Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Volumetric Mass Density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The density (more precisely, the volumetric mass density; also known as specific mass), of a substance is its mass per unit volume. The symbol most often used for density is ρ (the lower case Greek letter rho), although the Latin letter D can also be used. Mathematically, density is defined as mass divided by volume: ρ=m/V where ρ is the density, m is the mass, and V is the volume. In some cases (for instance, in the United States oil and gas industry), density is loosely defined as its weight per unit volume, although this is scientifically inaccurate – this quantity is more specifically called specific weight.

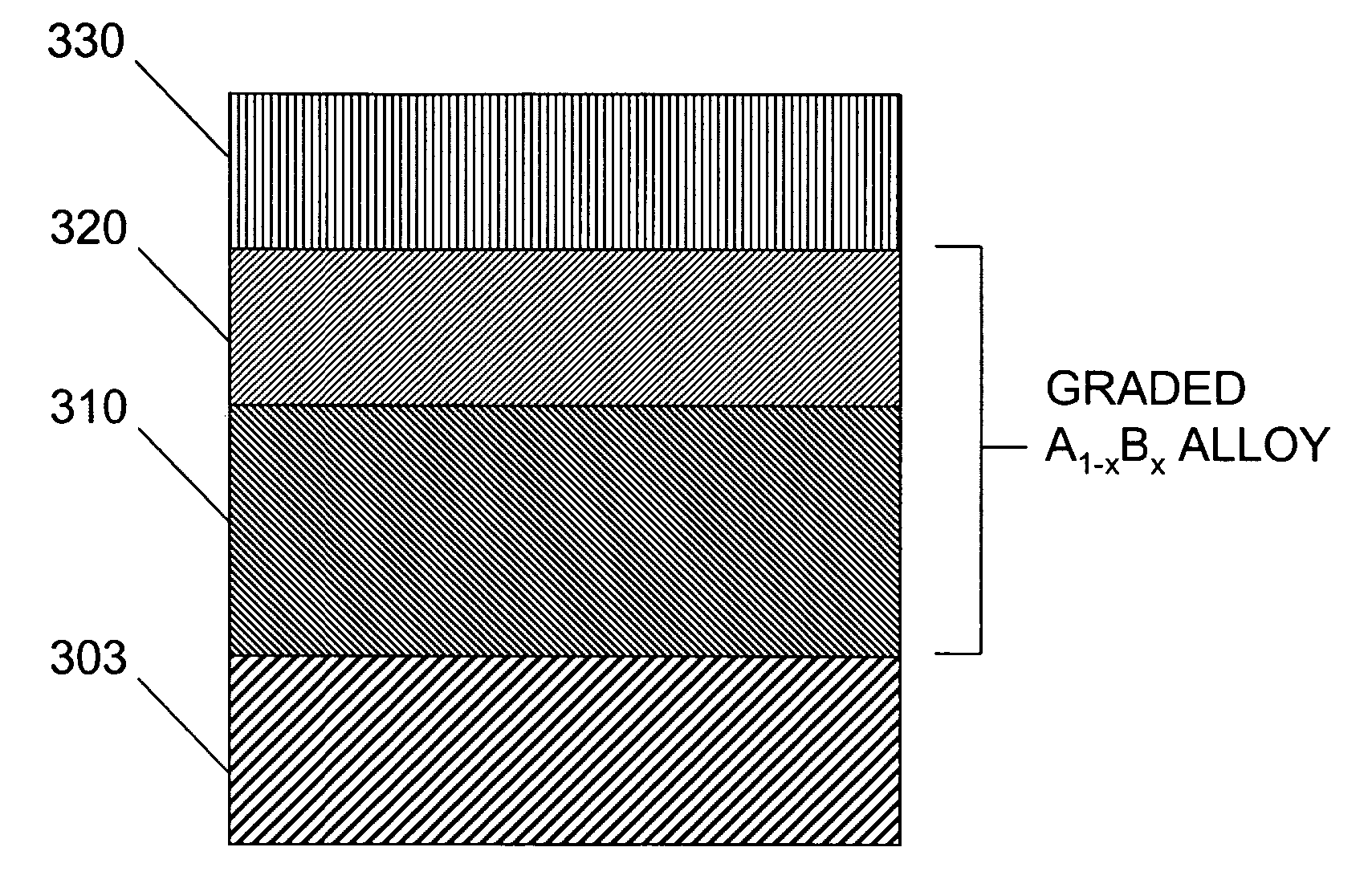

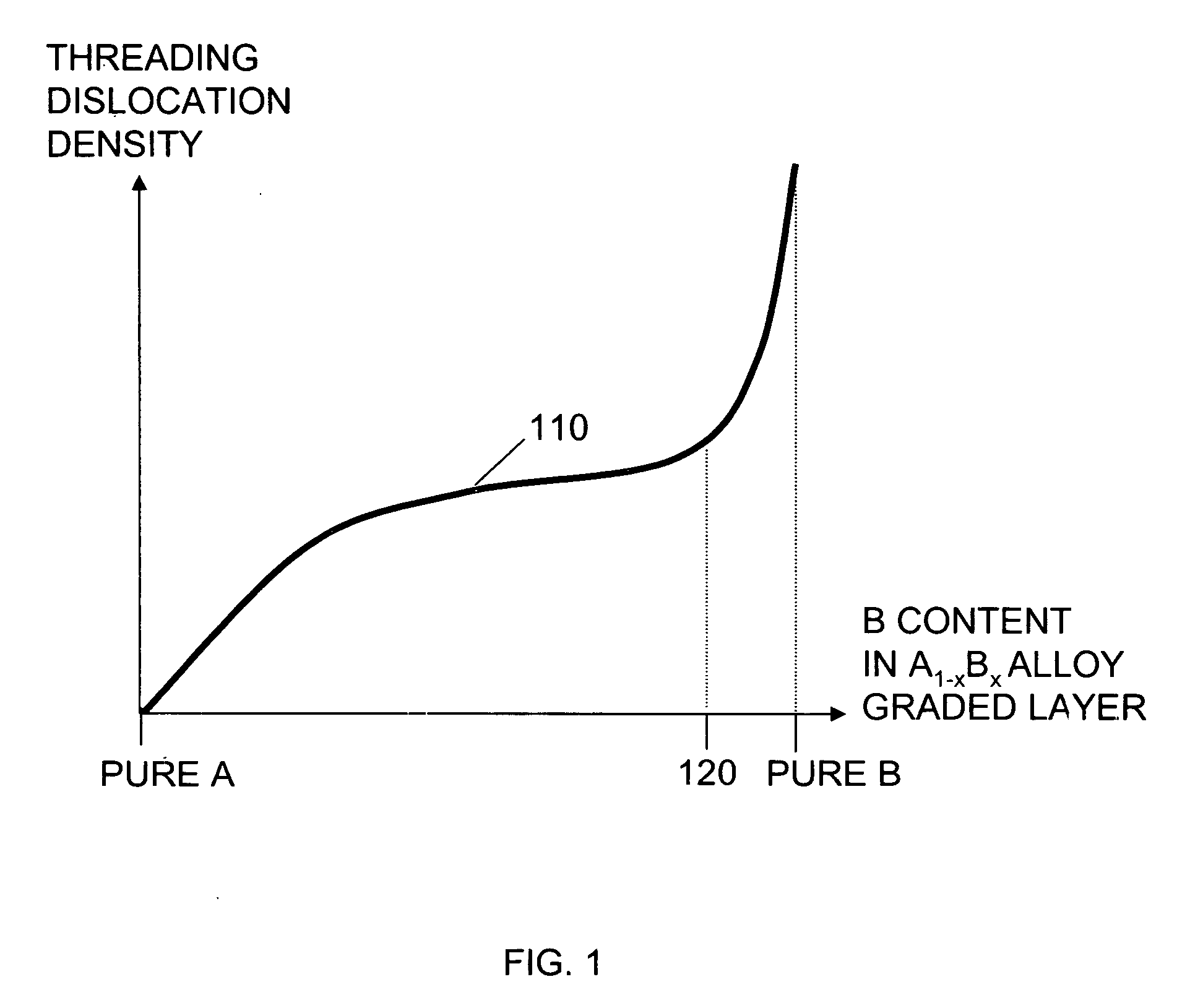

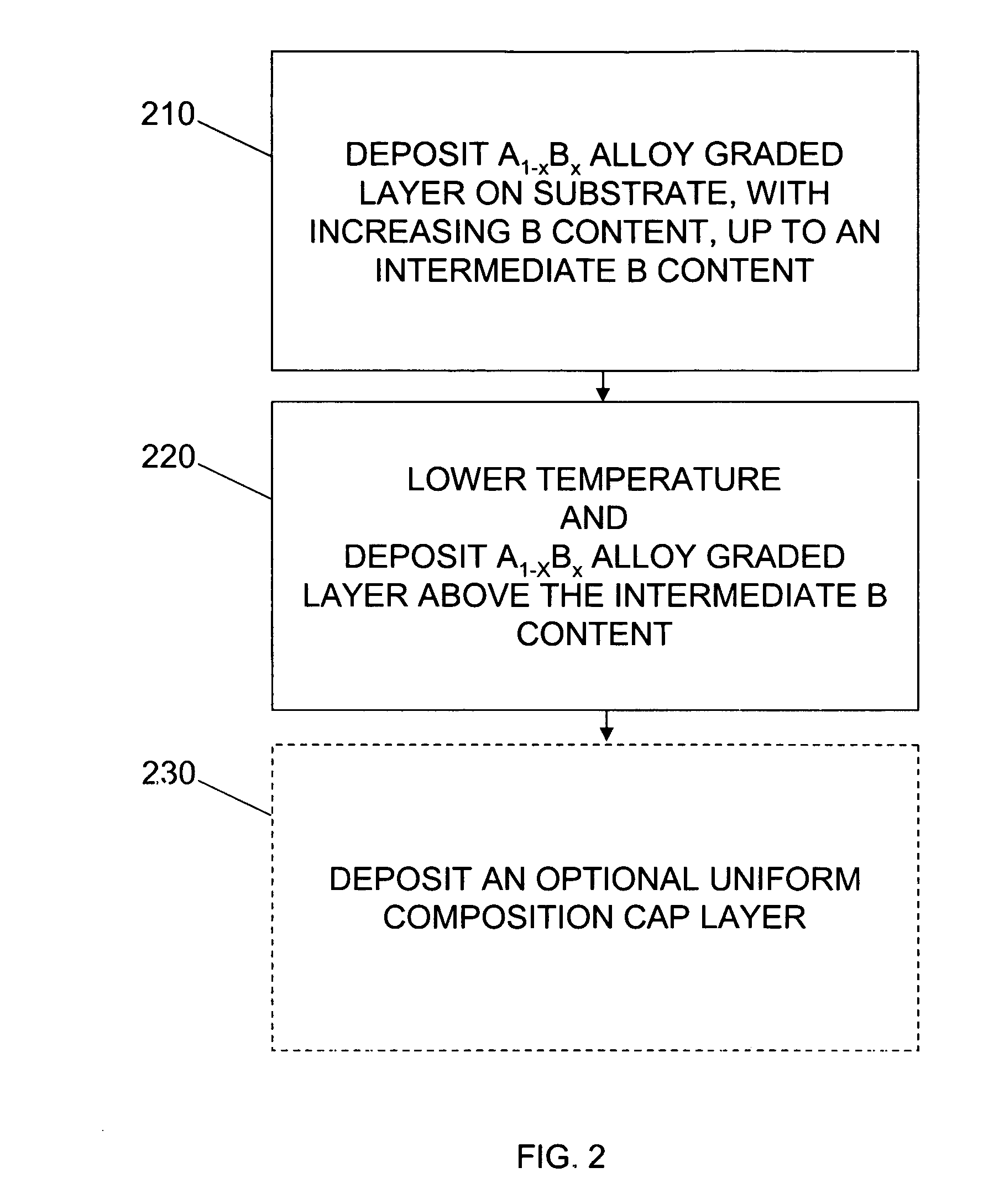

Method for forming low defect density alloy graded layers and structure containing such layers

ActiveUS20060113542A1Reduce threading dislocation densityLight-sensitive devicesSemiconductor/solid-state device manufacturingDeposition temperatureVolumetric Mass Density

Owner:MASSACHUSETTS INST OF TECH

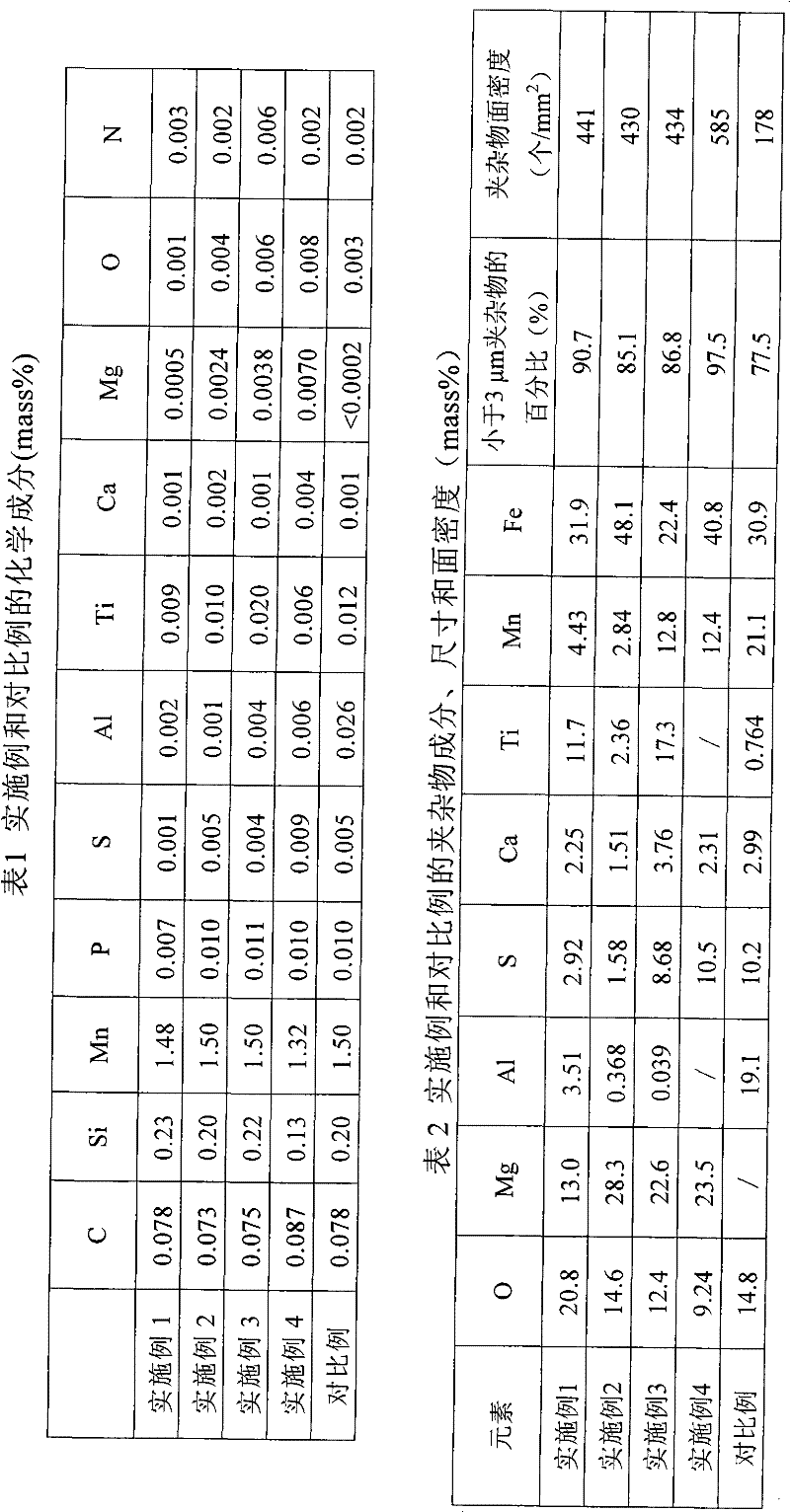

Control method of inclusions in thick steel plate used for high heat input welding

Owner:BAOSHAN IRON & STEEL CO LTD

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

Small pore diameter silicone rubber sponge and preparation method thereof

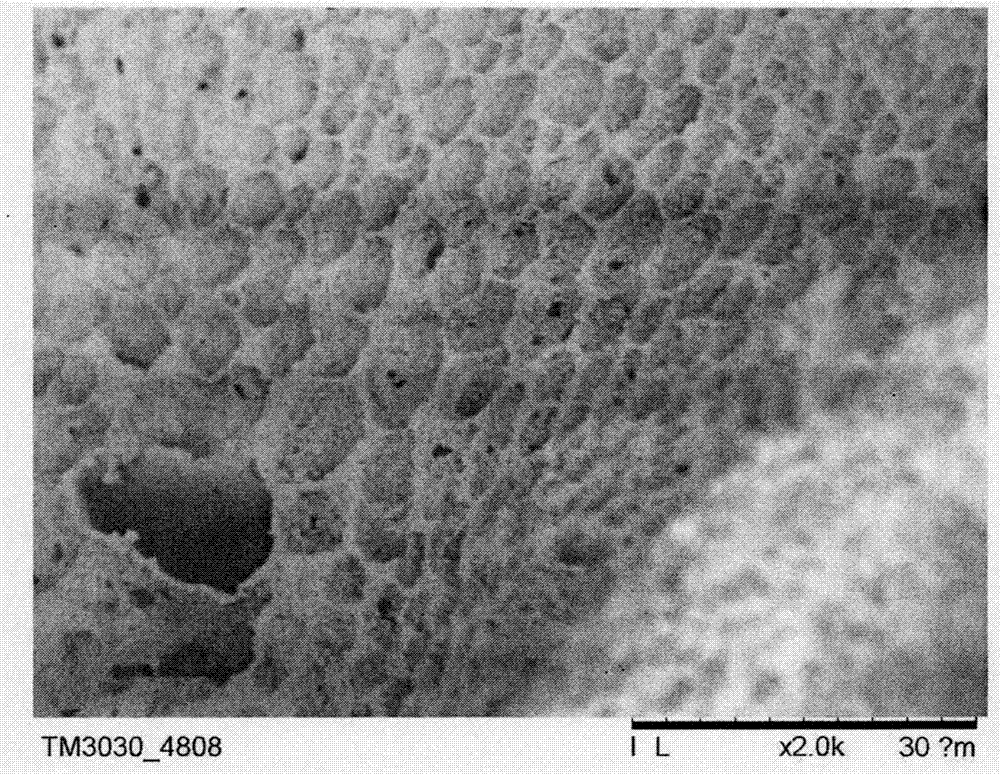

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

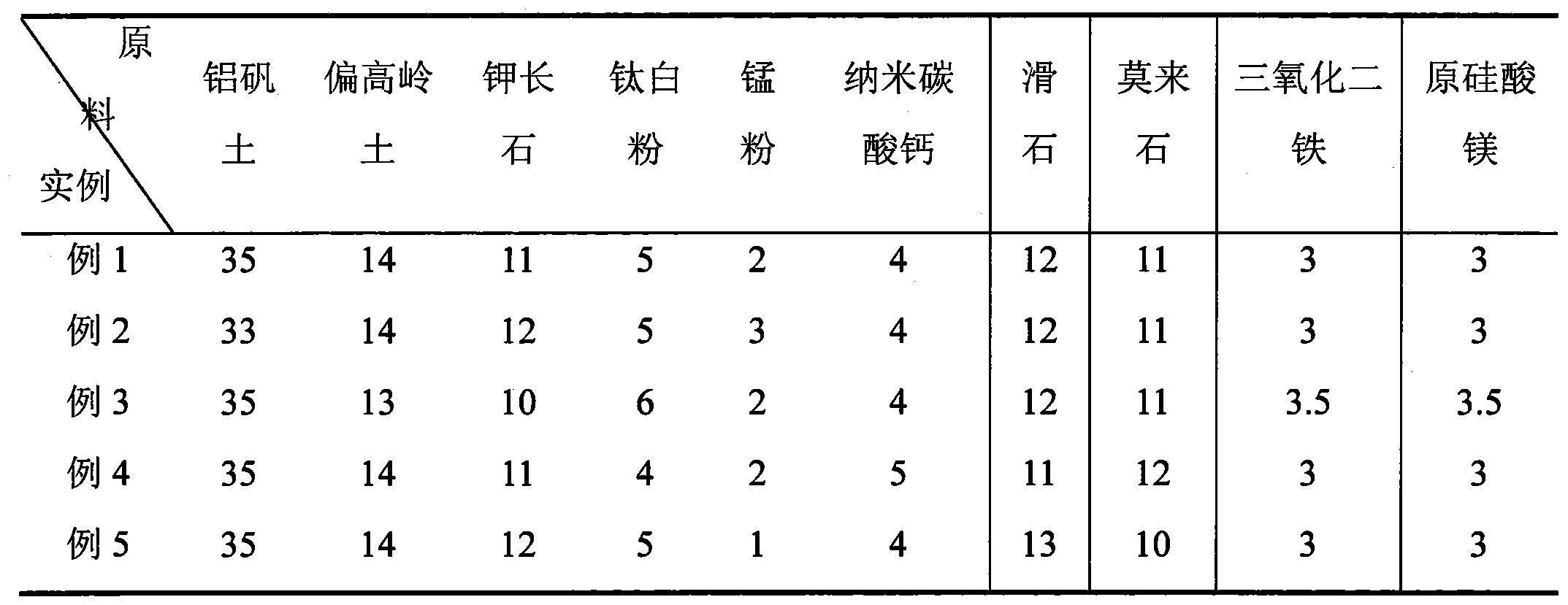

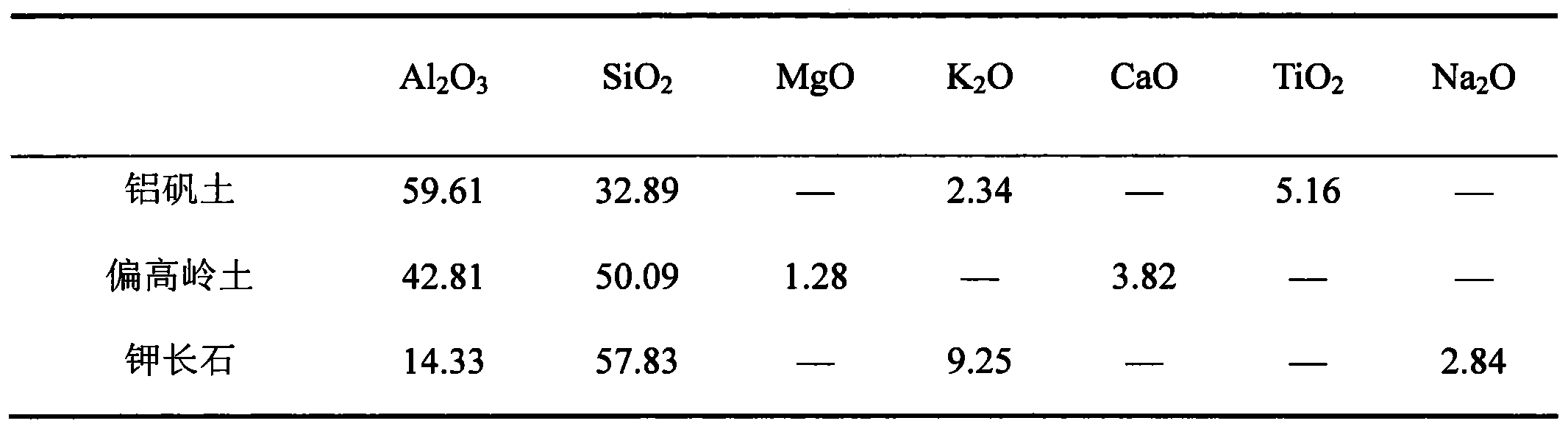

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

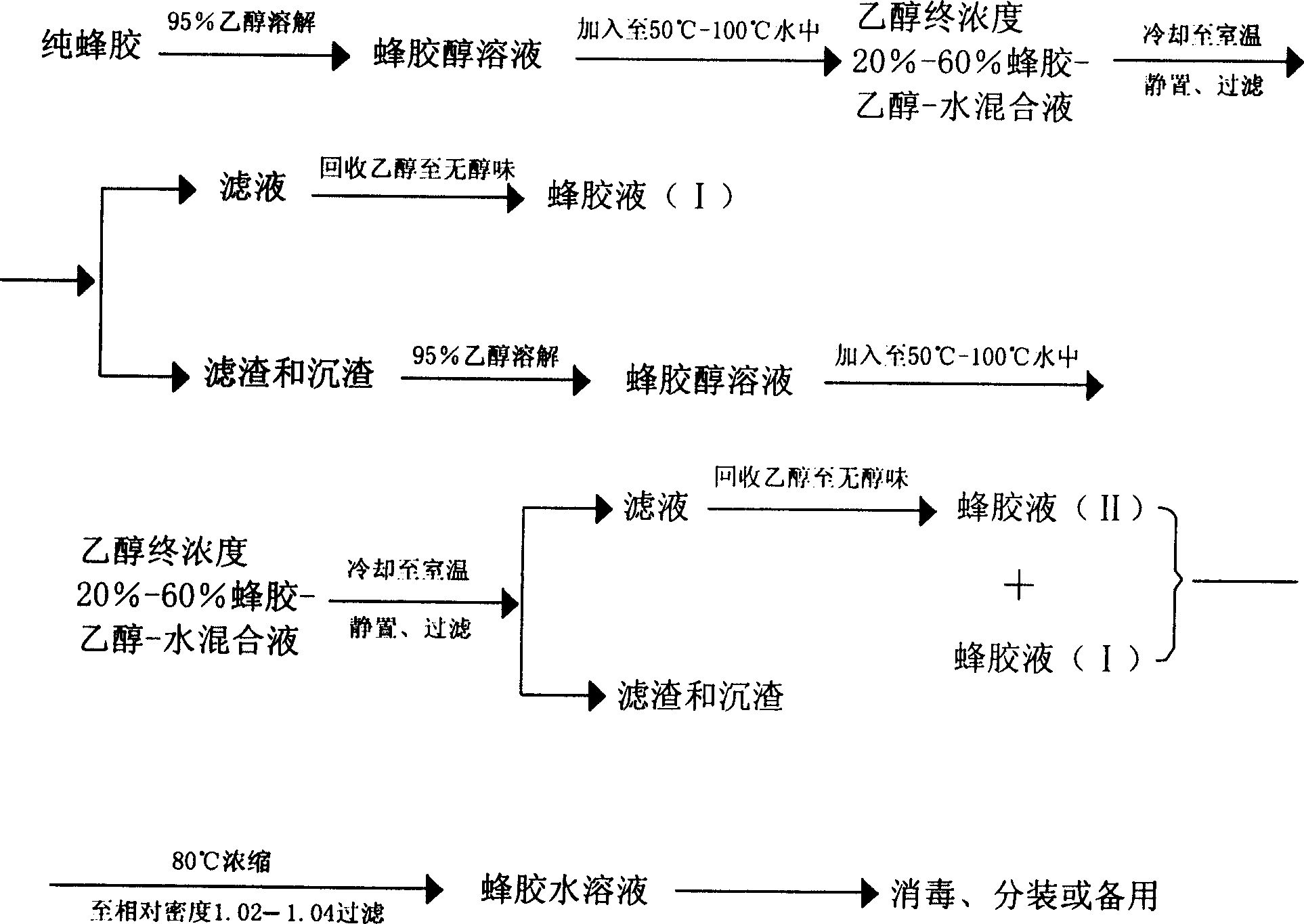

Process for preparing bee glue water solution and use

InactiveCN1682770ASimple processHigh in flavonoidsAnthropod material medical ingredientsMetabolism disorderAlcohol contentPropolis

Owner:ZHEJIANG ACAD OF TRADITIONAL CHINESE MEDICINE

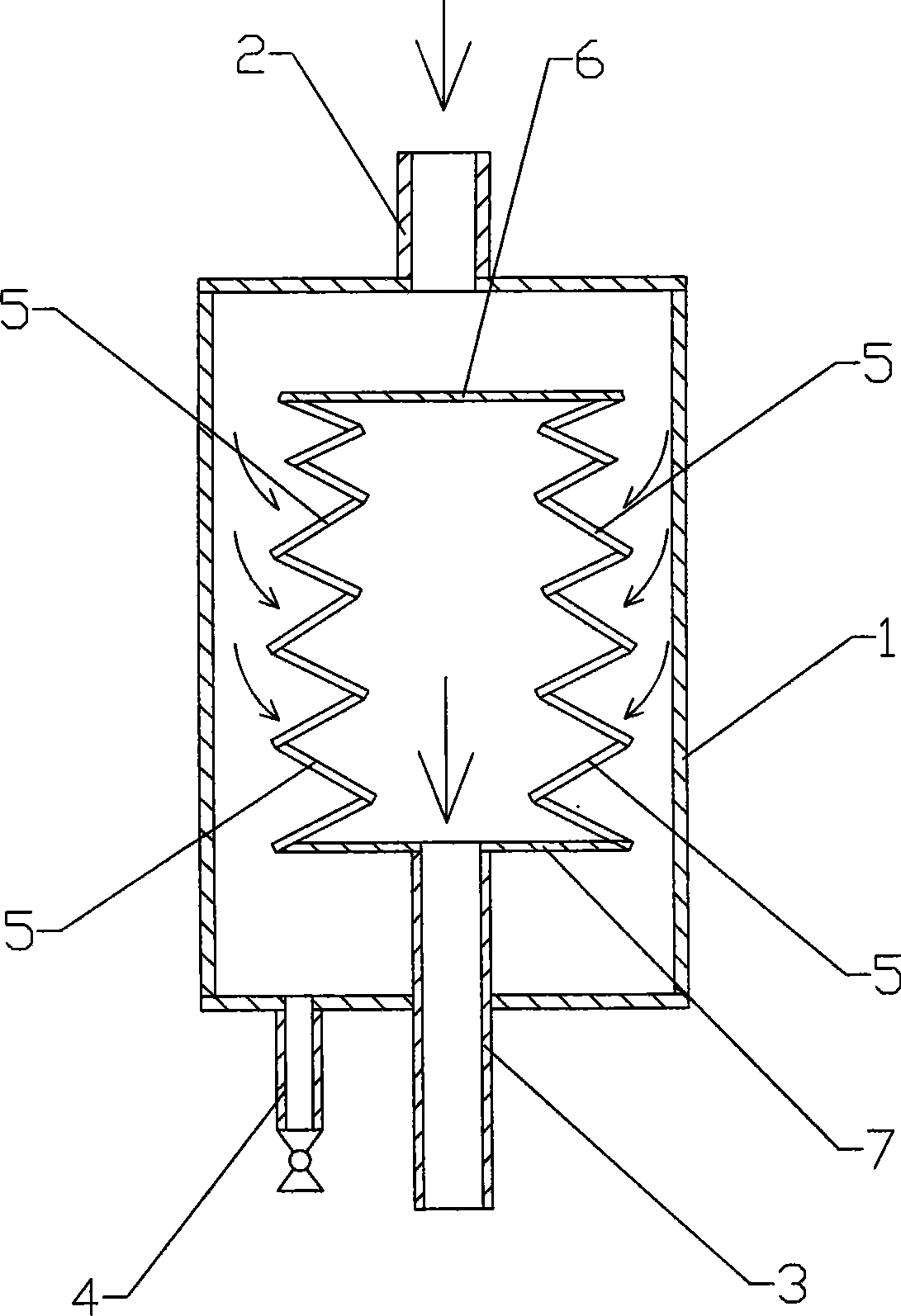

Filter

InactiveCN101462019ASmall apertureHigh densityDispersed particle filtrationBiochemical engineeringFiltration

Owner:薛文伟

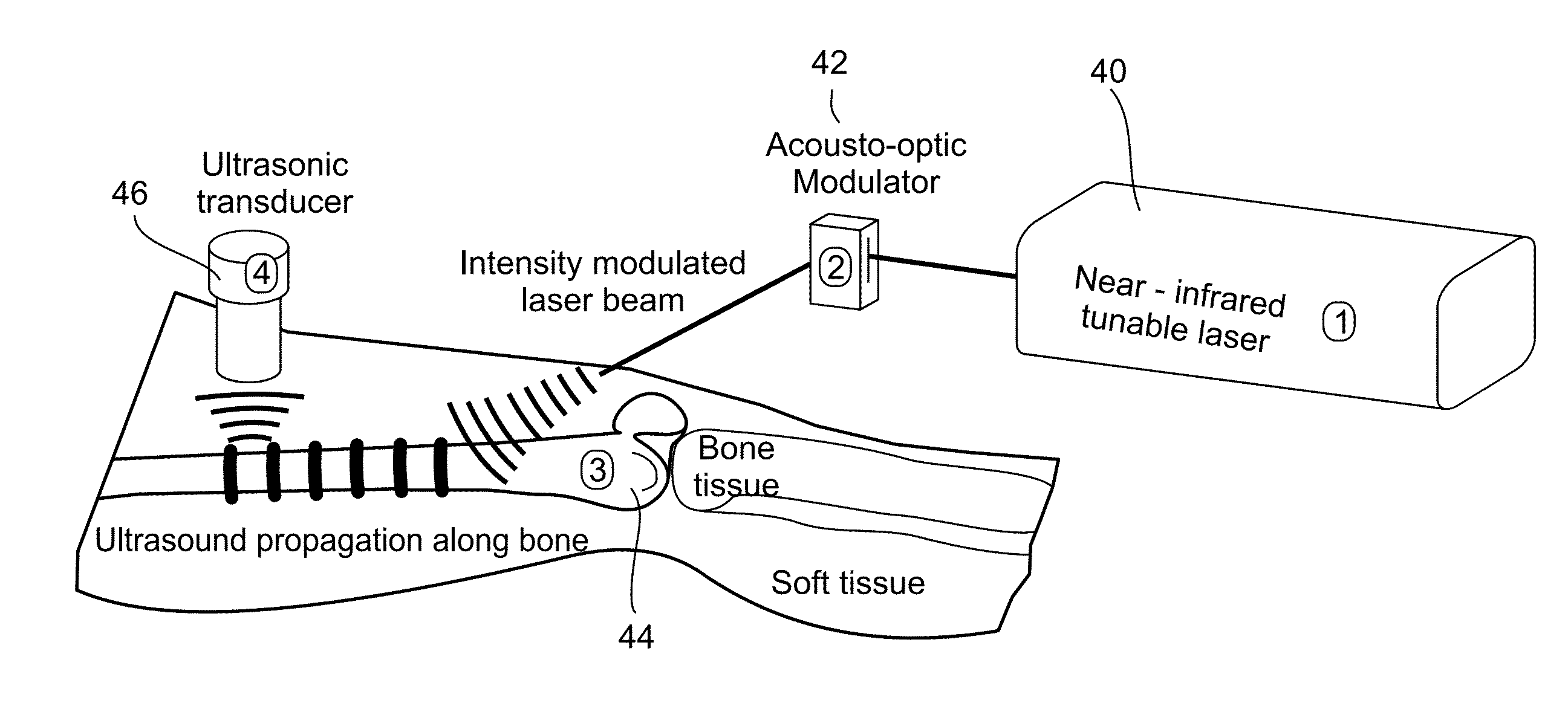

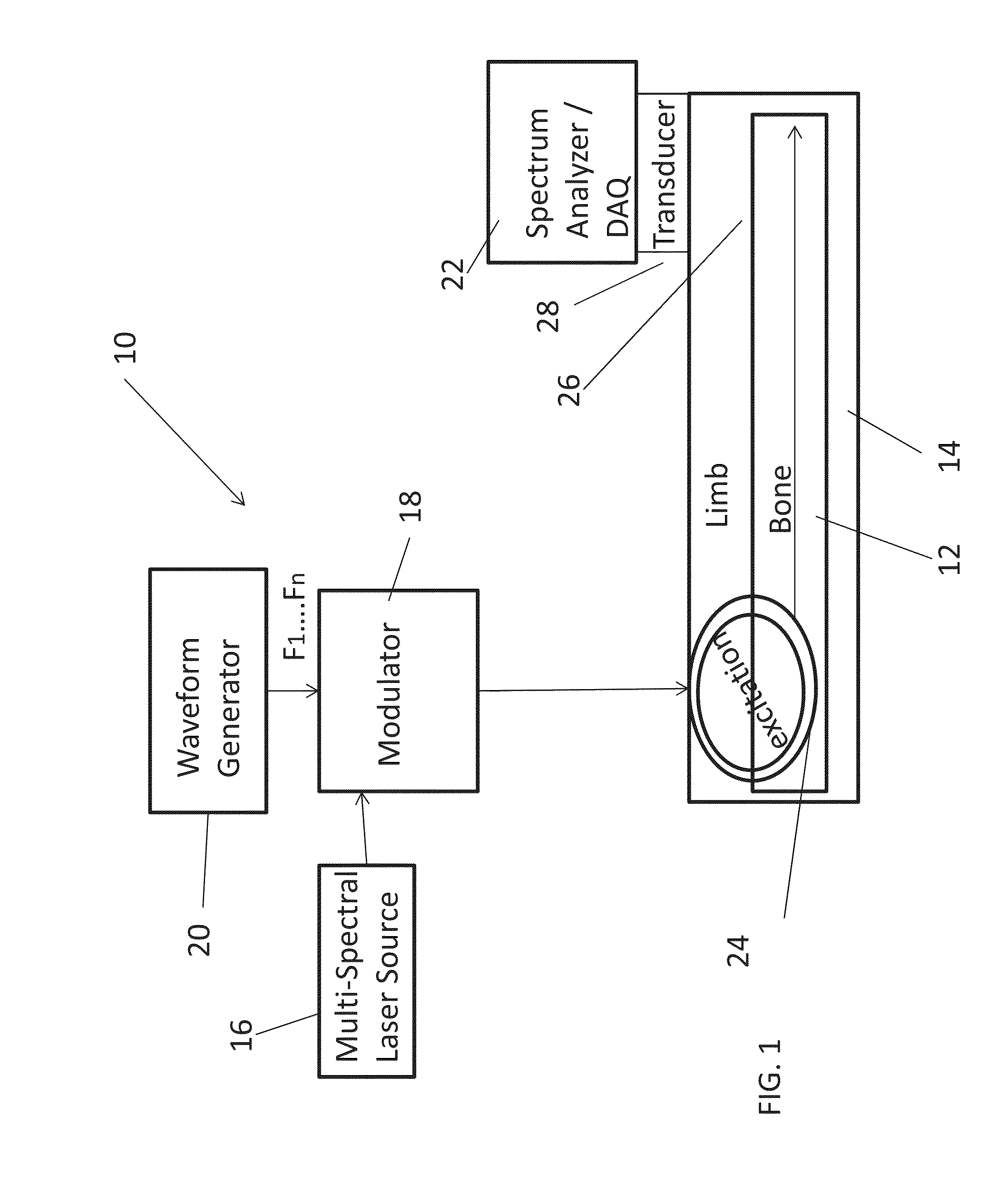

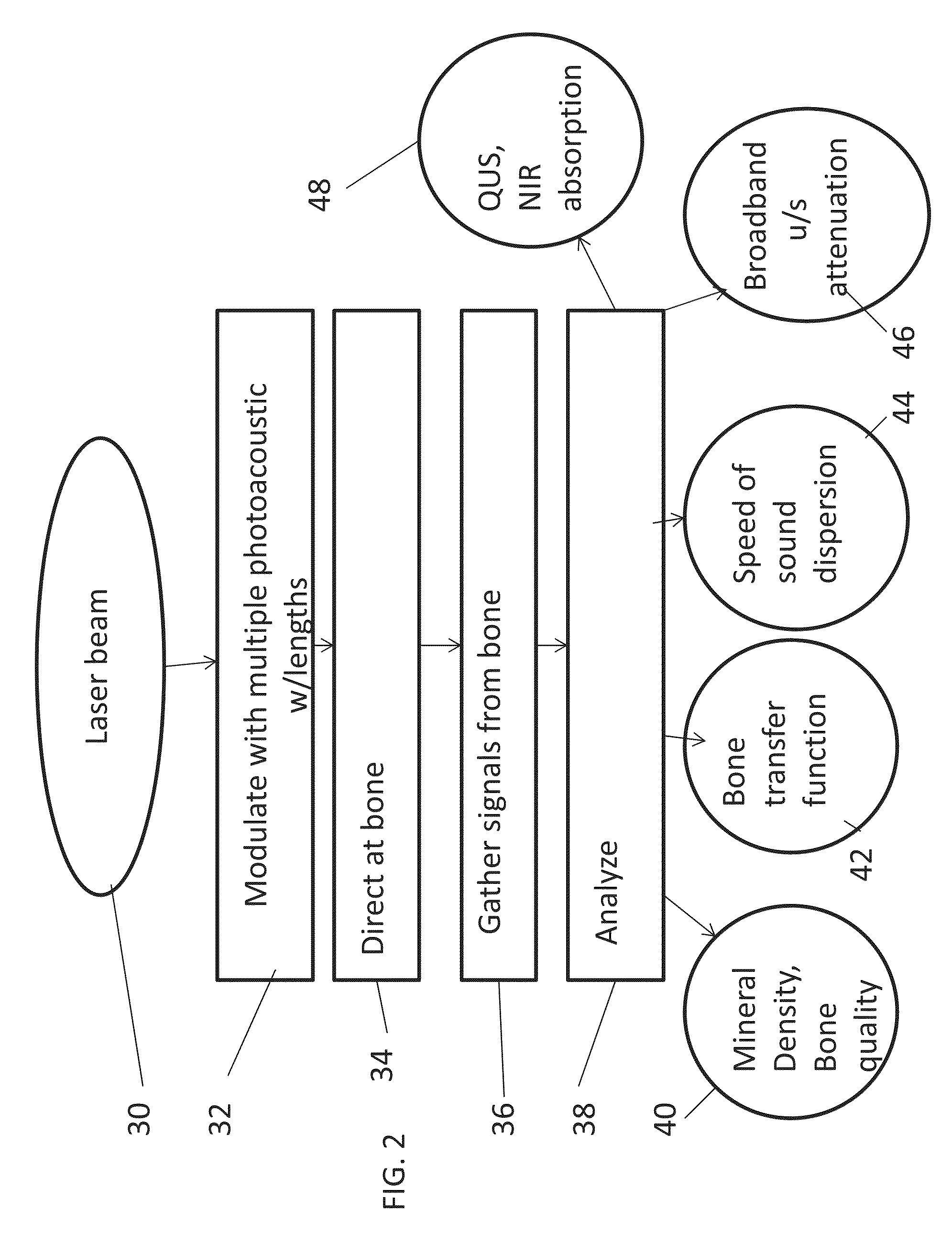

Detection, diagnosis and monitoring of osteoporosis by a photo-acoustic method

Owner:RAMOT AT TEL AVIV UNIV LTD

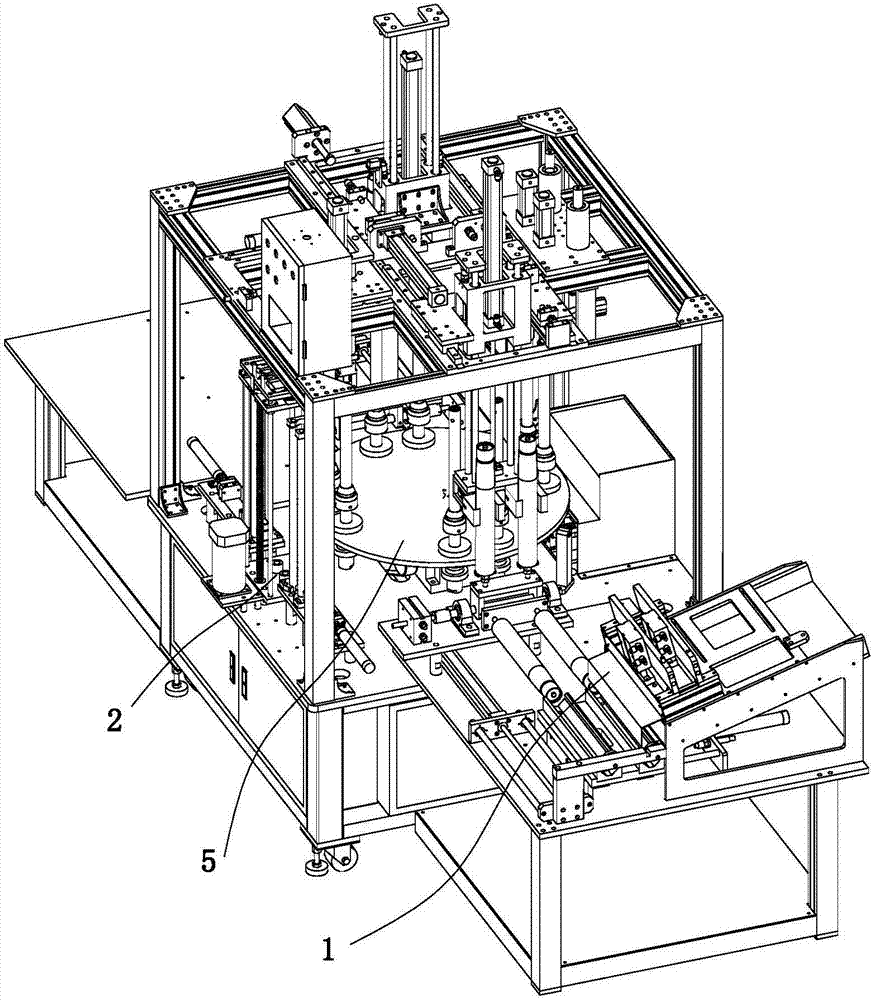

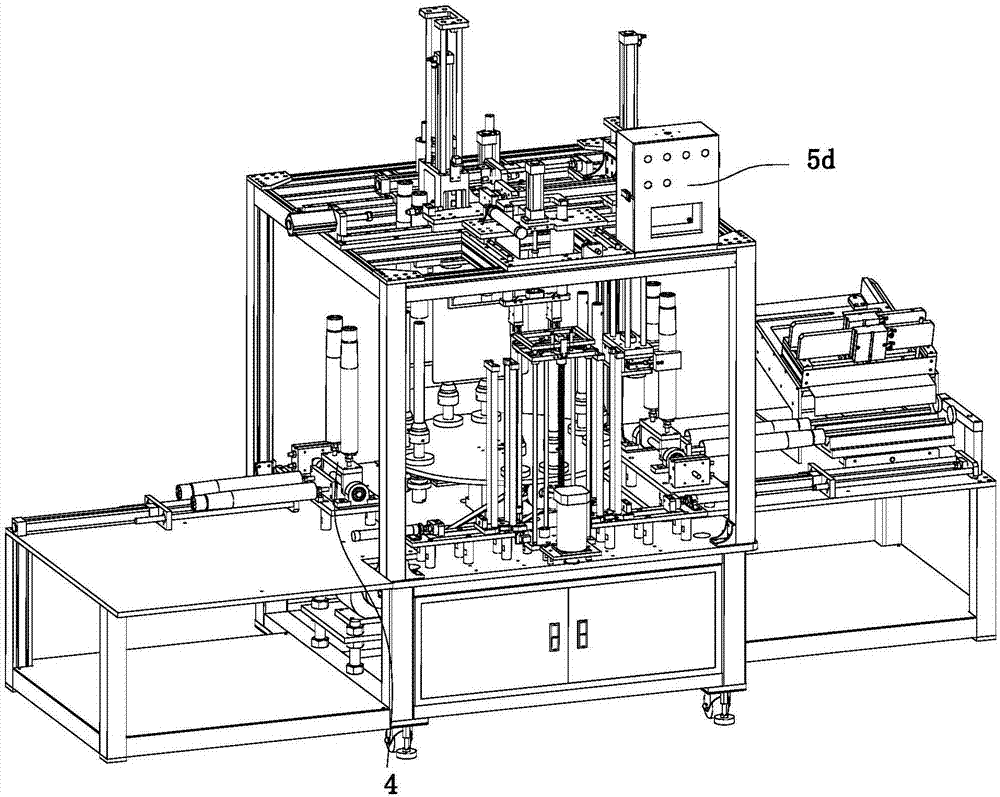

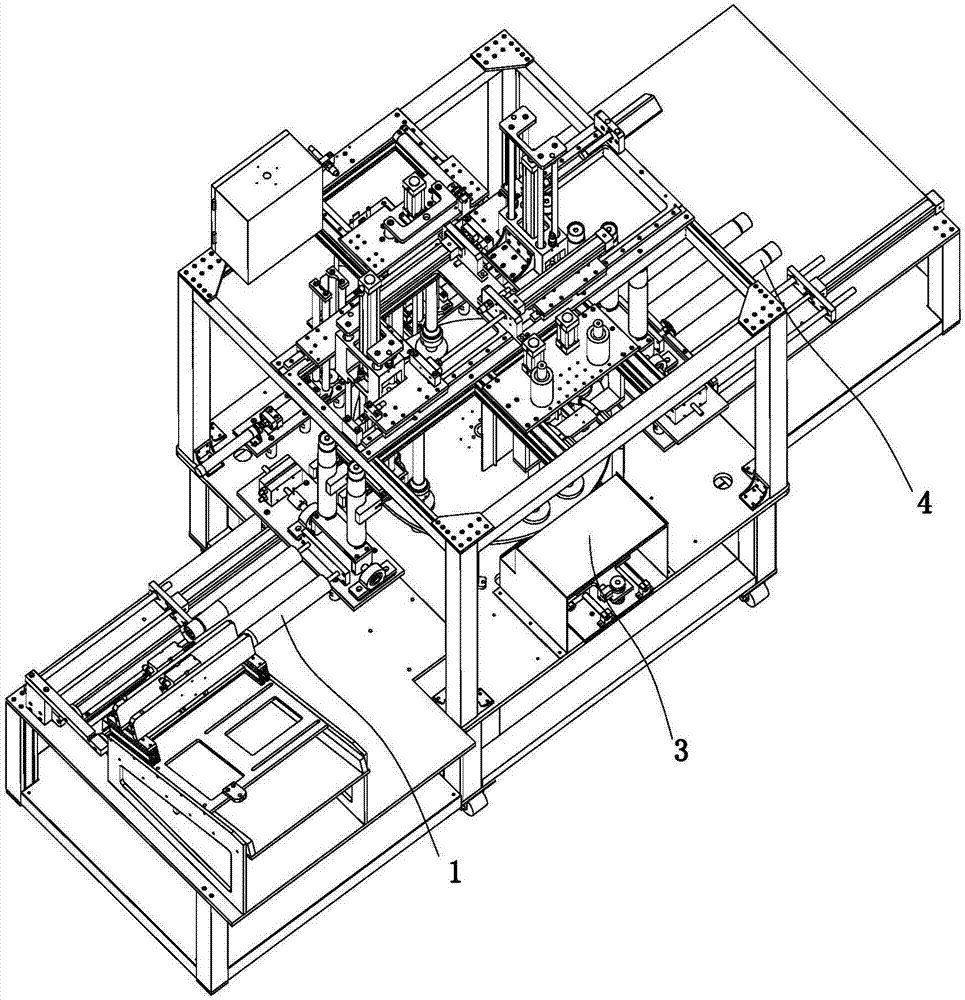

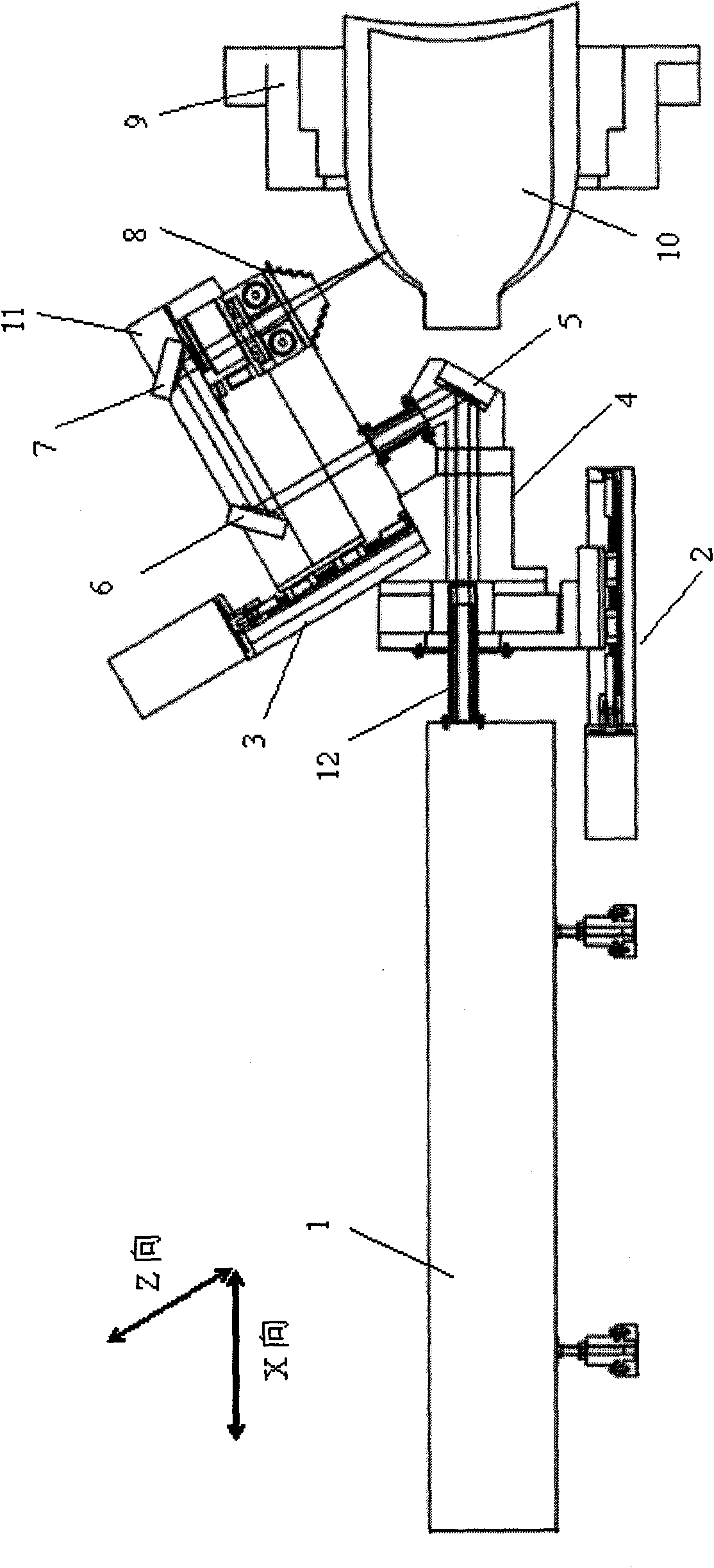

Full-automatic welding machine

ActiveCN107378321APrecise feedingWay accurateWelding/cutting auxillary devicesAuxillary welding devicesVolumetric Mass DensityEngineering

Owner:安徽荣盛精密科技有限责任公司

High-temperature resistant heat insulating material using vermiculite as main raw material and method for manufacturing same

InactiveCN101560087ASolve the strength problemSolve temperature problemsSolid waste managementMixing operation control apparatusPhosphateVolumetric Mass Density

Owner:佛山市冠富贸易有限公司 +1

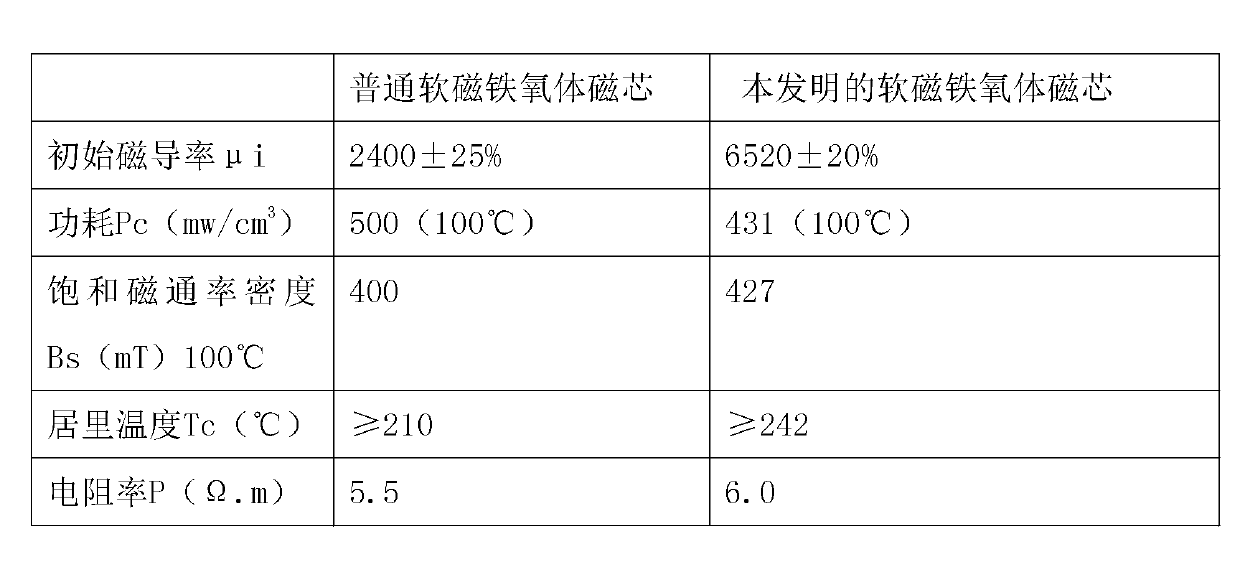

Preparation method of MnZn (Manganese-Zinc) soft magnetic ferrite material containing modified nanoscale titanium dioxide

Owner:浙江大通磁业科技有限公司

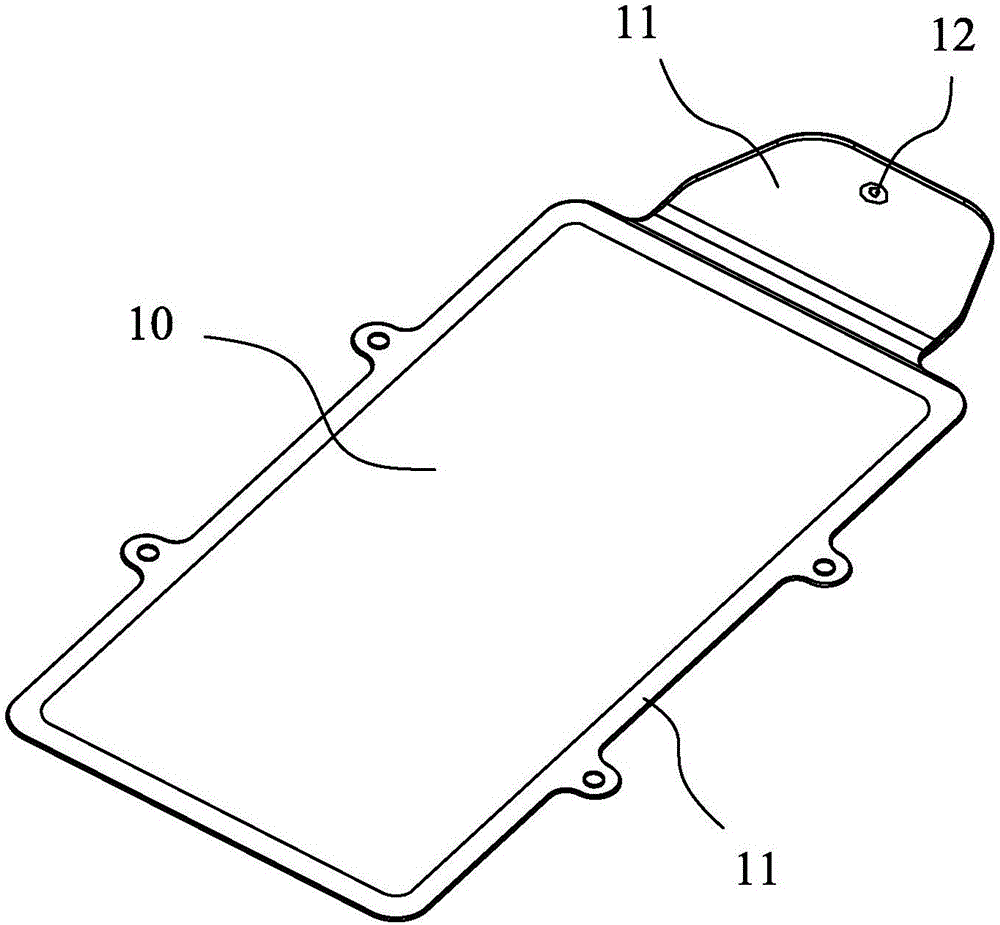

Manufacturing method of high-hardness plastic screen and housing of mobile phone and mobile phone screen and housing manufactured thereby

ActiveCN105922525AHigh hardnessReduce use costSynthetic resin layered productsTelephone set constructionsRainbowAdhesive

Owner:DONGGUAN JIAOJIN ELECTRONICS TECH CO LTD

Method for preparing foam glass with high foaming rate by utilizing lead-free high-barium abandoned lamp tube

InactiveCN106630649AHigh foaming rateLow melting pointGlass shaping apparatusFoaming agentSodium phosphates

The invention discloses a method for preparing foam glass with a high foaming rate by utilizing a lead-free high-barium abandoned lamp tube and belongs to the field of foam glass. The method comprises the following steps: carrying out ball milling on the lead-free high-barium abandoned lamp tube to form a glass powder raw material; feeding foaming agents, namely manganese dioxide and calcium carbonate, a fluxing agent, namely sodium fluorosilicate, and a stabilizer, namely sodium phosphate into a ball mill to be subjected to ball milling; feeding mixture obtained through ball milling into a high-temperature-resistant mould, preheating for 15-20 minutes at the temperature of 400-430 DEG C, then heating up to 800-820 DEG C, and carrying out heat preservation for 20-30 minutes; then cooling to 500-550 DEG C, annealing, and carrying out heat preservation for 35-40 minutes; and finally carrying out furnace cooling to room temperature. The prepared foam glass is uniform in pore diameter, closed pores are formed mainly, the average pore diameter reaches about 4.2mm, the density is 0.58g / cm<3>, the compressive strength is 3.78MPa, the performance is excellent, and the application standard of the foam glass can be met.

Owner:YANGZHOU UNIV

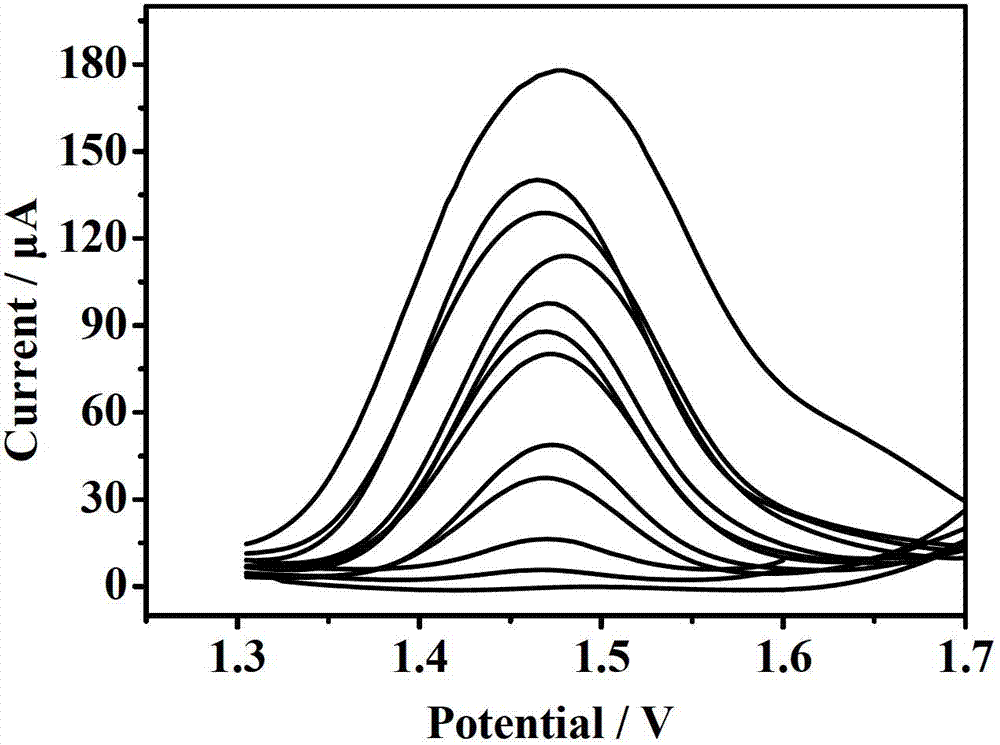

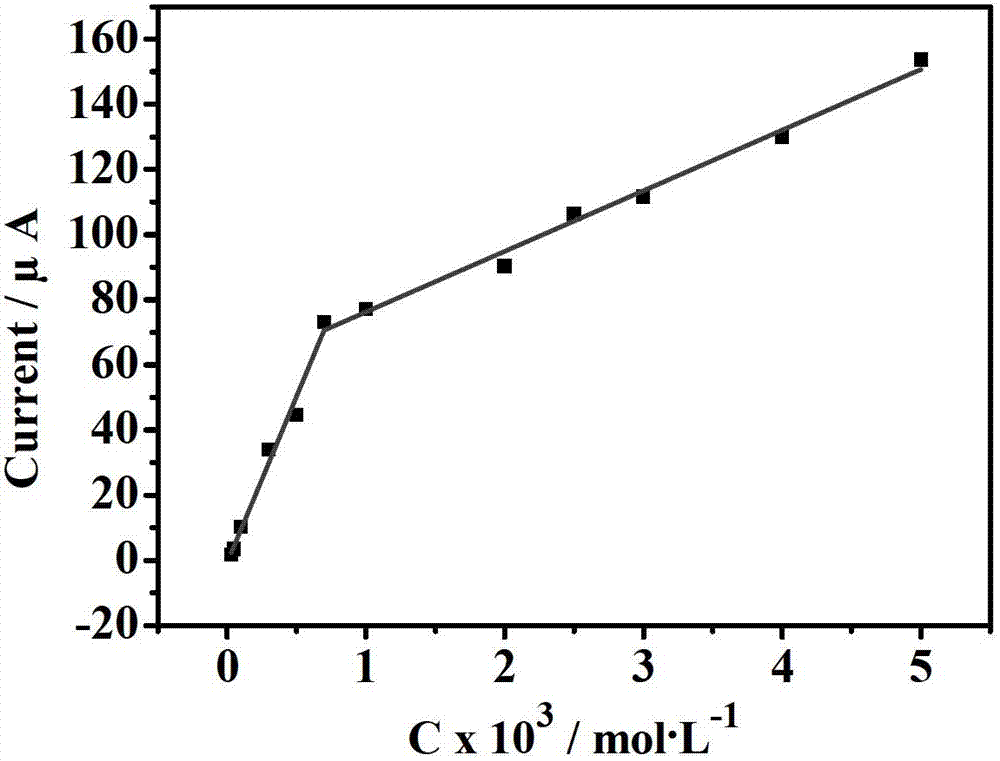

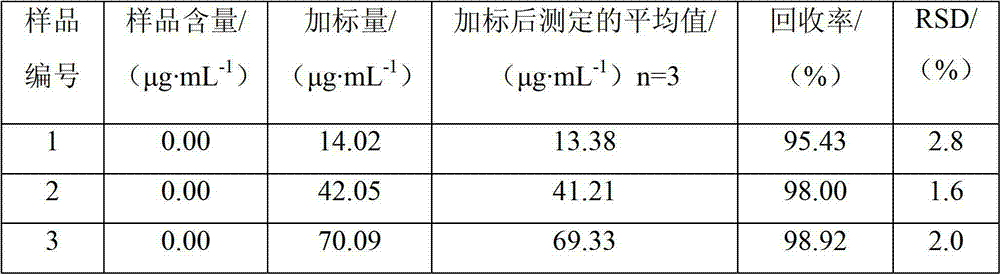

Electrochemical method for detecting banned additive urotropin in food

InactiveCN102735739AEasy to makeImprove performanceMaterial electrochemical variablesHexamethylenetetraminePhosphate

Owner:CHANGZHOU UNIV +1

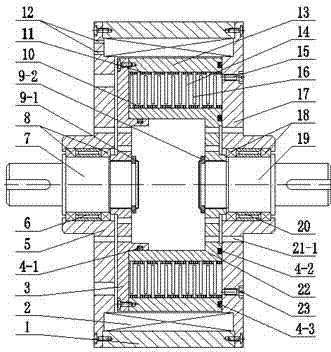

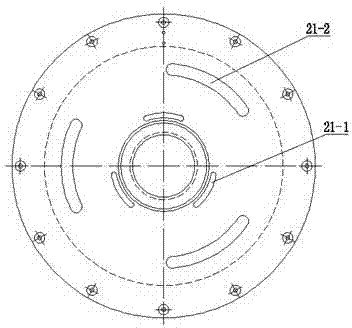

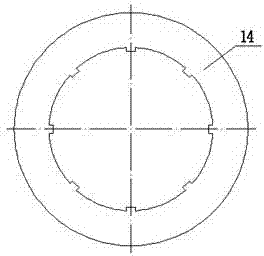

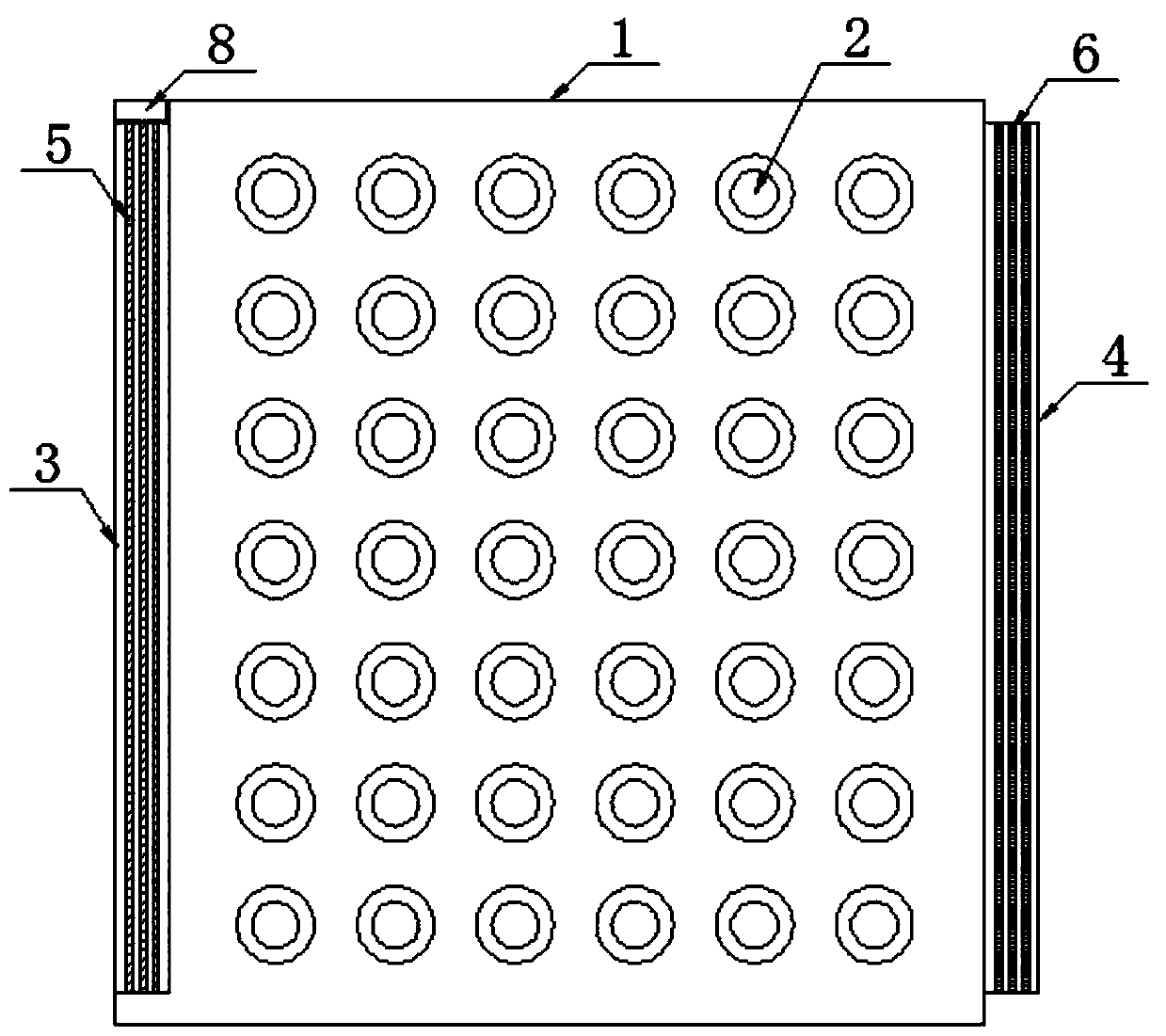

A multi-chip magneto-rheological soft start device

ActiveCN102297213AEasy to change sizeSimple structureConveyorsFluid clutchesMagnetorheological fluidEngineering

Owner:苏州方德锐精密机电科技有限公司

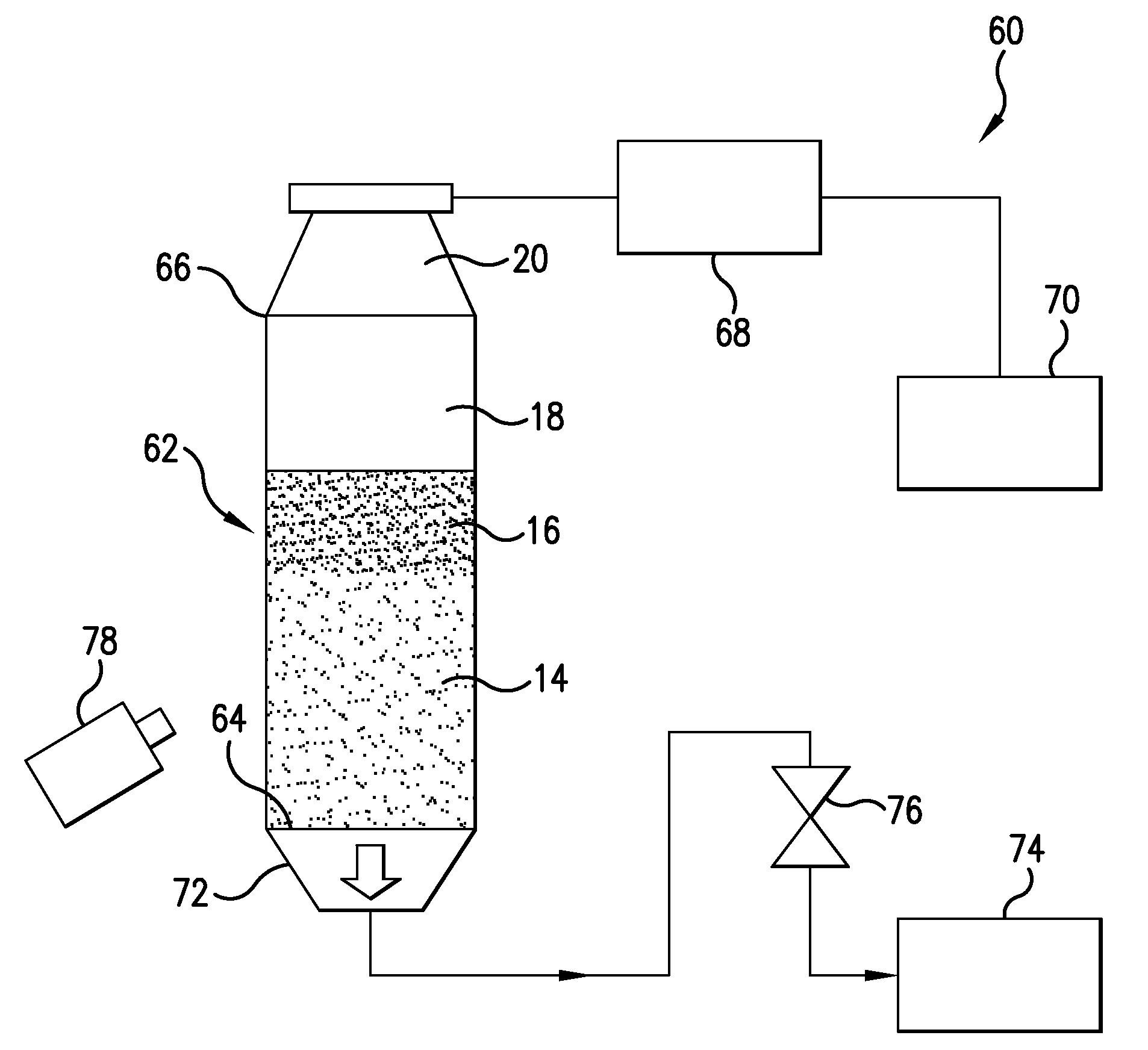

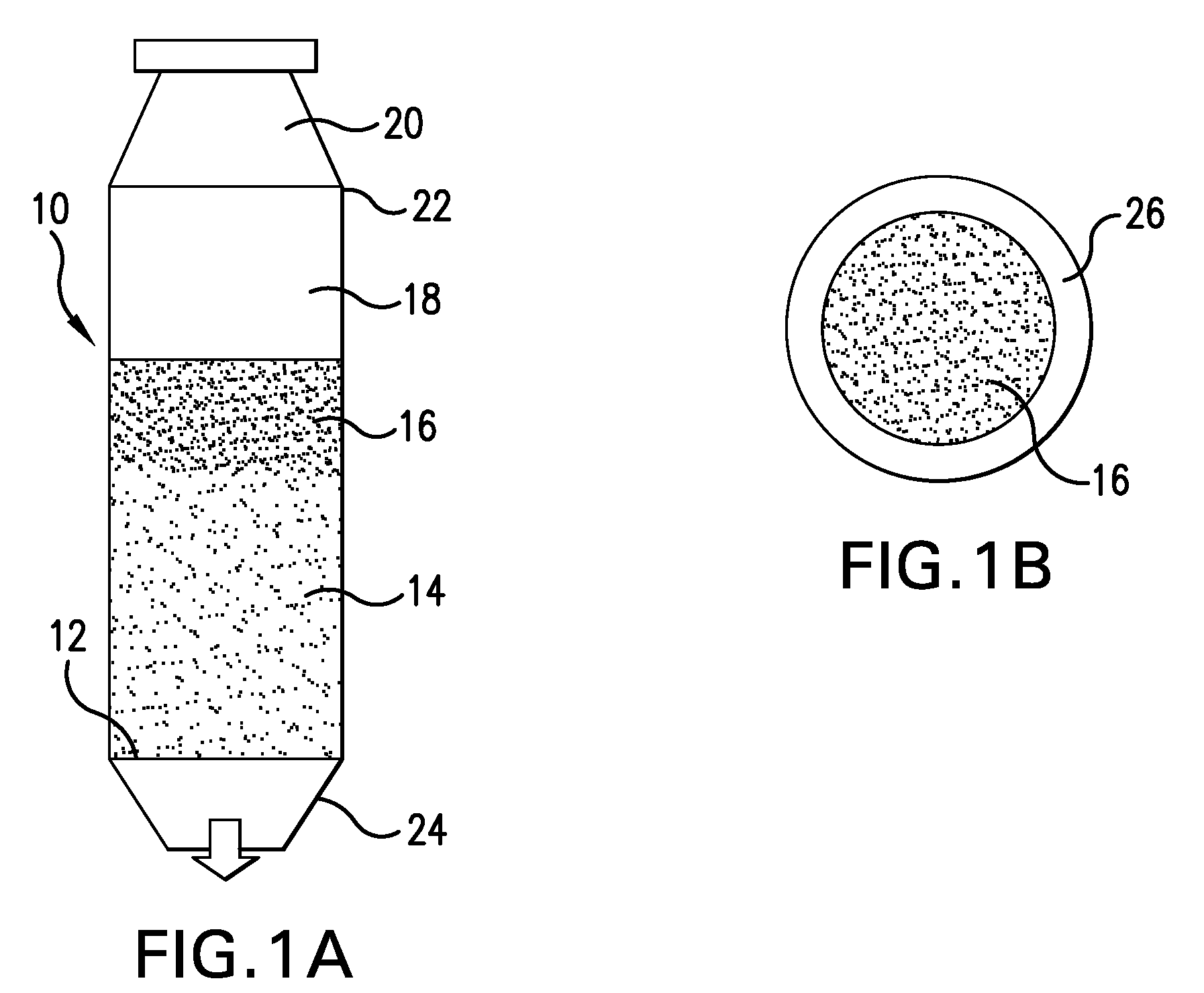

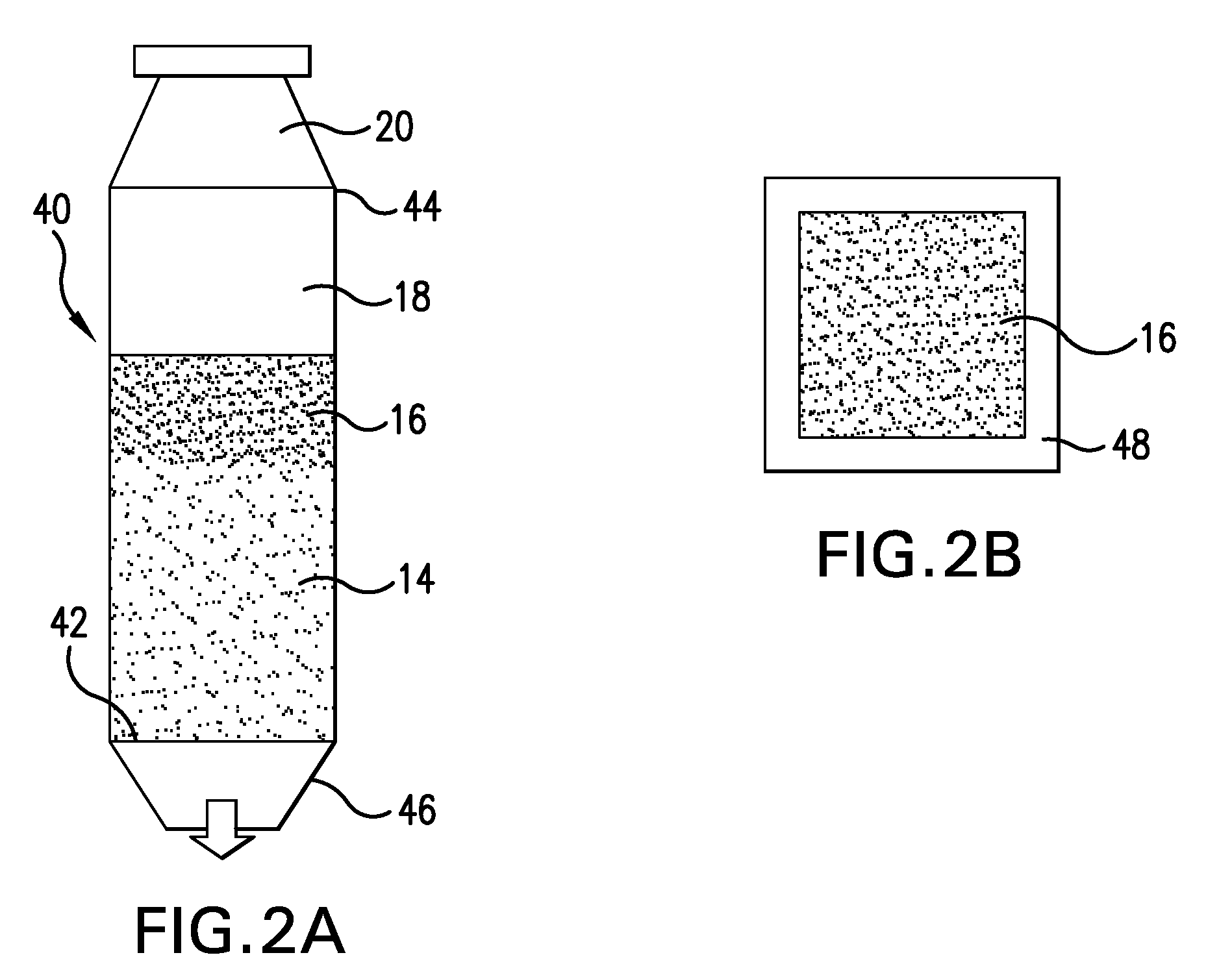

Mixing and packing of particles

InactiveUS20090272078A1Well mixedLower the volumeShaking/oscillating/vibrating mixersPackaging by pressurising/gasifyingParticulatesVolumetric Mass Density

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY +1

Preparation method for preparing nylon porous material on large scale

ActiveCN107353634ALarge specific surface areaWith insulationOther chemical processesWater/sewage treatment by sorptionPorositySodium bicarbonate

Owner:TIANJIN POLYTECHNIC UNIV

Method for manufacturing cross winding bobbin

To produce a cross wound bobbin (11), at the workstation (2) of a bobbin winder (1), the yarn (30) is wound at the start of a winding cycle at a crossing angle to increase the density of the bobbin core. The crossing angle is increased significantly during the winding cycle, so that the density of the wound bobbin is reduced progressively outwards. The increased crossing angle acts against the yarn laying width, and the stroke movement of the reciprocating yarn guide (29) has a defined increase.

Owner:SAURER GERMANY GMBH & CO KG

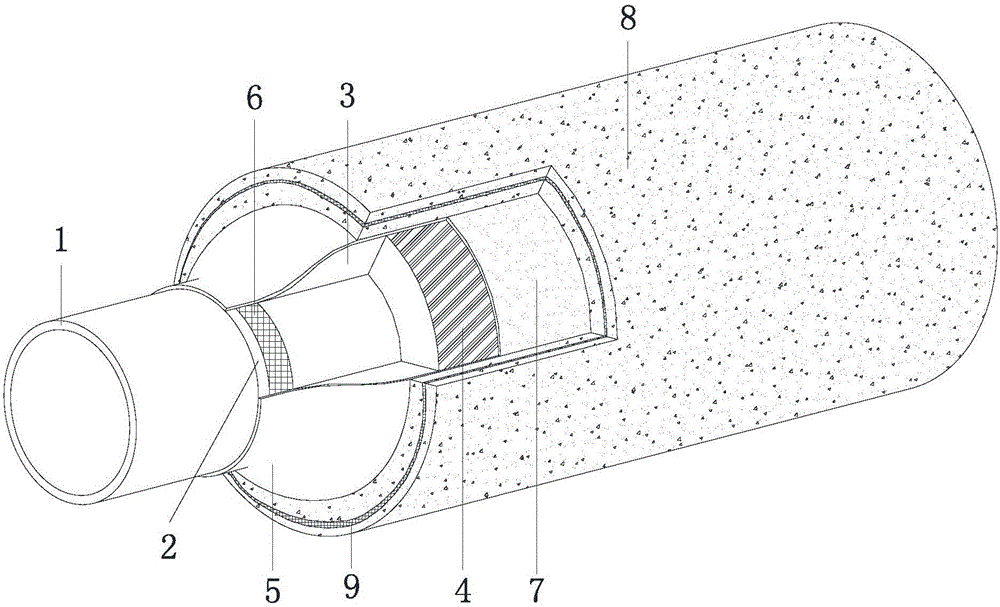

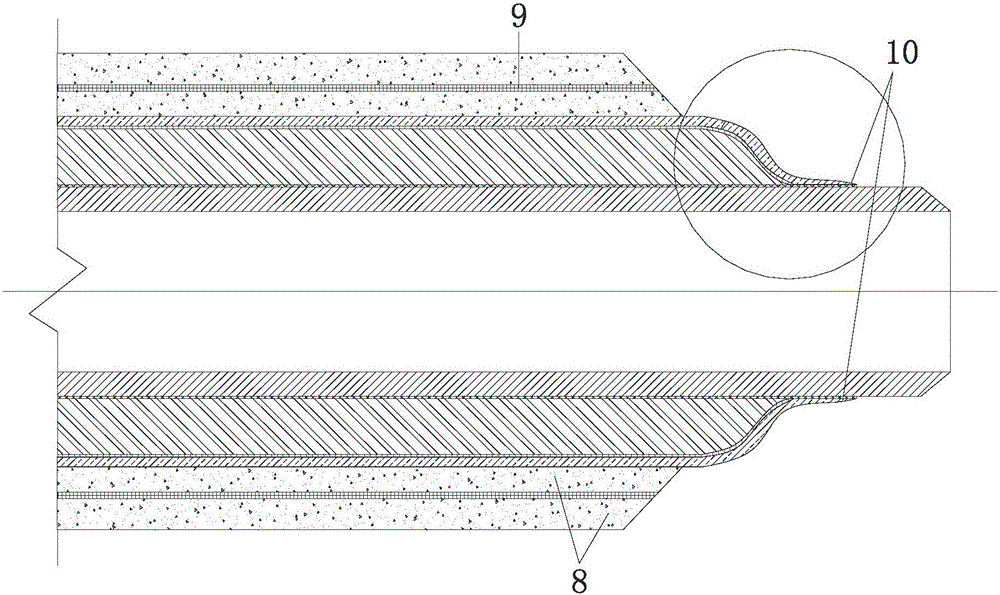

Marine polyurethane spraying prefabricated thermal insulation balance weight pipe and preparation method thereof

InactiveCN105909883AEnsure consistencyAvoid your own flawsThermal insulationPipe protection by thermal insulationPolyolefinAdhesive

Owner:CHINA NAT OFFSHORE OIL CORP +1

Aluminum alloy guide wheel manufacturing method and product thereof

InactiveCN107511640AImprove corrosion resistanceHigh structural densityAnodisationDie castingVolumetric Mass Density

Owner:邓南月

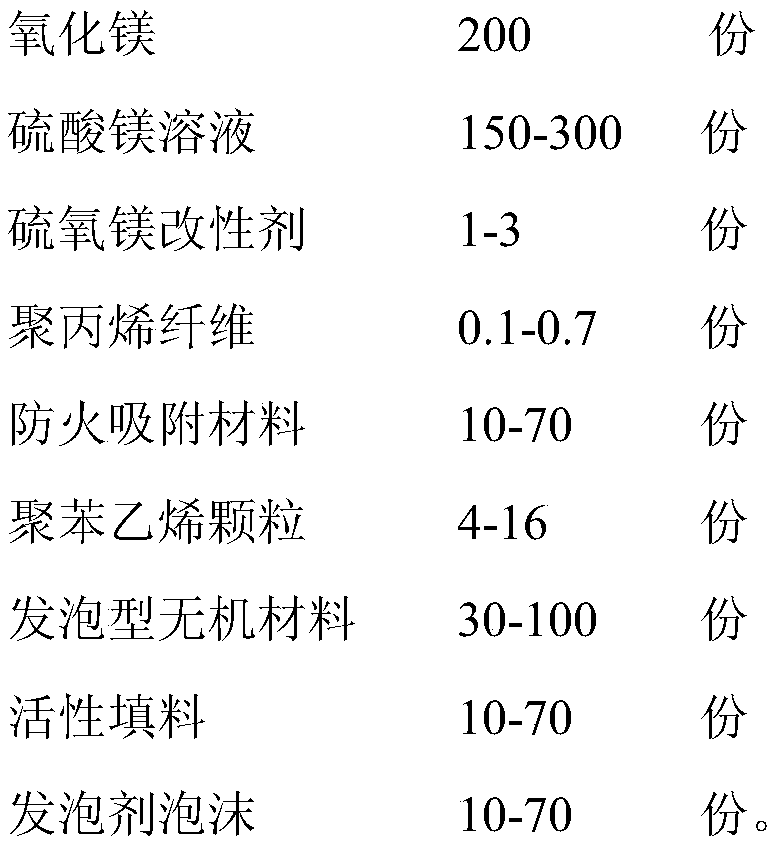

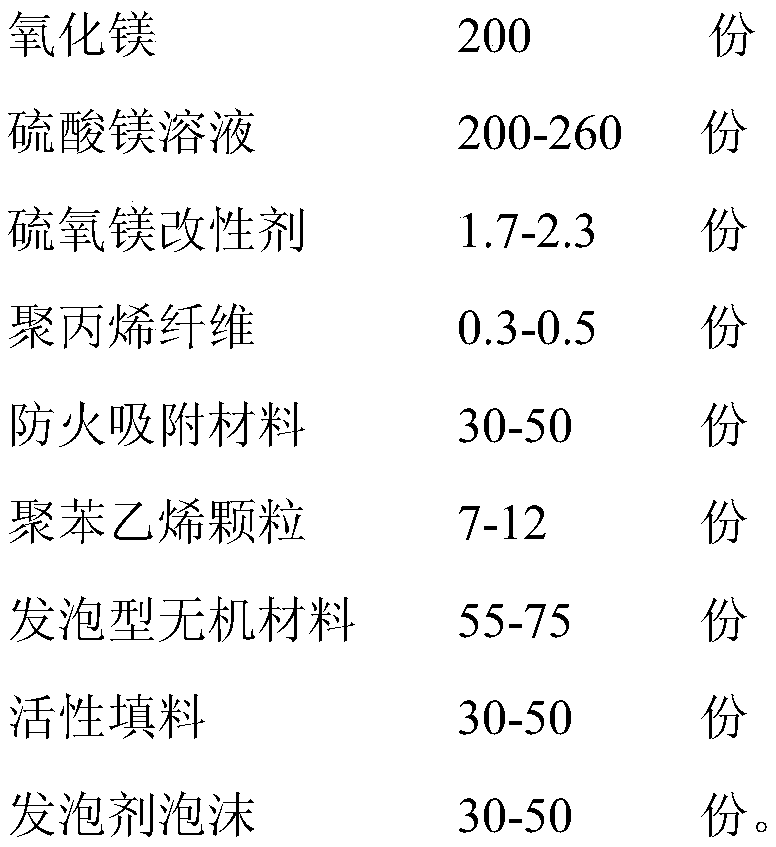

Heat-preservation sound-insulation magnesium oxysulfate fireproof material applied to wallboard and preparation method thereof

InactiveCN110294619ALow densityEasy to carryGlass/slag layered productsFoaming agentVolumetric Mass Density

Owner:常州布鲁科技有限公司

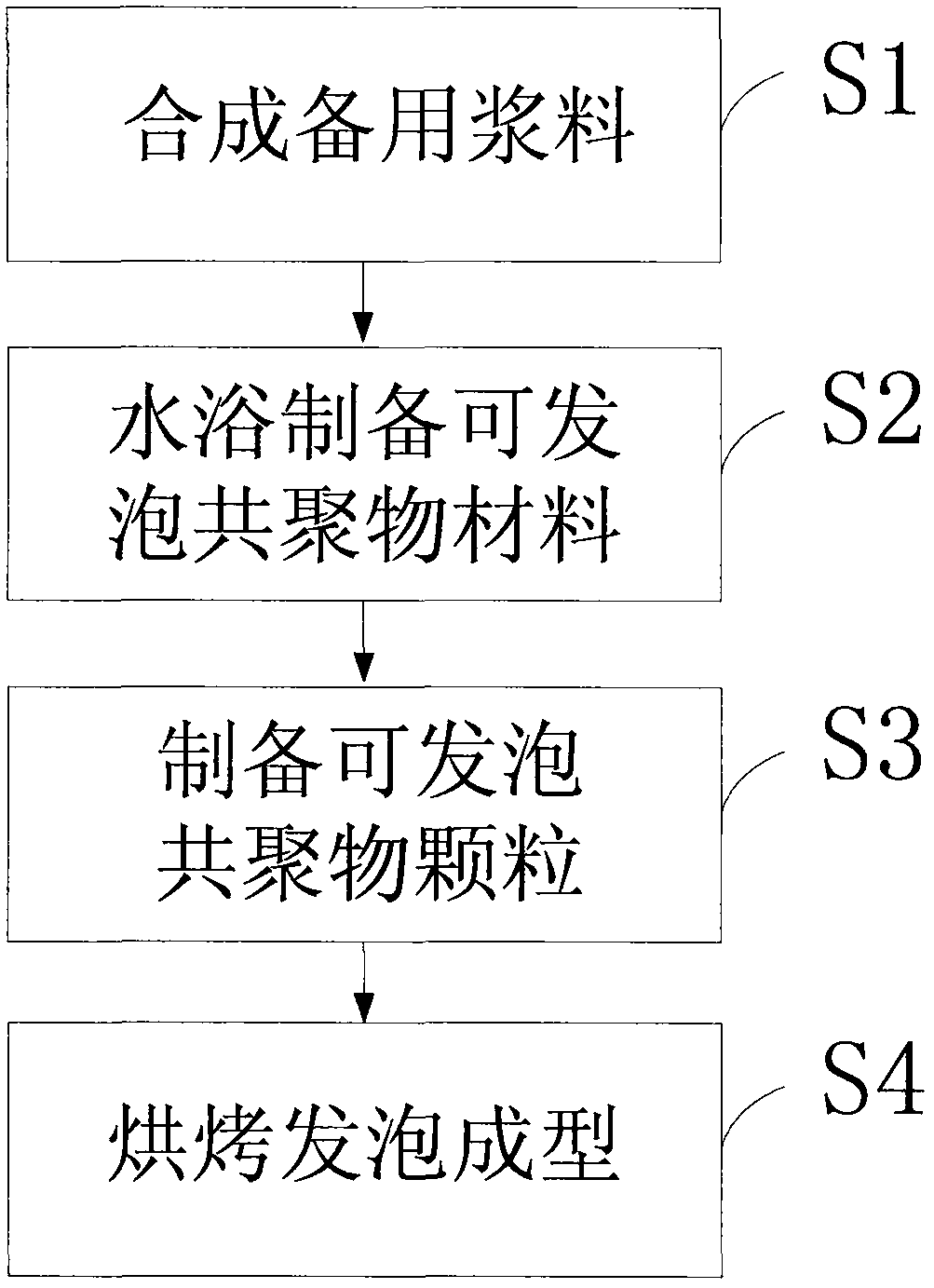

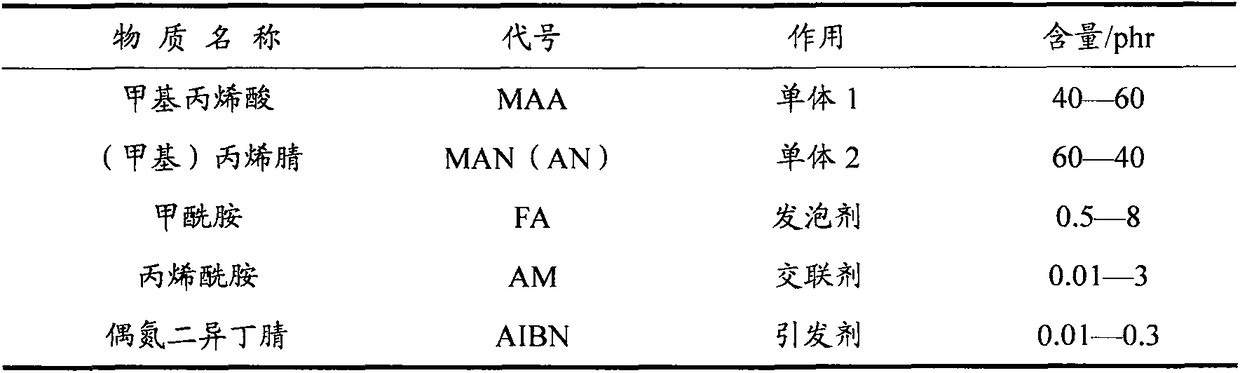

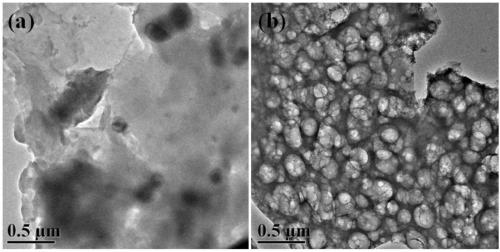

Preparation method of PMI (Polymethacrylimide) foam plastic

Owner:威海维赛新材料科技有限公司

Paint spraying technology for water screen vortex roll spray room

InactiveCN104174519AImprove purification efficiencySimple structureSpray nozzlesLacquerVolumetric Mass Density

The invention discloses a paint spraying technology for a water screen vortex roll spray room. The technology comprises the following processes: a conveying fixture carrying a paint spraying product travels along a conveying track and the paint spraying product is then sprayed with paint by an automatic spray gun on one side of the conveying fixture; paint mist generated in the paint spraying process flows to a serration plate along with the air flow under the action of a suction groove; high-speed air flow and negative pressure are formed at notches of the serration plate due to the fact that the ventilation section area is suddenly decreased, so that water at the notches is atomized and the high-speed air flow passes through the serration plate and then enters a vortex roll plate; paint grains with greater density is in full contact with water under the action of centrifugal force and then collected and taken down by water; the rest of paint mist collides and in contact with atomized water repeatedly for many times in the vortex roll along with the air flow, condenses into water droplets containing paint mist and enters a circulating water pool. The paint spraying technology is good in paint mist capturing effect, and besides, the water screen vortex roll spray room is simple in structure, pipelines are less prone to blockage, and the purification efficiency is high.

Owner:CHANGXING HUARUI MACHINERY EQUIP

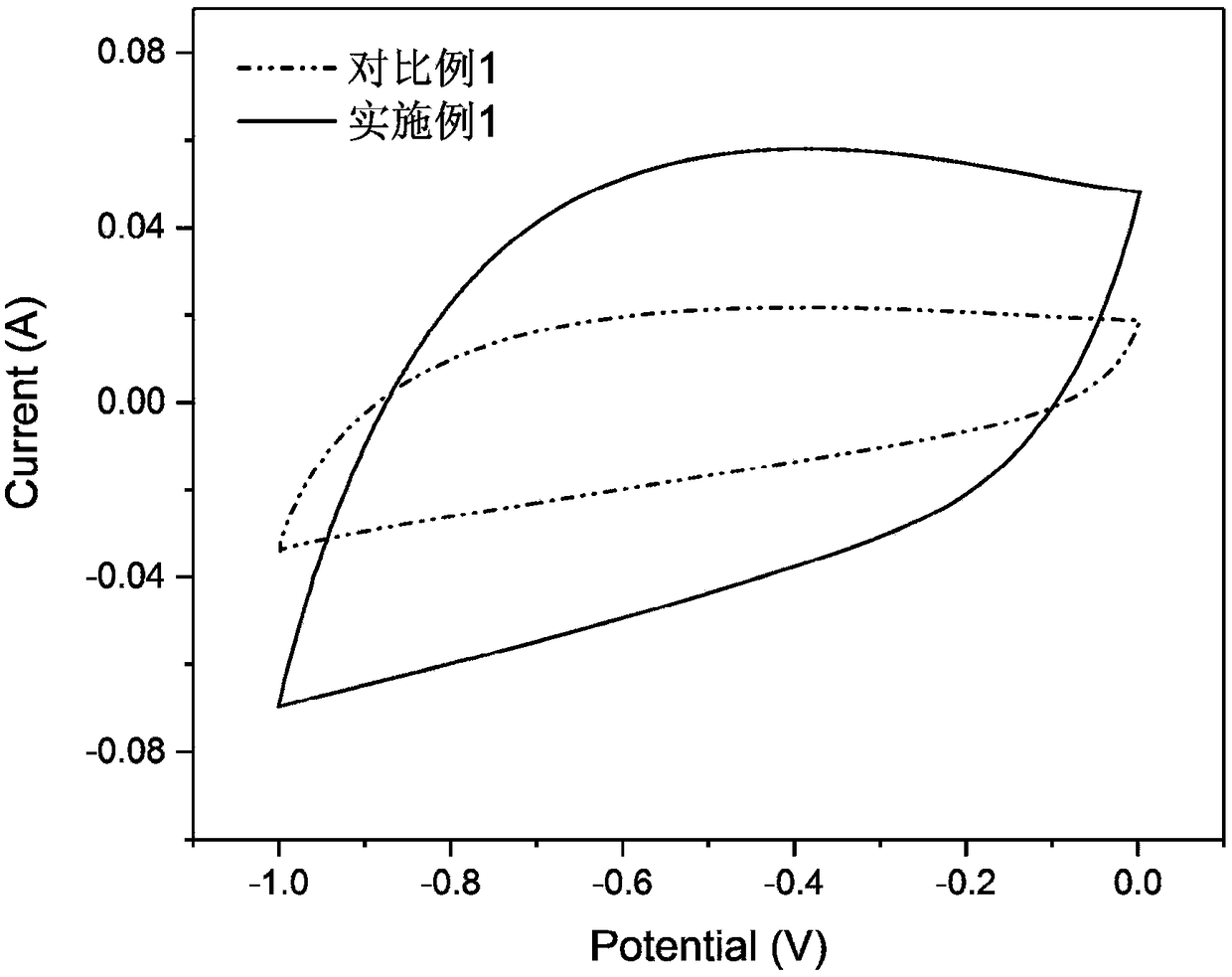

Porous carbon material prepared by using self-modification of pseudomonas putida and preparation method and application thereof

ActiveCN109399604AShorten the growth cycleIncrease added valueHybrid capacitor electrodesCarbon preparation/purificationPorous carbonPseudomonas putida

Owner:CENT SOUTH UNIV

A laser engraving machine for steel cylinders

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

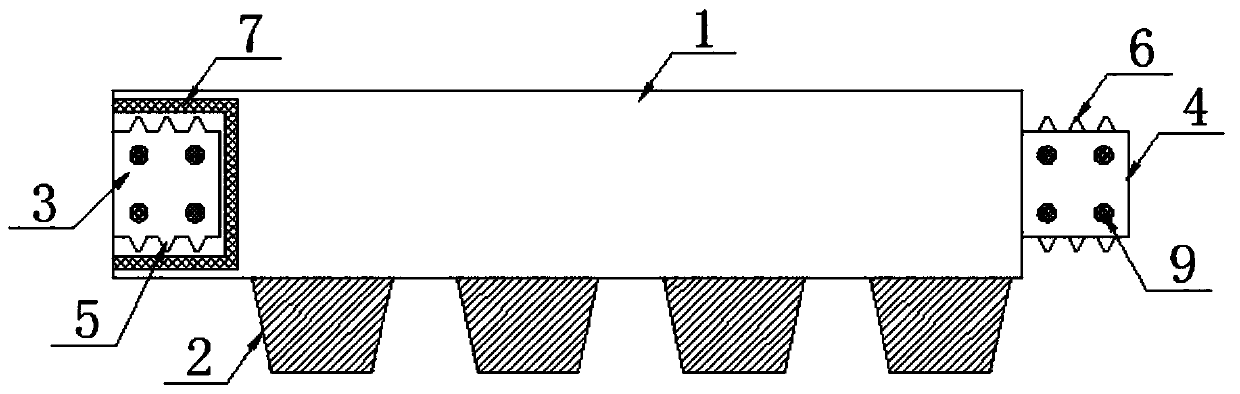

Machine tool, its manufacture method and welding plate therefor

InactiveCN100415434CContains inhomogeneityTool workpiece connectionReaming toolsVolumetric Mass DensityThermal expansion

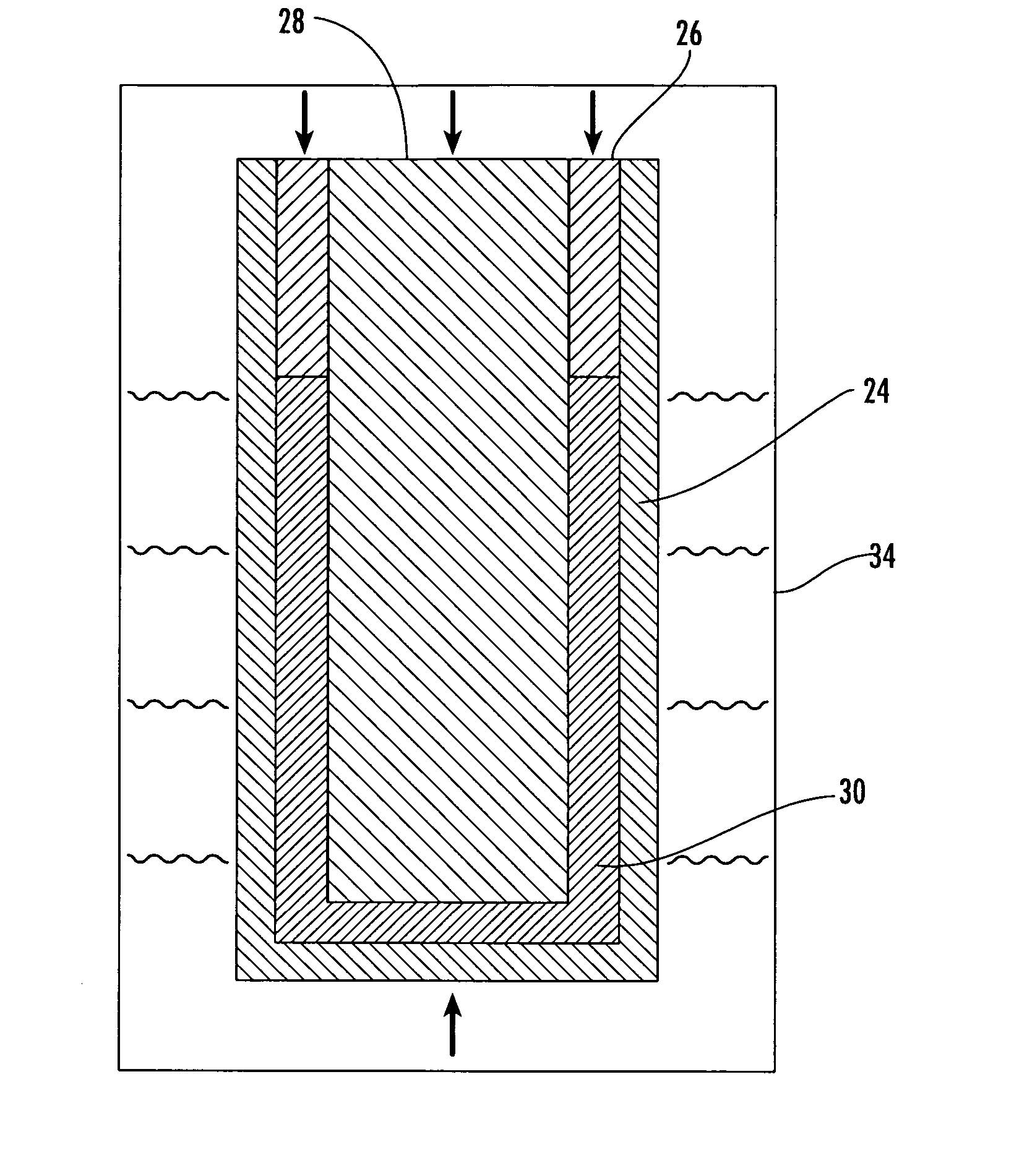

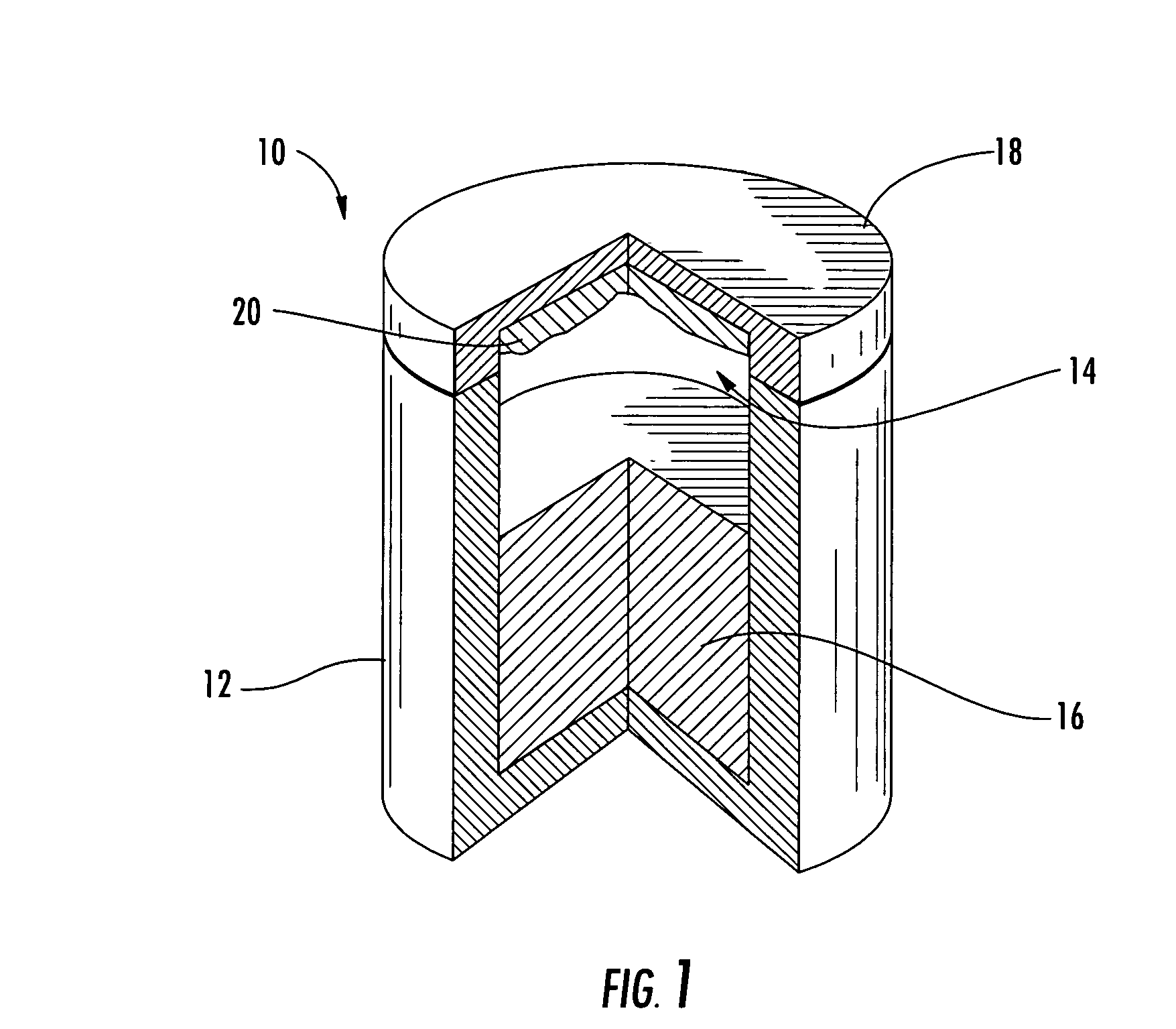

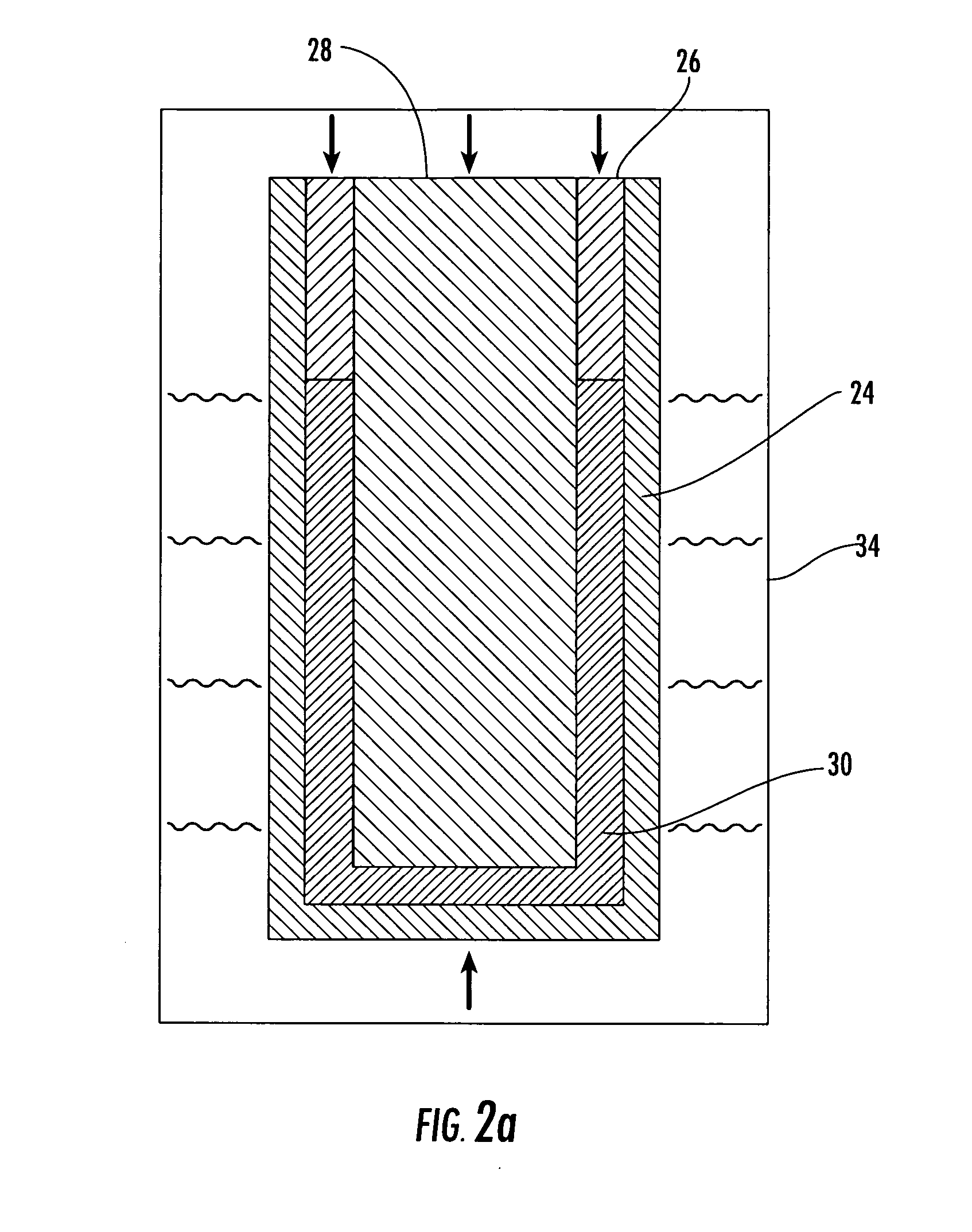

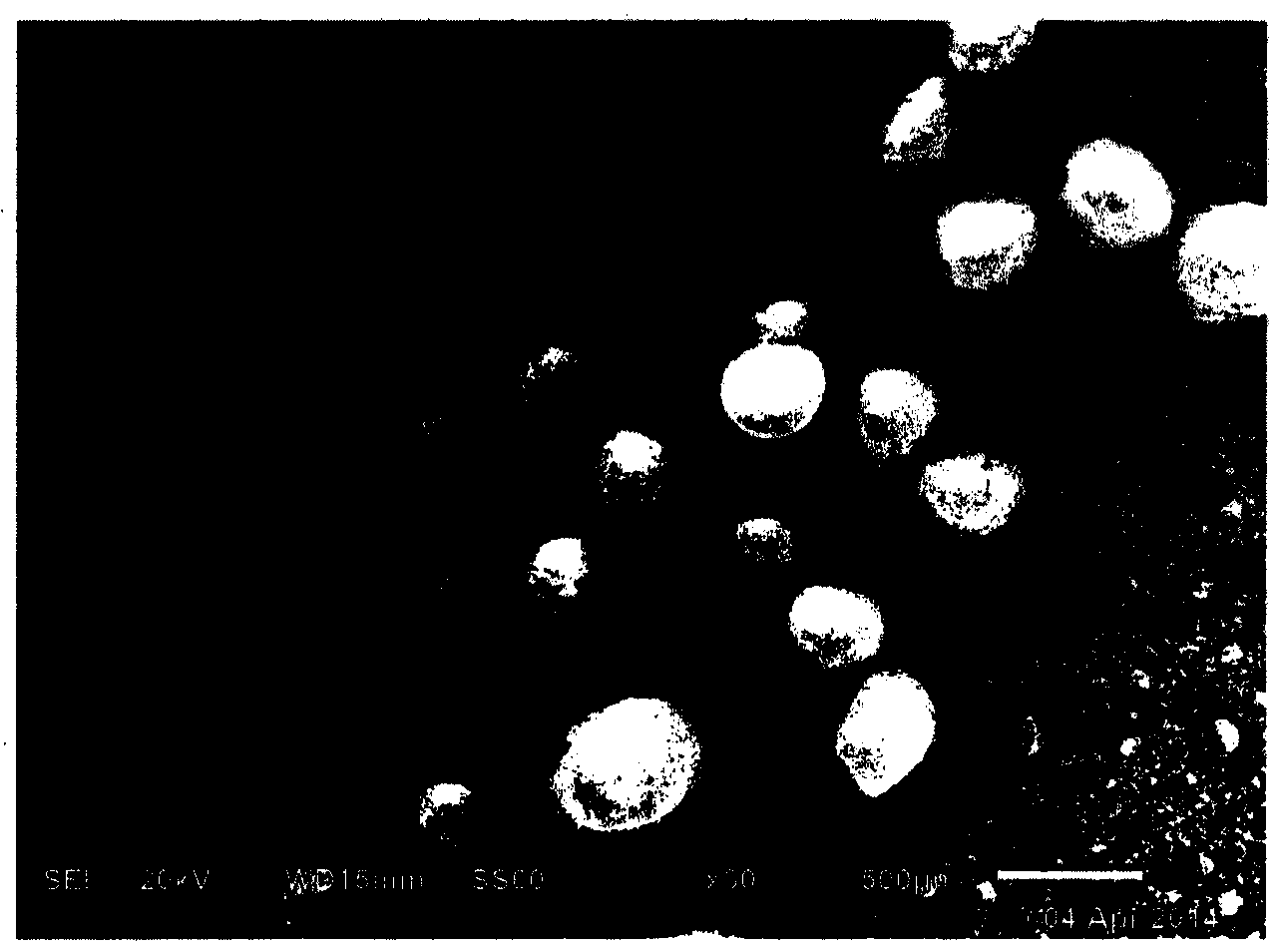

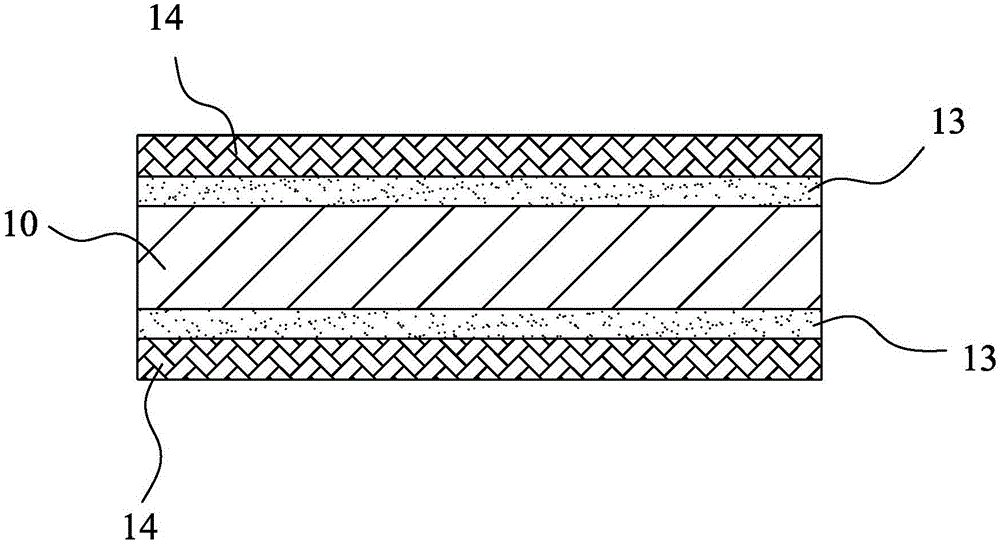

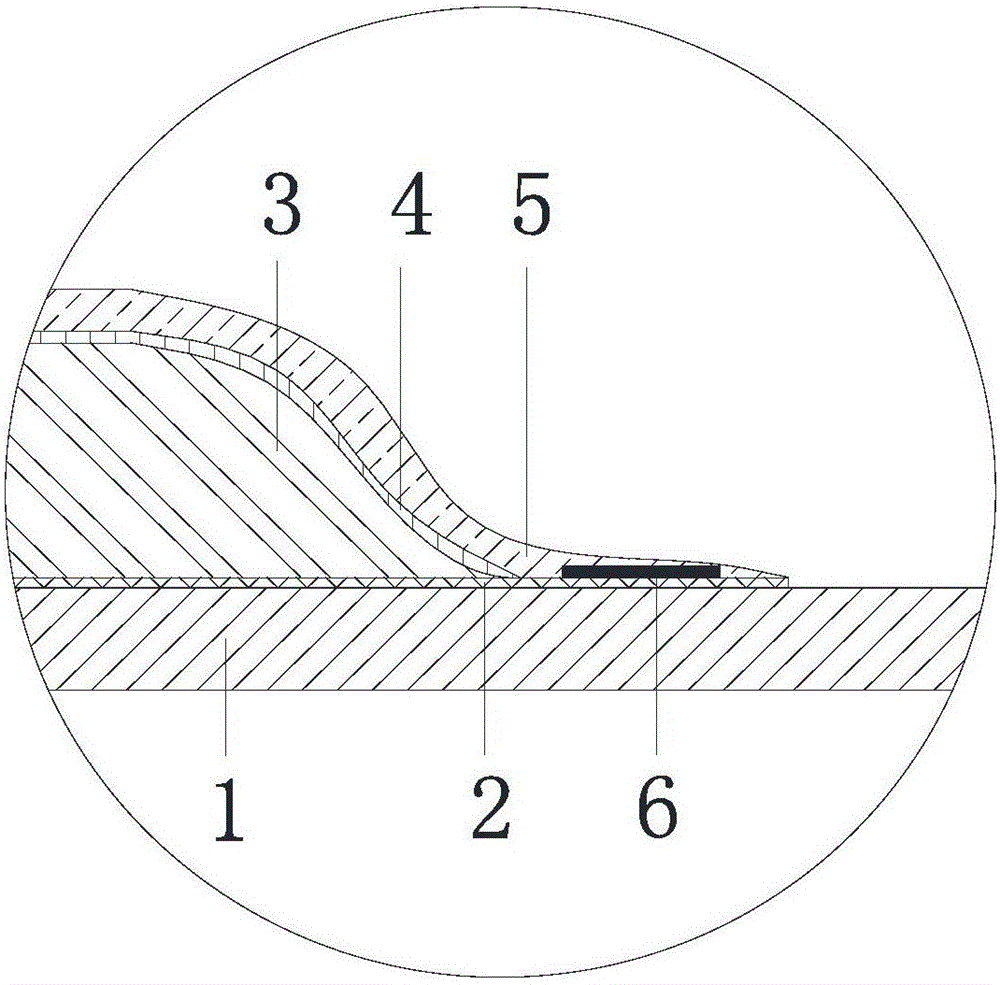

The invention relates to a machine tool with a tool shank (10) and a cutting head (12) made from different materials, which are joined to each other on opposite joint surfaces (14,16) in a positive material fit by means of a joint layer (18') made of a ductile solder material. According to the invention, in order to obtain a solder connection which is substantially stress-free, powder particles (31) made of a temperature-resistant material with a thermal expansion coefficient which is lower than the solder material (30) are embedded into the joint layer (18') and the density of the powder particles (31) varies along the entire thickness of the joint layer (18').

Owner:KOMET GROUP GMBH

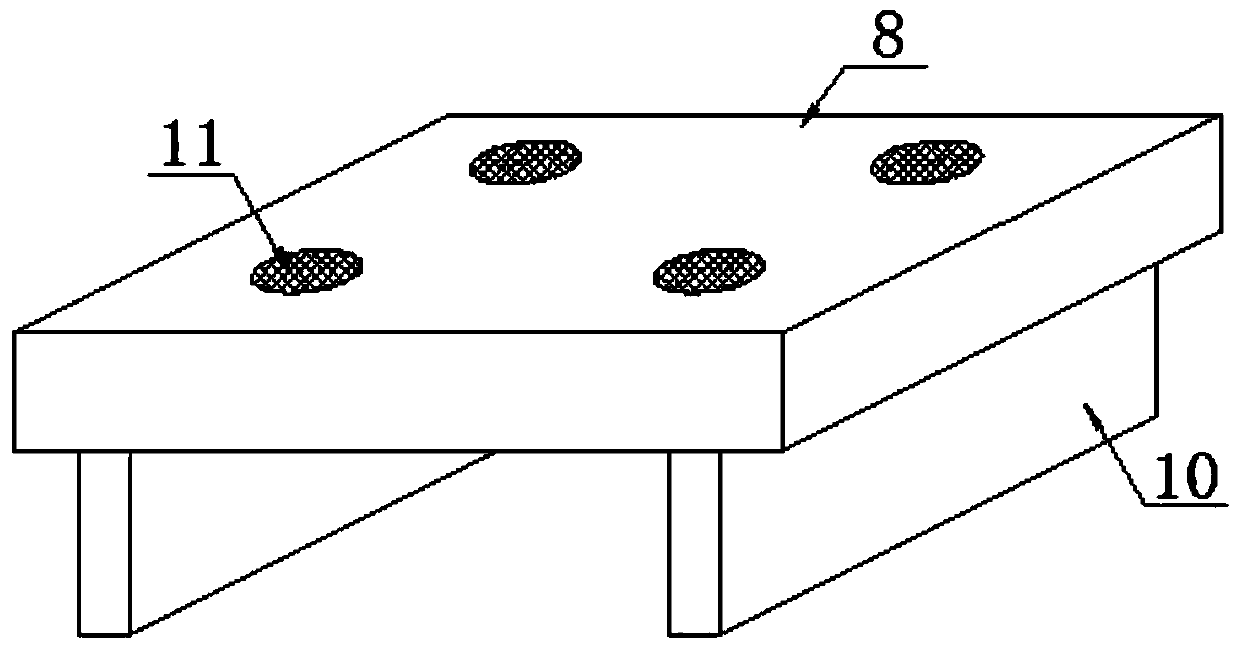

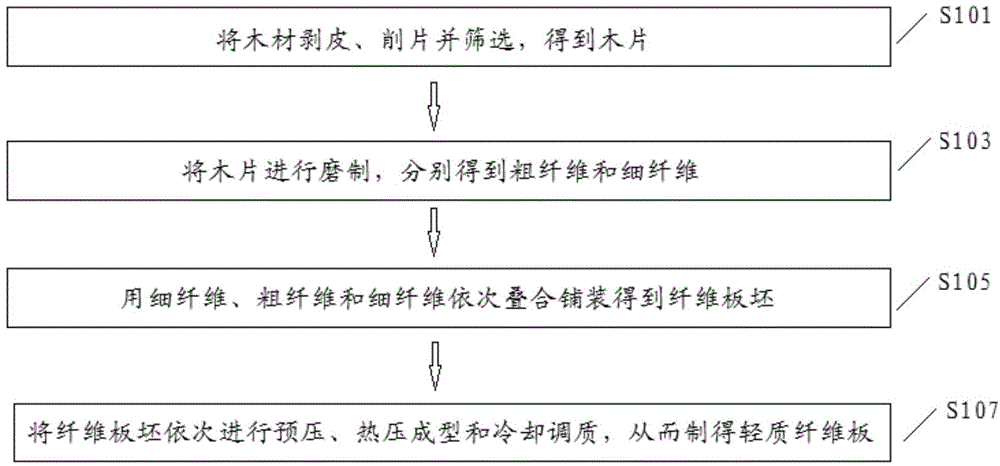

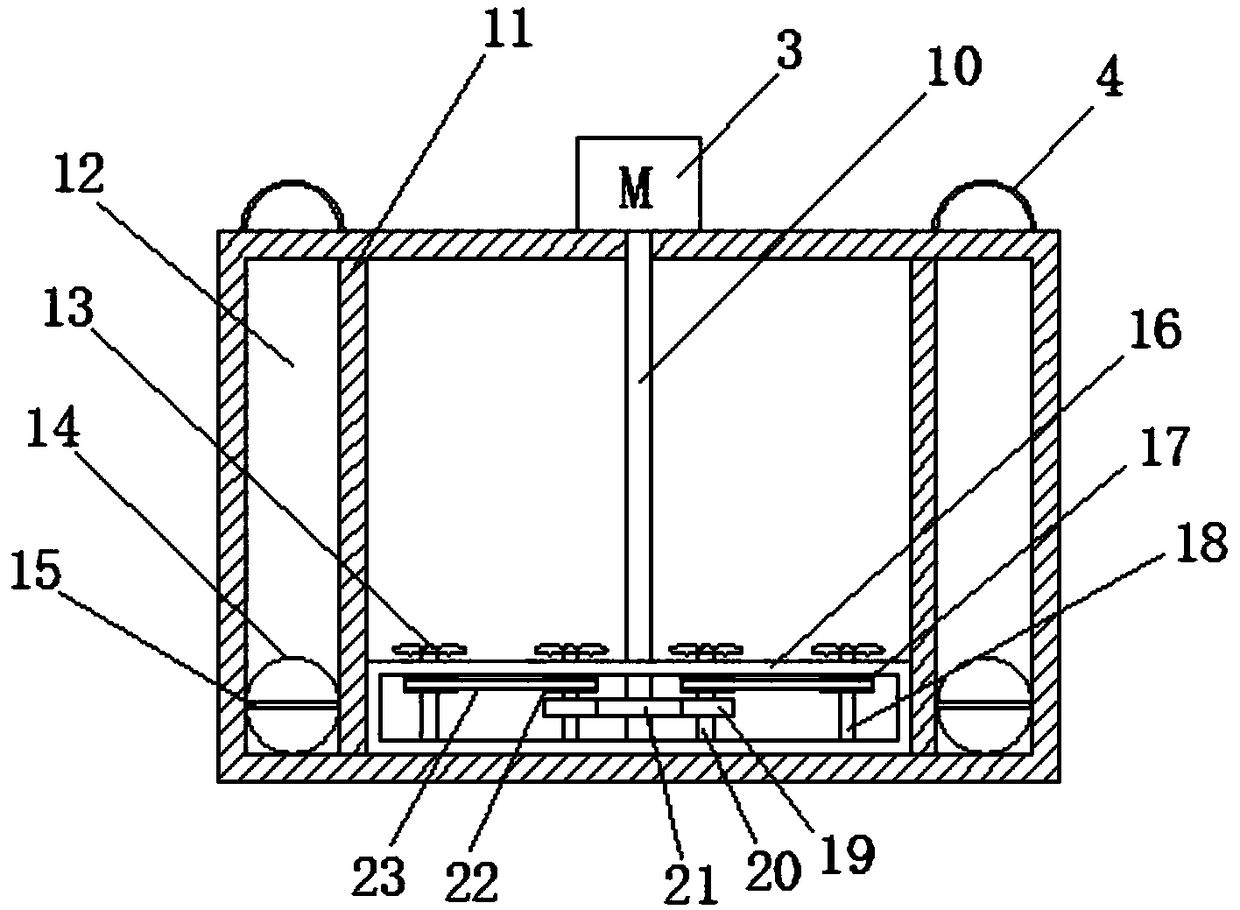

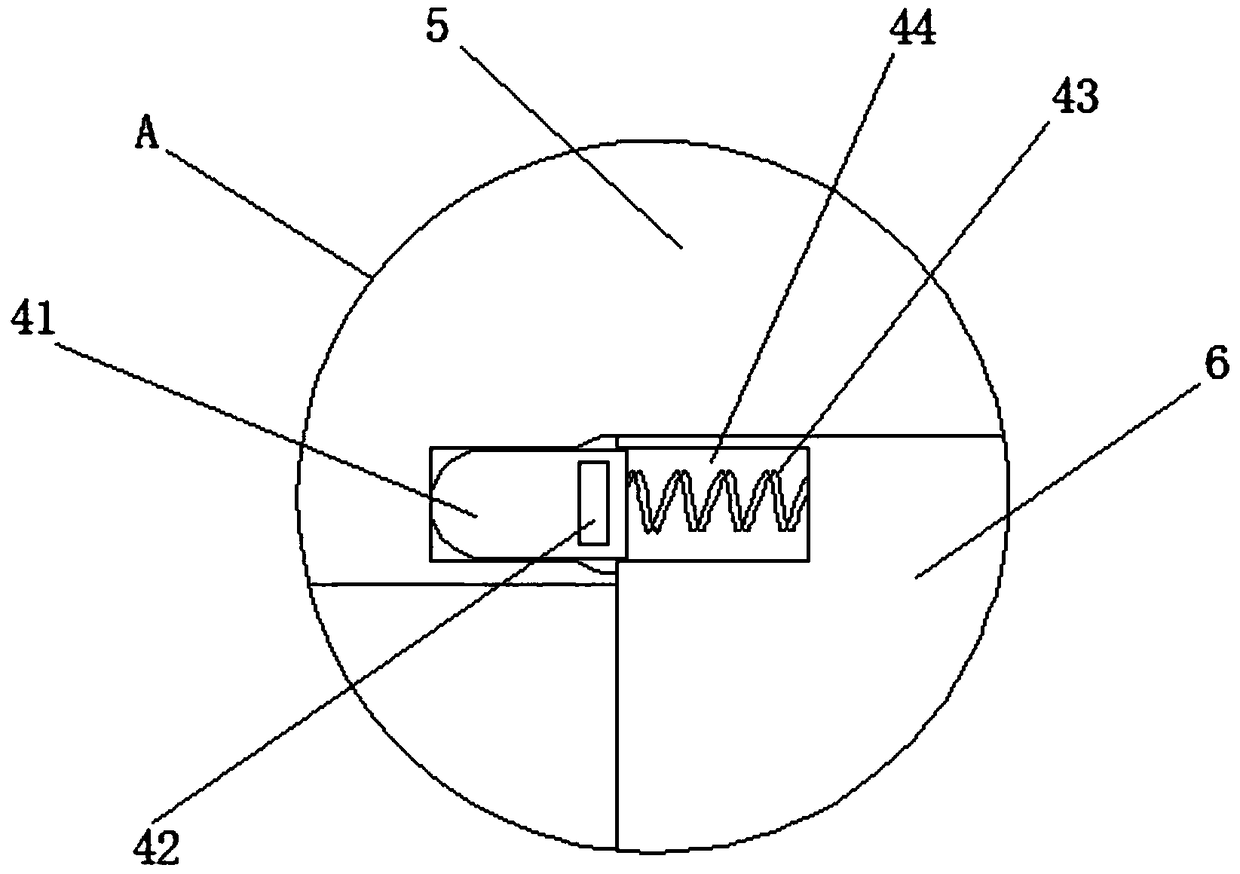

Method for manufacturing light-weight fiberboard

InactiveCN104669394AImprove mechanical propertiesLow densityWood working apparatusFlat articlesFiberSurface layer

Owner:CHINA FOMA GROUP

Energy-saving filling machine based on Internet of Things and capable of realizing uniform filling

InactiveCN108996455AUniform densityImprove filling product qualityLiquid bottlingGear driveGear wheel

Owner:郑胜利

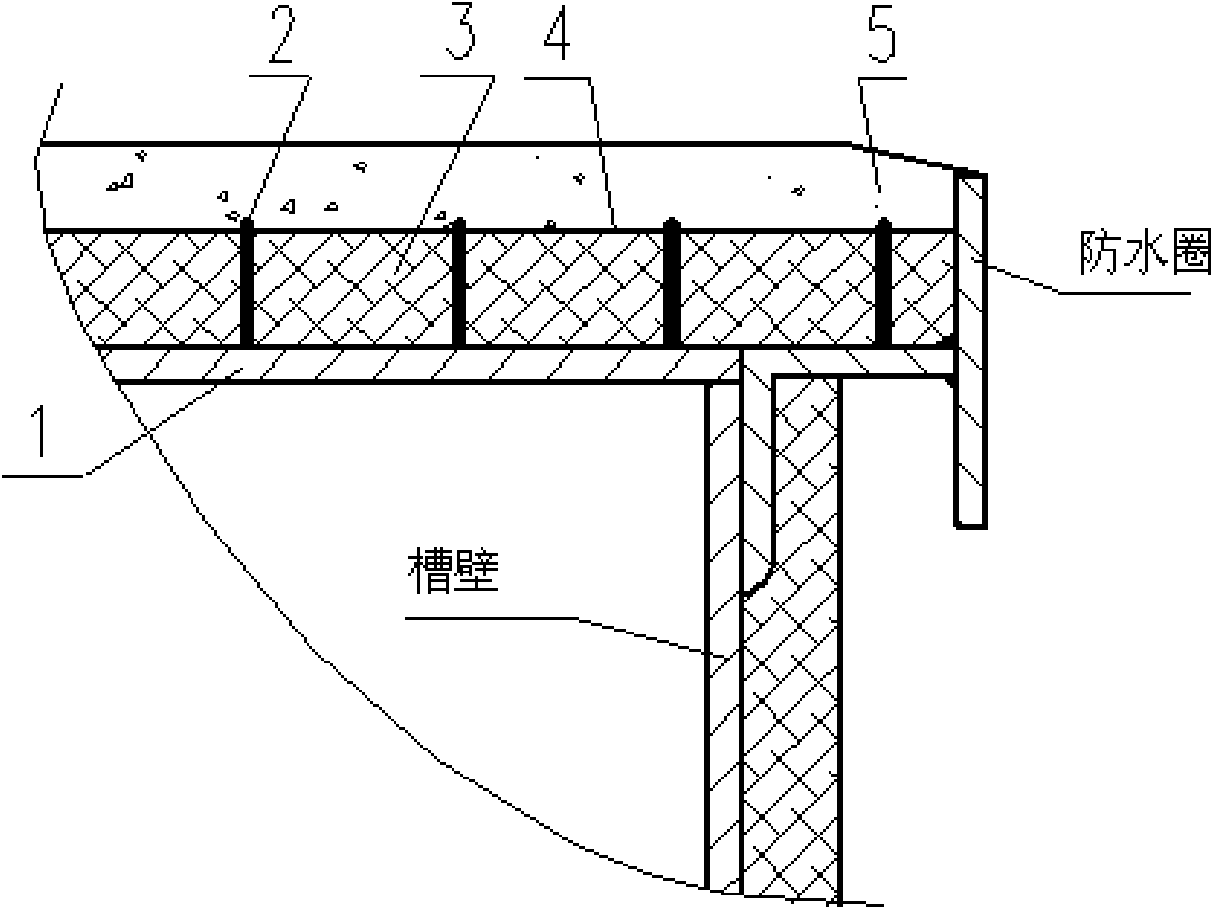

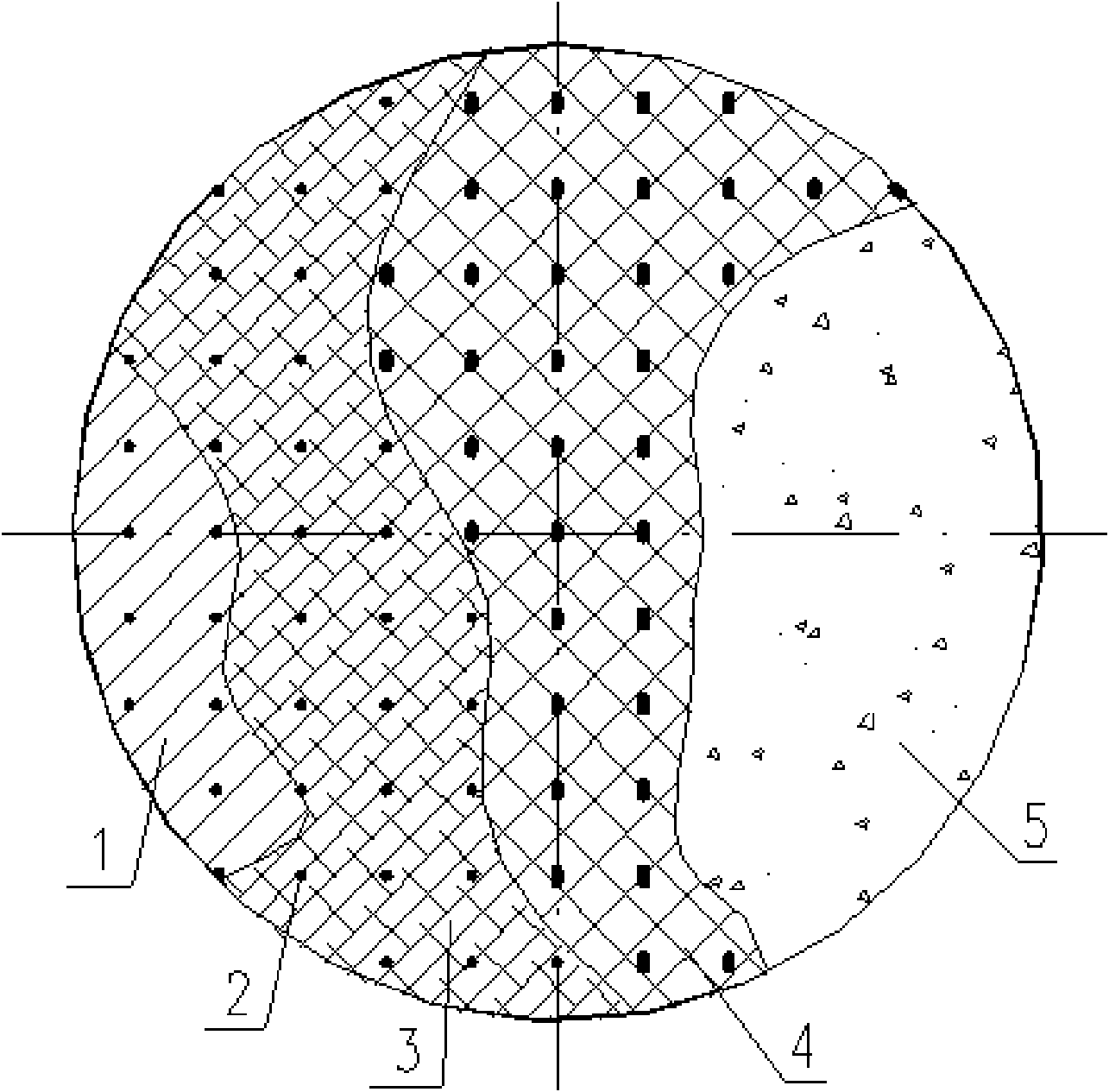

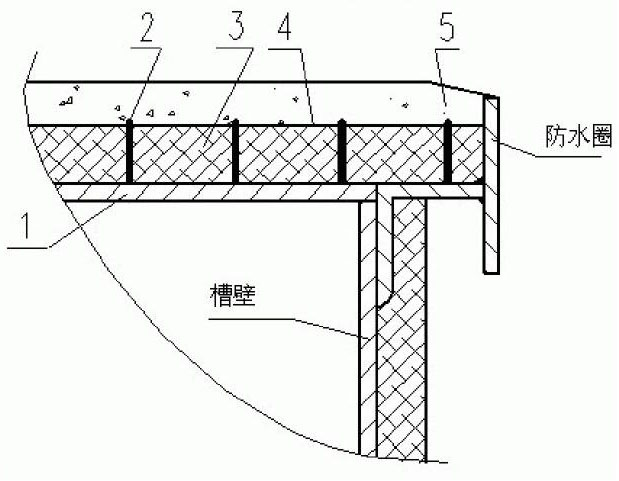

Heat-insulating structure at top of open-air atmospheric storage tank

InactiveCN101927885ANo local subsidenceWill not happenLarge containersLeaking waterVolumetric Mass Density

Owner:GUIYANG AL-MG DESIGN & RES INST

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap