Impact type particle separator made of mutually inverted U-shaped elements

a technology of u-shaped elements and particle separators, which is applied in the field of improved impact-type particle separator constructions, can solve the problems of limiting the length of collection elements of suitable alloys, and achieve the effects of reducing time and cost, preventing accidental disassembly during operation, and simplifying assembly and disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

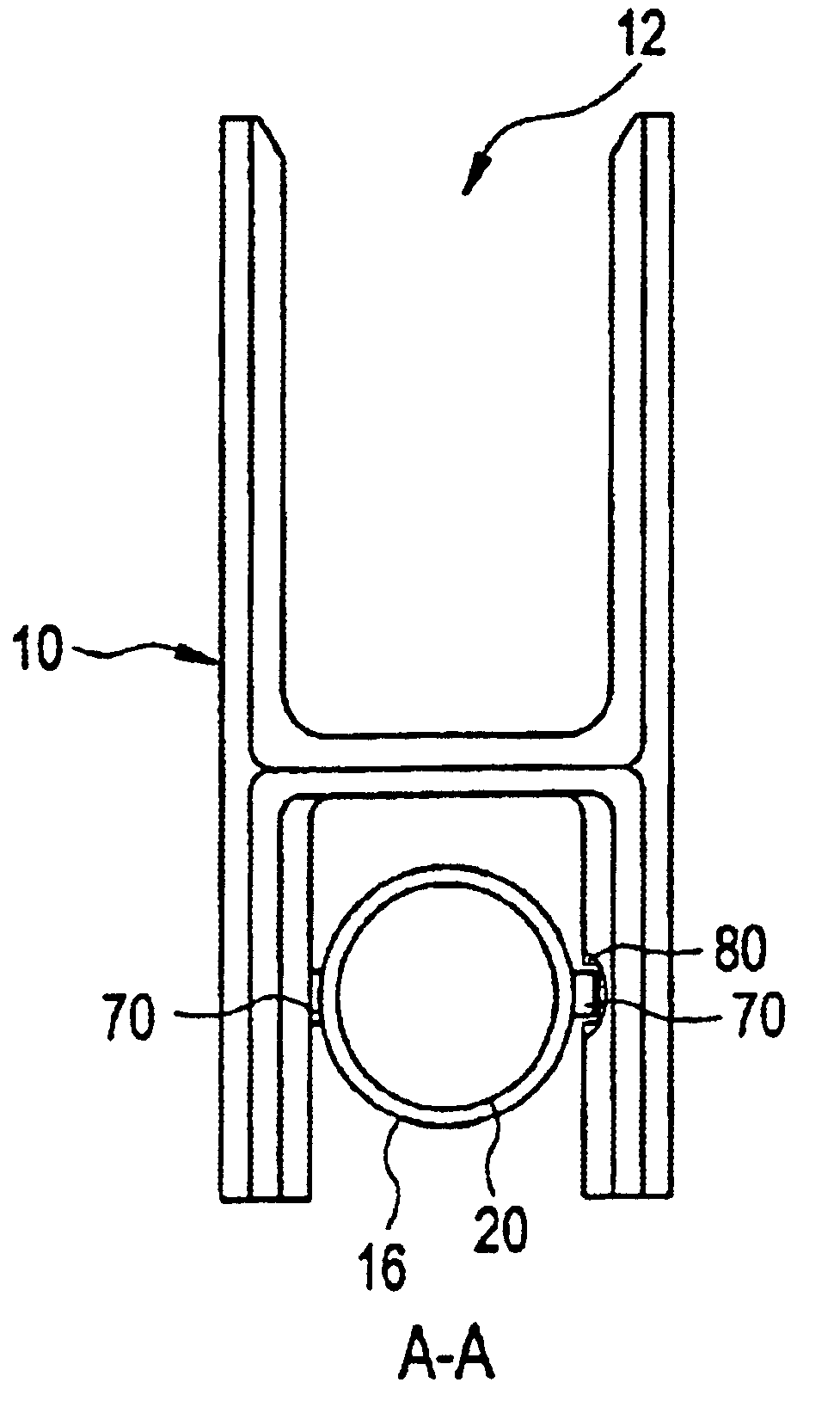

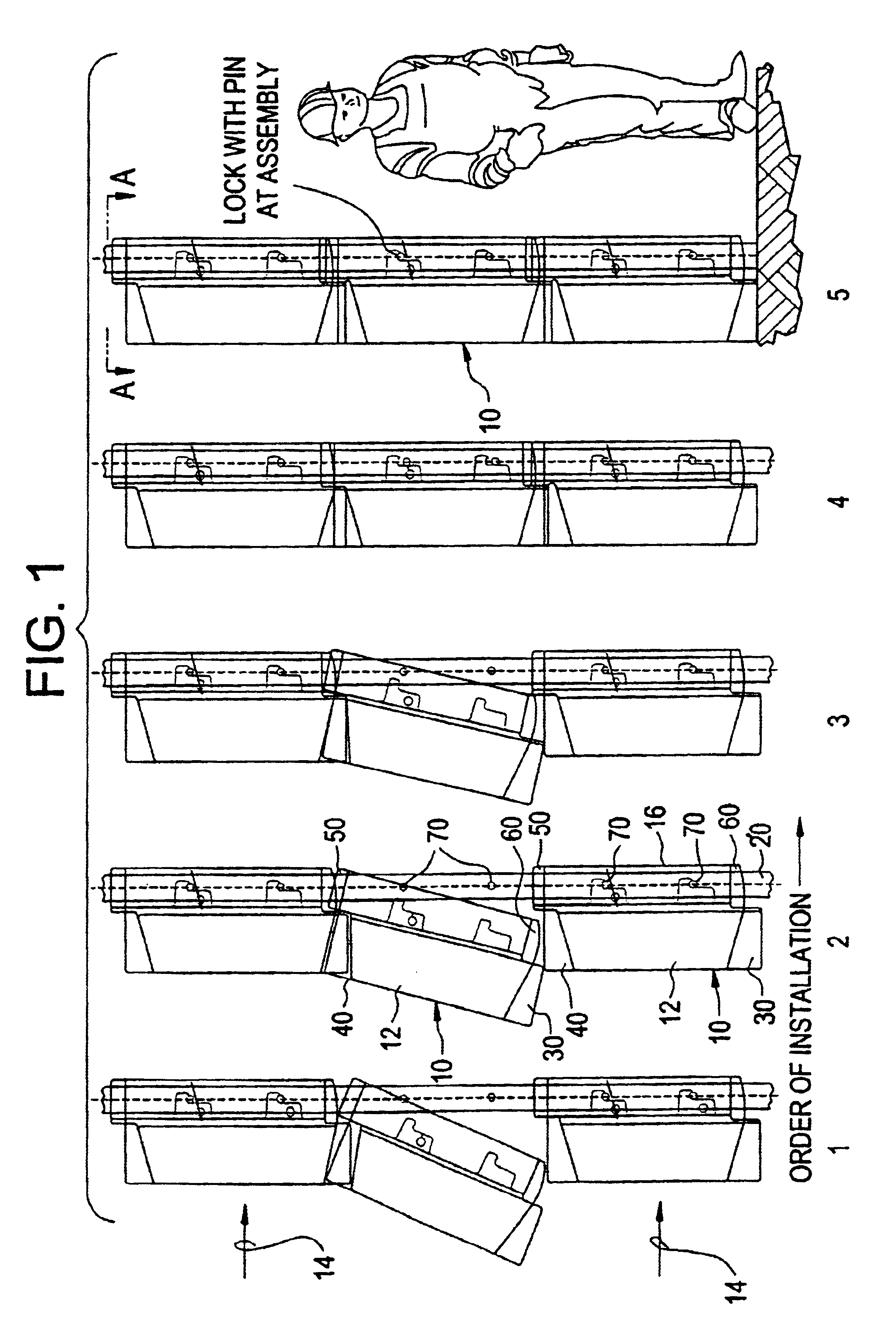

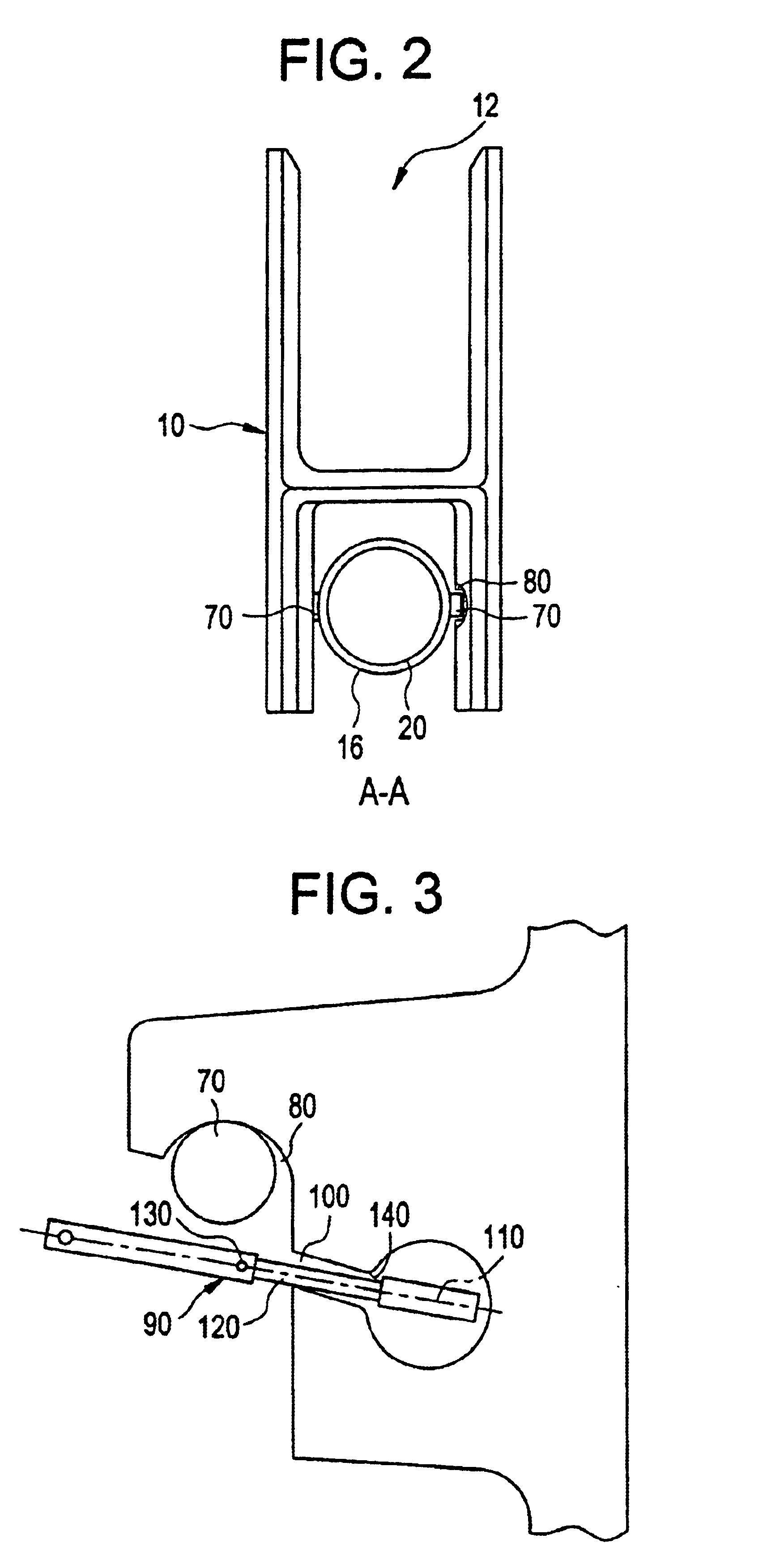

As used herein, the term CFB boiler will be used to refer to CFB reactors or combustors wherein a combustion process takes place. While the present invention is directed particularly to boilers or steam generators which employ CFB combustors as the means by which the heat is produced, it is understood that the present invention can readily be employed in a different kind of CFB reactor. For example, the invention could be applied in a reactor that is employed for chemical reactions other than a combustion process, or where a gas / solids mixture from a combustion process occurring elsewhere is provided to the reactor for further processing, or where the reactor merely provides an enclosure wherein particles or solids are entrained in a gas that is not necessarily a byproduct of a combustion process. Similarly, the term U-beam is used in the following discussion for the sake of convenience, and is meant to refer broadly to any type of concave impingement members or impact type particle

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap