Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about "Biochemistry cleaning apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

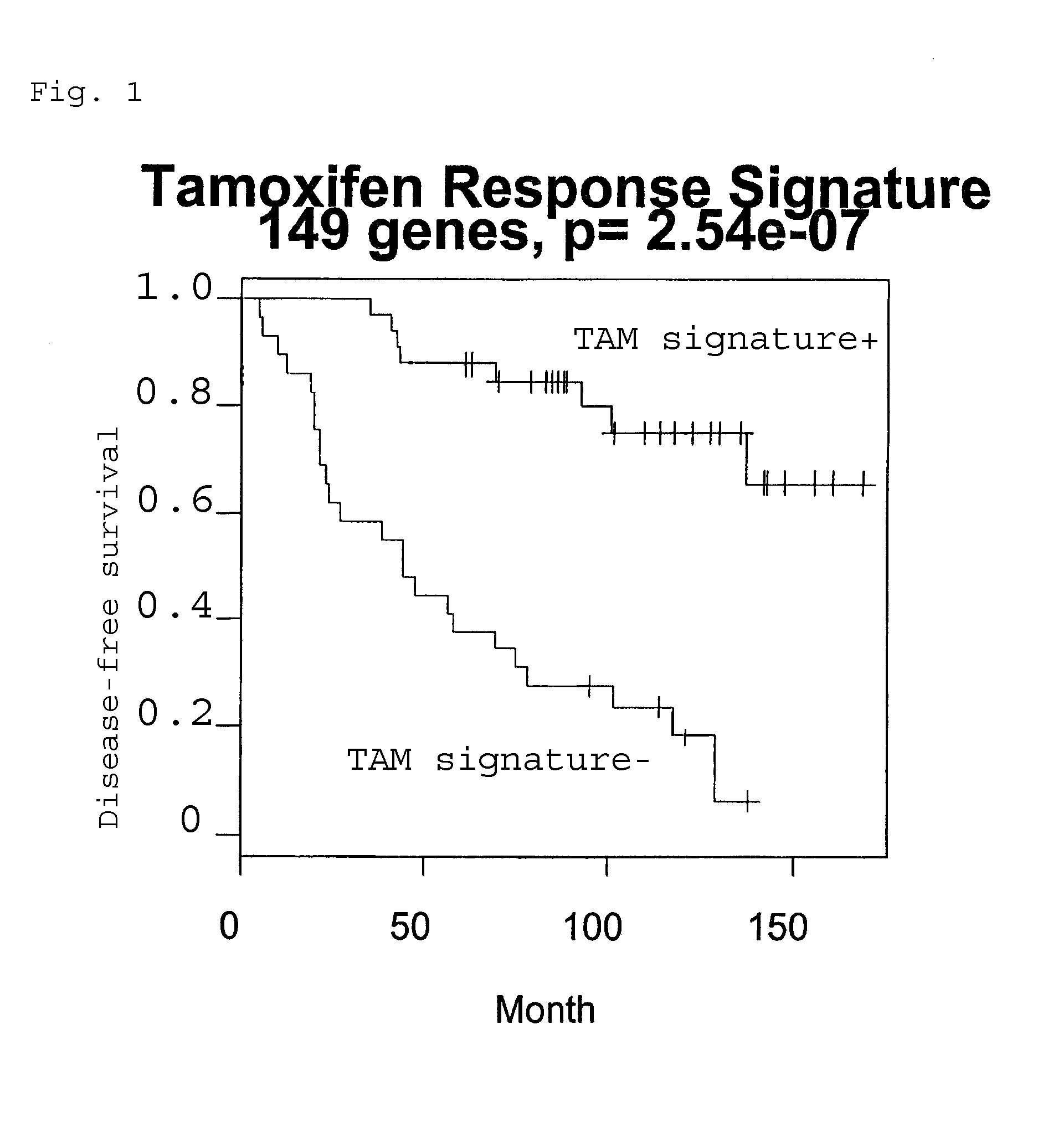

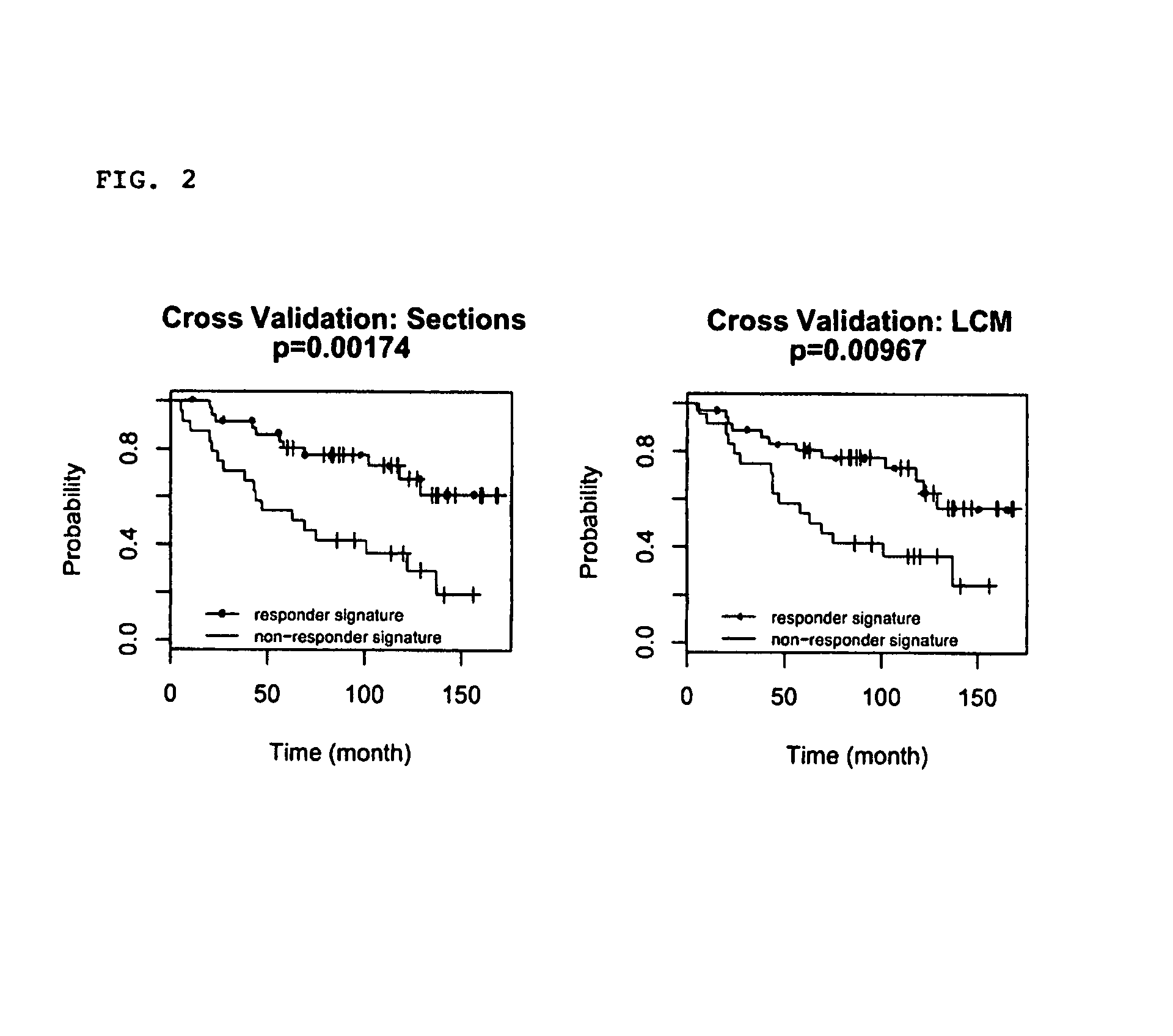

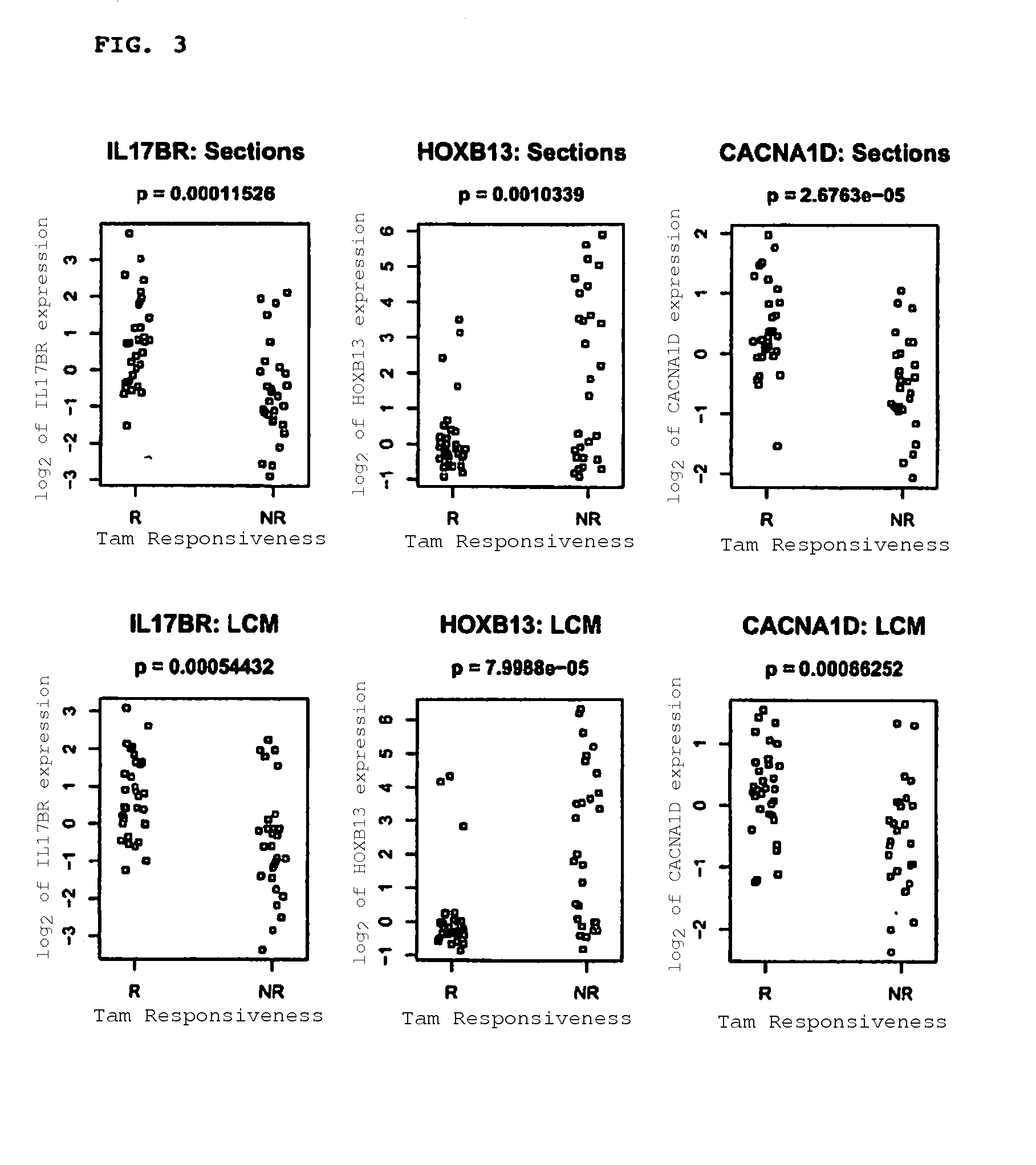

Predicting outcome with tamoxifen in breast cancer

ActiveUS7504214B2Improve predictive performanceBioreactor/fermenter combinationsBiological substance pretreatmentsTamoxifen treatmentOncology

Owner:BIOTHERANOSTICS +1

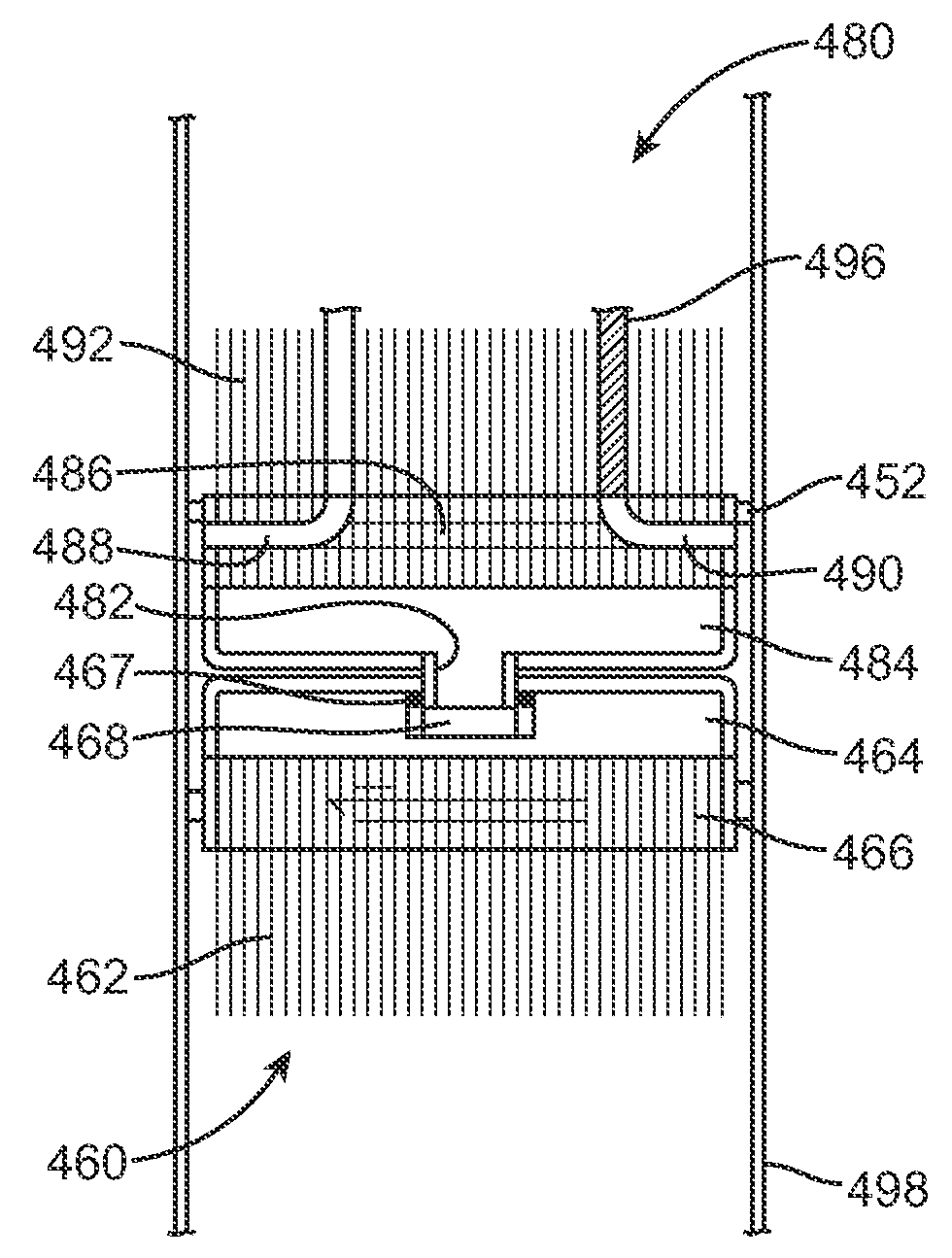

Sample measurement device, sample measurement system and sample measurement method

ActiveUS20100283488A1Reduce measurement errorImmobilised enzymesBioreactor/fermenter combinationsMeasurement deviceVoltage source

A sample measurement device (110), in which a biosensor (30) having an electrode is mounted, voltage is applied to the electrode, and the concentration of a specific component in a sample deposited on the biosensor (30) is measured, comprises a voltage source (19) configured to apply voltage to the electrode, a time measurement component (22), and a controller (18) configured to control the voltage to be applied and measure the concentration of the specific component. The time measurement component (22) measures a detection time, which is the length of time between the mounting of the biosensor (30) and the deposition of a sample on the biosensor (30). The controller (18) changes a set value for measuring the concentration of a specific component according to the detection time. Consequently, measurement accuracy can be improved regardless of the temperature of the biosensor (30).

Owner:PHC HLDG CORP

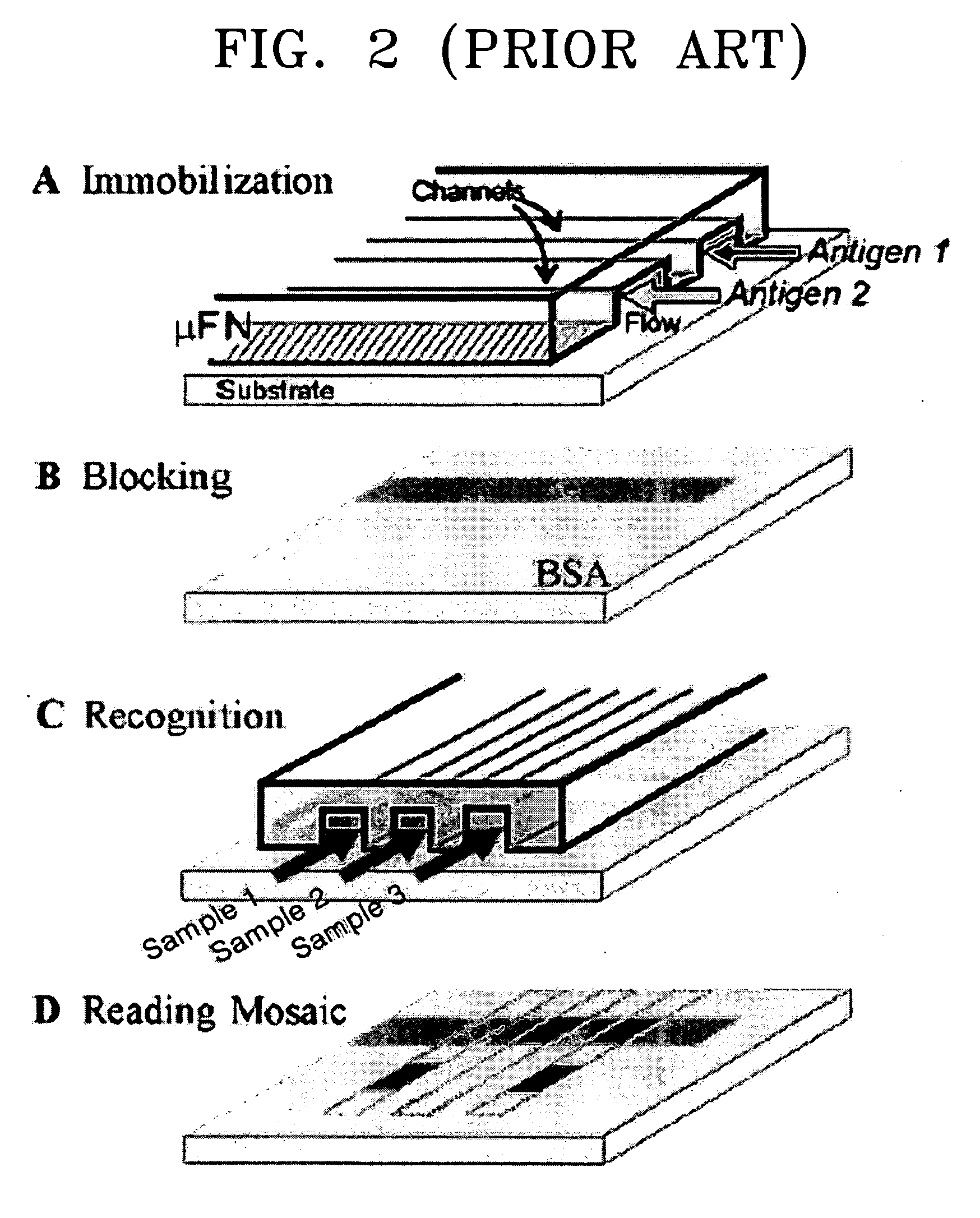

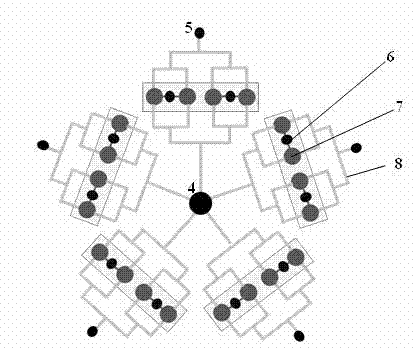

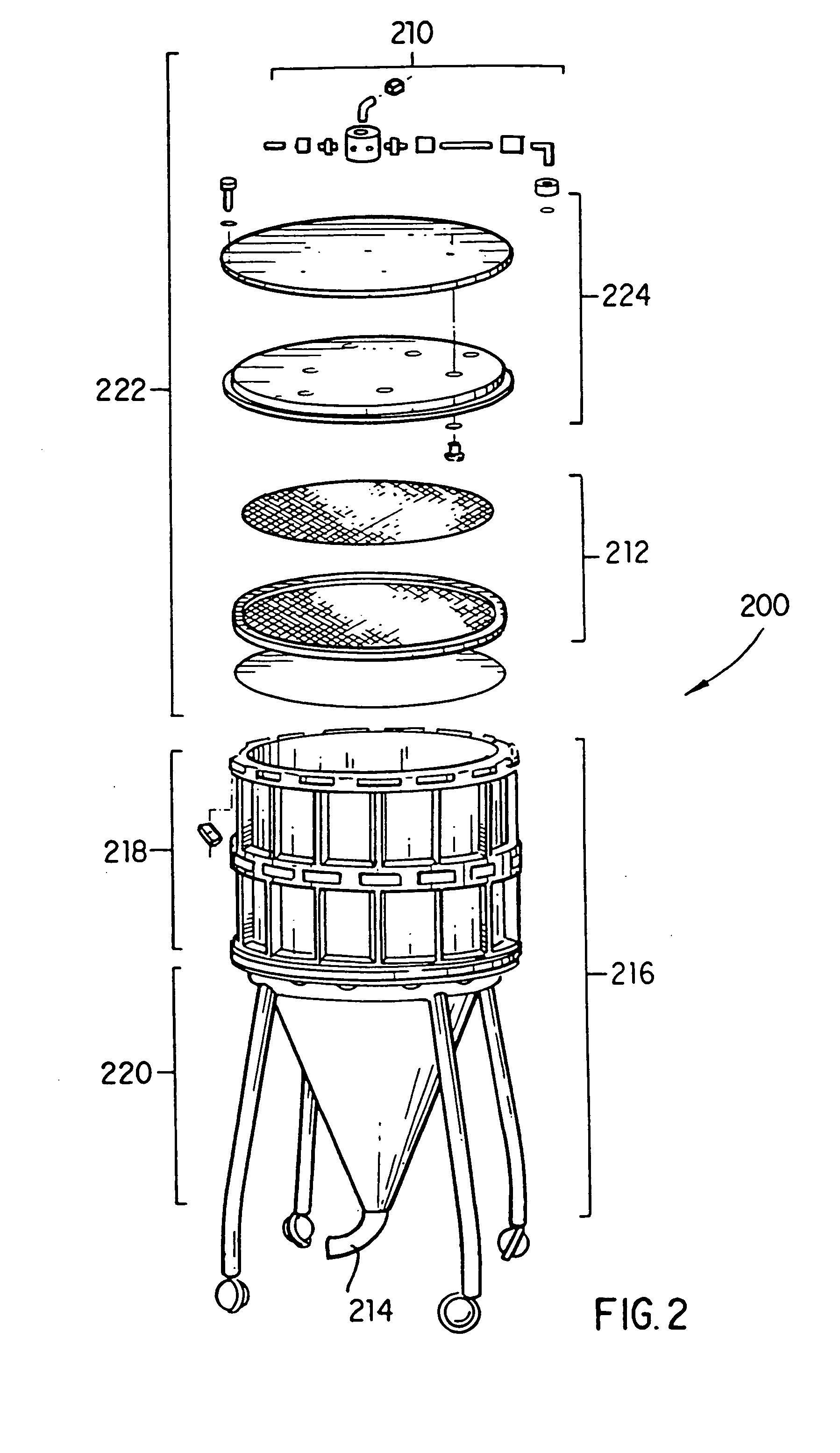

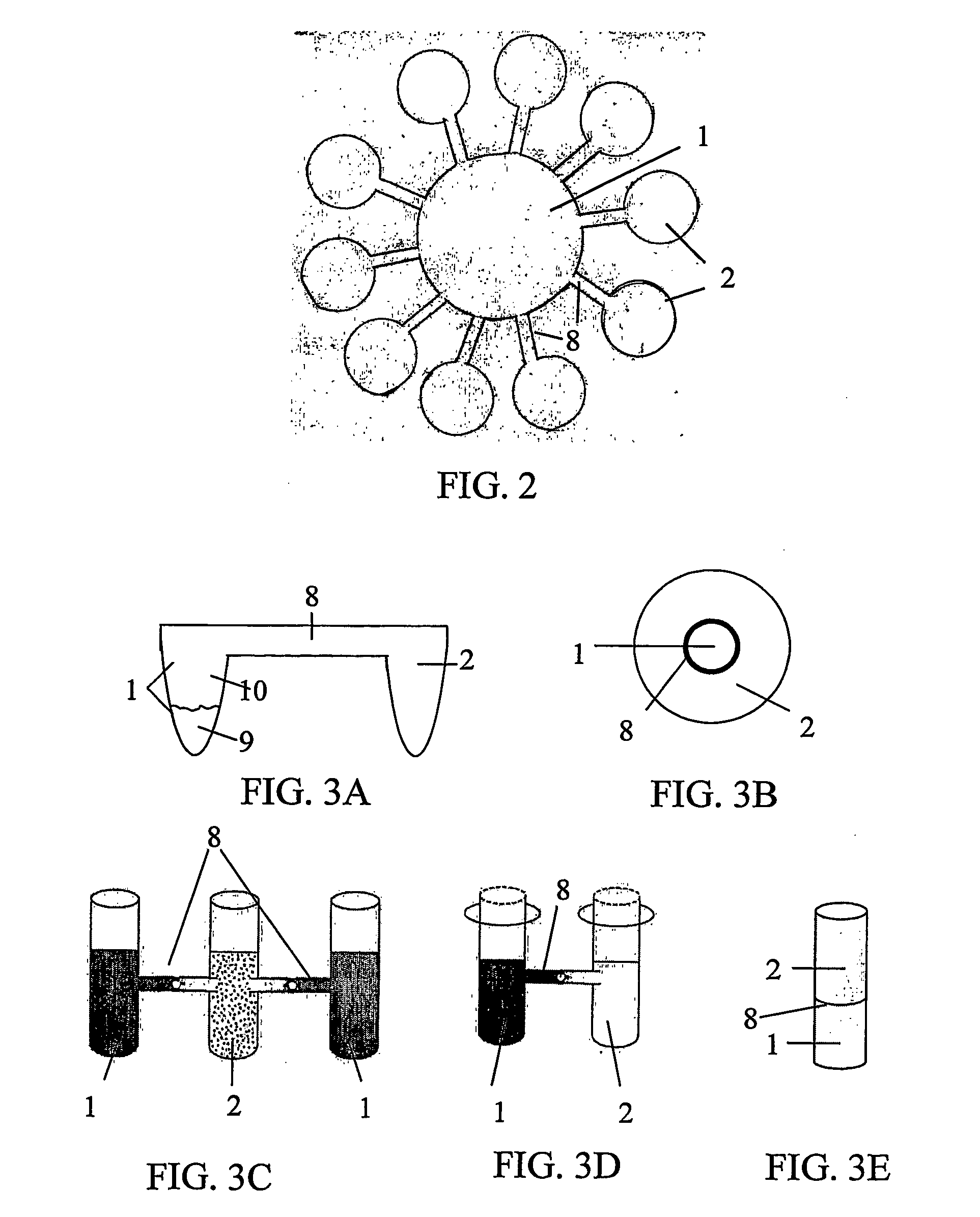

Device for arraying biomolecules and for monitoring cell motility in real-time

The invention relates to devices, devices for arraying biomolecules, including cells, methods for arraying biomolecules, assays for monitoring cellular movement, and systems for monitoring cellular movement. The devices include a support; a first layer configured to be placed in fluid-tight contact with the support, the first layer having an upper surface and defining a pattern of micro-orifices, each micro-orifice of the pattern of micro-orifices having walls and defining a micro-region on the support when the first layer is placed in fluid-tight contact with the support such that the walls of said each micro-orifice and the micro-region on the support together define a micro-well; and a second layer configured to be placed in fluid-tight contact with the upper surface of the first layer, the second layer defining a pattern of macro-orifices, each macro-orifice of the pattern of macro-orifices having walls and defining a macro-region when the first layer is placed in fluid-tight contact with the support and the second layer is placed in fluid-tight contact with the first layer such that the walls of the macro-orifice and the macro-region together define a macro-well.

Owner:SURFACE LOGIX INC

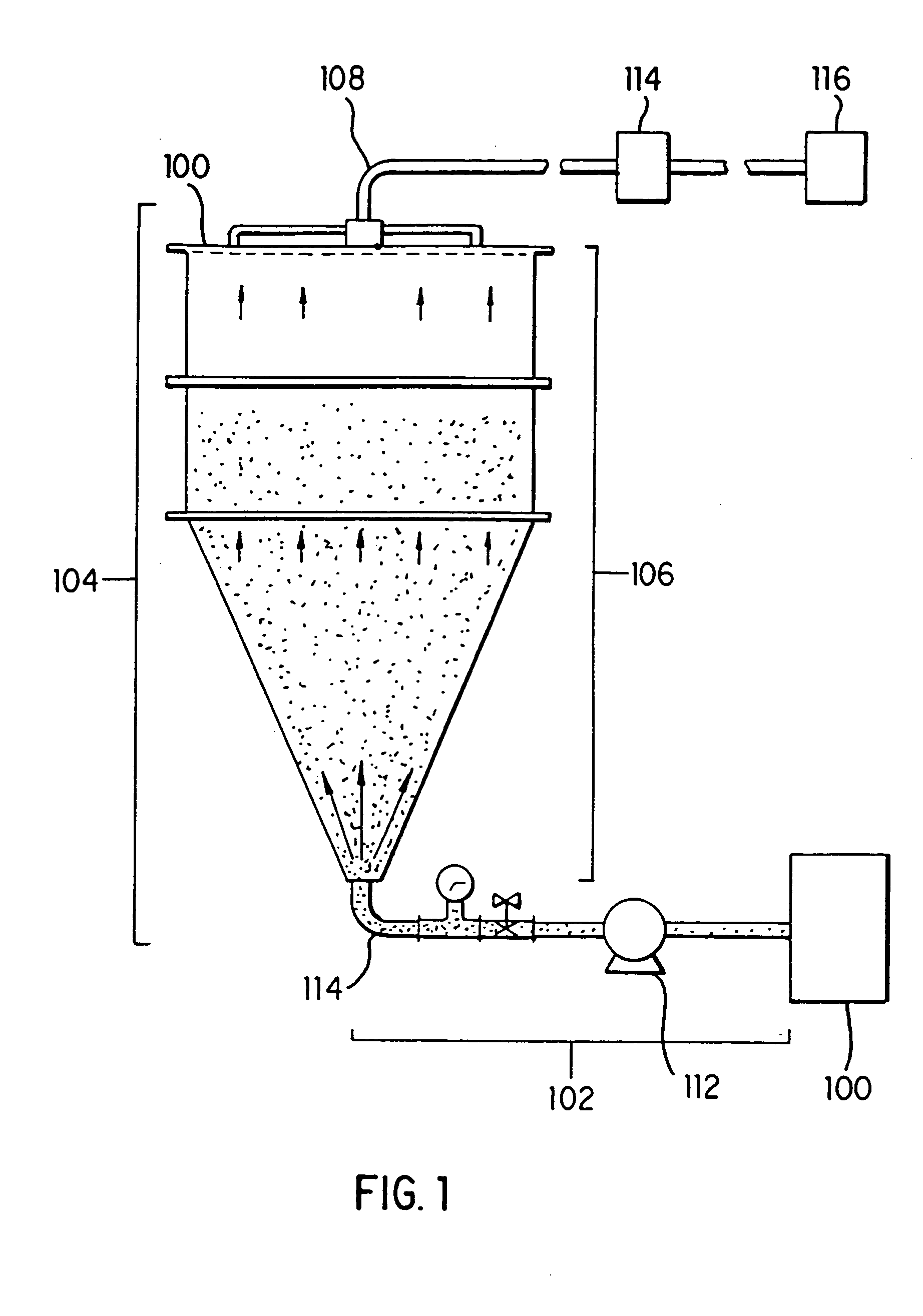

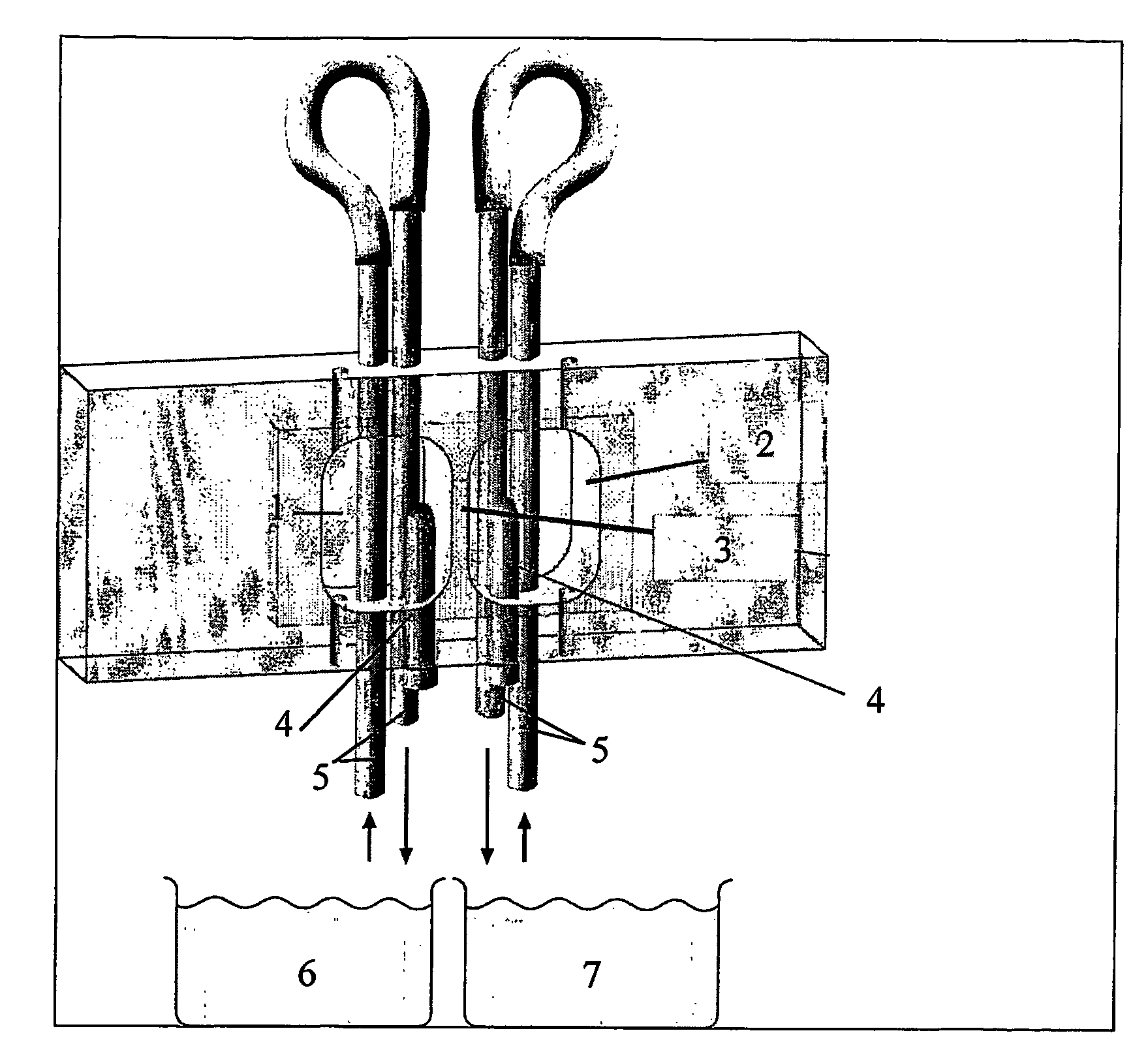

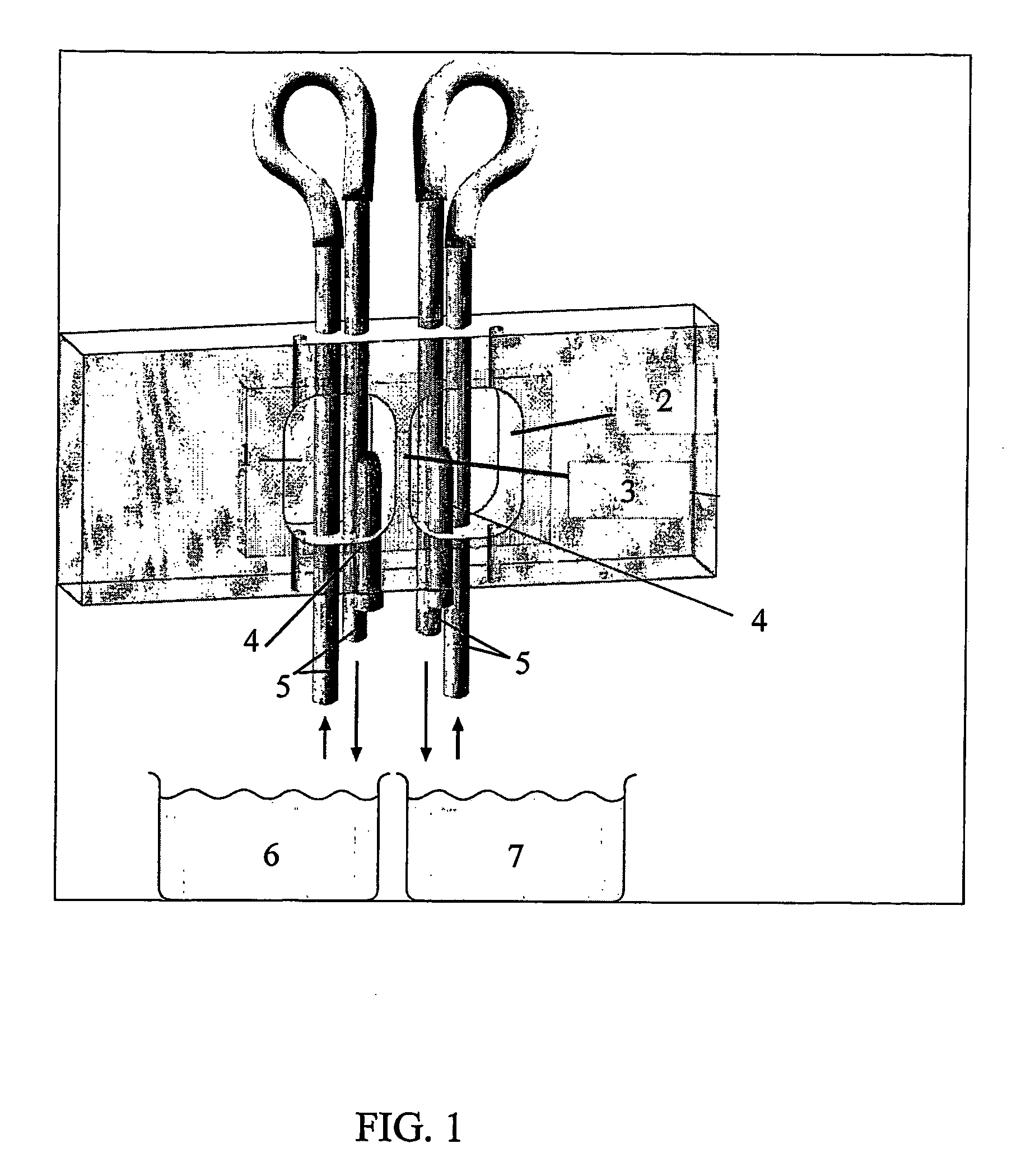

On site microbial bioremediation system and method of using said system

InactiveUS6087155ABioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismMicrobiology

An on site bioremediation system that delivers logarithmically growing, active microorganisms from the culture vessel directly to the biodegradable waste to be metabolized is disclosed. The system includes a controller, culture vessel and separate containers of stock microorganisms and nutrient medium. The periodic or continuous addition of stock microorganisms and fresh nutrient media is controlled by a computer. After a particular cell density is reached, the active, logarithmically growing microorganisms flow out of the system to the waste site on a periodic or continuous basis.

Owner:YORK BILLY G +3

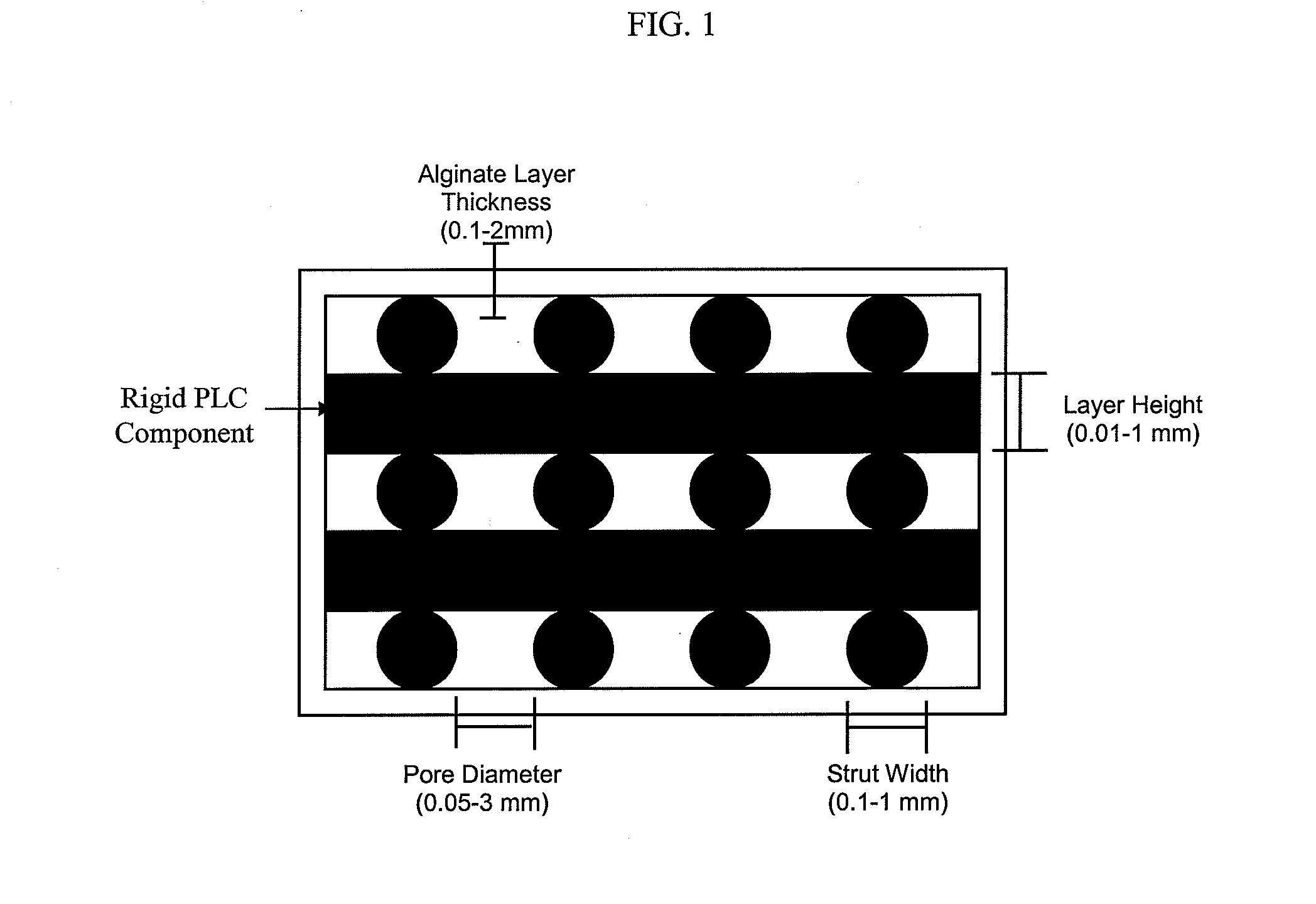

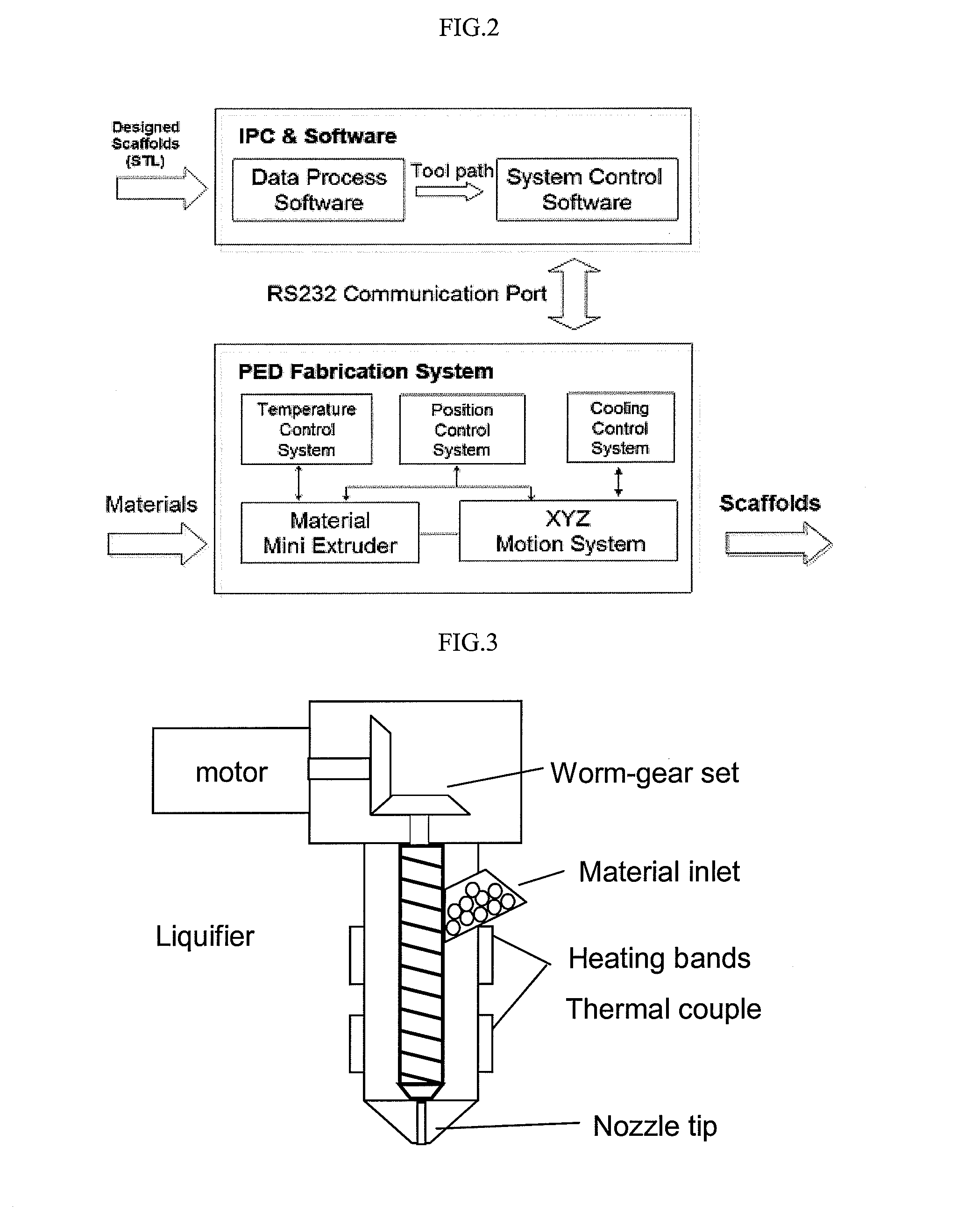

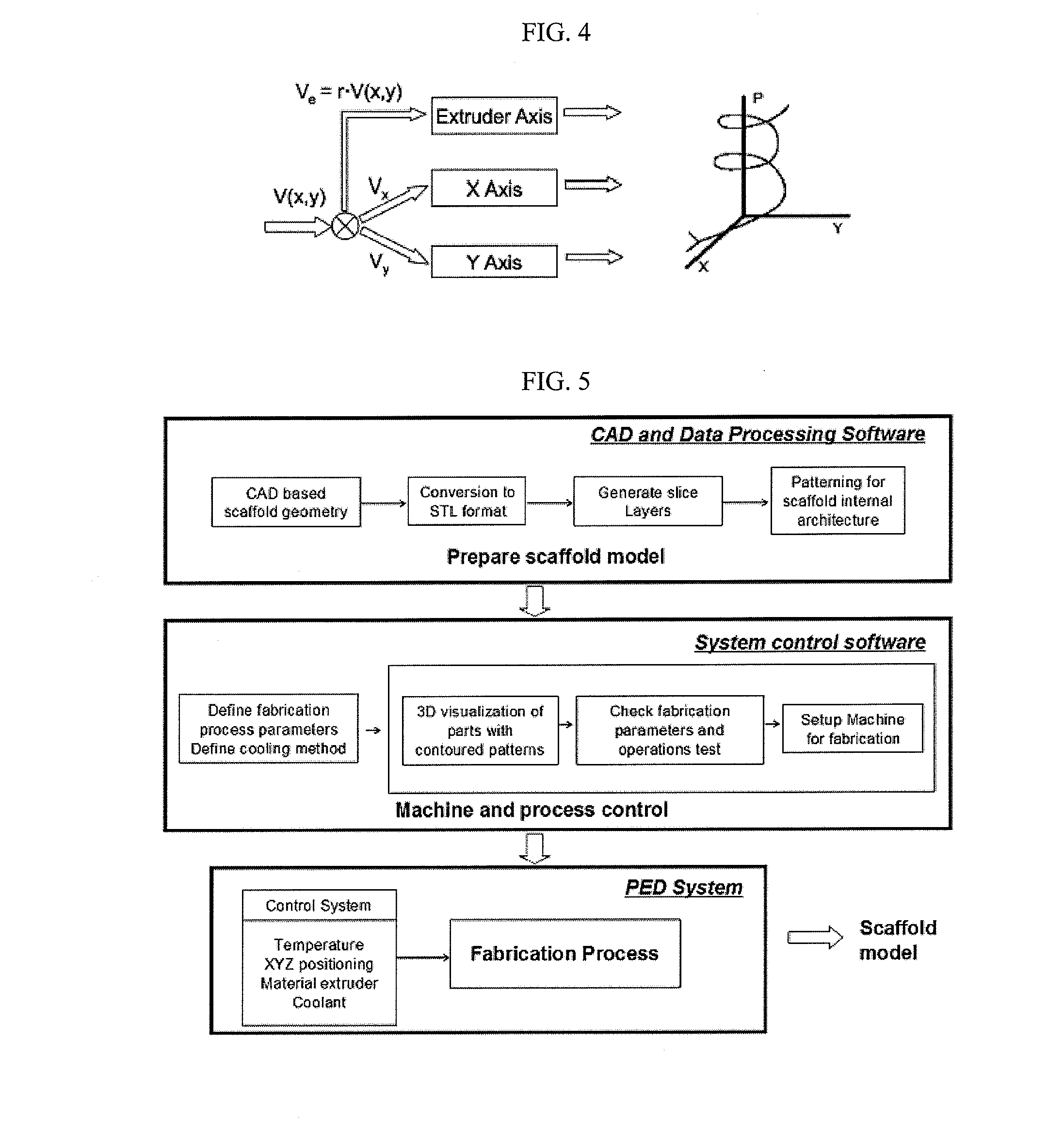

Super-sparger microcarrier beads and precision extrusion deposited poly-epsilon-caprolactone structures for biological applications

Owner:DARLING ANDREW +3

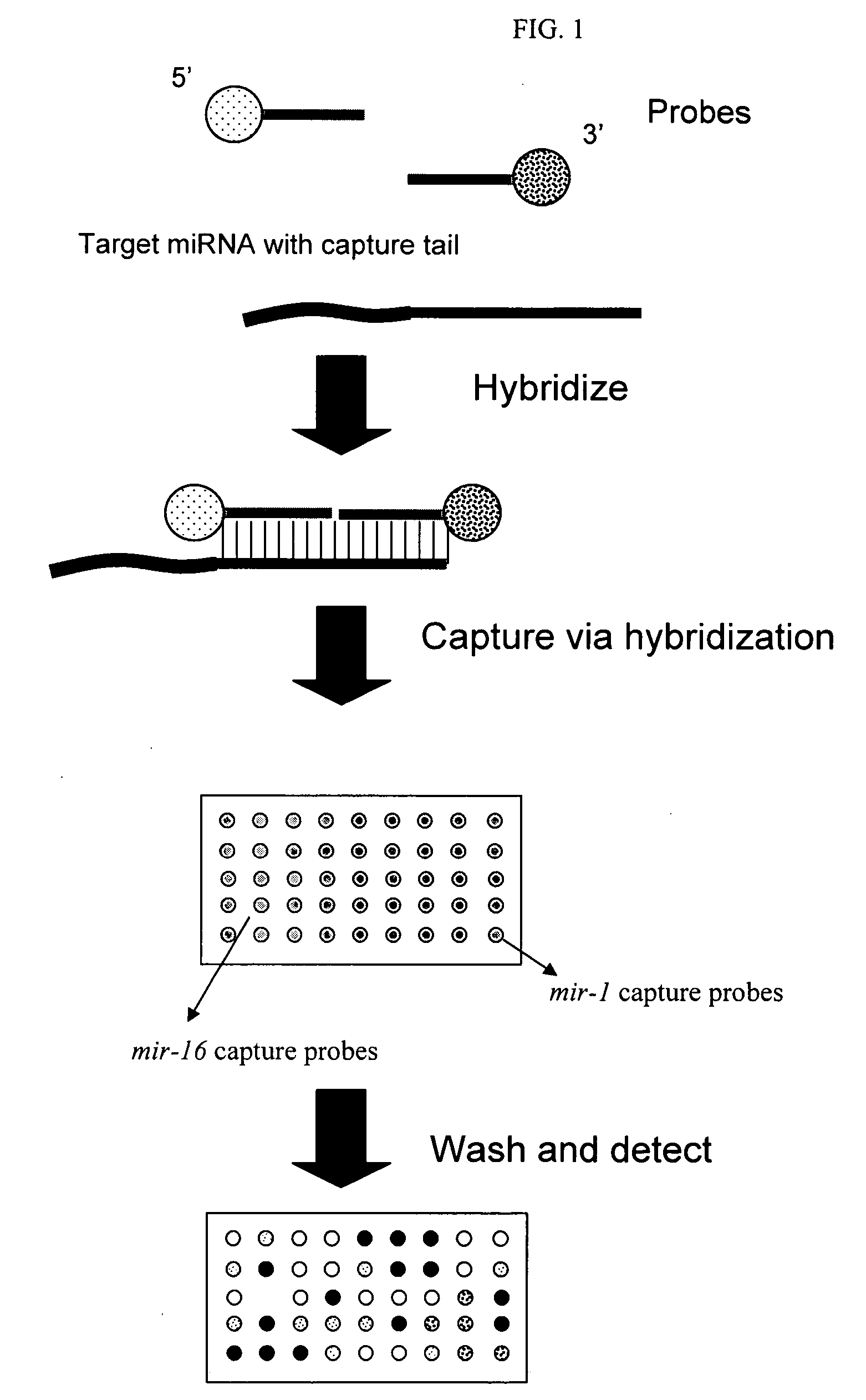

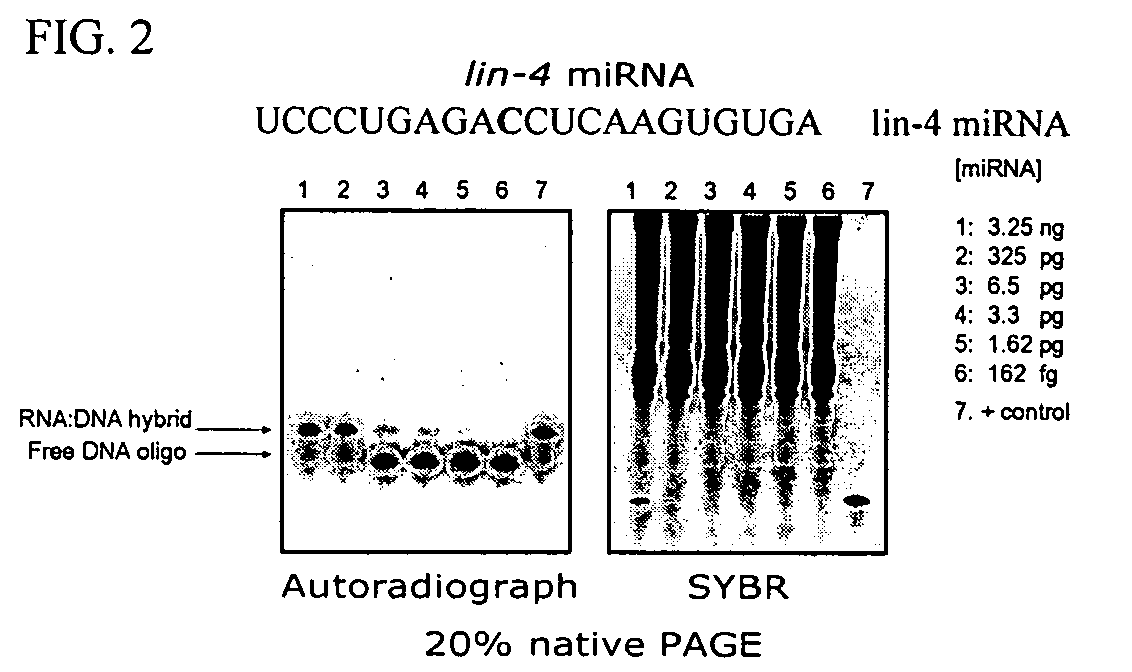

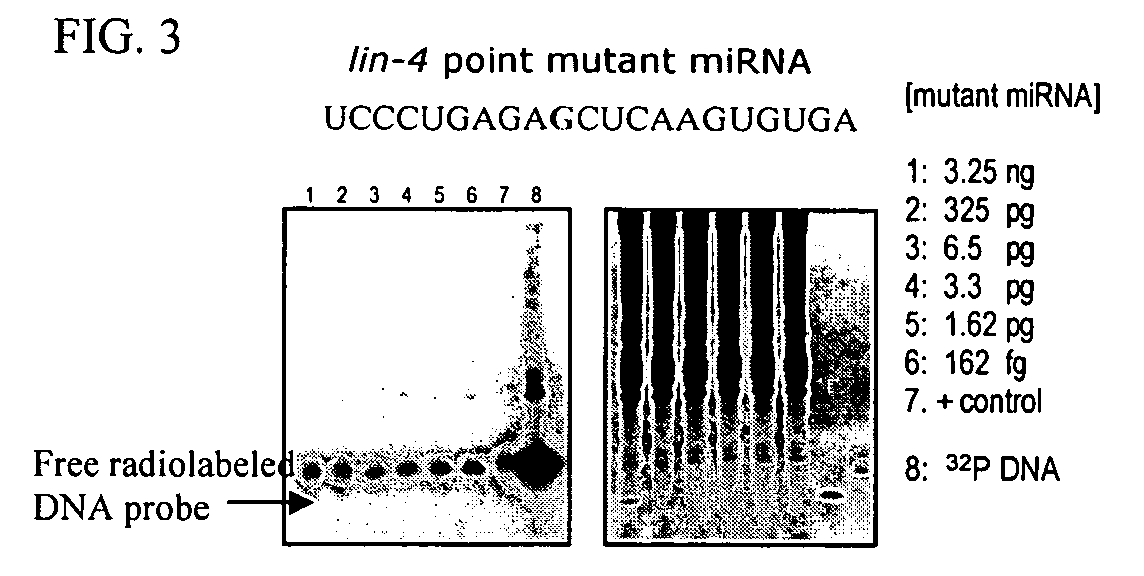

Methods and compositions for analysis of microRNA

InactiveUS20060292617A1Strong specificityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroRNABioinformatics

Owner:U S GENOMICS INC

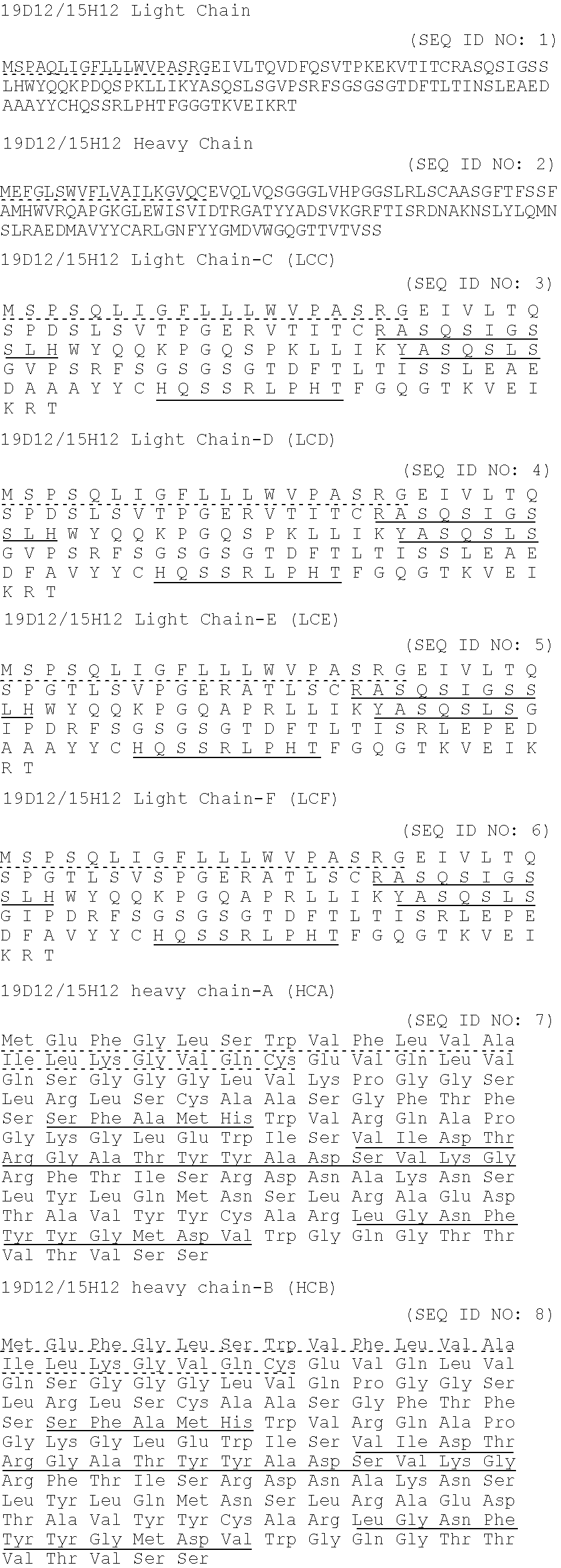

High titer antibody production

InactiveUS20110229933A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCell culture mediaAntibody production

Owner:MERCK SHARP & DOHME CORP

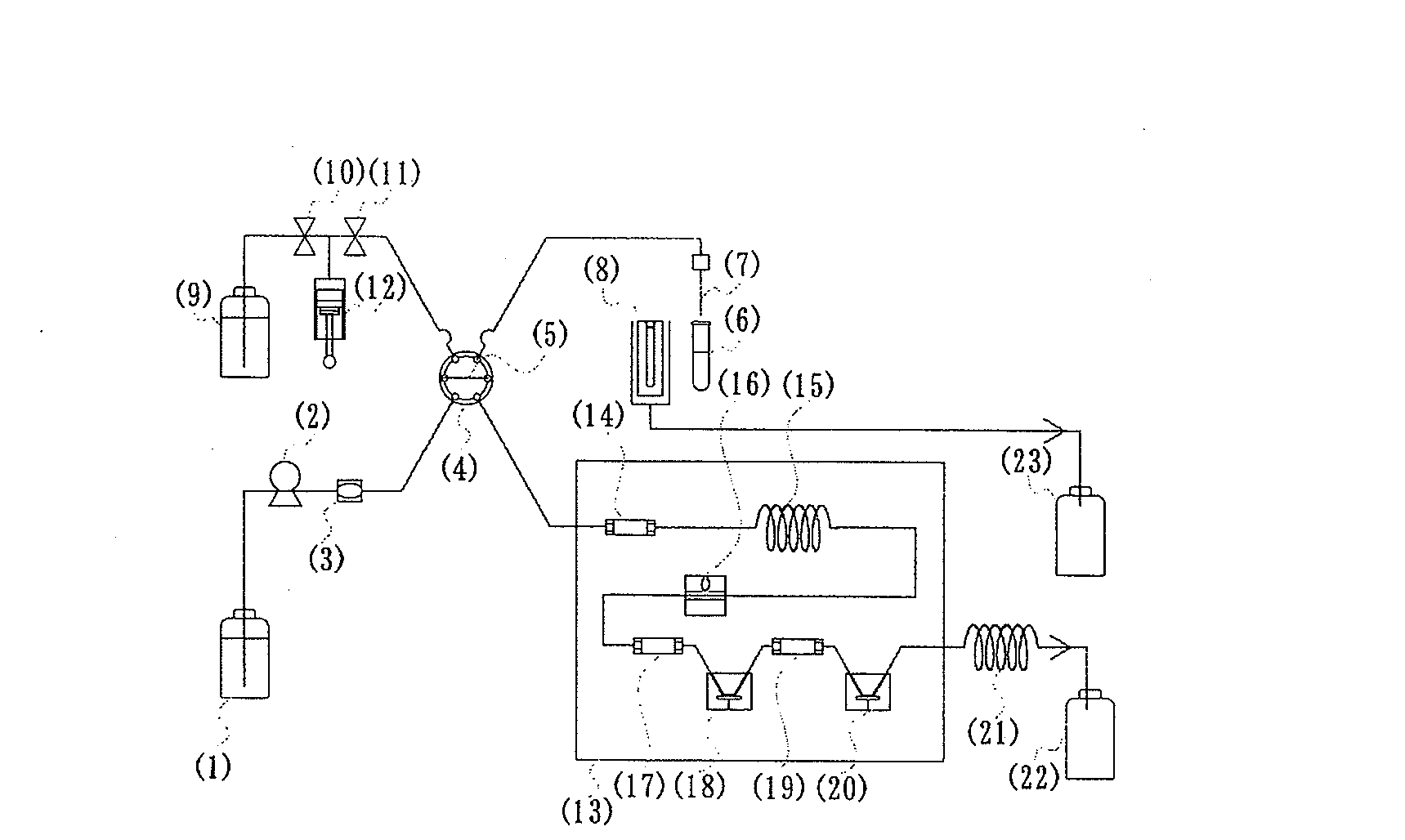

Method and circuit arrangement for treating biomaterial

ActiveUS20060094095A1Successful cell treatmentAvoid and offsetBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityVoltage pulse

The invention relates to a method for treating biomaterial using at least one electrical field generated by a first voltage pulse which is terminated once the value for an electrical parameter has exceeded or dropped below a preset limit. After the first voltage pulse has been terminated, it is continued by an additional voltage pulse. The invention also relates to a circuit arrangement comprising at least one storage device for electrical charges to generate at least one voltage pulse by selectively discharging the storage device, and at least one control unit for controlling the discharge. The present invention provides a controller for monitoring the chronological progression of the voltage pulse, said controller controlling at least one continuation of discharge after termination.

Owner:LONZA COLOGNE AG

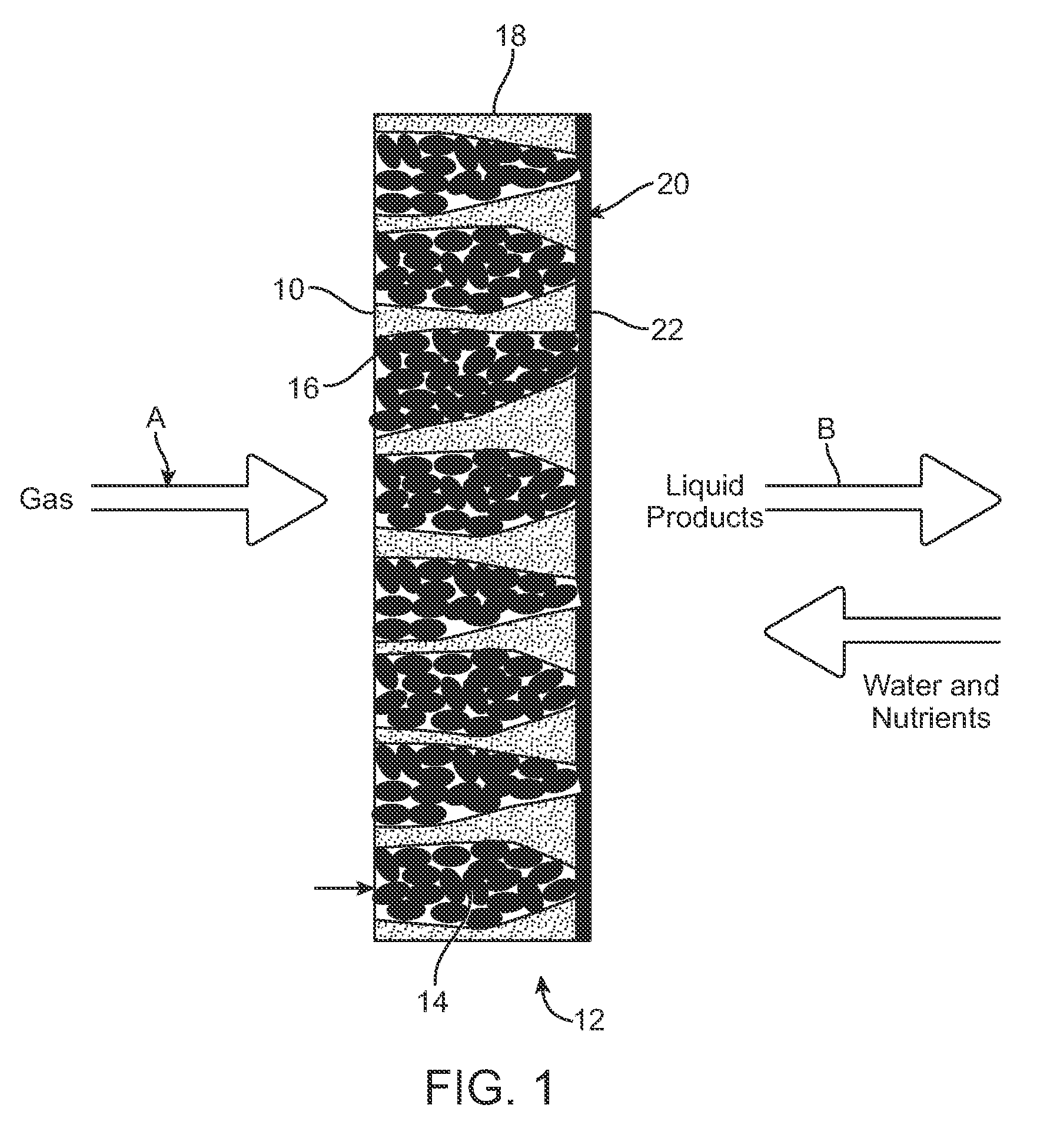

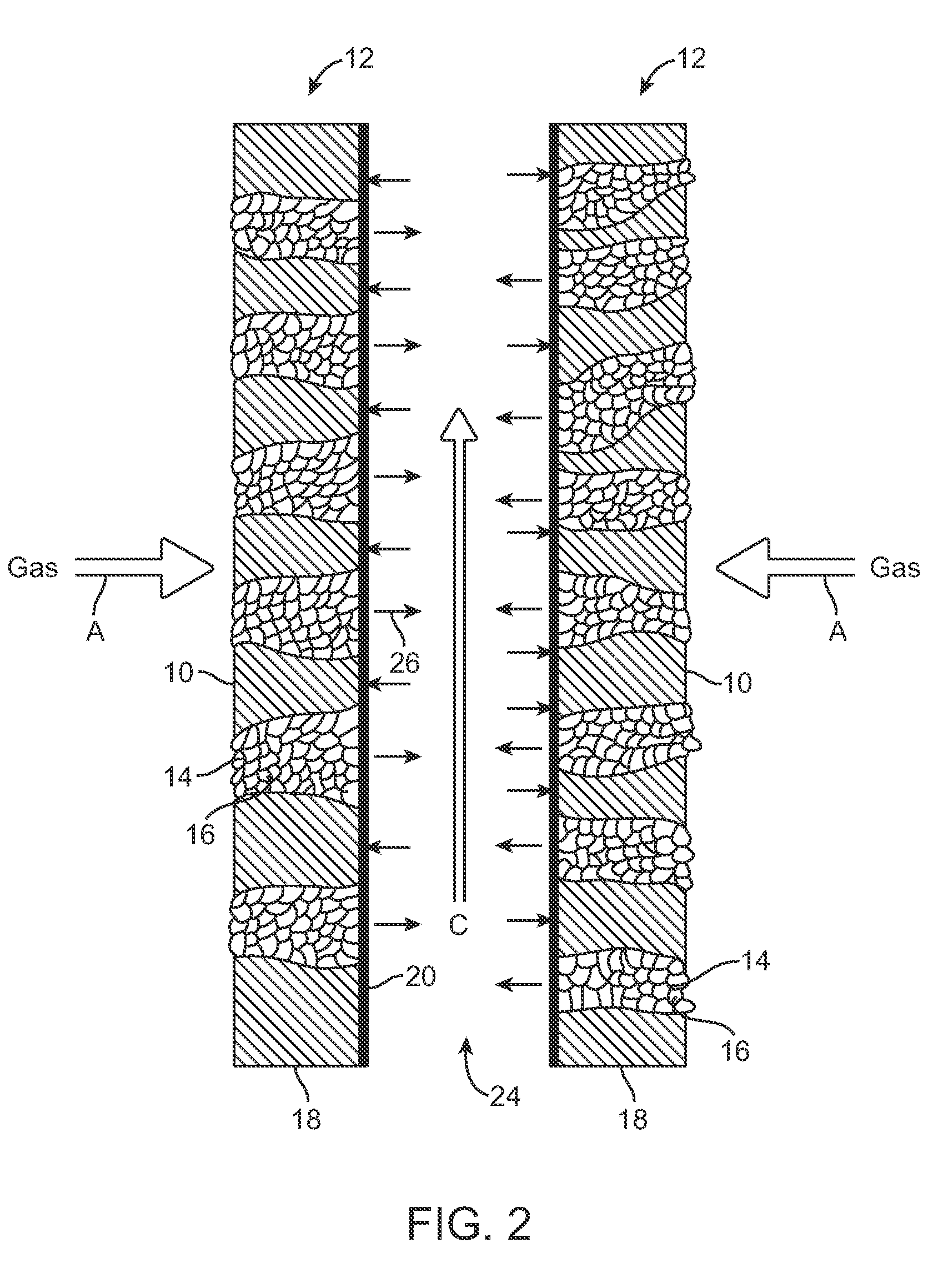

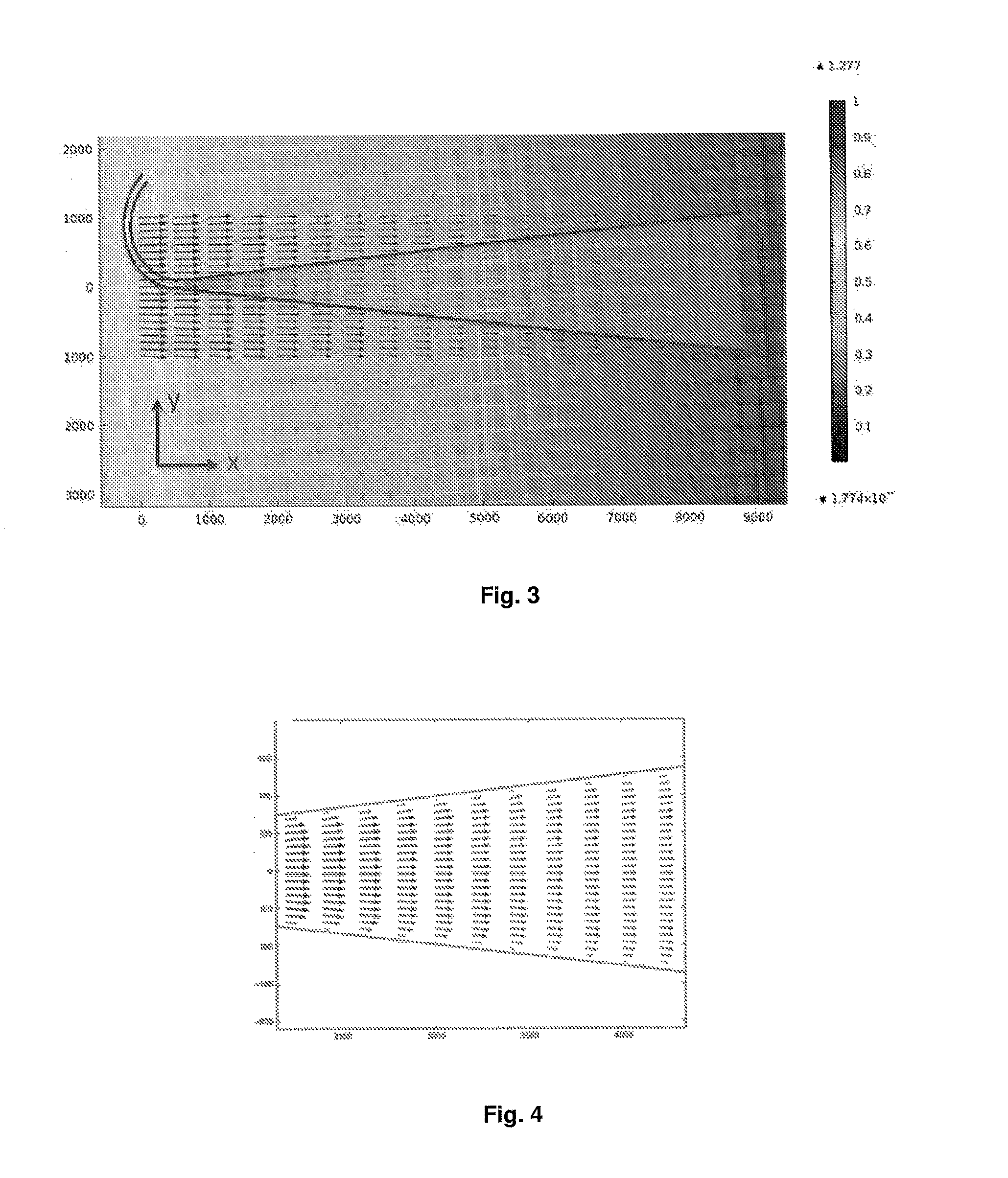

Stacked Array Bioreactor for Conversion of Syngas Components to Liquid Products

InactiveUS20090215153A1Promote and controlLess permeabilityBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid productFiber

Owner:SYNATA BIO INC

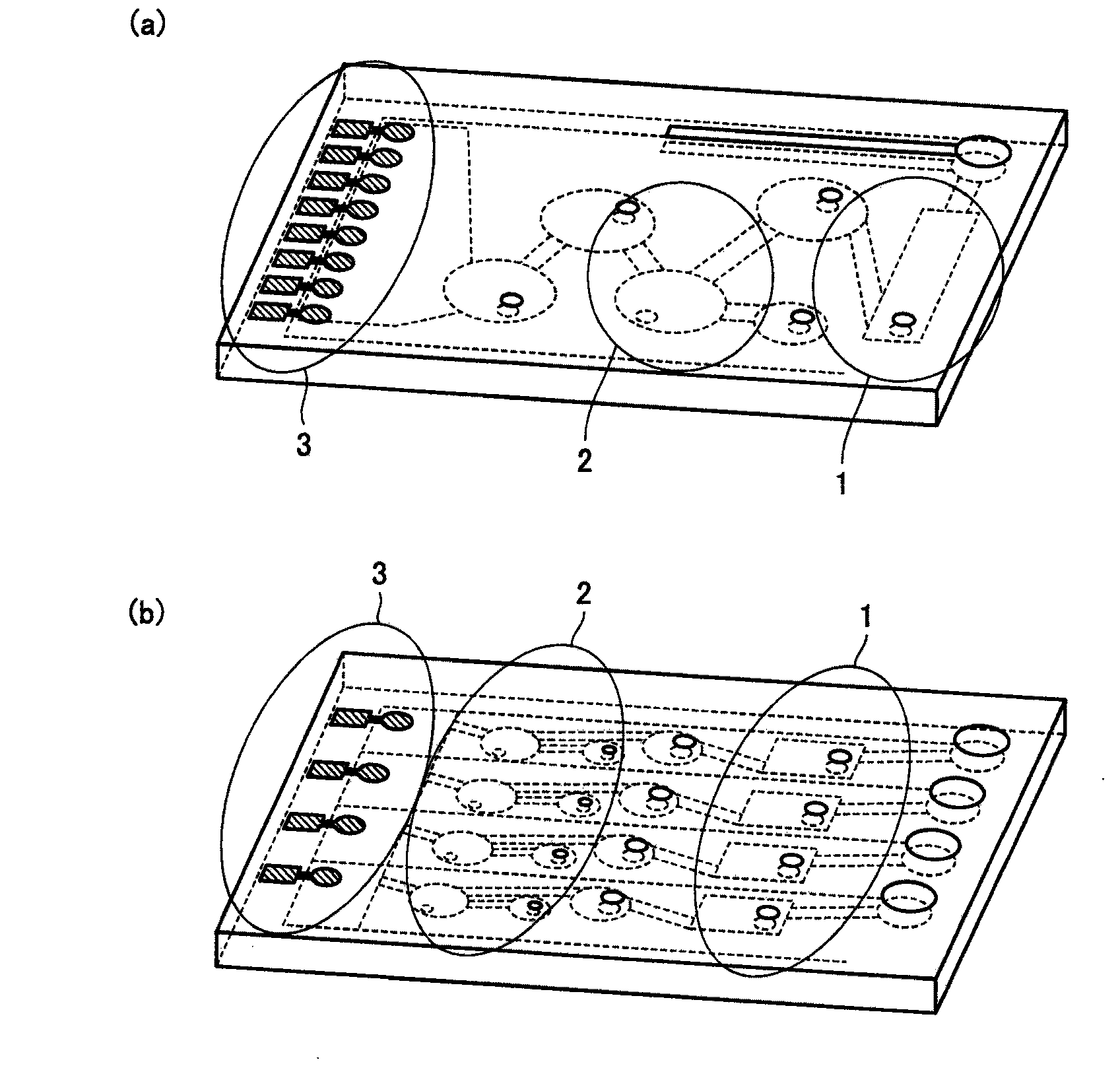

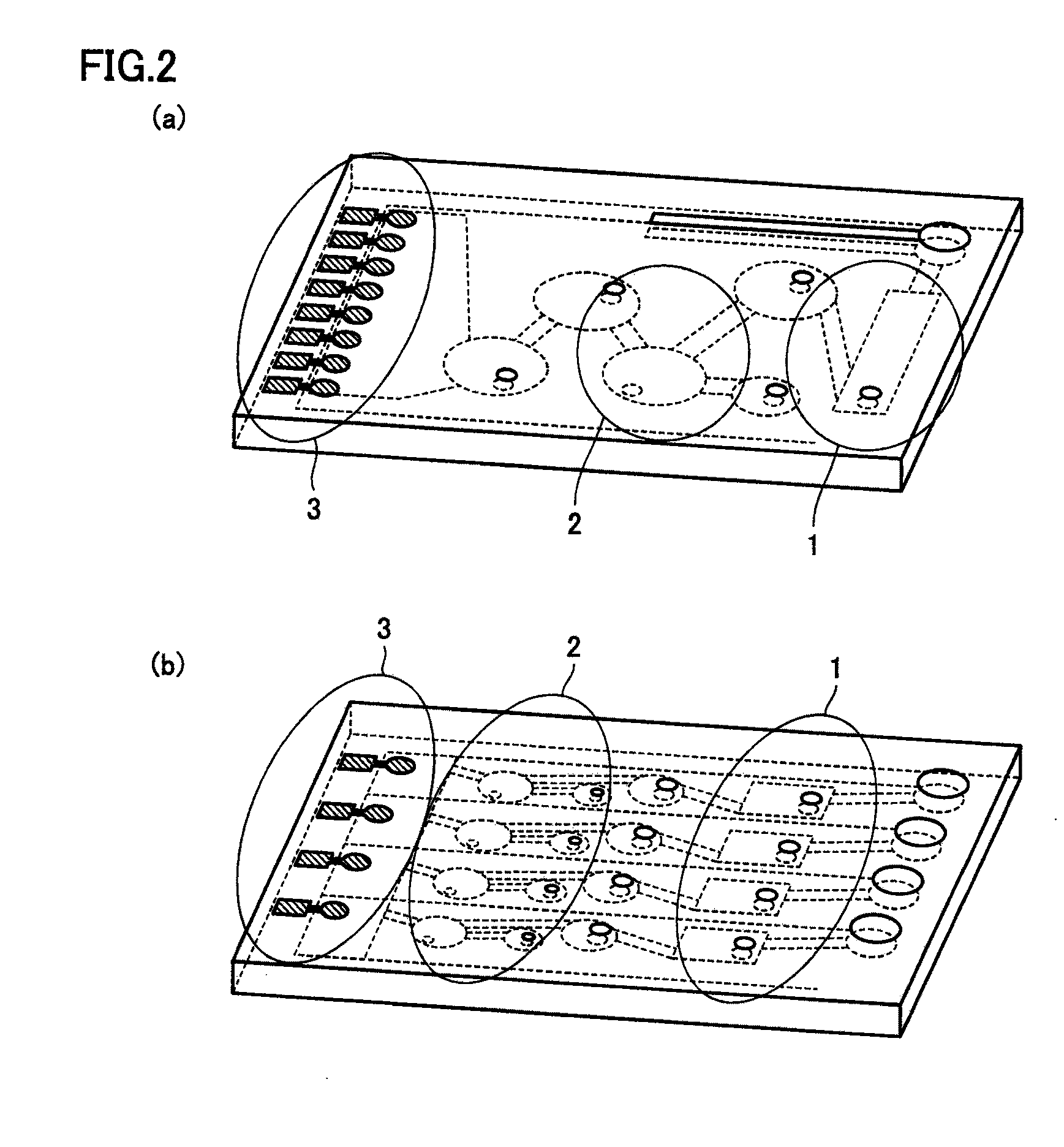

Microfluidic chip for multiple bioassay and method of manufacturing the same

InactiveUS20060188906A1Avoid mixingMaterial nanotechnologyBioreactor/fermenter combinationsEngineeringMicrofluidic channel

Owner:SAMSUNG ELECTRONICS CO LTD

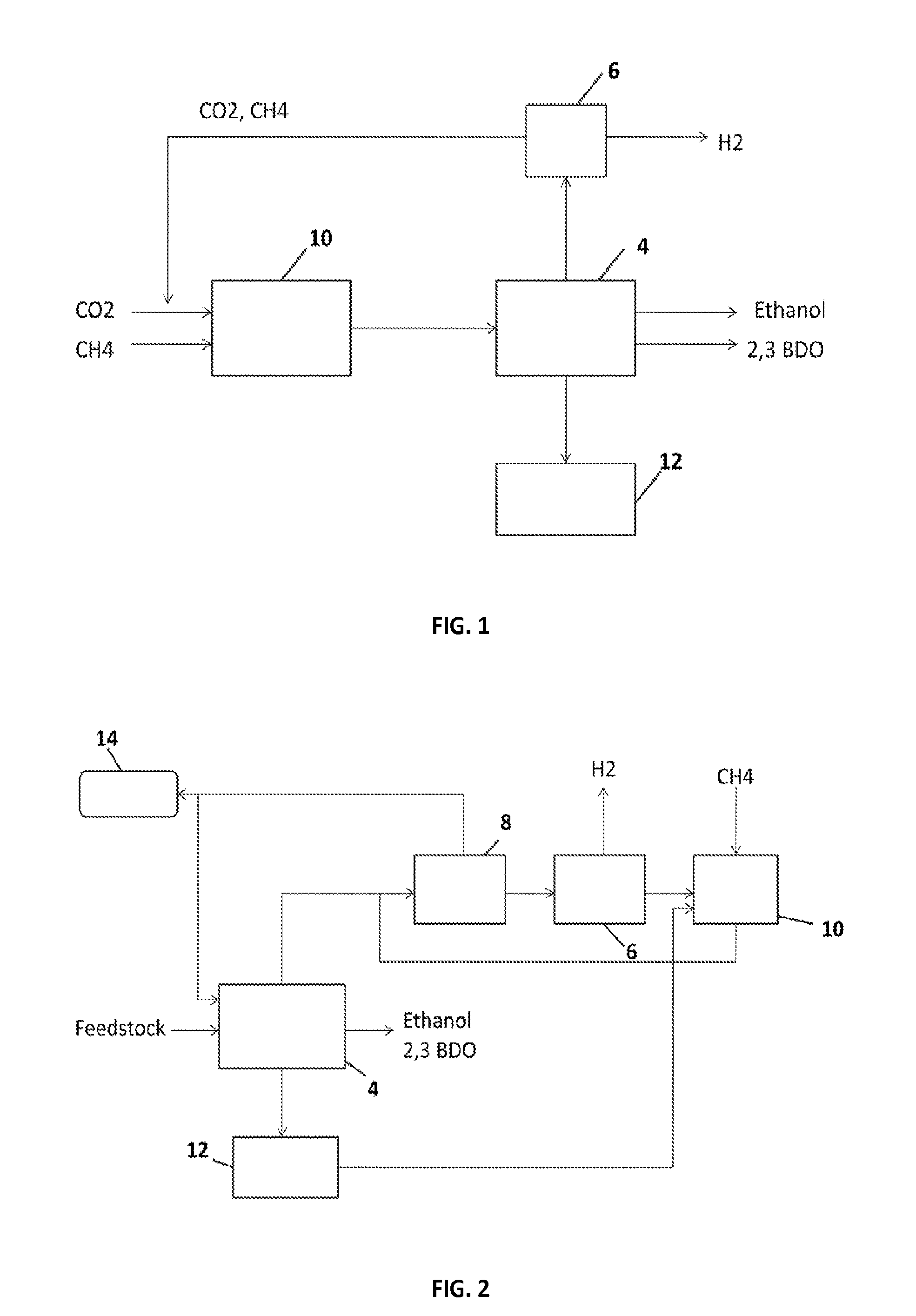

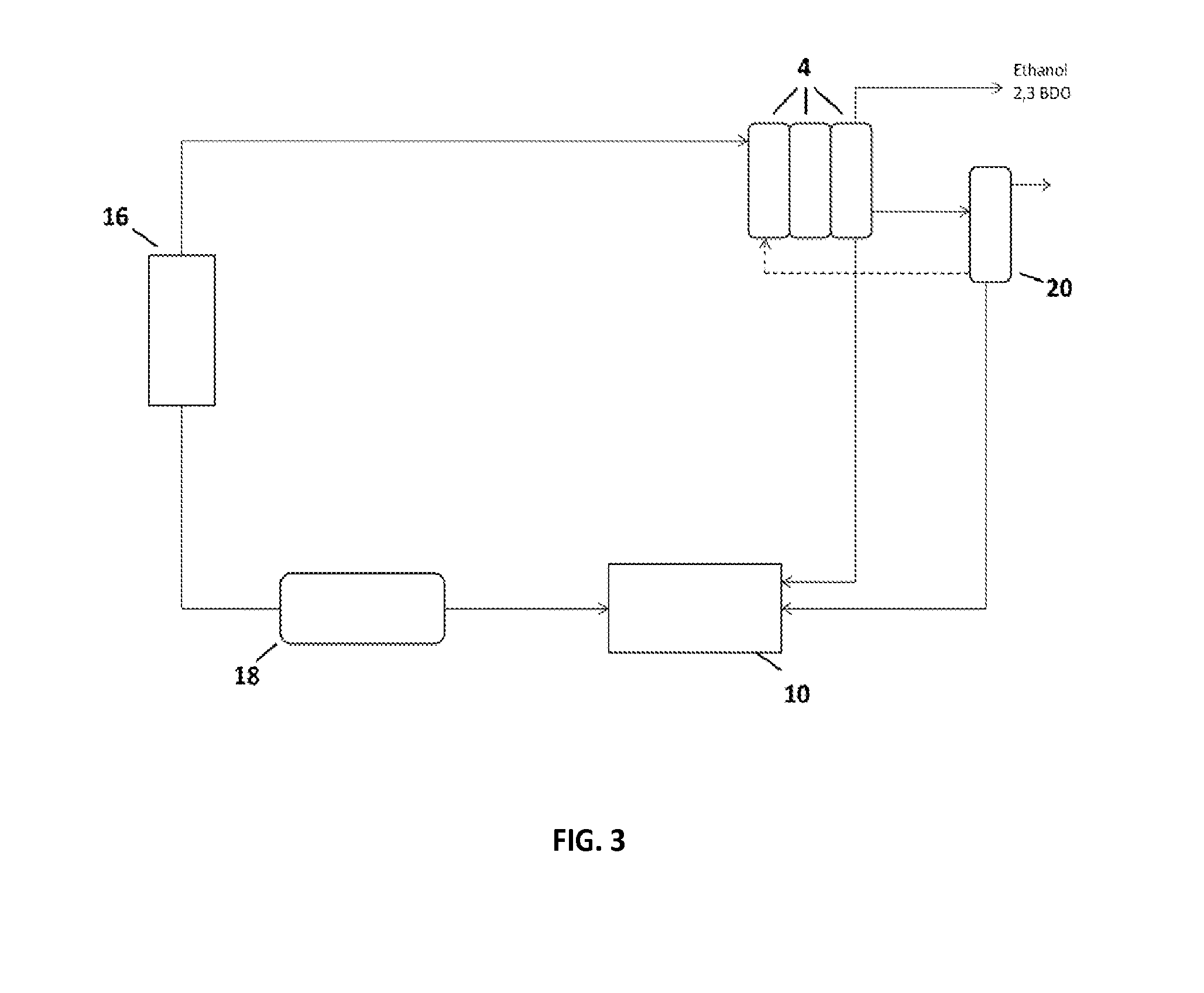

Methods and Systems for the Production of Hydrocarbon Products

InactiveUS20130203143A1Bioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorHydrocarbon

Owner:LANZATECH NZ INC

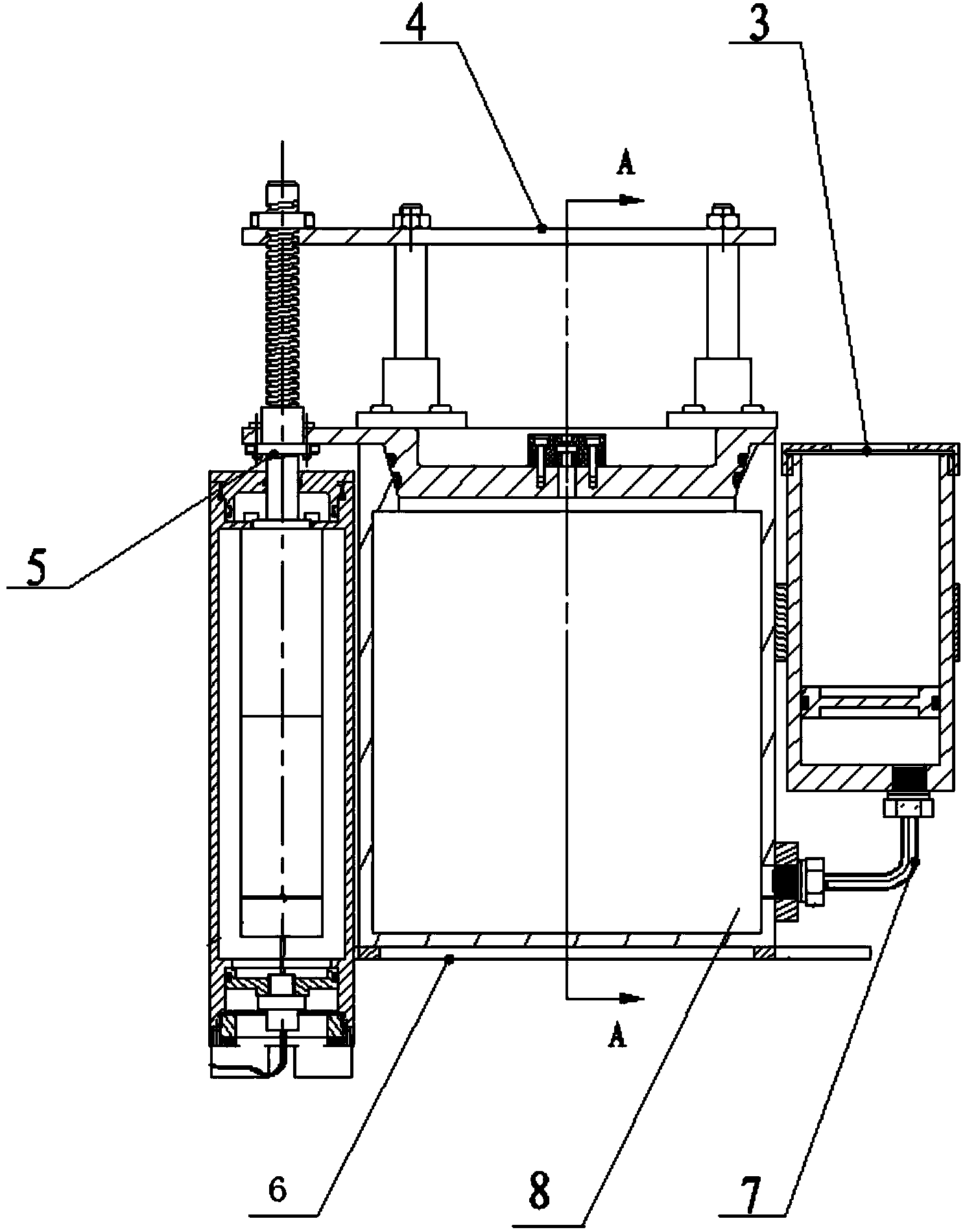

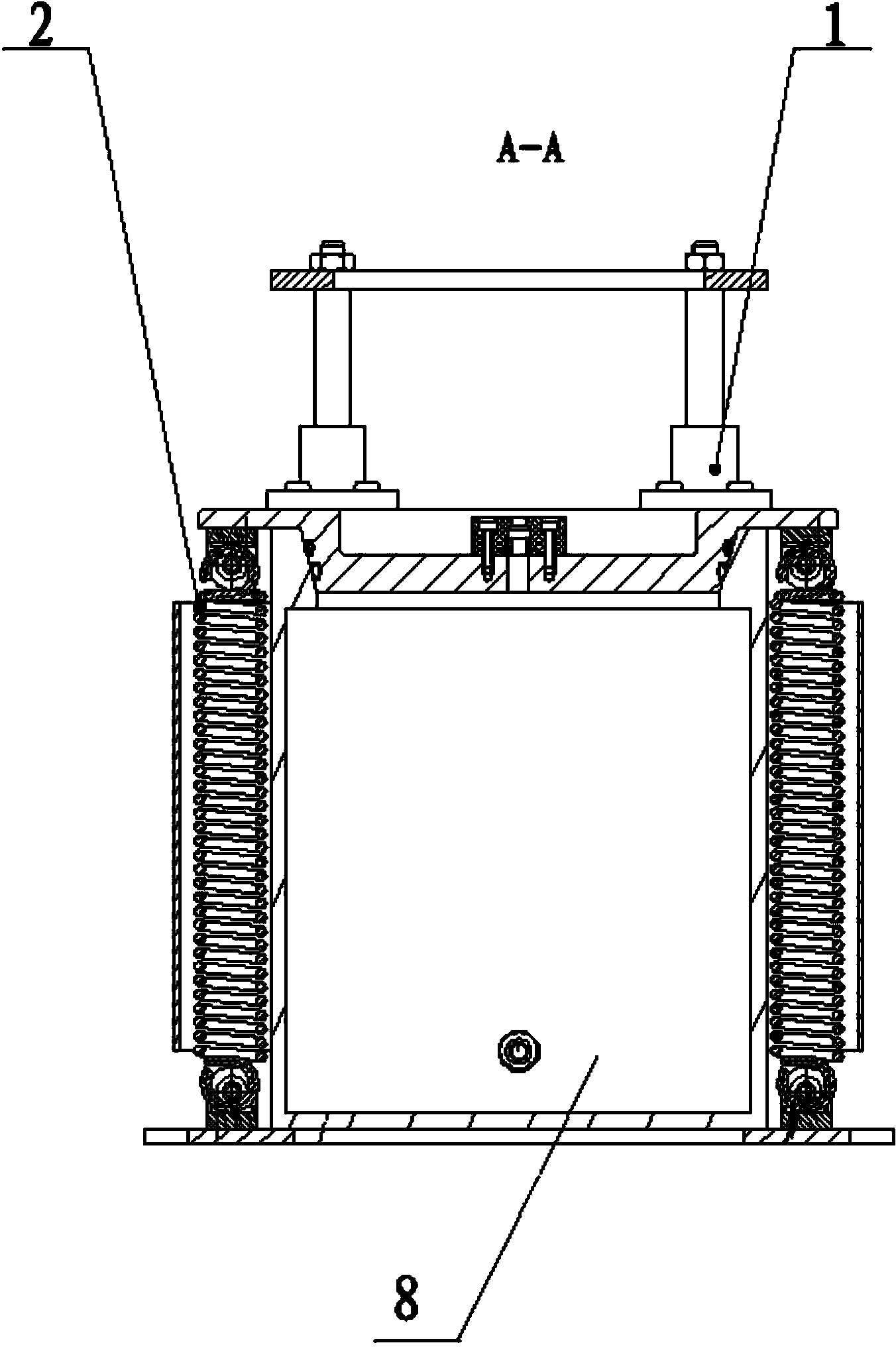

Uncovered culture cabin for deep-sea microorganisms

InactiveCN103484355AImprove the level of research and development technologyImprove independent innovation capabilitiesBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

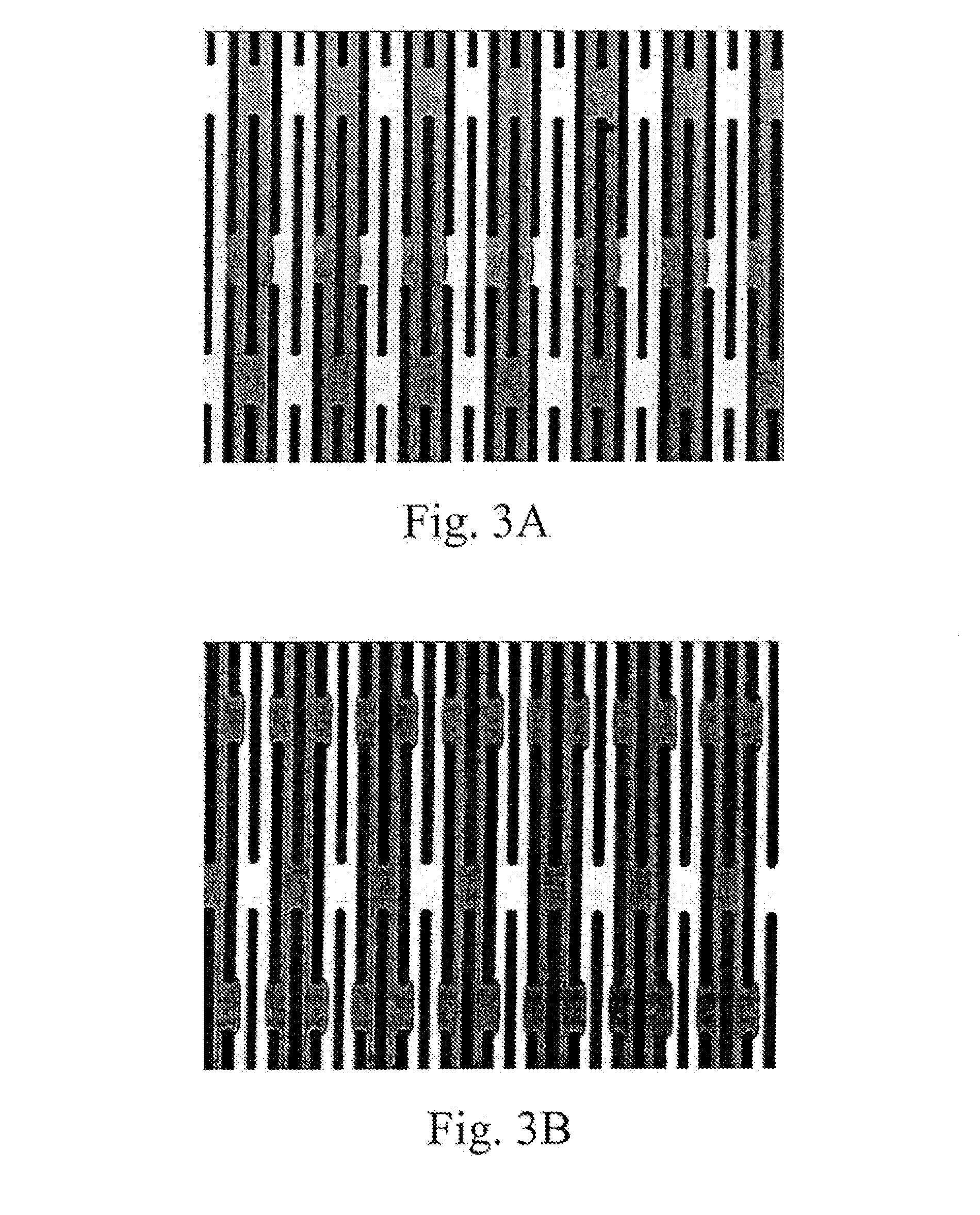

Microfluidic device for cell motility screening and chemotaxis testing

InactiveUS20130244270A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMotilityCell locomotion

Owner:CAPITALBIO CORP +1

Cell culture device and methods

ActiveUS20200063081A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCell-Extracellular MatrixCell aggregation

A method of vascularising a cell aggregate on a microfluidic device, microfluidic cell culture devices comprising perfusable vascular networks and kits and assays using the microfluidic cell culture devices are described. The microfluidic devices comprise one or more capillary pressure barriers allowing for formation of an extracellular matrix gel within a confined area of the network, in which cells can be cultured for different uses.

Owner:MIMETAS BV

Automated cell sample enrichment preparation method

ActiveUS20060183220A1Bioreactor/fermenter combinationsBiological substance pretreatmentsCell enrichmentBiophysics

A method for automated cell enrichment preparation where biological cells are injected into a first subchamber and flowed through the first subchamber, through a large pore filter and into a second subchamber so that the large pore filter retains particles large particles in the first subchamber, while the biological cells pass through the first filter into the second subchamber and are retained by a small pore filter. After clearing, the biological cells are stained. A solvent exchange leaves the biological cells in solvent and they are released into a concentration module where a portion of the solvent is removed to form an enriched concentrated cell suspension.

Owner:VISIONGATE

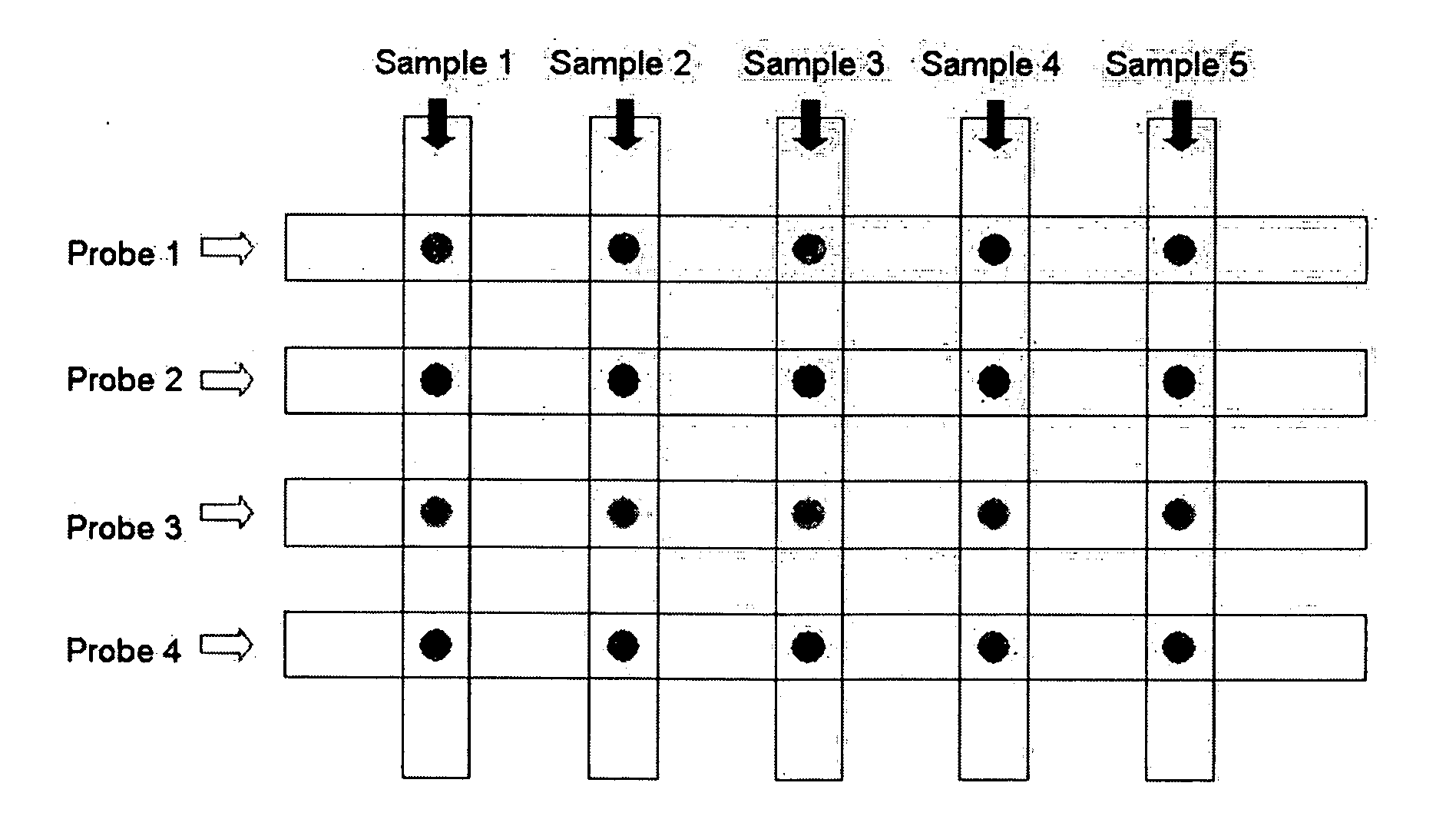

Method of making and using hybrid polymeric thin films for bio-microarray applications

InactiveUS20050048554A1Peptide librariesBioreactor/fermenter combinationsPolyelectrolyteCost effectiveness

Platforms for easy and cost-effective fabrication of bio-microarrays are disclosed. In one embodiment, the platform contains a substrate having a surface coated with a film of alternating polycationic and polyanionic polymers. In another embodiment, the platform contains a substrate having a surface coated with a polyelectrolyte-silica sol-gel film. Also disclosed are bio-microarrays fabricated using the above platforms and methods of making the platforms and the microarrays.

Owner:UT BATTELLE LLC

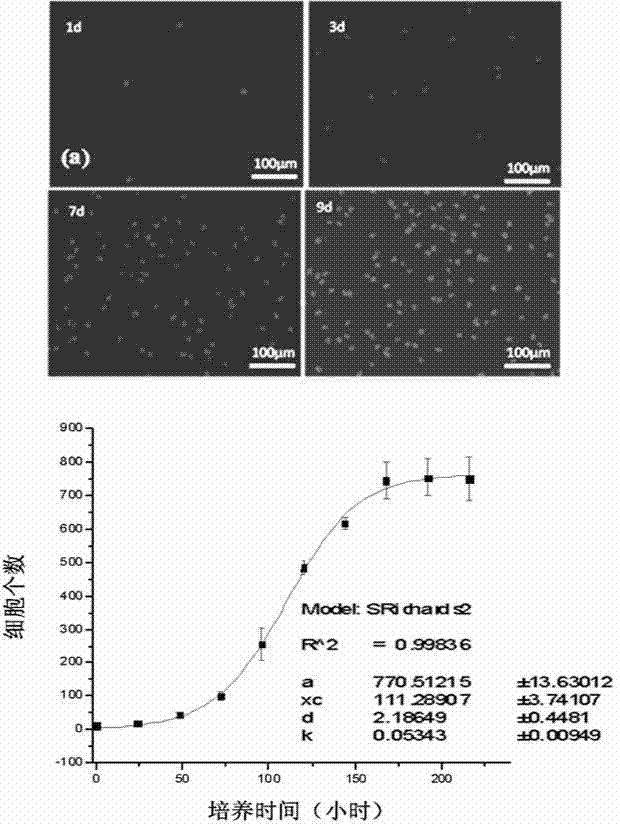

Microfluidic chip system for culture and multiplication behavior research of marine microalgae

InactiveCN102876562AImprove throughputSimple and fast operationBioreactor/fermenter combinationsBiological substance pretreatmentsProcess integrationBiology

Owner:DALIAN UNIV

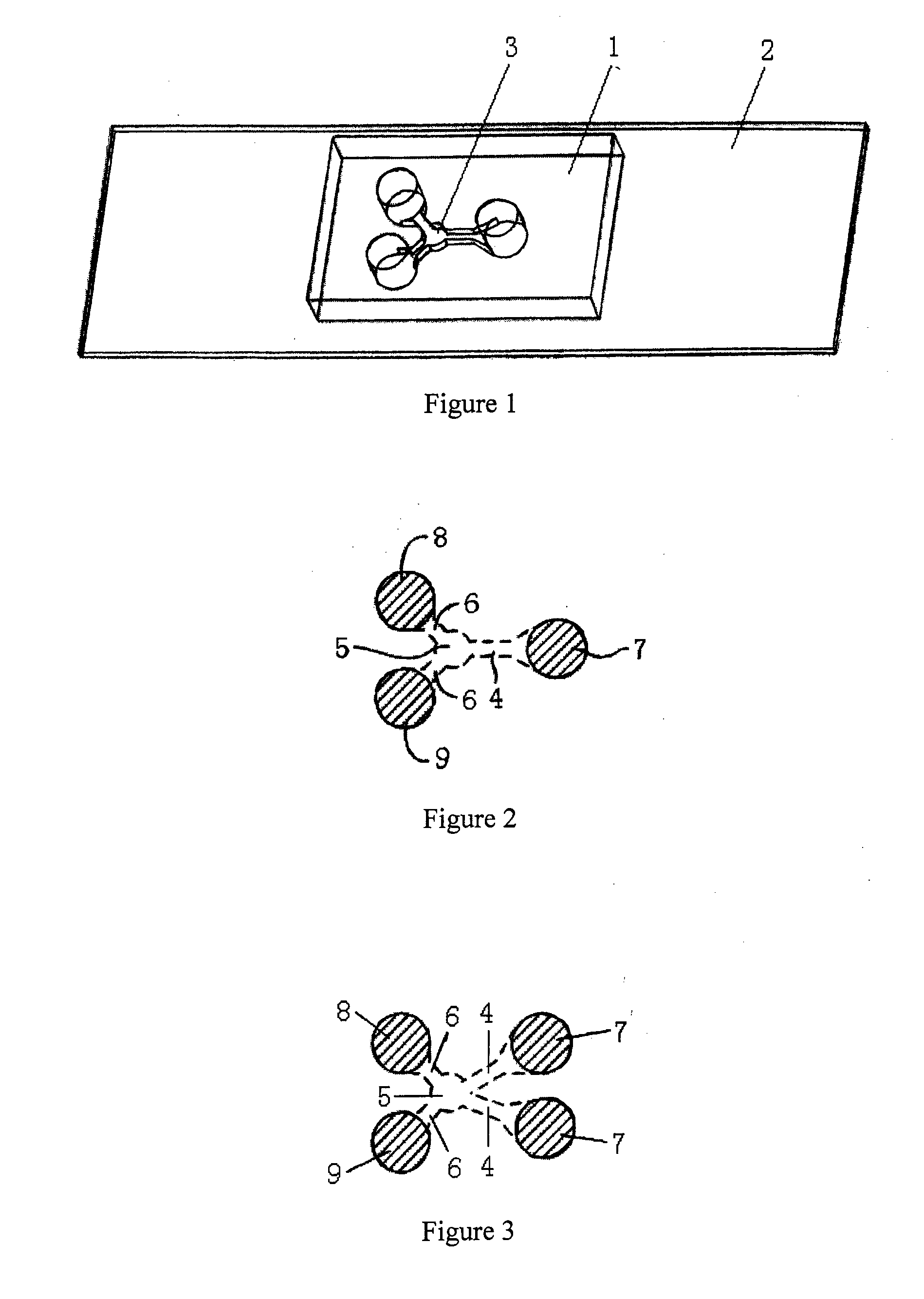

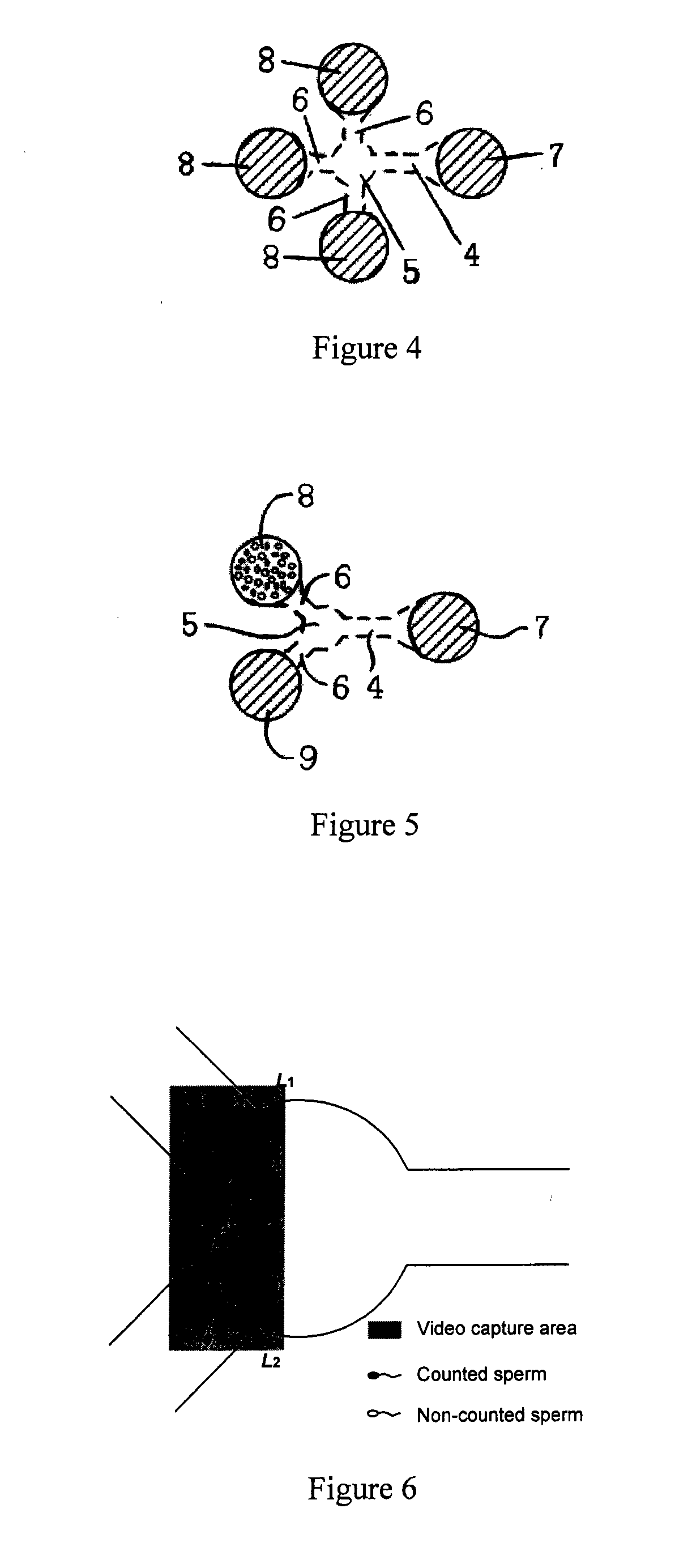

Methods and devices for breaking cell aggregation and separating or enriching cells

InactiveUS20160237397A1Reduce lossesStep can be unnecessaryBioreactor/fermenter combinationsBiological substance pretreatmentsCell AggregationsChemistry

Owner:AVIVA BIOSCI

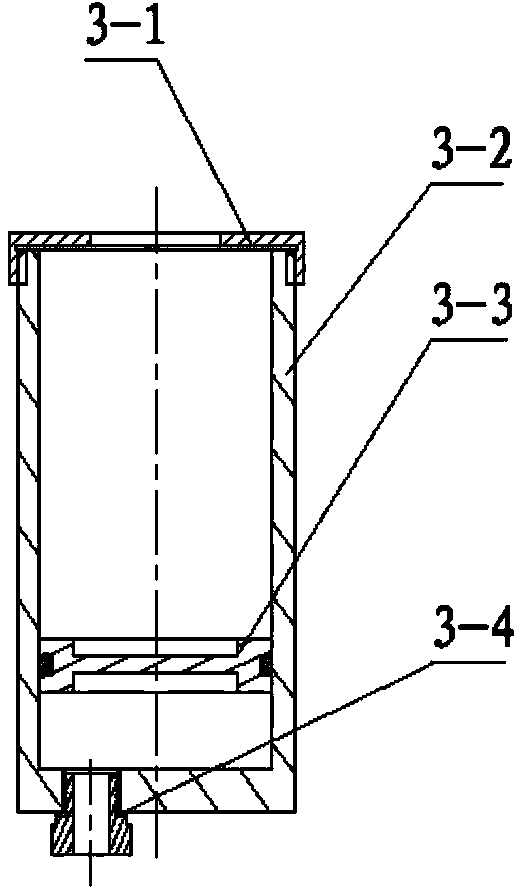

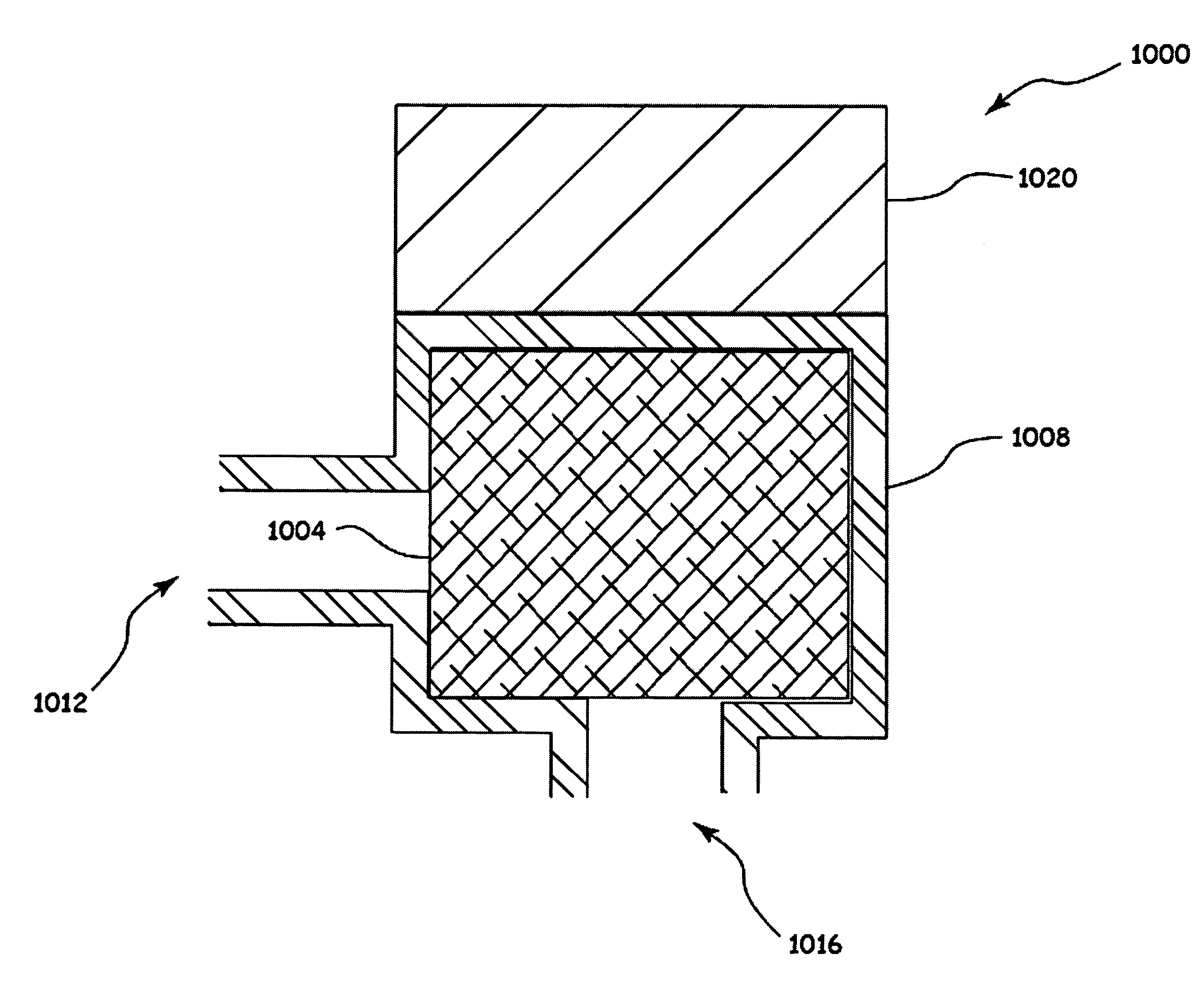

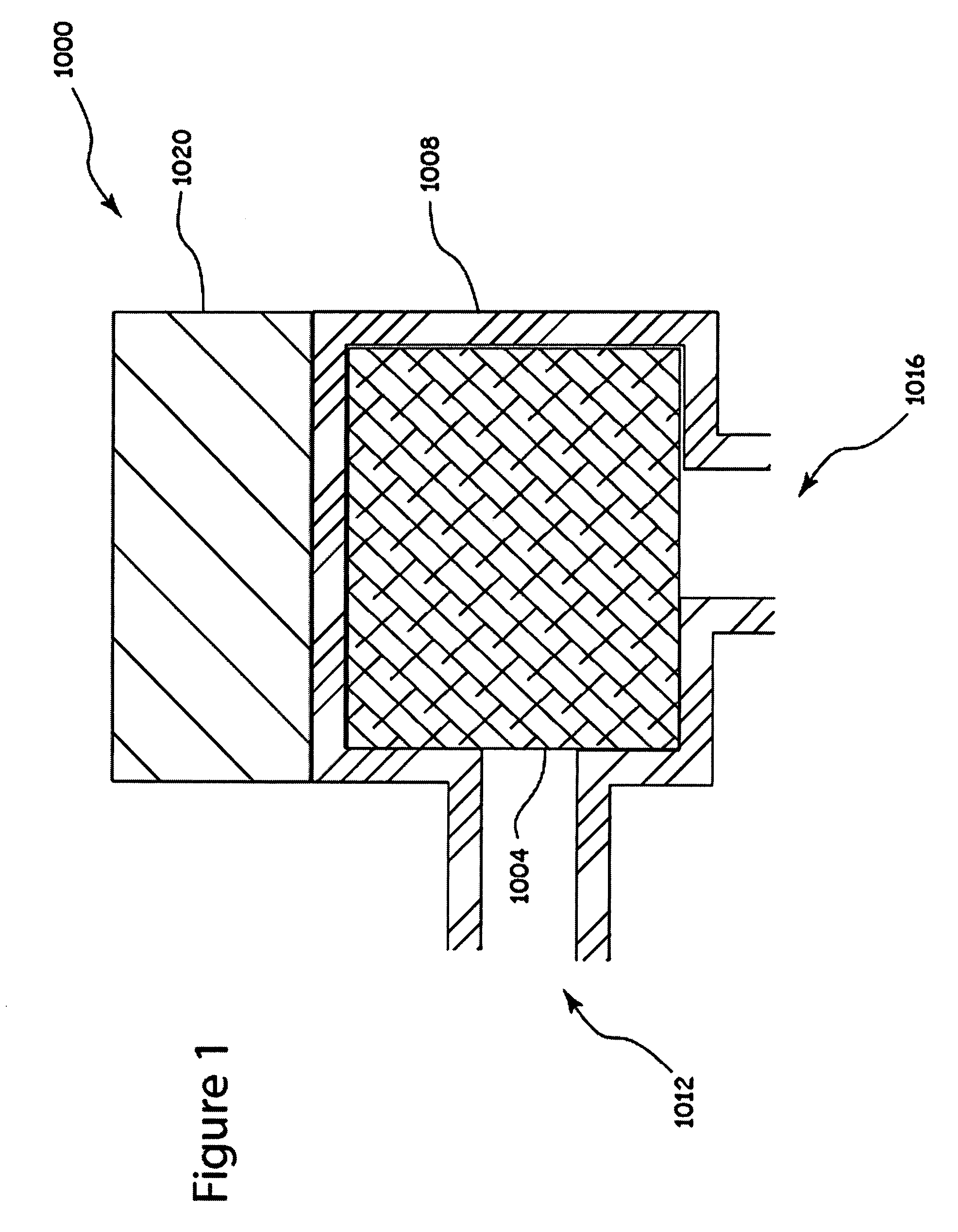

Apparatus, system, and method for purifying nucleic acids

ActiveUS20090107927A1Bioreactor/fermenter combinationsBiological substance pretreatmentsFritAmount of substance

Owner:AKONNI BIOSYSTEMS INC

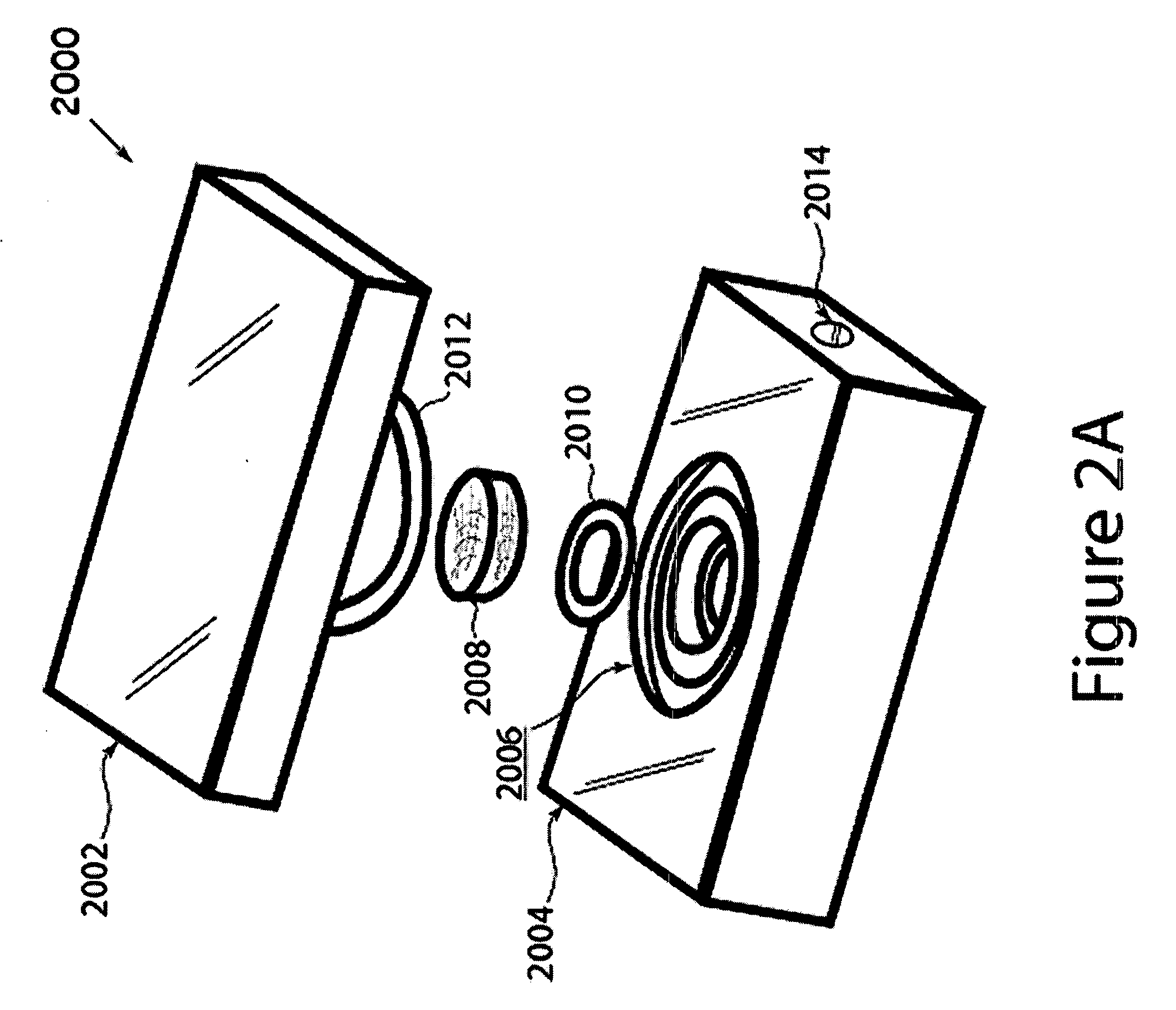

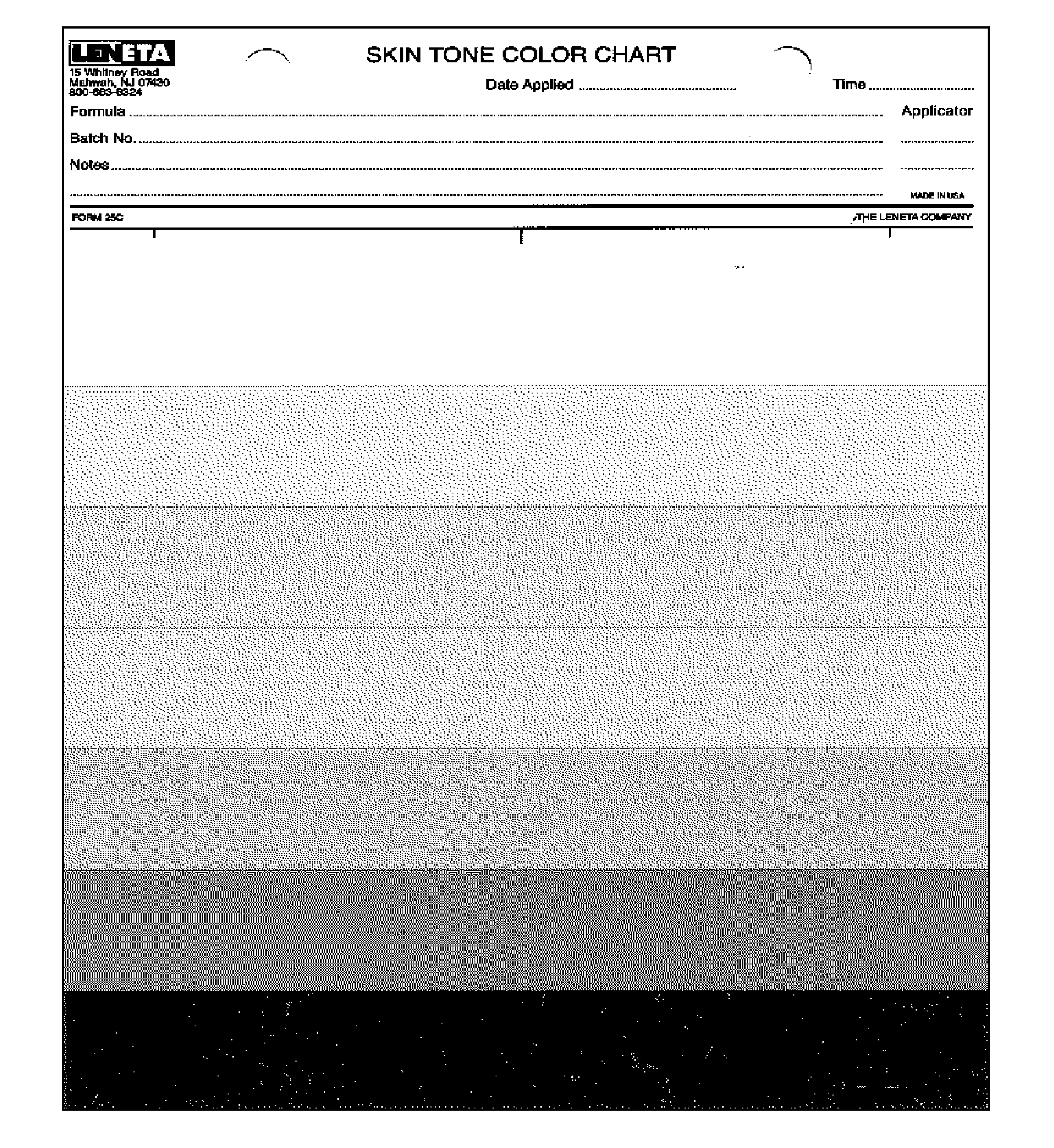

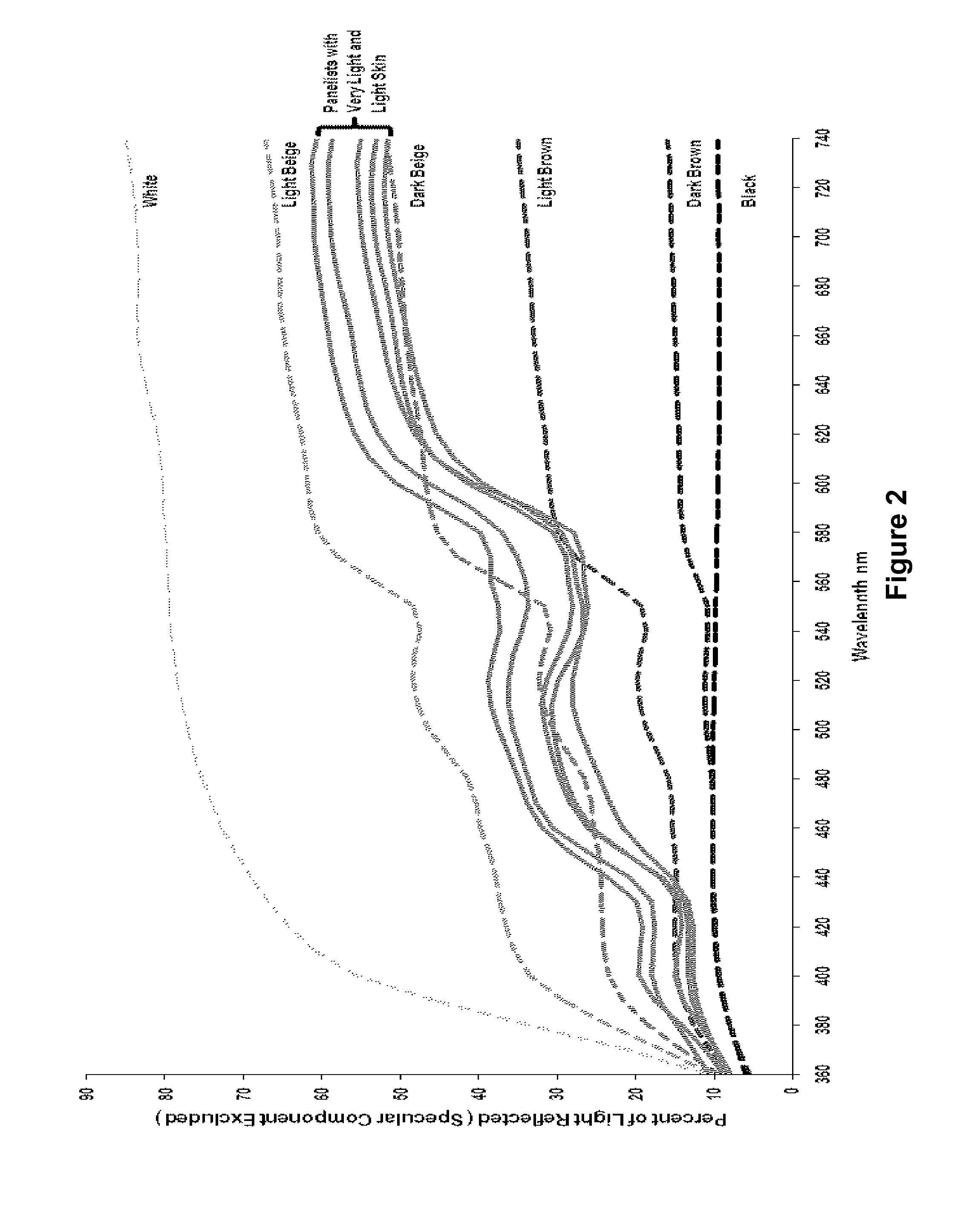

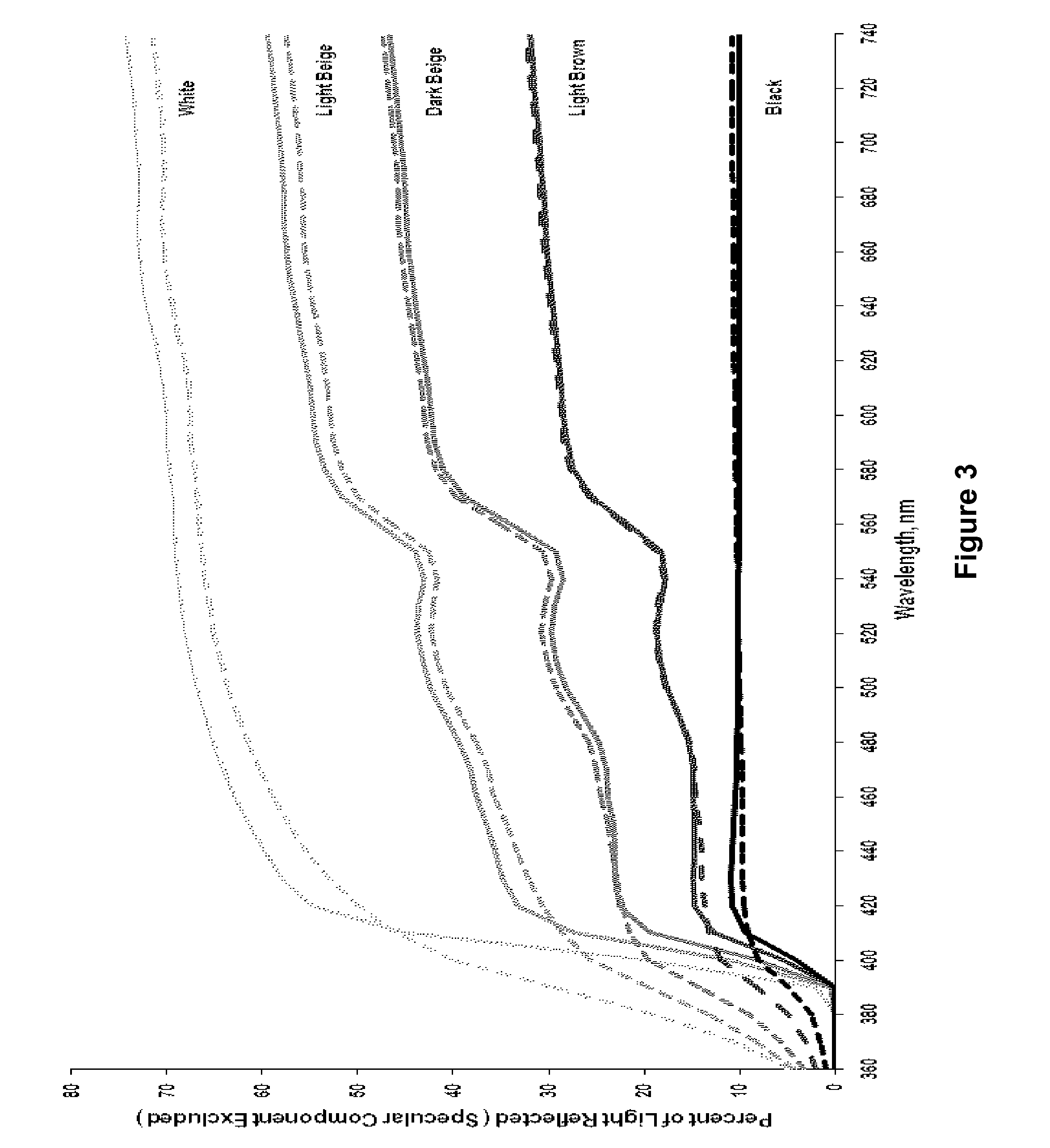

In vitro method and apparatus for determining efficacy and action mechanisms of a topical composition on various skin color types

Owner:AKZO NOBEL SURFACE CHEM LLC

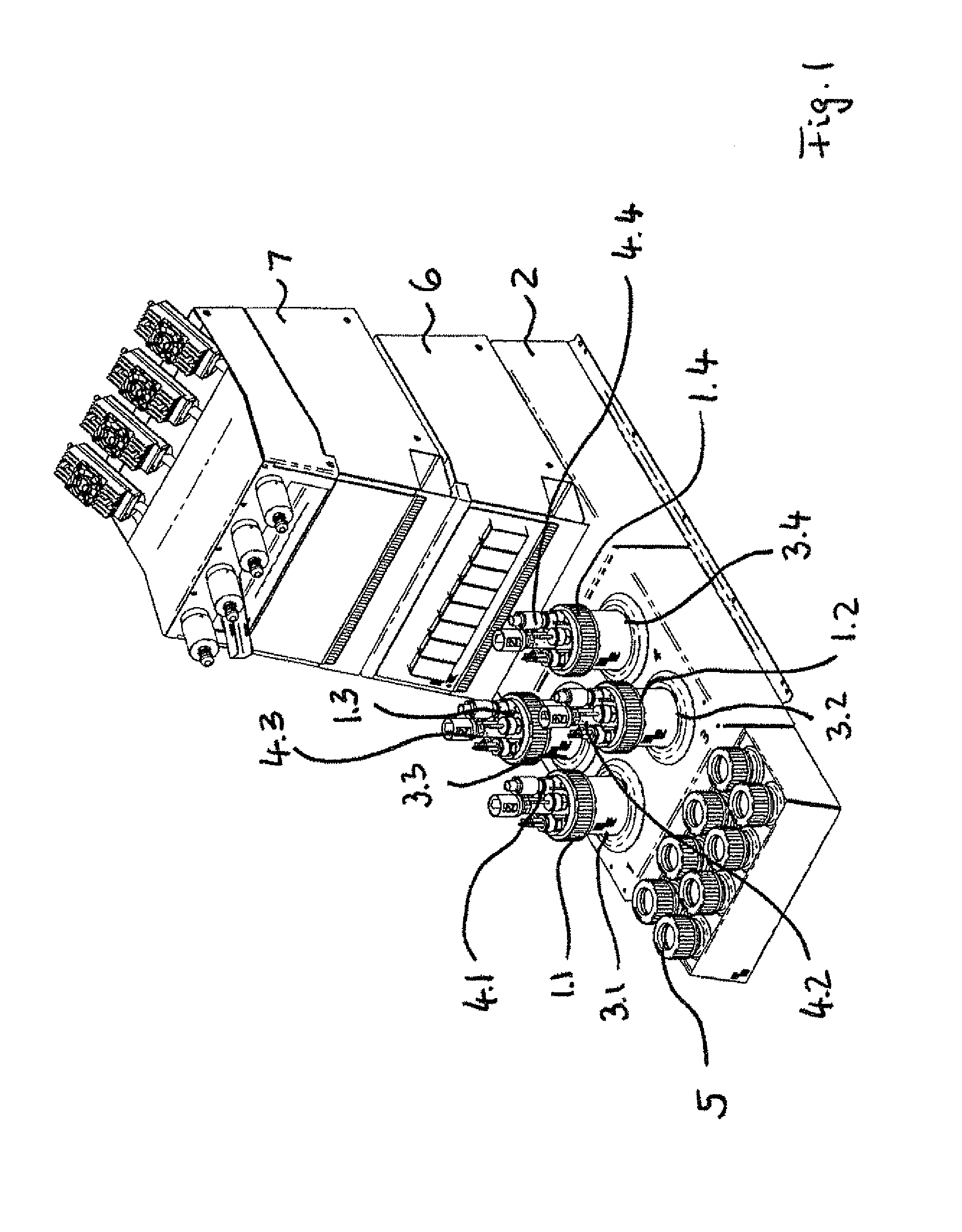

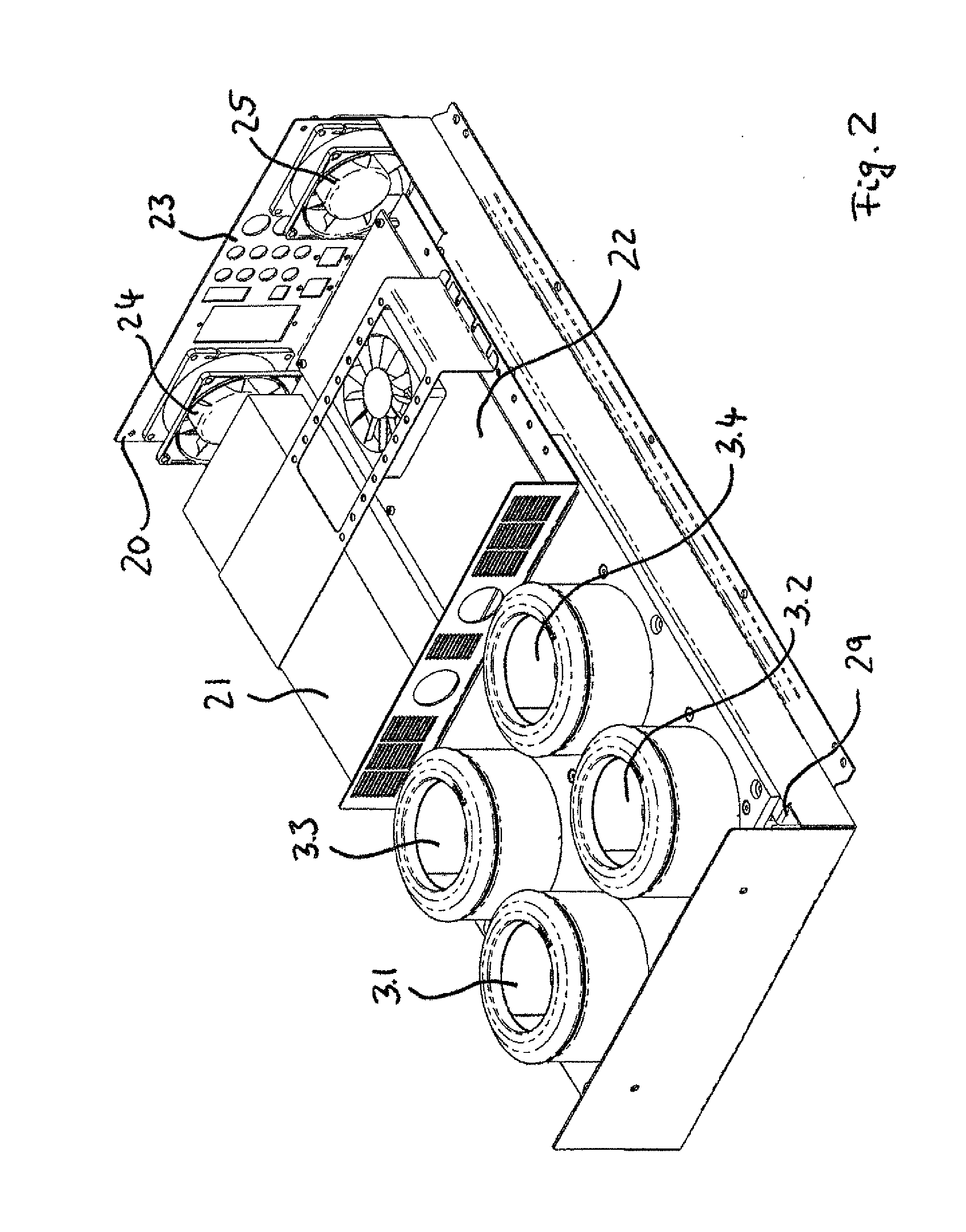

Method for controlled operation of a biotechnological apparatus and bioreactor system

ActiveUS20140255910A1Easy to operateDc network circuit arrangementsBioreactor/fermenter combinationsTemperature controlBioreactor

Owner:DASGIP INFORMATION & PROCESS TECH

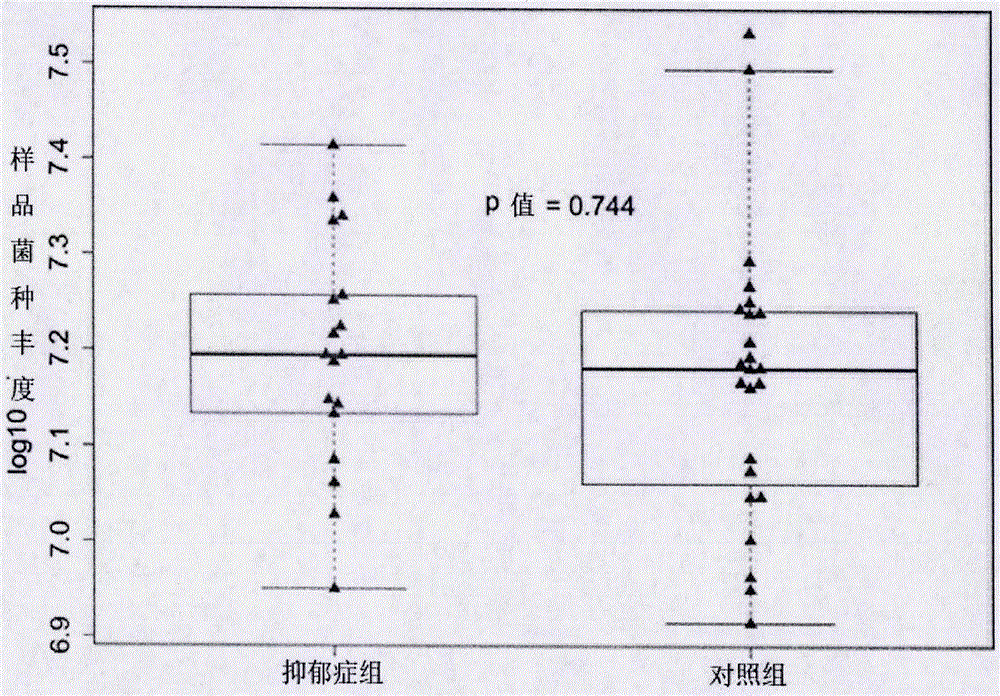

Depressive disorder biomarker and use thereof

InactiveCN106554998AImprove diagnostic accuracySimplify the diagnostic processBioreactor/fermenter combinationsBiological substance pretreatmentsScreening methodSaccharomonospora viridis

Owner:SHENZHEN KANGNING HOSPITAL SHENZHEN MENTAL HEALTH INST SHENZHEN MENTAL HEALTH CENT

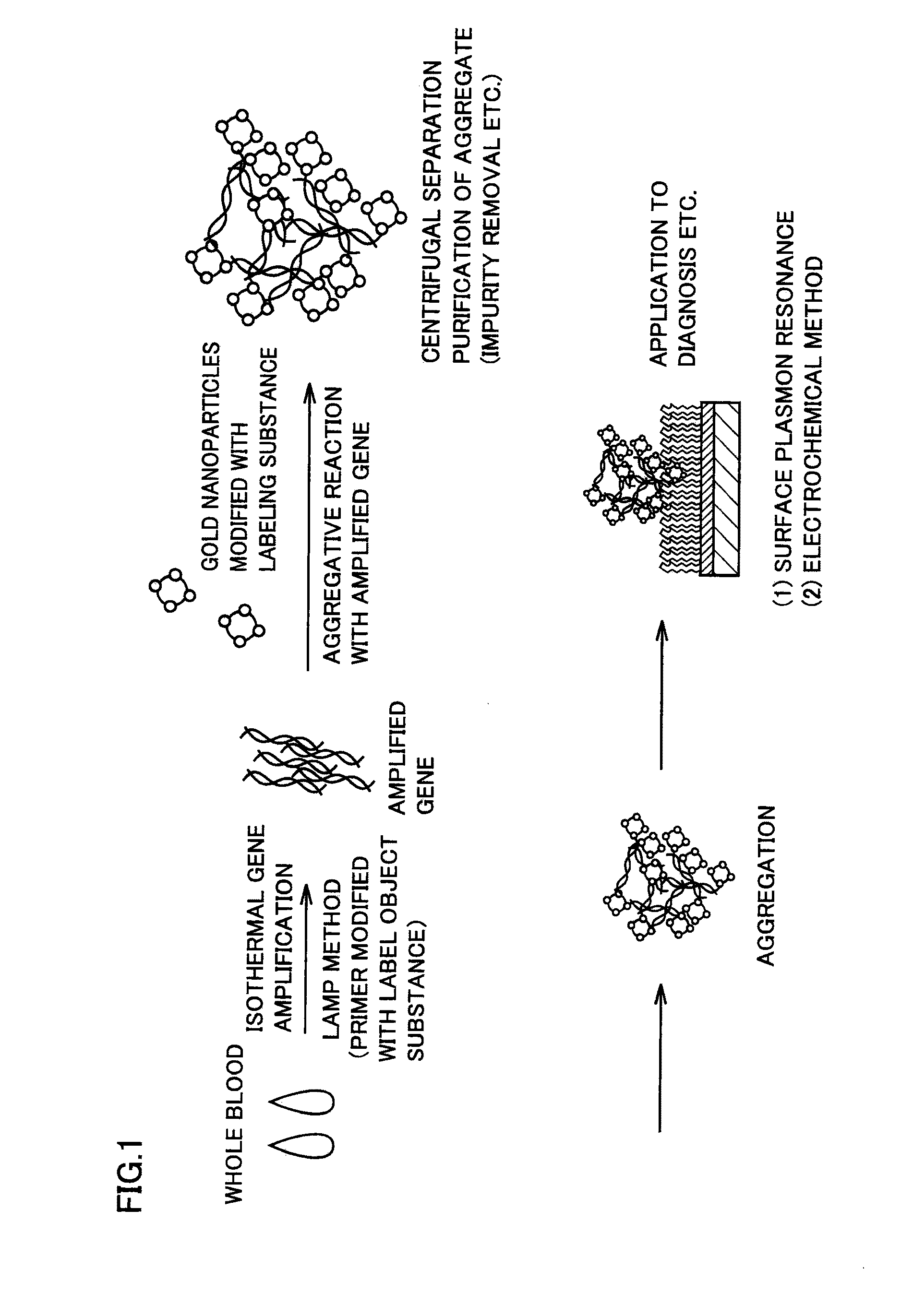

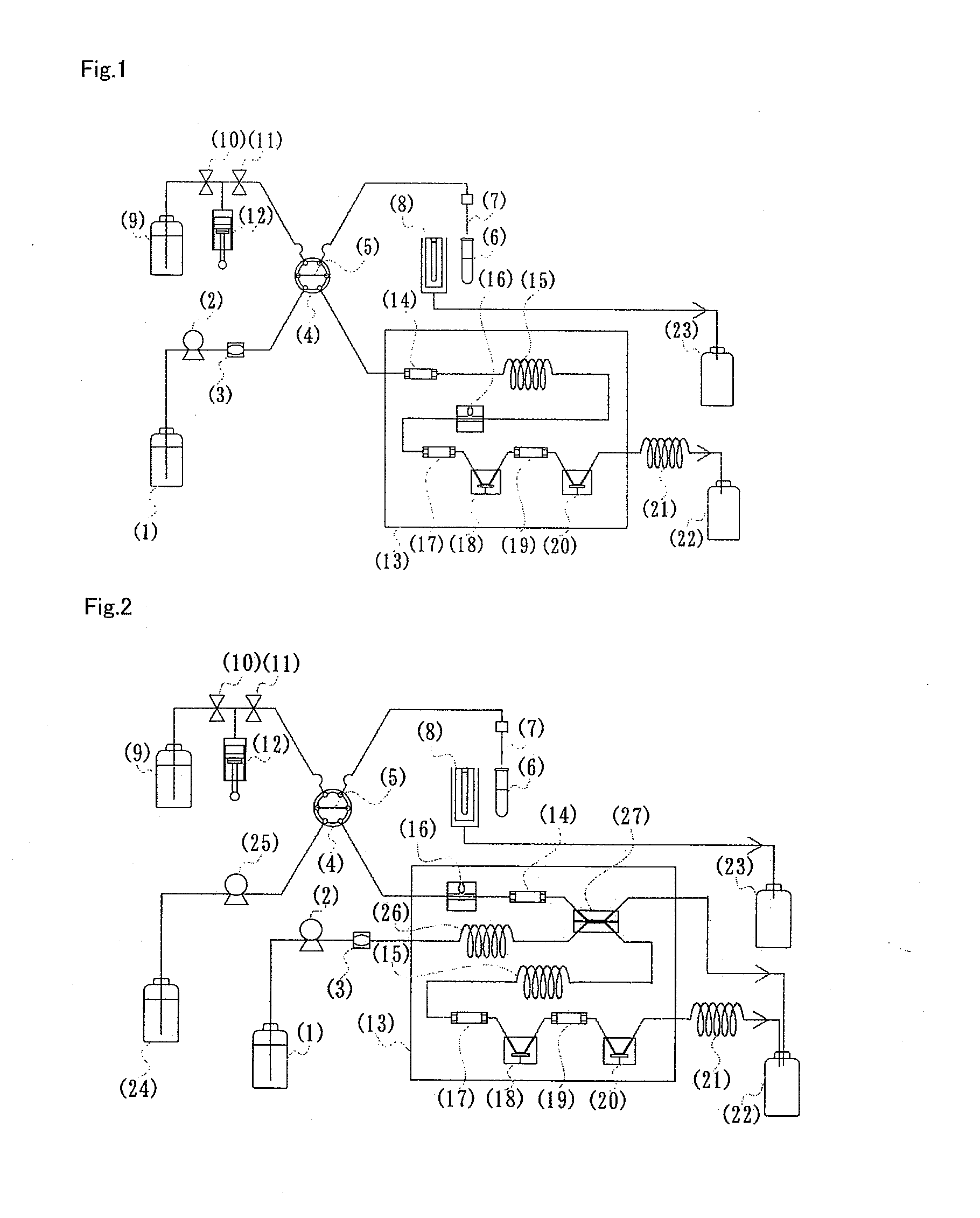

Separation purification method and microfluidic circuit

InactiveUS20110003285A1Easy to separate and purifyPerformed accurately and rapidlyImmobilised enzymesBioreactor/fermenter combinationsParticulatesPurification methods

Owner:ROHM CO LTD

Use of fibrous protein fibers for chemical sensing and radiation detection

InactiveUS20060194198A1Bioreactor/fermenter combinationsBiological substance pretreatmentsReference sampleAnalyte

Owner:LICATA CARLO

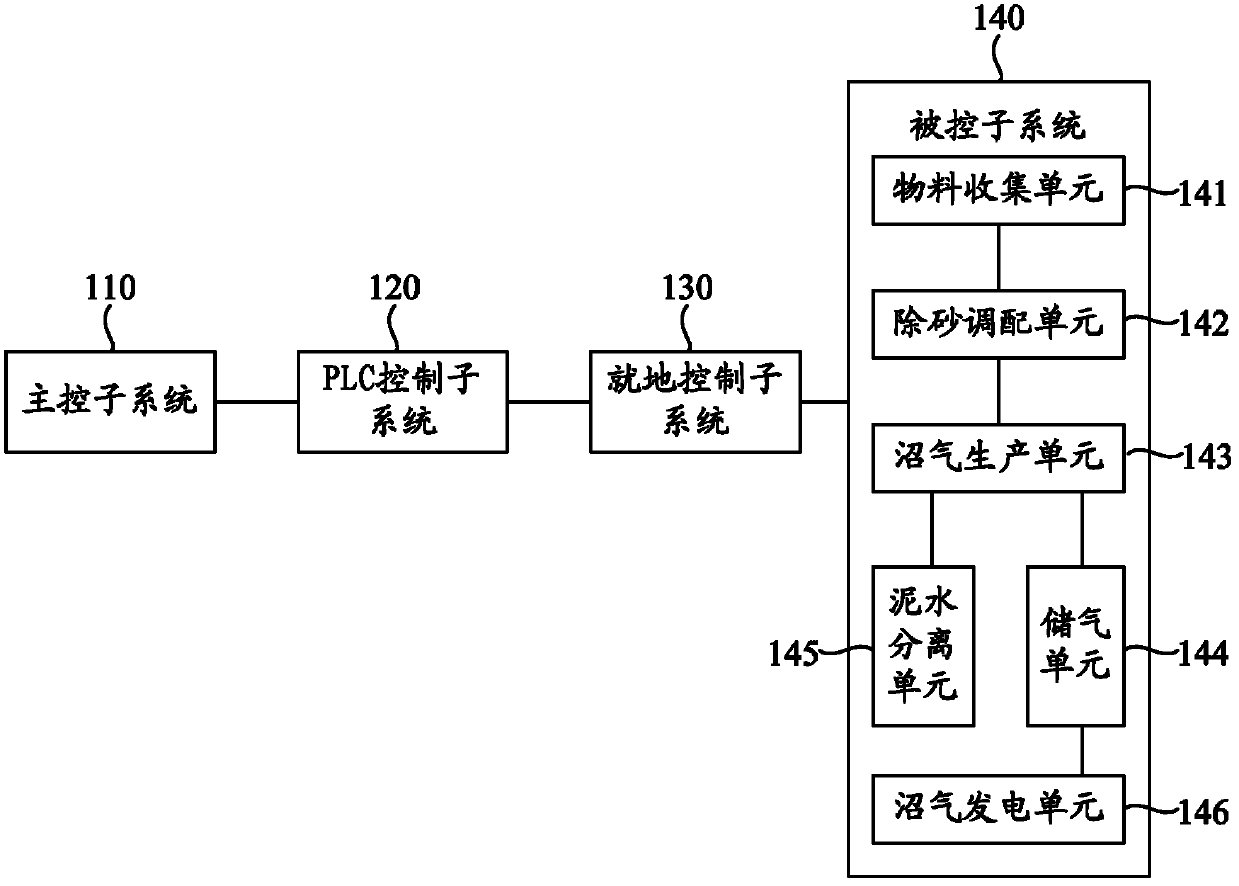

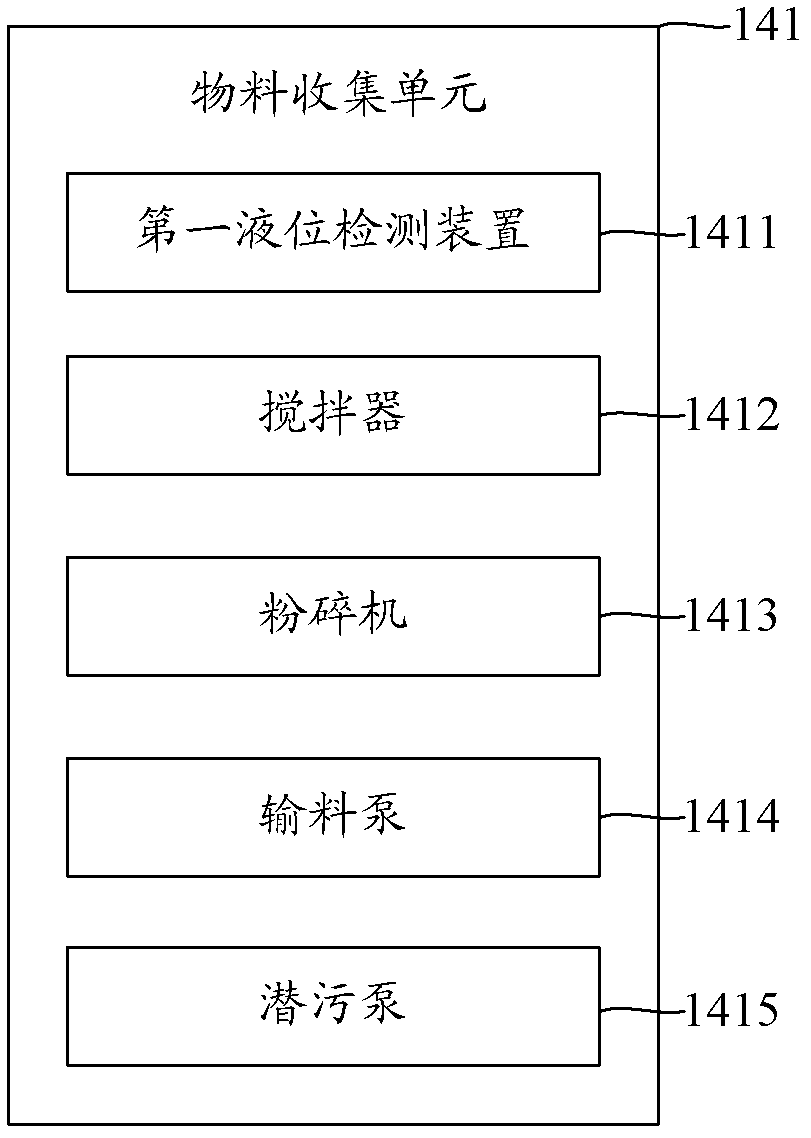

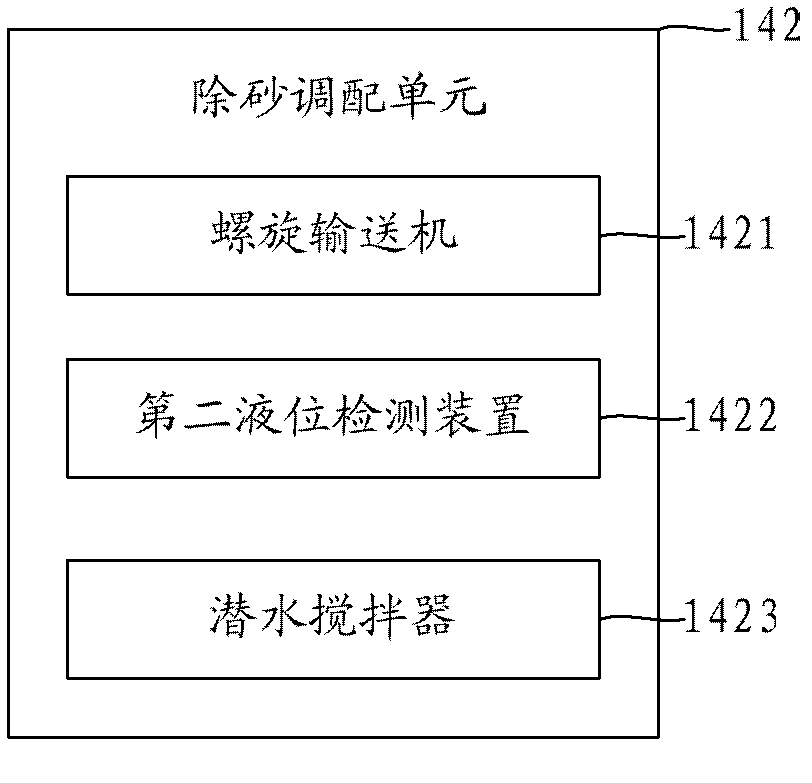

Biogas fermentation gas supply engineering control system

InactiveCN103305413AImprove real-time performanceImprove stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlEngineering controls

Owner:北京愿景宏能源环保科技发展有限公司

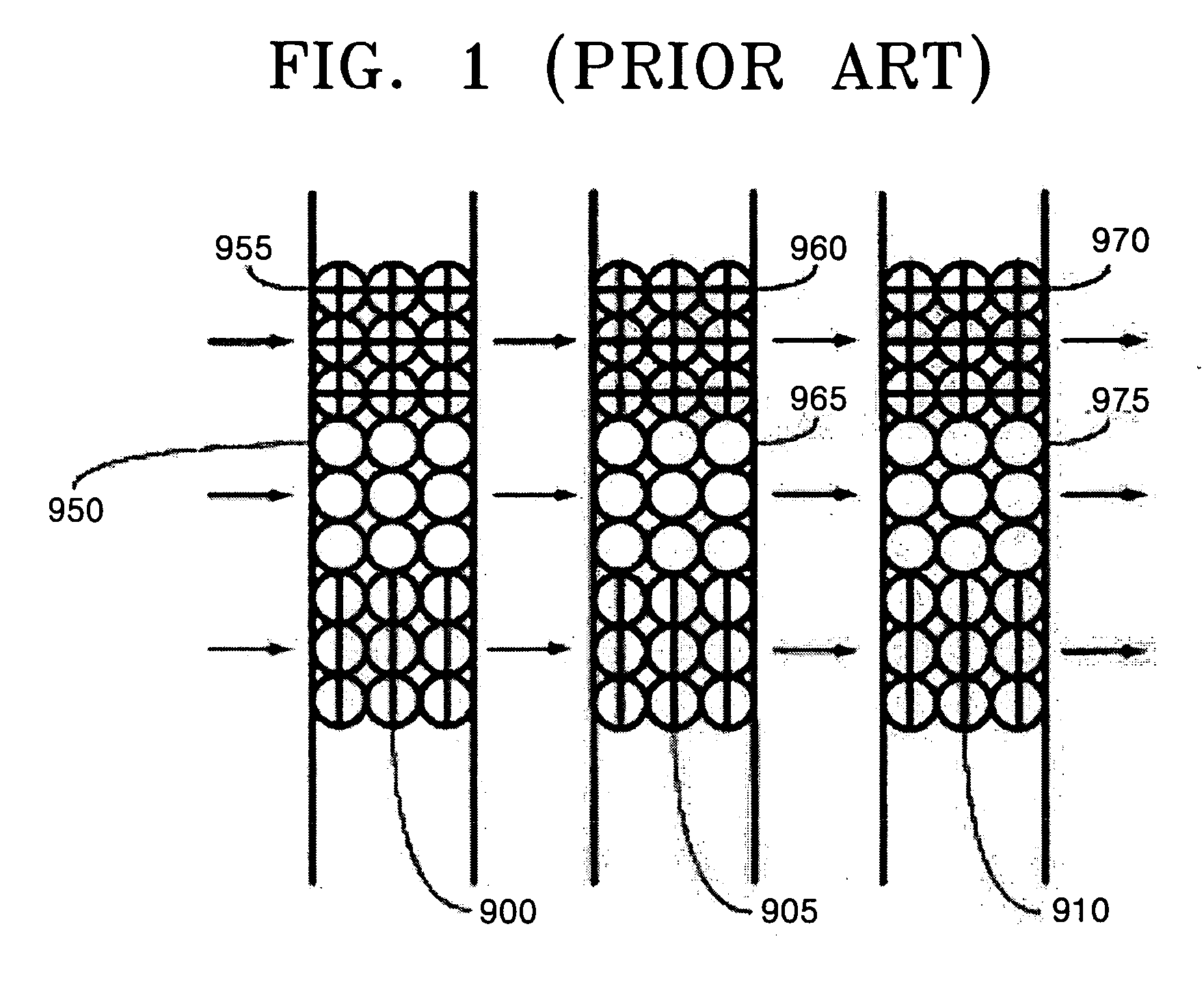

Methods for cultivating cells and propagating viruses

InactiveUS20050019913A1Bioreactor/fermenter combinationsBiological substance pretreatmentsMicrobiologyVirus

Owner:SCHERING CORP

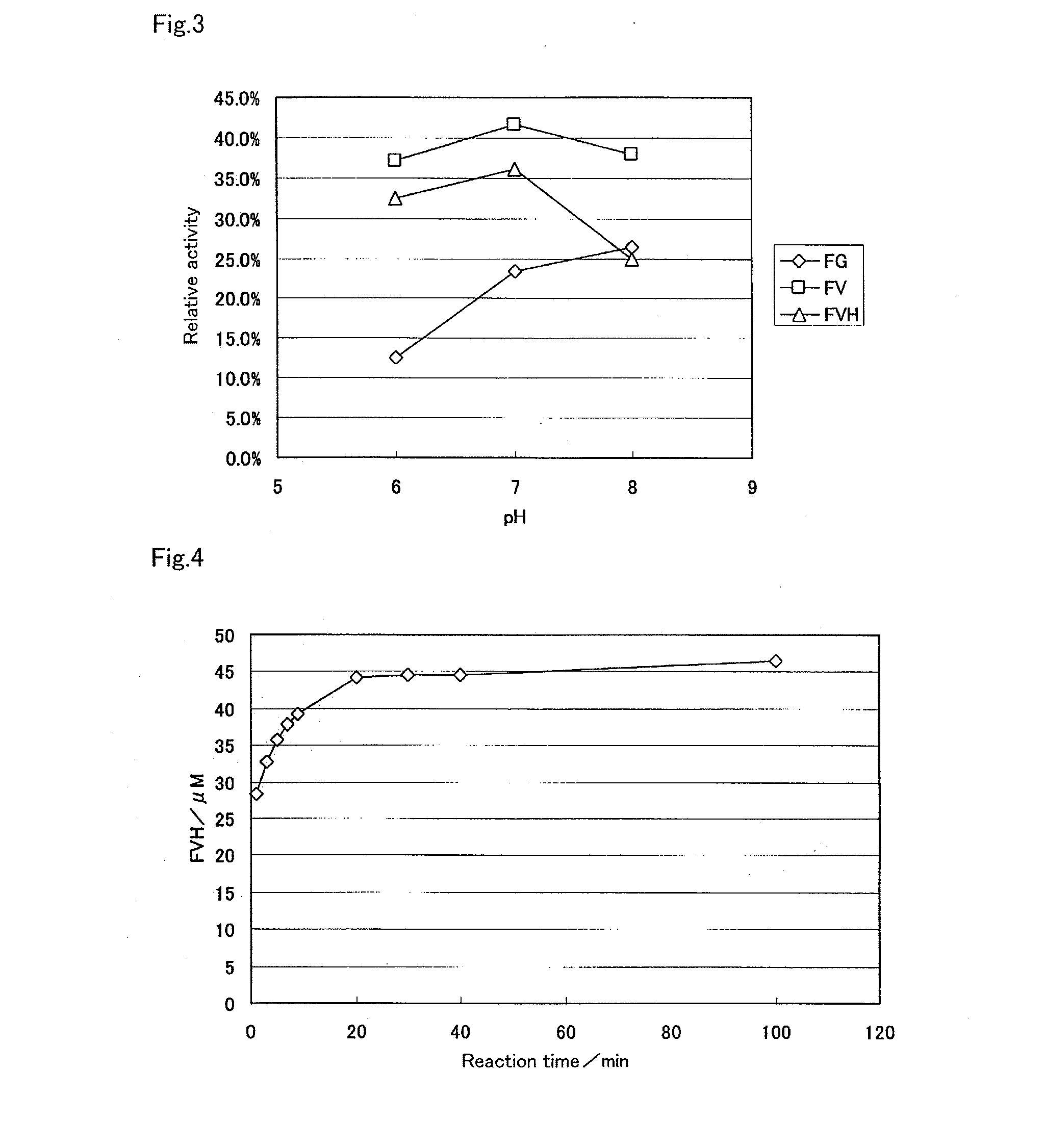

Analysis Apparatus and Analysis Method for Glycosylated Hemoglobin

InactiveUS20080223733A1Simple and highly accurate determinationRapid determinationImmobilised enzymesBioreactor/fermenter combinationsGlucose polymersD-Glucose

Owner:OJI PAPER CO LTD +1

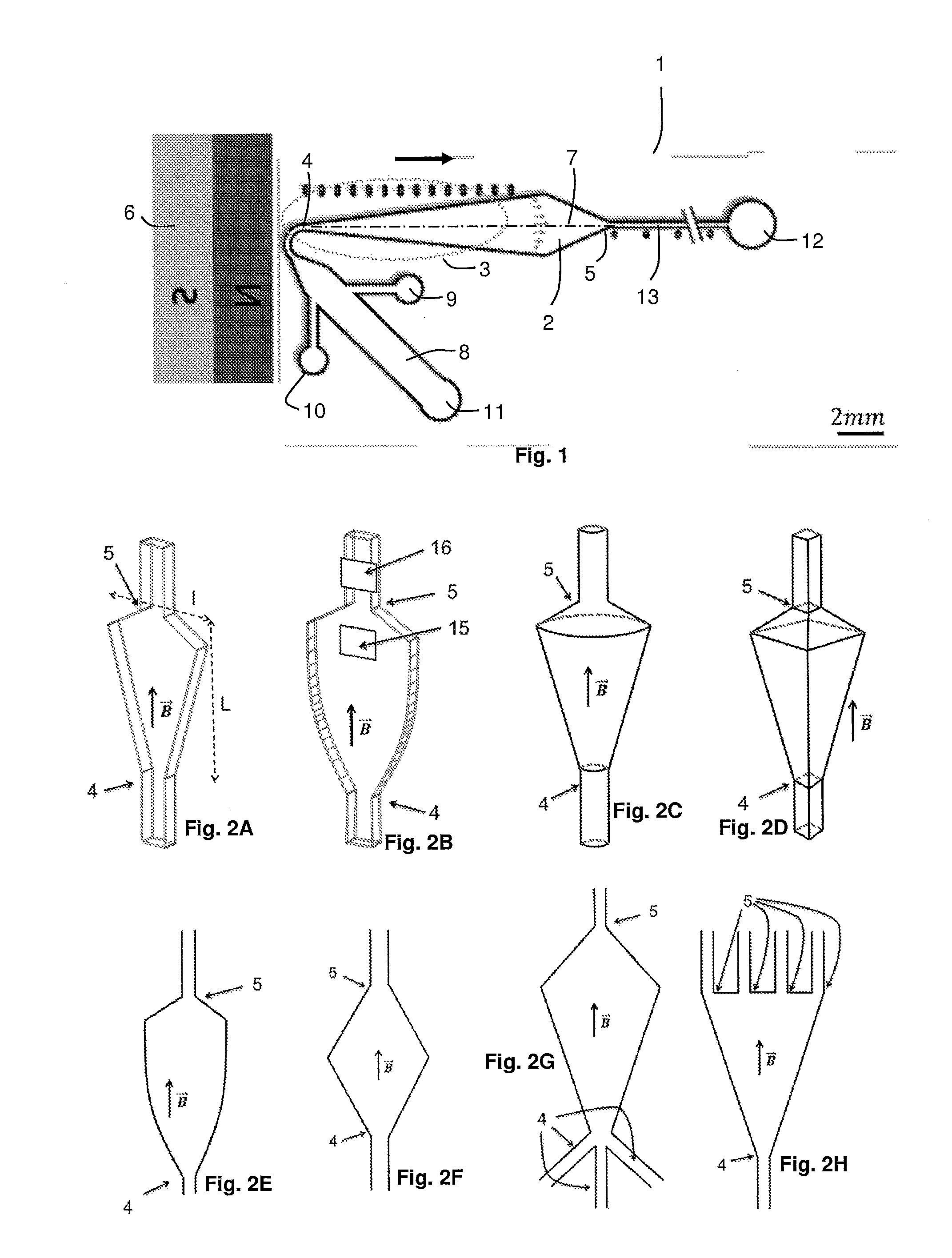

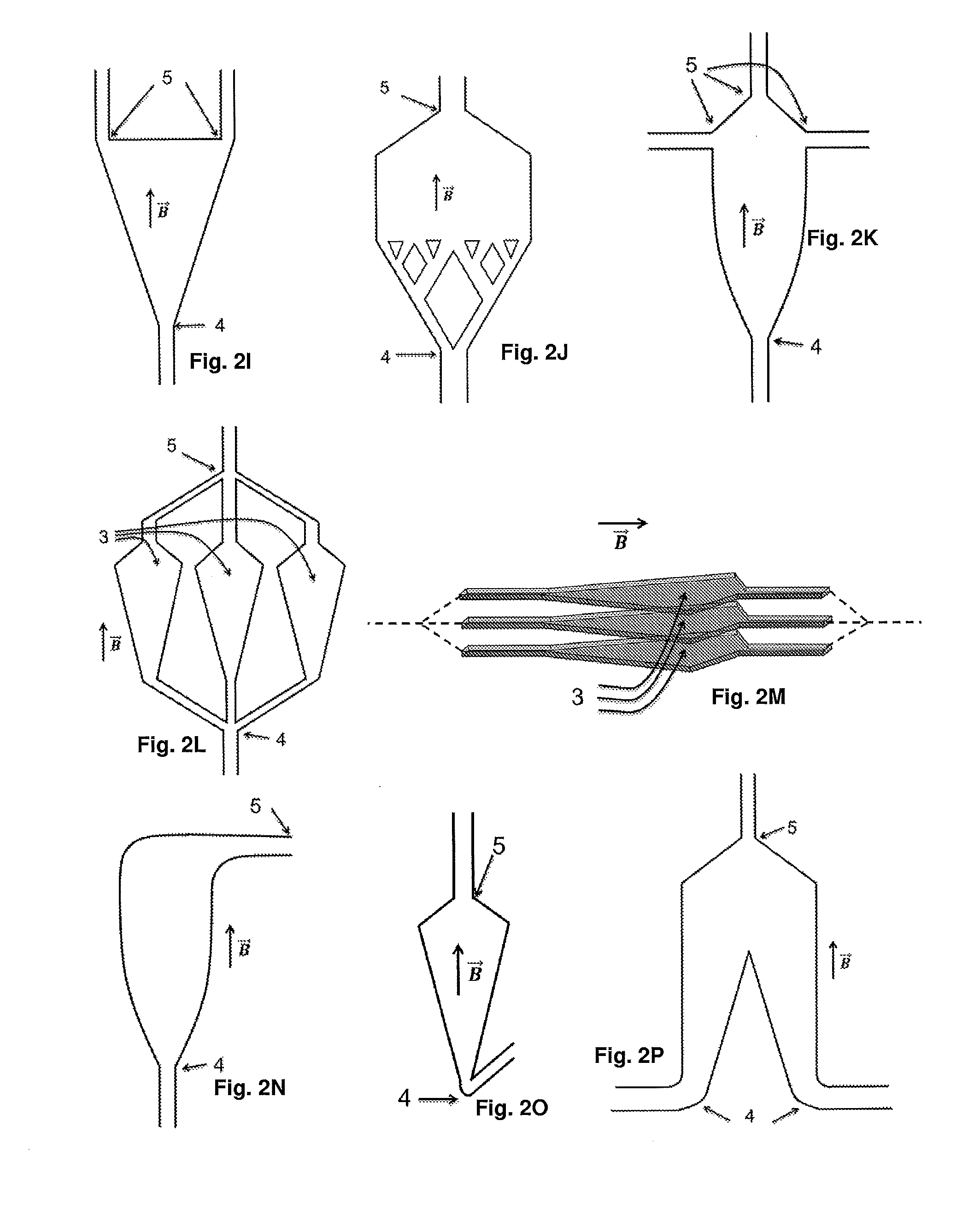

Microfluidic system having a magnetic particle bed

ActiveUS20150219650A1Optimising exchangeOptimising flow rateBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMechanical engineering

Owner:VIOVY JEAN LOUIS +3

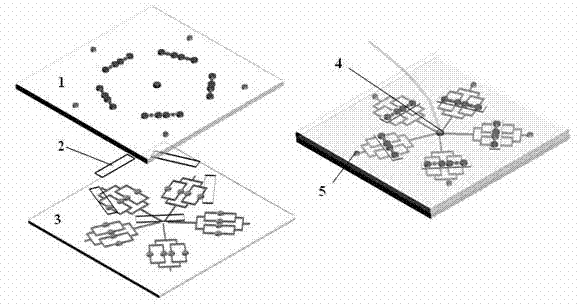

Apparatus and Methods For Selecting Capacitated Spermatozoa and Uses Thereof

InactiveUS20080299537A1Maintaining sperm motilityIncrease successBioreactor/fermenter combinationsBiological substance pretreatmentsFertilityBiology

Owner:YEDA RES & DEV CO LTD

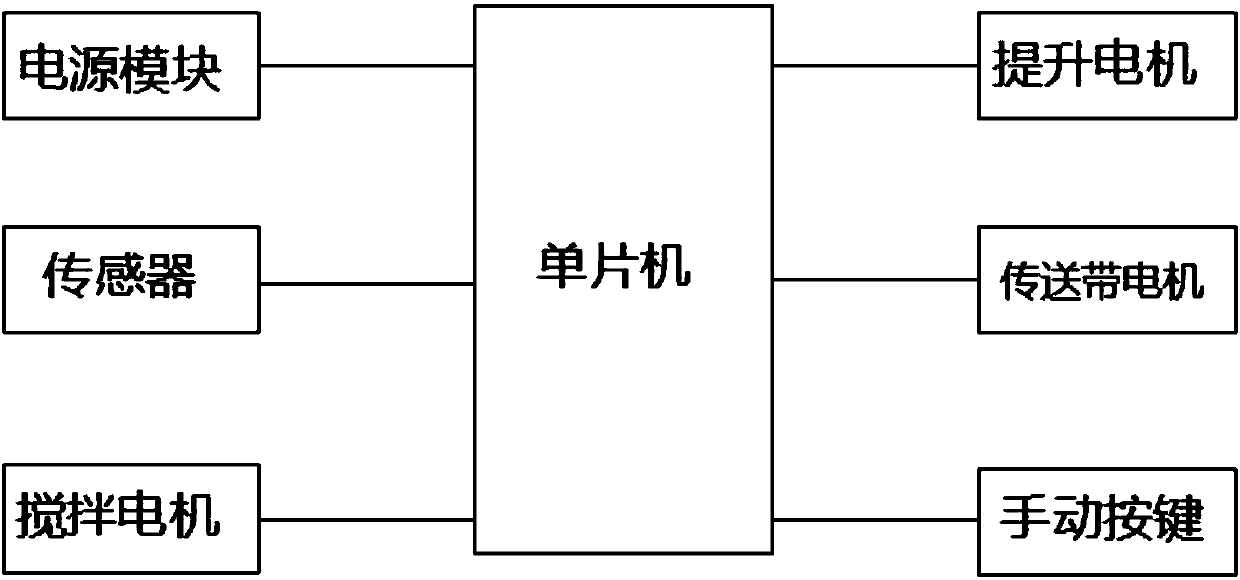

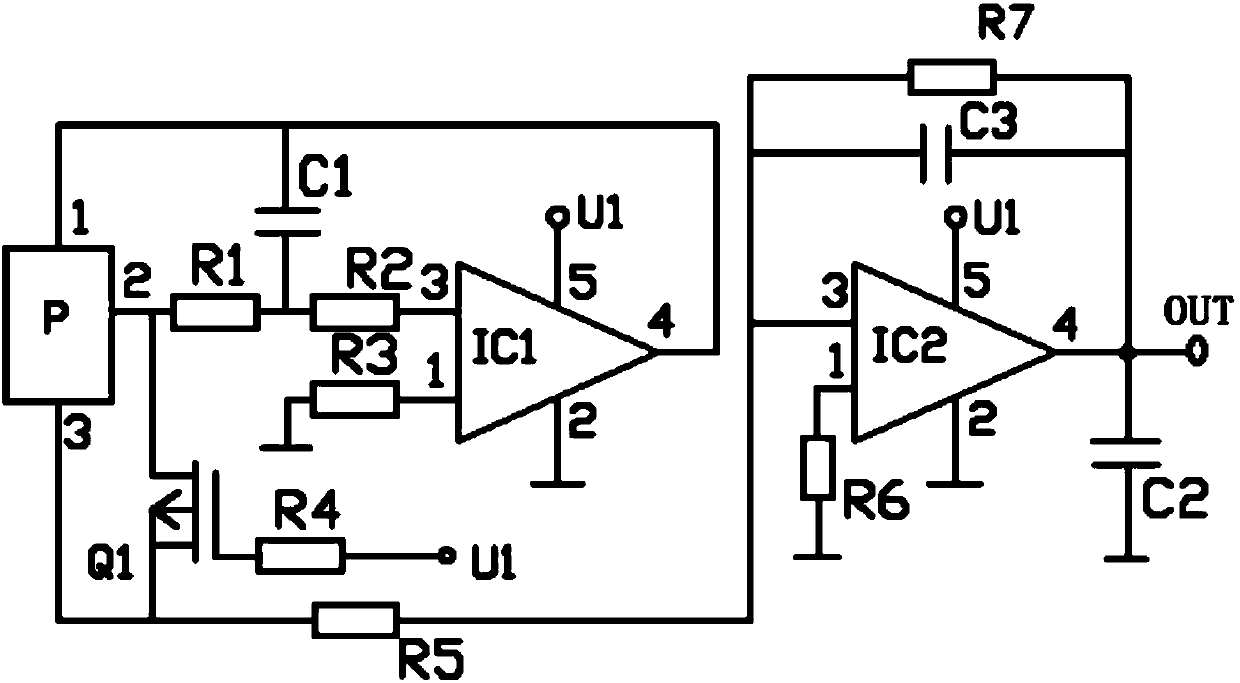

Intelligent marsh gas material reaction box

InactiveCN107674823ABoost auto-excludeRealize intelligent operation controlProgramme controlBioreactor/fermenter combinationsMicrocontrollerEngineering

Owner:HUNAN WANGLONG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap