Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Tar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tar is a dark brown or black viscous liquid of hydrocarbons and free carbon, obtained from a wide variety of organic materials through destructive distillation. Tar can be produced from coal, wood, petroleum, or peat. Production and trade in pine-derived tar was a major contributor in the economies of Northern Europe and Colonial America. Its main use was in preserving wooden sailing vessels against rot. The largest user was the Royal Navy of the United Kingdom. Demand for tar declined with the advent of iron and steel ships.

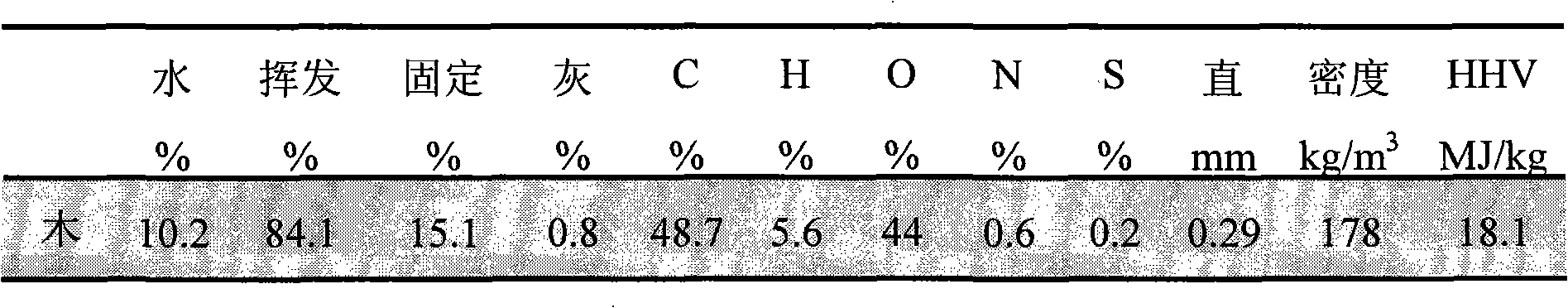

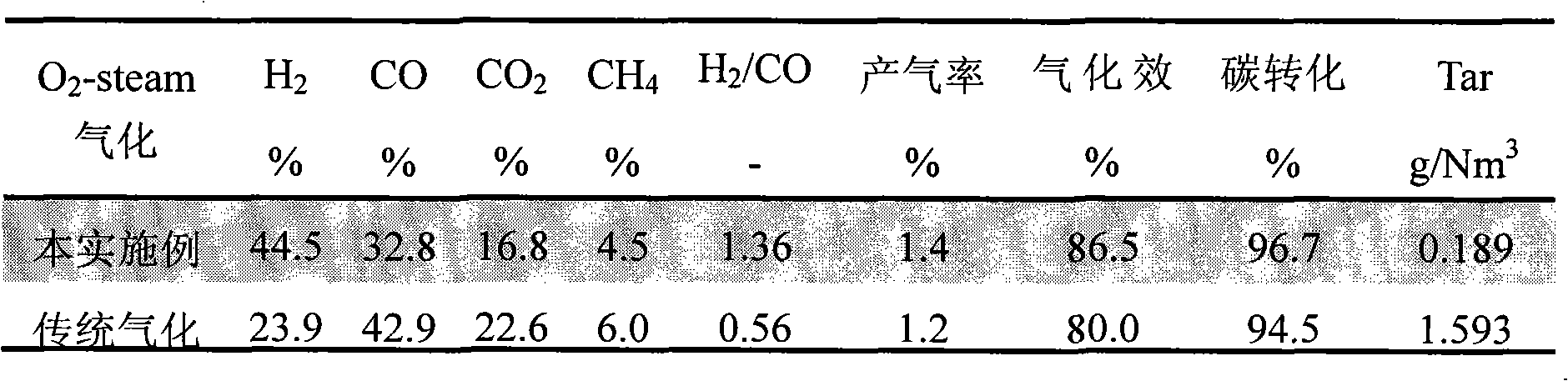

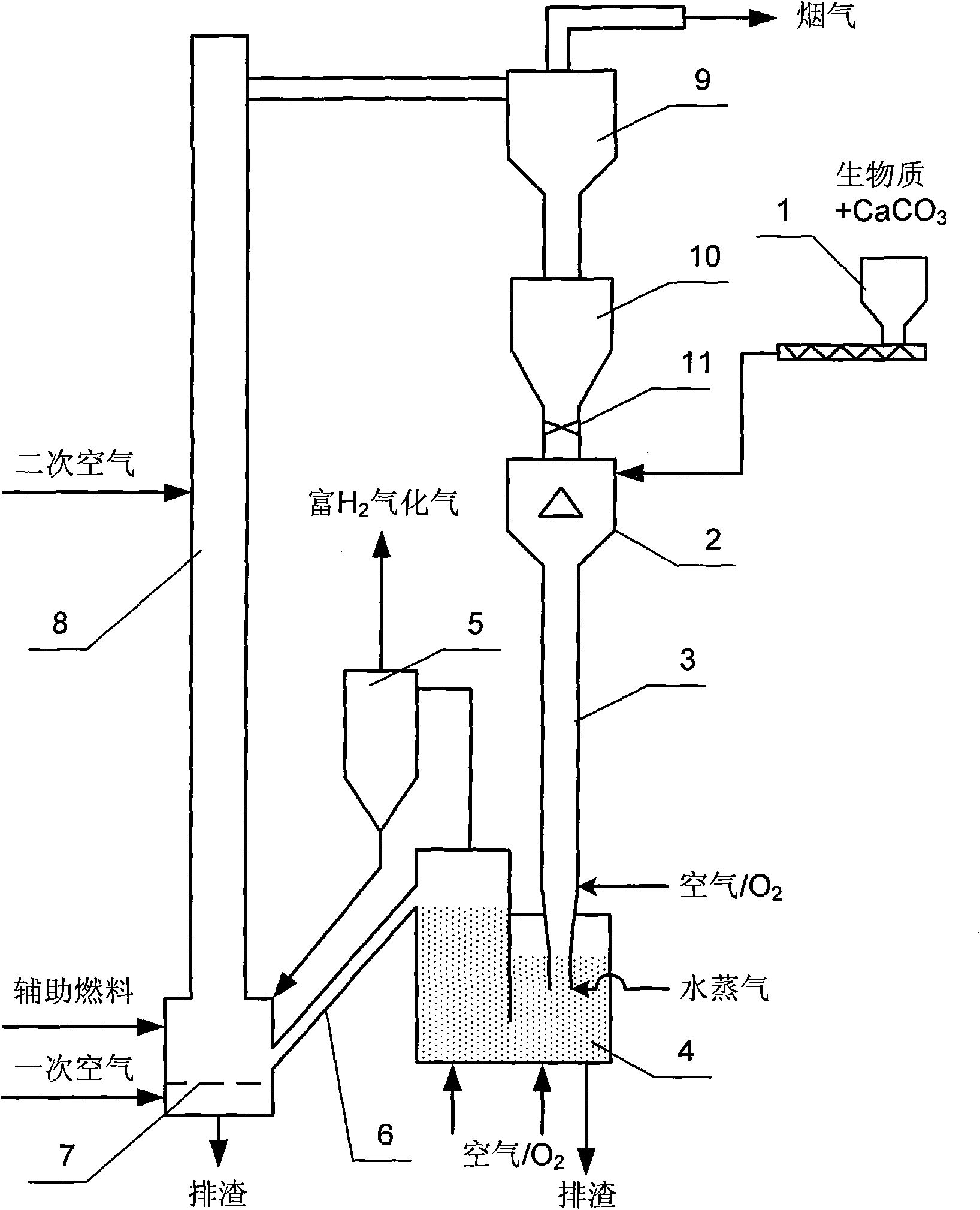

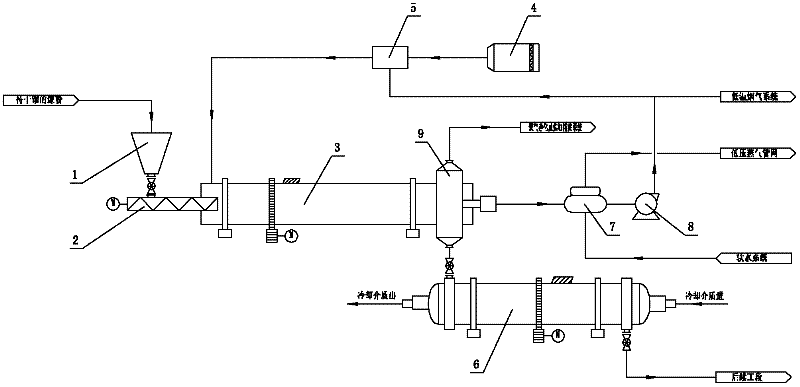

Gasification device and method for preparing hydrogen-rich synthetic gas from biomass

ActiveCN101880552AGranular/pulverulent flues gasificationTarHeat carrier

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Directional pyrolysis method of combustible wastes

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

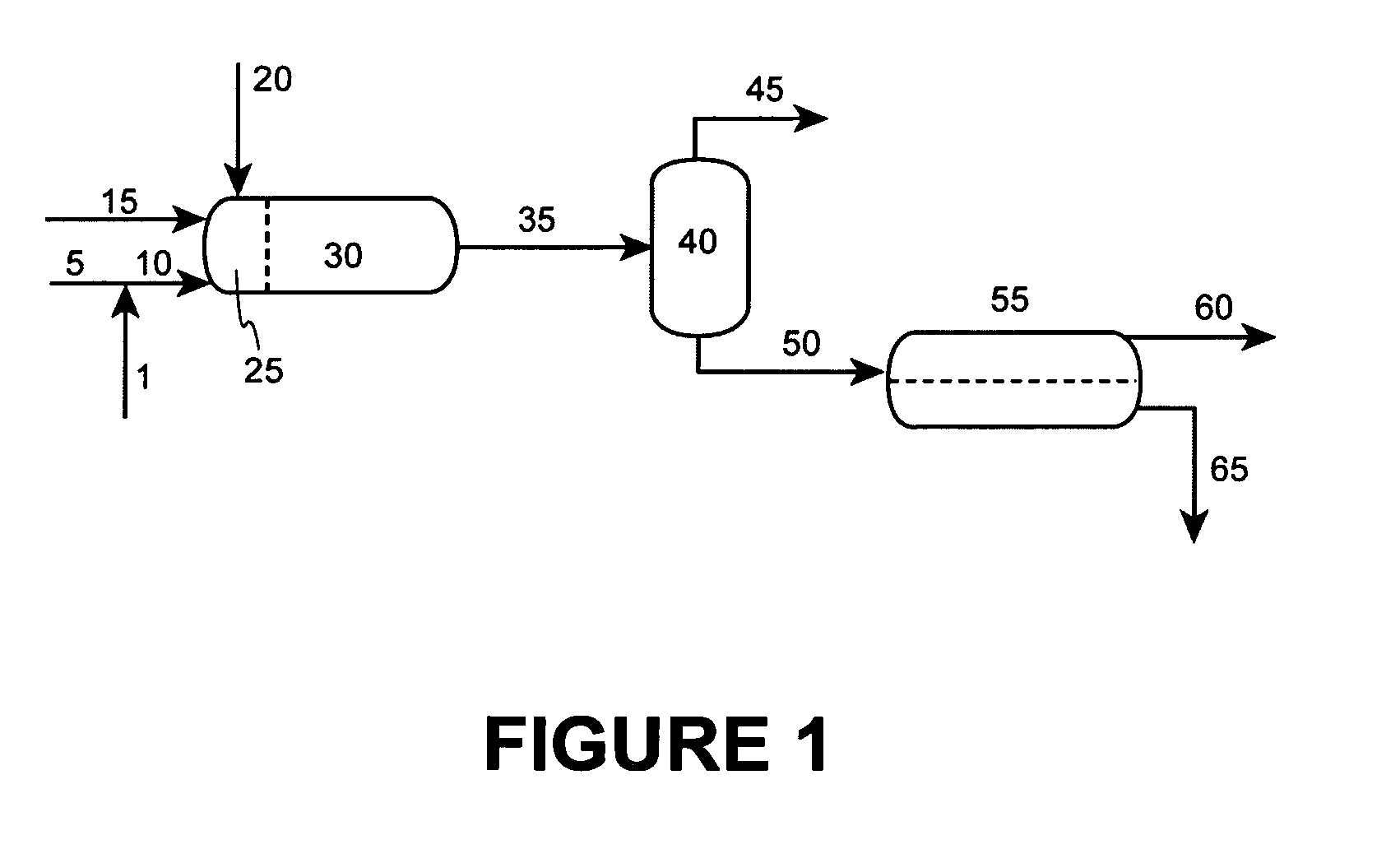

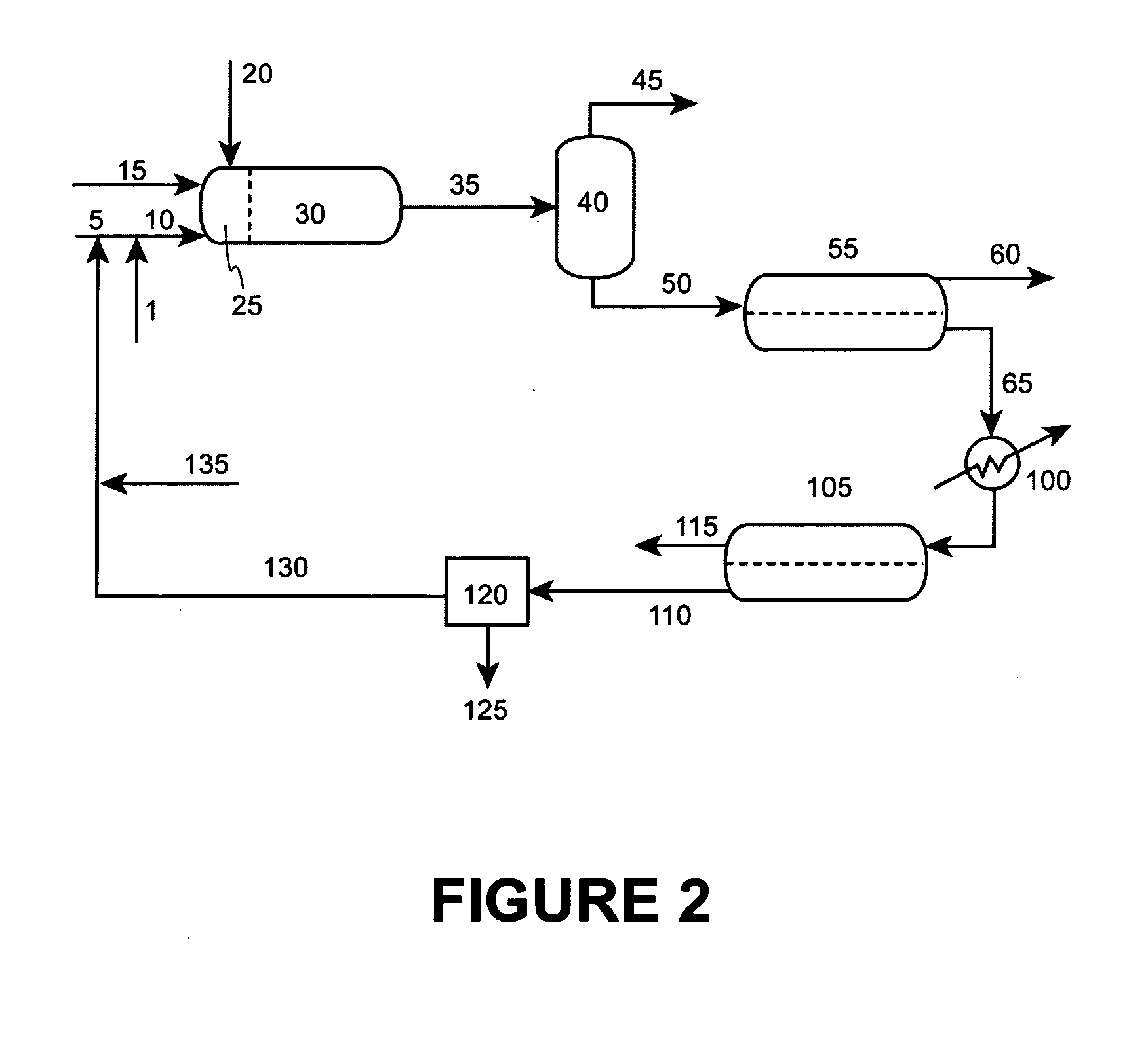

Process for the desulfurization of heavy oils and bitumens

InactiveUS20090152168A1Reduce sulfur contentImprove propertiesRefining with aqueous alkaline solutionsRefining to eliminate hetero atomsTarAlkali hydroxide

Owner:EXXON RES & ENG CO

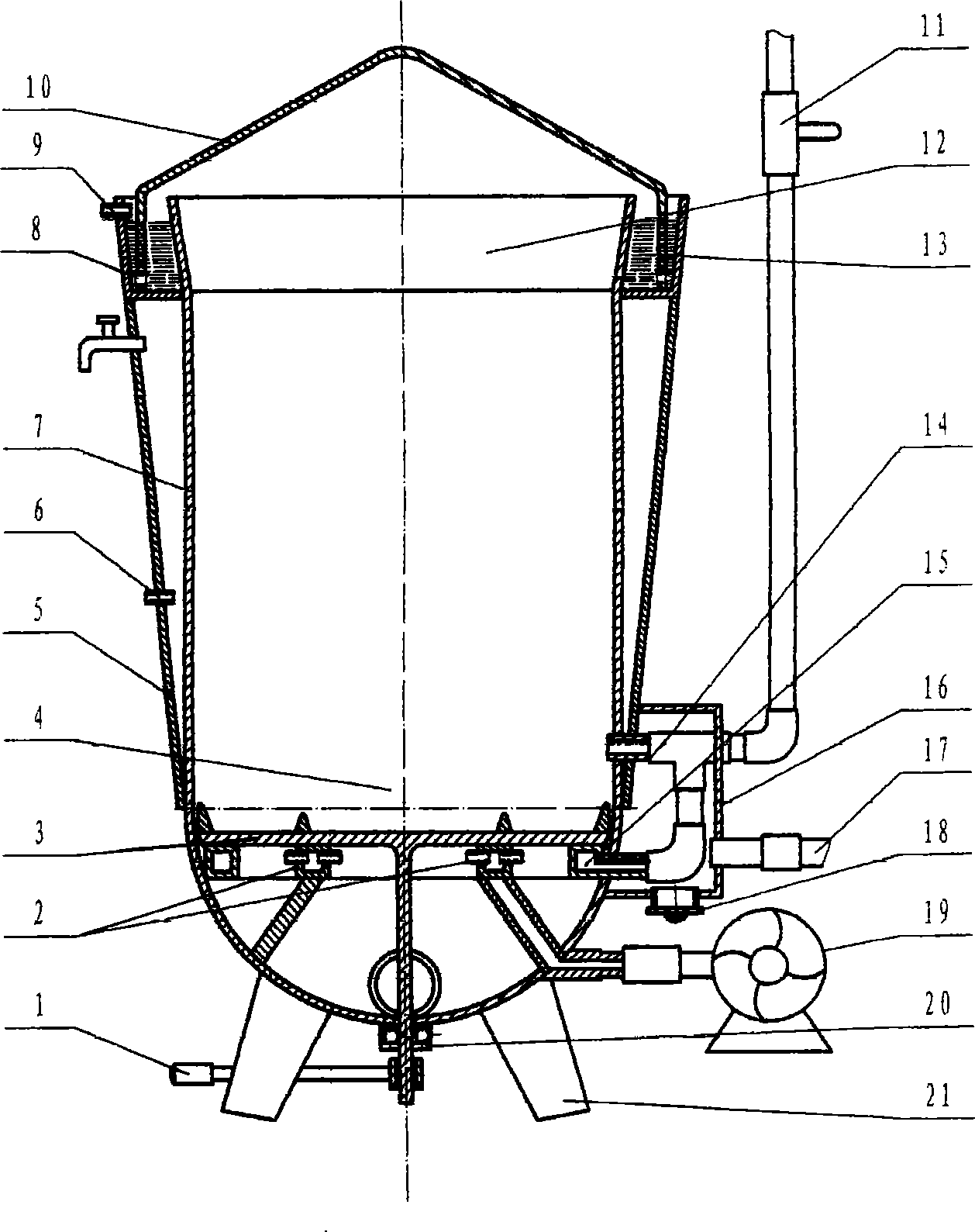

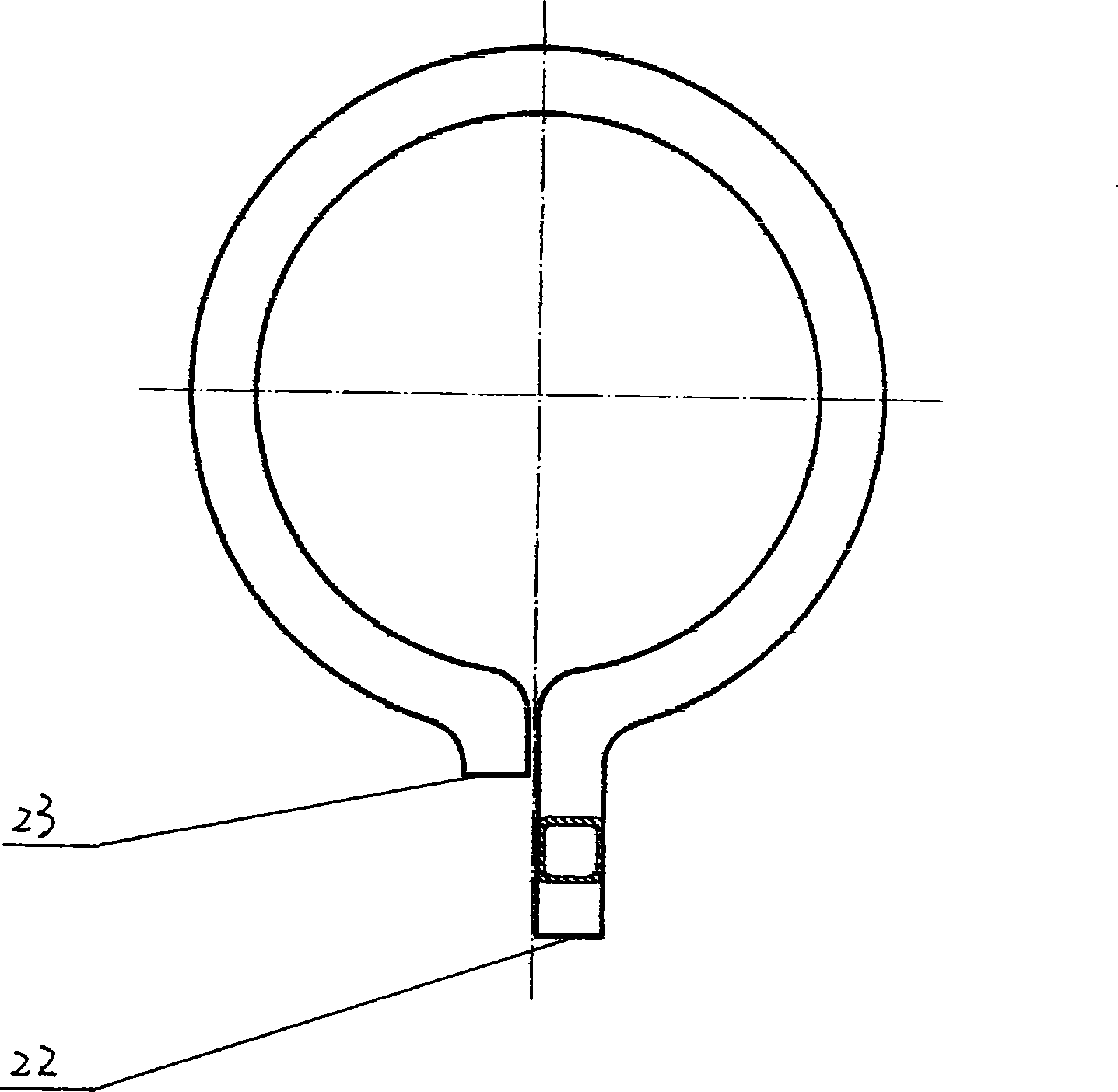

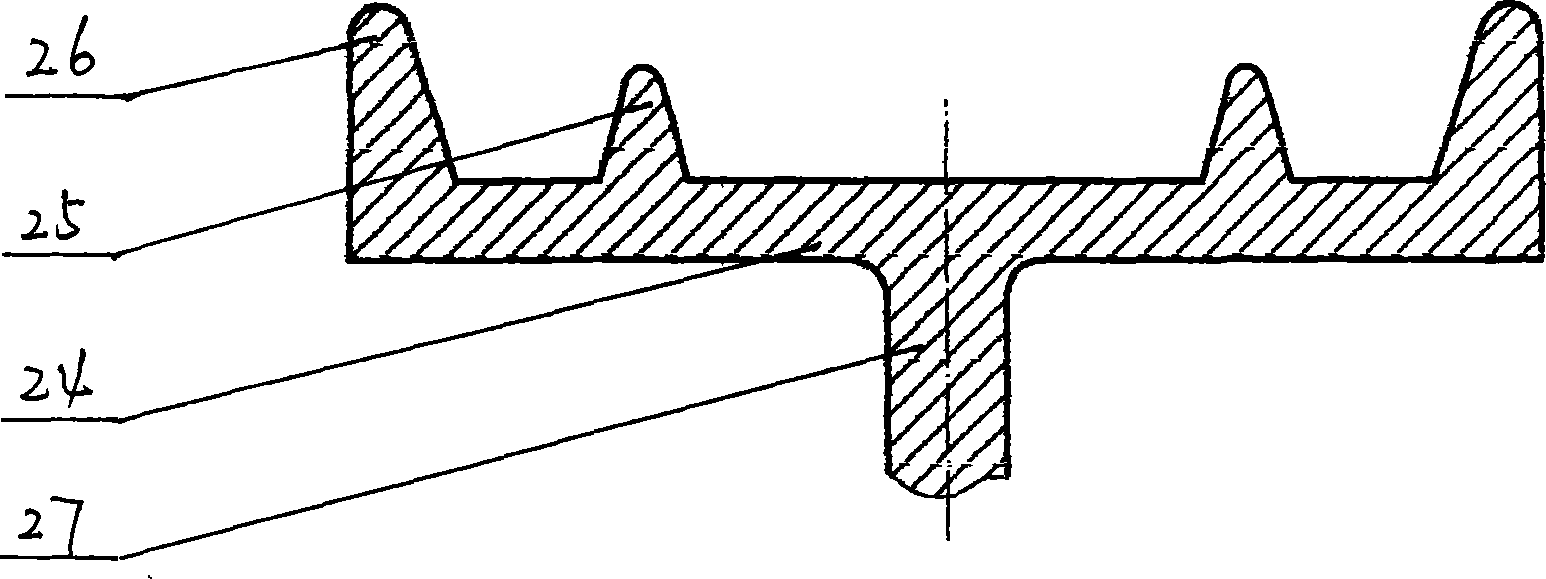

Pulverization-free, dampness-resistant, coke tar-free biomass gasification oven preventing burning out

InactiveCN101240904AWide variety of sourcesWon't clogProductsDomestic stoves or rangesBiomass gasifierOxygen

Owner:沈桀

Preparation of solid bio-fuel block

Owner:NORTHEAST FORESTRY UNIVERSITY +1

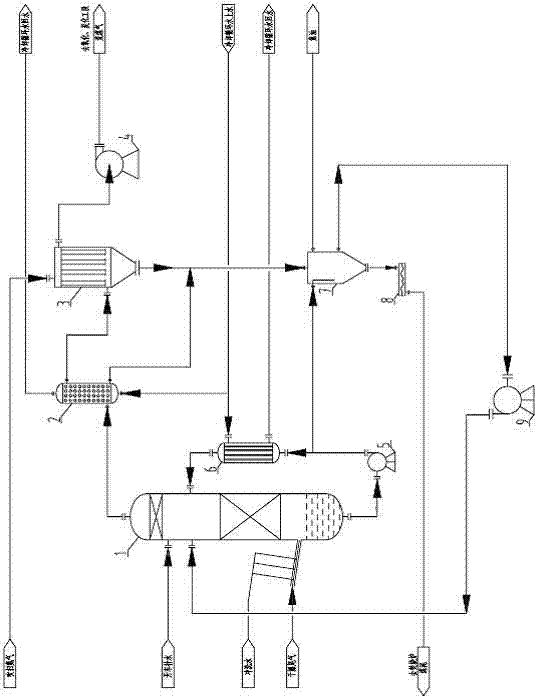

Multi-pipe revolving low-temperature dry distillation technology of fine coal

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Preparation of active carbon and fuel oil by use of petroleum residue and tar residue together

Owner:SHENYANG INST OF ENG

Preparation method of activated carbon tobacco sheet

Owner:SUZHOU GULI BIOTECH

Biochar-based organic fertilizer and production method thereof

InactiveCN110357727AReduce pollutionLight weightExcrement fertilisersNitrogenous fertilisersPotassiumSlurry

Owner:湖北金日生态能源股份有限公司

Modified peanut hull porous material and application thereof to cigarettes

ActiveCN103689797ATobacco smoke filtersTarPeanut hull

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Data obtaining method and electronic cigarette

InactiveCN110169595AIncrease or decrease intake substance parametersEasy to controlTobacco devicesTarElectronic cigarette

The invention discloses a data obtaining method and an electronic cigarette. The data obtaining method comprises the steps that the time, the temperature and the concentration of tobacco tar sucking of a cigarette holder are obtained under the situation that tobacco tar in an electronic cigarette body is atomized; the time, the temperature and the concentration are determined as intake substance parameters; and the intake substance parameters are sent to a data processing terminal. Through the data obtaining method and the electronic cigarette, the technical problems that in the prior art, tobacco tar is stilled generated when the tobacco tar burns, and the intake amount of the tobacco tar cannot be monitored are solved.

Owner:JOUZ LTD

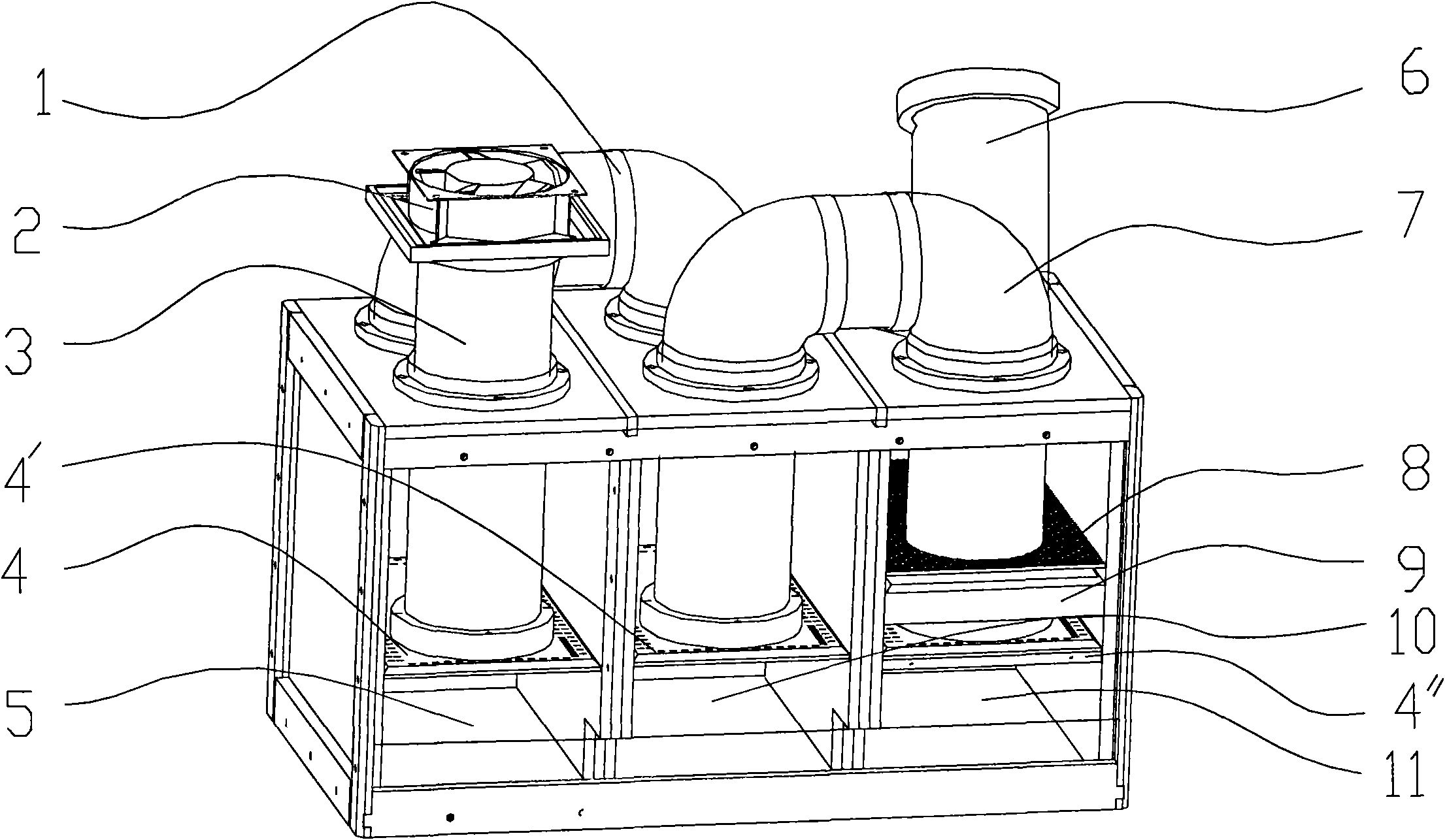

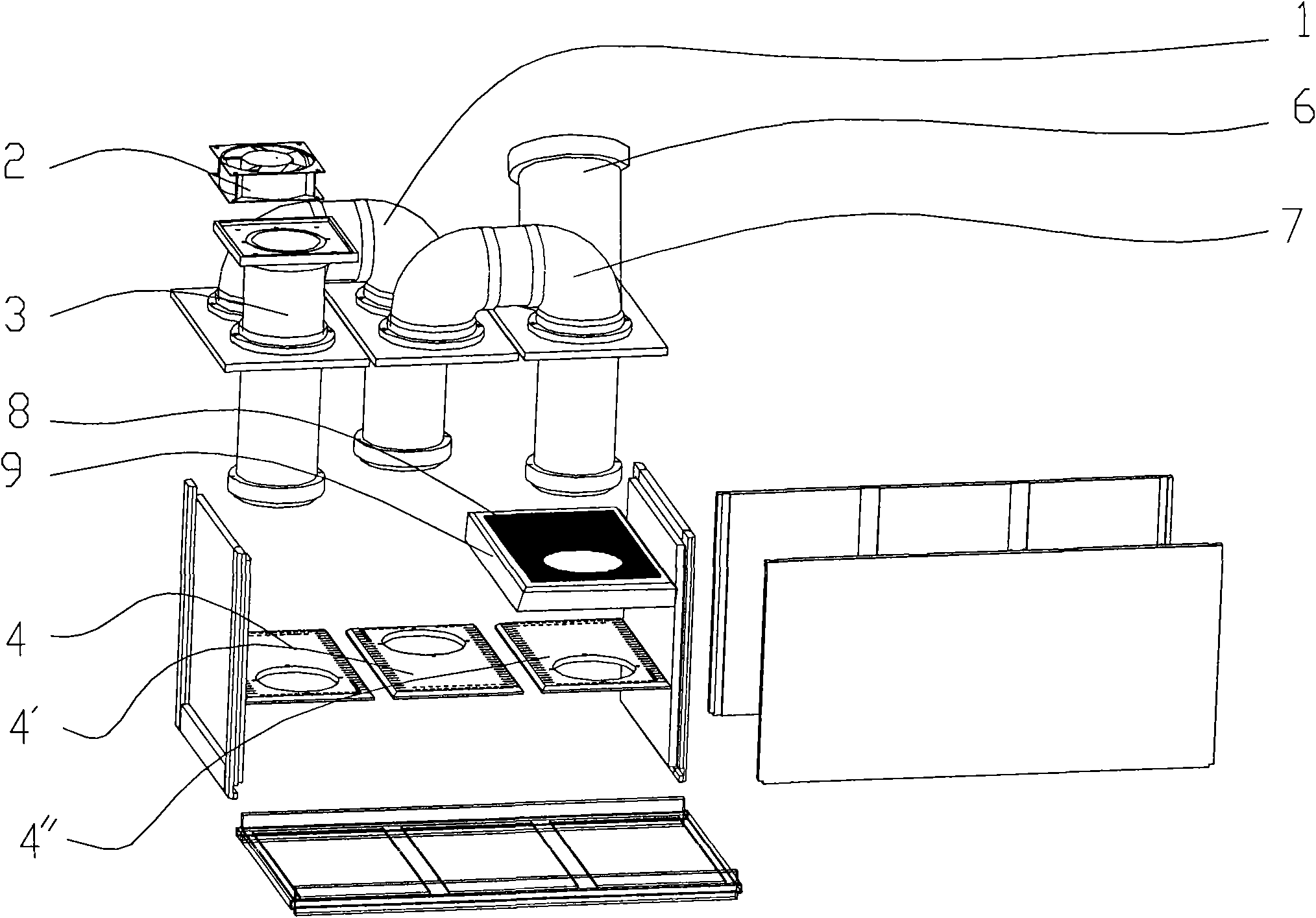

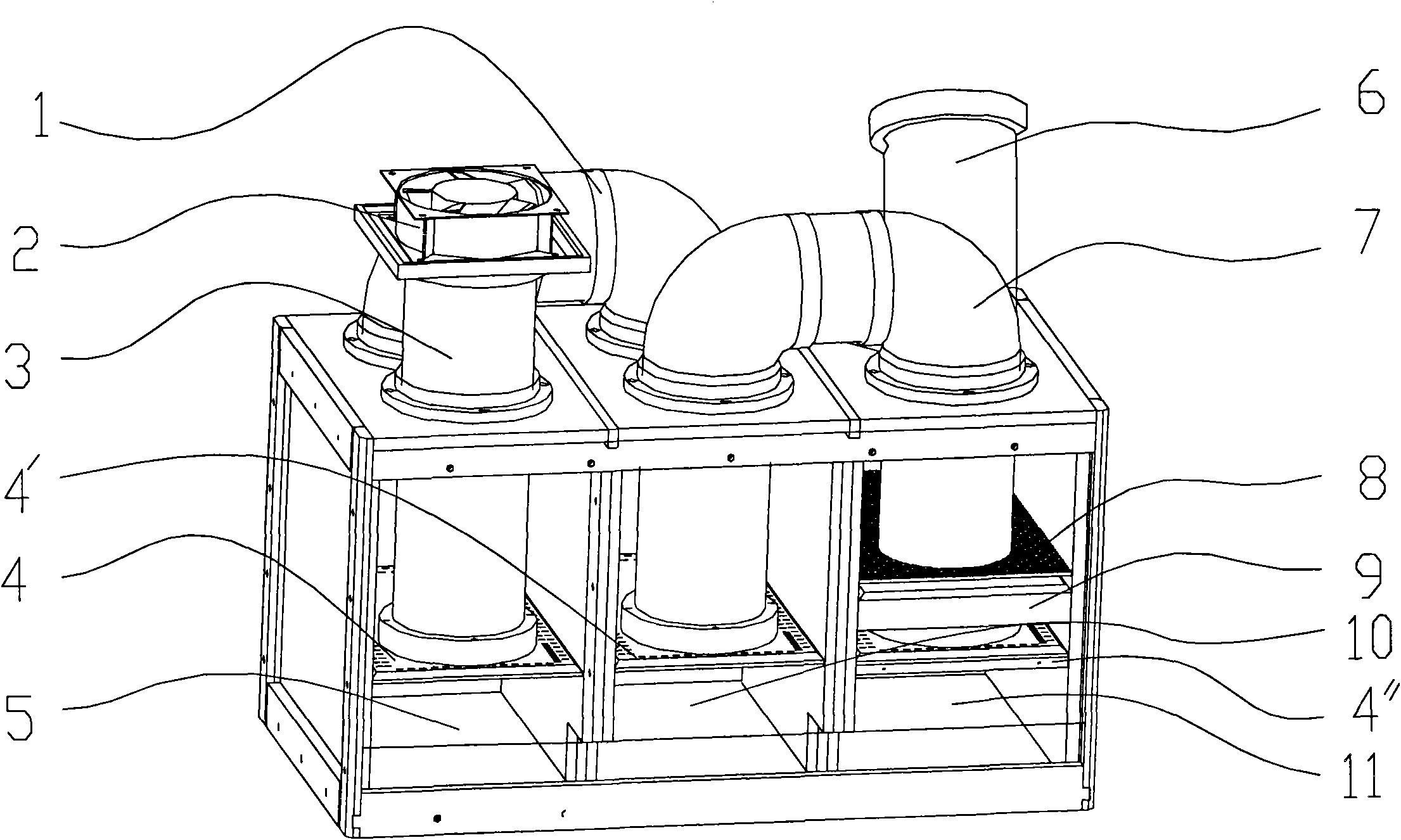

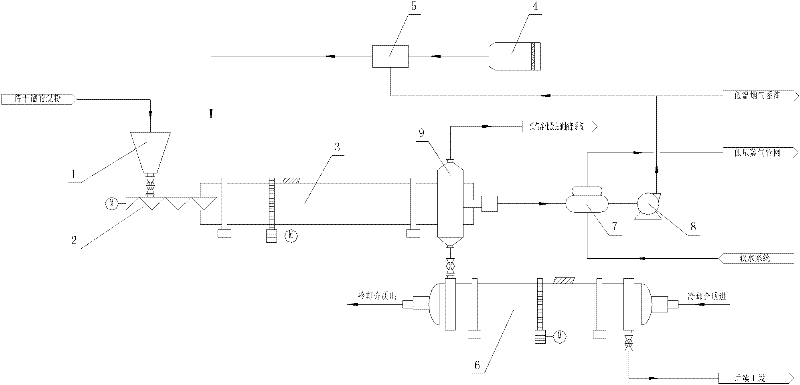

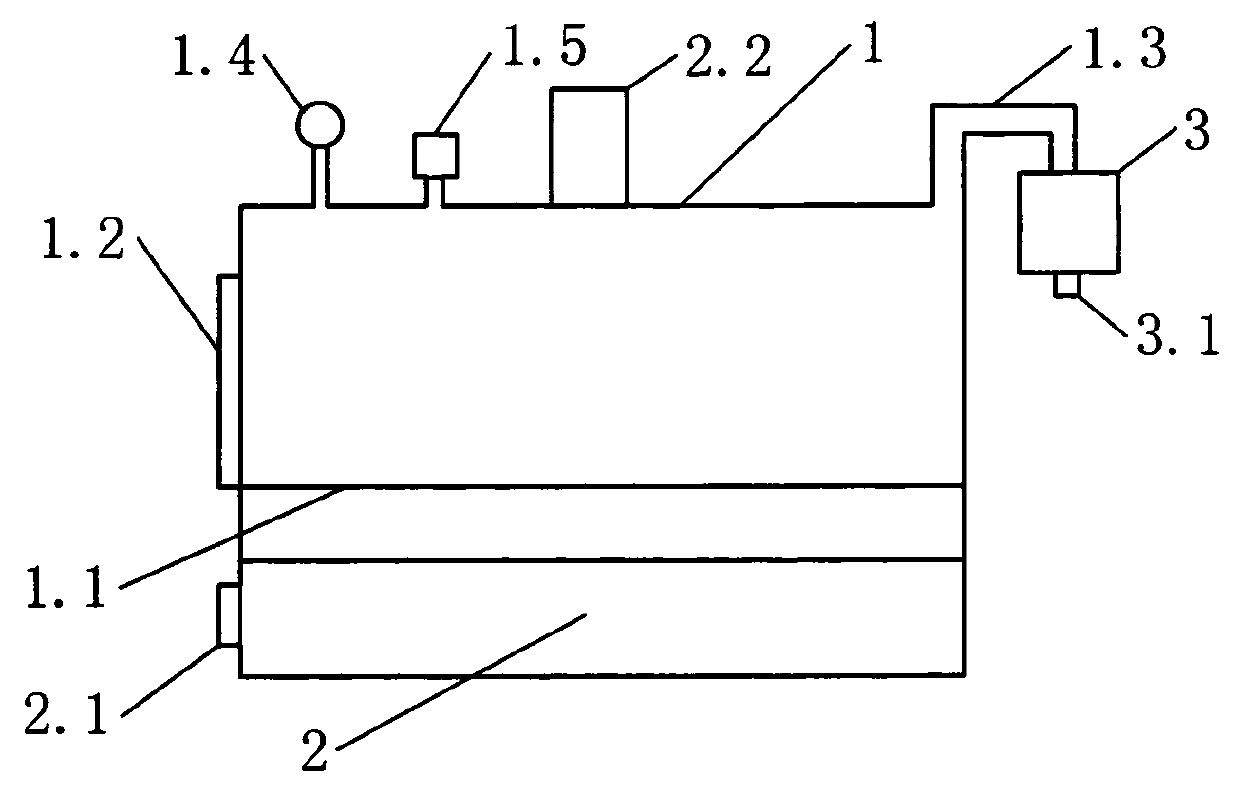

Carbonized tail gas processing system of external heated rotary carbonization furnace and application method thereof

The invention relates to a carbonized tail gas processing system of an external heated rotary carbonization furnace. The system comprises a tail gas washing tower, a tail gas heat exchanger, an electric tar catcher, a cooler, and a settling basin. One side of the tail gas washing tower is provided with a driving water supply pipeline, a pipeline I, a washing water pipeline, and a drying carbonized tail gas pipeline, the other side is connected with the cooler, the top is connected with the tail gas heat exchanger, and the bottom is connected with a pipeline V; the cooler is connected with a cooling circulation water return pipeline I, and a cooling circulation water feeding pipeline; the top of the tail gas heat exchanger is connected with a cooling circulation water return pipeline II, the bottom is connected with the cooling circulation water feeding pipeline, and one side is provided with pipelines VII and VIII; the pipeline VII is connected with the electric tar catcher, the electric tar catcher is connected with a blowing nitrogen pipeline, a pipeline IX, and a crude gas pipeline; the pipelines IX is connected with the pipeline VIII and the settling basin, the settling basin is provided with pipelines XI and XII, a tar pipeline, and a coal slurry pipeline; and the pipeline XII is connected with the pipeline I. In addition, the invention discloses an application method for the system. The system and the method are capable of effectively improving the utilization efficiency.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

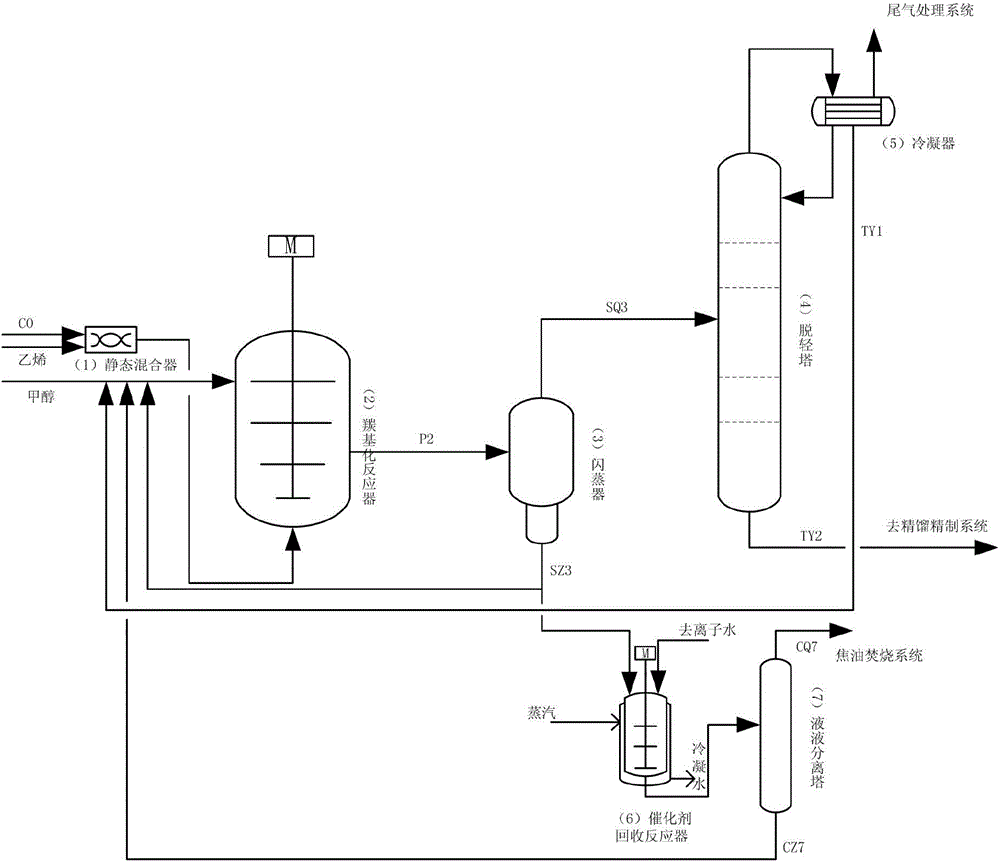

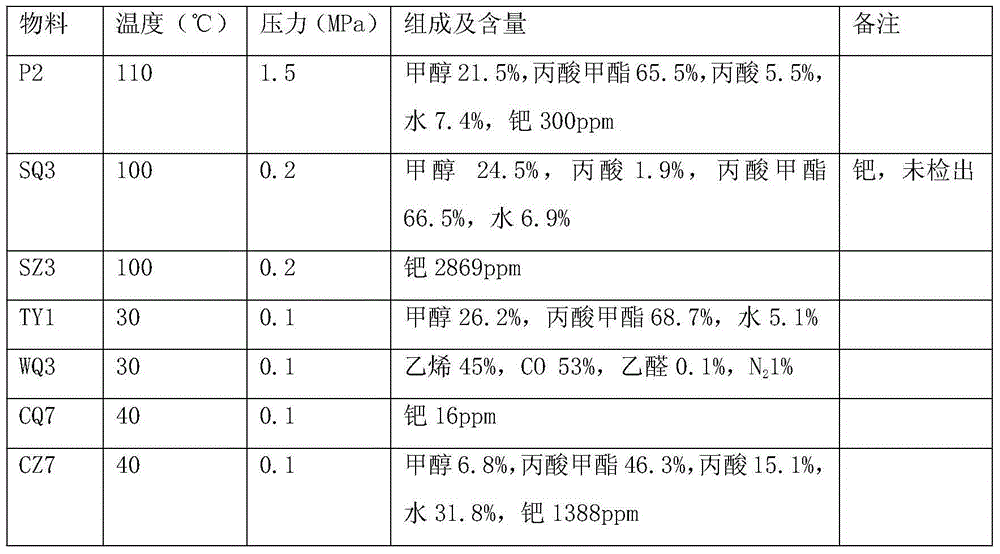

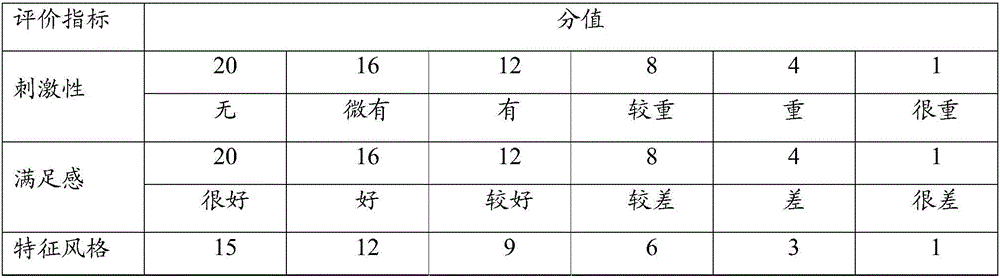

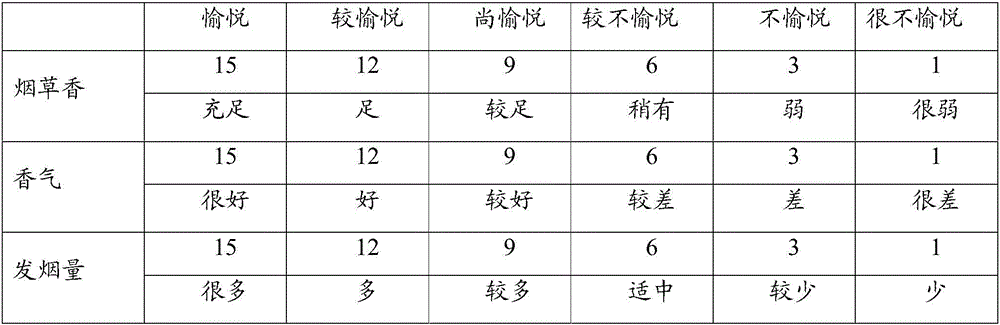

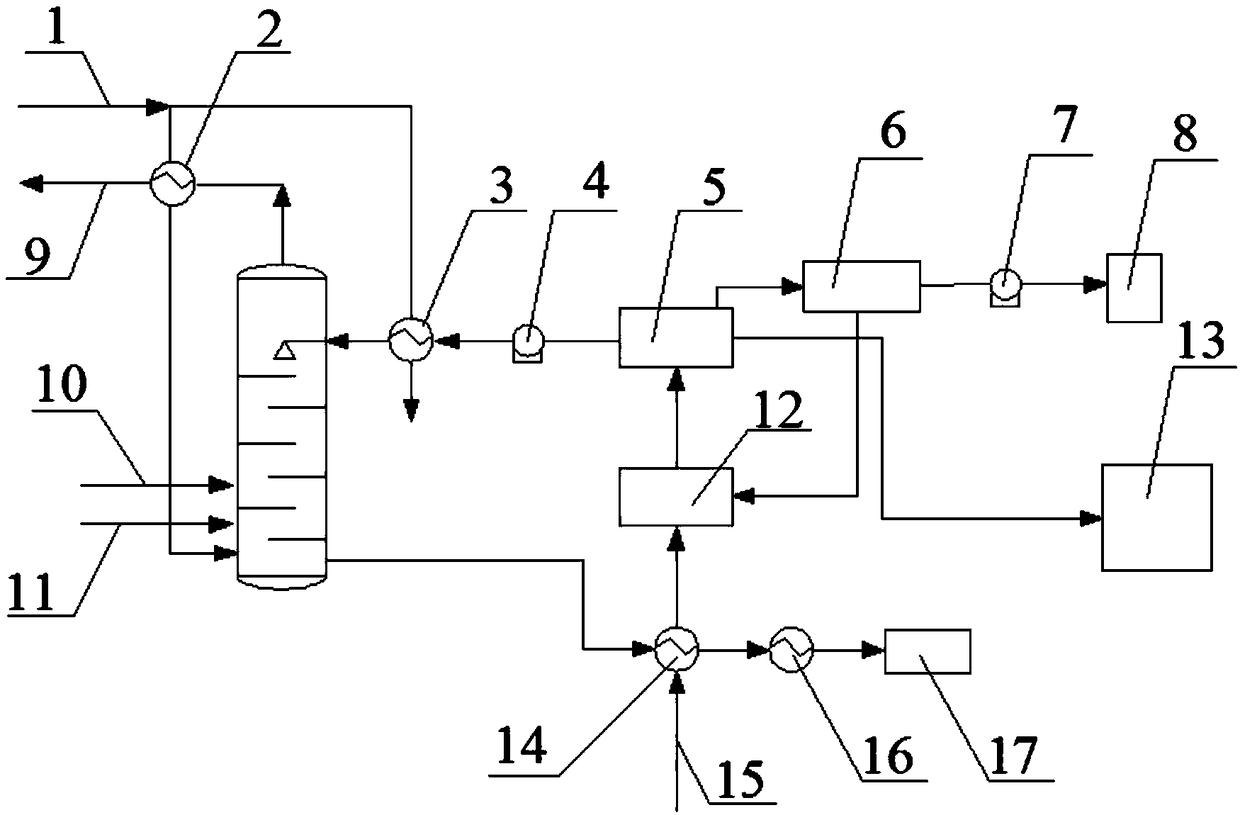

Reaction device and method for producing methyl propionate

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Electronic cigarette tobacco tar and preparing method thereof

InactiveCN106820267ARich aromaMild and comfortable tasteOrganic active ingredientsTobacco treatmentFlavorOrganic solvent

Owner:SHENZHEN HANGSEN STAR TECH

Emission technology of vapor containing nitrogen oxide and tar

ActiveCN108854458AImprove the efficiency of absorbing harmful components in exhaust gasPrevent control failure problems caused by errorsGas treatmentDispersed particle separationAtmospheric airExhaust gas emissions

The invention discloses an emission technology of vapor containing nitrogen oxide and tar. The emission technology comprises the following steps: opening a cutoff valve, a circulating water pump and an exhaust fan, wherein the circulating water pump starts a water circulation process; opening a discharging valve and releasing calcium hydroxide into water in a stepped overflow pool, and opening thedischarging valve when the pH value of the water in the stepped overflow pool is smaller than or equal to 8.0; closing the discharging valve when the pH value of the water in the stepped overflow pool is greater than or equal to 8.7; when an adjustment target is to prevent haze and the temperature of exhaust gas is greater than or equal to 90 DEG C, stopping the temperature-regulating operation;opening the temperature-regulating operation again when the temperature of the exhaust gas is smaller than 80 DEG C; stopping the temperature-regulating operation again when the adjustment target is to prevent thermal pollution and the difference value between the temperature of the exhaust gas and the atmospheric temperature is smaller than 3 DEG C; opening the temperature-regulating operation when the difference value between the temperature of the exhaust gas and the atmospheric temperature is greater than 6 DEG C. The emission technology disclosed by the invention can efficiently remove sulfur dioxide and nitrogen oxide from water, the weak alkalinity of water is maintained on the premise of ensuring safety and the emission temperature of the exhaust gas is correspondingly controlled according to different adjustment targets.

Owner:HENAN SONGYUE CARBON

Gas liquor purification treatment system after coal gasification

PendingCN108911345AReduce contentReduce pollutionWater treatment parameter controlFatty/oily/floating substances removal devicesEngineeringImpurity

Owner:SHANXI HEIMAO JIAOHUA CO LTD

Filter Cigarette Holder

InactiveUS20180360105A1Increasing the thicknessIncrease airflowCigarette manufactureTobacco smoke filtersFiltrationTar

This invention relates to a filtering device for use with cigarettes and other smoking products. Embodiments of the invention include a cigarette holder equipped with pressure filtering. Embodiments may be smaller than about 20 mm, include a separate semi-closed collection chamber to prevent “backwash” of tar which would otherwise occur due to the filter's small size, require less material than current cigarette filters, enable more effective filtration, increase filter capacity for holding tar, and provide additional benefits resulting from the greater likelihood of use by smokers. Another embodiment would include the replacement of the plastic casing with paper, creating a filter made mostly of naturally biodegradable material.

Owner:HIGGINS EUGENE

Two-section semi-hollow cigarette preventing lower half tobacco shreds from taste change caused by fumigation

Owner:长沙深蓝未来智能技术有限公司

Transport vehicle crown rubber

Owner:QINGDAO SANHUI RUBBER MACHINERY MFG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap