Gas liquor purification treatment system after coal gasification

A technology for purification treatment and coal gasification, which is applied in oxidation water/sewage treatment, gaseous discharge wastewater treatment, water/sewage treatment, etc. Effects of pollution, reduced consumption, and reduced energy consumption in water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

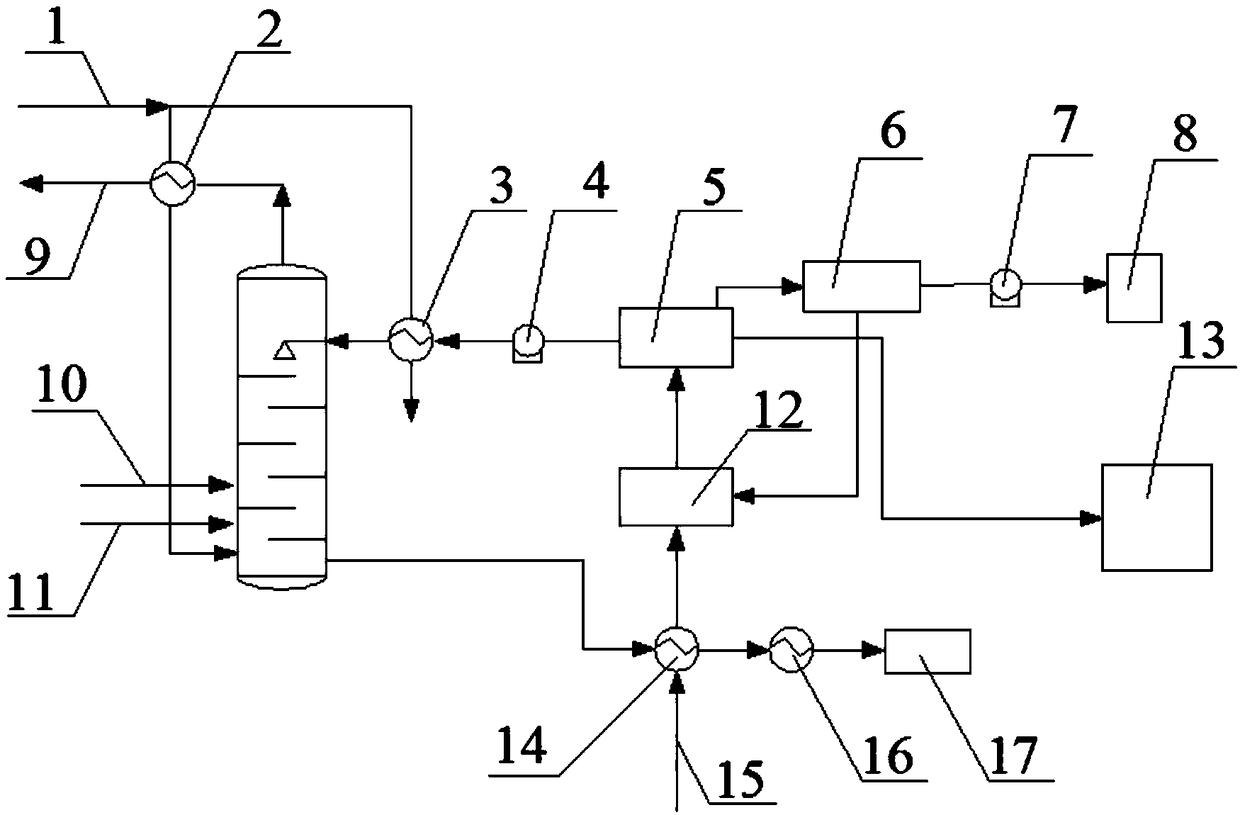

[0015] The invention discloses a system for purifying gas water after coal gasification, such as figure 1 As shown, the gas water enters the main pipeline 15, and the gas water main pipeline 15 is high-temperature and dusty gas water. 15 is connected to the cold source inlet of the third heat exchanger 14, and through the third heat exchanger 14, the high-temperature dusty gas water and the gas water treated by the stripping tower are exchanged to make full use of heat energy and reduce production costs.

[0016] The cold source outlet of the third heat exchanger 14 is connected to the raw material inlet of the stripper through the decompression separation unit, and the decompression separation unit is also connected with a tar collection unit, and the decompression separation unit is used to remove the tar in the gas water, and the stripper Us

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap