Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Asphalt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt, also known as bitumen (UK: /ˈbɪtjʊmɪn/, US: /bɪˈtjuːmən, baɪ-/), is a sticky, black, and highly viscous liquid or semi-solid form of petroleum. It may be found in natural deposits or may be a refined product, and is classed as a pitch. Before the 20th century, the term asphaltum was also used. The word is derived from the Ancient Greek ἄσφαλτος ásphaltos.

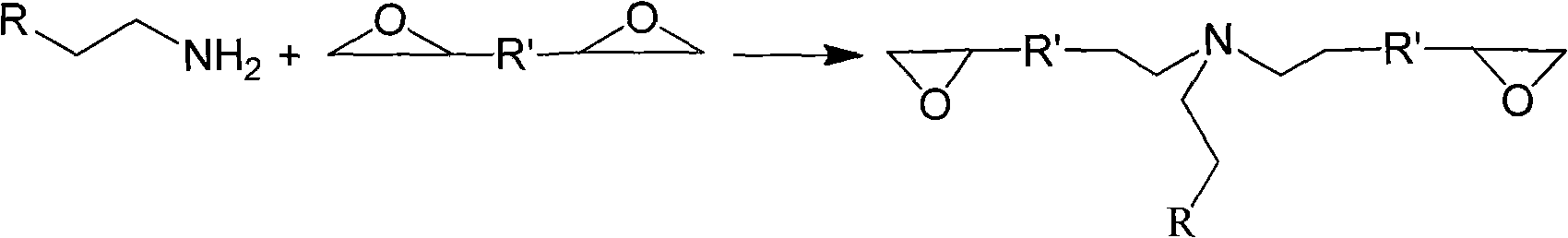

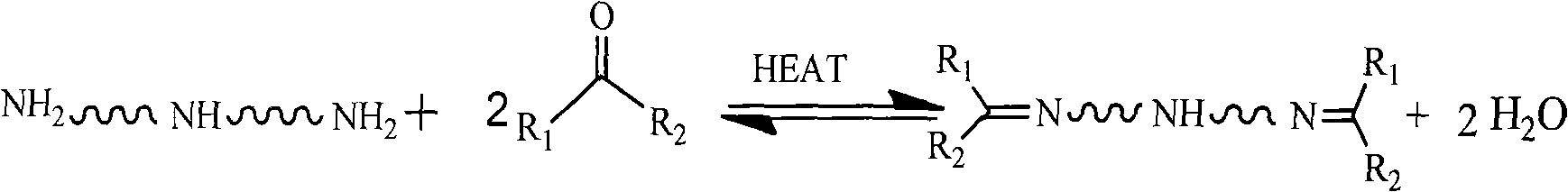

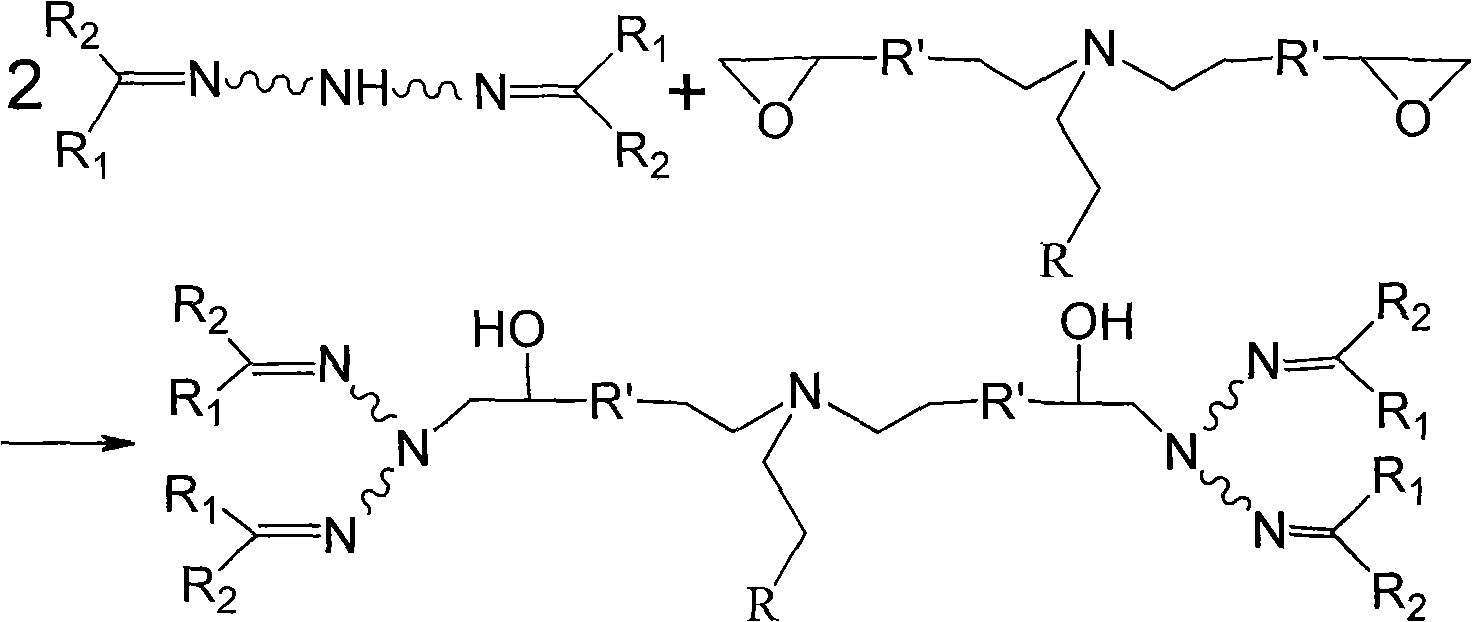

Preparation and application of latent nonionic self-emulsifying epoxy curing agent

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Emulsified acrylic acid modified asphalt cement group waterproof coating material and method for producing the same

InactiveCN101220233AGood alkali resistanceAvoid demulsificationAntifouling/underwater paintsPaints with biocidesEmulsionAsphalt

The invention relates to an acrylic acid modified asphalt cement-based and water-proof coating and a preparation method. The emulsified acrylic acid modified asphalt cement-based and water-proof coating consists of component A and component B; wherein, the mixture ratio of the component A to the component B is from 1 : 0.5 to 1.5 (in weight); wherein, the raw materials of component A and the weight percentage thereof are respectively as follows: acrylic emulsion or amphetamine emulsion accounting for 40 to 70 percent, emulsified asphalt accounting for 10 to 50 percent, filler accounting for 8 to 20 percent, accessory ingredient accounting for 0.1 to 3 percent and water accounting for 1 to 19.0 percent; the raw materials of component B and the weight percentage thereof are as follows respectively: cement accounting for 70 to 100 percent and filler accounting for 0 to 30 percent. The acrylic acid modified asphalt cement-based and water-proof coating has the advantages of strong binding power with the base, high tensile strength, large unit extension, low cost and environment protection.

Owner:WUHAN YANGGUANG CONSTR NEW MATERIAL

Method for extracting multiple chemical products from coal-tar oil

ActiveCN101139527AIncrease added valueQuality improvementTar working-up by water removalTar working-up by distillationAnthraceneHigh concentration

The invention discloses a method for extracting a plurality of chemicals from a coal tar, which comprises such procedures as heating the coal tar to 120-130 DEG C, dehydrating, fore running, separating, fine rectifying, and heavy-oil distilling, and getting 95 naphthalene, methyl naphthalene, anthracene oil, asphalt and heavy oil. The invention is of simple process, easy operation, rectifies coal tar several times; the extracted chemical products are of steady quality, the naphthalene is of high concentration, and the asphalt is of good quality. The invention is of low energy consumption, hence improves better the added value in processing coal tar in China.

Owner:ZHEJIANG MEIYANG INTL PETROCHEMICAL MEDICINE DESIGN CO LTD

Technical method and schedule for preparation of foam carbon material used asphalt as raw material

Owner:DALIAN UNIV OF TECH

Asphalt modified thermoplastic polyolefin water-proof coiled material and preparation method thereof

InactiveCN101550729AImproves UV resistanceExcellent ozone resistanceRoof covering using flexible materialsBuilding insulationsPolymer sciencePolyolefin

Owner:胜利油田大明新型建筑防水材料有限责任公司

Castable for blast-furnace tapping channel and preparation method thereof

Owner:JIANGSU REFUTA NEW MATERIALS CO LTD

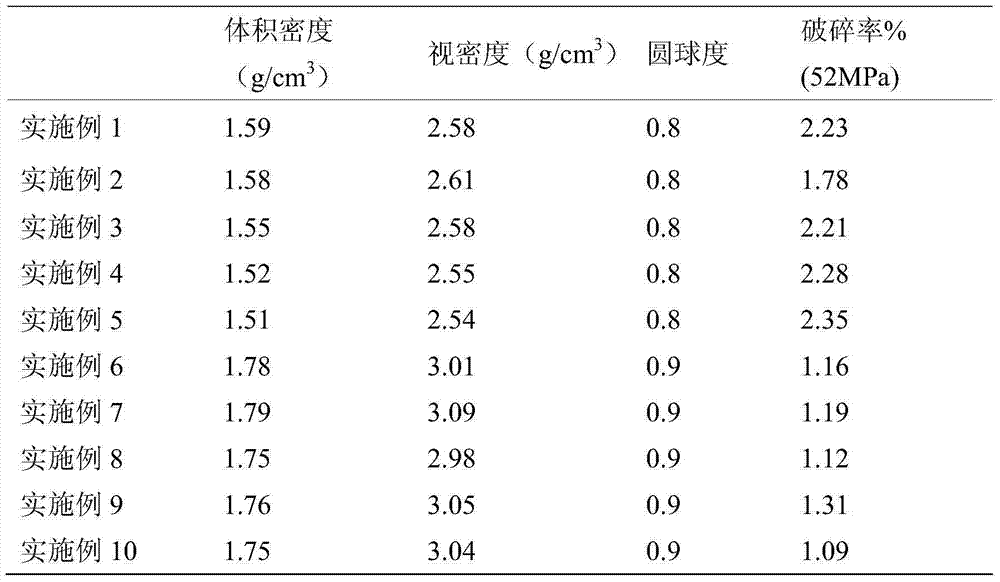

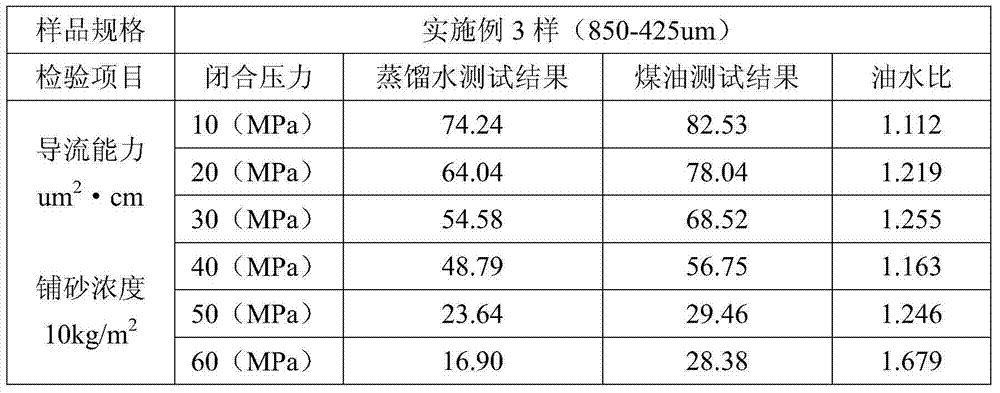

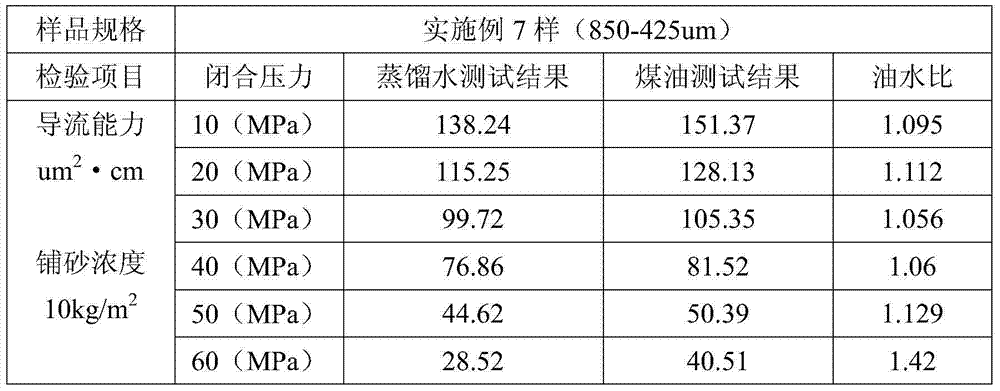

Preparation method of oleophilic hydrophobic coated proppant

InactiveCN104277821AIncrease oil outputIncrease productionFluid removalDrilling compositionProduction ratePlasticizer

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

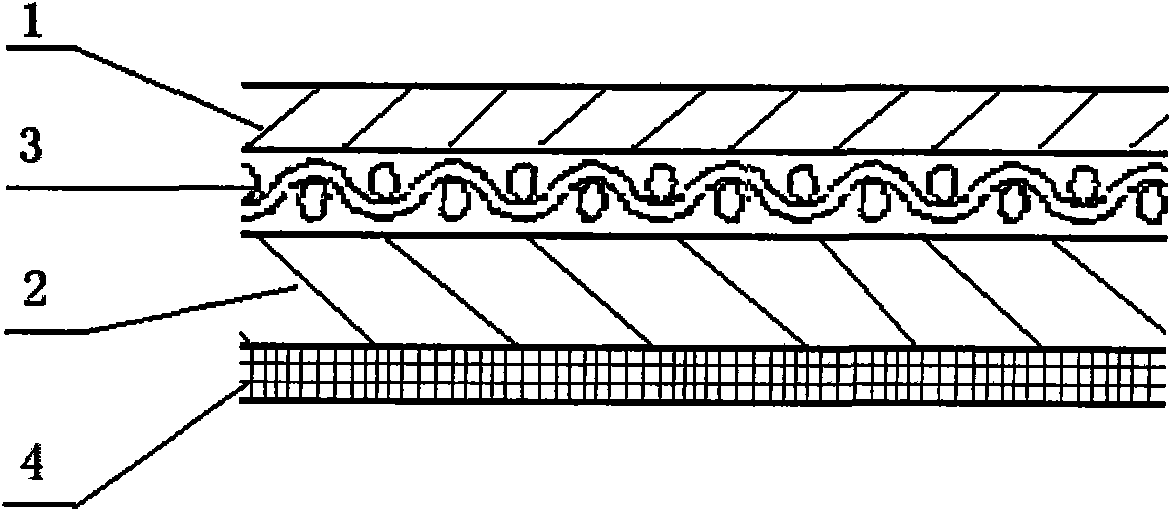

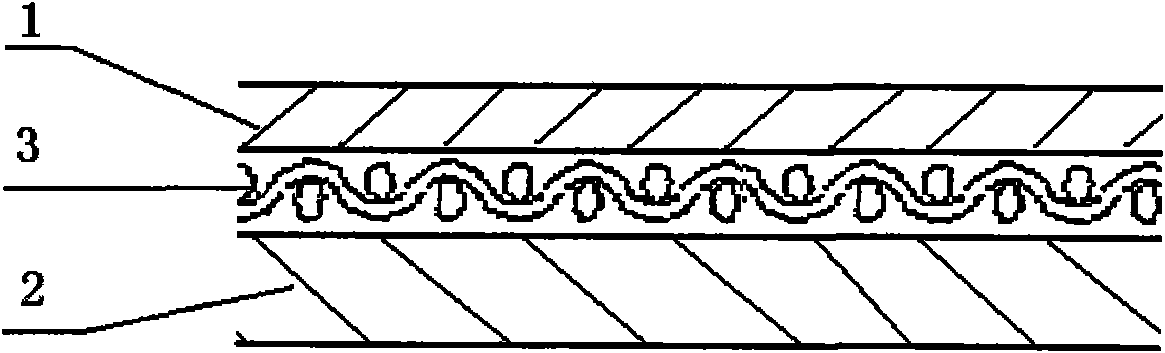

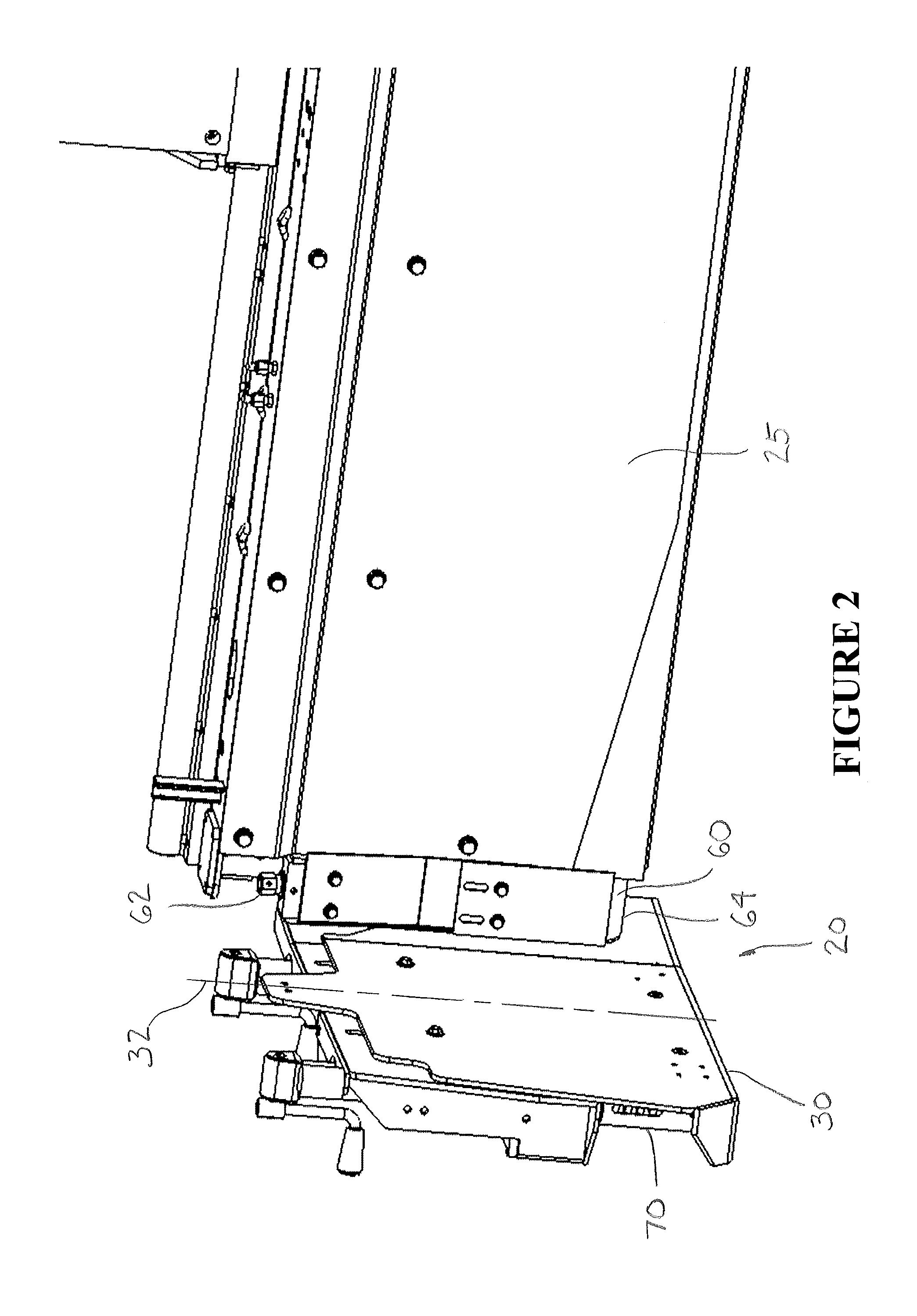

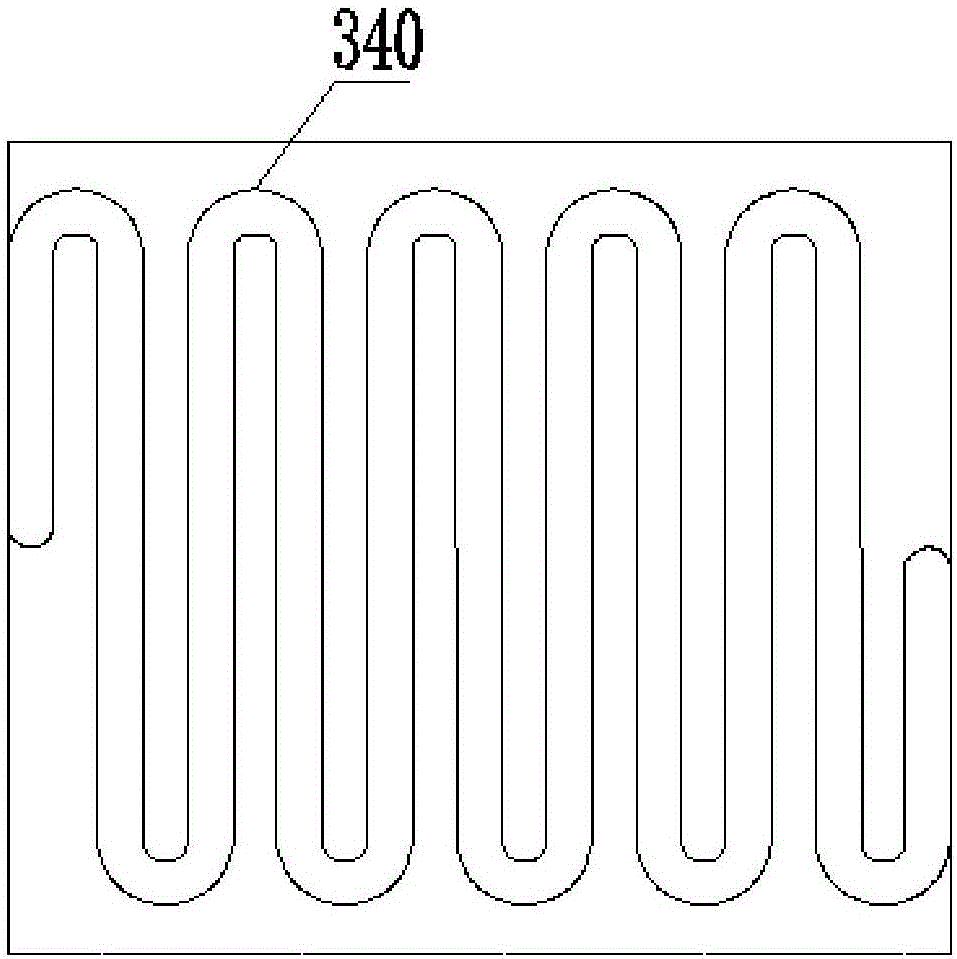

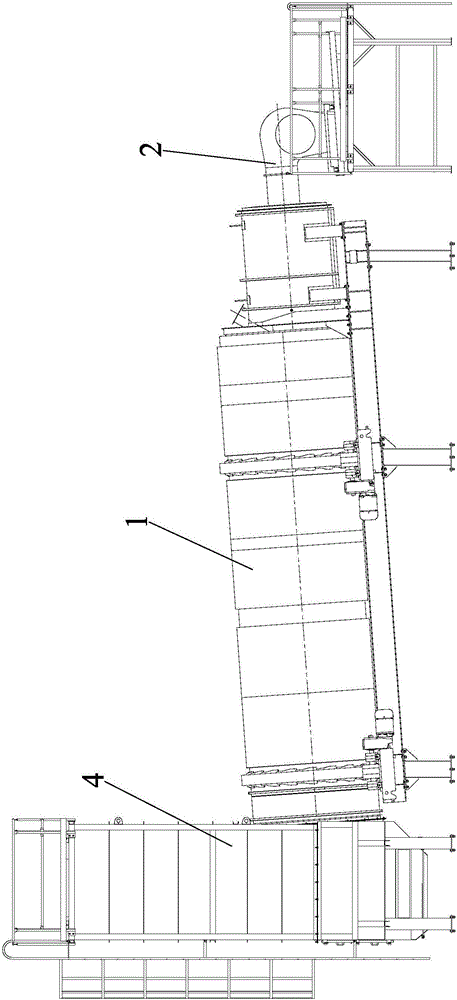

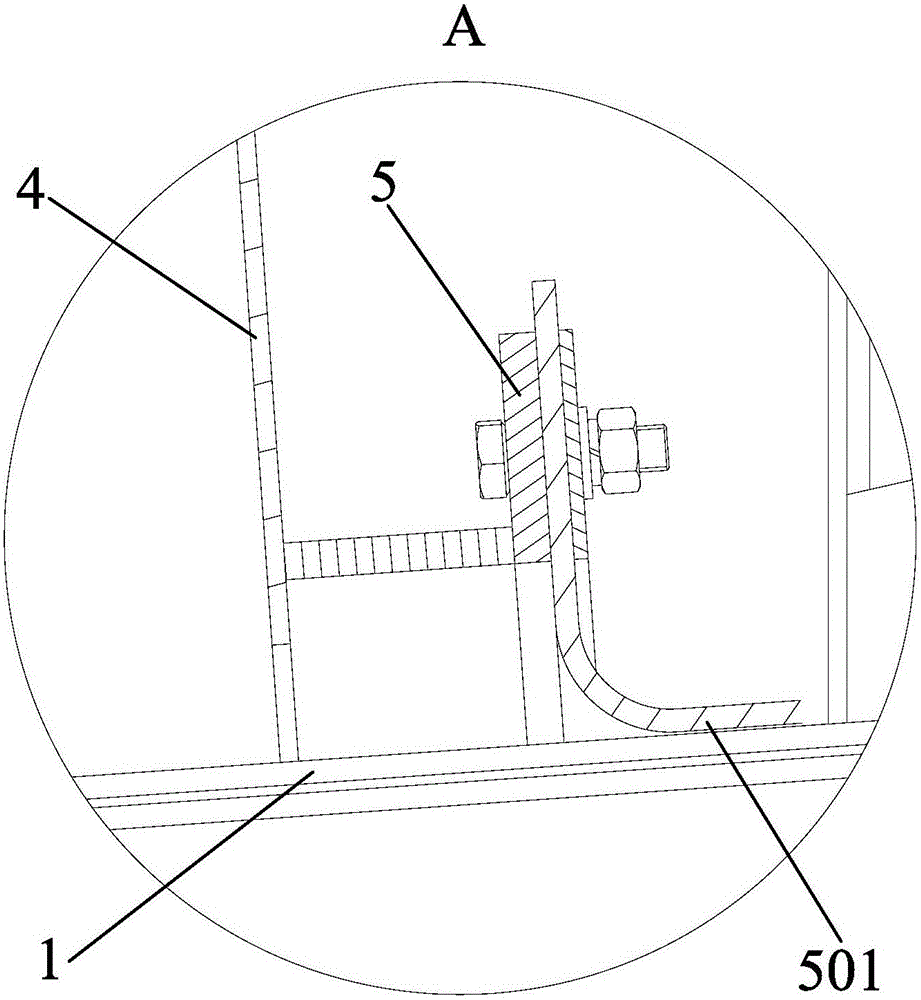

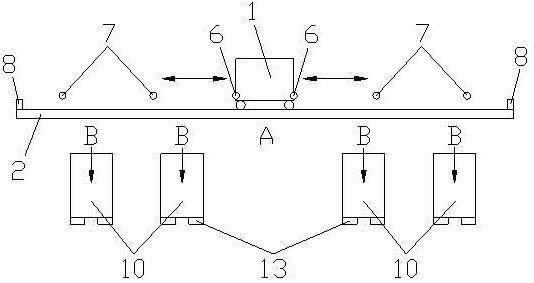

Asphalt mixture regenerating heating stirring roller

The invention discloses an asphalt mixture regenerative heating rod and mixing roller, and belongs to the concrete stirring technical field. The invention has a tilted roller supporting frame, a rolling ring, a roller and a roller driving device, wherein, the rolling ring is sleeved on the roller and supported by a rolling wheel arranged on the roller supporting frame, a burner is arranged at the lower end of the roller, a material outlet is arranged on the roller at the lower part of the burner, a material inlet is arranged at the other end of the roller, and a smoke outlet is arranged on the roller; wherein, an inner screening tube is sleeved inside the roller positioned at the material inlet end, and the inner screening tube is connected with the roller, the outer peripheral wall of the inner screening tube is composed of a screening mesh, a circular filtering mesh is sealed at the end part on the inner side of the inner screening tube, the material inlet is communicated with the inner screening tube, and an asphalt nozzle is arranged inside the roller positioned below the burner at the outlet end. The invention has compact and rational structure and high heat exchange efficiency, does not require secondary breakup of the waste asphalt mixture, can directly heat the block shape waste asphalt mixture for recycling; and the regenerated asphalt mixture can be directly utilized.

Owner:HENAN ROADY ROAD MACHINERY

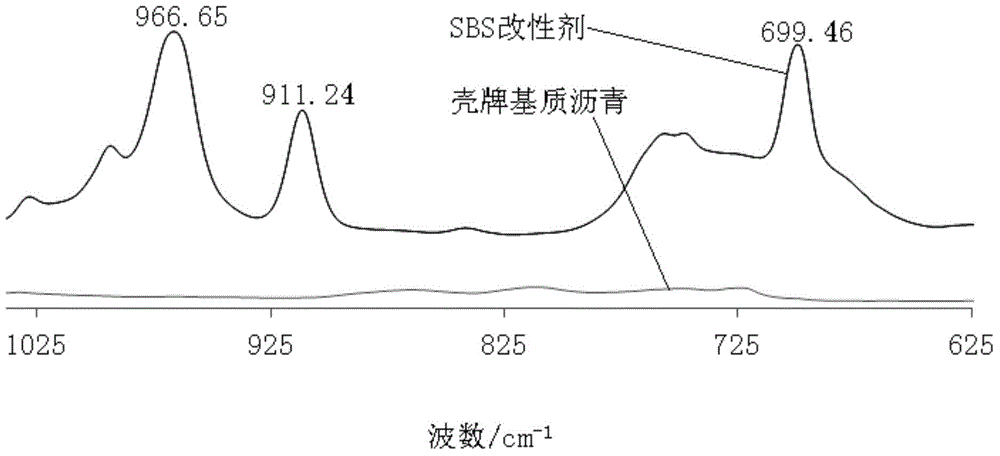

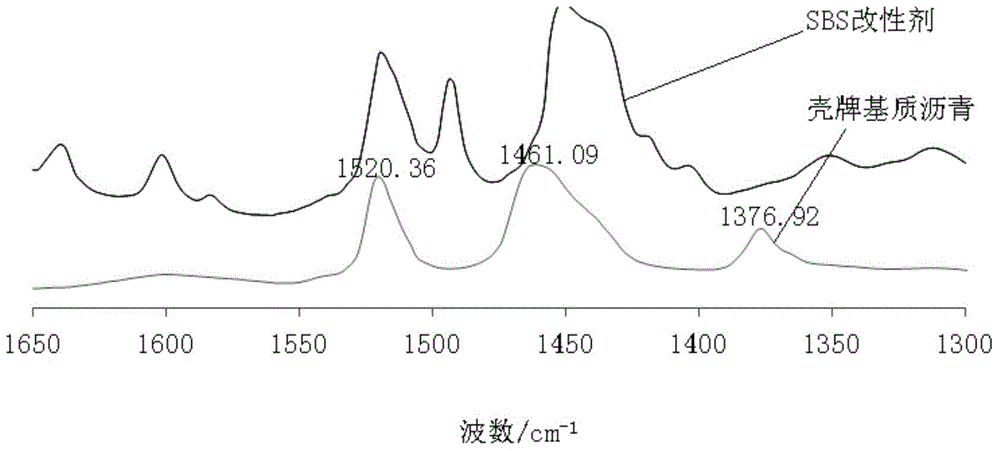

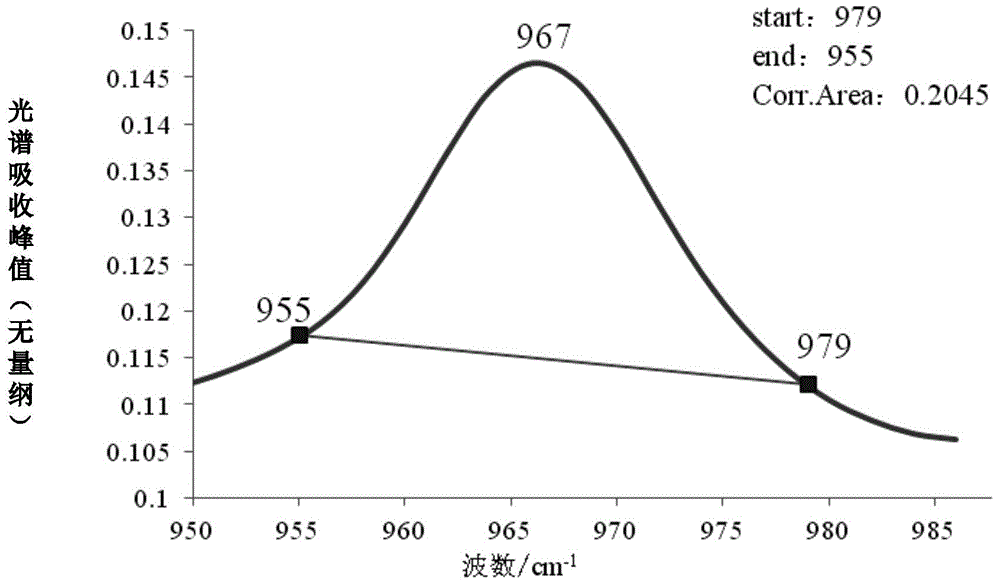

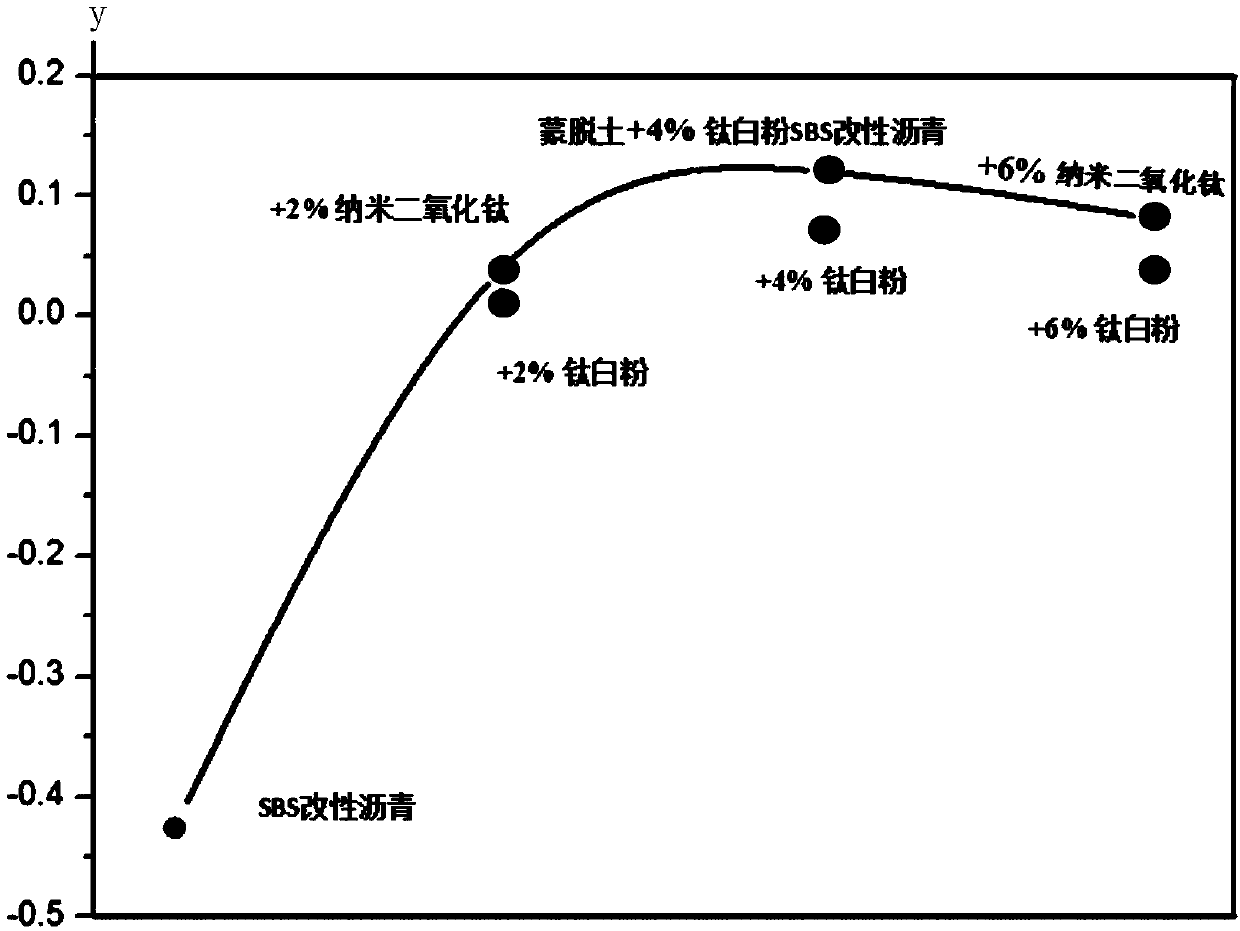

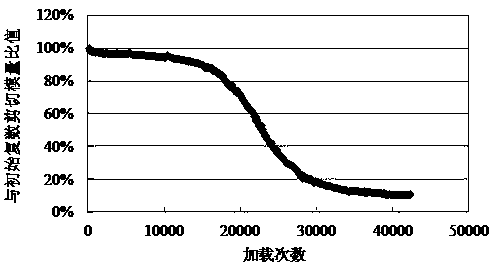

High-precision detection method for SBS (styrene butadiene styrene) contents in SBS modified asphalt

ActiveCN104819950AEliminate the effects ofQuick checkMaterial analysis by optical meansTest samplePeak area

Owner:SUZHOU UNIV OF SCI & TECH +1

Preparation method of durable modified asphalt

Owner:宁夏路桥工程股份有限公司

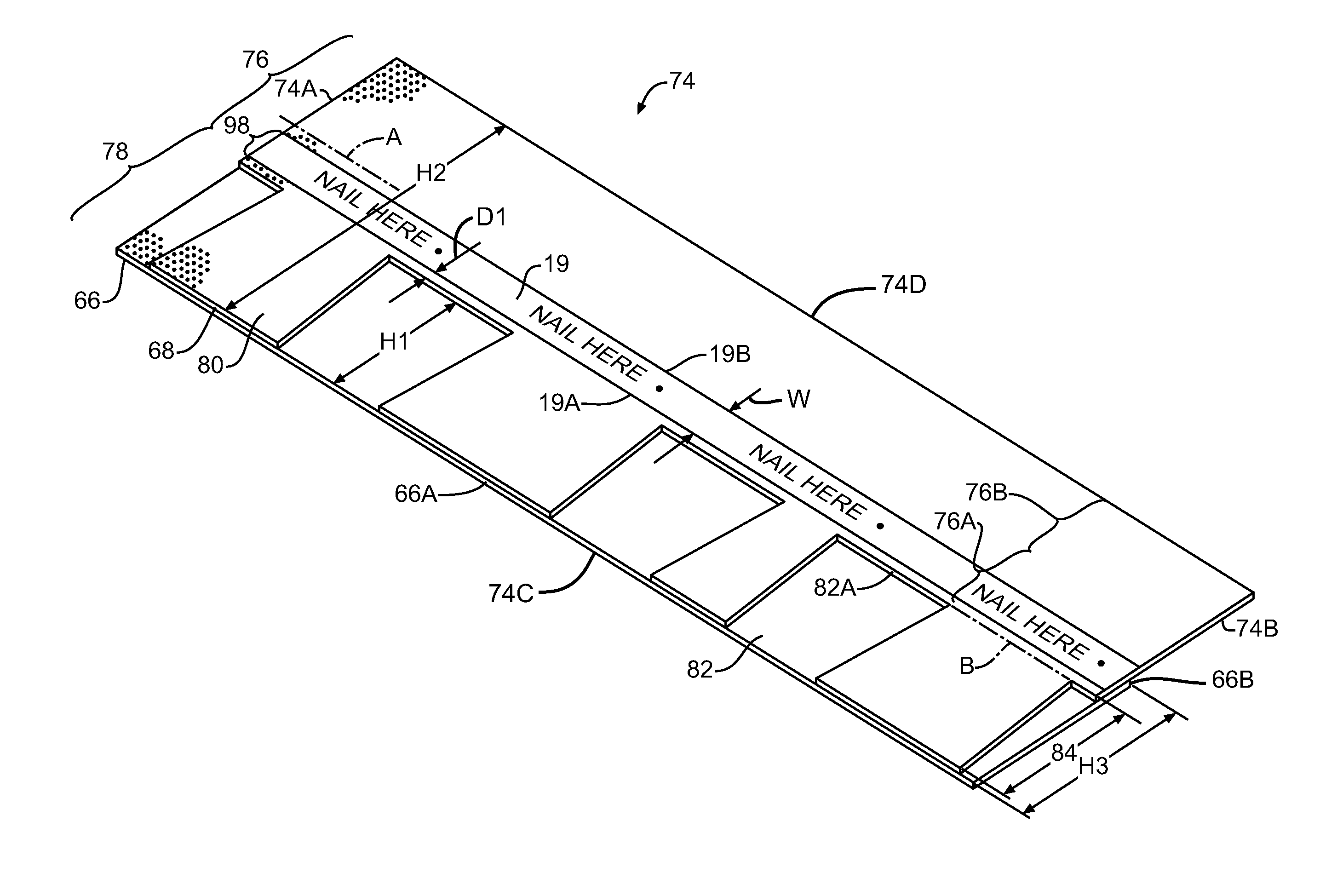

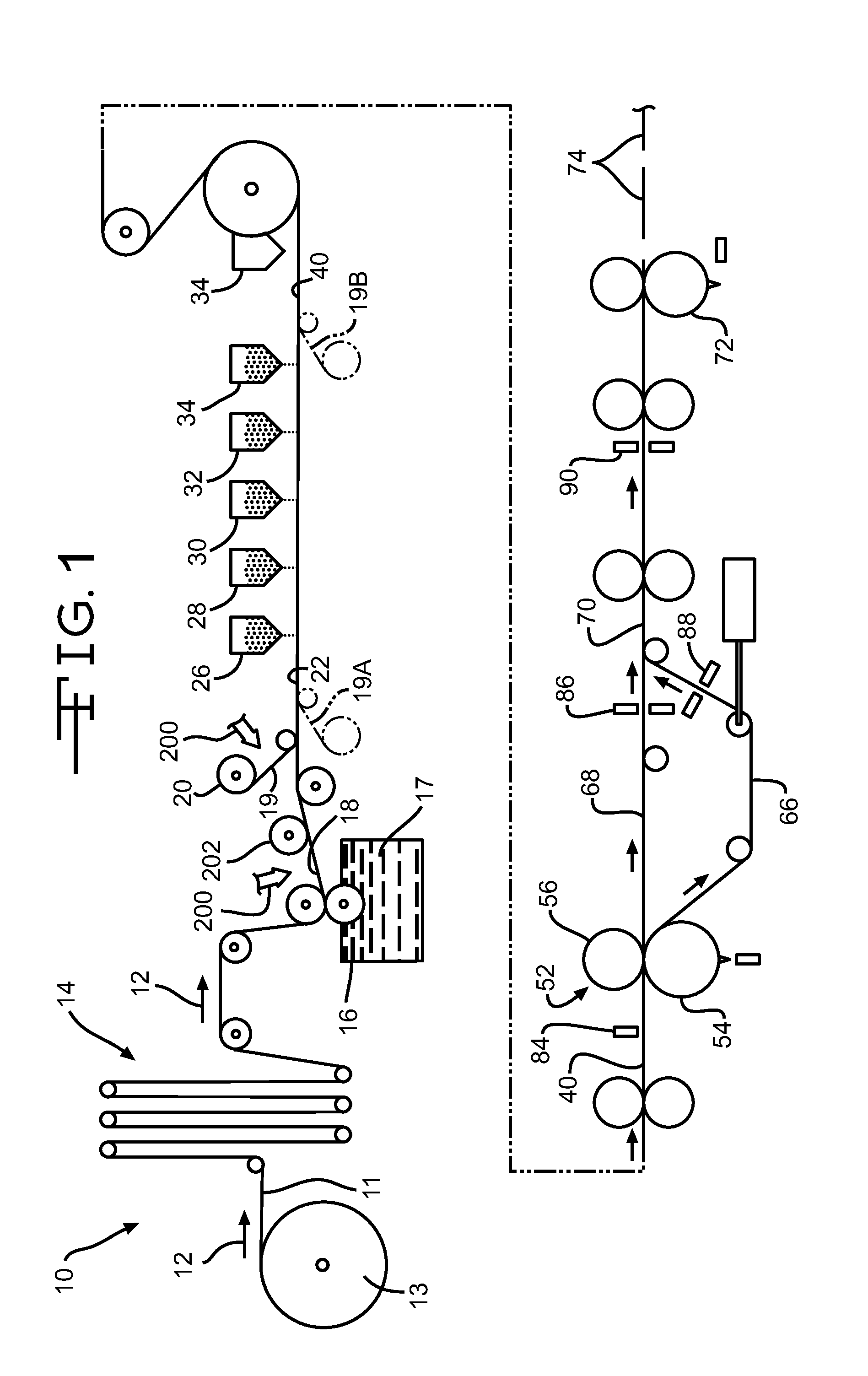

Method of manufacturing a shingle with reinforced nail zone

InactiveUS20130025771A1Amount be controlAdhesive processesLamination ancillary operationsAsphaltBiomedical engineering

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Strong anti-corrosion treatment technique for surface of carbon steel valve

ActiveCN105772370AImprove anti-corrosion performanceEasy to usePretreated surfacesSpecial surfacesEpoxyCross cut

Owner:浙江标盛阀门制造有限公司

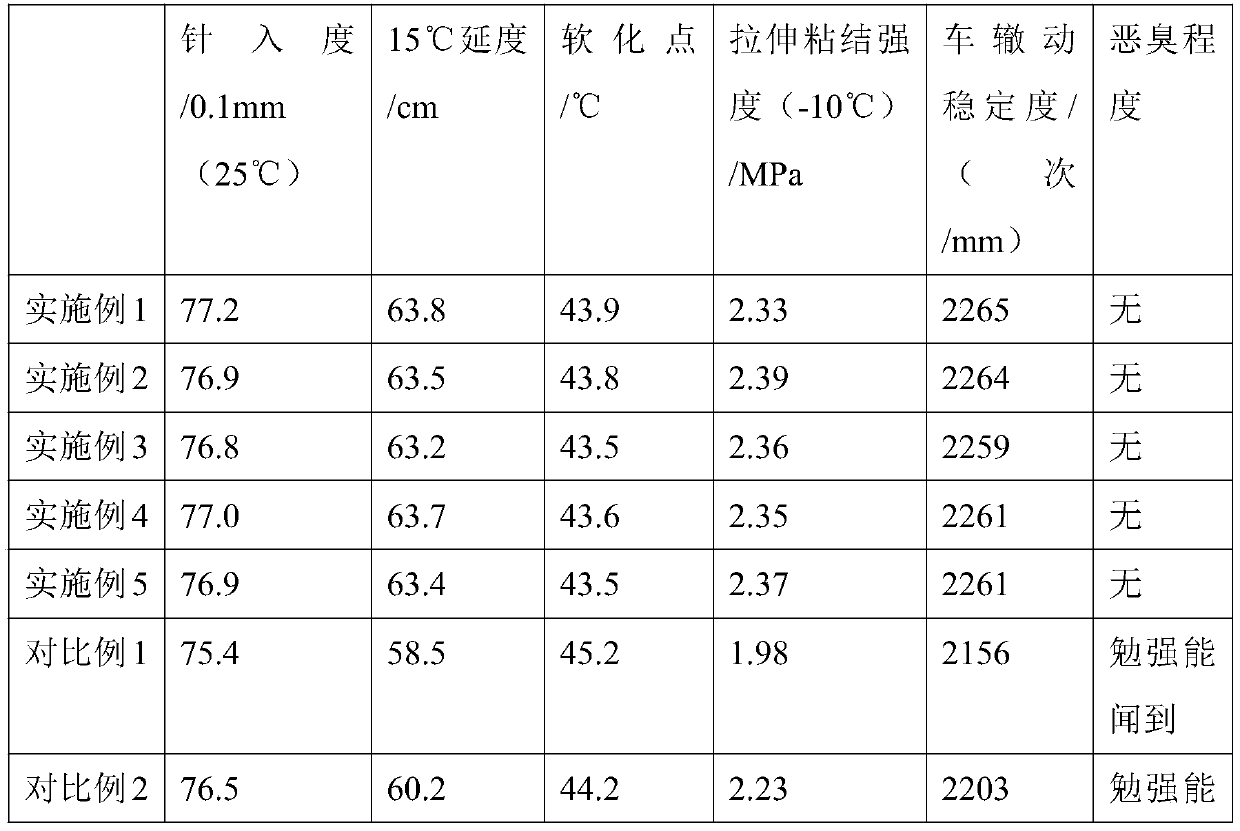

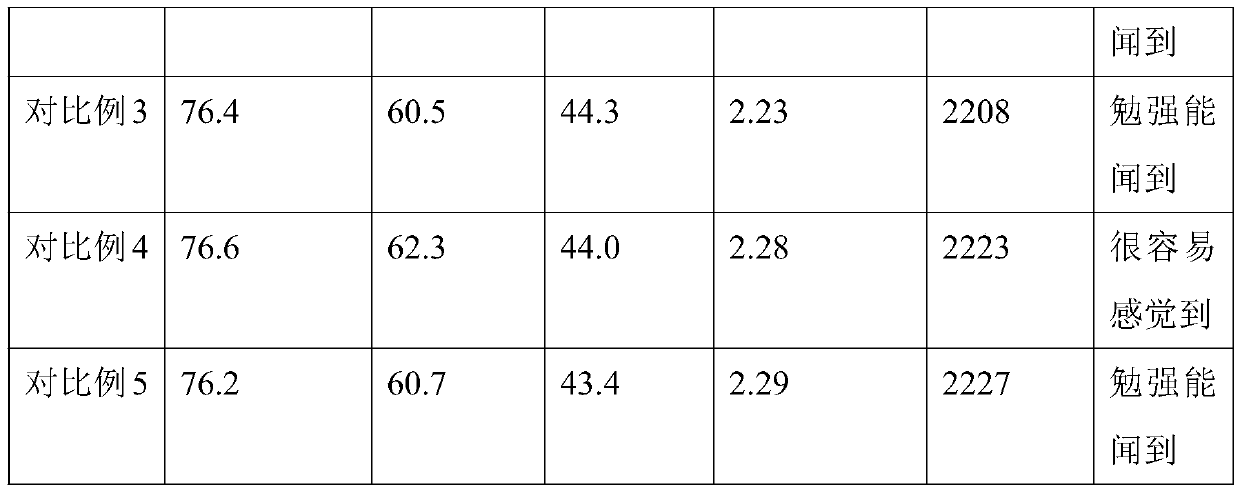

Cation emulsified asphalt for reducing corrosivity during production process and preparation method thereof

InactiveCN107722656AChange state of chargeGood corrosion inhibition effectBuilding insulationsOrganic acidAsphalt

The invention relates to cation emulsified asphalt for reducing the corrosivity during a production process and a preparation method thereof. The cation emulsified asphalt is prepared from the following raw materials in percentage by weight: 53 to 70 percent of asphalt, 0.8 to 3.0 percent of an emulsifier, 3.0 to 5.0 percent of a modifier, and the balance of water. The cation emulsified asphalt has the innovation point of a difunctional asphalt emulsifier required for producing the cation emulsified asphalt; a basic component is prepared from organic polyamine and organic acid which serve as raw materials; then the basic component, an acidic component and organic aldehyde with the molar ratio being 1: (1-1.3): (1-1.3) are reacted, so that the difunctional asphalt emulsifier is formed; themolecular structure of the difunctional asphalt emulsifier comprises a plurality of adsorption centers which can form an adsorption protective film and have emulsification and corrosion inhibition double functions. The emulsified asphalt has low corrosivity during a preparation process, and the hidden danger of corrosion during emulsification, storage and conveying process can be greatly reduced without a corrosion inhibitor. The emulsified asphalt is simple in production technology, wide in source of raw materials and excellent in performance, and can be applied to micro-surfacing and slurrysurfacing.

Owner:WEIFANG UNIVERSITY

Heat-resistant modified asphalt

Owner:WUJIANG HUAWEI SPECIAL OIL

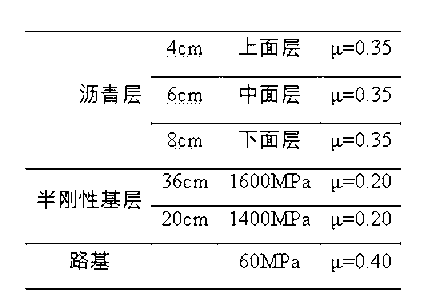

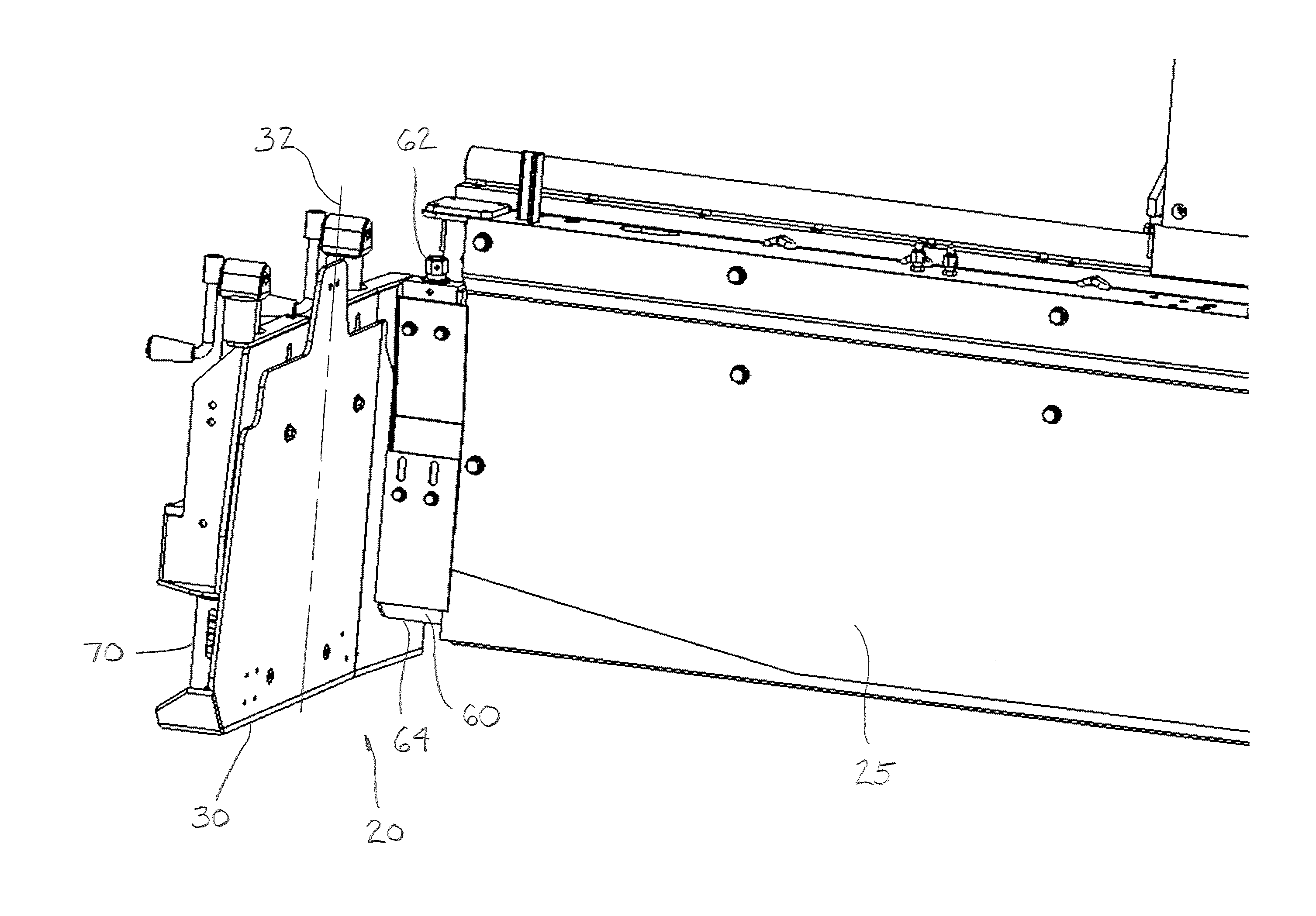

Apparatus and method for a joint density bolt-on assembly

Owner:CARLSON PAVING PRODS

Energy-saving road asphalt crack pouring machine

Owner:CHANGSHU GAOSIDA INSTR EQUIP

Ground asphalt cracking device for road construction

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

Asphalt composition and method of using same in tack coats

PendingUS20210017388A1Facilitate cross-linkingReduce compositionClimate change adaptationBuilding insulationsPolymer scienceButadiene Dioxide

Owner:BASF AG

Trichloroethylene recovery device and recovery method

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

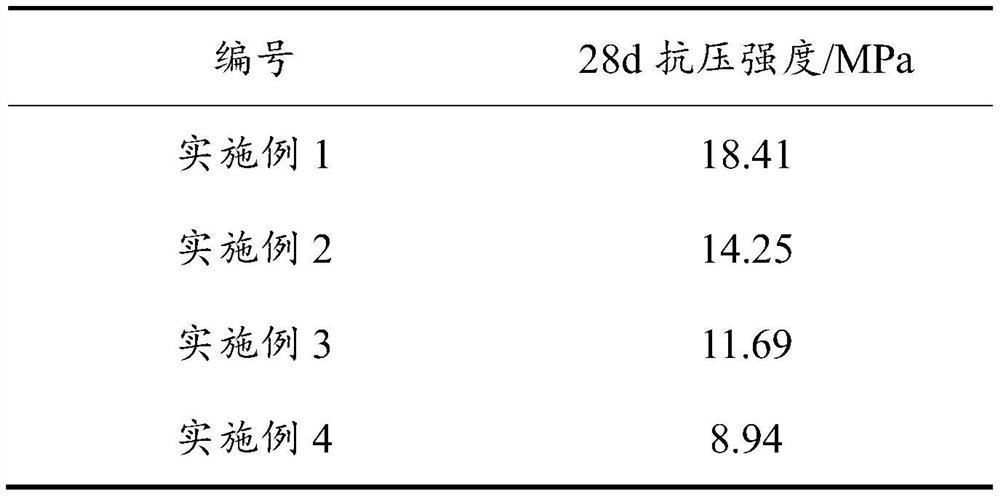

Solid waste-based baking-free environment-friendly hollow brick and preparation method thereof

Owner:SHANDONG UNIV +1

Method for preparing modified asphalt by utilizing waste transfusion bag film in one step

Owner:FUJIAN NORMAL UNIV

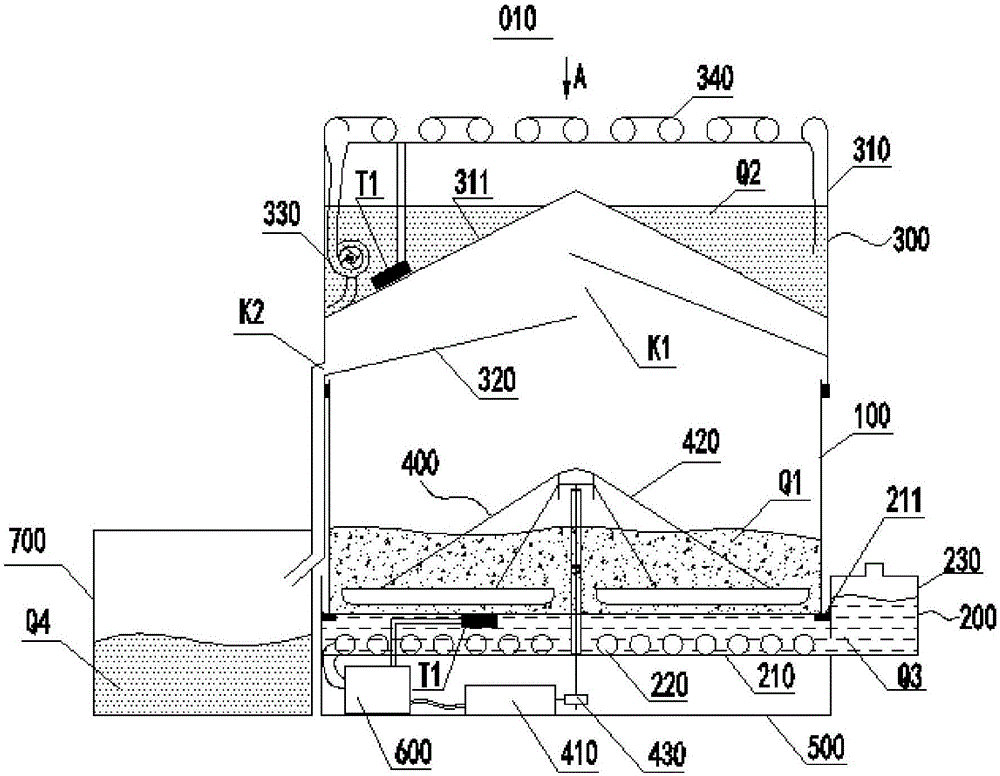

Device and process for purifying and treating tar tail gas and asphalt fume

ActiveCN110425550ASolve the problem that it is difficult to purify asphalt fumeImprove thermal efficiencyIncinerator apparatusChimneysCombustion chamberEnvironmental geology

The invention relates to a device and process for purifying and treating tar tail gas and asphalt fume. The device comprises an incinerator and a chimney, wherein the incinerator is composed of a first combustion chamber, a second combustion chamber, a first heat storage chamber and a second heat storage chamber, the first combustion chamber is arranged below the second combustion chamber, and thefirst combustion chamber and the second combustion chamber communicates with each other; the two ends of the first combustion chamber communicates with the top of the first heat storage chamber and the top of the second heat storage chamber respectively, a first combustor is arranged inside the first combustion chamber, a second combustor is arranged inside the second combustion chamber, and a heat accumulator is arranged inside the first heat storage chamber and the second heat storage chamber. By adopting a process combining a heat storage type incinerator and a direct combustion type incinerator, the tar tail gas and the asphalt fume can be purified at the same time, the problem that the heat storage type incinerator is difficult to purify the asphalt fume and the direct combustion type incinerator is low in heat efficiency is solved, meanwhile, waste gas waste heat is recycled, the operation cost of the incinerator is reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Water-proof roof glue

InactiveCN101225288AImprove waterproof and thermal insulation performanceGood weather resistanceBituminous material adhesivesHydrocarbon polymer adhesivesAdhesivePolystyrene

The invention relates to a building waterproof material, in particular to a waterproof roof adhesive, which aims to solve the problems in prior roof waterproof material of poor weatherability, easy bubbling and peeling, and poor permeability and air permeability, comprising asphalt, coal tar, waste polystyrene foam, lime and sawdust. Firstly, the waste polystyrene foam is ground to particles; secondly, the coal tar is added into a vessel and heated to 650 to 700 degrees; and the asphalt is added into the vessel, and then the former mixture is agitated homogeneously and keep on warming up to 750 degrees, after the asphalt is dissolved, the mixture is cooled to 400 to 500 degrees; at last, waste polystyrene foam, lime and sawdust are added into mixture successively, the mixture is agitated homogeneously and cooled to a paste shape, and then the finished product is obtained. The building waterproof material has the advantages that: the building waterproof material integrates the advantages of waterproof, heat preservation and heat insulation and has admirable waterproof and heat preservation effect, good weatherability, no fluid and cracks, high adhesive strength; meanwhile, the material meet the national specified standard; more importantly, the aim of waste reuse, pollution treatment, environment protection and cost saving are realized by using the waste polystyrene foam.

Owner:亢吉田

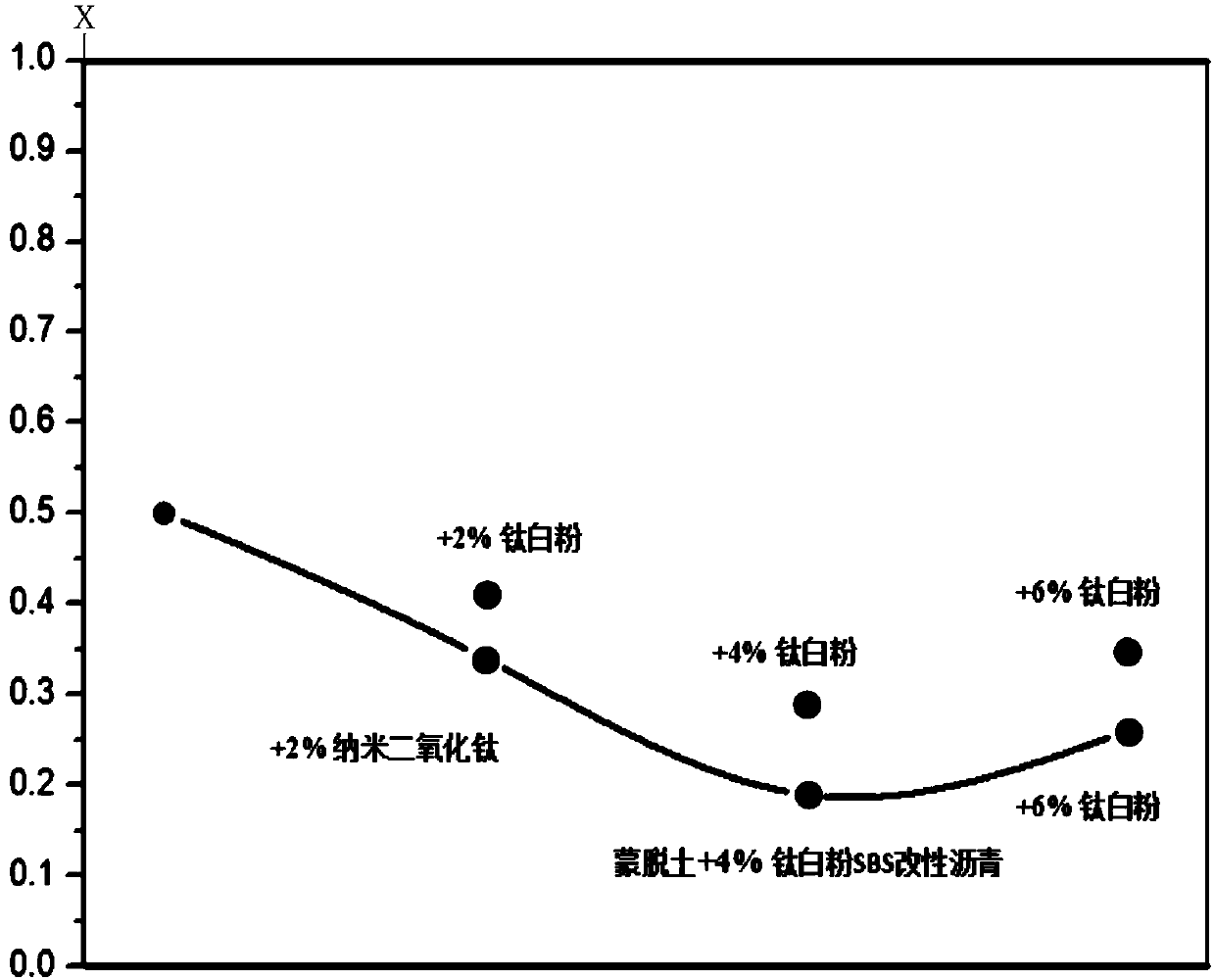

Odorless asphalt mixture, preparation method thereof and application of odorless asphalt mixture on pavement

ActiveCN111234541AHigh strengthImprove rheologyIn situ pavingsBuilding insulationsVegetable oilCarbon nanotube

Owner:湖南省溆怀高速公路建设开发有限公司

Preparation method for zeolite-activated carbon composite adsorbent

InactiveCN107876009AIncrease the areaLarge adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesSorbentCarbonization

Owner:SHAANXI SHENGMAI PETROLEUM

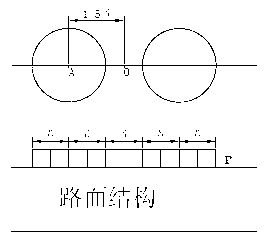

Grouting material, grouting method and road maintenance method

ActiveCN104177846AReduce penetrationWon't clogIn situ pavingsBuilding insulationsSolubilityTrichloroethylene

The invention discloses a grouting material, a grouting method and a road maintenance method. The grouting material is prepared from the following raw materials: hard asphalt, sasobit, an SBS (styrene butadiene styrene) modifier and asphalt master batch; and control indexes of the grouting material are as follows: the asphalt penetration is smaller than 10, an asphalt softening point is 85 DEG C-93.5 DEG C and the solubility is greater than 99.3% in trichloro ethylene. The grouting material provided by the invention has good mobility, low economic cost and quick freezing rate; while the grouting material is applied to the road maintenance, maintenance is not needed, so that the traffic can be opened immediately. The road maintenance method provided by the invention can be used for effectively evaluating the effects before grouting, during grouting and after grouting, so that the defect that the grouting is judged completely according to the experience of a constructor is overcome.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD +2

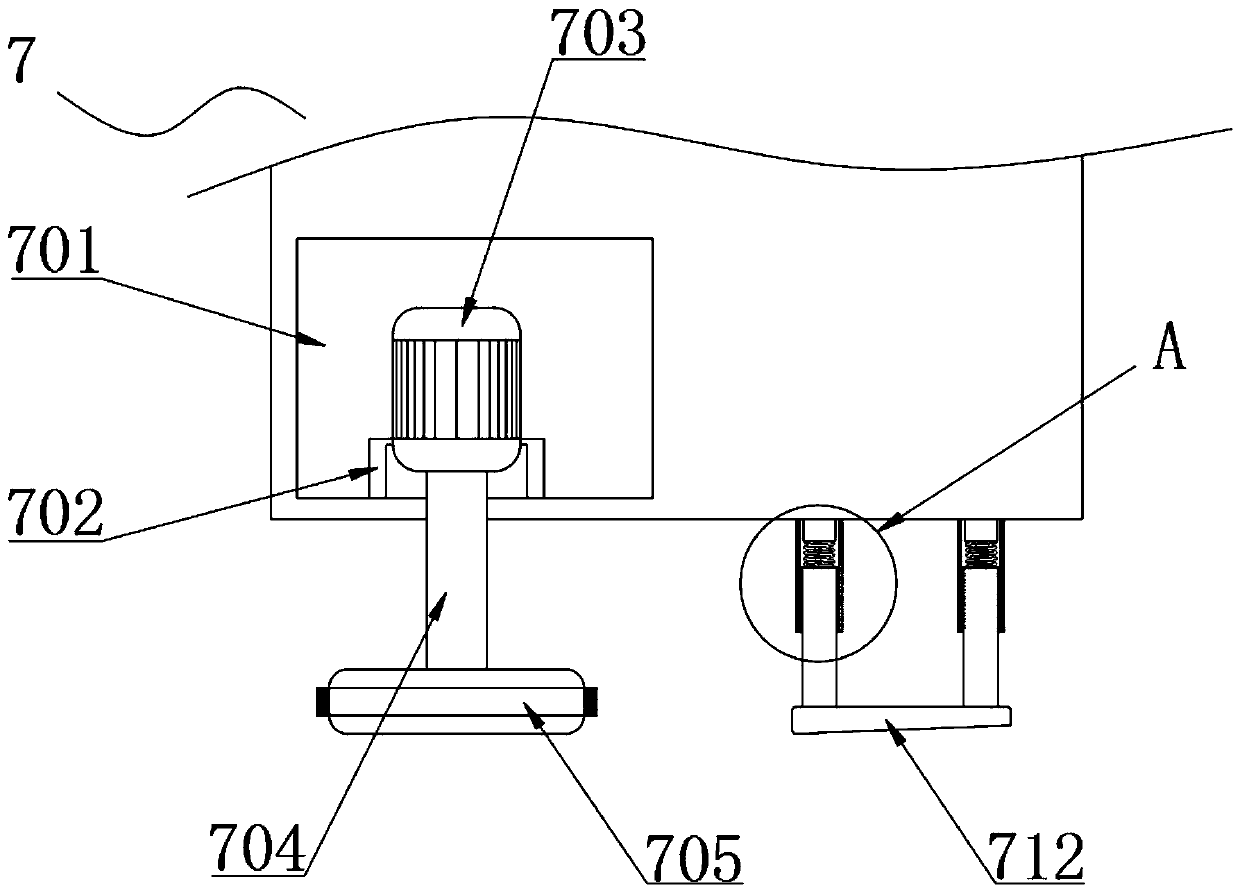

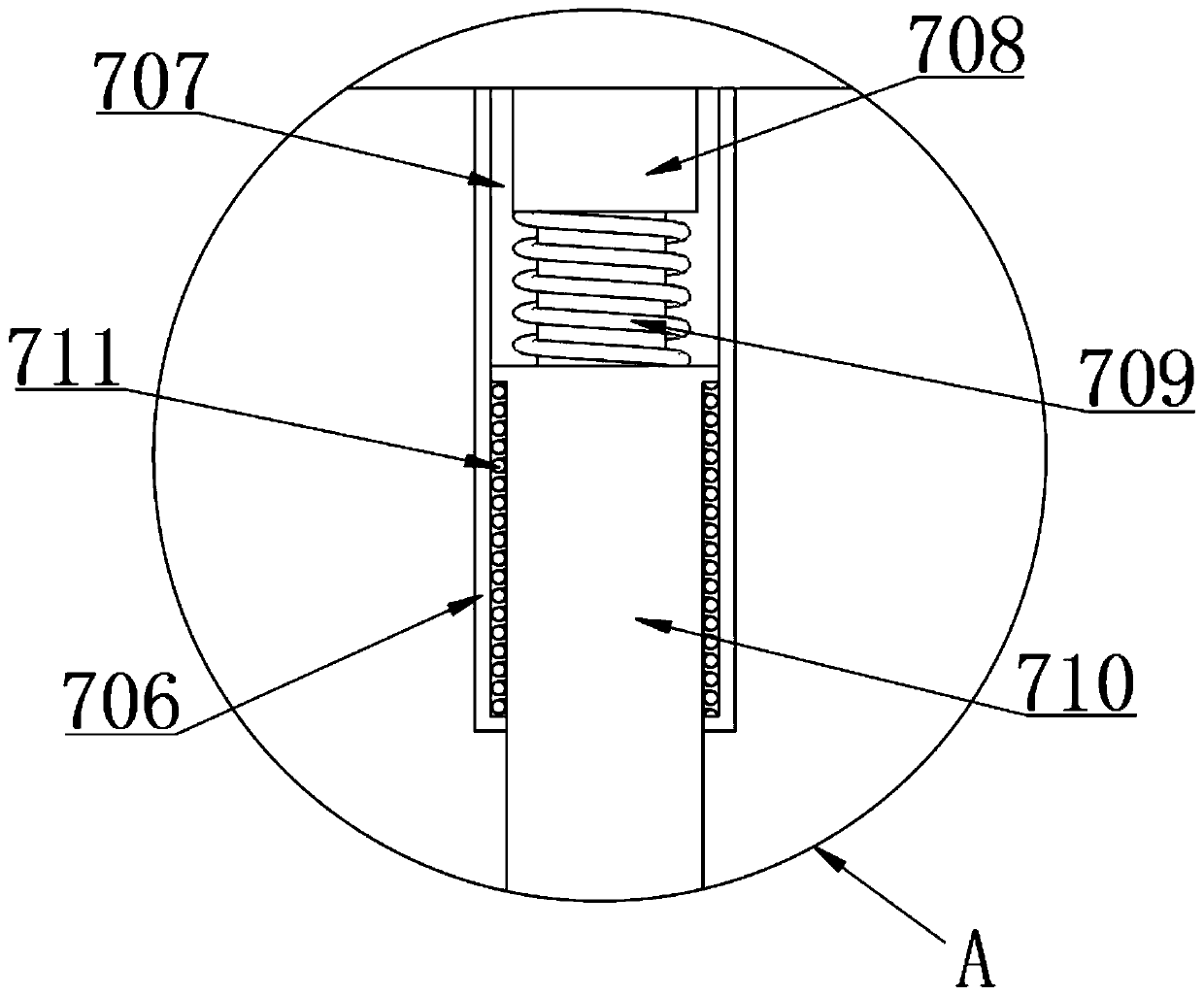

Recycled asphalt heating device

Owner:HUNAN SANY ROAD MACHINERY

Chemical pump inner cavity insulated oil paint and preparation method thereof

InactiveCN106046954AUniform textureGuaranteed to workRubber insulatorsRubber derivative coatingsRare earthPyrophosphate

Owner:安徽天富泵阀有限公司

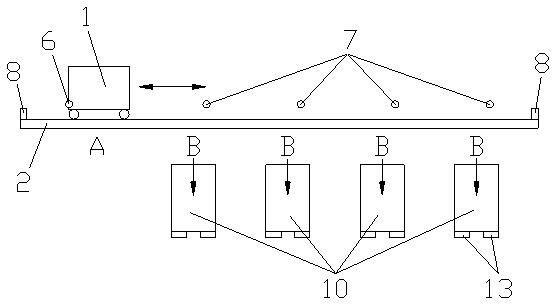

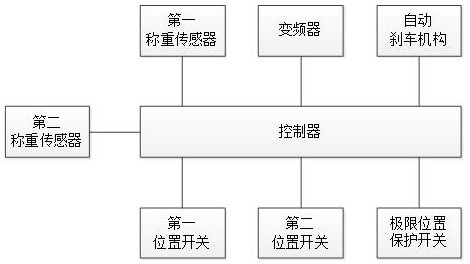

Efficient feeding system and method for asphalt mixture level batching bins

InactiveCN112061707ATimely replenishmentImprove efficiencyControl devices for conveyorsWeighing apparatus with automatic feed/dischargeFrequency changerAutomatic braking

Owner:FUJIAN QUANCHENG MACHINERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap