Filter

A filter and filter screen technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems affecting the accuracy of the sensor, deviation of measurement results, clogging of the filter, etc., and achieves easy cleaning and density reduction. Small, the effect of improving the filtering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

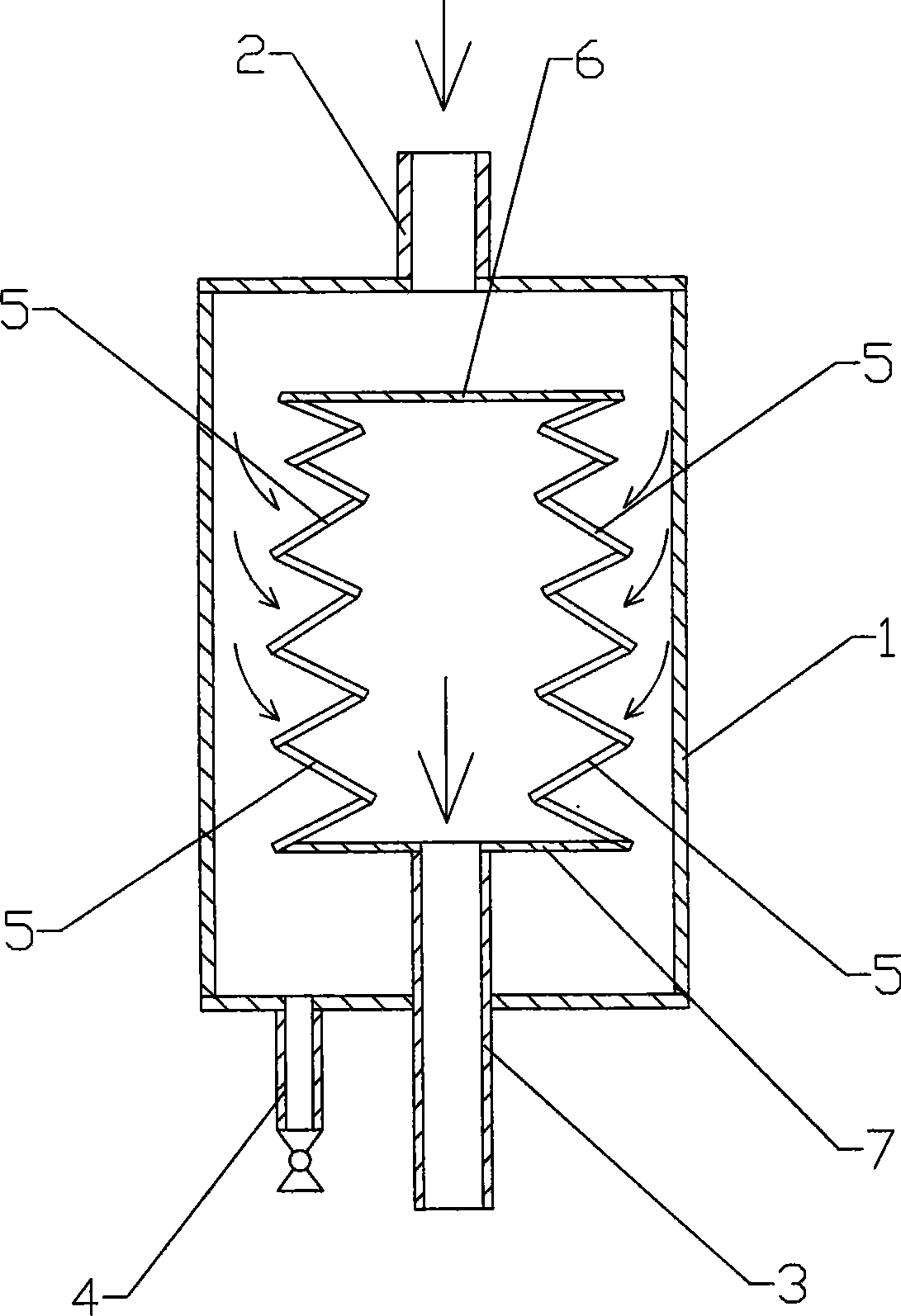

[0010] Example 1, such as figure 1 As shown, the filter includes a cylindrical filter housing 1, the upper part of the filter housing 1 is provided with an air inlet pipe 2, and the lower part is provided with a sewage pipe 4, and a filter element is arranged in the filter housing 1, and the filter element Including an upper support plate 6 and a lower support plate 7, between the upper support plate 6 and the lower support plate 7 is a foldable annular filter screen 5 arranged in a V shape, and the filter layer of the filter screen 5 is a stretchable textile When the upper support plate 6 compresses it under pressure, the pore diameter of the filter layer becomes smaller and the density increases. An air outlet pipe 3 is provided, and the air outlet end of the air outlet pipe 3 extends out of the filter housing 1 and is sealed with the filter housing 1 . When in use, the sample gas enters the filter housing 1 from the intake pipe 2, and under the pressure of the sample gas thro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap