Integrated backflow-free A2O equipment based on fluidized bed

A non-reflux, fluidized bed technology, applied in chemical instruments and methods, multi-stage water treatment, water/sludge/sewage treatment, etc., can solve the problems of short hydraulic retention time, insufficient carbon source, high energy consumption, etc., to achieve The effect of reducing hydraulic concentration and dead zone, shortening the start-up period, and high volume utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

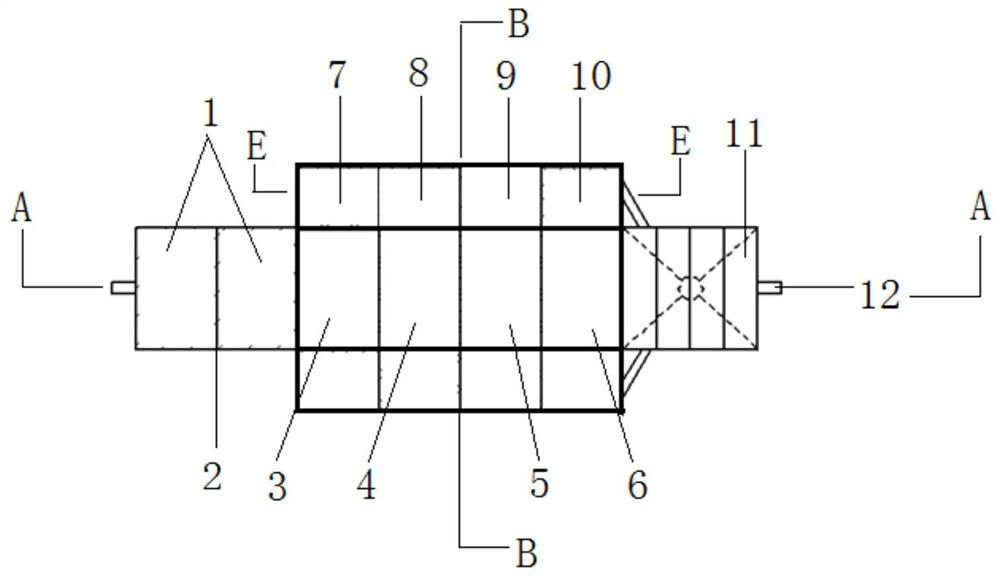

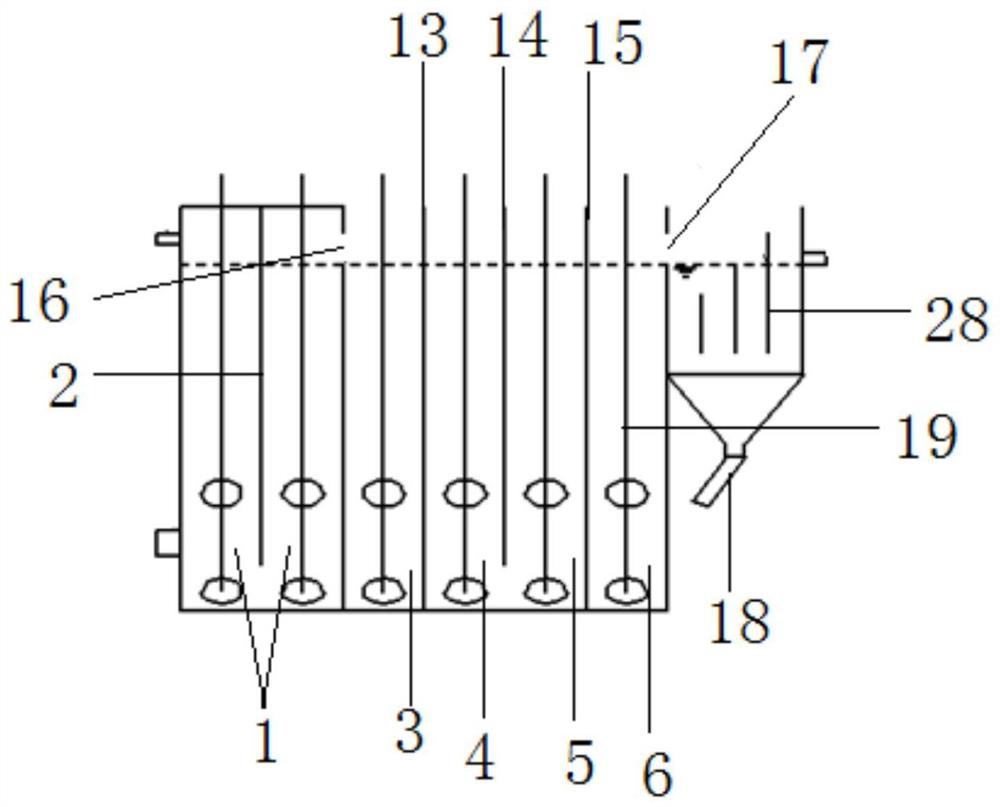

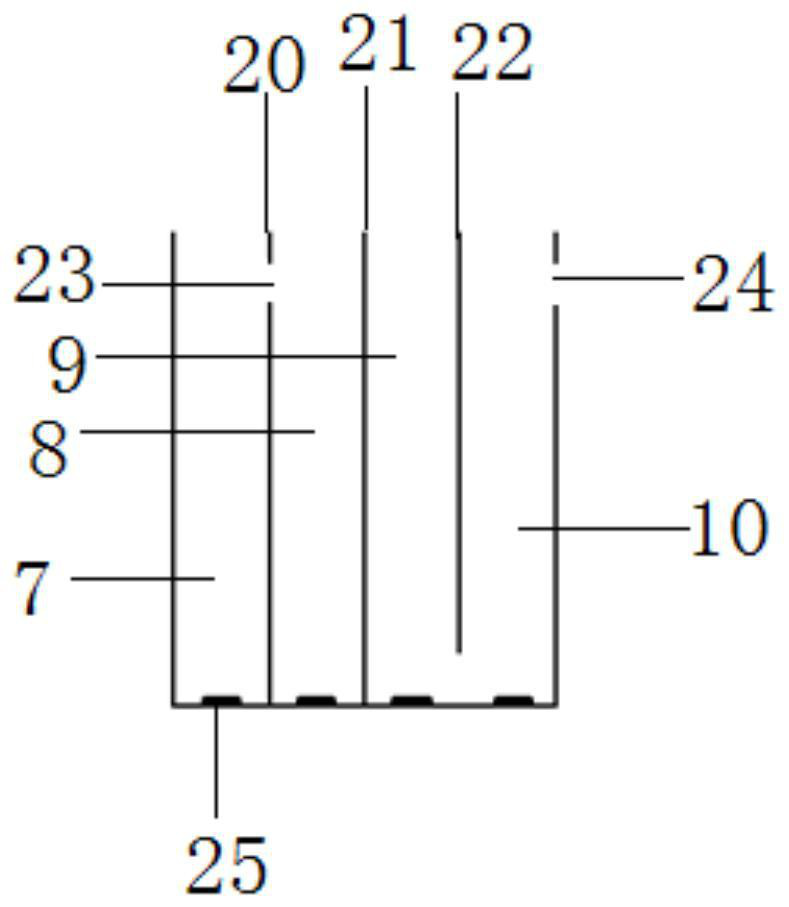

[0024] Embodiment 1: as Figure 1-Figure 6 as shown,

[0025] An integrated non-reflux A2O equipment based on fluidized bed, including anaerobic zone 1, anoxic zone, aerobic zone and sedimentation tank 11, anaerobic zone 1, anoxic zone and sedimentation tank 11 are set in sequence and pass through the overflow The aerobic zone is arranged on both sides of the anoxic zone and communicates with the anoxic zone and the sedimentation tank 11. The anoxic zone and the aerobic zone are separated by deflectors 26, and the deflectors 26 are arranged from top to bottom. At least two circulation ports 27; the bottom of the aerobic zone is provided with an aeration pan 25, the anaerobic zone 1 and the anoxic zone are provided with a stirring device 19; the bottom of the sedimentation tank 11 is provided with a sludge return port and a sludge discharge port 18, and the sludge The mud return port communicates with the anaerobic zone 1, and a water outlet 12 is set on the top of the side wall

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap