Mobile multi-point measuring device and measuring method for multiphase flow parameters of gas-solid fluidized bed

A multi-point measurement, fluidized bed technology, applied in measurement devices, instruments, etc., can solve the problems of high cost, large influence of the parameter field in the bed, limited space, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

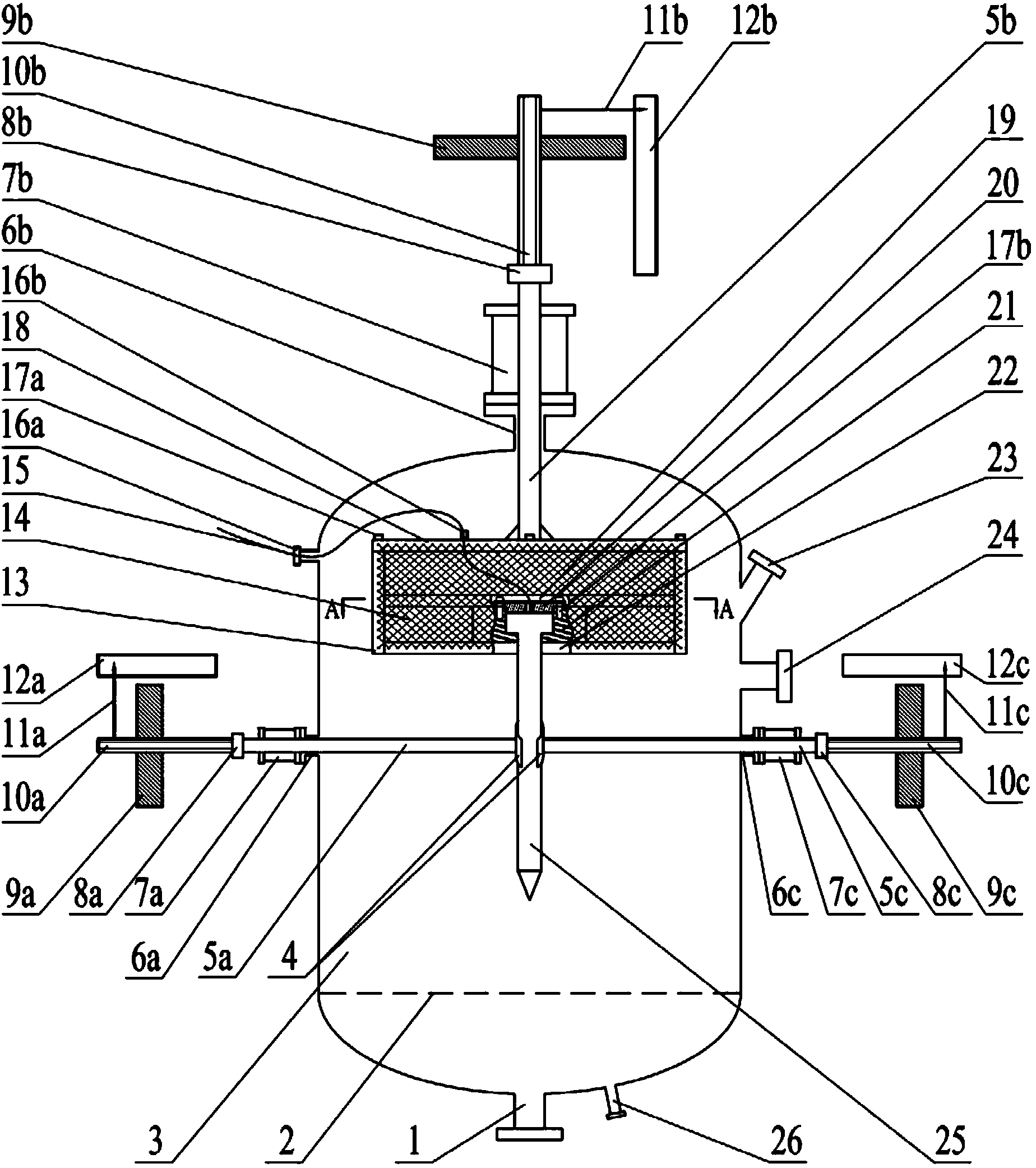

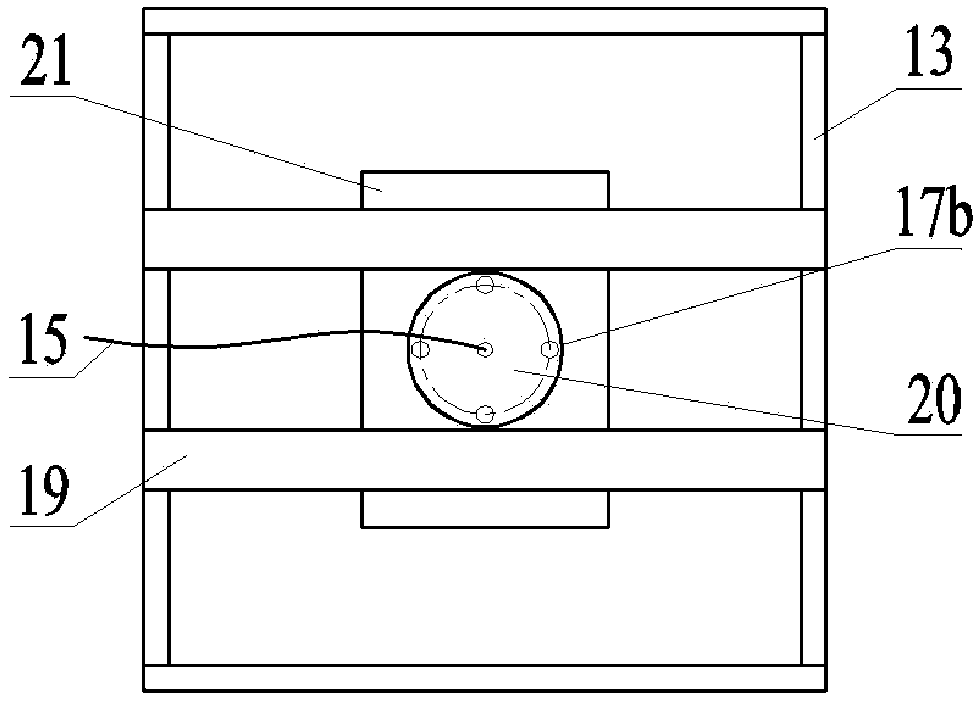

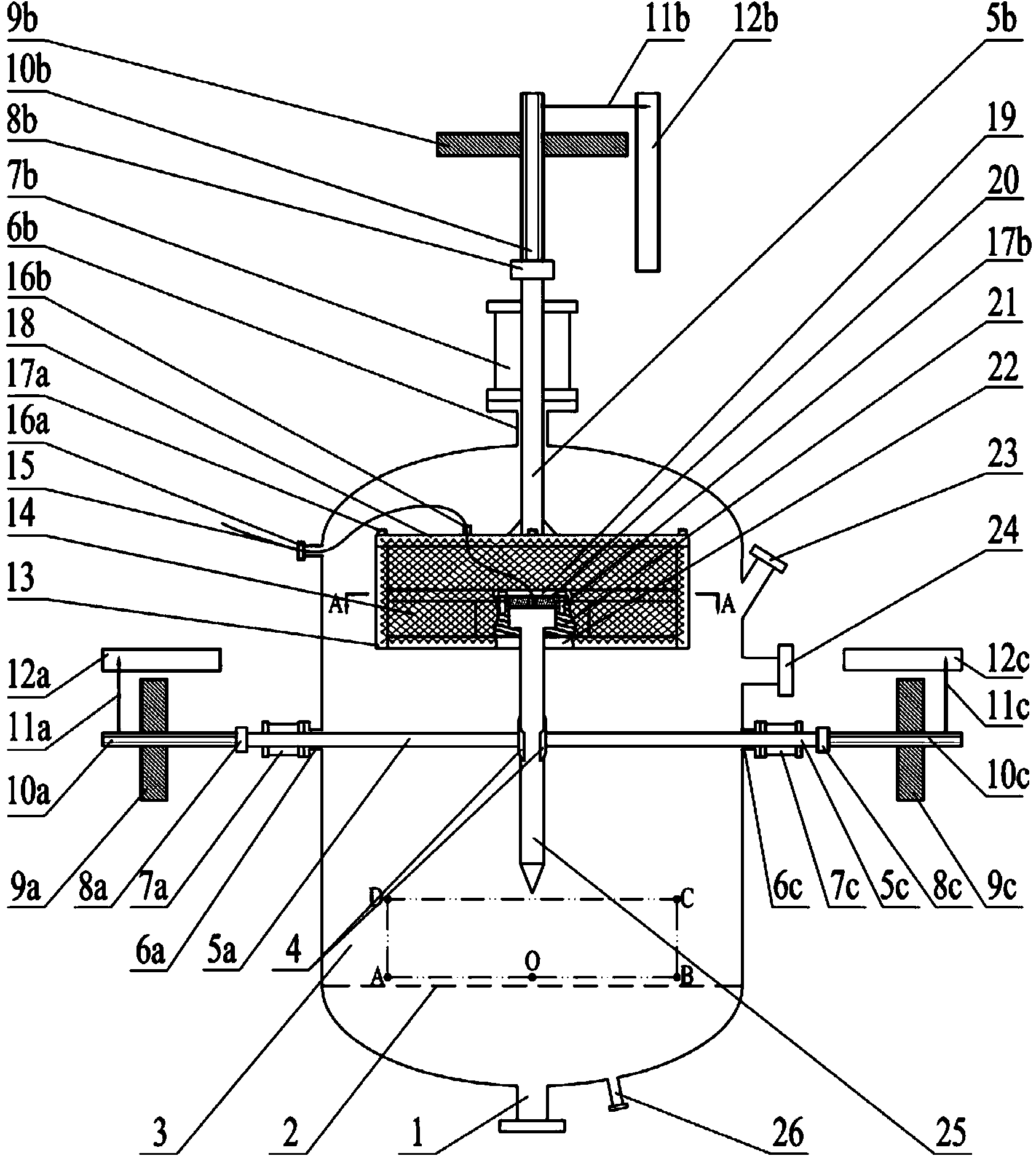

[0037] A mobile multi-point measuring device and measurement method for multiphase flow parameters of a gas-solid fluidized bed, which includes a gas-solid fluidized bed, a moving sealing part, a displacement indicating part, a probe support frame and a sensor part, the gas-solid flow The fluidized bed includes a gas inlet 1, a gas distributor 2, and a fluidized bed shell 3. The top of the fluidized bed shell 3 has an interface 6b, a lead wire interface 16a, the upper part has a feed port 23, a gas outlet 24, and the middle part has a Interface 6a and interface 6c, with a discharge port 26 at the bottom; fluidization gas enters the fluidized bed shell 3 from the gas inlet 1, flows upward through the gas distributor 2 and enters the fluidization zone, and the fluidization gas continues to move upward through the flow The upper gas outlet 24 of the chemical bed is discharged. The solid bed material particles are fed into the bed through the feed port 23 and discharged through the d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap