Microfluidic chip for multiple bioassay and method of manufacturing the same

a microfluidic chip and bioassay technology, applied in the field of microfluidic chips, can solve problems such as cross-contamination and problems, alignment of channels and immobilized probes, and probability of probe damage, and achieve the effect of preventing the mixing of target samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Manufacture of Microfluidic Chip

[0050] SU-8 (available from Microchem Inc.) was spin-coated on a silicon substrate, and a pattern was formed therein using photolithography, which was used as a mold for a microfluidic structure. Then, a PDMS prepolymer mixture (Sigard 184, obtained from Dowcorning Inc.) was poured added into the mold, hardened at 80° C., and separated from the substrate, thereby resulting in a PDMS structure. The PDMS structure was treated with O2 plasma and coupled to a glass substrate used as a lower plate (heat treatment at a temperature of 50-80° C.). In order to facilitate covalent bonding between the polymer and the substrate in the microchannel structure, the probe channels were surface-modified with 3-(trichlorosilyl) propyl methacrylate (TPM) to activate the unmodified glass surface in acrylate form and increase the binding force between the glass substrate and GMA gel pads. Probe immobilization regions were defined using GMA photopolymerization. In detail, th

example 2

Immunoassay

[0052] Specific immunoreactions were induced on GMA gel pads in the microfluidic chip according to Example 1. After the GMA gel pads according to Example 1 were formed, 0.1 g / L of human IgG and 0.1 g / L of mouse IgG were alternatively injected into the probe channels as probe proteins and immobilized in the same manner as in Example 1. After blocking walls were formed in the same manner, 100 μg / L of anti-human IgG and 100 μg / L of anti-mouse IgG labeled with FITC were respectively injected into the sample channels perpendicular to the probe channels, immunoreacted with the probe proteins at room temperature for 20 minutes, and washed in the same manner as in Example 1.

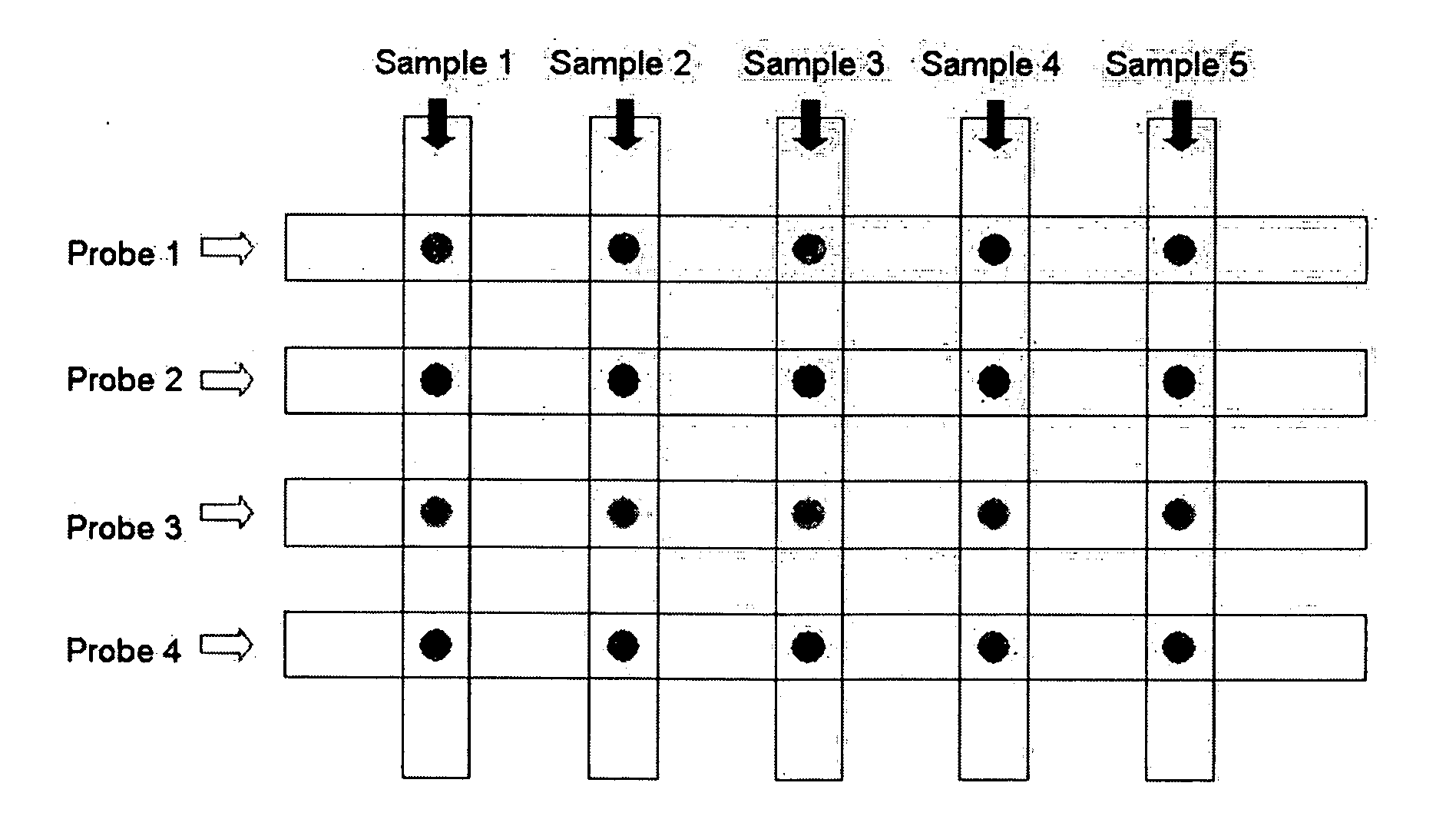

[0053]FIG. 12 is a schematic view illustrating an immunoassay according to Example 2. Reference numerals 1, 2, 3, and 4 denote probe immobilization regions formed at the intersections between the sample channels and the probe channels. The types of probes (capture proteins) and target samples (target pr

example 3

Height Control of Probe Immobilization Region

[0055] A microfluidic chip was fabricated in the same manner as in Example 1, except that the height of the probe immobilization regions was controlled not to reach the ceiling of the microfluidic channels. When the probe immobilization regions are separated from the ceiling of the microfluidic channels, the surface area of the probe immobilization regions to which probes bind increases, so that a probe-target sample binding signal with a large amplitude can be obtained. The left image in FIG. 14 is a fluorescent microscopic photograph of a probe immobilization region that is high enough to contact the ceiling of the microfluidic channel. In this photograph, the probes are bound only to the side of the probe immobilization gel pad, so that a florescent signal in an annular pattern appears. The right image in FIG. 14 is a fluorescent microscopic photograph of a probe immobilization region that is separated from the ceiling of the microfluidi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap