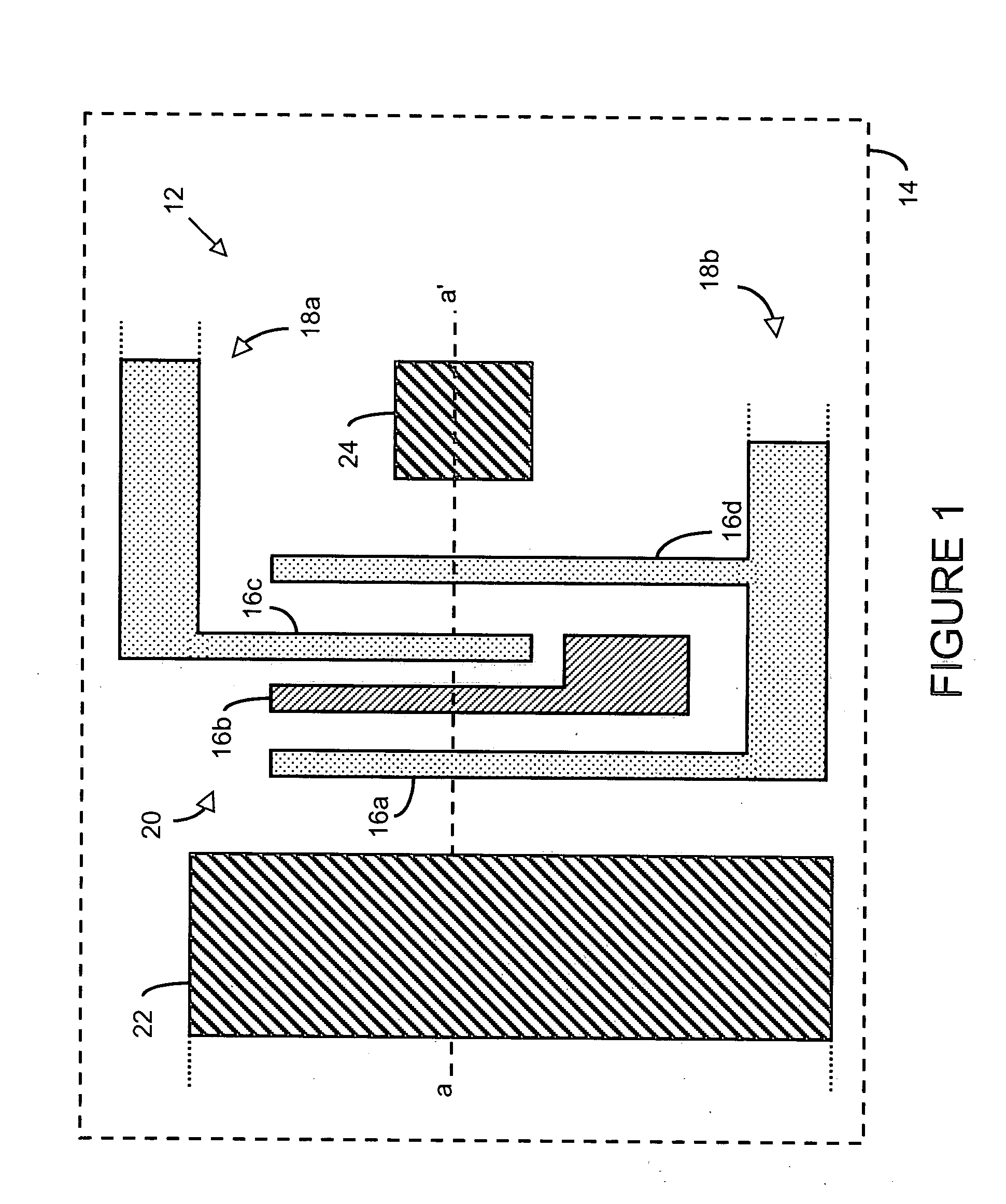

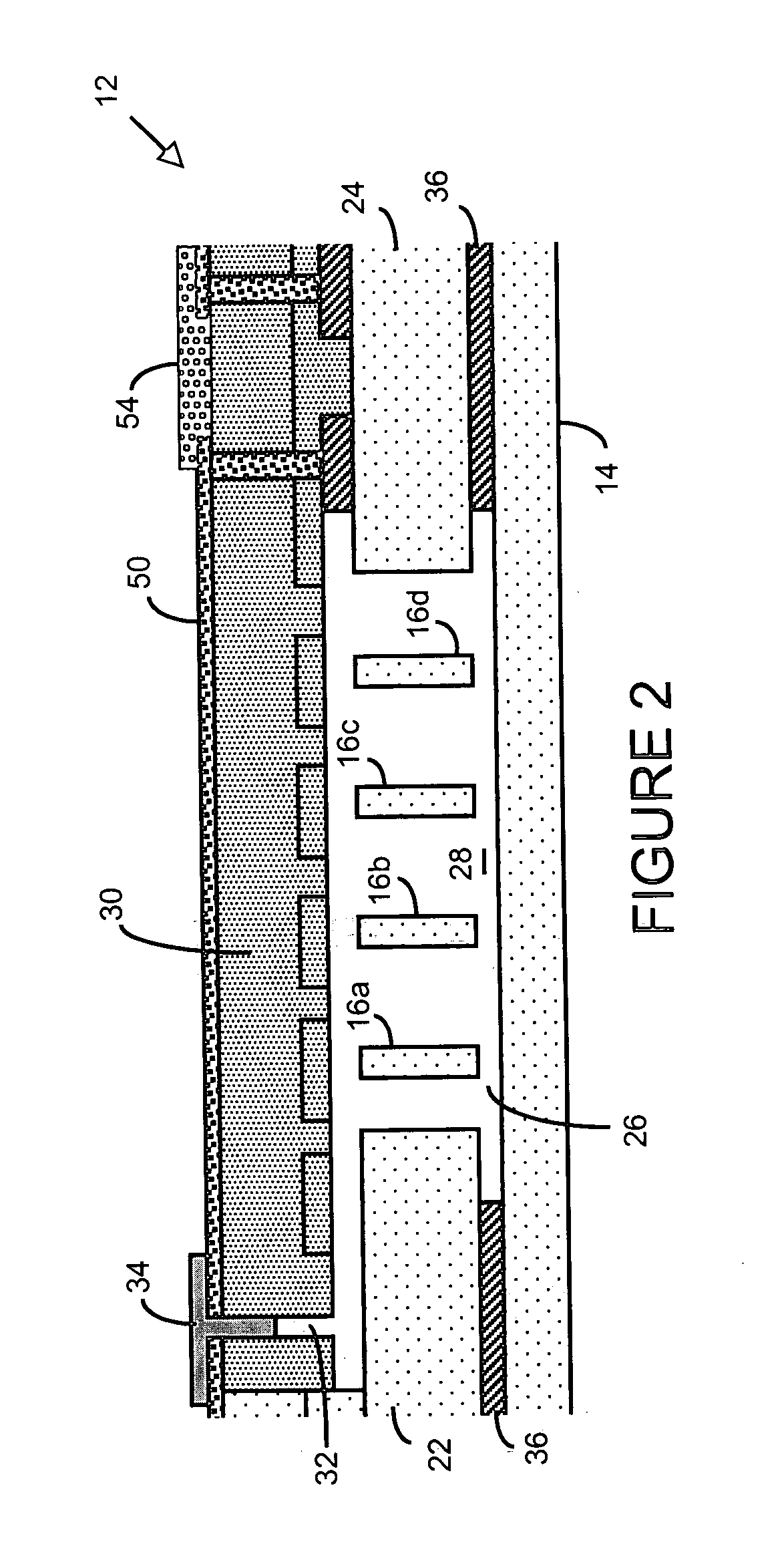

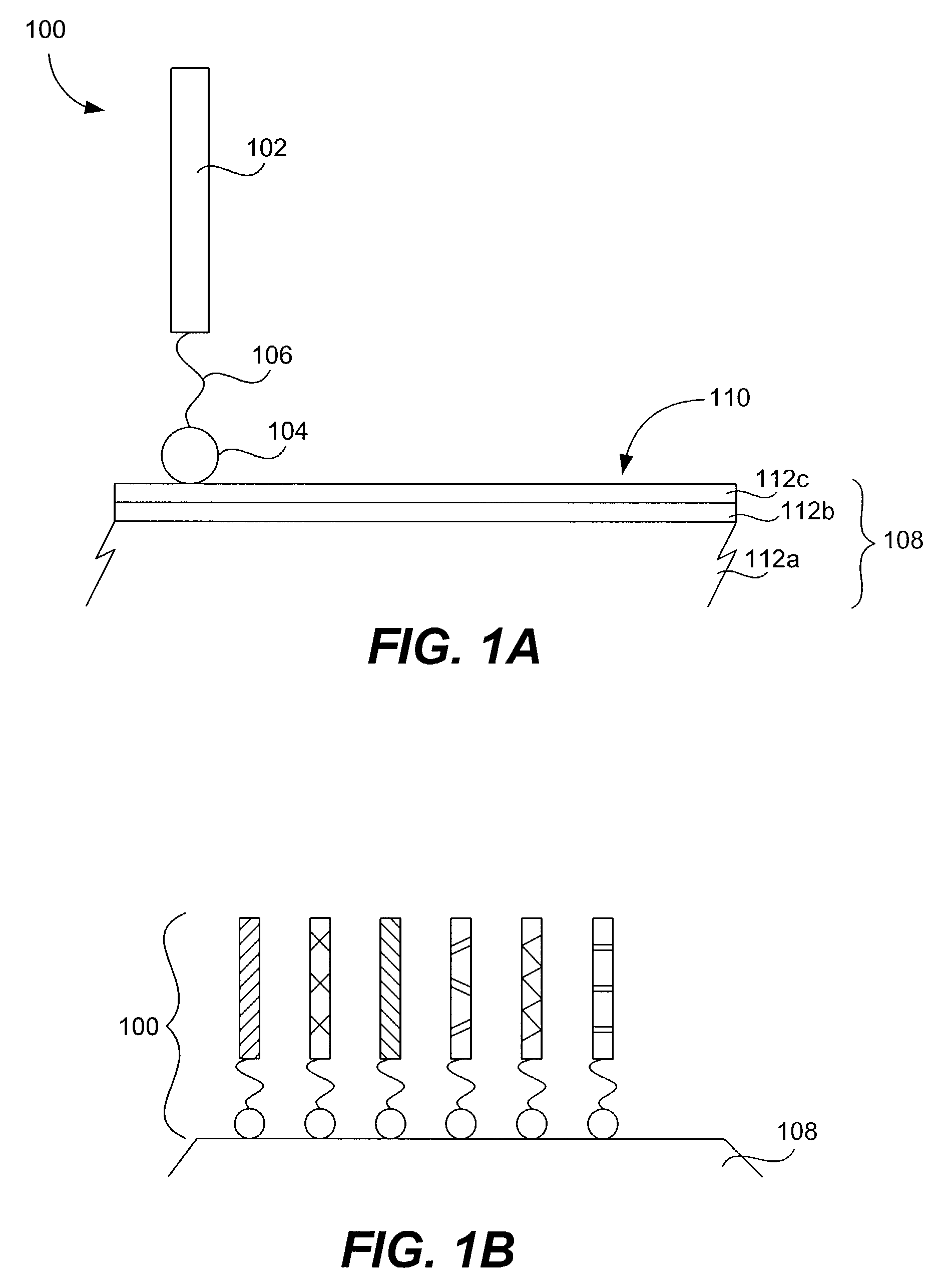

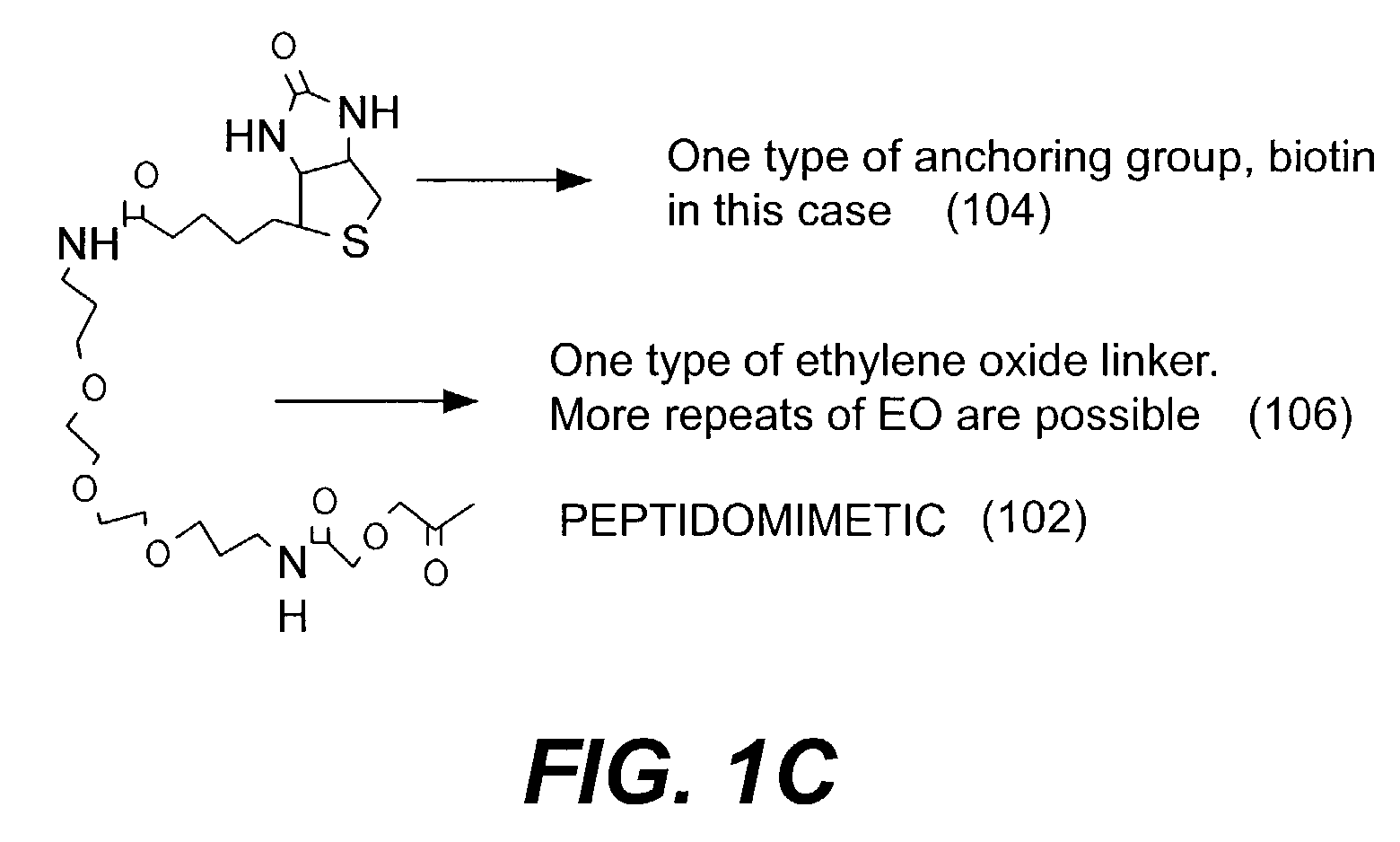

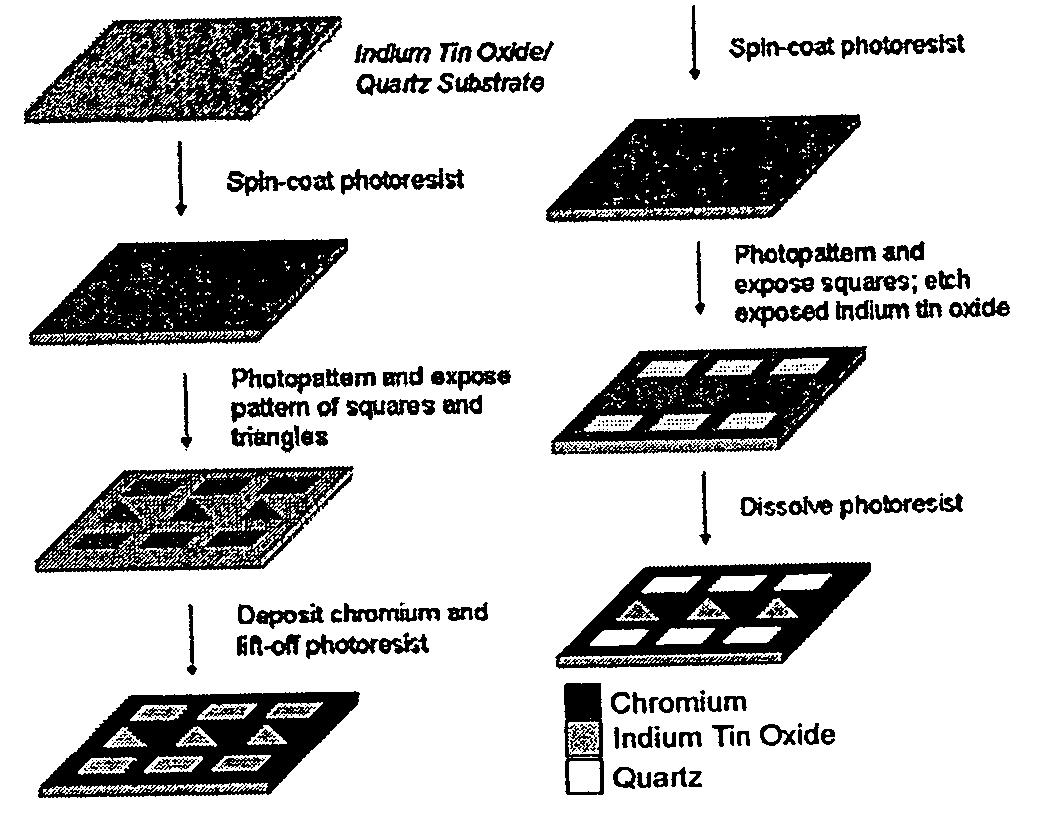

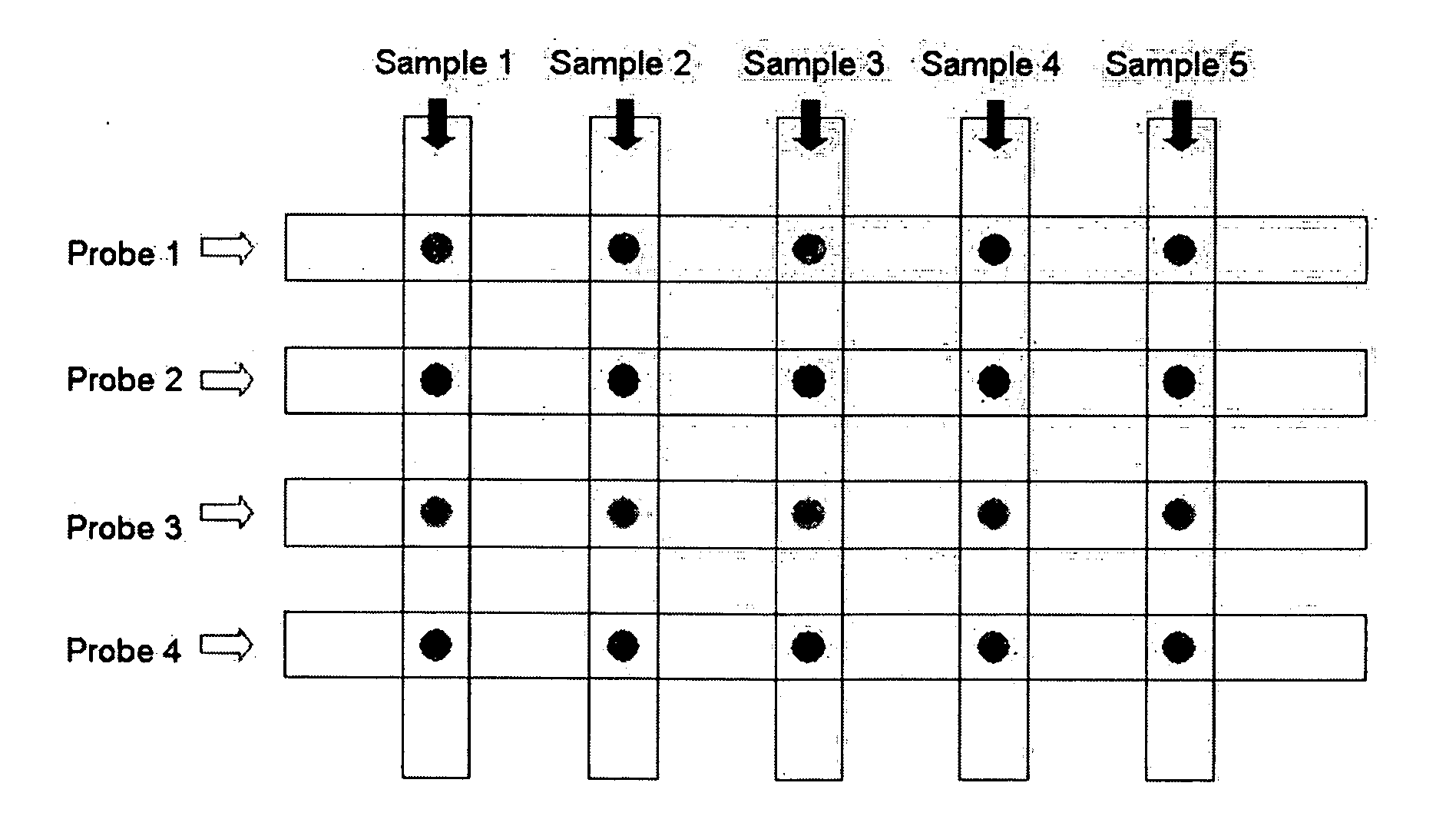

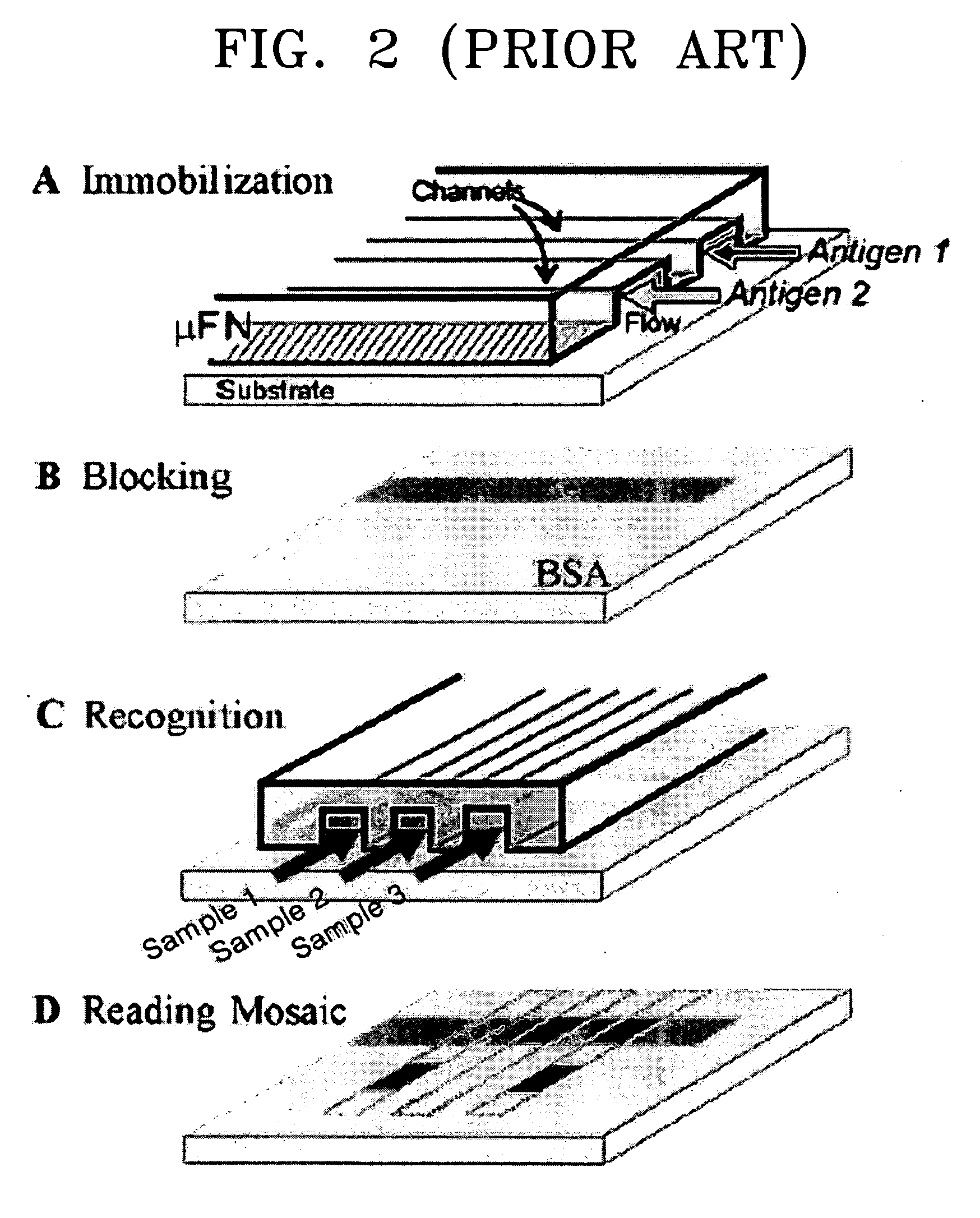

Device for arraying biomolecules and for monitoring cell motility in real-time

The invention relates to devices, devices for arraying biomolecules, including cells, methods for arraying biomolecules, assays for monitoring cellular movement, and systems for monitoring cellular movement. The devices include a support; a first layer configured to be placed in fluid-tight contact with the support, the first layer having an upper surface and defining a pattern of micro-orifices, each micro-orifice of the pattern of micro-orifices having walls and defining a micro-region on the support when the first layer is placed in fluid-tight contact with the support such that the walls of said each micro-orifice and the micro-region on the support together define a micro-well; and a second layer configured to be placed in fluid-tight contact with the upper surface of the first layer, the second layer defining a pattern of macro-orifices, each macro-orifice of the pattern of macro-orifices having walls and defining a macro-region when the first layer is placed in fluid-tight contact with the support and the second layer is placed in fluid-tight contact with the first layer such that the walls of the macro-orifice and the macro-region together define a macro-well.

Owner:SURFACE LOGIX INC

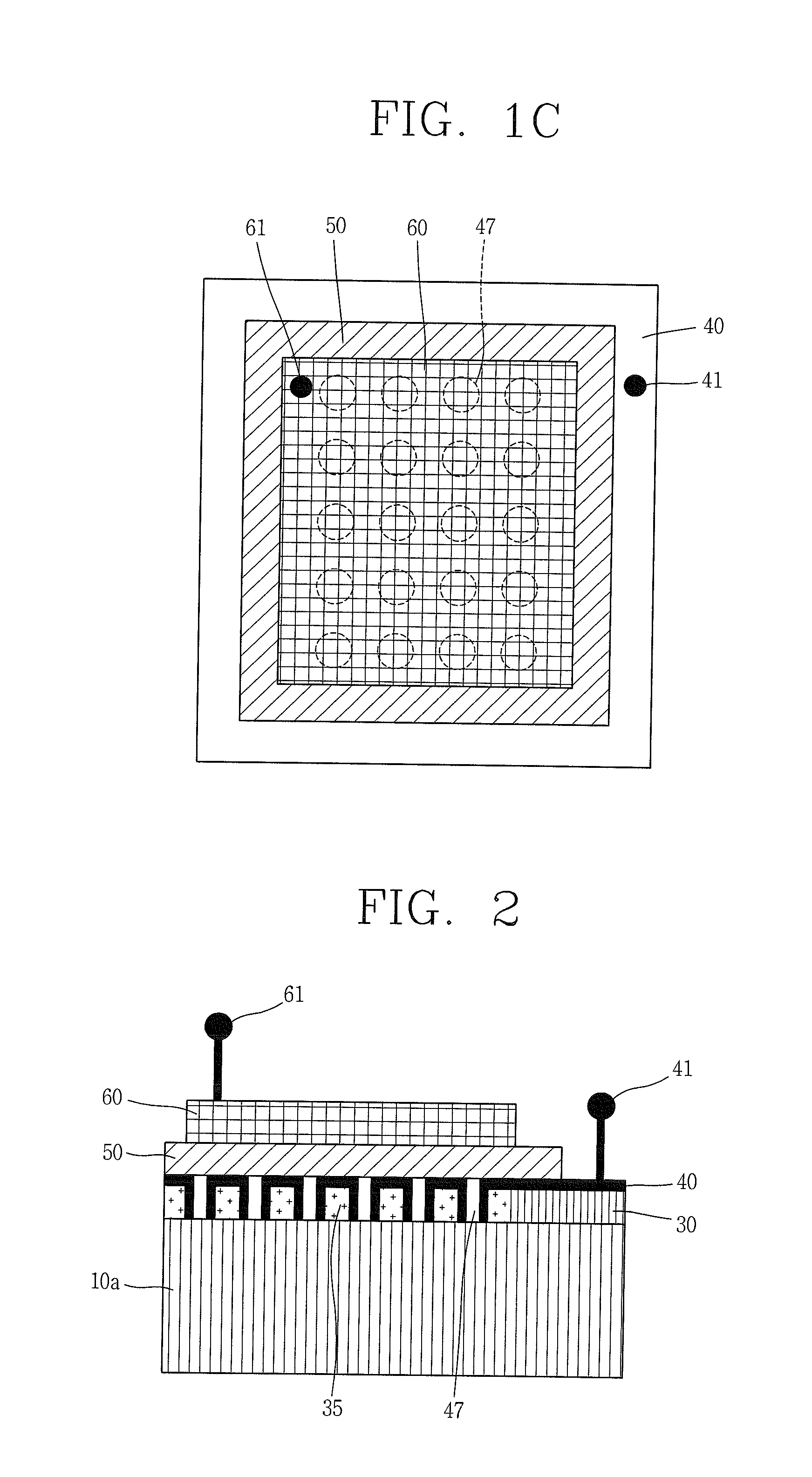

Supercapacitors and method for fabricating the same

Owner:LUXON ENERGY DEVICES CORP

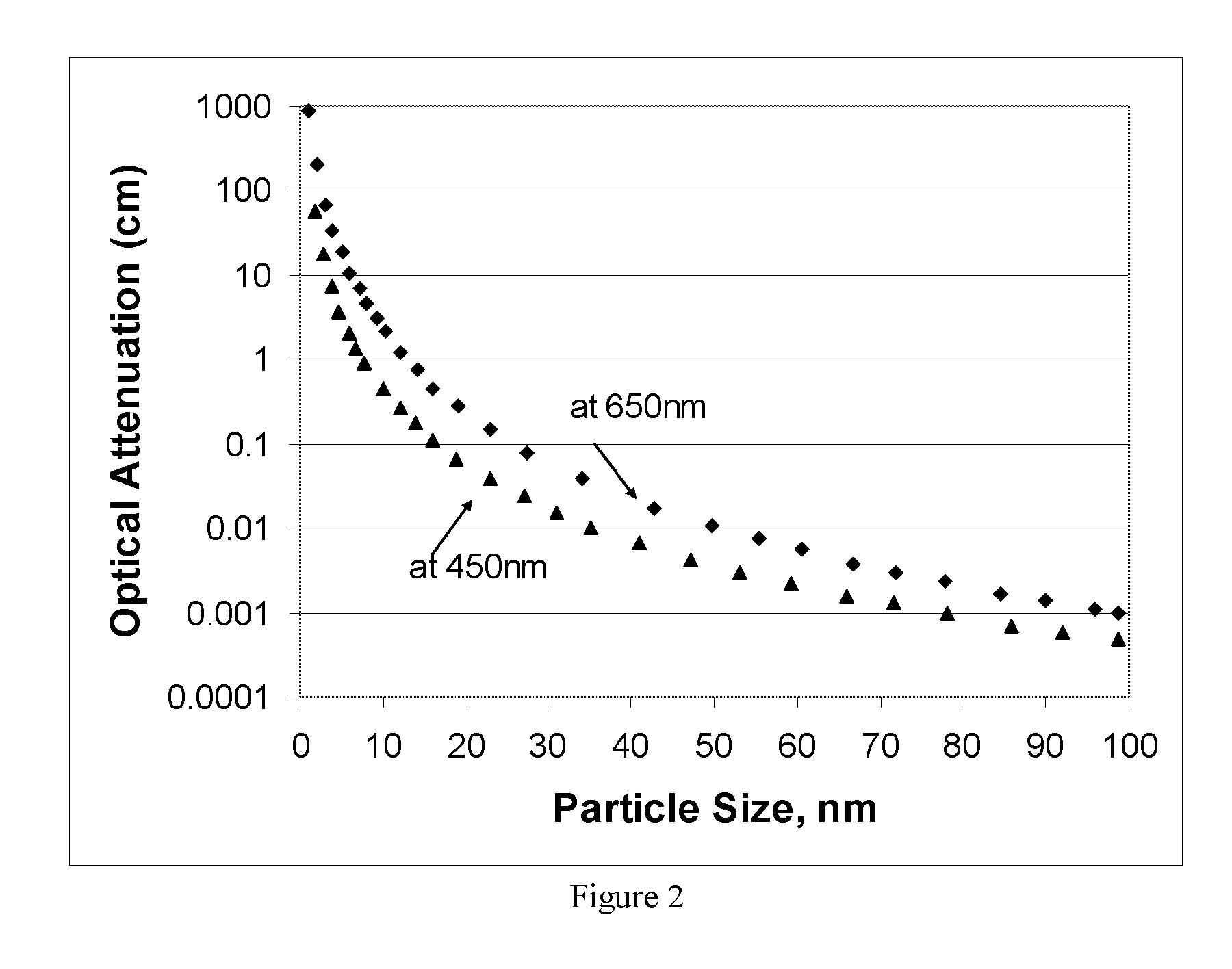

High refractive index materials and composites thereof

This invention discloses composite materials utilizing high refractive index matrices and their use with phosphors and scintillators. Further, the index of refraction difference between the matrix and the particles is less than 0.15.

Owner:AJJER

Solid Electrolytic Capacitor Containing a Poly(3,4-Ethylenedioxythiophene) Quaternary Onium Salt

ActiveUS20120147529A1Highly solubleEasily and cost-effectively formedMaterial nanotechnologyHybrid capacitor electrolytesDielectricElectrolysis

A solid electrolytic capacitor a solid electrolytic capacitor that includes an anode body, a dielectric overlying the anode body, and a solid electrolyte overlying the dielectric is provided. The capacitor also comprises a conductive polymer coating that overlies the solid electrolyte and includes nanoparticles formed from a poly(3,4-ethylenedioxythiophene) quaternary onium salt.

Owner:CENT FOR ORGANIC CHEM +1

Non-volatile, resistive memory cell based on metal oxide nanoparticles, process for manufacturing the same and memory cell arrangement of the same

ActiveUS20070045704A1Improve storage densityLow costMaterial nanotechnologySolid-state devicesMetal oxide nanoparticlesContact position

Disclosed is a non-volatile memory cell including a first conductive electrode region, a second conductive electrode region and a memory region disposed therebetween. The memory region includes one or a plurality of metal oxide nanoparticles, which contact and electrically connect the first and the second electrode region via contact locations and which exhibit a bistable resistance properties when applying an external voltage.

Owner:POLARIS INNOVATIONS LTD

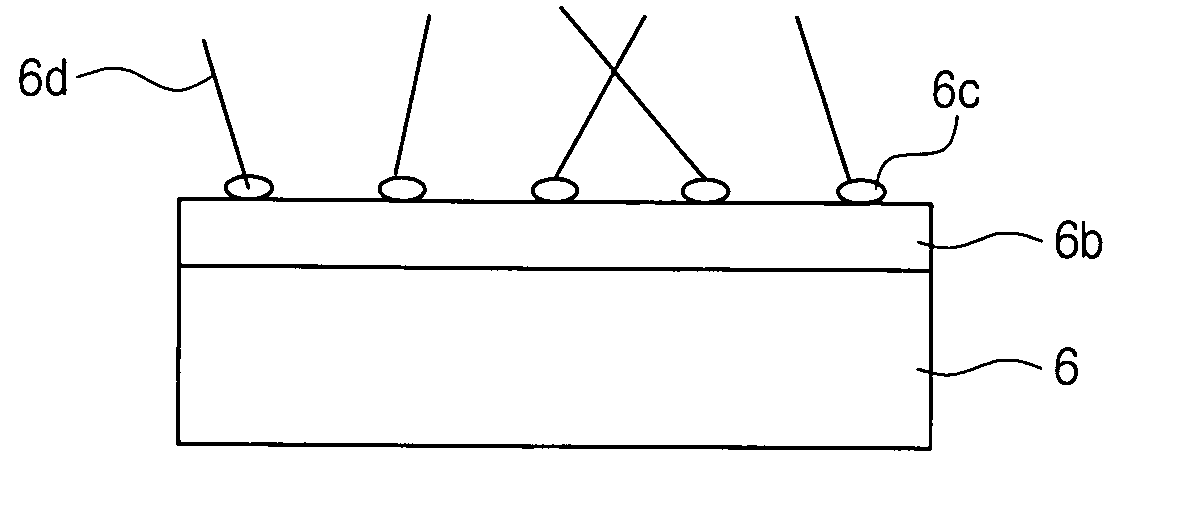

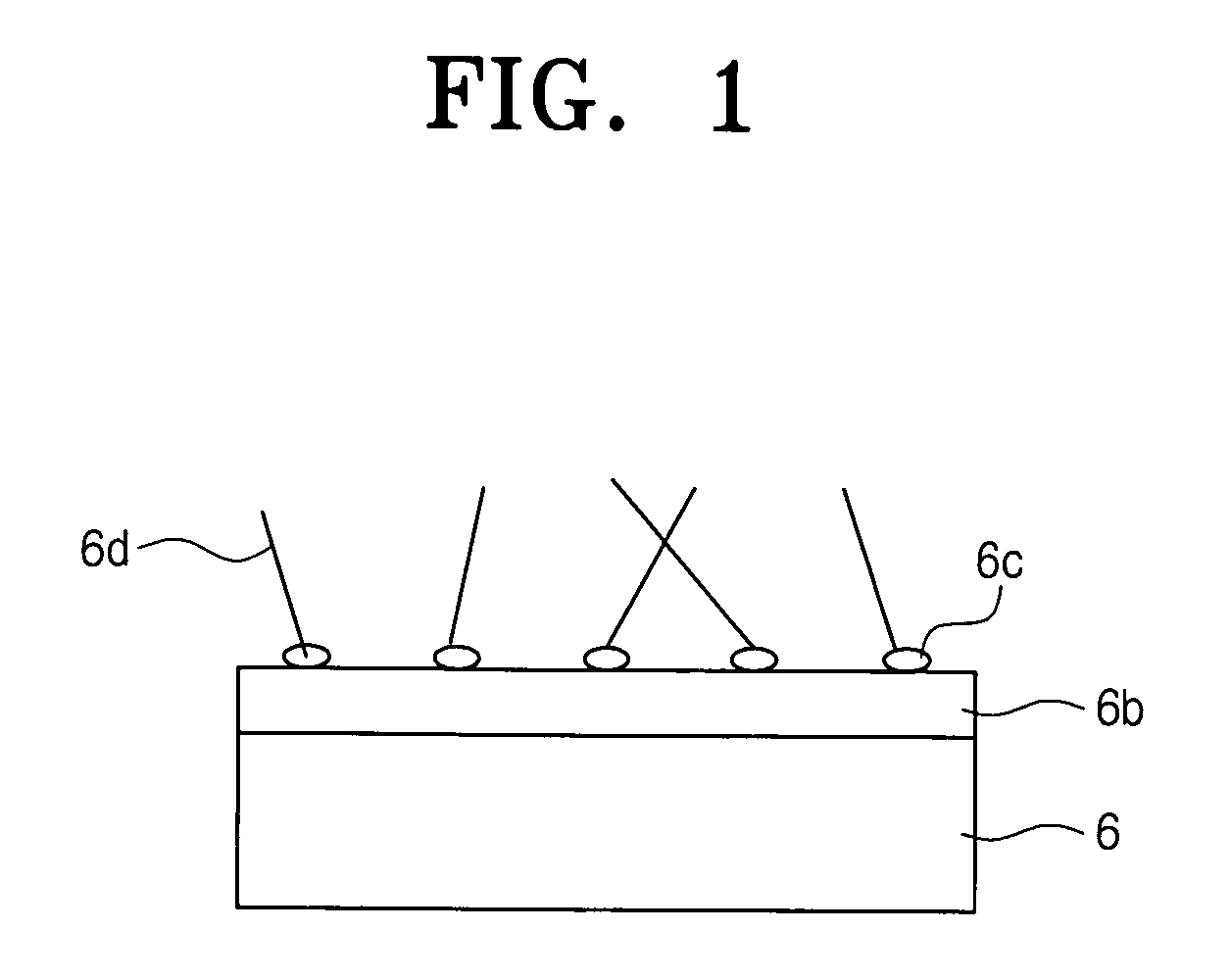

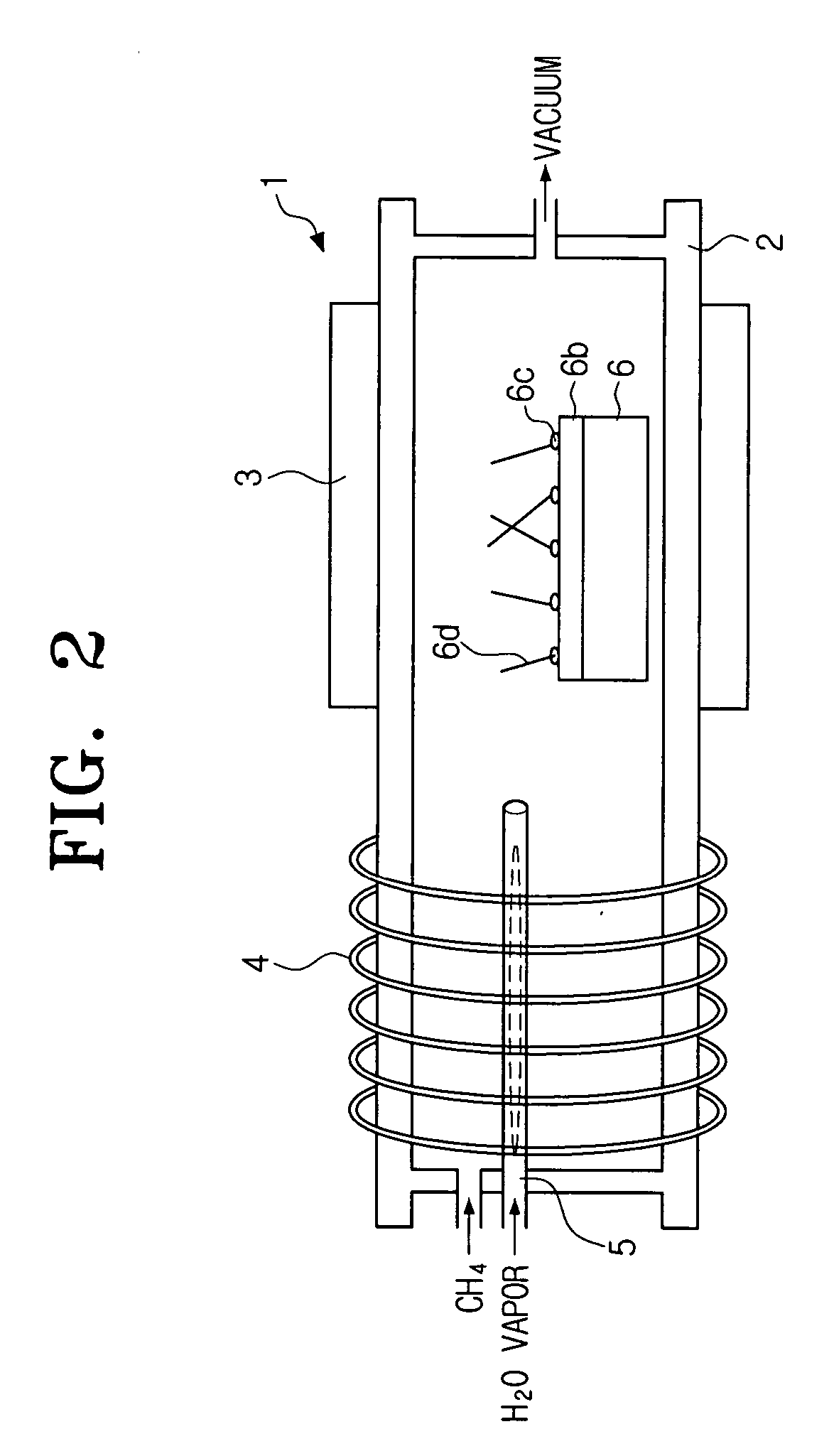

Method for manufacturing single-walled carbon nanotube on glass

InactiveUS20070154623A1Reduce the temperatureSpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeMaterials science

Owner:SAMSUNG ELECTRONICS CO LTD

Nanocomposite microcapsules for self-healing of composite articles

Nanocomposite microcapsules for self-healing of composites. The nanocomposite microcapsules comprise a urea-formaldehyde shell encompassing a liquid core of polymerizable healing agent. The microcapsules further comprise nanoparticulates encompassed in the core and also present on the outer surface of the microcapsule shell. Self-healing composites with the nanocomposite microcapsules embedded in the composite polymer matrix are also described. Methods of making and using the same are also disclosed.

Owner:THE WICHITA STATE UNIV

Microarrays on mirrored substrates for performing proteomic analyses

Owner:CHIRON CORP

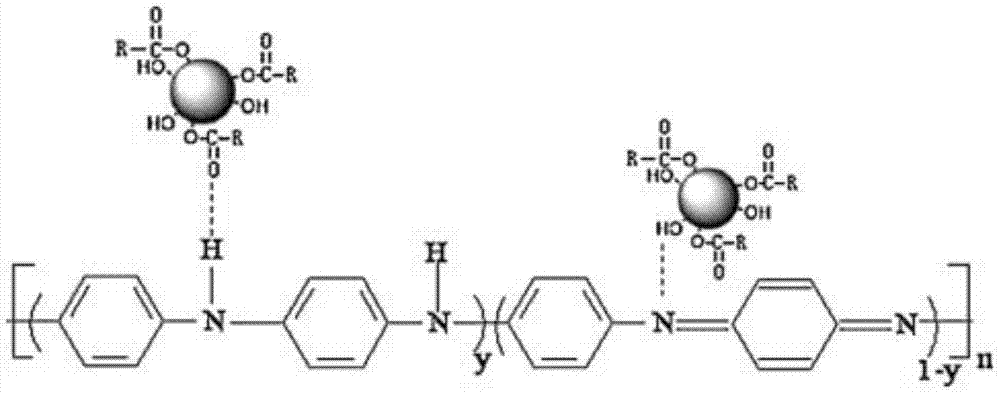

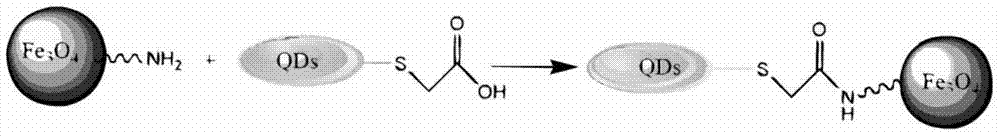

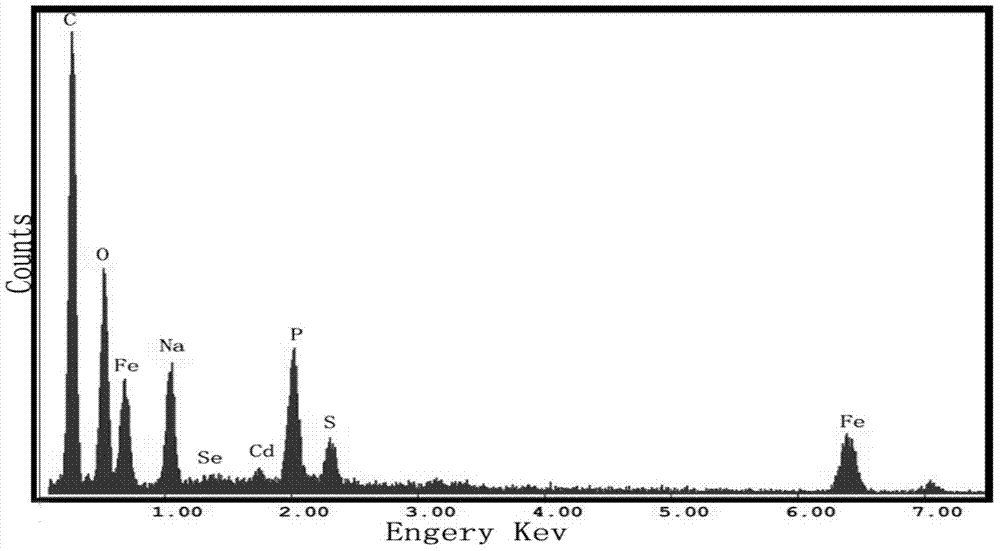

Magnetically fluorescent bifunctional microspheres prepared by connection of polyaniline magnetic microspheres and fluorescent quantum dots

InactiveCN103571493AWith magnetic and fluorescent dual functionsGood fluorescence propertiesMaterial nanotechnologyNanomagnetismMicrosphereBifunctional

Owner:SUZHOU UNIV OF SCI & TECH

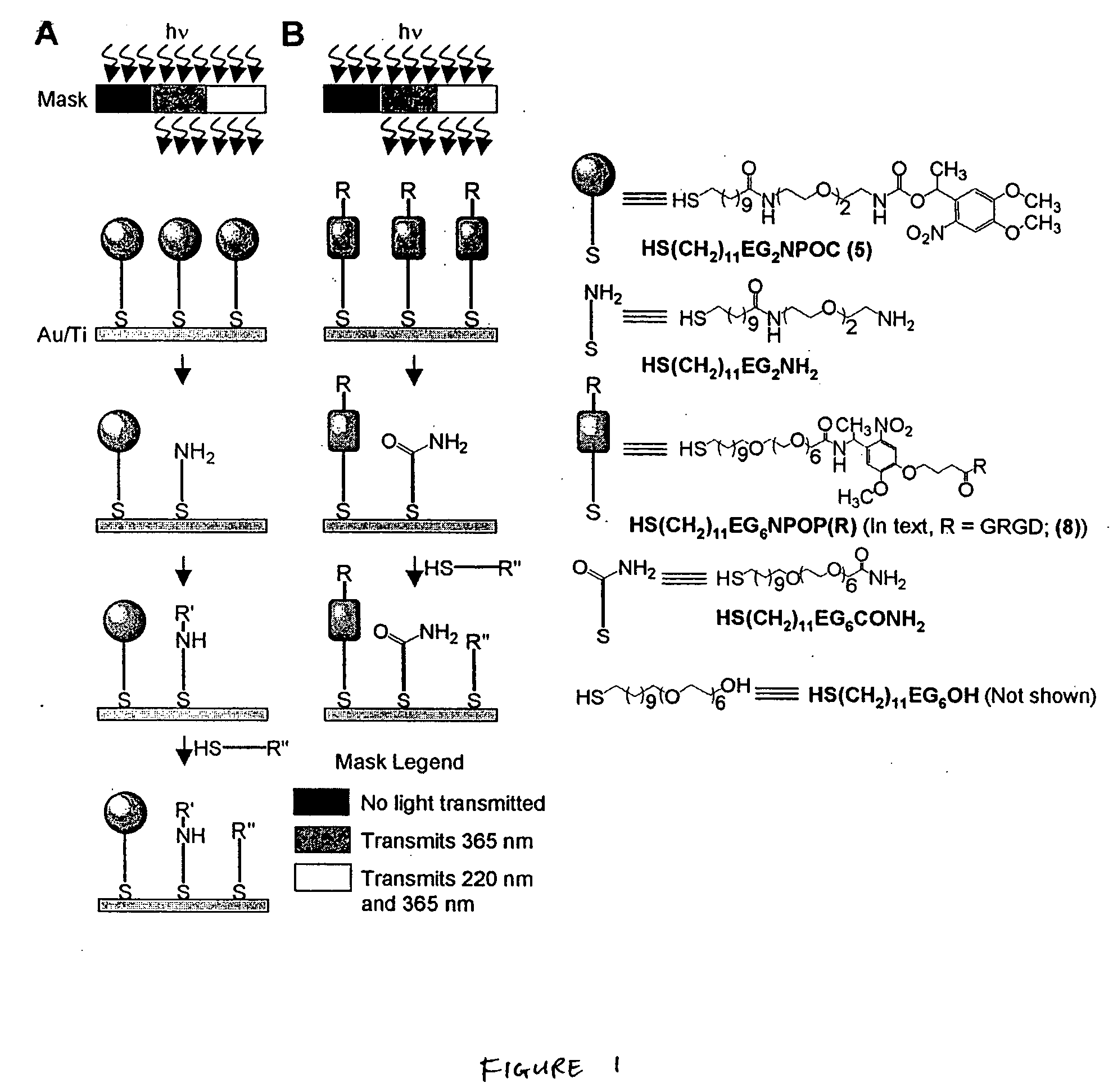

Patterning and alteration of molecules

Owner:RYAN DECLAN +7

Manufacturing method of micrometer and nanometer composite spherical metal powder of core-shell structure

Owner:NANJING UNIV

Infrared Reflecting Black Pigment, Paint and Resin Composition

InactiveUS20080134941A1Good infrared reflection performanceGood blacknessMaterial nanotechnologyPigmenting treatmentLength waveCopper

Owner:TODA IND

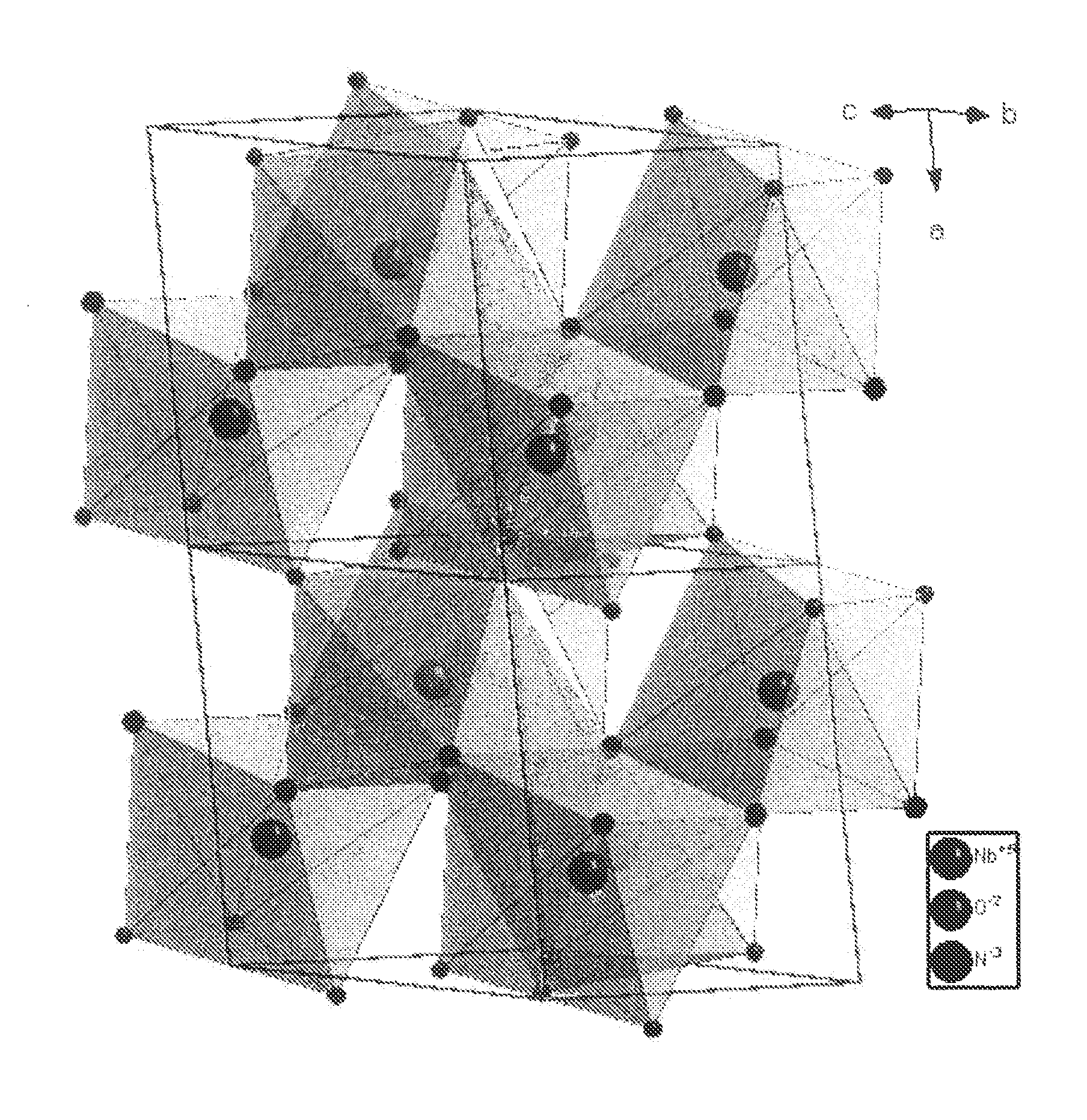

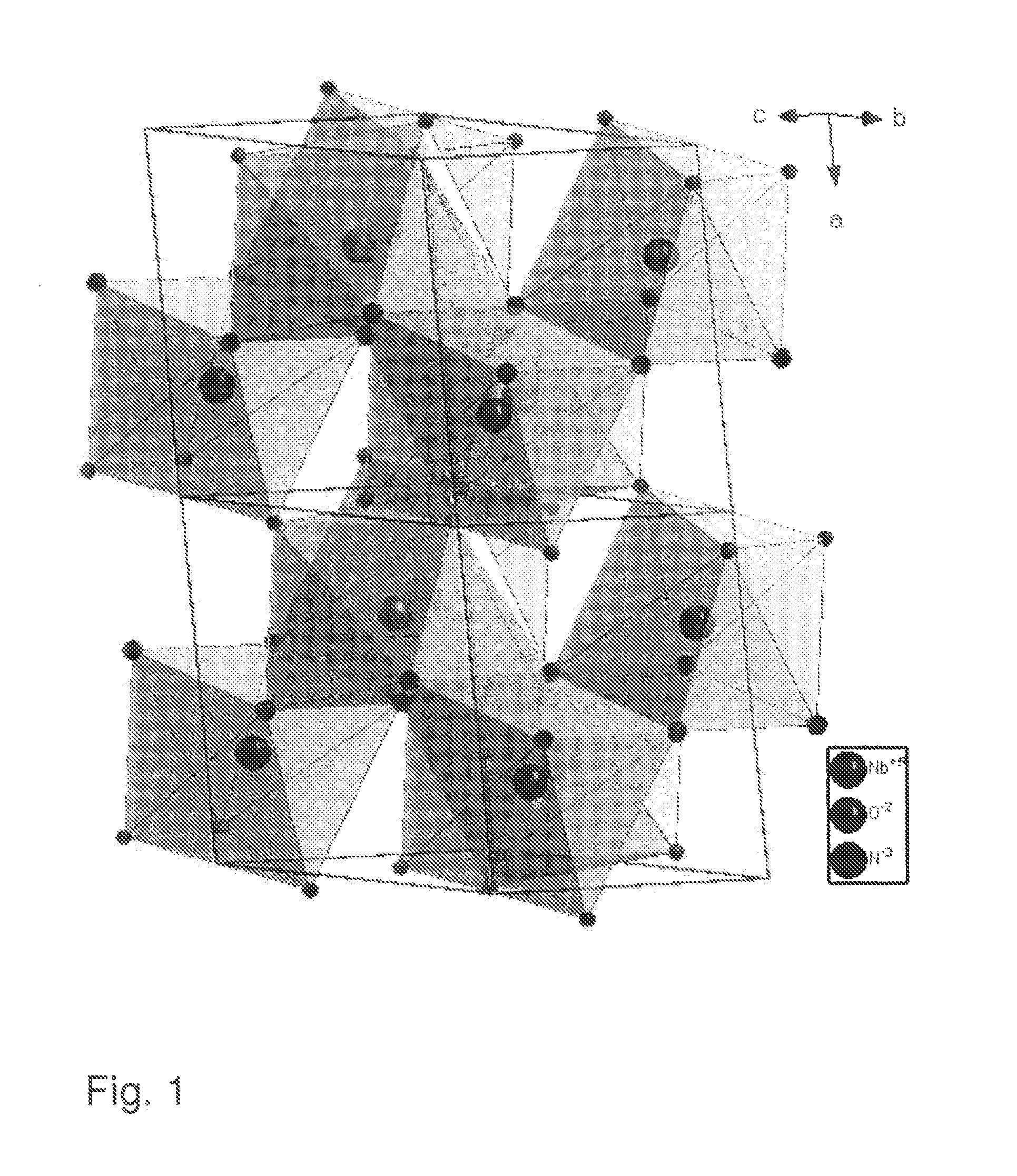

Transition metal oxidenitrides

ActiveUS20110305949A1Weight increaseImprove electrical performanceMaterial nanotechnologyNitrogen compoundsElectrical conductorNanoparticle

Owner:BELENOS CLEAN POWER HLDG

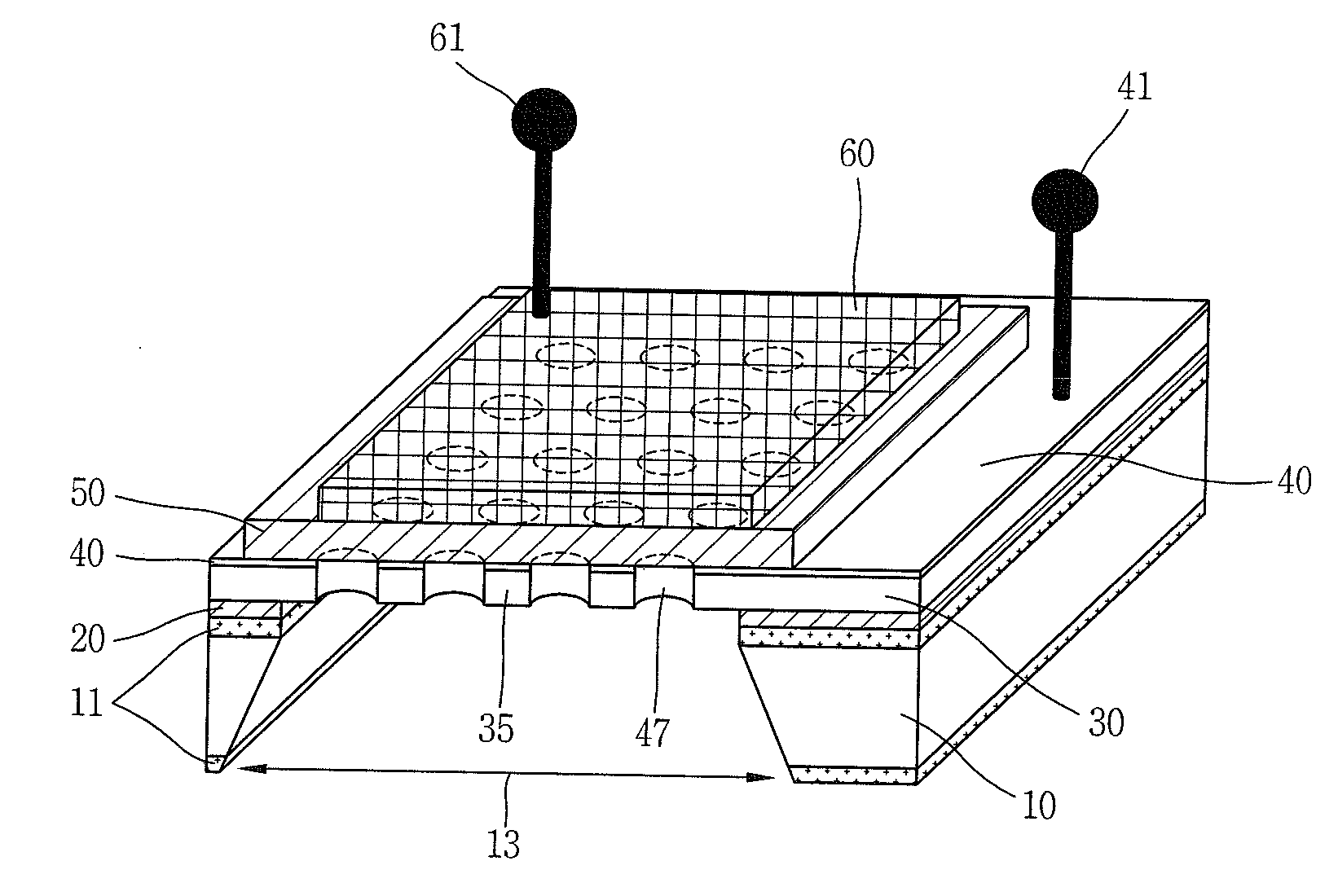

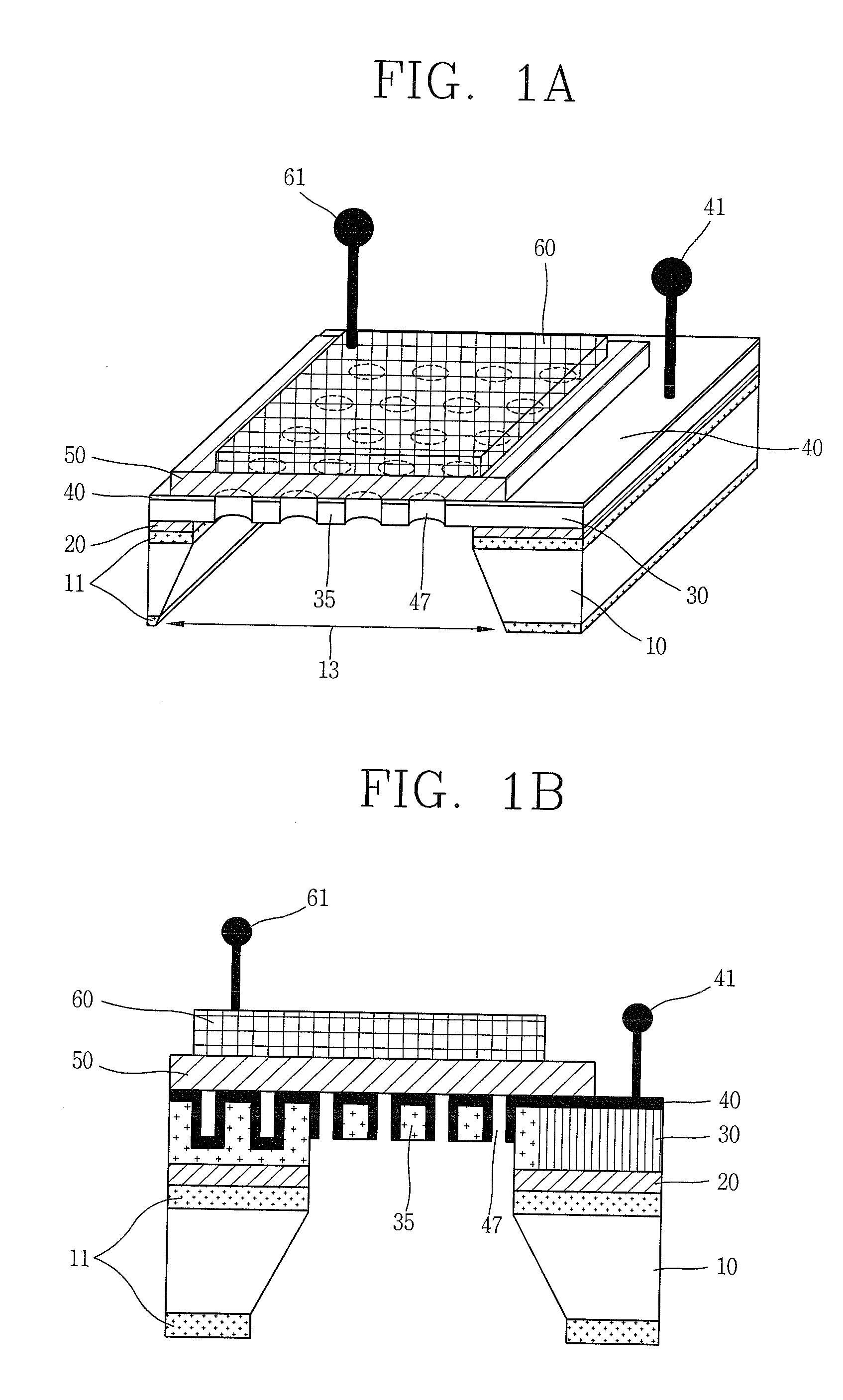

Micro fuel cell, fabrication method thereof, and micro fuel cell stack using the same

InactiveUS20090181278A1Keep the structure stablePrevent coagulationAnodisationMaterial nanotechnologyAnodizingMicro cell

Owner:KOREA INST OF SCI & TECH

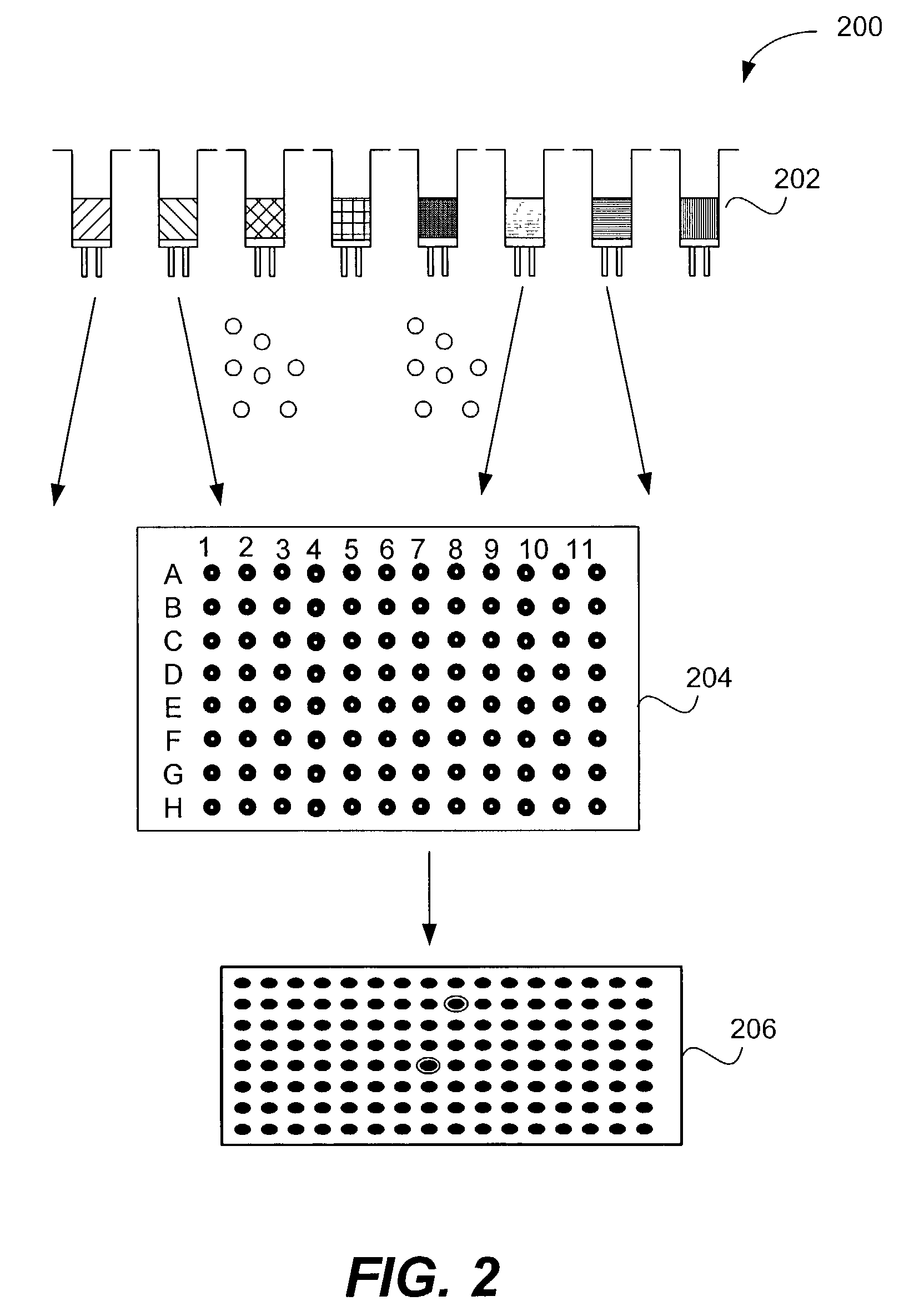

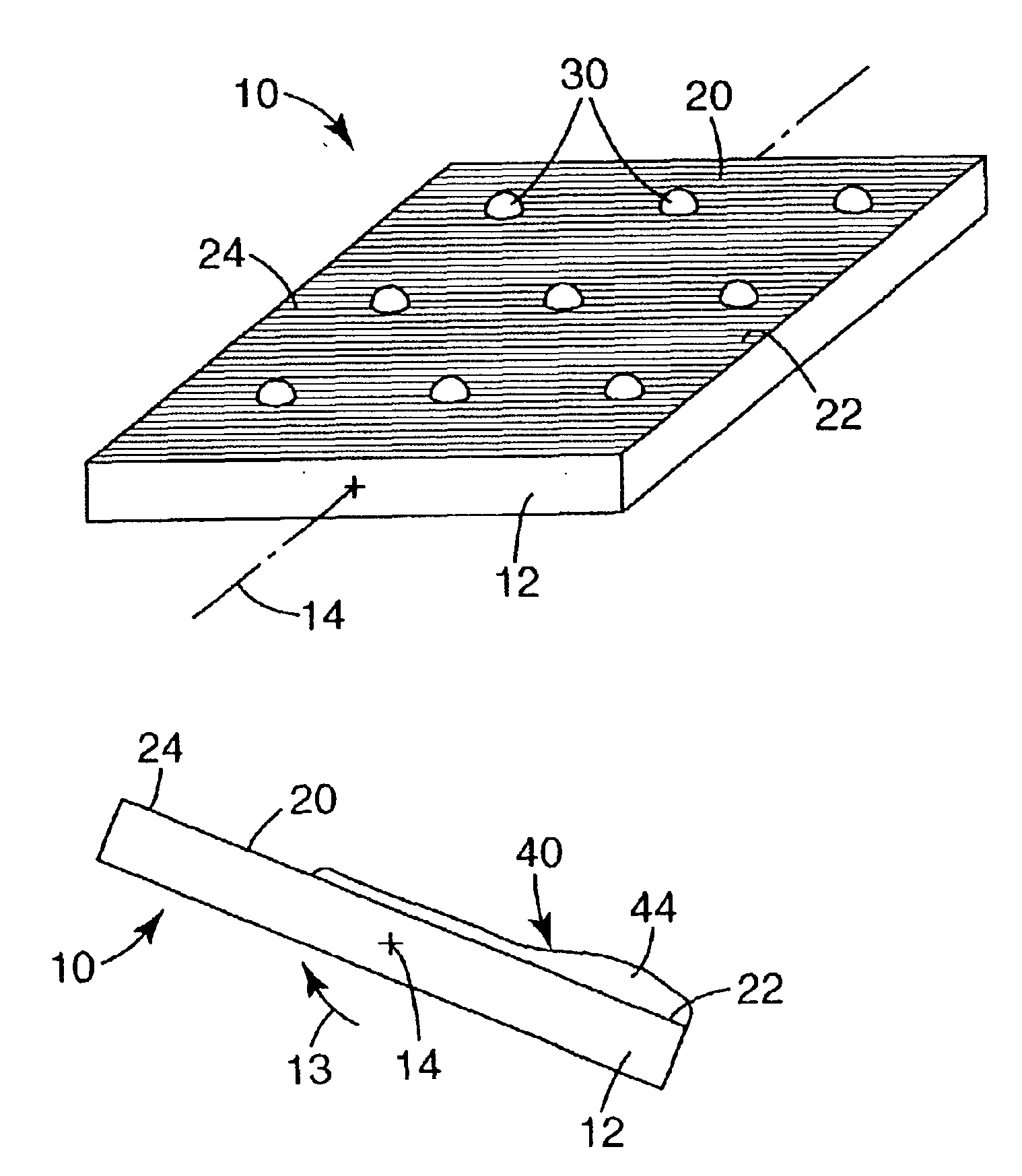

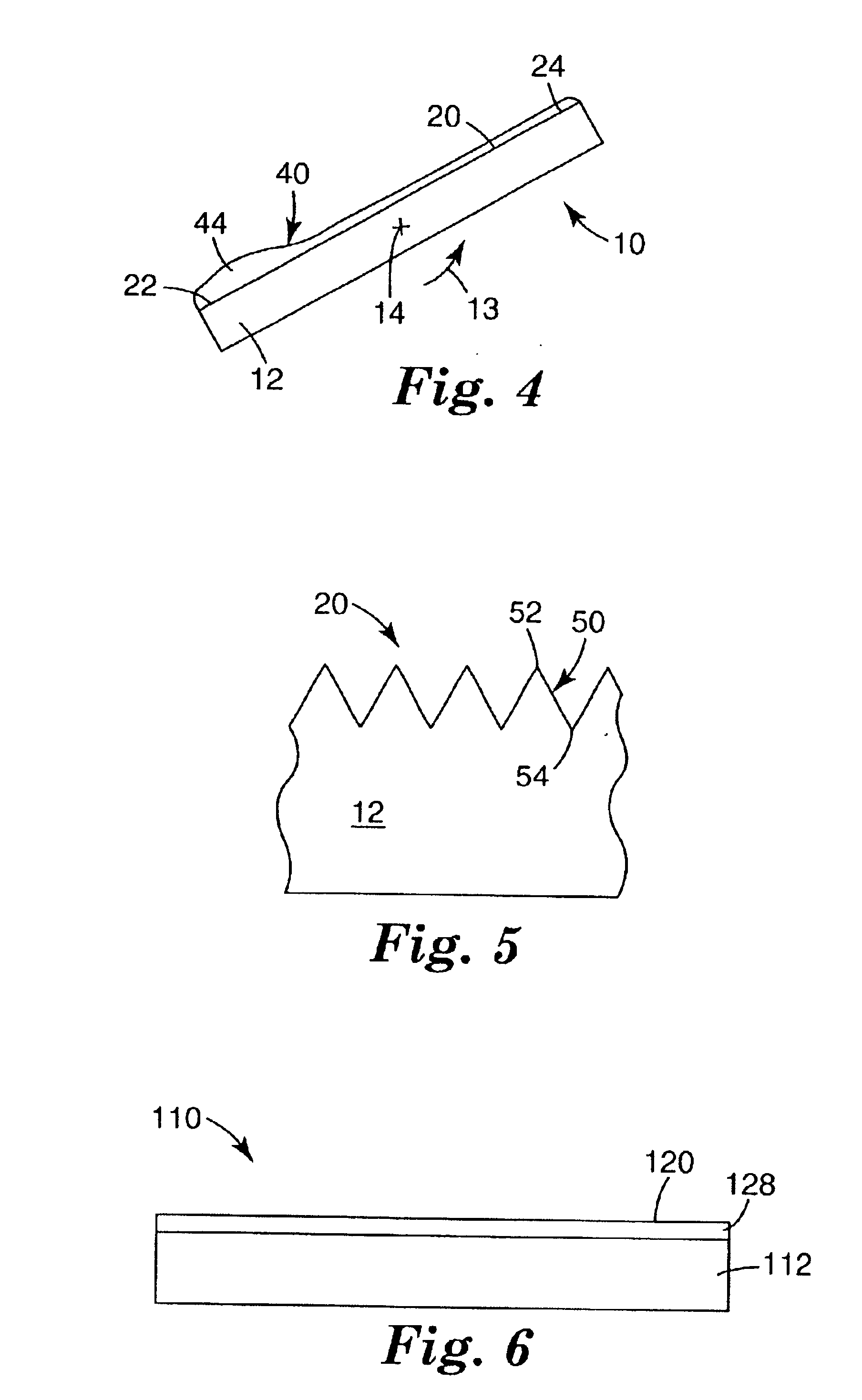

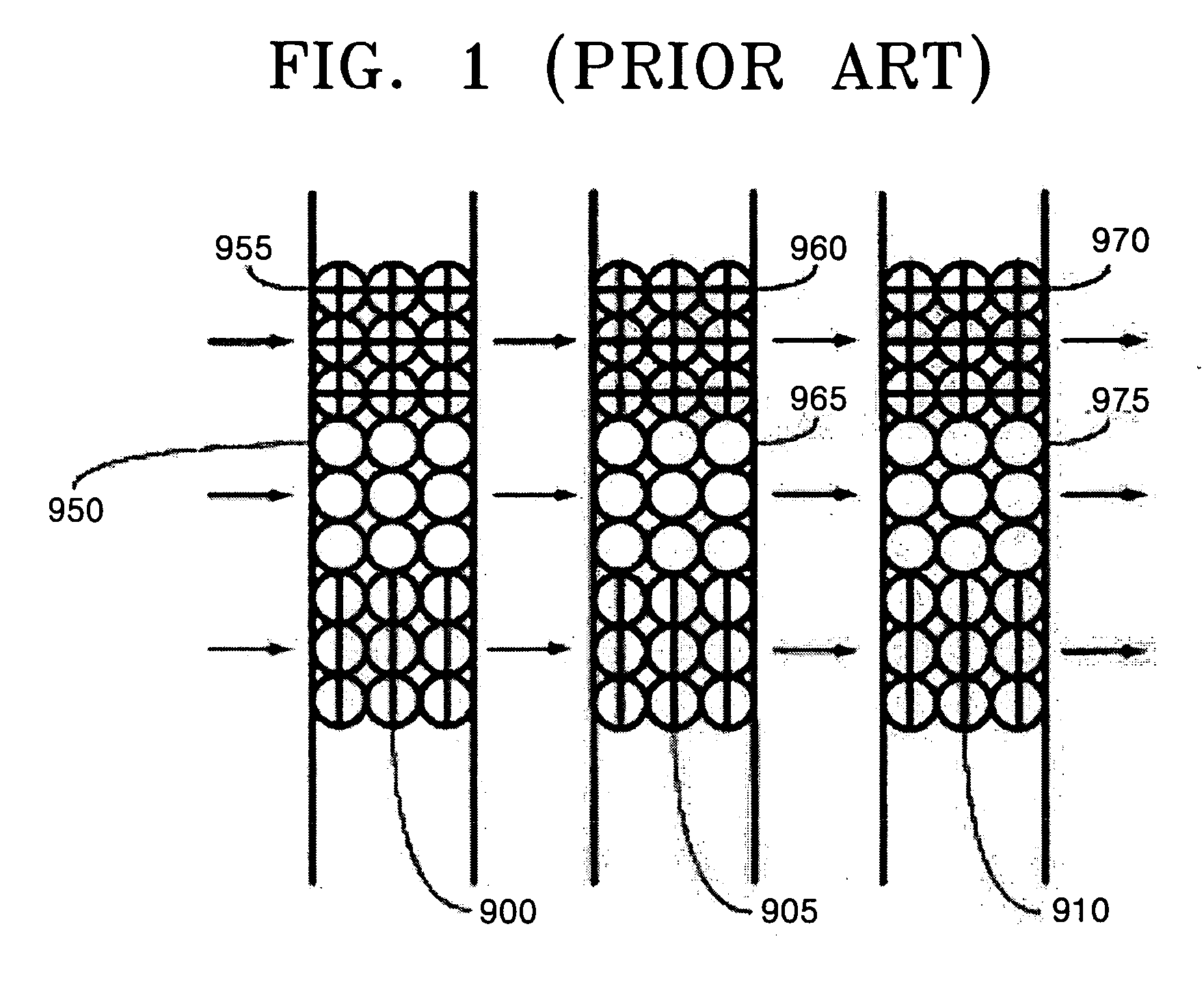

Devices, methods and systems for low volume microarray processing

InactiveUS6913931B2Reduction and elimination of liquid retention interfaceAvoid the needMaterial nanotechnologyAnalysis using chemical indicatorsAnalyteFluorescence

Owner:3M INNOVATIVE PROPERTIES CO

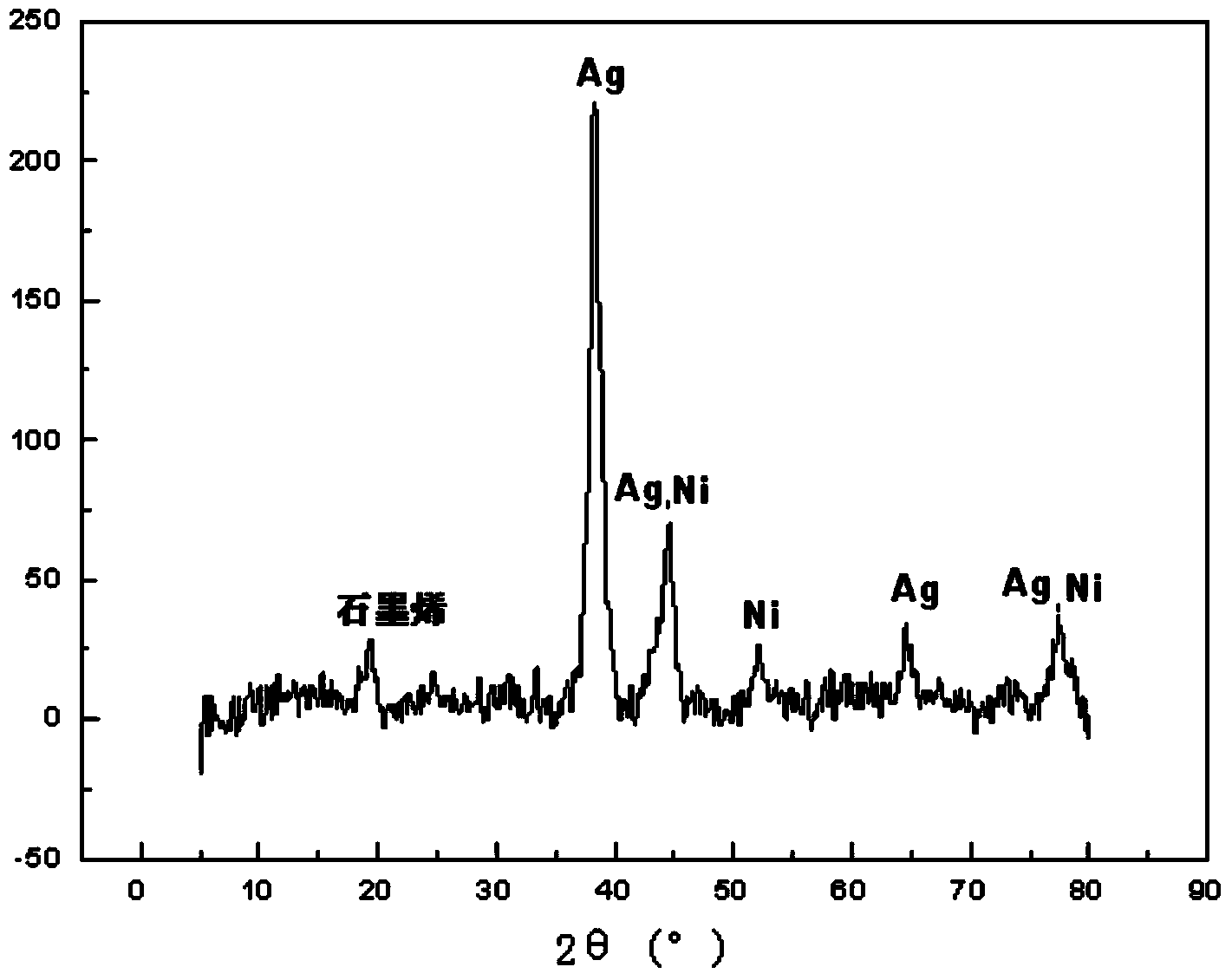

Method for preparing graphene load nano silver-nickel alloy composite powder materials

Owner:HEILONGJIANG UNIV

Carbon nanotube powder, carbon nanotubes, and processes for their production

InactiveUS8398949B2High purityImprove liquidityMaterial nanotechnologyBiocideCarbon nanotubeMaterials science

Owner:COVESTRO DEUTSCHLAND AG

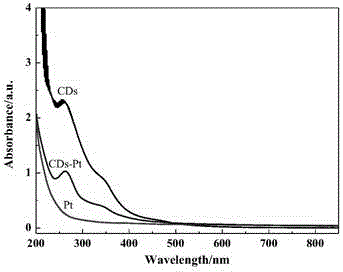

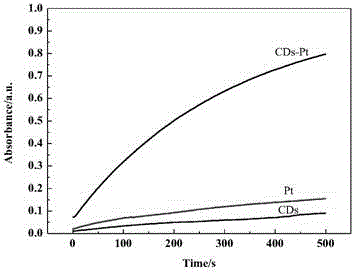

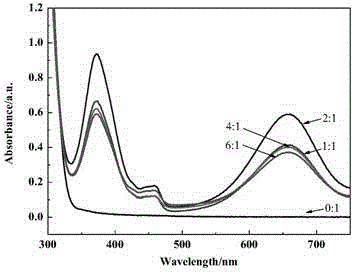

CDs-Pt nanomaterial with catalase catalytic properties

InactiveCN104549234AThe synthesis method is simpleNo pollution in the processMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsPlatinumGlucose detection

Owner:JIANGNAN UNIV

Microfluidic chip for multiple bioassay and method of manufacturing the same

InactiveUS20060188906A1Avoid mixingMaterial nanotechnologyBioreactor/fermenter combinationsEngineeringMicrofluidic channel

Owner:SAMSUNG ELECTRONICS CO LTD

Coating composition containing high-refractive-index metal oxide fine particles, and curable coating film obtained by applying the coating composition onto base

Owner:JGC CATALYSTS & CHEM LTD

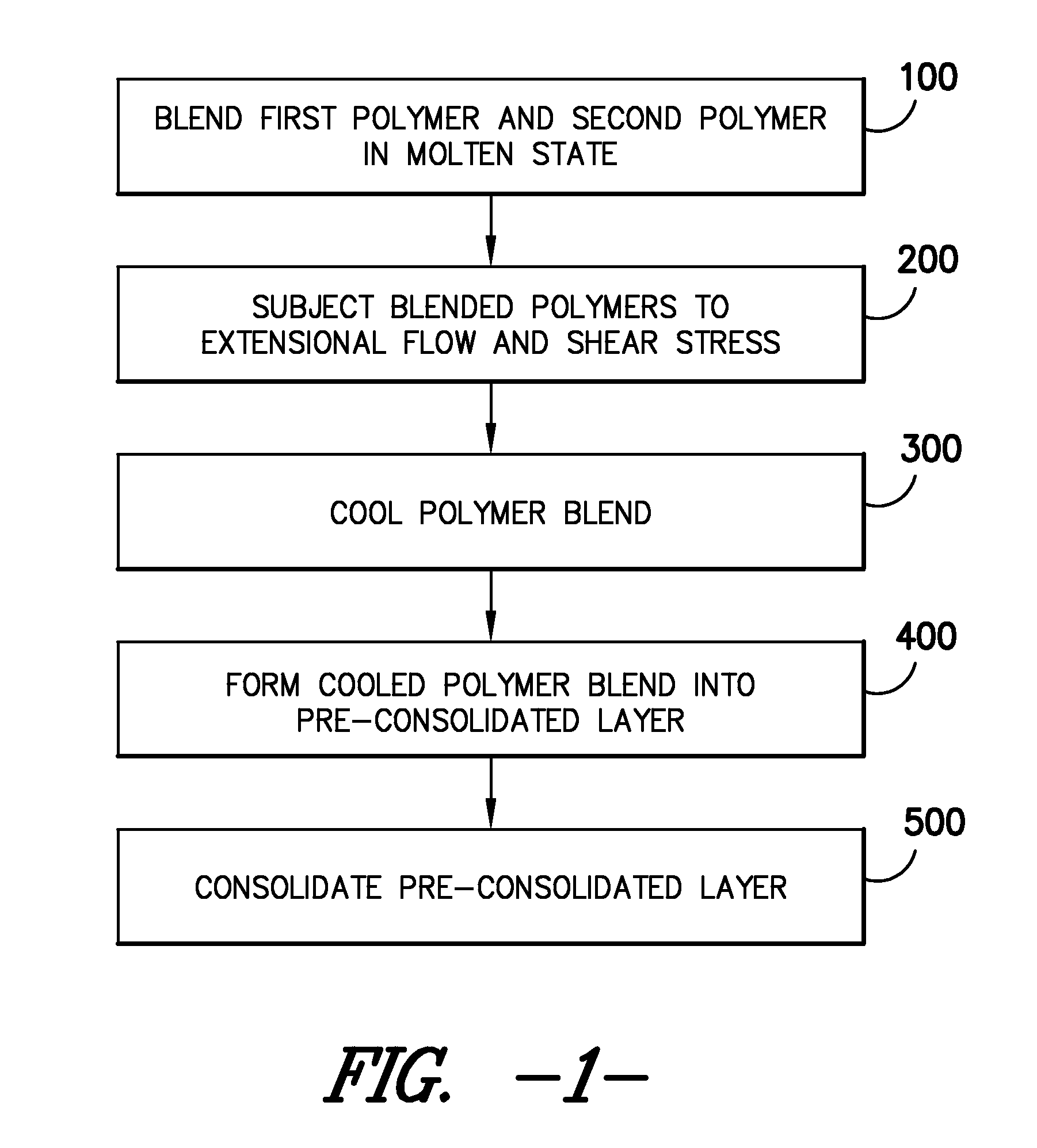

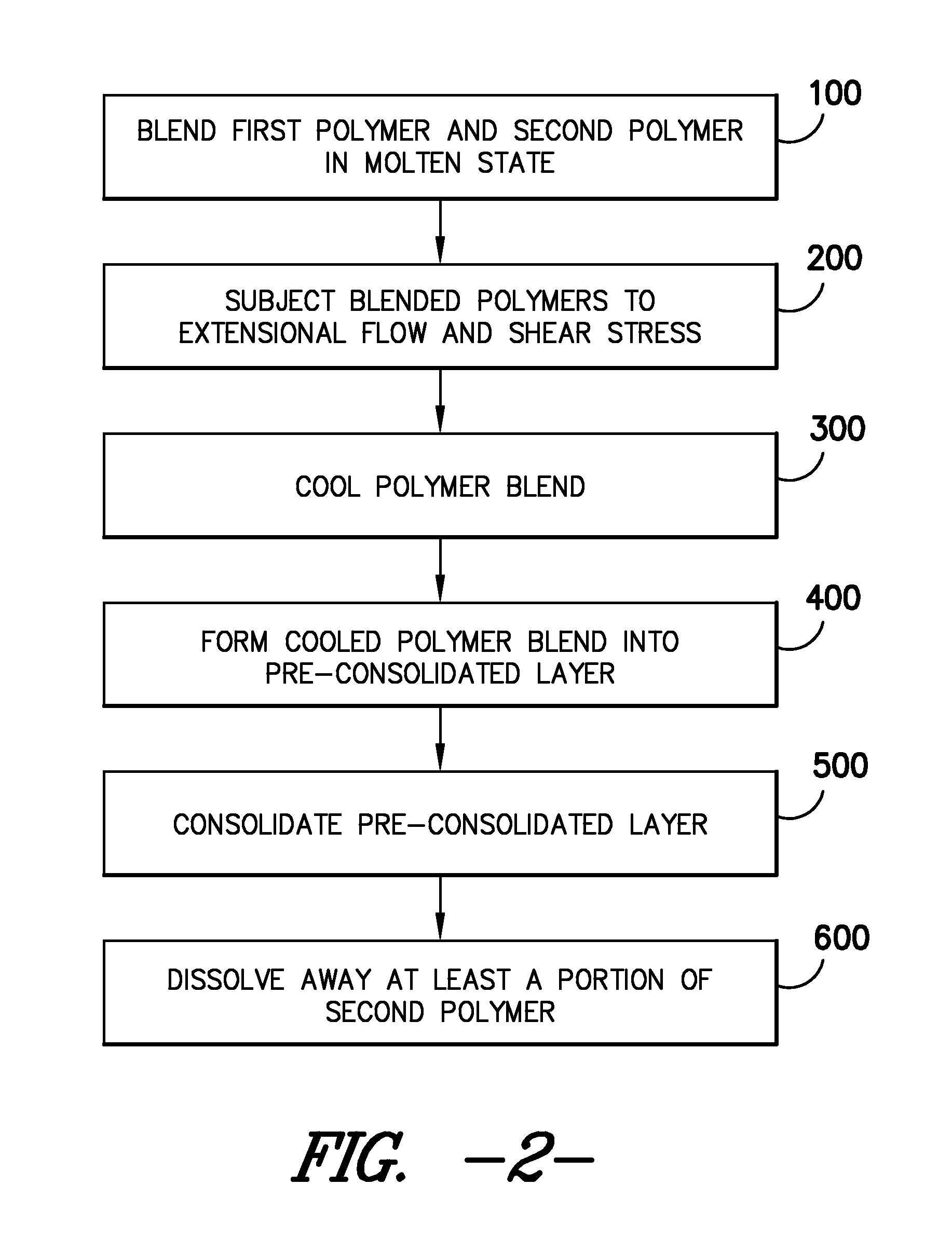

Process of Forming Nano-Composites and Nano-Porous Non-Wovens

Owner:MILLIKEN & CO

Method of forming nanocomposite materials

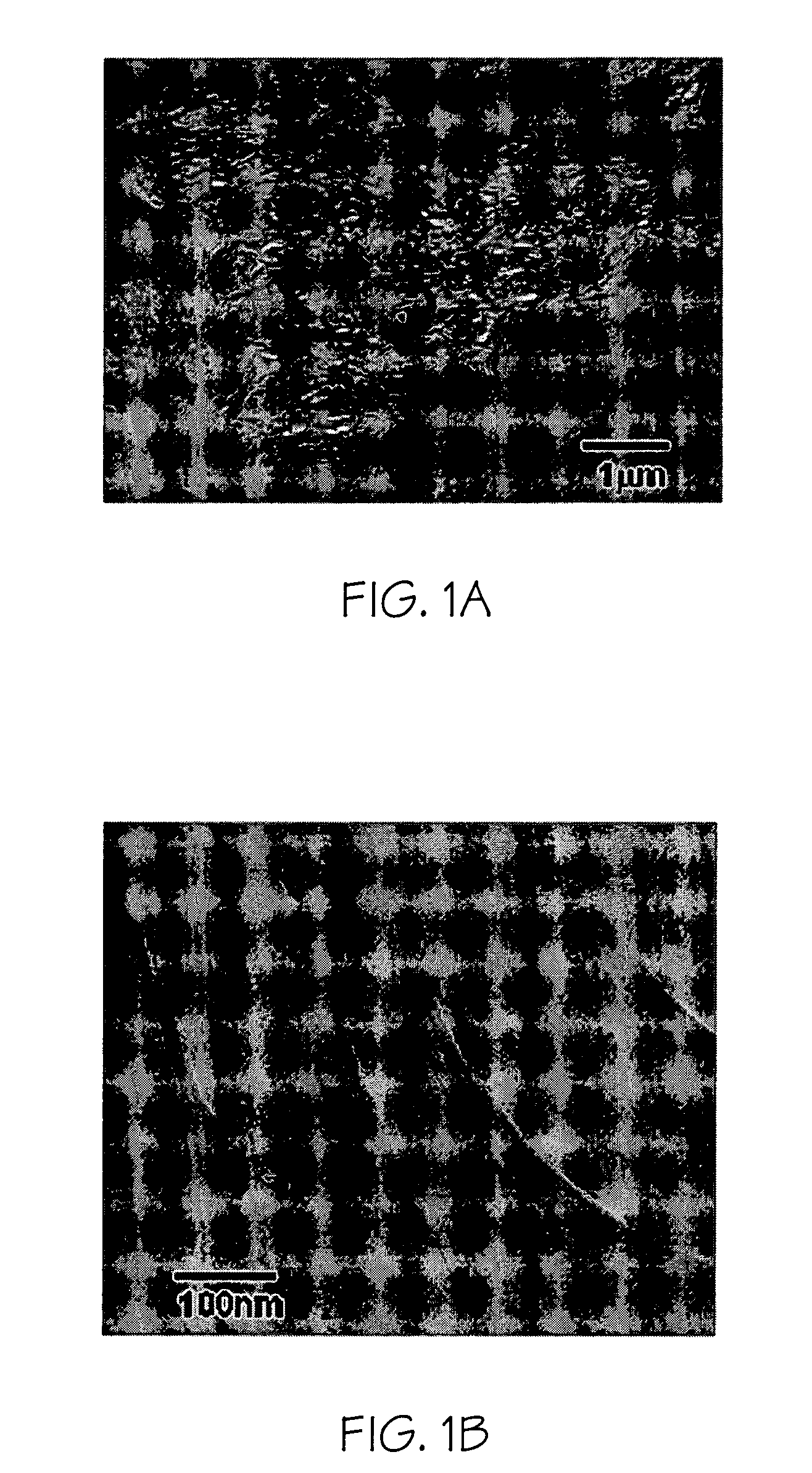

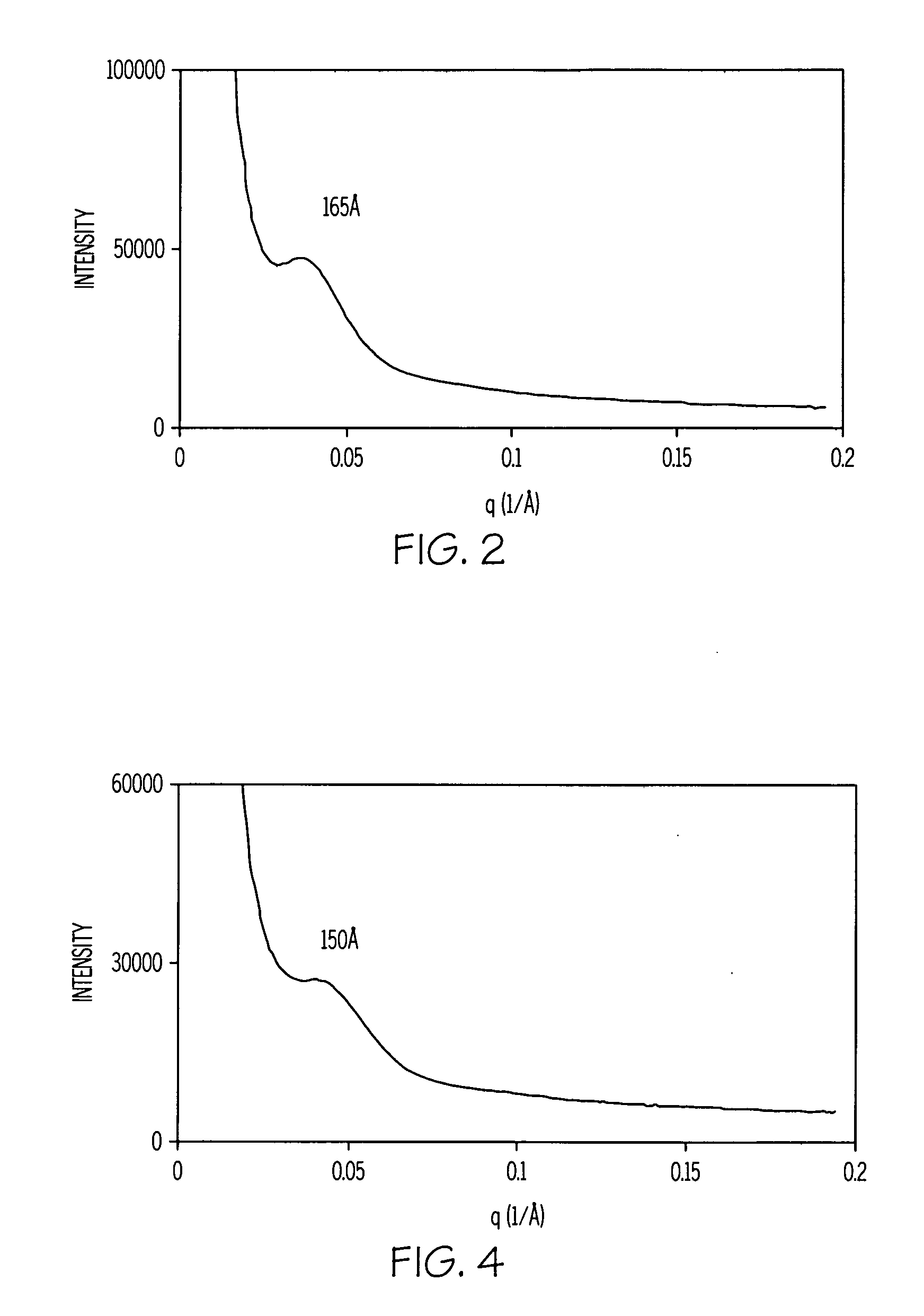

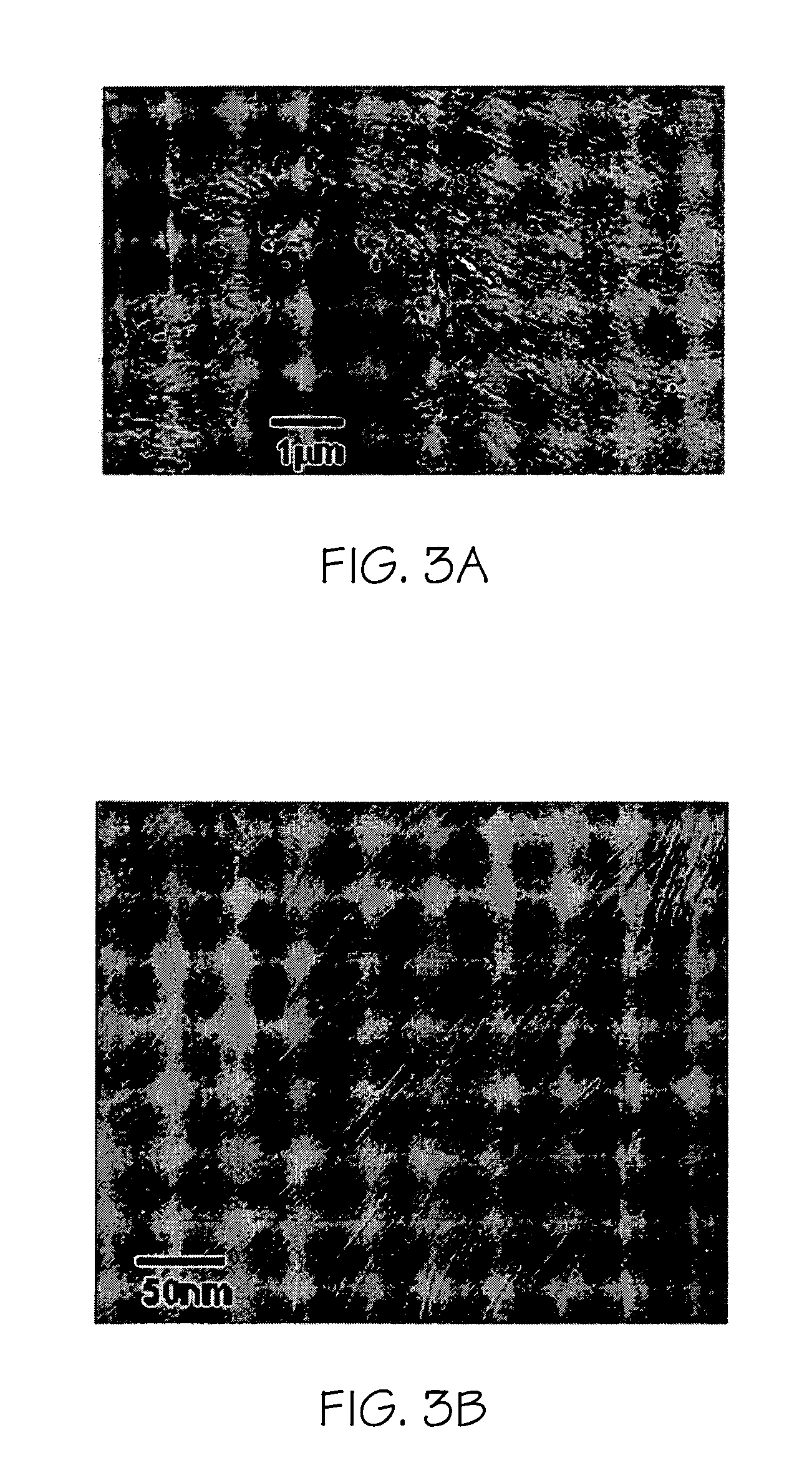

A method of making a polymeric nanocomposite material. The method includes combining nanosize materials, such as layered silicates, or nanosize sphered silica, with a polymer and a solvent to form a substantially homogeneous mixture, followed by removal of the solvent. The method forms a layered-silicate nanocomposite with an intercalated nanostructure with very large interplanar spacing or a combination of intercalated and exfoliated nanostructure.

Owner:UNIV OF DAYTON THE

Popular searches

Chemical/physical processes Non-conductive material with dispersed conductive material Semiconductor/solid-state device manufacturing Glass/slag layered products Thin material handling Metal layered products Synthetic resin layered products Cellulosic plastic layered products Machines/engines Water/sewage treatment using germicide/oligodynamic-process

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap