Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Sawdust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sawdust (or wood shavings) is a by-product or waste product of woodworking operations such as sawing, milling, planing, routing, drilling and sanding. It is composed of fine particles of wood. These operations can be performed by woodworking machinery, portable power tools or by use of hand tools. Wood dust is also the byproduct of certain animals, birds and insects which live in wood, such as the woodpecker and carpenter ant. In some manufacturing industries it can be a significant fire hazard and source of occupational dust exposure.

Water-proof roof glue

InactiveCN101225288AImprove waterproof and thermal insulation performanceGood weather resistanceBituminous material adhesivesHydrocarbon polymer adhesivesAdhesivePolystyrene

The invention relates to a building waterproof material, in particular to a waterproof roof adhesive, which aims to solve the problems in prior roof waterproof material of poor weatherability, easy bubbling and peeling, and poor permeability and air permeability, comprising asphalt, coal tar, waste polystyrene foam, lime and sawdust. Firstly, the waste polystyrene foam is ground to particles; secondly, the coal tar is added into a vessel and heated to 650 to 700 degrees; and the asphalt is added into the vessel, and then the former mixture is agitated homogeneously and keep on warming up to 750 degrees, after the asphalt is dissolved, the mixture is cooled to 400 to 500 degrees; at last, waste polystyrene foam, lime and sawdust are added into mixture successively, the mixture is agitated homogeneously and cooled to a paste shape, and then the finished product is obtained. The building waterproof material has the advantages that: the building waterproof material integrates the advantages of waterproof, heat preservation and heat insulation and has admirable waterproof and heat preservation effect, good weatherability, no fluid and cracks, high adhesive strength; meanwhile, the material meet the national specified standard; more importantly, the aim of waste reuse, pollution treatment, environment protection and cost saving are realized by using the waste polystyrene foam.

Owner:亢吉田

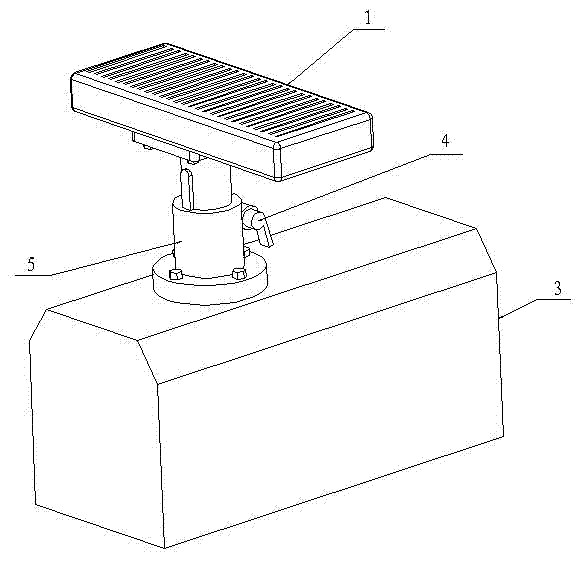

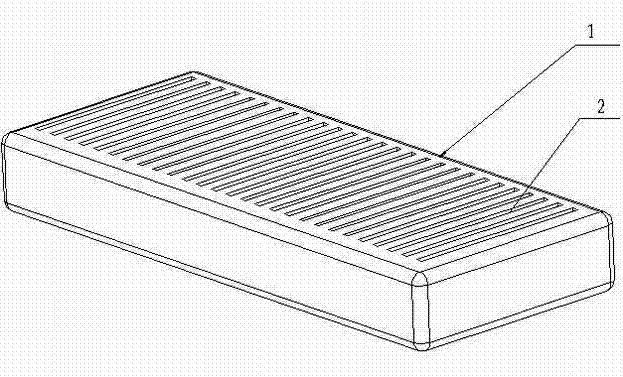

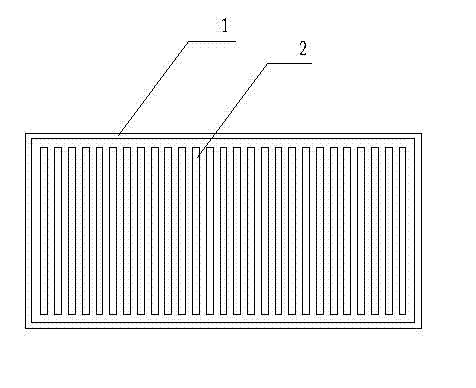

Processing platform assembly of wood polishing machine

InactiveCN102328264AIncrease resistanceNot easy to slideGrinding machine componentsPolishing machinesWood processorMachining process

Owner:芜湖宏春木业集团有限公司

Activated carbon preparation process

ActiveCN111874904AReduce processing efficiencyReduce air pressureCarbon compoundsDrying gas arrangementsActivated carbonHoneycomb

The invention belongs to the technical field of activated carbon preparation, and particularly relates to an activated carbon preparation process which comprises the following steps: step 1, drying and grinding: carbonizing and grinding sawdust after drying to obtain dried carbon powder; step 2, processing and forming: processing the carbon powder into a cylindrical carbon block by using a mold, and forming a plurality of honeycomb-shaped through holes; step 3, cleaning of the carbon block: washing the formed carbon block with water to remove impurities on the surface of the carbon block; step4, drying of the carbon block: drying the cleaned carbon block to remove moisture in honeycomb-shaped through holes of the carbon block, wherein the drying process of the cleaned carbon block in thestep 4 is completed by adopting an activated carbon preparation machine in a matching manner. The invention solves the problems that at present, when the interiors of cylindrical activated carbon honeycomb holes are dried, part of moisture on the inner walls of the honeycomb holes permeates into the surface layers of activated carbon, sufficient drying is difficult, and moisture residues are likely to be caused, and conveying and drying cannot be conducted synchronously, and the machining efficiency is low.

Owner:JIANGSU QIANHUIHE ENVIRONMENTAL REGENERATION CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap