Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24 results about "Fluidized bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fluidised bed is a physical phenomenon occurring when a quantity of a solid particulate substance (usually present in a holding vessel) is placed under appropriate conditions to cause a solid/fluid mixture to behave as a fluid. This is usually achieved by the introduction of pressurized fluid through the particulate medium. This results in the medium then having many properties and characteristics of normal fluids, such as the ability to free-flow under gravity, or to be pumped using fluid type technologies.

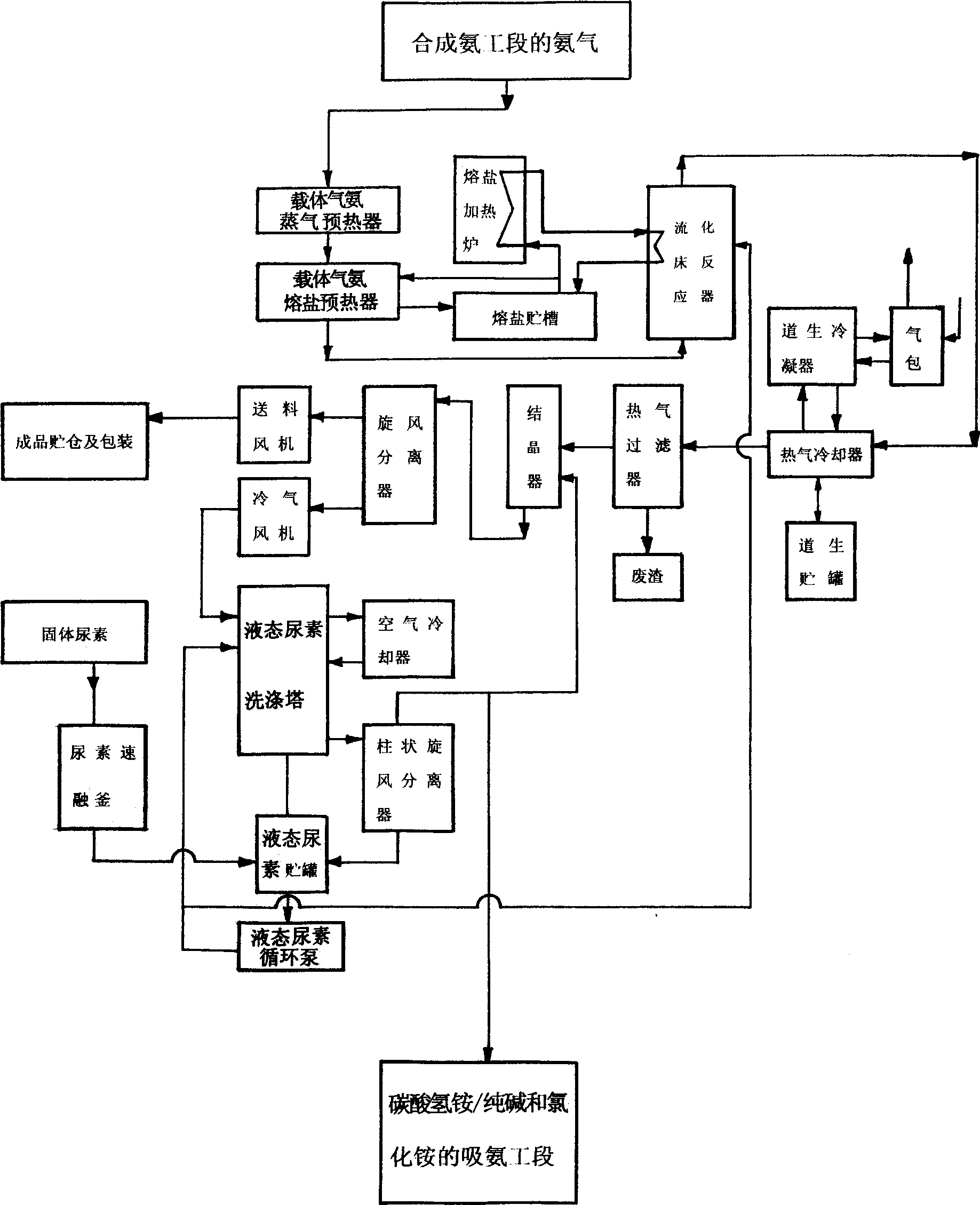

Trimeric cyanamide joint production method using one step method

InactiveCN1493565AImprove product qualityReduce labor intensityOrganic chemistryChemistryAmmonium chloride mixture

Owner:河南金山化工有限责任公司

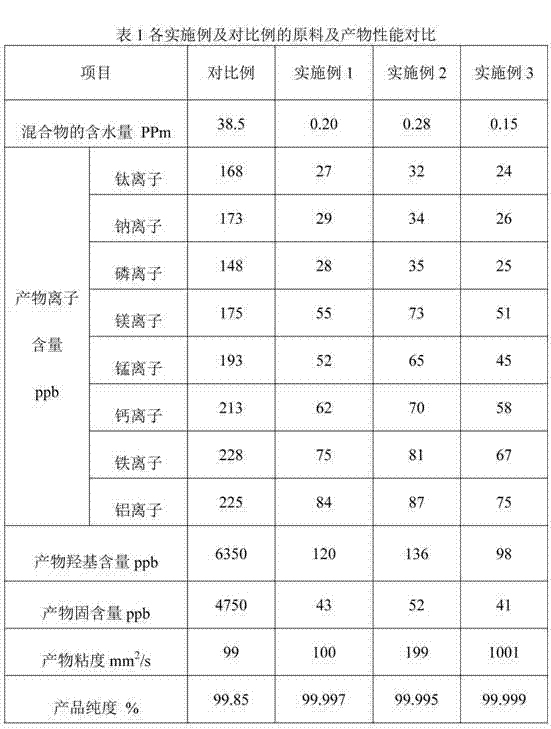

Continuous preparation technology of high-purity low-viscosity dimethicone

ActiveCN103073722AHigh purityMaintain catalytic activityChemical recyclingPtru catalystSilicone fluid

Owner:YICHANG COLLIN SILICON MATERIAL CO LTD

System for urban sludge flue gas drying middle-temperature pyrolysis carbonization

InactiveCN105602586AAvoid cokingAvoid blockingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEnergy gradientSludge

Owner:HUBEI JIADE TECH

Powder packaging device of electronic element based on the heating structure with controllable wind direction and speed

InactiveCN101032715ABreak through the technical problem of uneven thermal claddingLiquid surface applicatorsCoatingsHeat flowFluidized bed

Owner:XI AN JIAOTONG UNIV

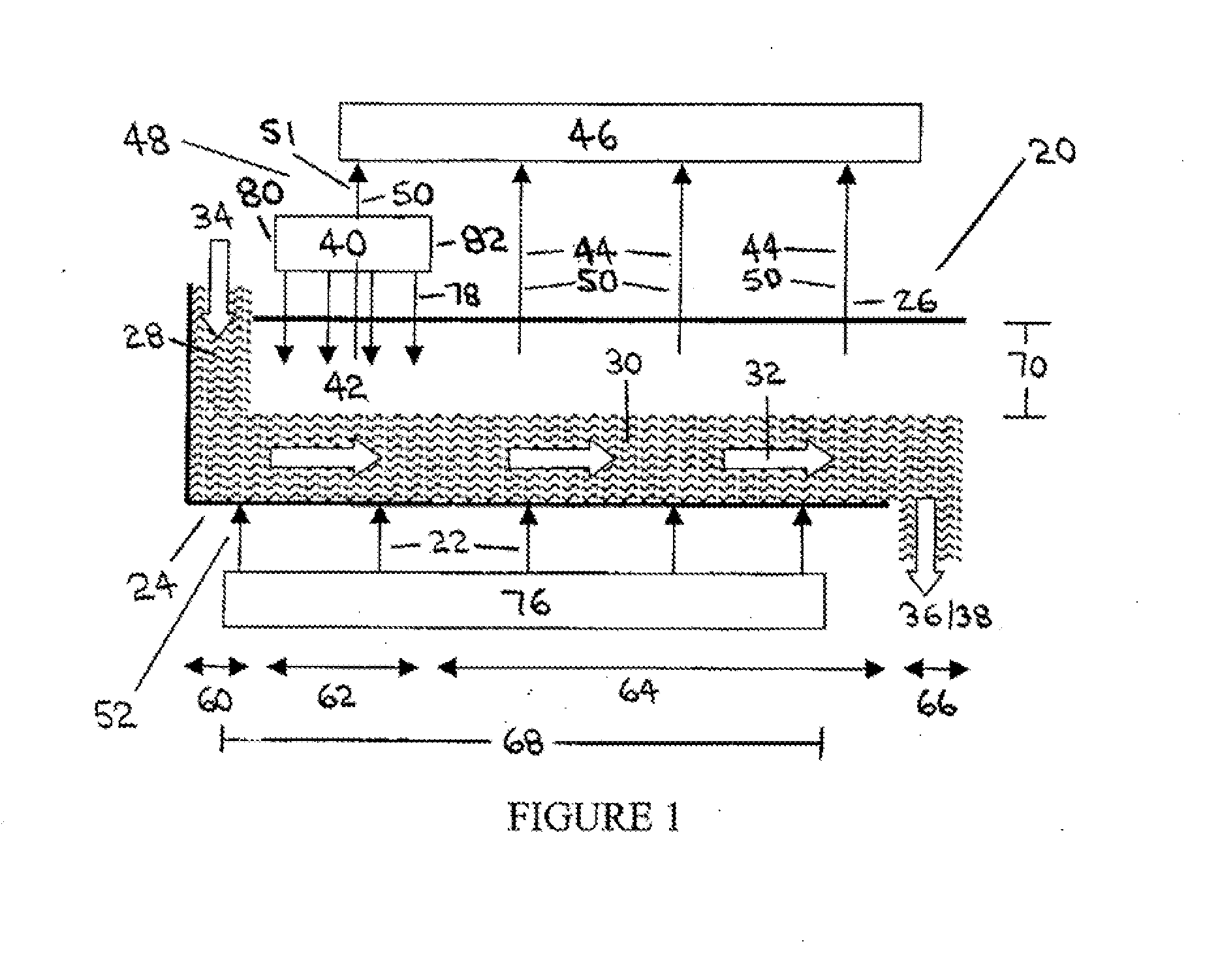

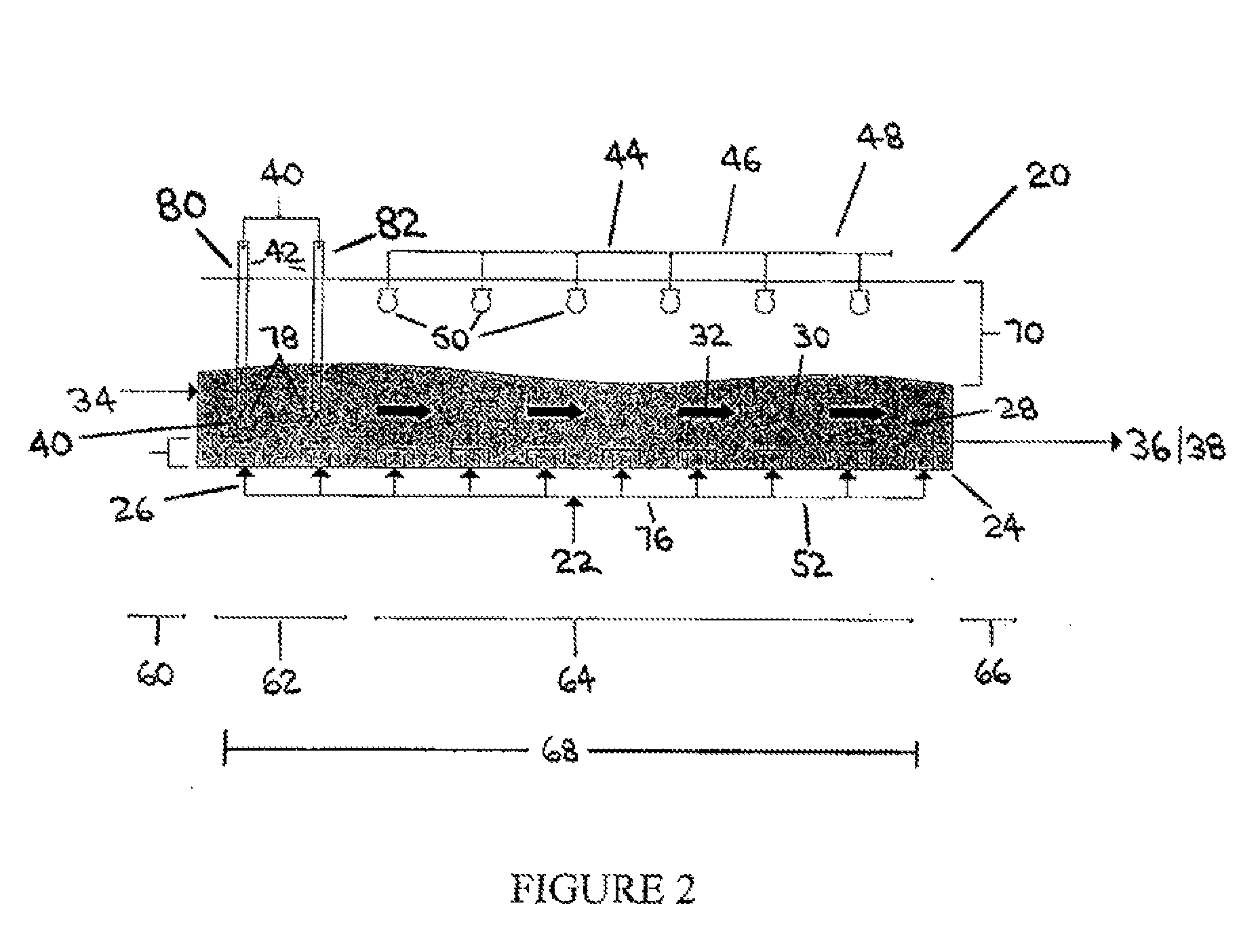

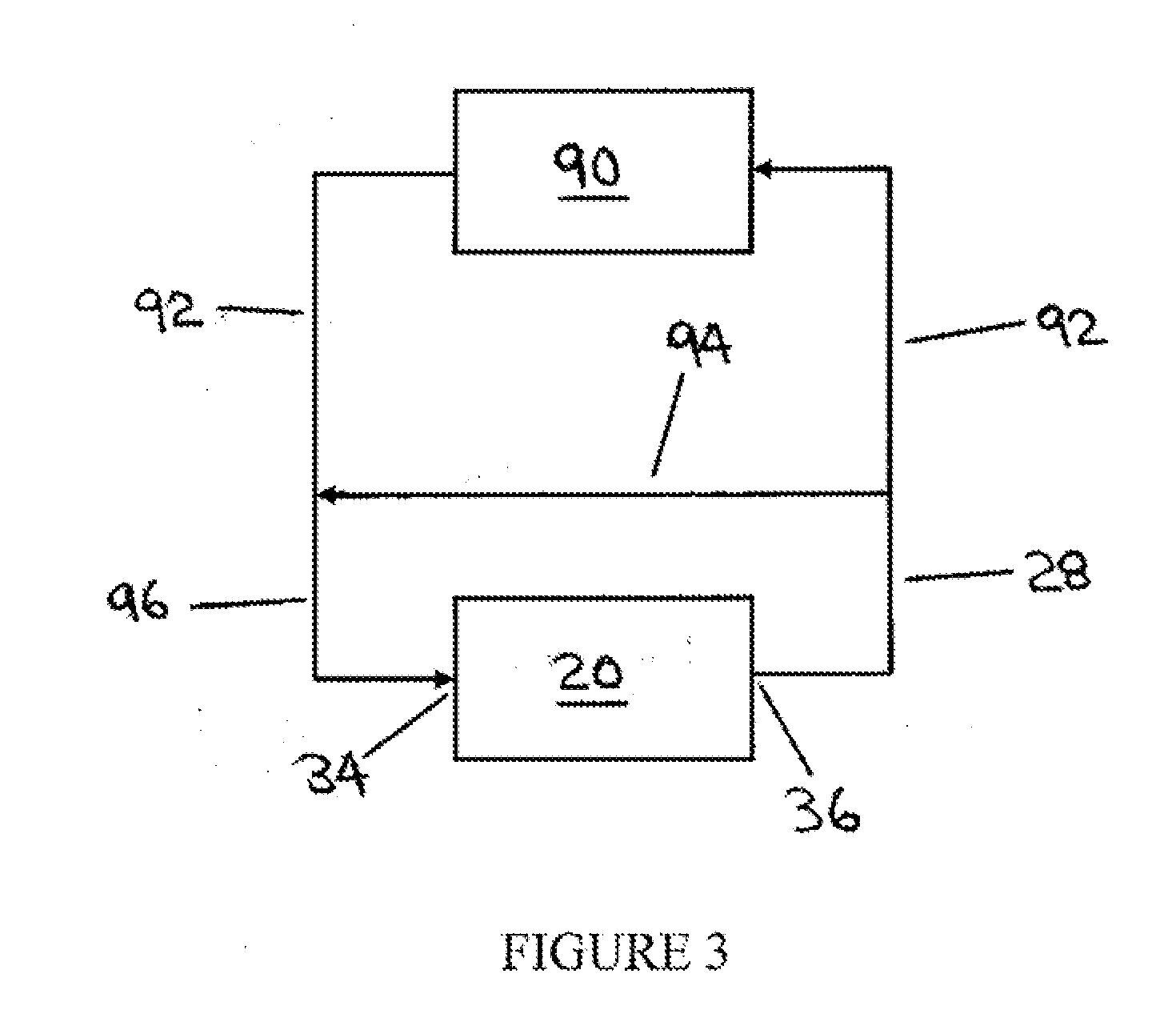

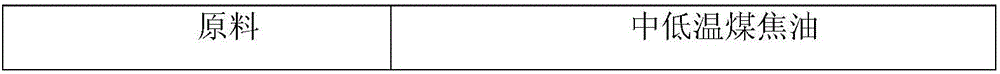

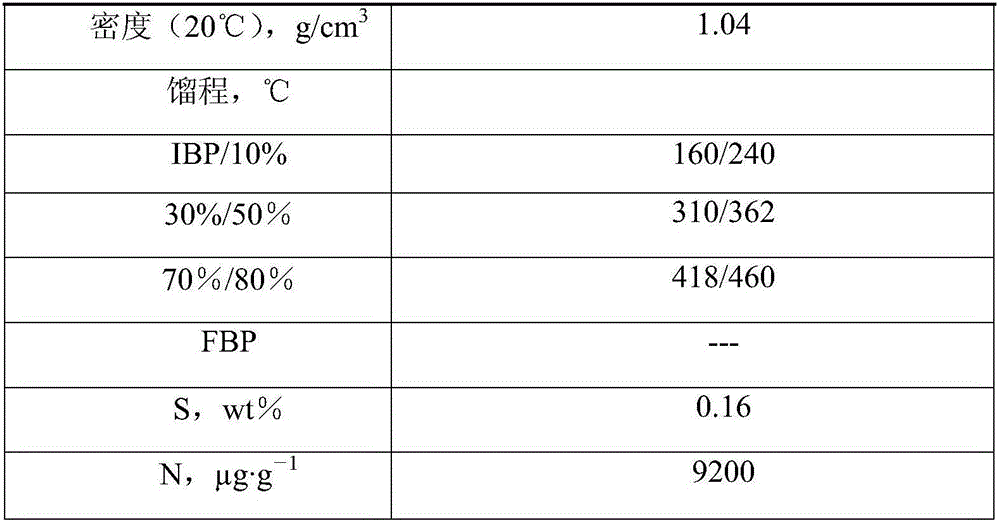

Process for converting a liquid feed material into a vapor phase product

InactiveUS20120211402A1High solids-to-oil ratioLower ratioThermal non-catalytic crackingRefining by heating/coolingFluidized bedGas phase

Owner:ETX SYST

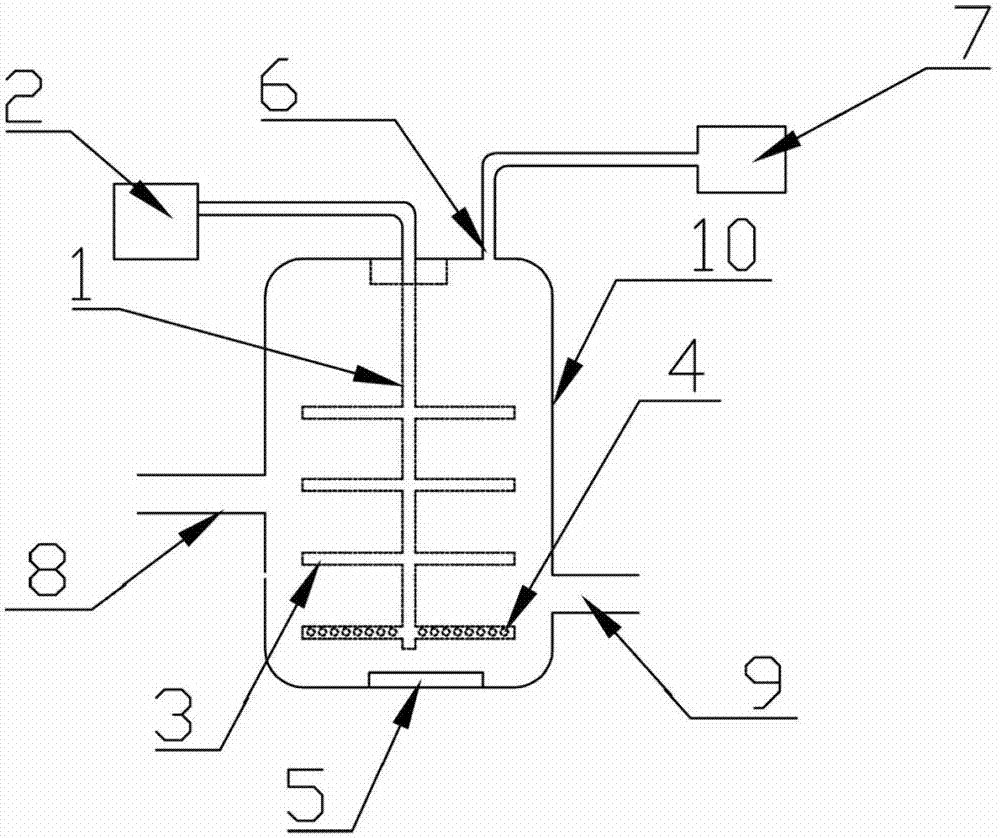

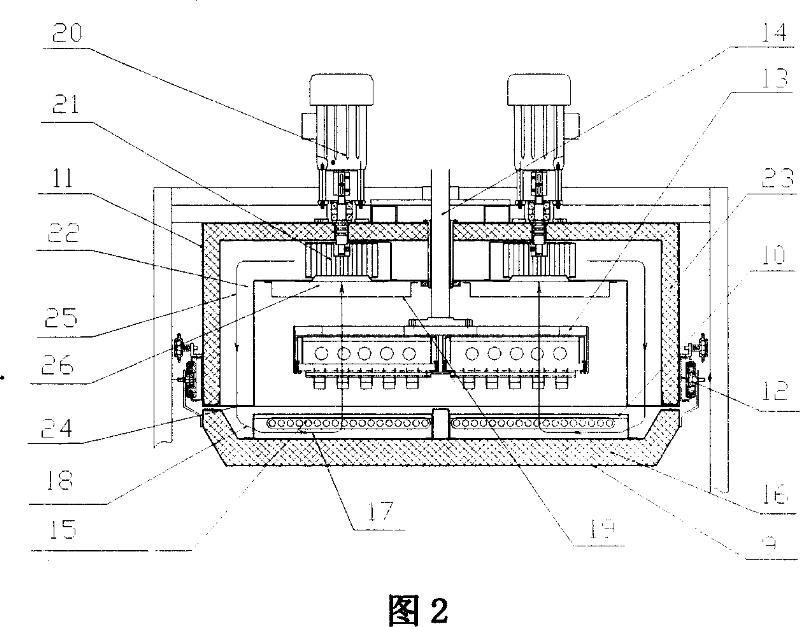

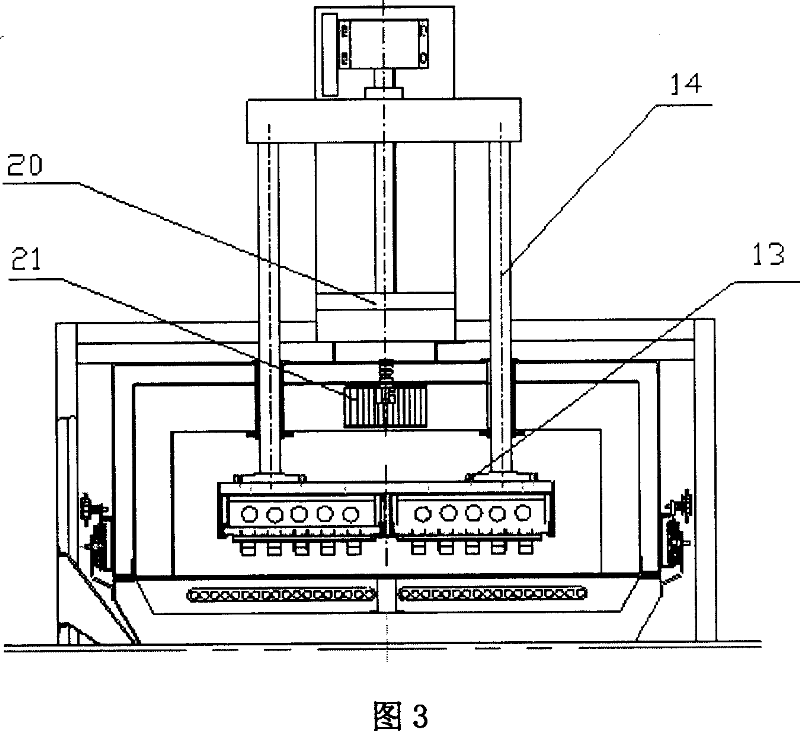

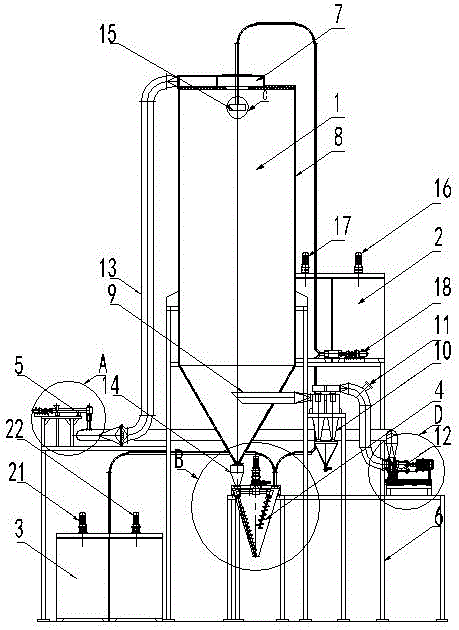

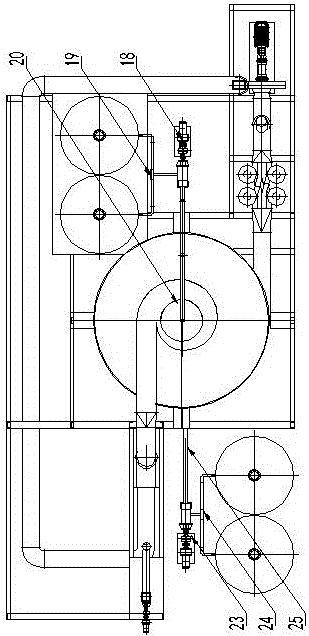

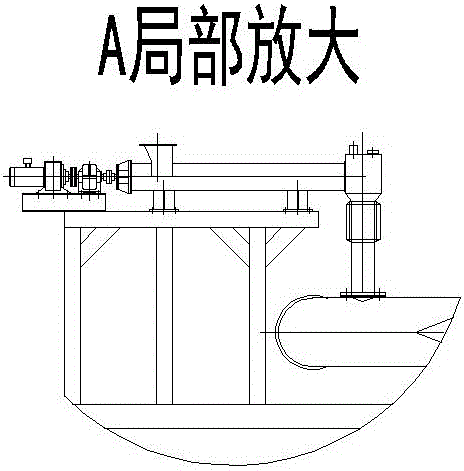

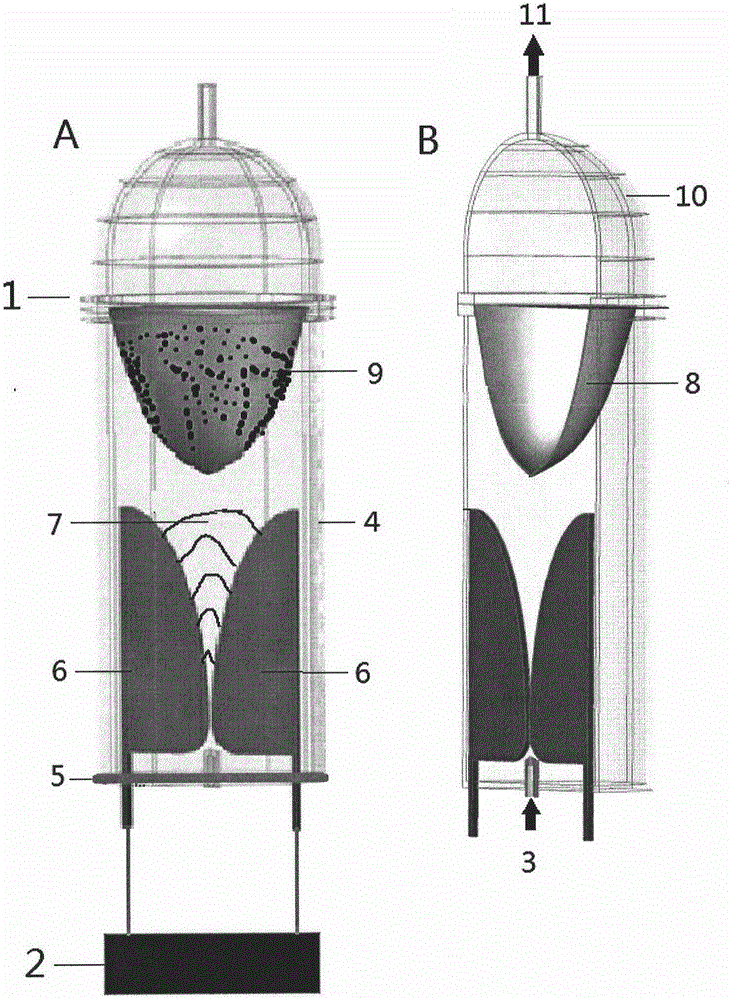

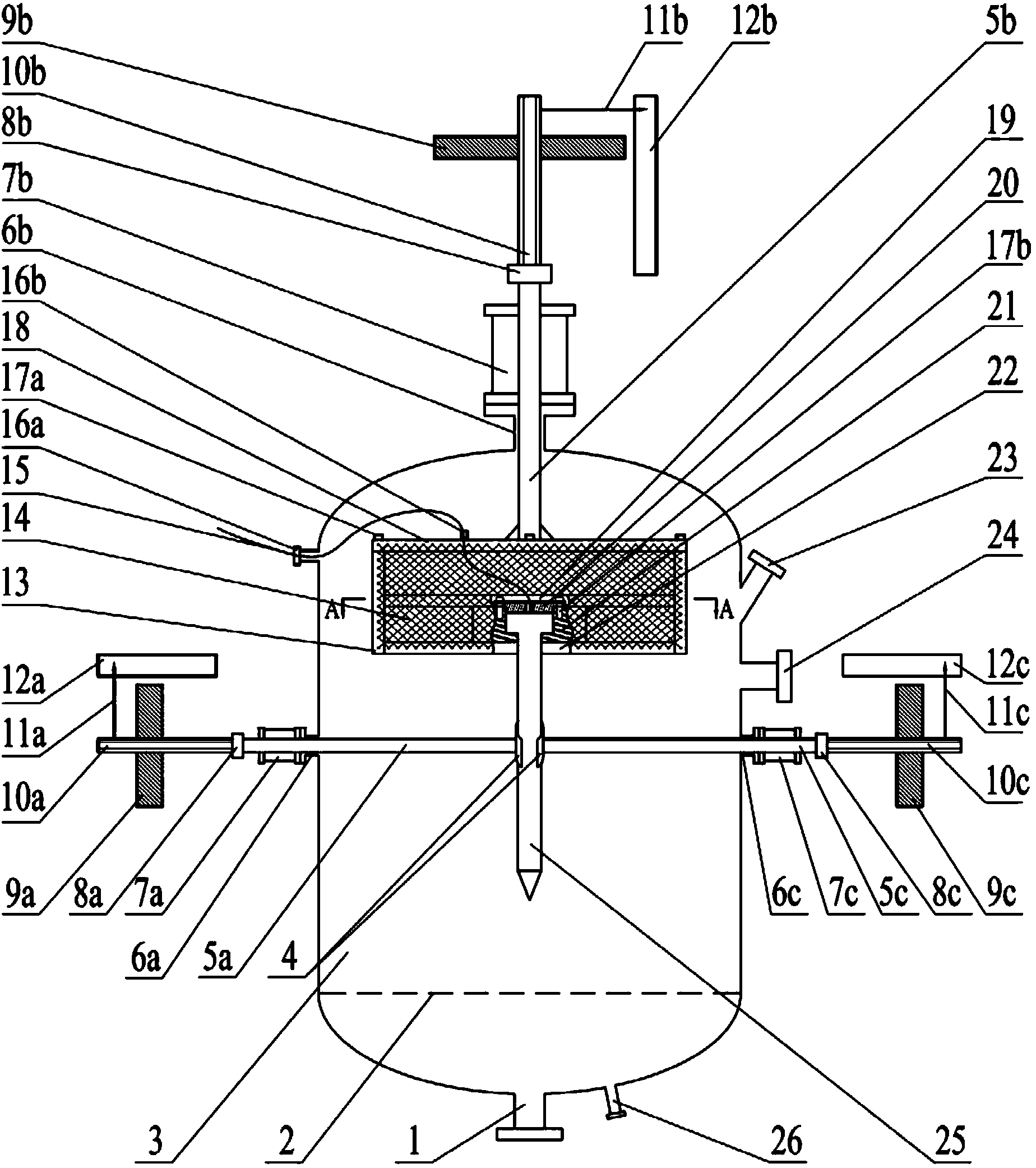

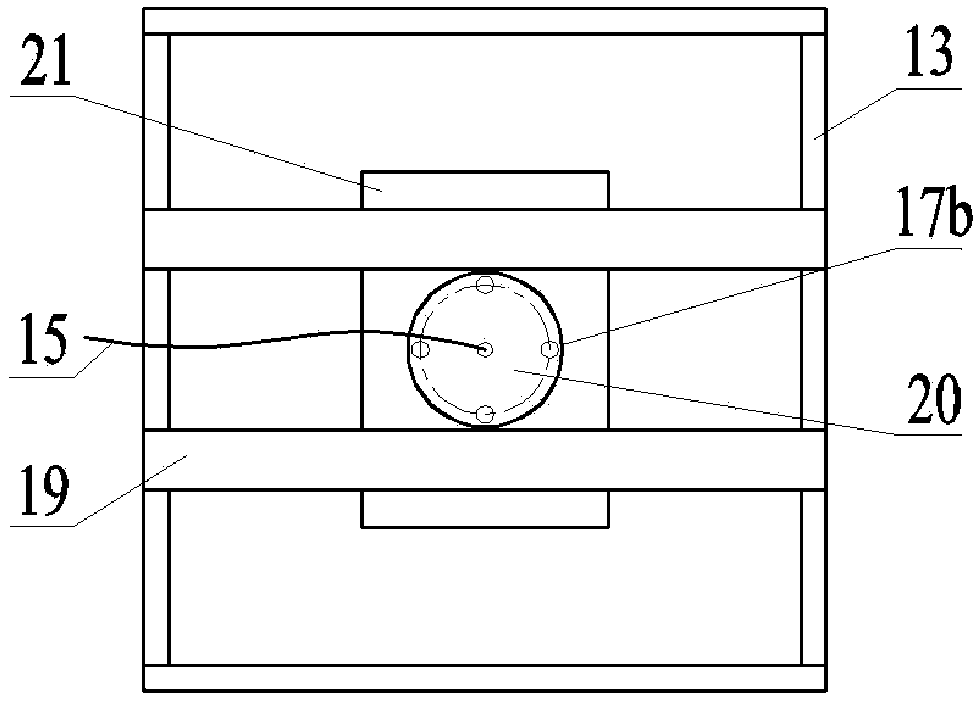

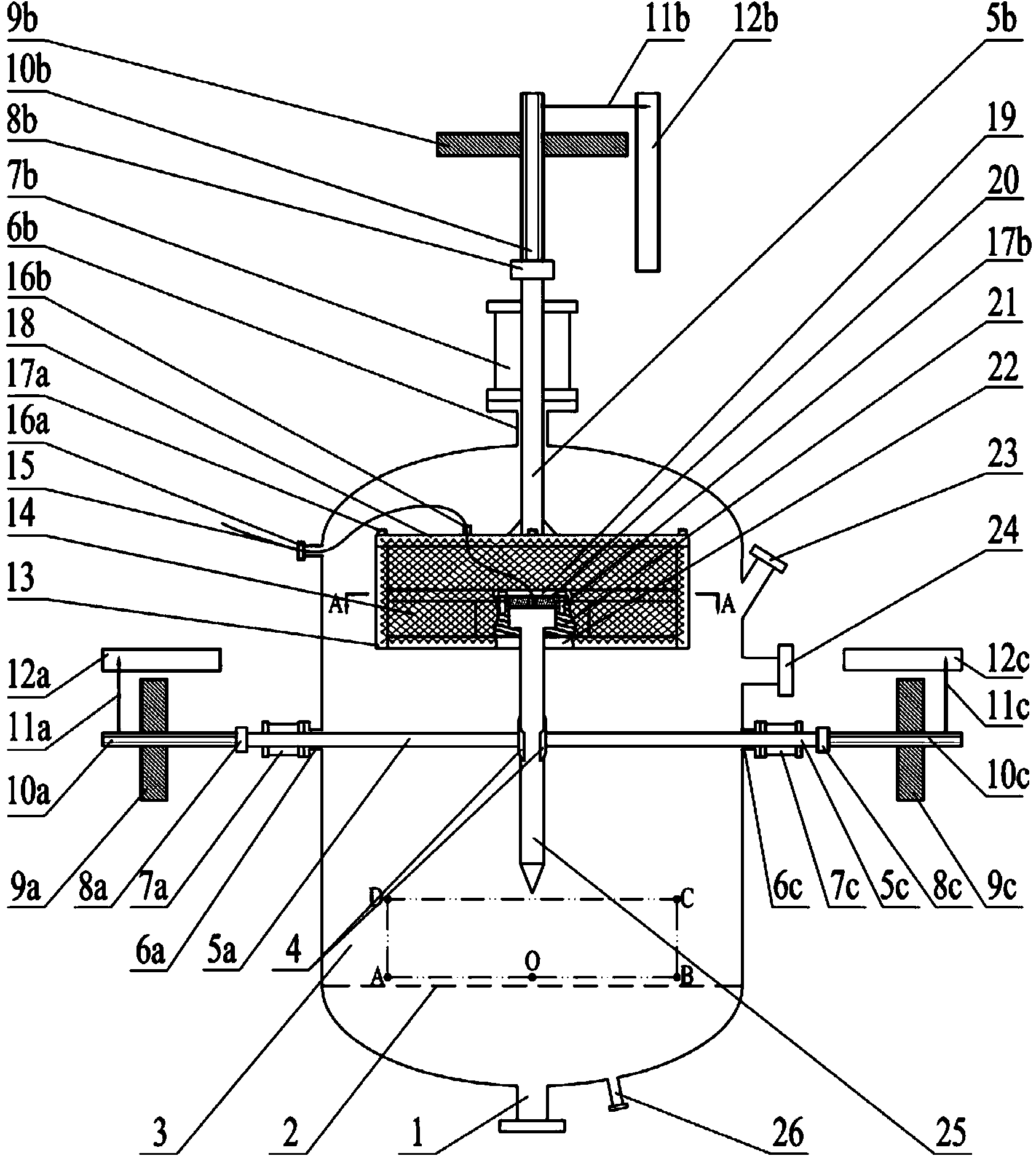

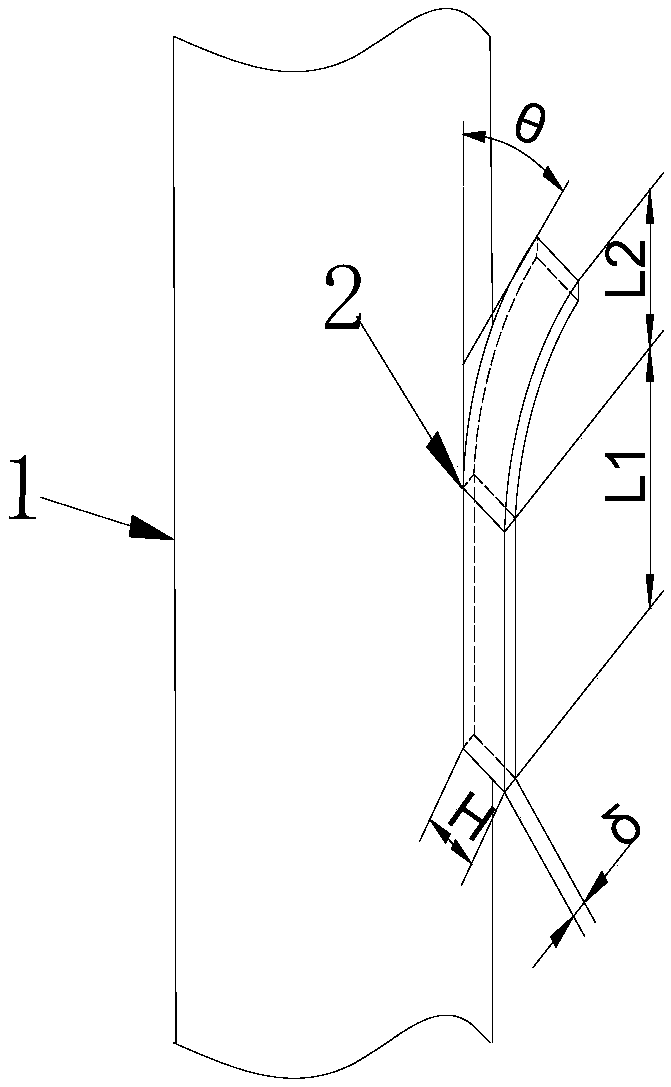

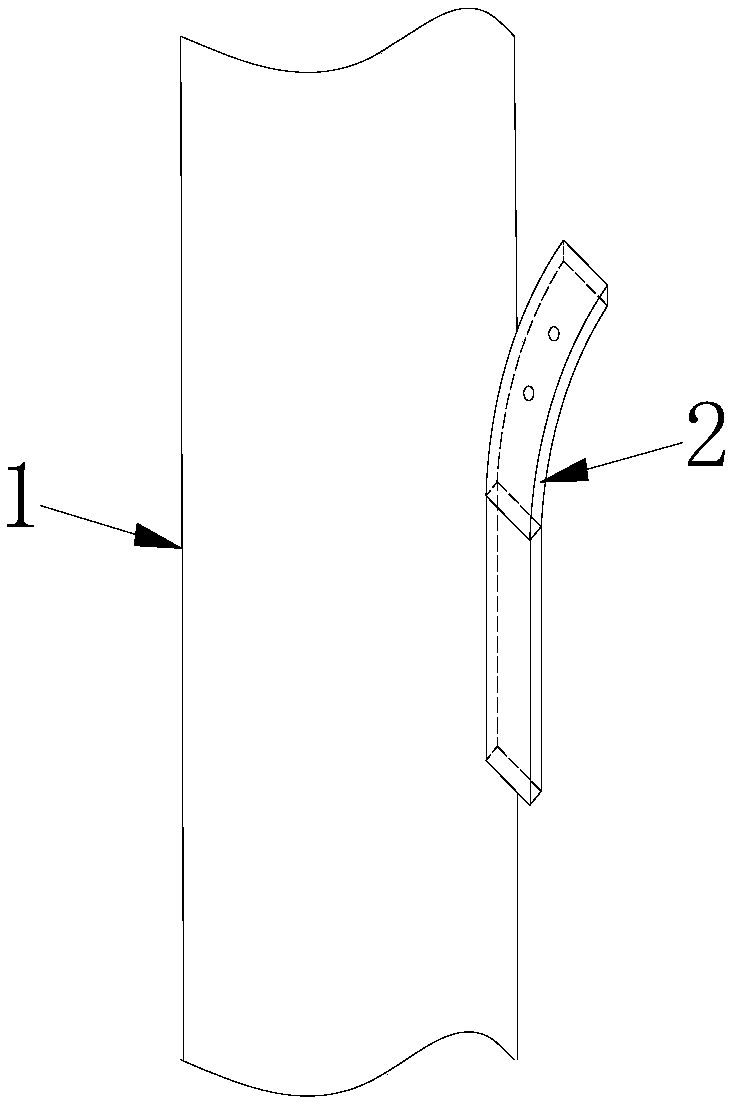

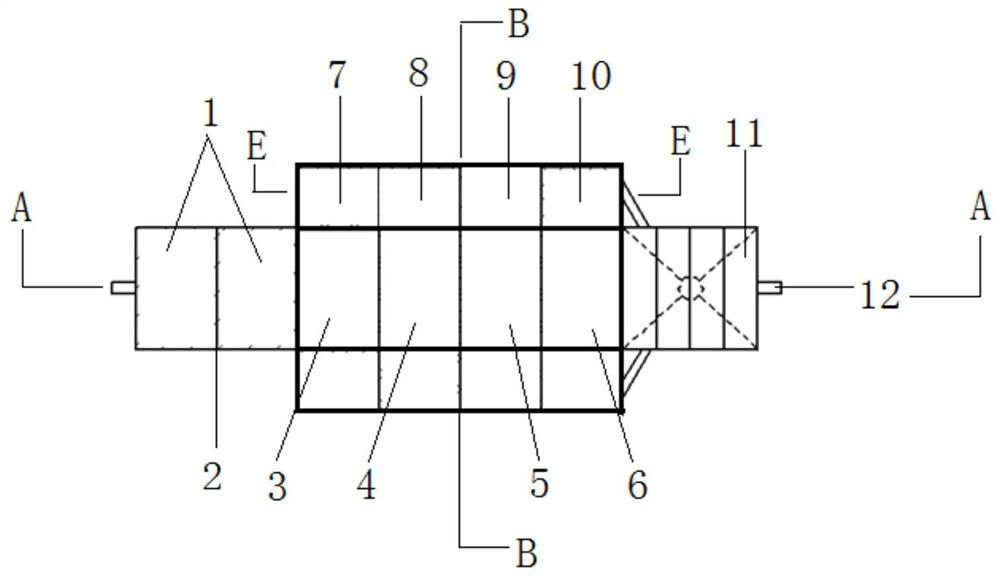

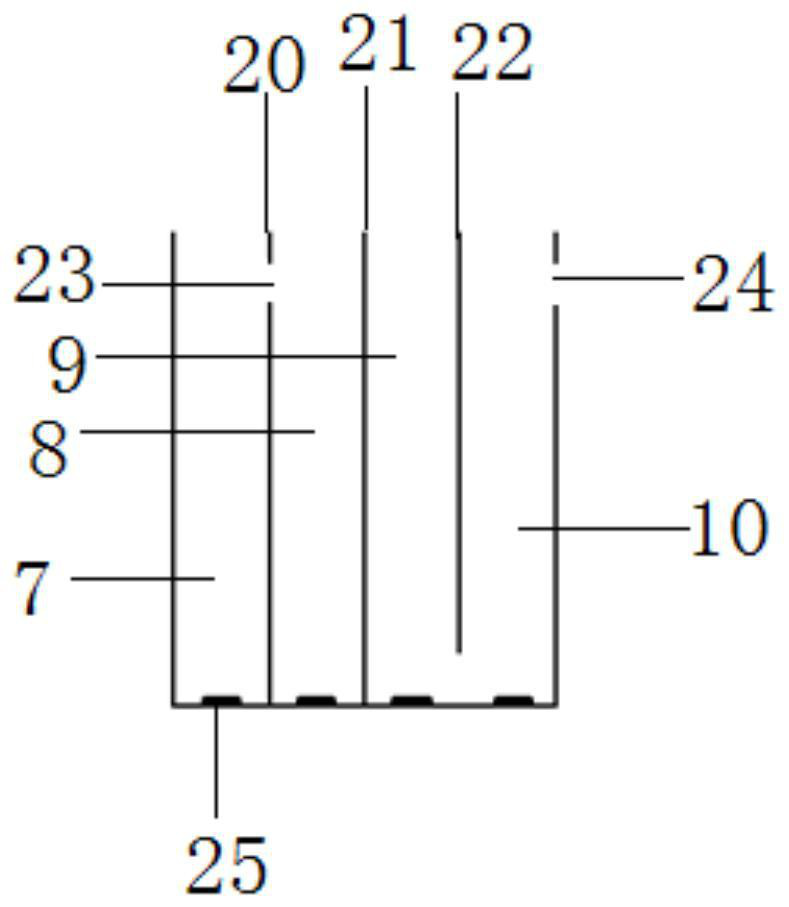

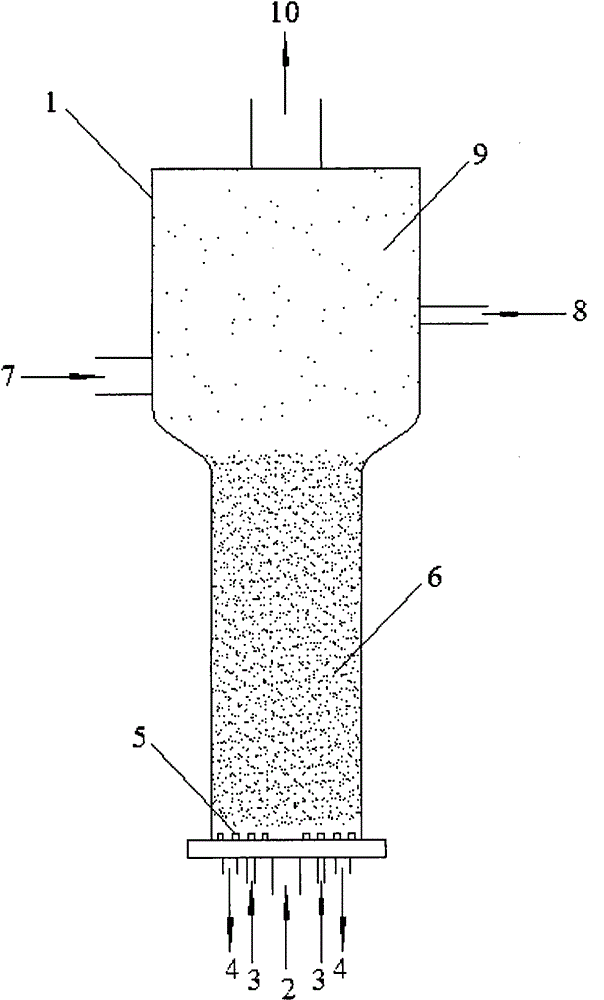

Large fluidized bed reactor for wide sieving fluidized particles

InactiveCN1425494AAdjust the fluidized cross-sectional areaImprove fluidization qualityChemical/physical processesFluidized bedProcess engineering

The present invention relates to chemical equipment technology. The large fluidized bed reactor consists of main bed, conic bed, internal finger-shaped tube heat-exchange member and gad distributor, and features the inner cone structure in the conic bed and sectional introduction of heat-exchange medium to the heat exchange pipe. Using the fluidized bed reactor of the present invention can regulate effectively the fluidizing cross-section area, improve fluidizing quality and realize industrial application easily.

Owner:TSINGHUA UNIV

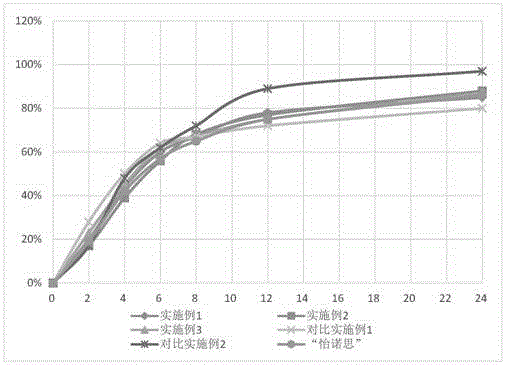

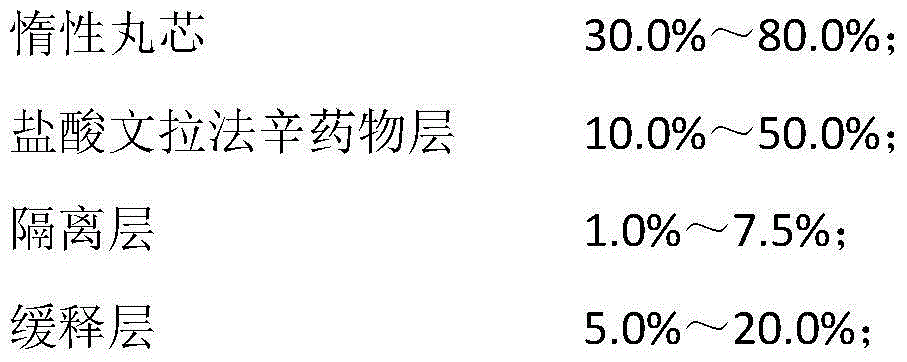

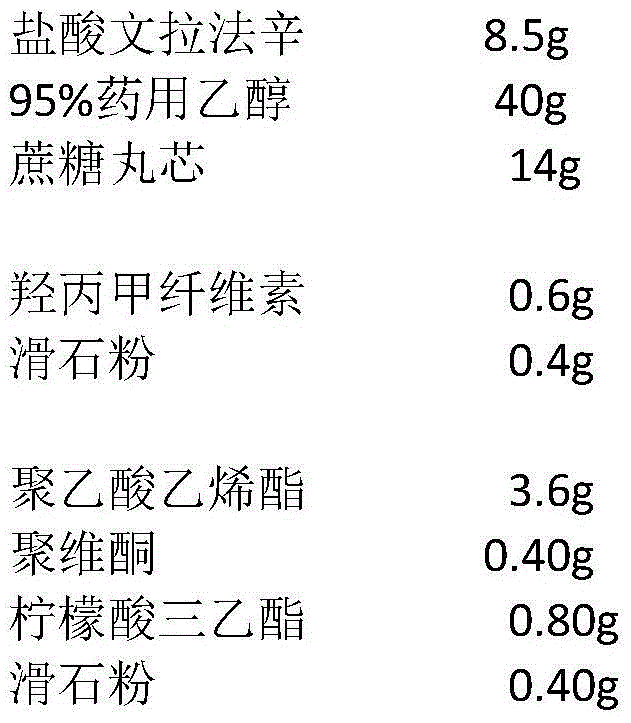

Venlafaxine hydrochloride sustained-release capsule and preparation method thereof

Owner:NANJING CHIA TAI TIANQING PHARMA

Flue gas desulfurization and denitration system and method

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

Powdery active coke combined desulfurization and denitration system and method

PendingCN108144443AImprove effective utilizationImprove desulfurization and denitrification efficiencyGas treatmentDispersed particle separationGas solidBaghouse

Owner:SHANDONG UNIV

Special preparation device for boiler flue gas desulfurization tower repairing agent

ActiveCN106079100AAvoid pollutionReduce investmentMixing operation control apparatusPretreatment controlFluidized bedFlue gas

Owner:桐乡市金琪塑料包装有限公司

Method Of Controlling A Polymerization Reactor

Embodiments of the invention provide a method of controlling a gas-phase polymerization process. The method includes determining a difference between a control variable of the polymerization process, such as the production rate, and the desired value of the control variable; adjusting or maintaining a first manipulated variable to at least partially compensate for the difference between the control variable and the desired value; and adjusting or maintaining a second manipulated variable to at least partially compensate for the effect of adjusting or maintaining the first manipulated variable. The first and second manipulated variables can include process variables such as the fluidized bed weight, the catalyst concentration, the concentration of one or more monomers, the flow of one or more comonomers, the ratio of one comonomer to another comonomer, the activator concentration, the ratio of an activator to selectivity control agent, the concentration of a chain transfer agent, and the retardant concentration.

Owner:DOW GLOBAL TECH LLC

Method for treating organic waste gas by using plasma fluidized bed

InactiveCN104474854AEfficient degradationEffective mineralizationDispersed particle separationFluidized bedStainless steel electrode

Owner:SUN YAT SEN UNIV

Method for processing fluidized-bed withered tea leaves

Owner:安徽良奇生态农业科技有限责任公司

Mobile multi-point measuring device and measuring method for multiphase flow parameters of gas-solid fluidized bed

ActiveCN104251720ARealize continuous mobile multi-point measurementLarge range of movementMeasurement devicesFluidized bedEngineering

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

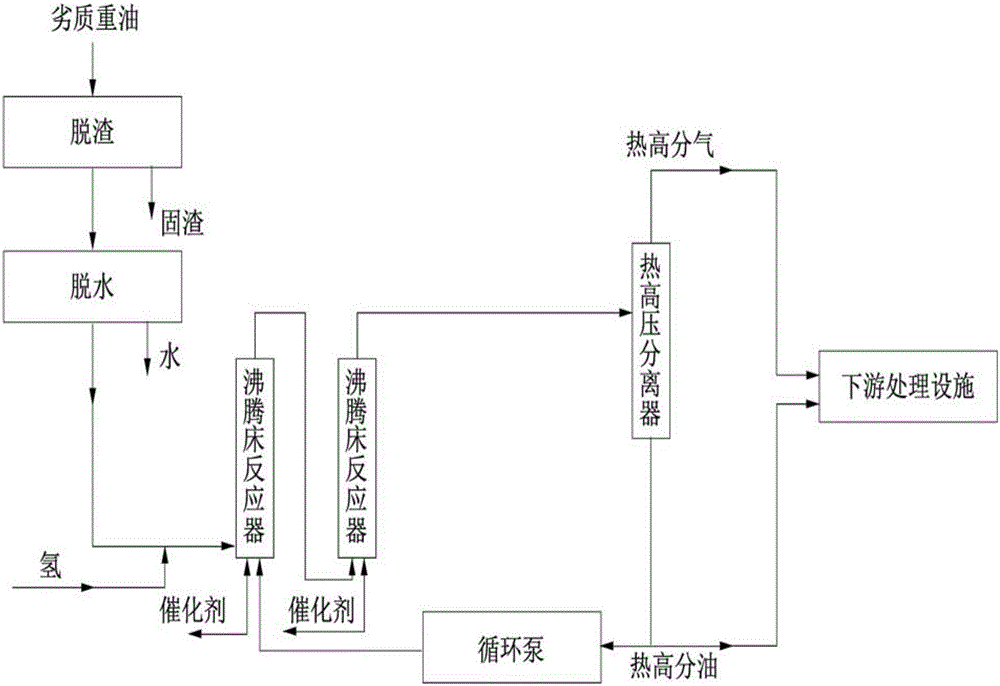

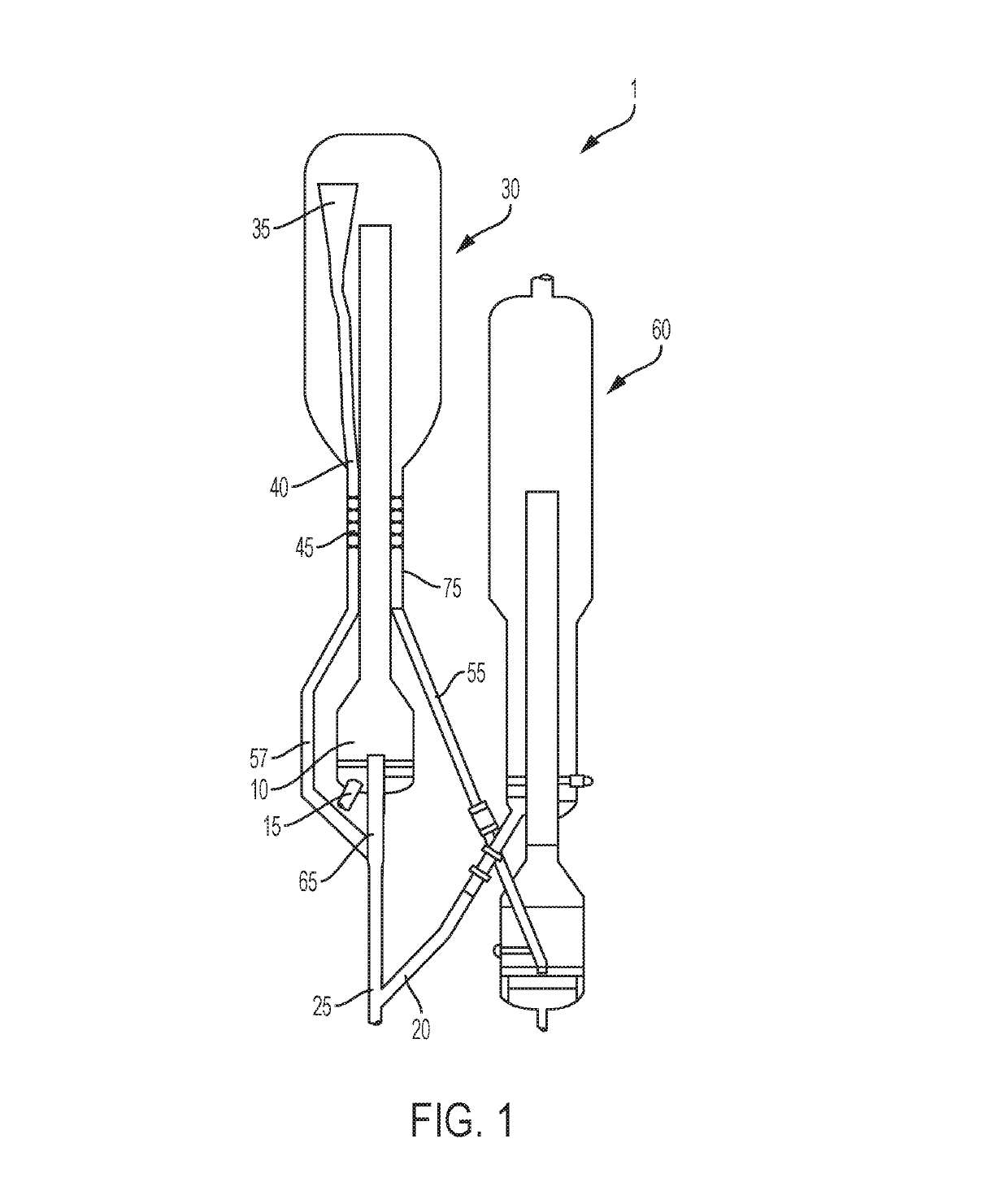

Method for arranging circulating pump in fluidized bed hydrogenation device

ActiveCN106701160AEfficient separationLess investmentHydrocarbon oils treatmentRefining to eliminate hetero atomsHydrogenEtching

Owner:上海竣铭化工工程设计有限公司

A process for reacting oxygen carrying regenerated catalyst prior to use in a fluidized bed reactor

ActiveUS20190099745A1Reduce the amount of oxygenCatalytic crackingCatalyst regeneration/reactivationFluidized bedHydrocarbon

Owner:DOW GLOBAL TECH LLC

Non-linear analysis method based online intelligent identification method for flow pattern of gas-solid fluidized bed

ActiveCN105139025AAvoid the impact of accuracyCharacter and pattern recognitionTransient statePattern recognition

The present invention discloses a non-linear analysis method based online intelligent identification method for a flow pattern of a gas-solid fluidized bed. The method comprises: performing sampling and analysis of a pressure pulsation signal on the gas-solid fluidized bed and extracting a feature value; performing objective clustering by means of a fuzzy cluster algorithm according to the feature value and the pressure pulsation signal; and establishing and training a flow pattern identification system according to the pressure pulsation signal, the feature value and an objective clustering result, and embedding the system into a computer to implement online intelligent identification of the flow pattern of the gas-solid fluidized bed. The method can avoid the influence of subjective factors on flow pattern identification accuracy, and perform dynamic analysis and flow pattern identification on a transient state parameter.

Owner:SOUTHEAST UNIV

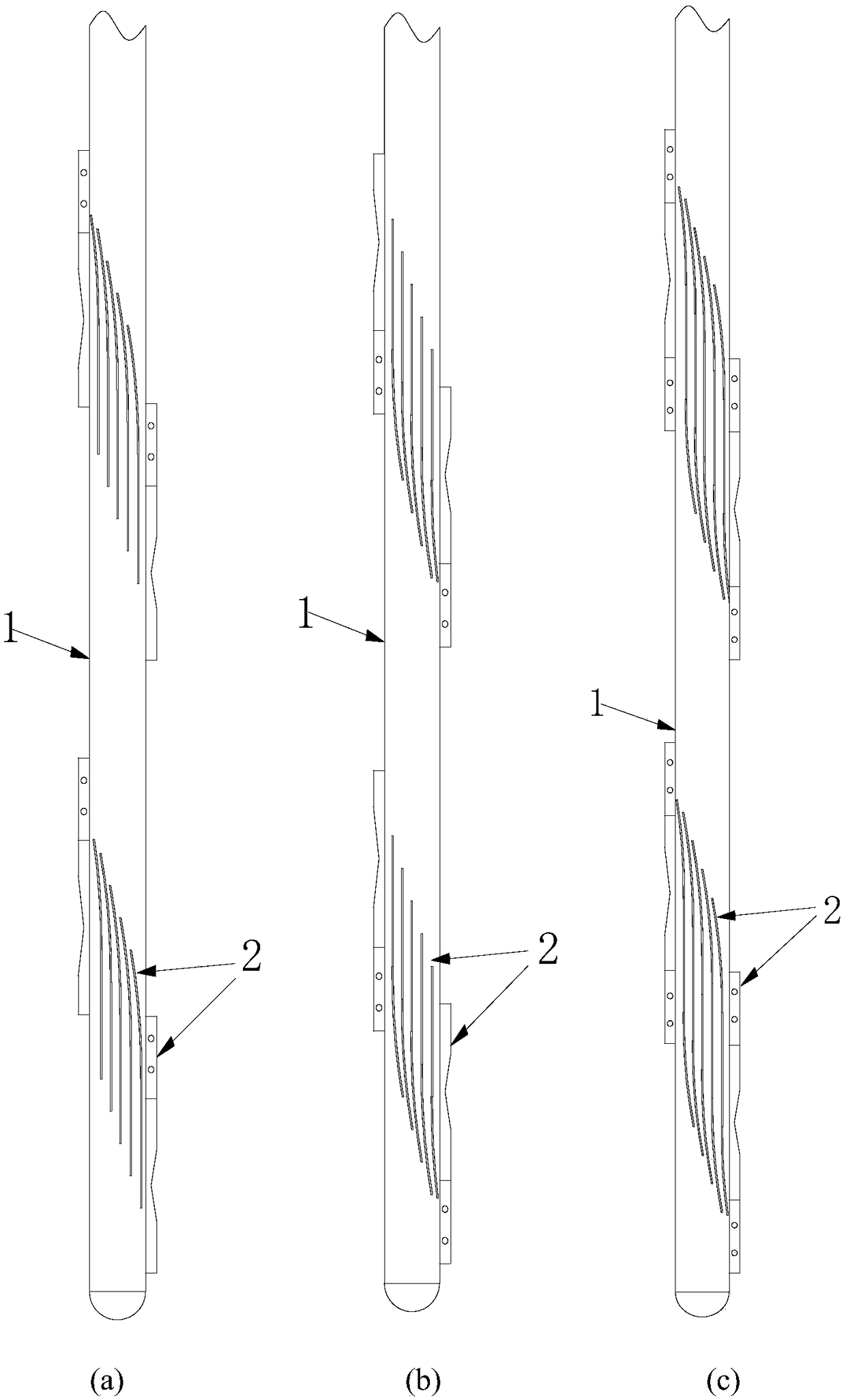

Finned tube fluidized bed heater

ActiveCN108827042AImprove heat transfer efficiencyIncreased turbulenceFluidised bed heat exchangersTubular elementsVertical tubeFluidized bed

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Semi-buried biogas mixed jacking fluffy soft body anaerobic fermentation system

InactiveCN110564591ADisperse operationEasy to clean with frictionBioreactor/fermenter combinationsBiological substance pretreatmentsVolumetric Mass DensityEngineering

The invention discloses a semi-buried biogas mixed jacking fluffy soft body anaerobic fermentation system. The system structurally comprises a square box shell, an indication lamp post, a thin film pad, a thick soft body block, a vent pipe cavity, a gas storage cell box, an anaerobic fermentation tank and a biogas connecting pipe seat. According to the invention, a thick soft body block is matchedwith the vent pipe cavity, the jacking and lagging biogas effect is achieved, the bulking degree of the thick soft body block is increased, the effect of turning over a fluidized bed up and down is achieved to form an interval balloon type granular sensation fluctuation effect, a vibration screen left-and-right pushing output operation is formed through an overturning rack, a double-air-whirl effect is also formed for the circulation of upper and lower air flows, a negative pressure air chamber obtains slow pressure reduction and release of the lagging air flow, an effect of balancing a bottom biogas layer in an upper row is formed for an external air pressure value, a single super-density sealing compression phenomenon is conveniently swept by disturbance air flow when the soft body is turned over, the intermittent air exchange shearing hierarchical system processing operation is achieved, and the potential safety hazard of anaerobic fermentation equipment is controllable.

Owner:NANAN HANCHENFENG TRADING CO LTD

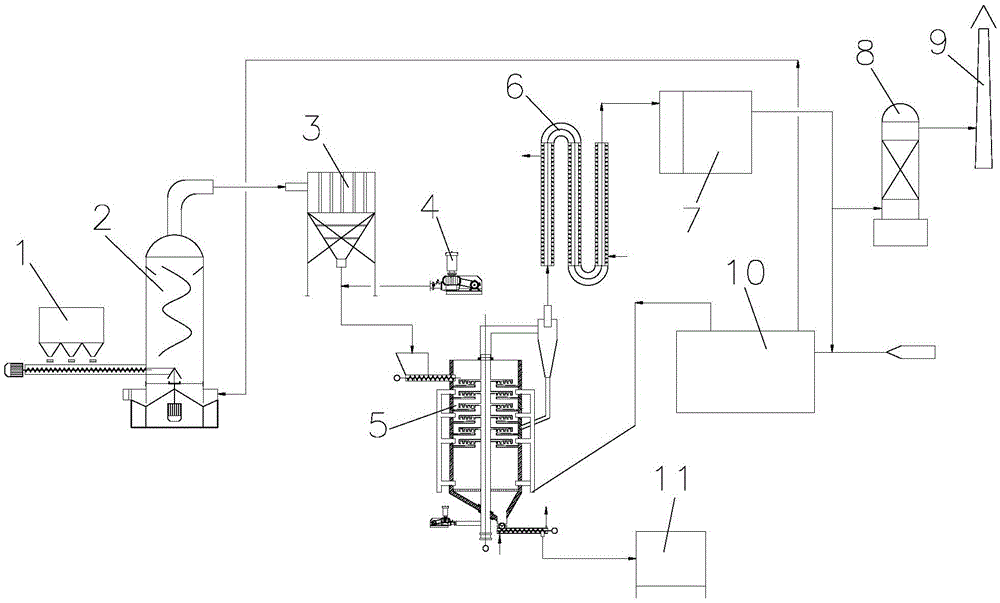

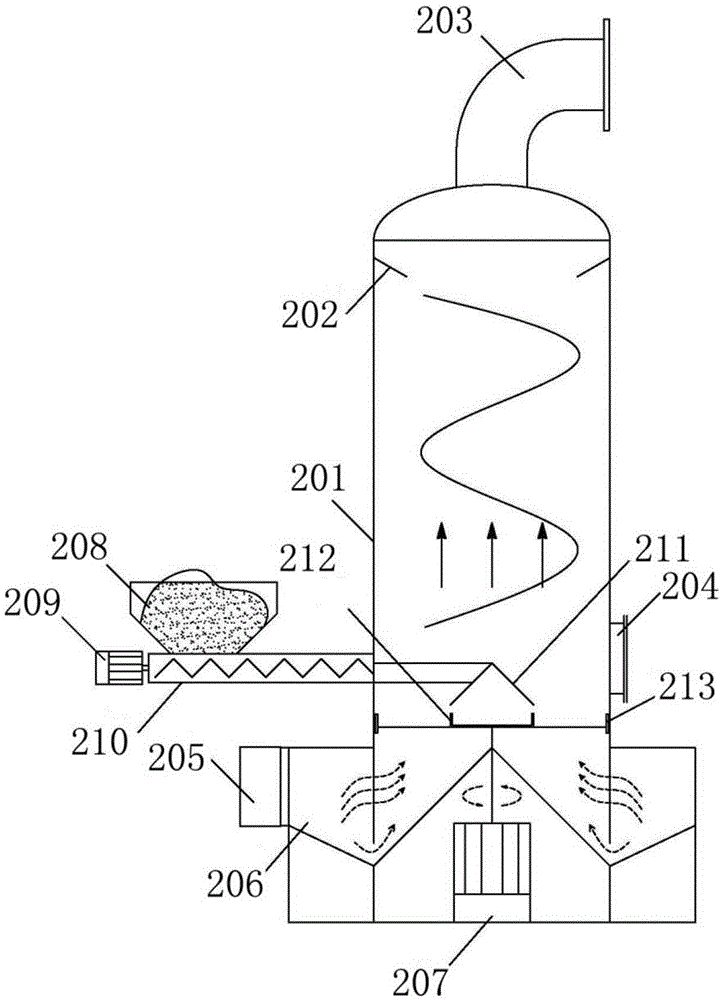

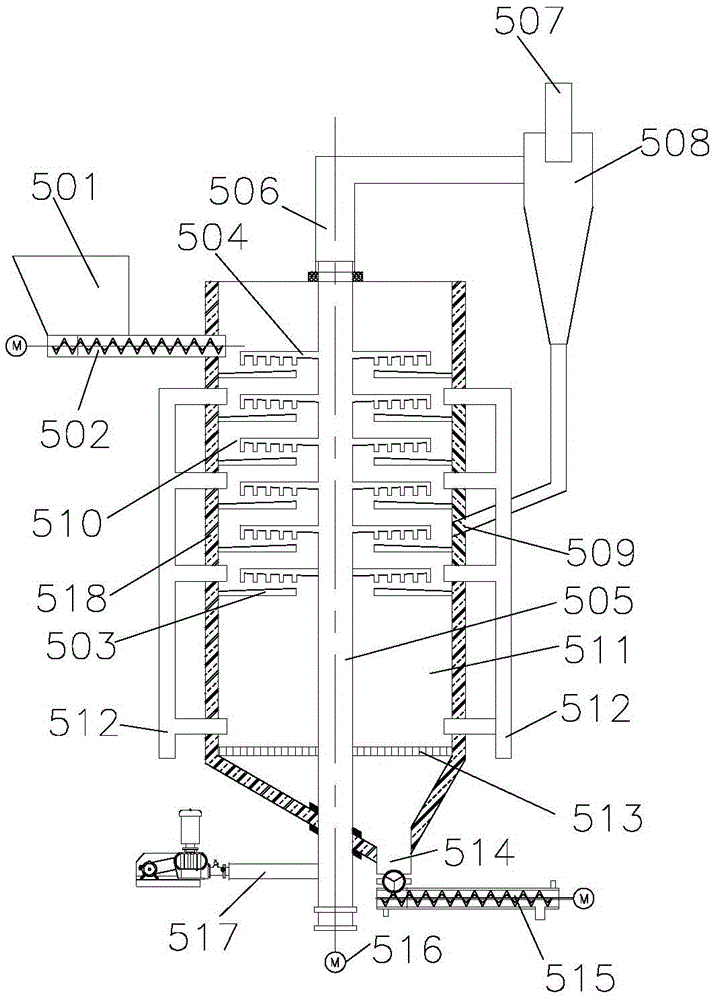

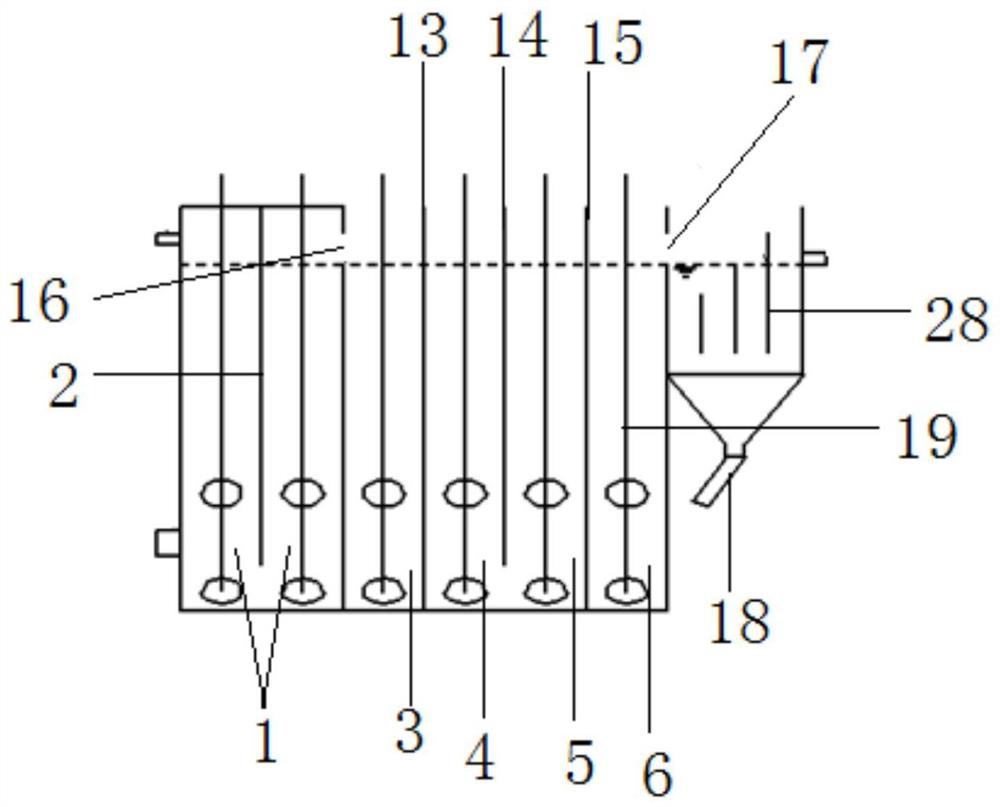

Small and medium sized fuel gas production device based on household refuse grading and flash pyrolysis and gasification

ActiveCN105907428AGasification processes detailsGranular/pulverulent flues gasificationFluidized bedIron removal

The invention provides a small and medium sized fuel gas production device based on household refuse grading and flash pyrolysis and gasification. The small and medium sized fuel gas production device comprises an iron-removal pulverizer, a riser, a circulating fluidized bed, a gas distributor, an ash discharging pipe, a gas inlet pipe, a feed inlet, a first-stage gas and solid separator, a coarse ash circulating pipe, a back feeder, a second-stage gas and solid separator, a fine ash circulating pipe, an entrained-flow bed, a fuel gas outlet, an air heat-exchanger and the like. The iron-removal pulverizer and the riser are arranged at the front end of the circulating fluidized bed sequentially; the gas distributor and the ash discharging pipe are arranged at the bottom of the circulating fluidized bed; the entrained-flow bed is arranged at the position which is 1000-2000 mm away from the bottom of the circulating fluidized bed; an oil gas inlet is arranged at the position which is 500-3000 mm away from the entrained-flow bed; the second-stage gas and solid separator is arranged at the top of the circulating fluidized bed; a coarse-particle ash circulating pipe of the first-stage gas and solid separator is connected to the bottom of the circulating fluidized bed, and a fine-particle ash circulating pipe of the first-stage gas and solid separator is connected to the entrained-flow bed through the back feeder; and a gas outlet is connected with the fuel gas outlet through the air heat exchanger.

Owner:田原宇

Integrated backflow-free A2O equipment based on fluidized bed

ActiveCN112777742ATreatment with aerobic and anaerobic processesSustainable biological treatmentFluidized bedBackflow

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

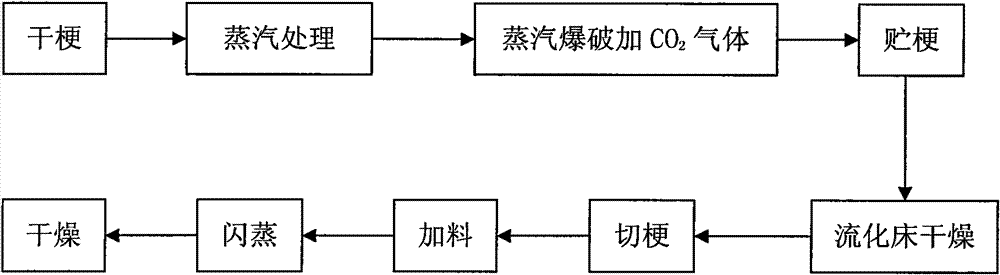

Steam explosion method for improving tobacco stalk quality by using carbon dioxide as exogenous gas

InactiveCN101912153BPromote decomposition and transformationReduce woodinessTobacco treatmentDelivery PerformanceFluidized bed

Owner:CHINA TOBACCO CHUANYU IND

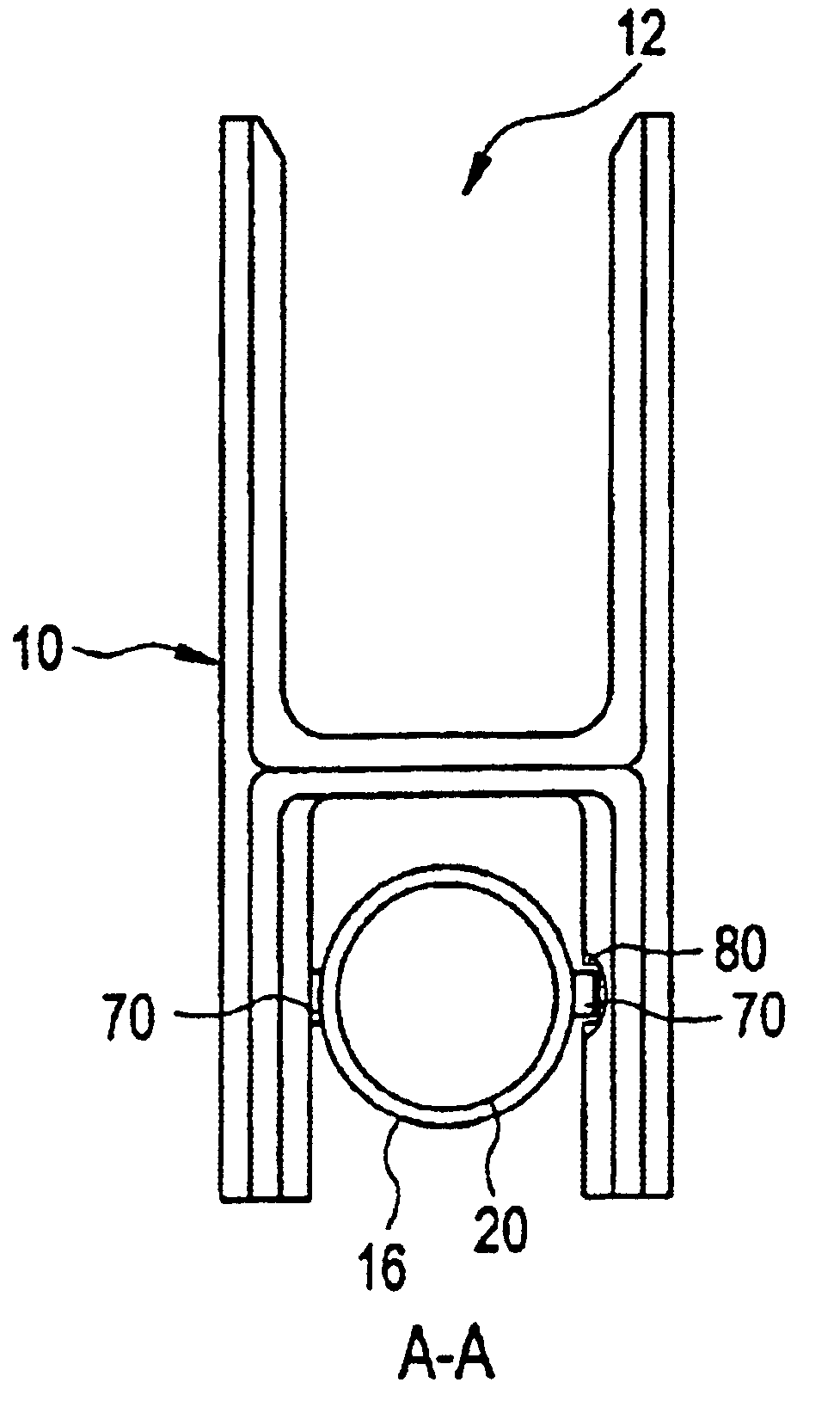

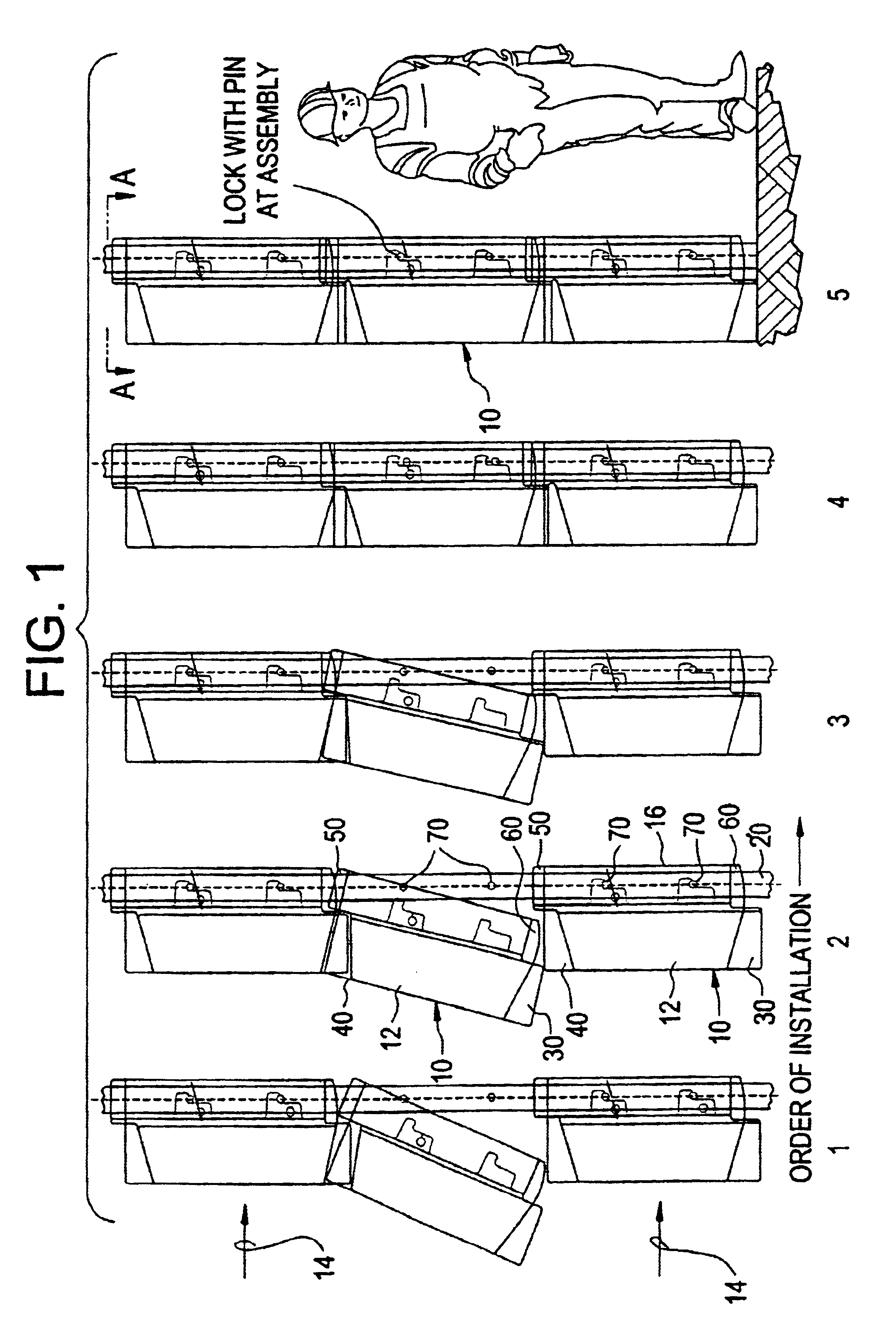

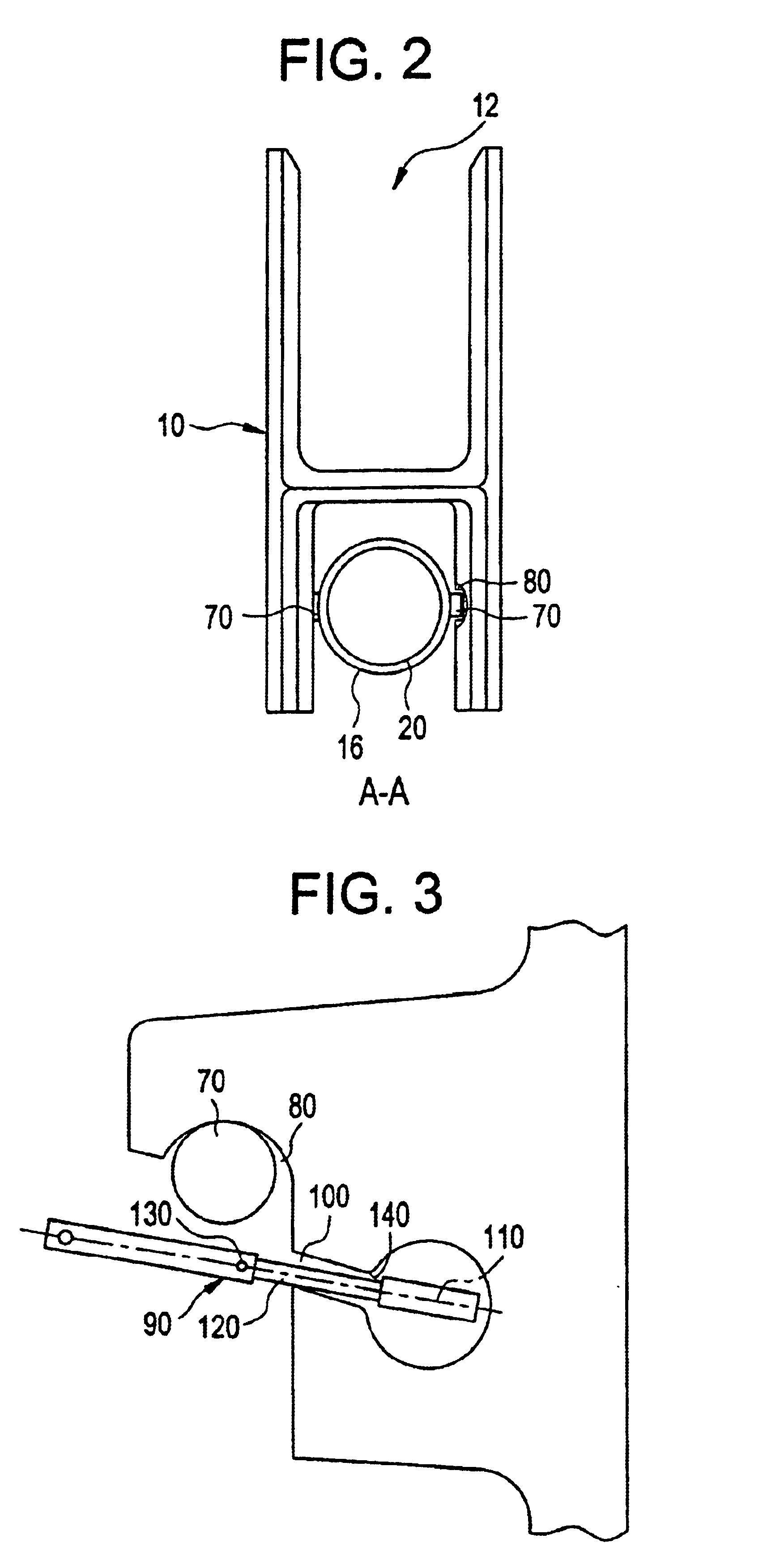

Impact type particle separator made of mutually inverted U-shaped elements

InactiveUS6869459B2Simplify disassemblyShorten the timeFluidized bed combustionDispersed particle separationFlue gasFluidized bed

Owner:THE BABCOCK & WILCOX CO

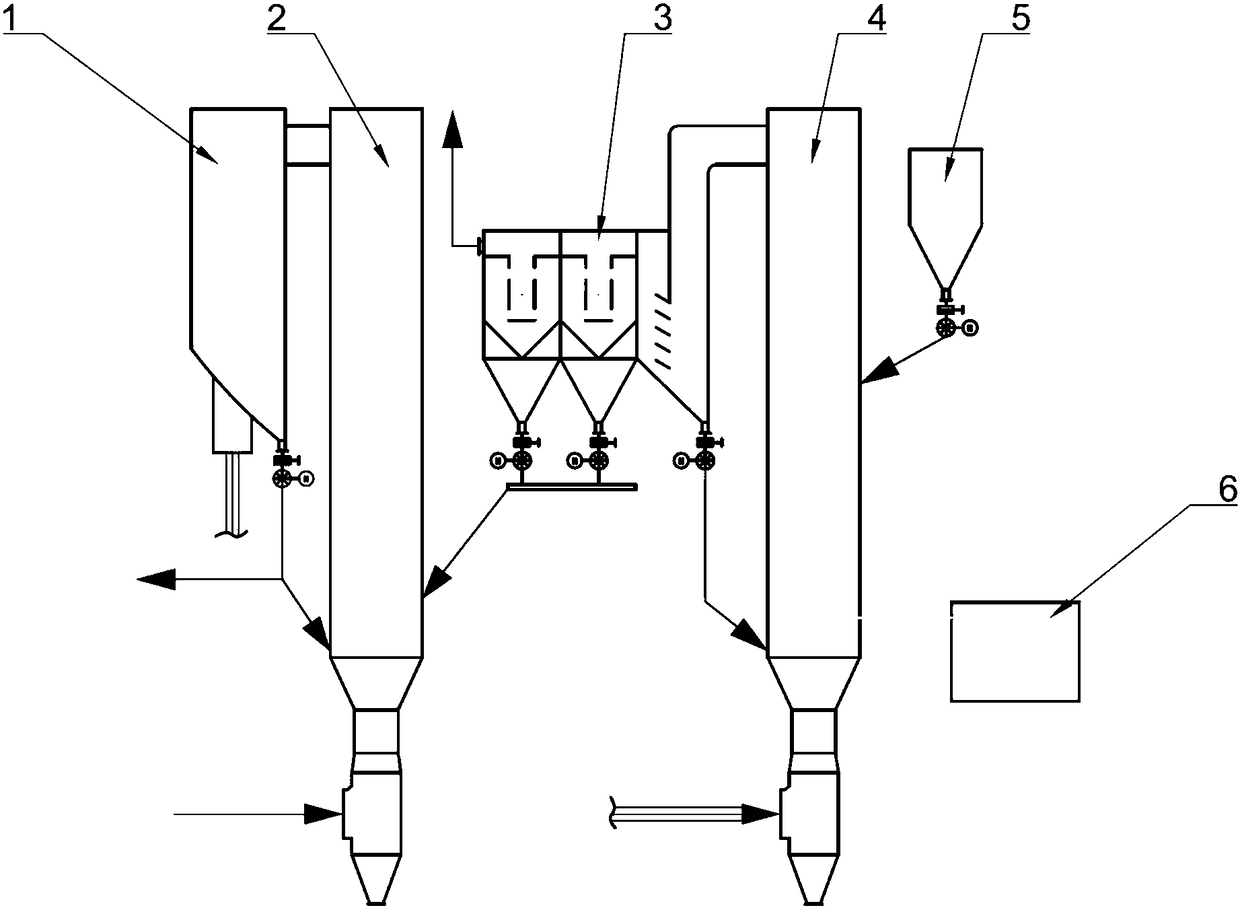

Method and device for producing granular polysilicon

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap