Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Ptru catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

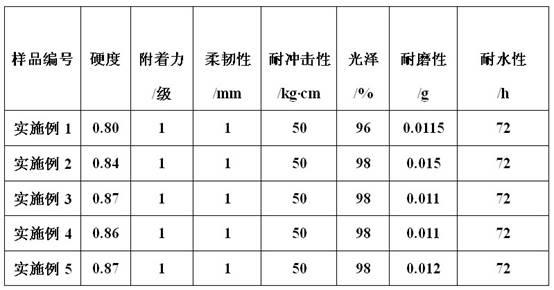

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

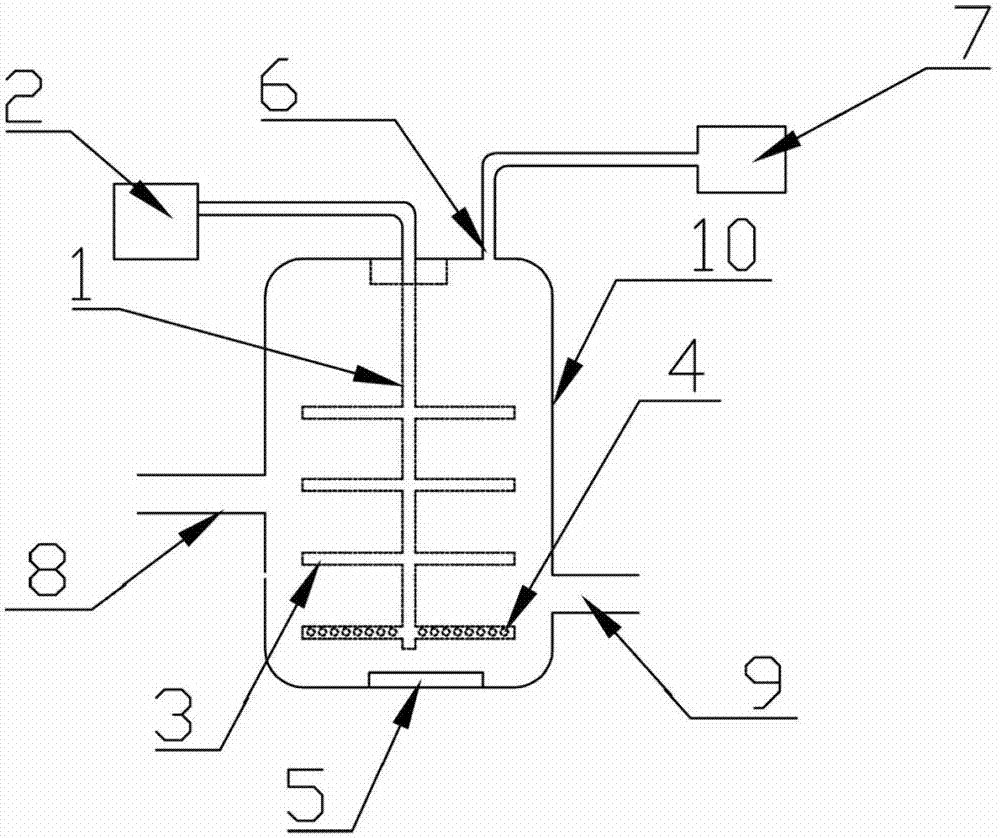

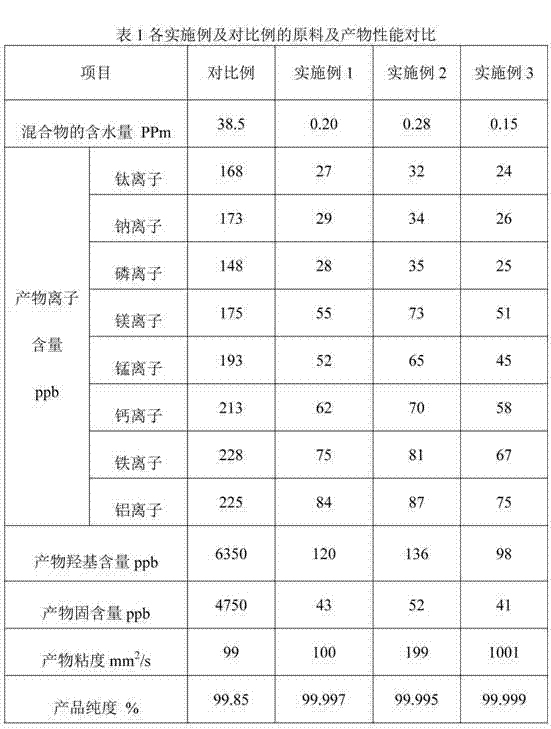

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

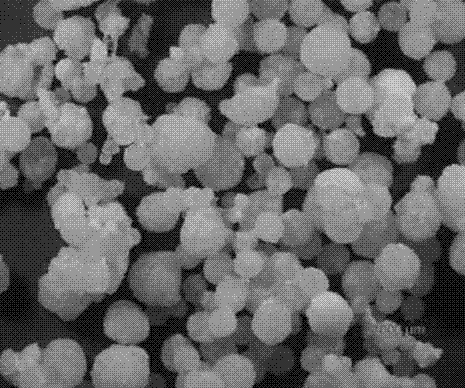

Spherical polybutylene-1 with high isotacticity and preparation method thereof

ActiveCN103288993AThe polymerization method is simpleSolve the difficulty of simultaneously controlling the isotacticity of polybuteneButenePolymer science

Owner:QINGDAO UNIV OF SCI & TECH

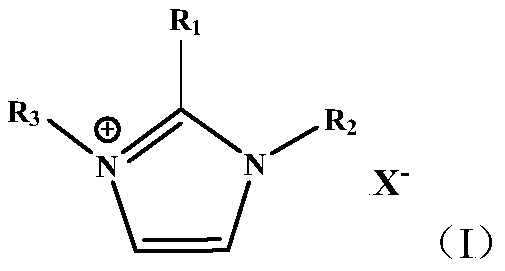

Novel disulfonic acid type alkyl imidazole ionic liquid, preparation and uses thereof

ActiveCN101508675AStable waterStrongly acidicOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystOrganic synthesis

The invention discloses a novel disulfonate type alkyl imidazole ionic liquid as well as a preparation method and application thereof. Structure of the ionic liquid is shown as formula (I), and the preparation method of the ionic liquid comprises the followings steps: trimethylsilylimidazole with structure shown as formula (II) is dropwise added to sultones with the structure shown as formula (III) for heat insulation reaction at the temperature of minus 20 DEG C to 30 DEG C, then water is dropwise added for continuing the heat insulation reaction to obtain an intermediate product (a zwitterionic compound) with the structure shown as formula (IV); an HY acid is dropwise added to aqueous solution of the zwitterionic compound to obtain a target product after full reaction at the temperature of 60-100 DEG C. The designed ionic liquid is hydrostable, almost has no steam pressure, especially has strong acidic properties, exhibits good catalytic activity when being applied to pechmann reaction, and a synthetic method thereof has environment-friendly feature, thus being expected to be applied to organic synthesis and catalysis fields as an environment-friendly solvent and catalyst.

Owner:ZHEJIANG UNIV OF TECH

Terpene resin and preparation method thereof

InactiveCN102633919AEliminate quality impactEliminate the effects ofFood preparationTrimethylsilyl chloridePolymer science

The invention discloses a terpene resin and a preparation method thereof. The preparation method comprises steps as follows: terpene substances are used as a raw material, AlCl3 in the presence of an aromatic solvent is used as a main catalyst, and a cocatalyst is used in the reaction; polymerization is carried out at low temperature to prepare the crude terpene resin product; and the crude terpene resin product is washed and distilled under reduced pressure to obtain the terpene resin product. The cocatalyst is trimethylchlorosilane, triethylchlorosilane, tripropylchlorosilane or tributylchlorosilane, and accounts for 1-5% of the total mass of the terpene substance raw material; the main catalyst AlCl3 accounts for 4-12% of the total mass of the terpene substance raw material; the elemental chlorine content in the prepared terpene resin product is less than 100mg / kg, and the metallic aluminum content is less than 10mg / kg; the terpene resin product does not contain metallic antimony; and the residue level of the volatile solvent is less than 25mg / kg. The product reaches to the food level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Preparation method of manganese-based composite metal oxide ozonolysis catalyst

InactiveCN109833868AHigh activityImprove stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOzonolysis

The invention provides a preparation method of a manganese-based composite metal oxide ozonolysis catalyst, and belongs to the fields of catalysis and environmental protection. The method uses a redoxprecipitation process to synthesize the nano-fibrous manganese-based composite transition metal oxide catalyst. The preparation method of the catalyst has the advantages of simple process, mild conditions, and realization of high stability of catalytic ozonolysis. The catalyst prepared by the method disclosed in the invention has a high ozone removal catalysis activity, and can realize complete removal of ozone at normal temperature.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

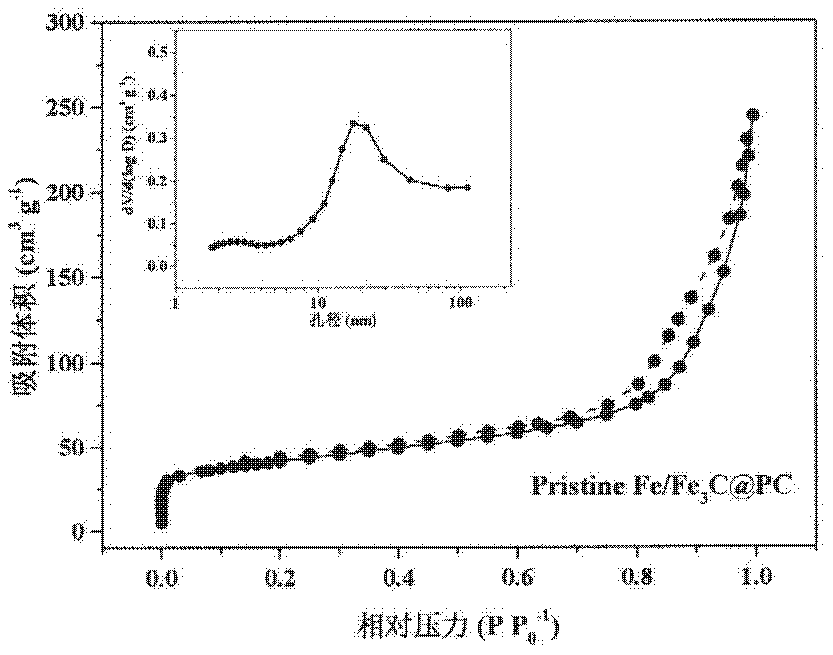

Metal organic framework derived iron-carbon catalyst suitable for heterogeneous electro-Fenton process and preparation method thereof

PendingCN111111661ASimple and fast operationLow equipment requirementsWater treatment compoundsWater contaminantsPtru catalystPorous carbon

Owner:NANKAI UNIV

Method for forming ultrathin-wall porous metal pipe fitting

Owner:UNIV OF SCI & TECH BEIJING

Ethylene oligomerization catalyst and use thereof

InactiveUS20110124938A1Easy to synthesizeLittle catalyst deteriorationHydrocarbons from unsaturated hydrocarbon additionCatalyst regeneration/reactivationOligomerPtru catalyst

Ethylene is oligomerized with a catalyst in which nickel is supported on a support containing silica and alumina. The catalyst has little deterioration over long periods and affords oligomers with high productivity.The ethylene oligomerization catalyst includes a support and a nickel compound supported on the support, the support including silica and alumina, and the amount of nickel supported is in the range of 0.0001 to 1 wt % based on the weight of the support, and the molar ratio of silica to alumina in the support (SiO2 / Al2O3) is in the range of 100 to 2000. In a process of the invention, ethylene is oligomerized with use of the catalyst.

Owner:MITSUI CHEM INC

Cobalt-aluminum composite oxide catalyst and preparation method and application thereof

PendingCN110433806ALarge specific surface areaLarge transport channelIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCatalytic transformationPtru catalyst

The invention relates to the technical field of catalyst preparation, and discloses a cobalt-aluminum composite oxide catalyst and a preparation method and application thereof. The preparation methodcomprises the steps that metal salt solutions of cobalt and aluminum are taken as precursors correspondingly, polymer microspheres are taken as a template agent, templates are soaked in the precursorsolutions, then impregnation and roasting are conducted, and thus the cobalt-aluminum composite oxide catalyst is obtained. A three-dimensional ordered hierarchical pore structure with a mesoporous and macroporous structure is created through the polymer microspheres, thus the specific surface area of the catalyst is increased, the prepared catalyst has a large transmission pore channel, reactantmodules enter the pore channel from all directions advantageously, the diffusion resistance is lowered, thus the convective mass transfer efficiency between gases is improved, and the catalytic activity of the cobalt-aluminum composite oxide catalyst is facilitated; and meanwhile, through the large transmission channel, the situation that the modules are blocked when reacting on the pore wall or the pore channel of the transmission channel, and consequently, the reaction progress is influenced can further be effectively avoided, and the catalytic conversion efficiency of the catalyst is improved.

Owner:FUZHOU UNIV

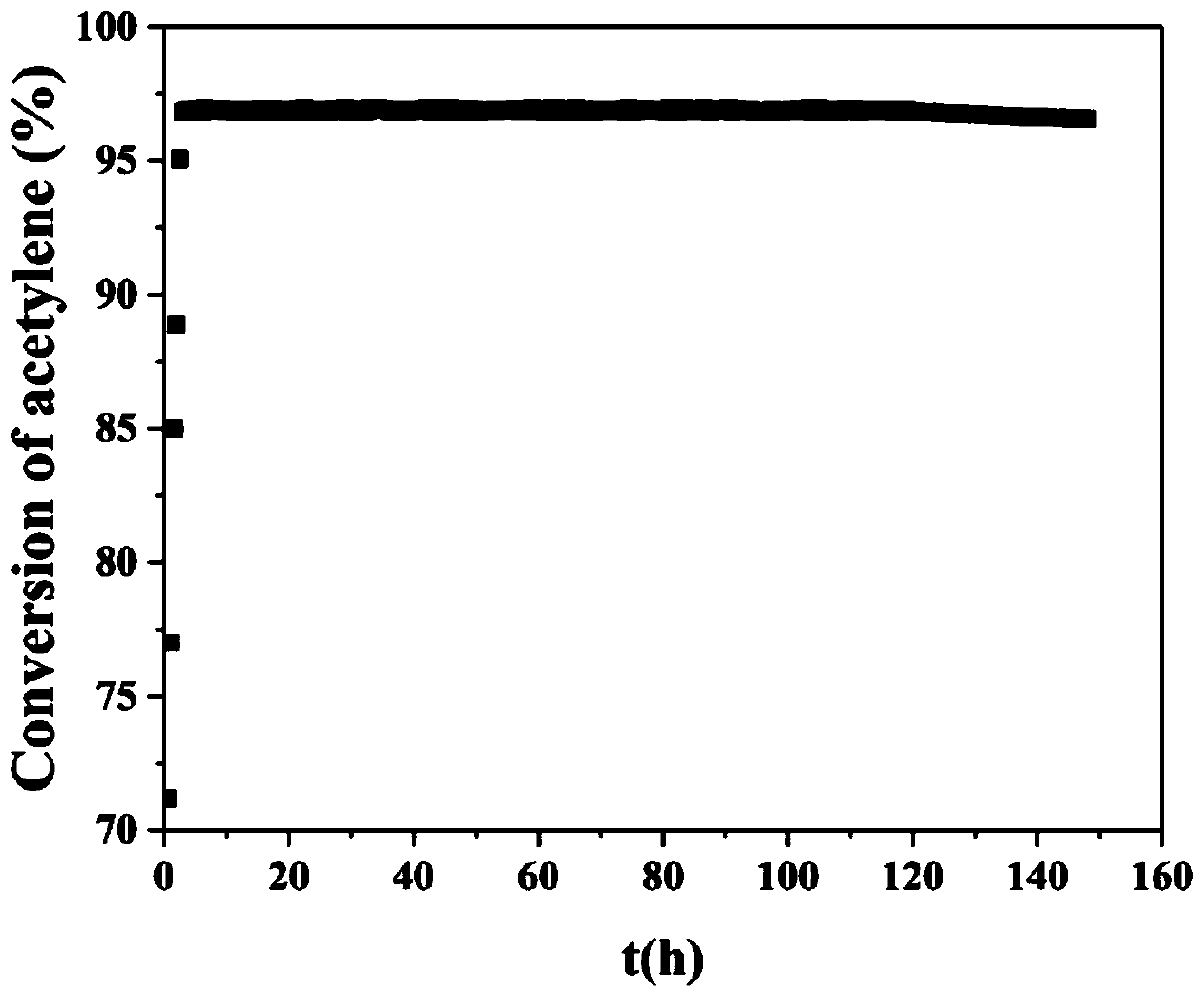

Trivalent copper catalyst and preparation method thereof and application to hydrochlorination of acetylene

ActiveCN110743621AStable structureImprove stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystNitrogenous heterocyclic compound

Owner:ZHEJIANG UNIV OF TECH

Special high-strength modified phenolic resin adhesive for precoated sand and preparation method of special high-strength modified phenolic resin adhesive

InactiveCN105348461AImprove pass rateImprove toughnessFoundry mouldsFoundry coresPolymer sciencePtru catalyst

The invention provides a special high-strength modified phenolic resin adhesive for precoated sand and a preparation method of the special high-strength modified phenolic resin adhesive. The adhesive comprises phenol, formaldehyde, a catalyst, a modifier 1, a modifier 2 and silane, wherein the mole ratio of phenol to formaldehyde is 1:(0.7-0.8), the adding quantity of the modifier 1 accounts for 3%-30% of the mass of phenol, the adding quantity of the modifier 2 accounts for 0.5%-10% of the mass of phenol, and the adding quantity of silane accounts for 0.3%-0.8% of the mass of phenol. The preparation method is simple and convenient to operate, and reduction of the enterprise cost and promotion of energy saving and emission reduction are facilitated. The adhesive and the preparation method can be applied to the field of adhesives.

Owner:ZHUHAI DOUMEN FULIAN MOLDING MATERIALS IND CO LTD

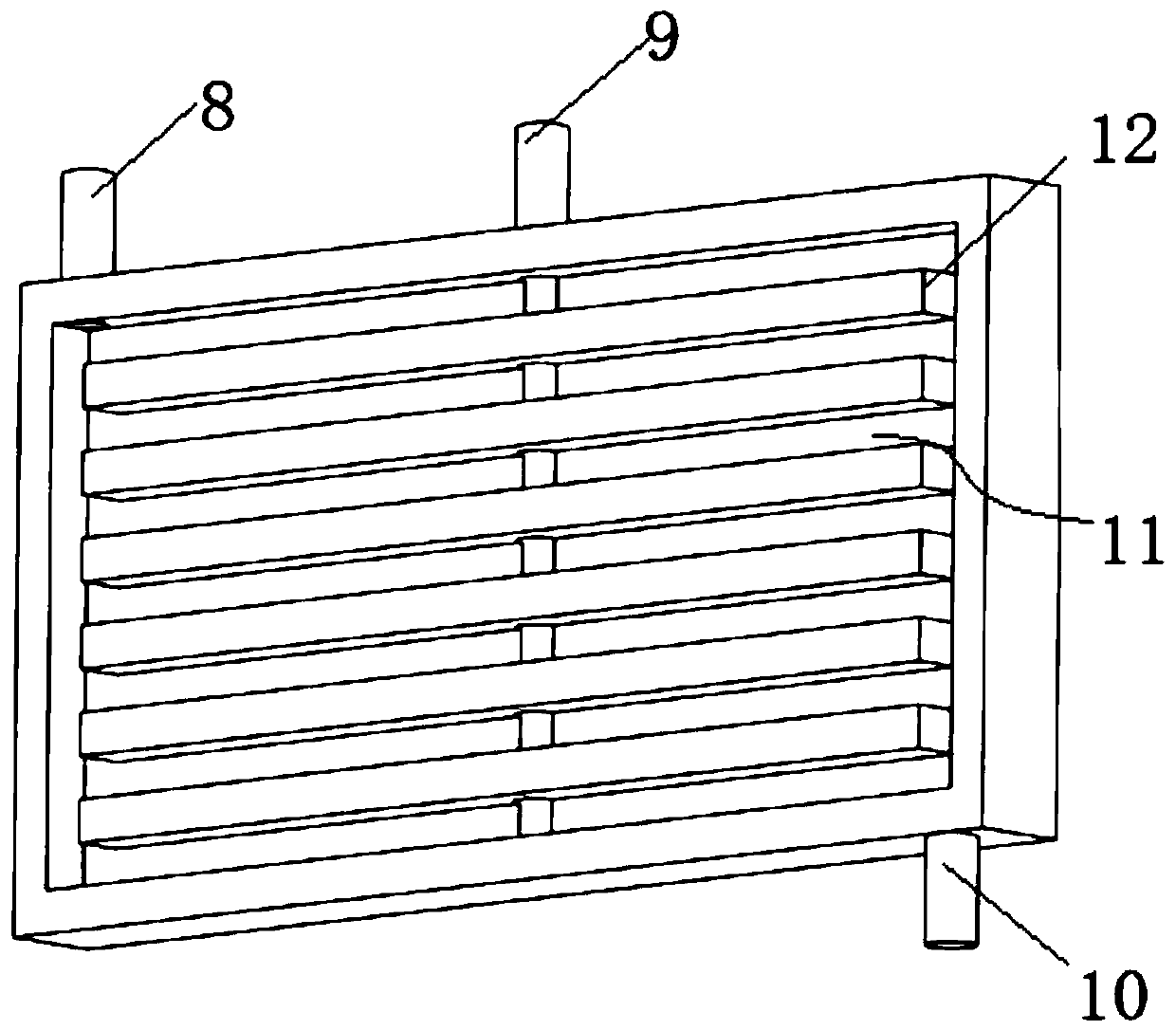

Fluidized-bed reaction device and fluidization reaction method for hydrogenation of nitrobenzene

ActiveCN111298727AImprove fluidization qualityReduce the presence of air bubblesOrganic compound preparationAmino compound preparationPtru catalystGas phase

The invention relates to a fluidized-bed reaction device and a fluidization reaction method for hydrogenation of nitrobenzene. The invention mainly aims to solve the problems of low gas-solid contactefficiency, large bubble size, low fluidization quality and the like in a fluidized bed. According to a technical scheme in the invention, at least one group of composite components are arranged in afluidized-bed reactor, so when gas and catalyst particles pass through the components, bubbles and particle clusters are broken, fluidization quality is effectively improved, and the above technical problems are well solved; and the device and the method can be applied to industrial production of gas-phase catalytic hydrogenation of nitrobenzene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation technology of perfluoropolyether for resin

Owner:XUZHOU ZENITH COATING

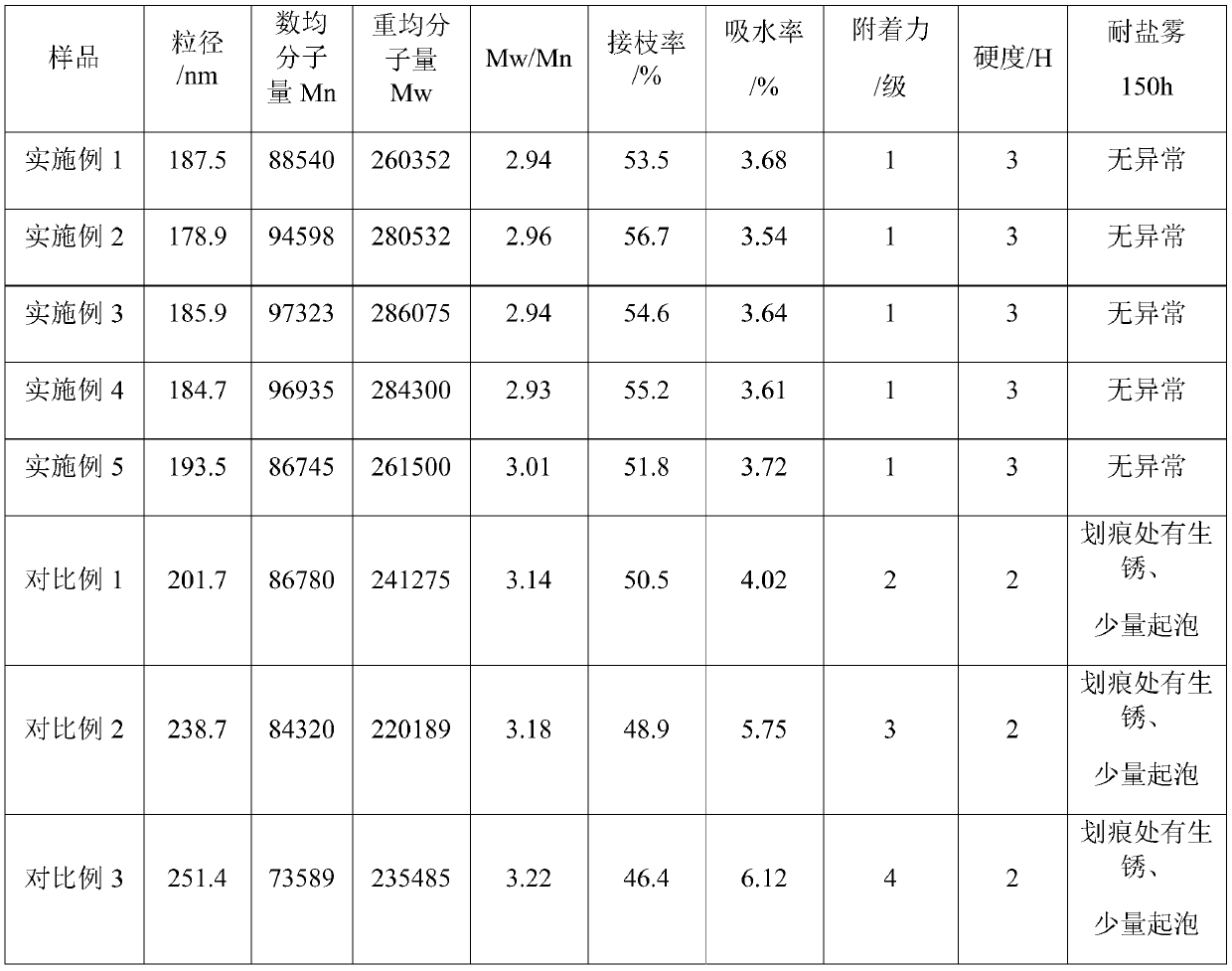

Water-based alkyd-acrylate dispersion as well as preparation method and application thereof

ActiveCN111138603AImprove compactnessImprove the level ofAnti-corrosive paintsPolymer sciencePtru catalyst

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ammoxidation catalyst and preparation method and application thereof

ActiveCN111135829AReduce usageImprove conversion rateHeterogenous catalyst chemical elementsPreparation by hydrocarbon ammoxidationXylylenePtru catalyst

Owner:WANHUA CHEM GRP CO LTD +1

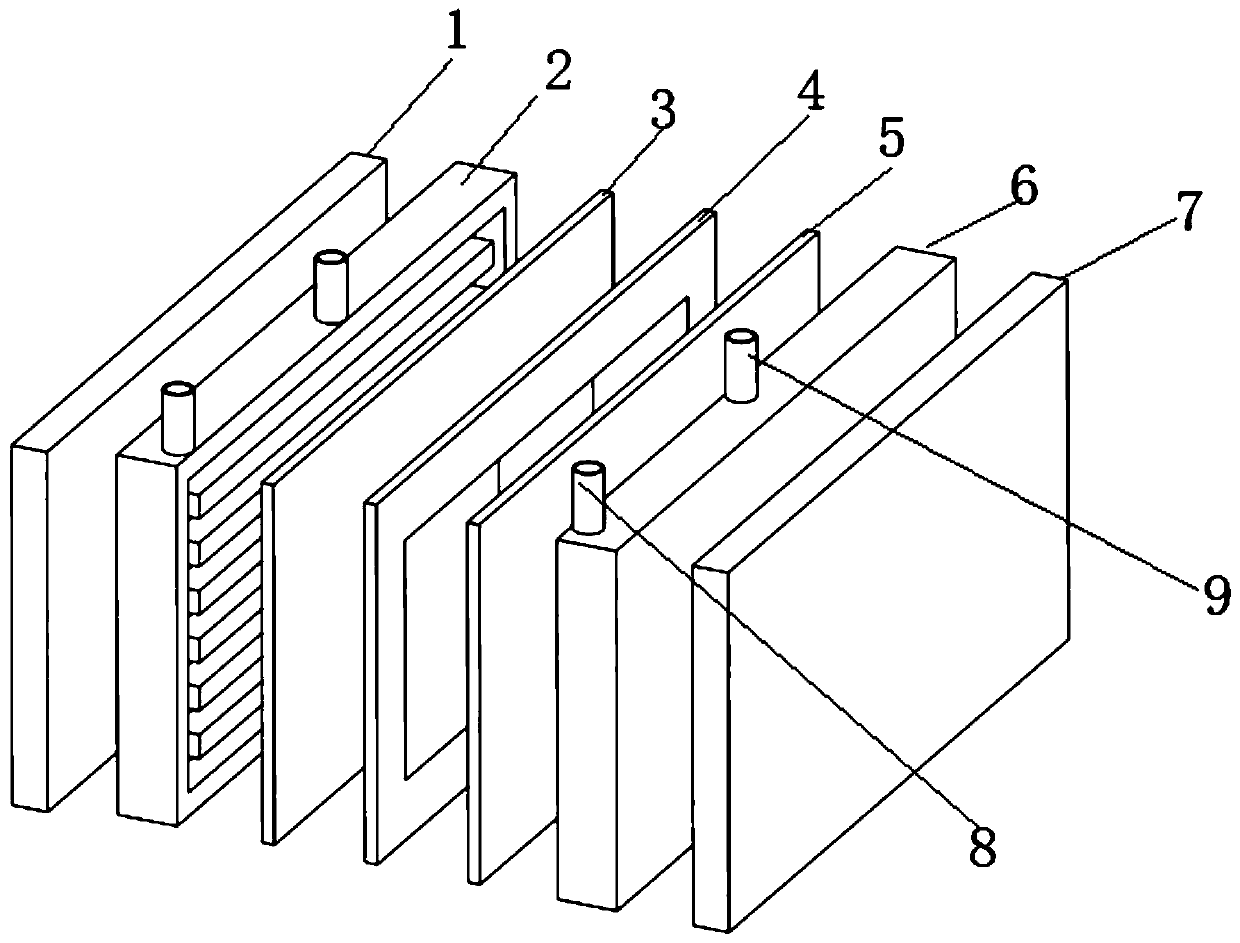

Fuel cell with cathode flow channel flow distribution design and catalyst layer Pt content gradient distribution

PendingCN110661013AEvenly distributedSave Pt amountCell electrodesFinal product manufacturePtru catalystChemical physics

Owner:TIANJIN UNIV OF COMMERCE

Novel fire retardant microencapsulated red phosphorus and preparation method thereof

The invention discloses a novel fire retardant microencapsulated red phosphorus which is formed by wrapping phenol-formaldehyde prepolymer (PFP) on the surface of superfine red phosphorus powder. Due to addition of a high-efficient catalyst in the preparation process, the surface activity of the red phosphorus is improved, the surface of the red phosphorus is tightly wrapped with a PFP layer, and meanwhile as methanol is added to prevent formaldehyde auto-agglutination and the pH value of a reaction solution in the wrapping process is controlled to be 1-6, the stability and the resistivity of the red phosphorus are improved, the machining property is improved, and meanwhile the moisture absorption rate and the PH3 release amount are greatly reduced.

Owner:NANJING UNIV OF SCI & TECH

Lower olefins producing catalyst and method for producing lower olefins using same

ActiveUS20120116143A1Improve efficiencyHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystPtru catalystOxygen compound

A lower olefin producing catalyst which has high olefin production efficiency and maintains its activity for a long period of time when lower olefins are produced from an oxygen-containing compound, which is a solid catalyst used in producing lower olefins from an oxygen-containing compound, includes a solid-state catalyst component containing an MFI-type zeolite, in which, at a position where the shortest distance to the outer surface is maximum among all positions inside a structure of the solid catalyst, the thickness defined as a distance twice the shortest distance from the point to the outer surface is in a range of from 0.1 to 2.0 mm, and a method for producing lower olefins.

Owner:MITSUBISHI CHEM CORP +1

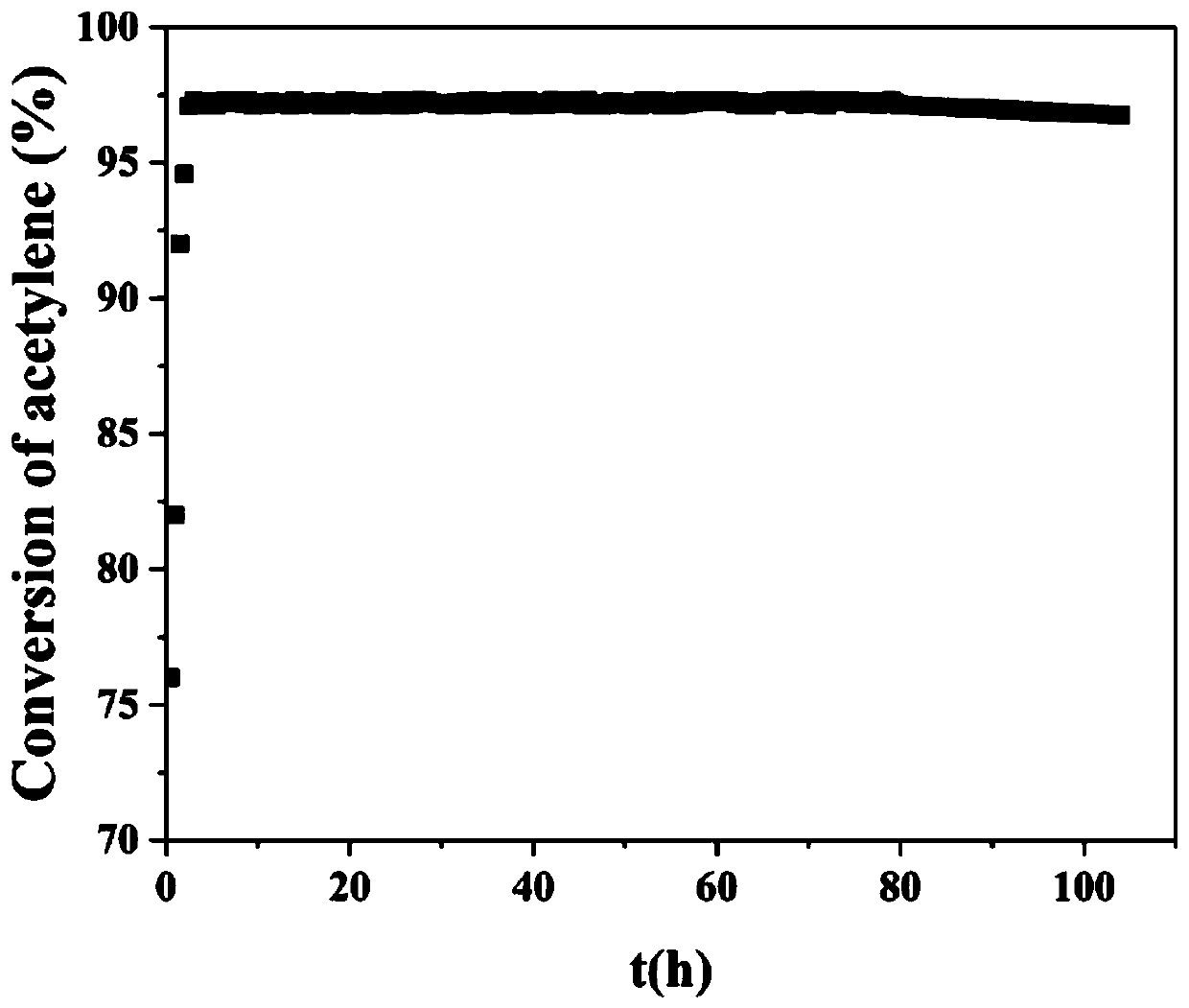

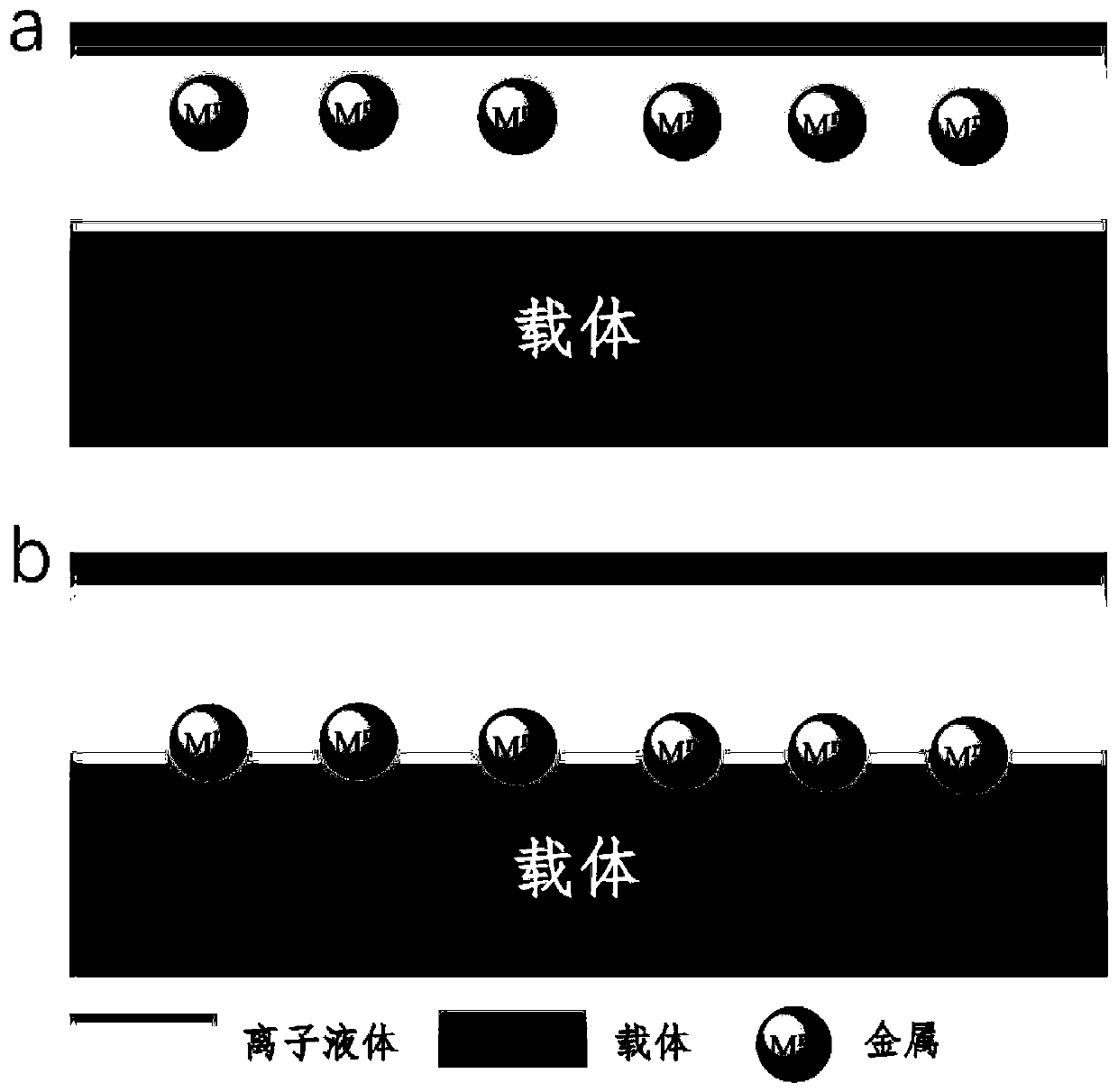

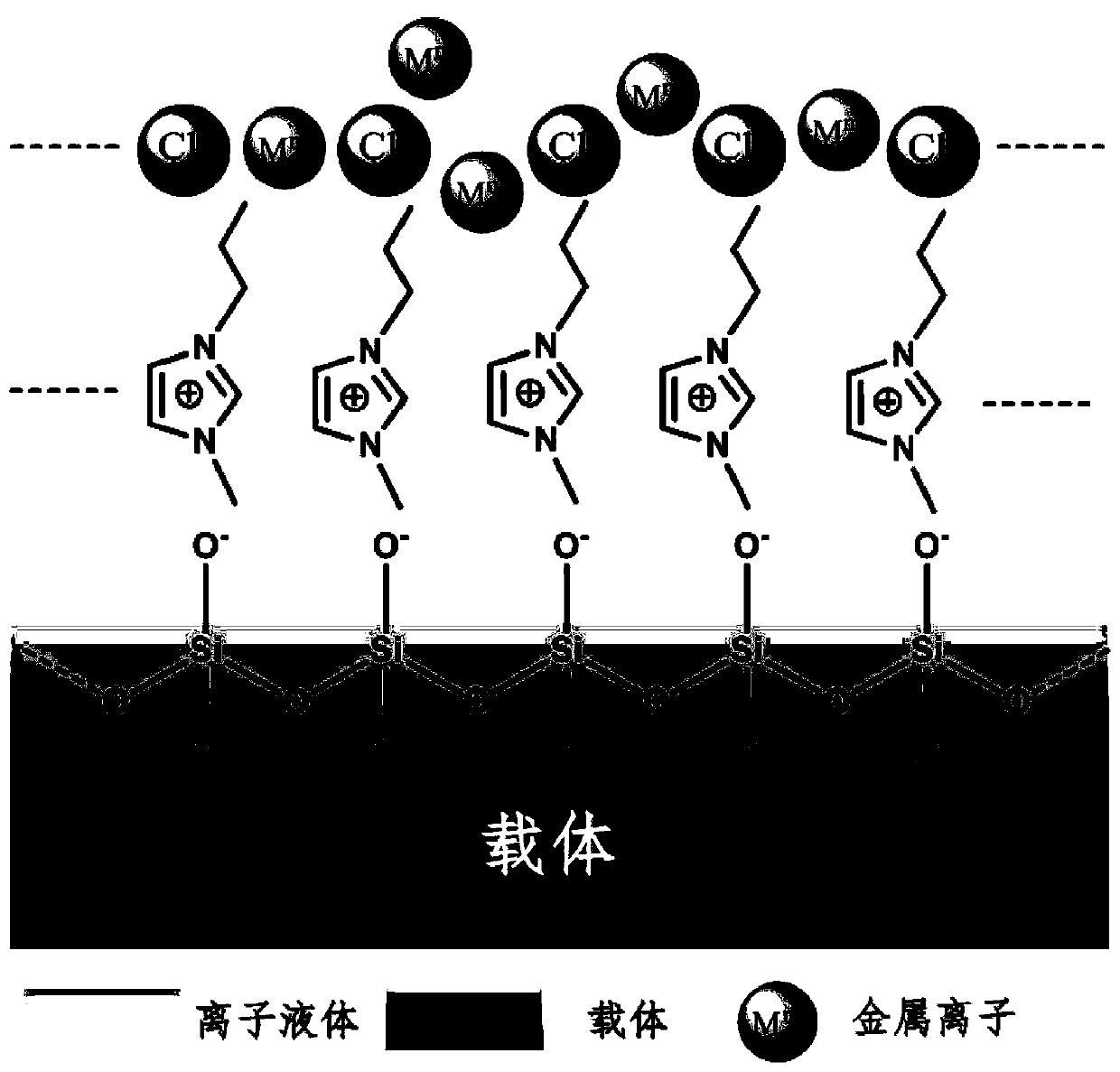

Catalyst loaded with ionic liquid and preparation method and application of catalyst

ActiveCN110743619APreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsMaterials sciencePtru catalyst

Owner:ZHEJIANG UNIV OF TECH

Continuous production equipment and process for hexafluoropropylene oxide oligomer

PendingCN111530383AContinuous operationReduce consumptionChemical recyclingCarboxylic acid halides preparationOligomerPtru catalyst

The invention provides continuous production equipment and a continuous production process for a hexafluoropropylene oxide oligomer. The continuous production equipment comprises a stirring kettle anda liquid phase separation kettle, wherein a stirrer is arranged in the stirring kettle; a discharge pipe is arranged at the bottom of the stirring kettle; a discharge pipe is arranged at the bottom of the liquid phase separation kettle; the discharging pipe is communicated with the discharge pipe through a feeding pipe; the feeding pipe is provided with a conveying pump; the top of the stirring kettle is communicated with the top of the liquid-phase separation kettle through a liquid-phase circulating pipe and a gas-phase circulating pipe respectively; the liquid-phase circulating pipe is provided with a circulating pump; the gas-phase circulating pipe is provided with a condenser; one end of the liquid-phase circulating pipe, which is positioned at the liquid-phase separation kettle, extends into the lower part of the liquid-phase separation kettle; and one end of the liquid-phase circulating pipe, which is positioned at the stirring kettle, is connected with a nozzle. The equipmentand the process have the advantages of continuous production, simplicity in operation, high production efficiency, stable product quality and the like, meanwhile, the catalyst, the solvent and byproducts can be recycled, and the process is low in cost and environmentally friendly.

Owner:JIUDING FLUORIN CHEM CO LTDZHANGPING FUJIAN

Method Of Controlling A Polymerization Reactor

Embodiments of the invention provide a method of controlling a gas-phase polymerization process. The method includes determining a difference between a control variable of the polymerization process, such as the production rate, and the desired value of the control variable; adjusting or maintaining a first manipulated variable to at least partially compensate for the difference between the control variable and the desired value; and adjusting or maintaining a second manipulated variable to at least partially compensate for the effect of adjusting or maintaining the first manipulated variable. The first and second manipulated variables can include process variables such as the fluidized bed weight, the catalyst concentration, the concentration of one or more monomers, the flow of one or more comonomers, the ratio of one comonomer to another comonomer, the activator concentration, the ratio of an activator to selectivity control agent, the concentration of a chain transfer agent, and the retardant concentration.

Owner:DOW GLOBAL TECH LLC

Preparation method of porous rod-shaped spinel structured catalyst

InactiveCN105854892AHigh catalytic activitySynthesis temperature is lowGas treatmentDispersed particle separationAnhydrous ethanolPtru catalyst

The invention relates to a preparation method of a catalyst, and concretely relates to a preparation method of a porous rod-shaped spinel structured catalyst. The preparation method comprises the following steps: respectively preparing an A type metal salt solution and a B type metal salt solution by using deionized water; measuring the above two solutions, and uniformly mixing the two solutions under magnetic stirring to obtain a clarified dark blue solution; gradually adding an NH4(OH) solution to the above obtained mixed solution, and adding cetyltrimethylammonium chloride to water to form gel; preparing an aqueous solution of hydrazine hydrate, continuously heating the above stirred mixed solution, and cooling the heated mixed solution to room temperature in order to obtain a green fluffy solid product; washing the solid product with deionized water and anhydrous ethanol multiple times, and drying the washed solid product to obtain solid powder; and transferring the solid powder to a quartz reactor, and heating and calcining the solid powder to obtain fluffy powder. The catalyst solves the technical problem of unsatisfactory purification of PM in diesel car tail gas.

Owner:SHENYANG UNIV

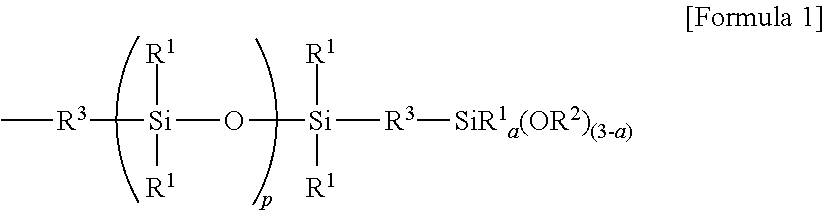

Process for producing polyethylene

The present invention relates to a process for producing ethylene copolymers in a multistage process comprising at least one slurry phase polymerization stage and at least one gas phase polymerization stage in the presence of Ziegler Natta catalyst comprising a solid catalyst component, a cocatalyst of a compound of group 13 metal and an external additive selected from alkoxysilanes of formula (I) R1nSi(OR2)4-n, (I) where n is an integer 0 to 3, each R1 are equal or different and are selected among H, halogen, alkyl groups of 1 to 6 10 carbon atoms optionally substituted with one or more halogen atoms, alkenyl groups of 2 to 6 carbon atoms optionally substituted with one or more halogen atoms, and aryl groups of 6 to 12 carbon atoms optionally substituted with one or more halogen atoms, or the R1 groups can form with the Si atom they are linked to a ring of 3 to 8 ring atoms, provided that all R1 are not hydrogen, R2 are equal or different and are selected among alkyl groups of 1 to 6 carbon atoms optionally substituted with one or more halogen atoms, alkenyl groups of 2 to 6 carbon atoms optionally substituted with one or more halogen atoms, and aryl groups of 6 to 12 carbon atoms optionally substituted with one or more halogen atoms, or the OR2 groups can form with the Si atom they are linked to a ring of 3 to 8 ring atoms, halogen is Br, Cl or F. The invention further relates to the catalysts and use thereof in said multistage process r for producing ethylene copolymers having melt flow rate ratio FRR21 / 5 at least 40 and / or polydispersity index PDI of at least 27.

Owner:BOREALIS AG

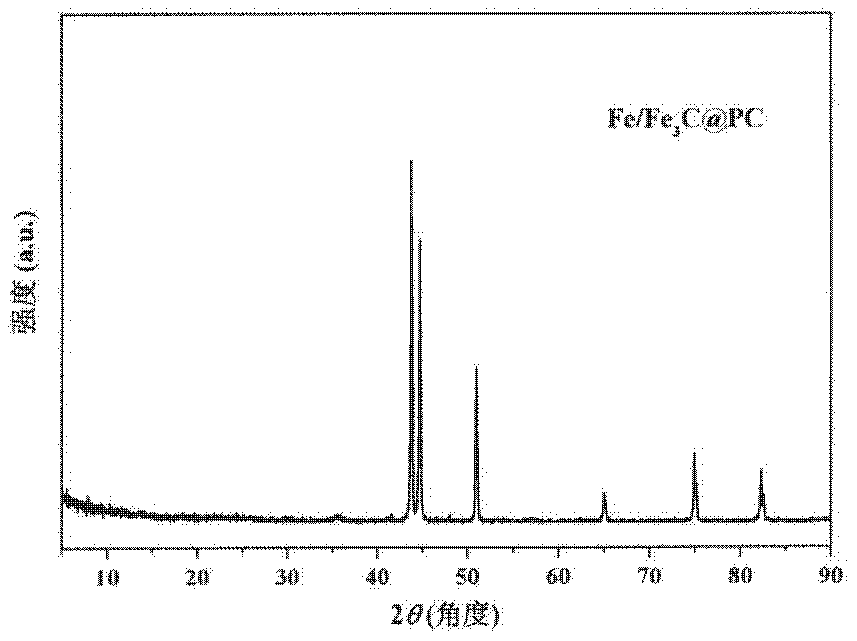

Preparation method and application of hierarchical porous molecular sieve-supported PtRu catalyst

ActiveCN107971019AHighly reactive bit density CelsiusOpen cell structureMolecular sieve catalystsOrganic compound preparationMolecular sieveEmulsion

The invention relates to a preparation method for a hierarchical porous molecular sieve-supported PtRu catalyst and a method for reducing 4-nitrophenol. According to the present invention, PtRu alloynano-particles are successfully introduced into microporous channels of a hierarchical porous molecular sieve EMT-FAU / SBA-15 by using of microwave assisted heating and a specific blended microcrystalline emulsion synthetic method, and the PtRu alloy nano-particles prepared by the method has relatively high stability because of confinement effect of the molecular sieve, meanwhile, the prepared PtRu / EMT-FAU / SBA-15 catalyst shows excellent catalytic performance in a reduction reaction of 4-nitrophenol, and results show that the element proportions in PtRu alloy plays an important role in the reduction reaction of 4-nitrophenol.

Owner:UNIV OF JINAN

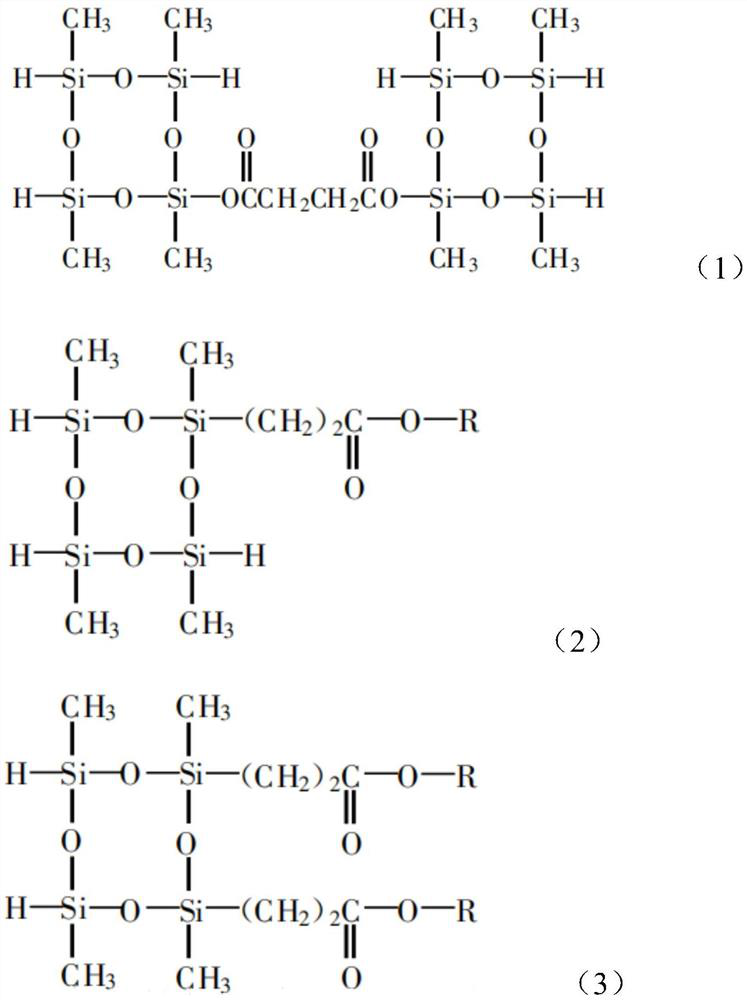

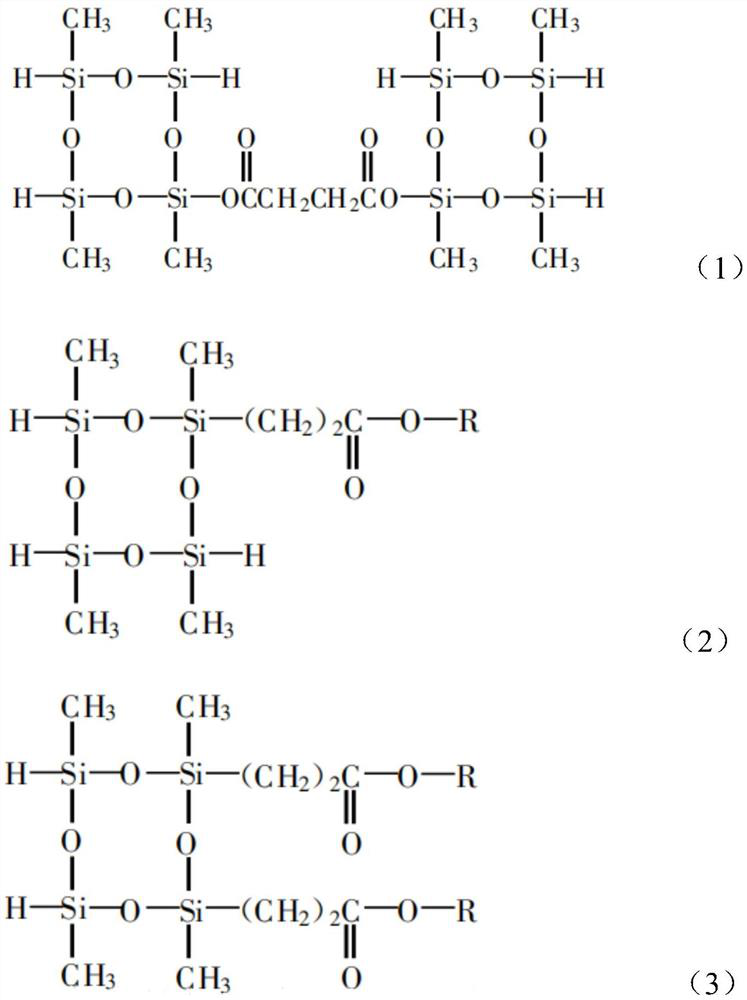

Thermally-conductive silicone gel composition, thermally-conductive member, and heat dissipation structure

ActiveUS20200239758A1Improve liquidityGood peeling effectSemiconductor/solid-state device detailsSecondary cellsPolymer sciencePtru catalyst

Owner:DOW TORAY CO LTD

Honeycomb denitration catalyst with water resistance and preparation method therefor

InactiveCN105413678AHigh mechanical strengthExtended service lifeGas treatmentDispersed particle separationPtru catalystFlue gas

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

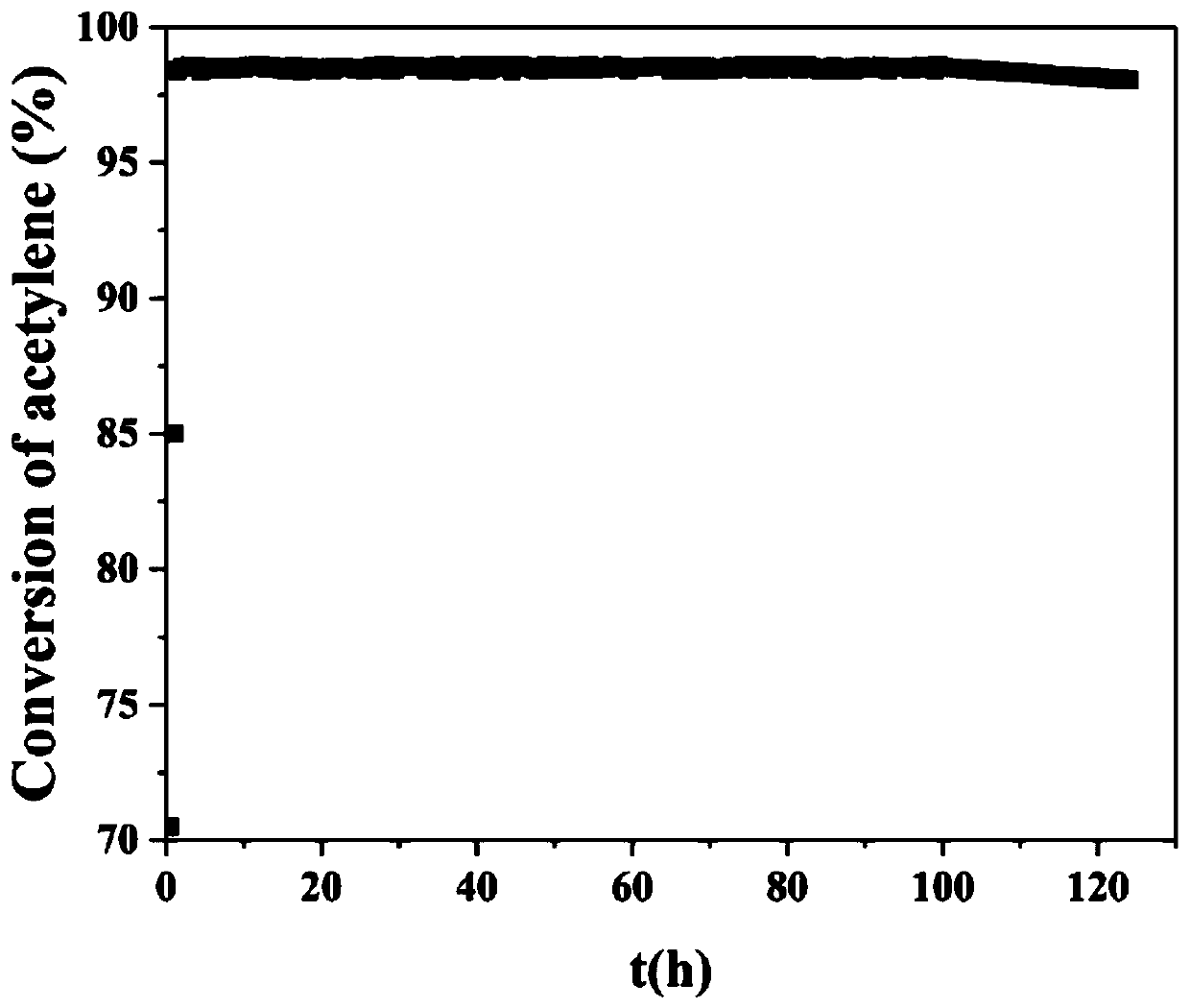

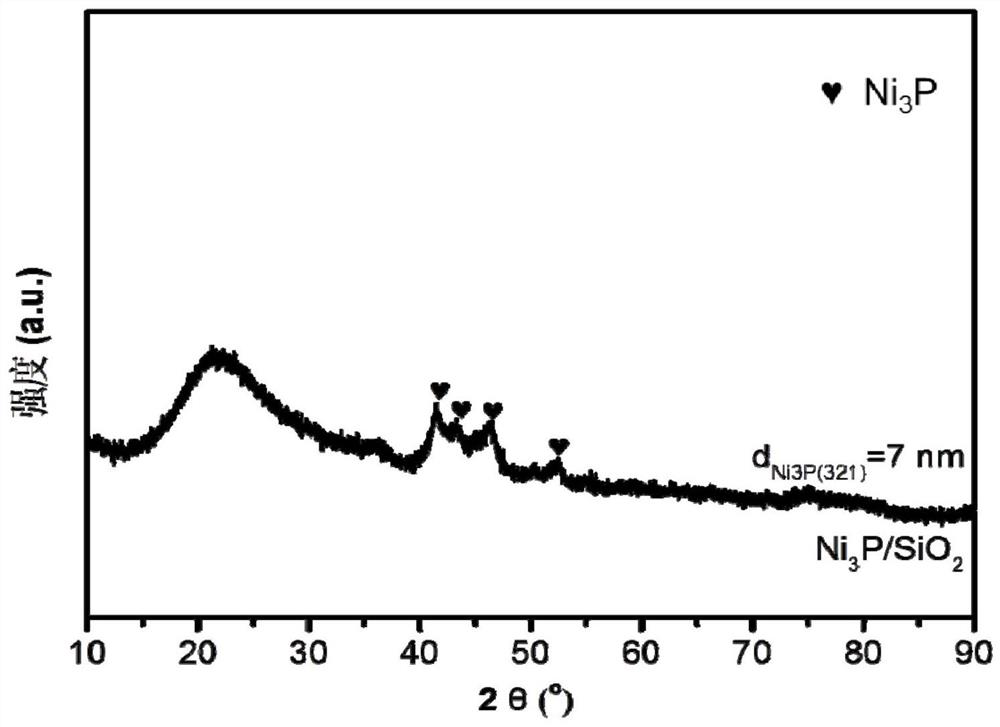

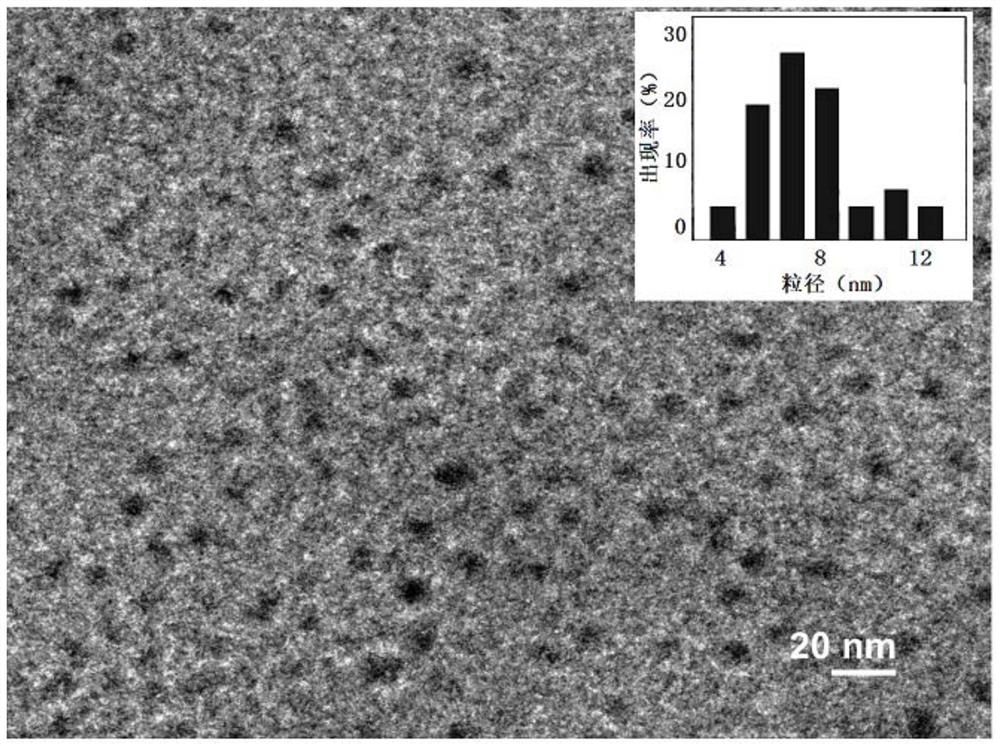

Ni3P/SiO2 catalyst as well as preparation method and application thereof

ActiveCN113145144AHigh selectivityAvoid signs of inactivationPhysical/chemical process catalystsOrganic compound preparationPtru catalystCombinatorial chemistry

Owner:EAST CHINA NORMAL UNIV

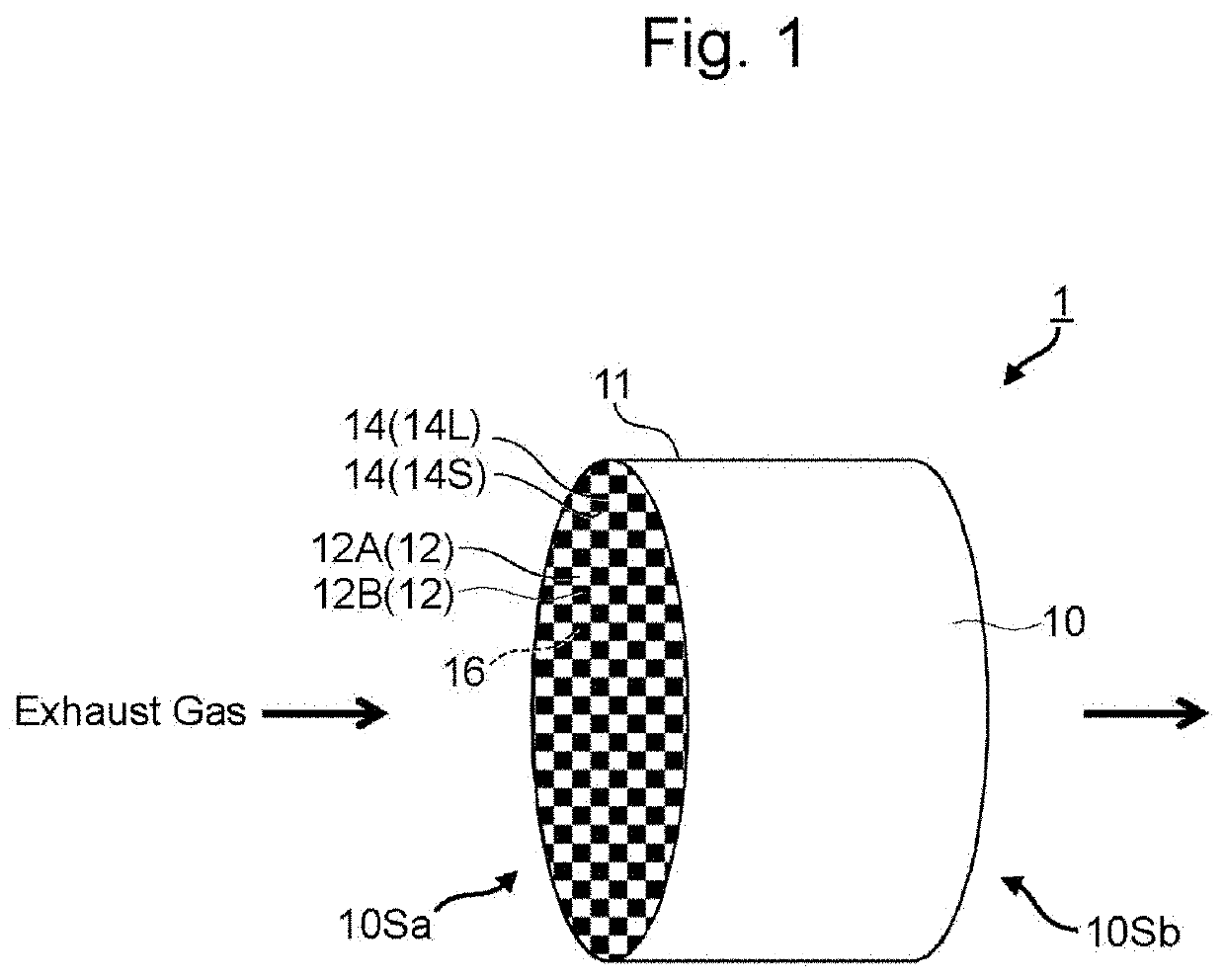

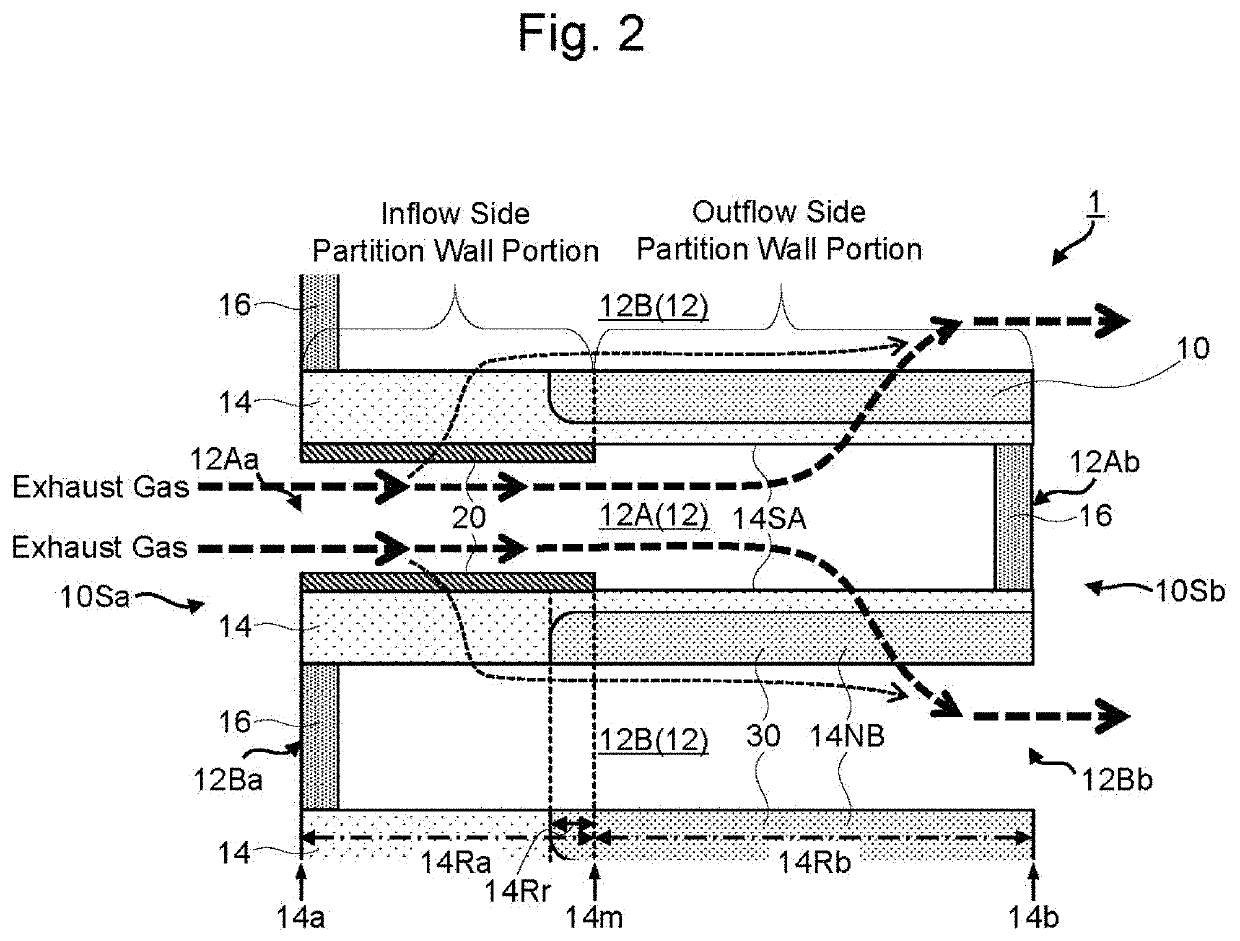

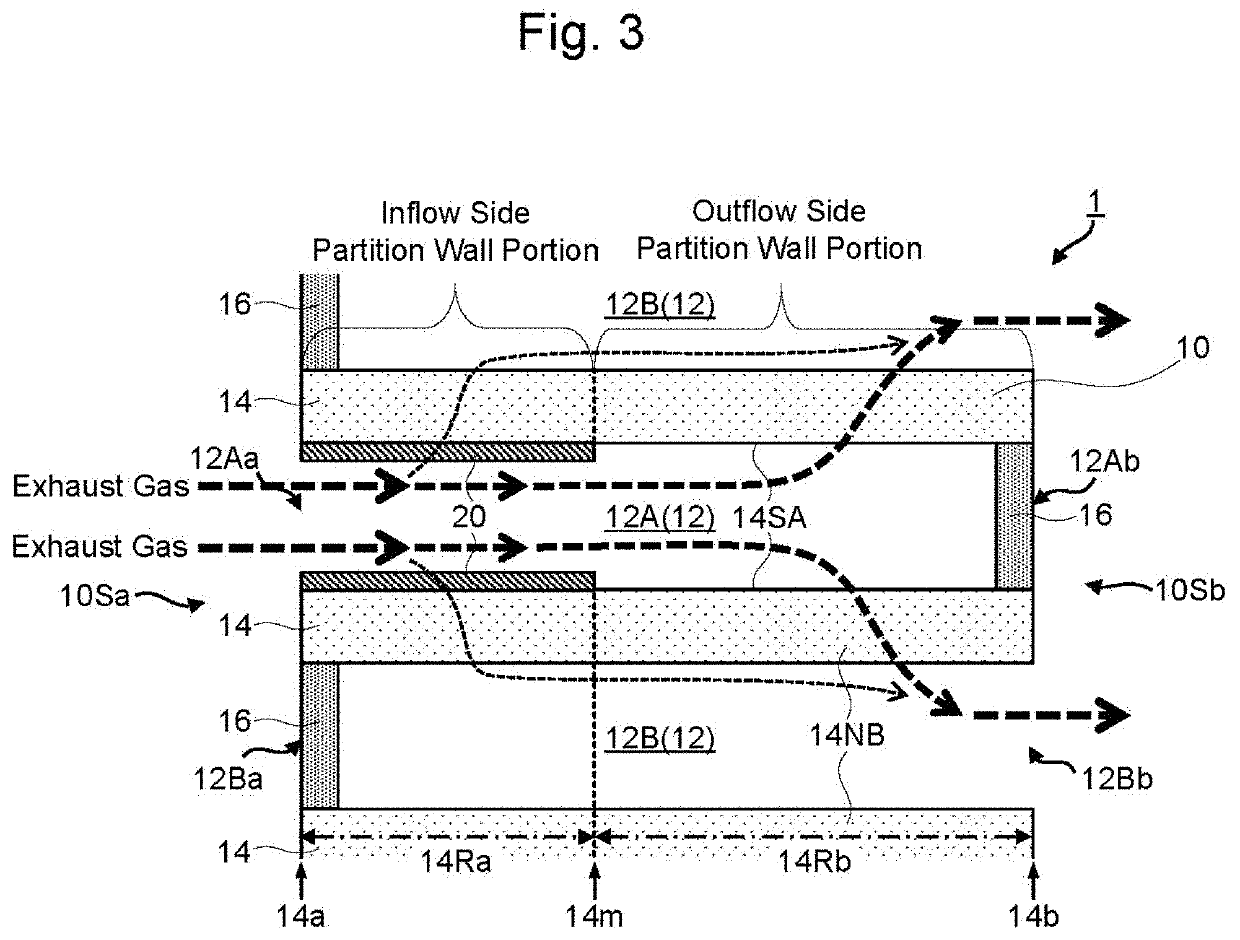

Exhaust gas purification device

ActiveUS20210283589A1Improve purification effectSuppress pressure lossGas treatmentInternal combustion piston enginesPtru catalystExhaust fumes

Owner:TOYOTA JIDOSHA KK +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap