Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about "Spray nozzles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

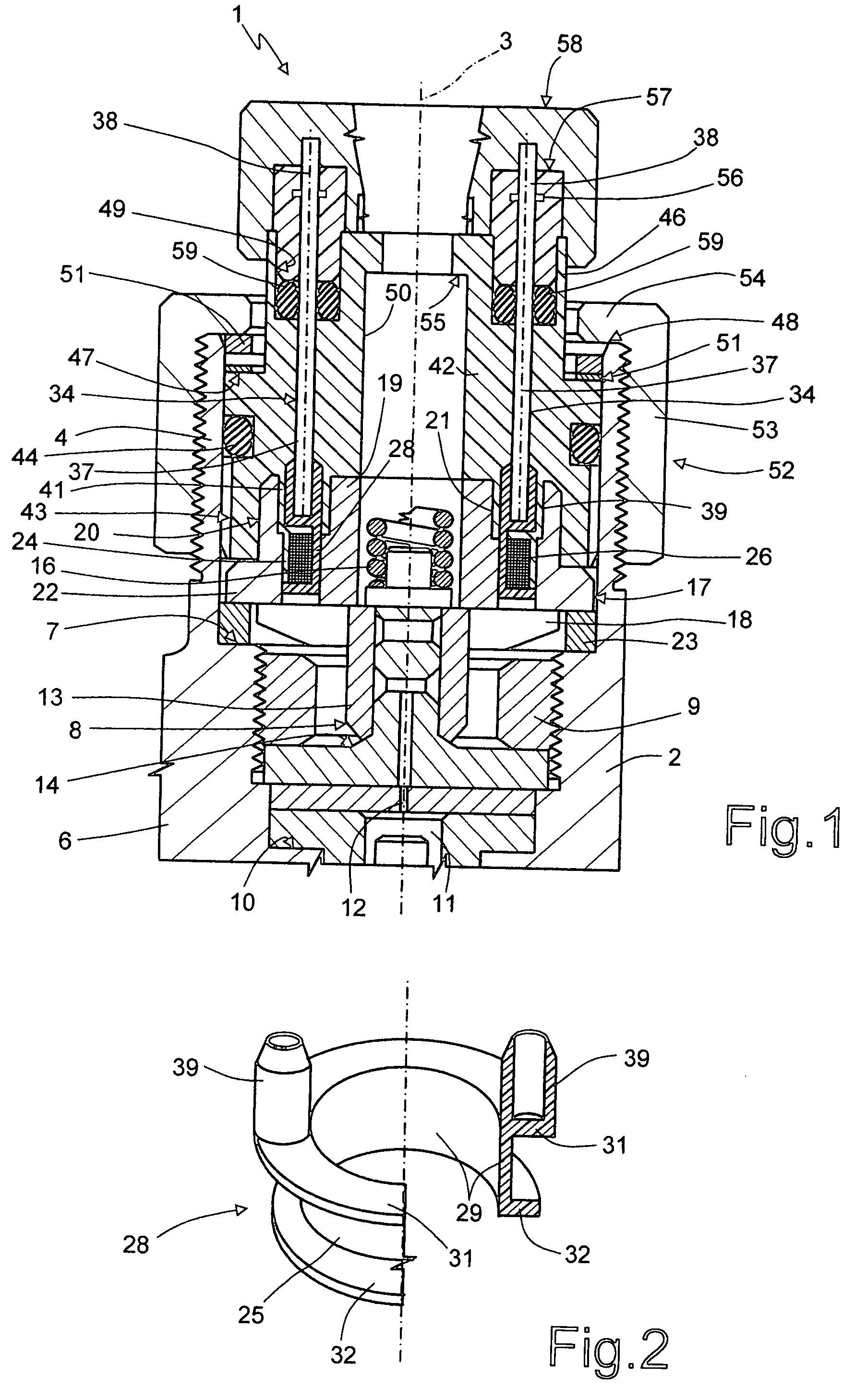

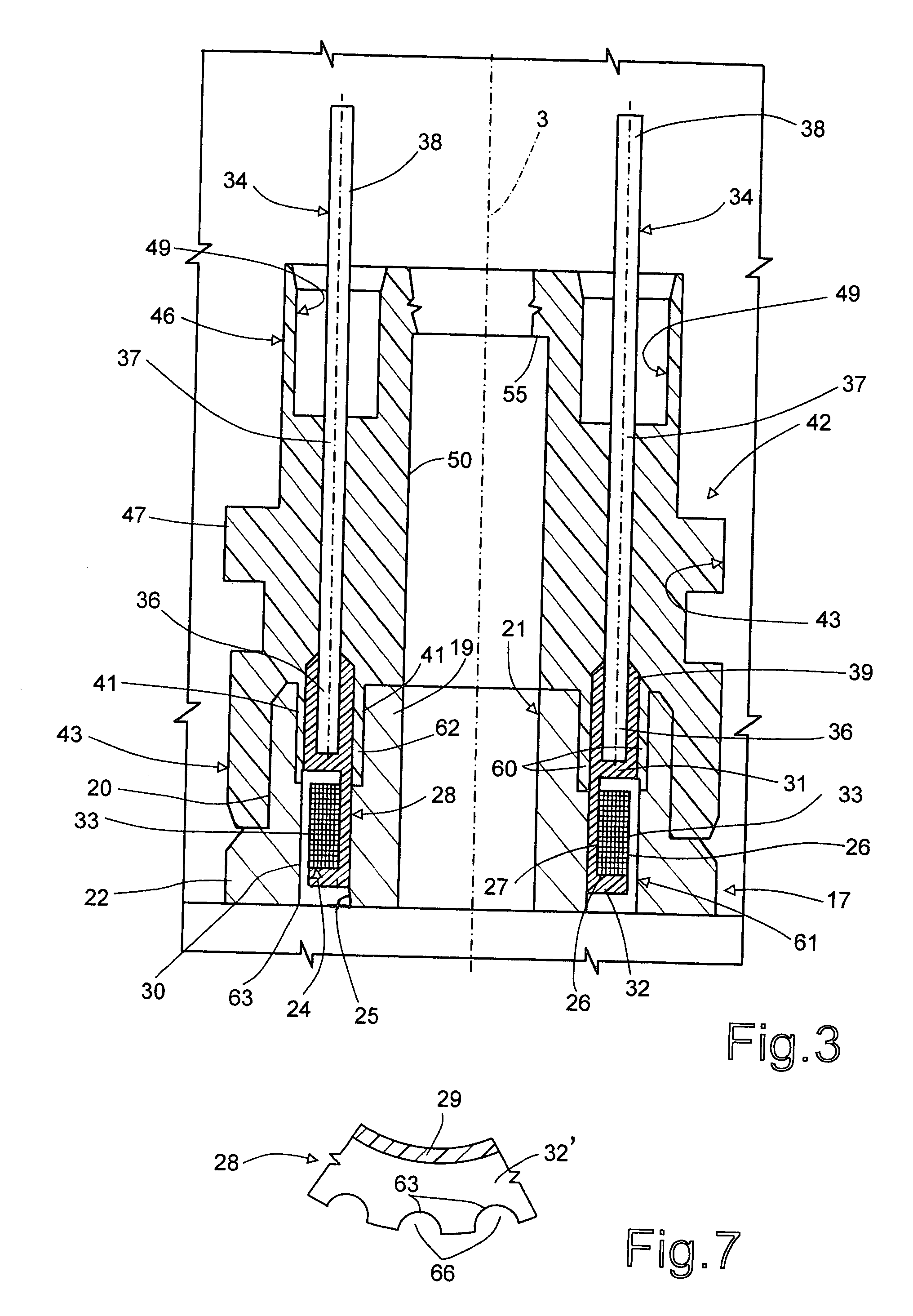

Spray head

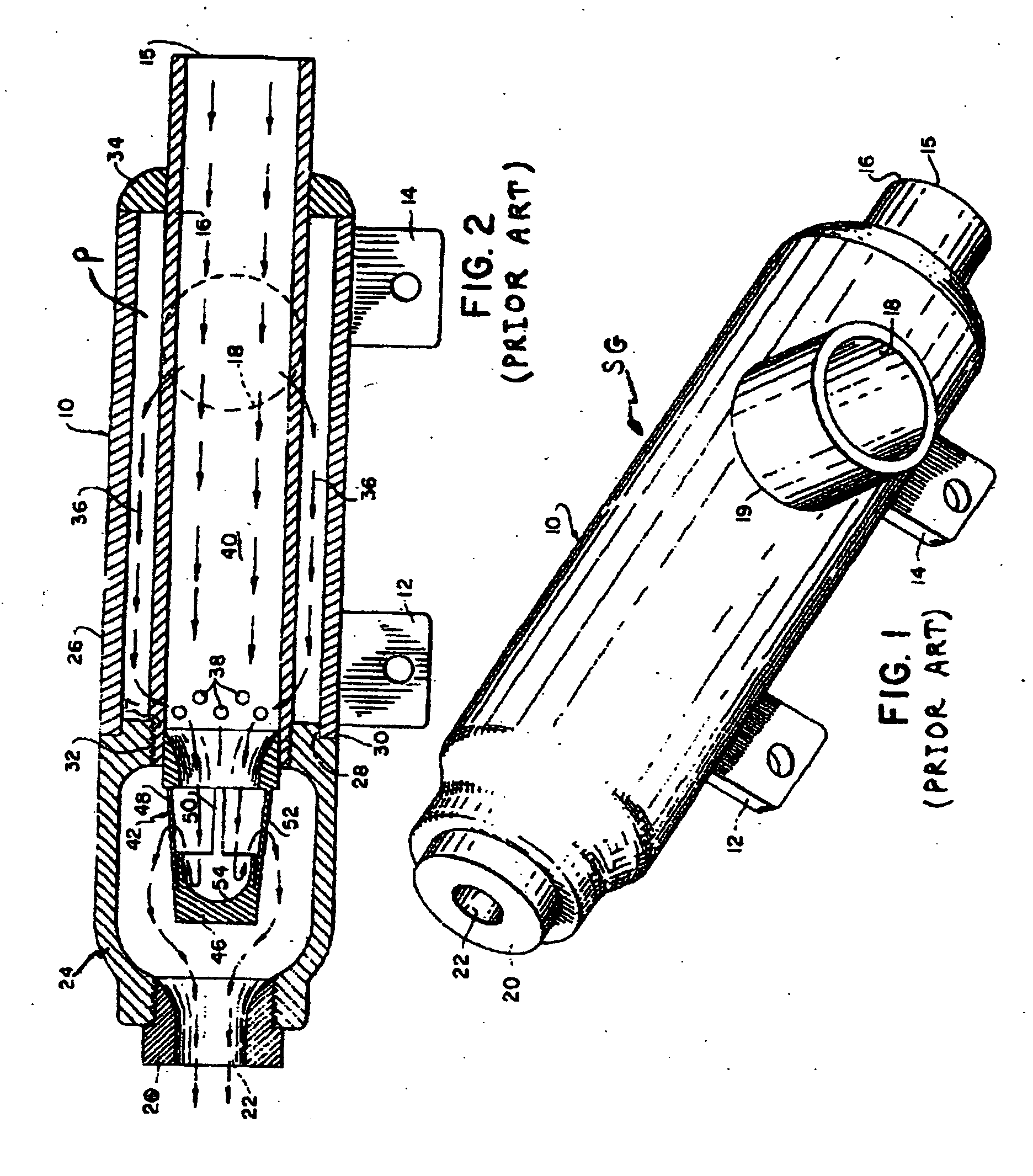

InactiveUS7040554B2Eliminate the problemEasy to disassembleLiquid surface applicatorsDust removalLiquid productCoupling

Owner:ASEPT INT

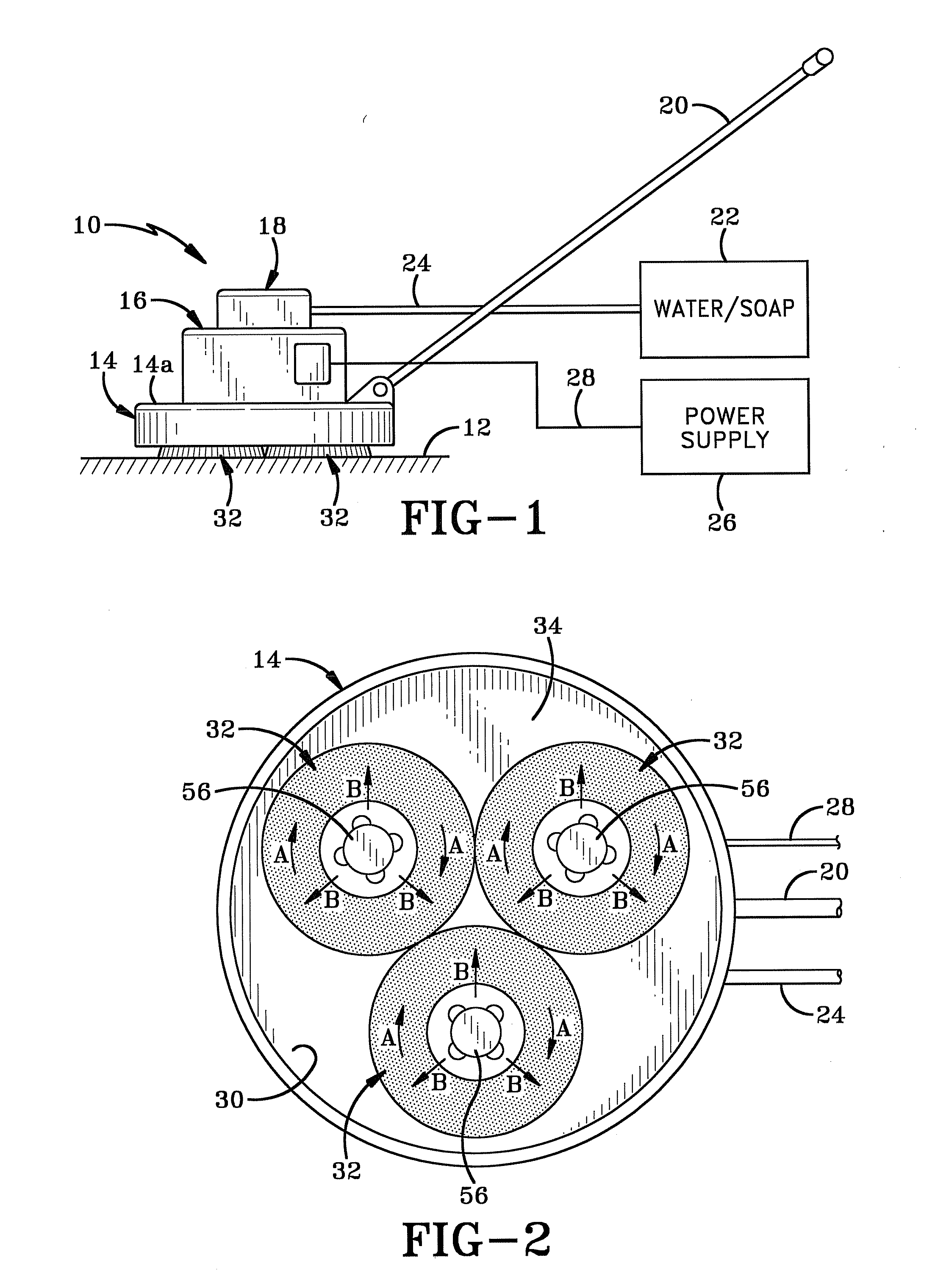

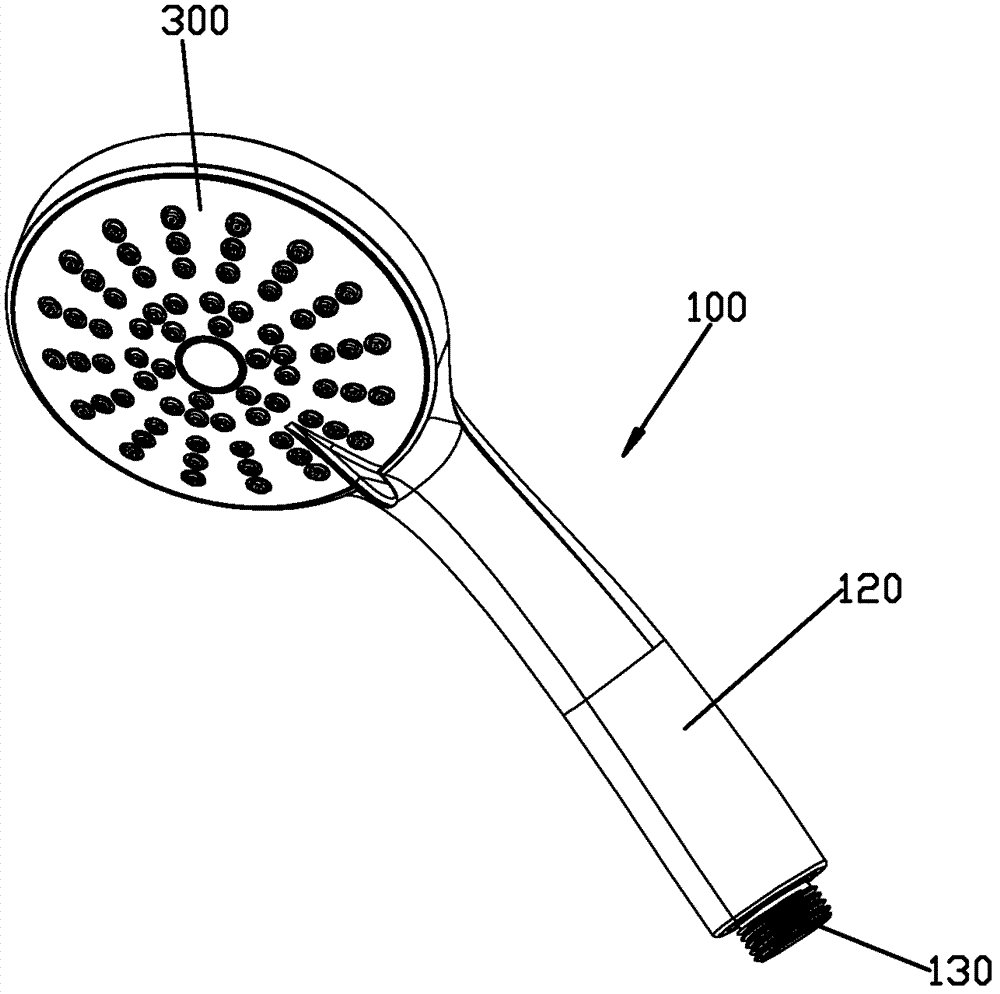

Multifunctional sprinkler structure

ActiveUS7255291B1Accurate operationEqually distributedMovable spraying apparatusSpray nozzlesImpellerWater discharge

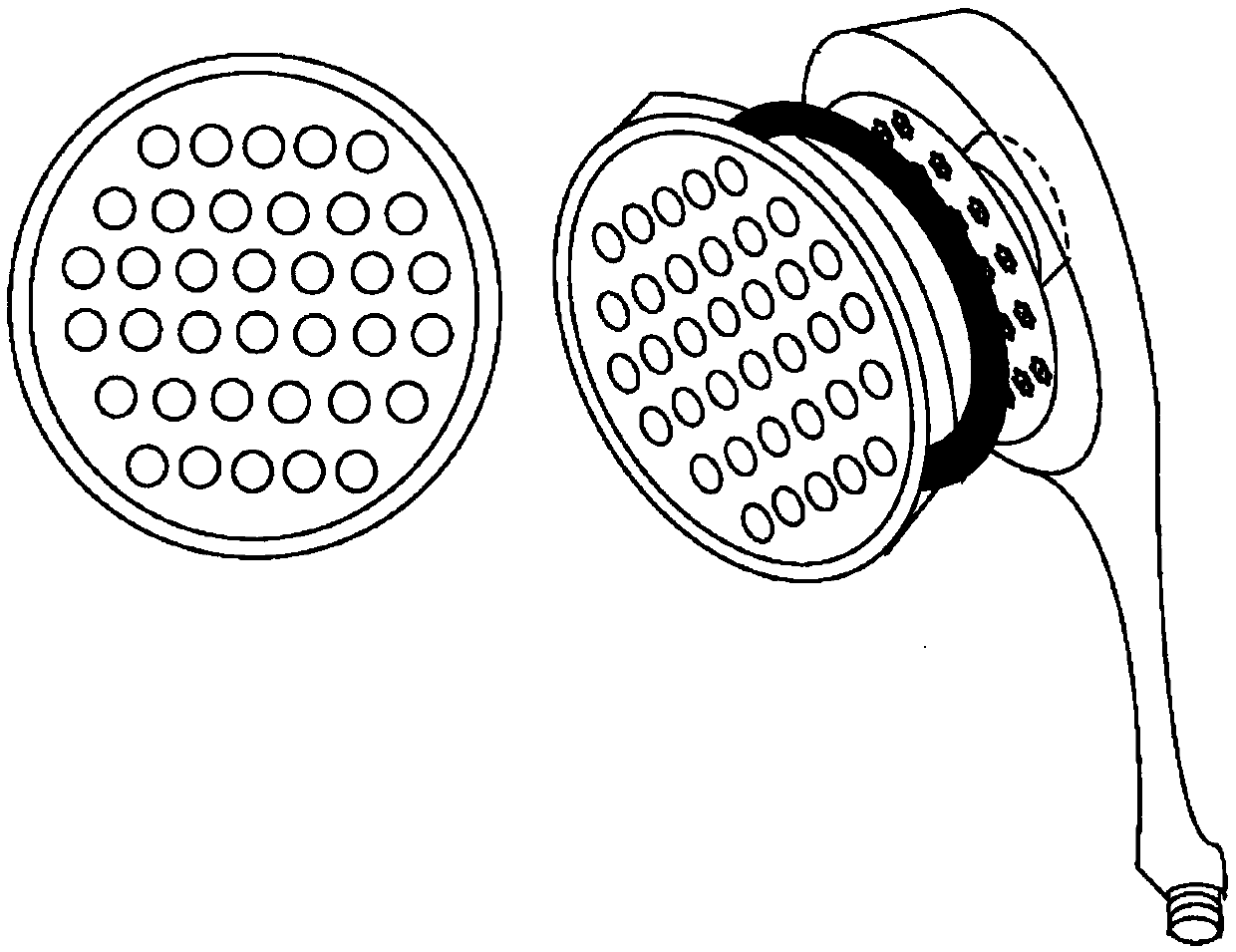

A multifunctional sprinkler structure comprises a water motor having an outlet seat and a top cover mounted to a top-end side, and two adjusting seats and a water supply seat assembled onto a bottom-end side. The bottom-end side of the water motor has a guide groove with a restrictive hole for the extension of a switch shaft there-through. The outlet seat has a water-discharge chamber with multiple barriers extending thereon corresponding to an impeller of the water motor, and an oblique-extending central guide port matching to a spray nozzle having multiple water-guiding ribs obliquely extending towards the same direction therein. Therefore, the barriers of the outlet seat and the water-guiding ribs of the spray nozzle are utilized to correspond to the direction of the water flow so that the water discharge can be easily switched to eject either in more direct and forceful column-like spray or in more expanding spray.

Owner:YUAN MEI CORP

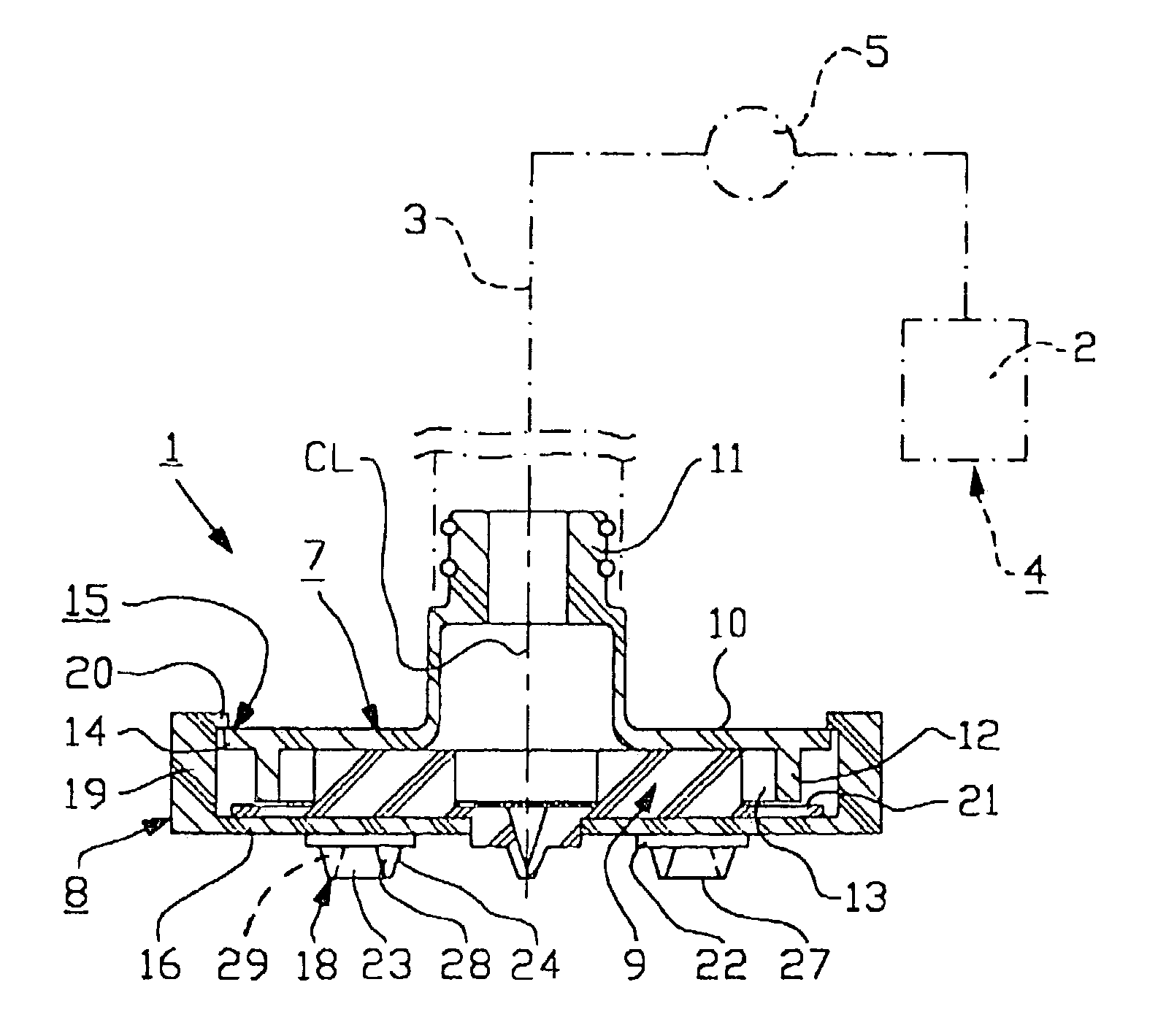

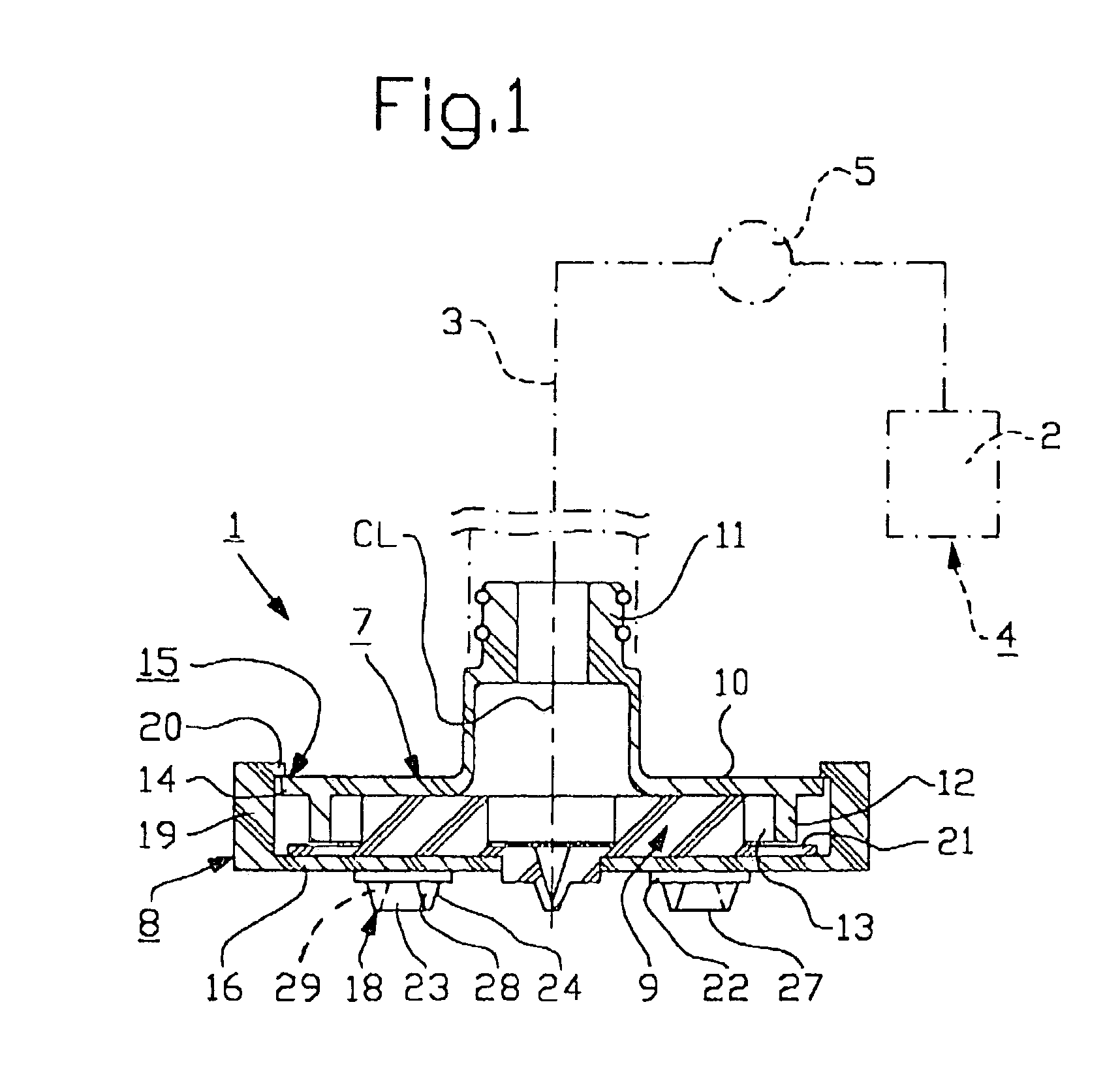

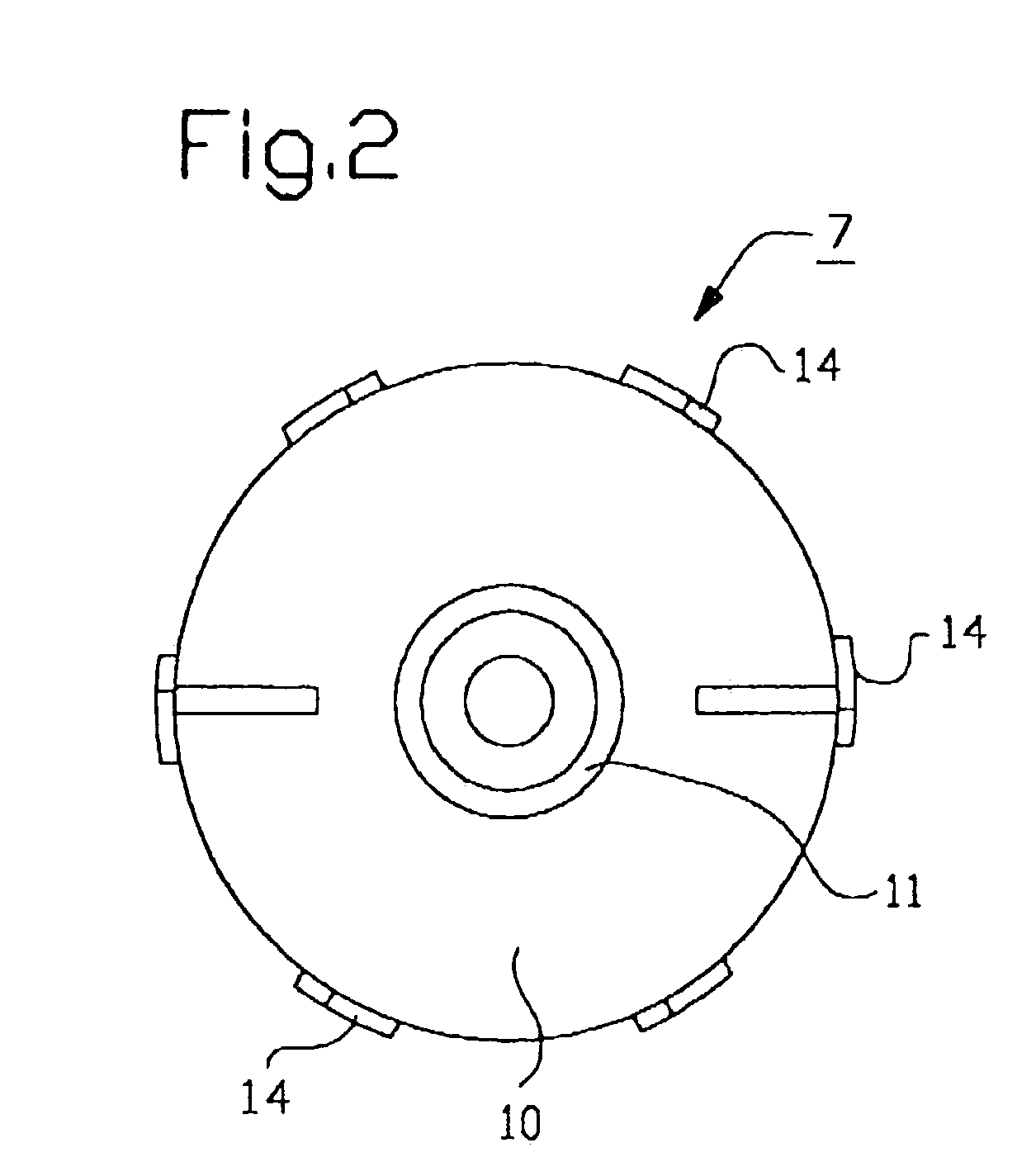

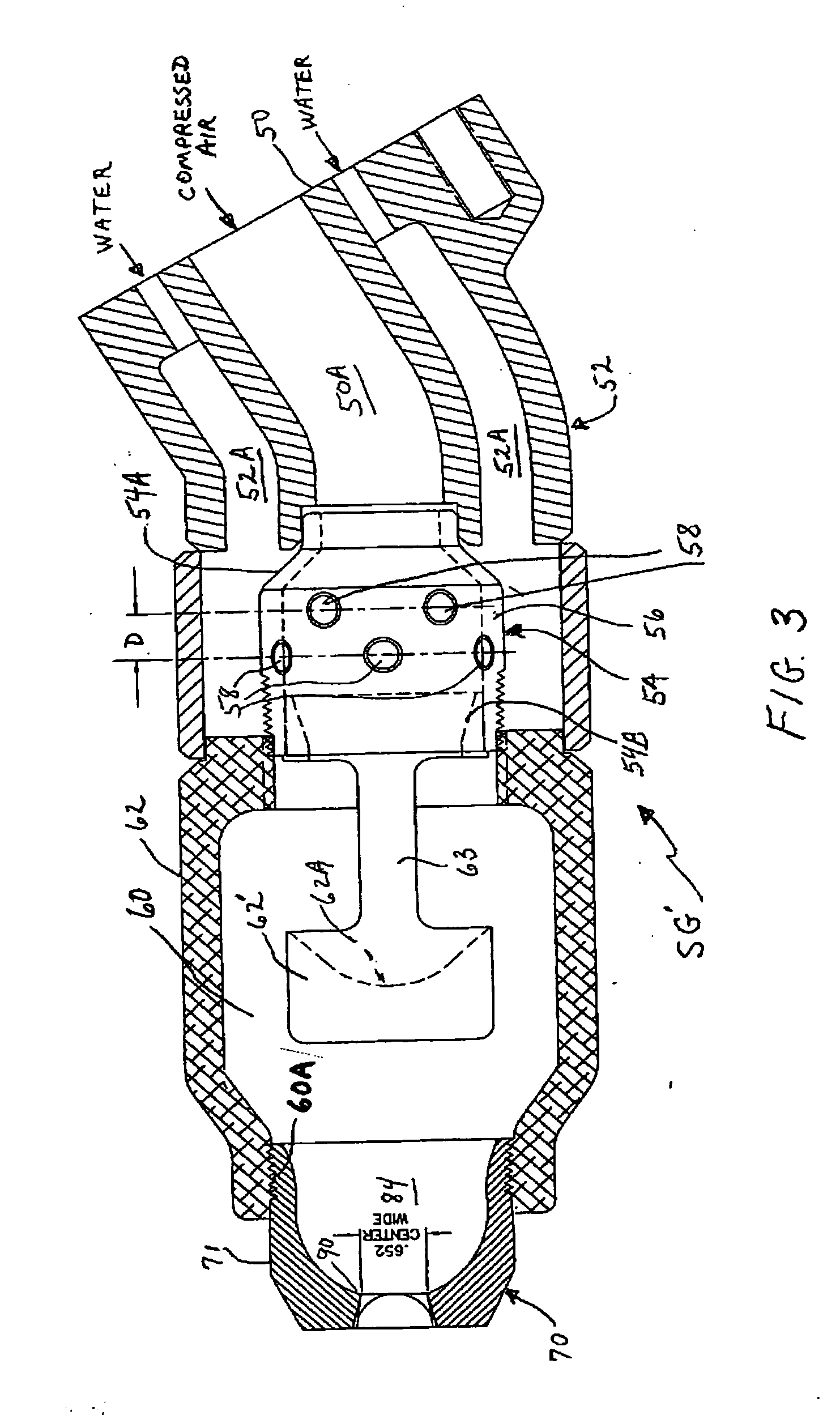

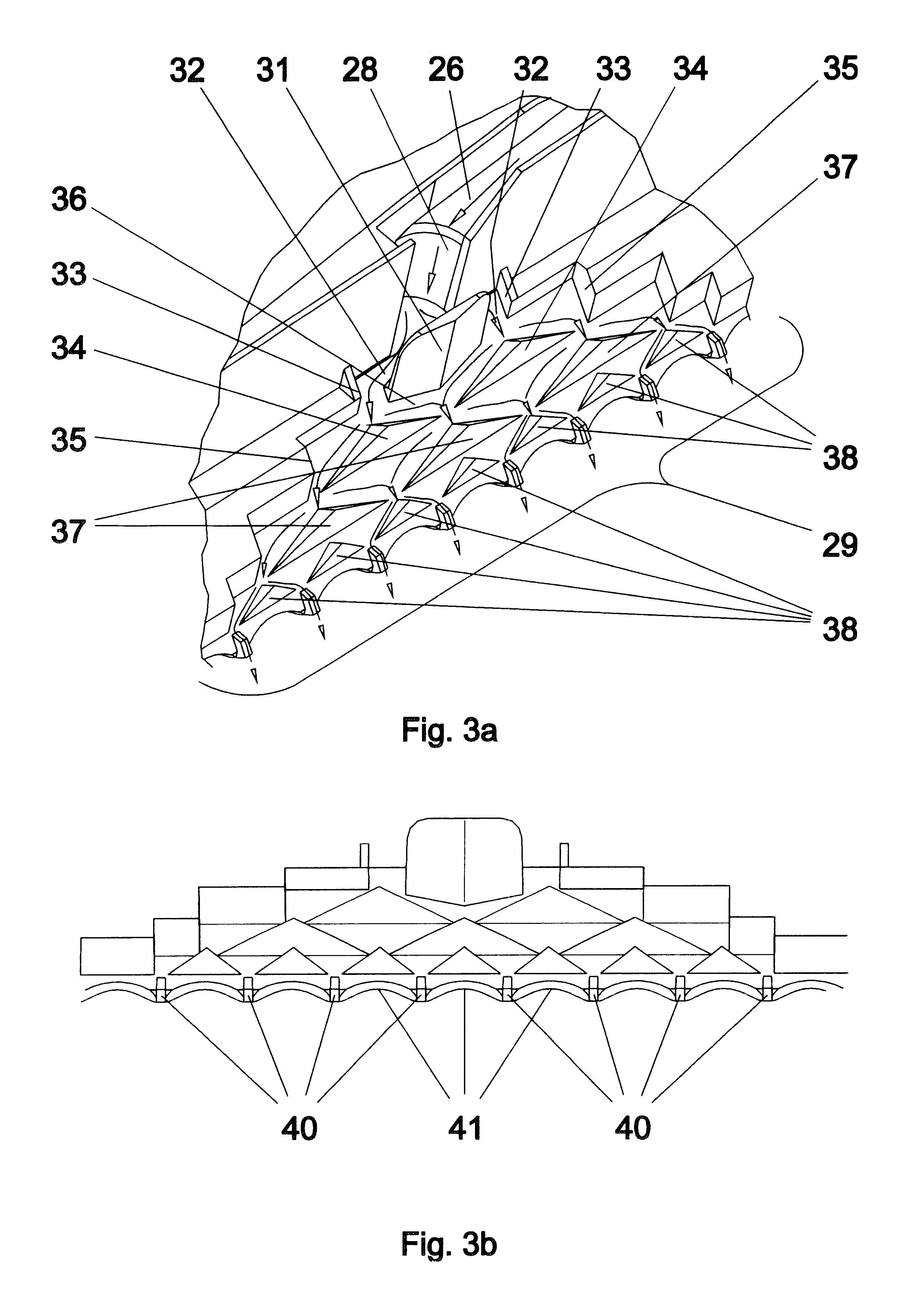

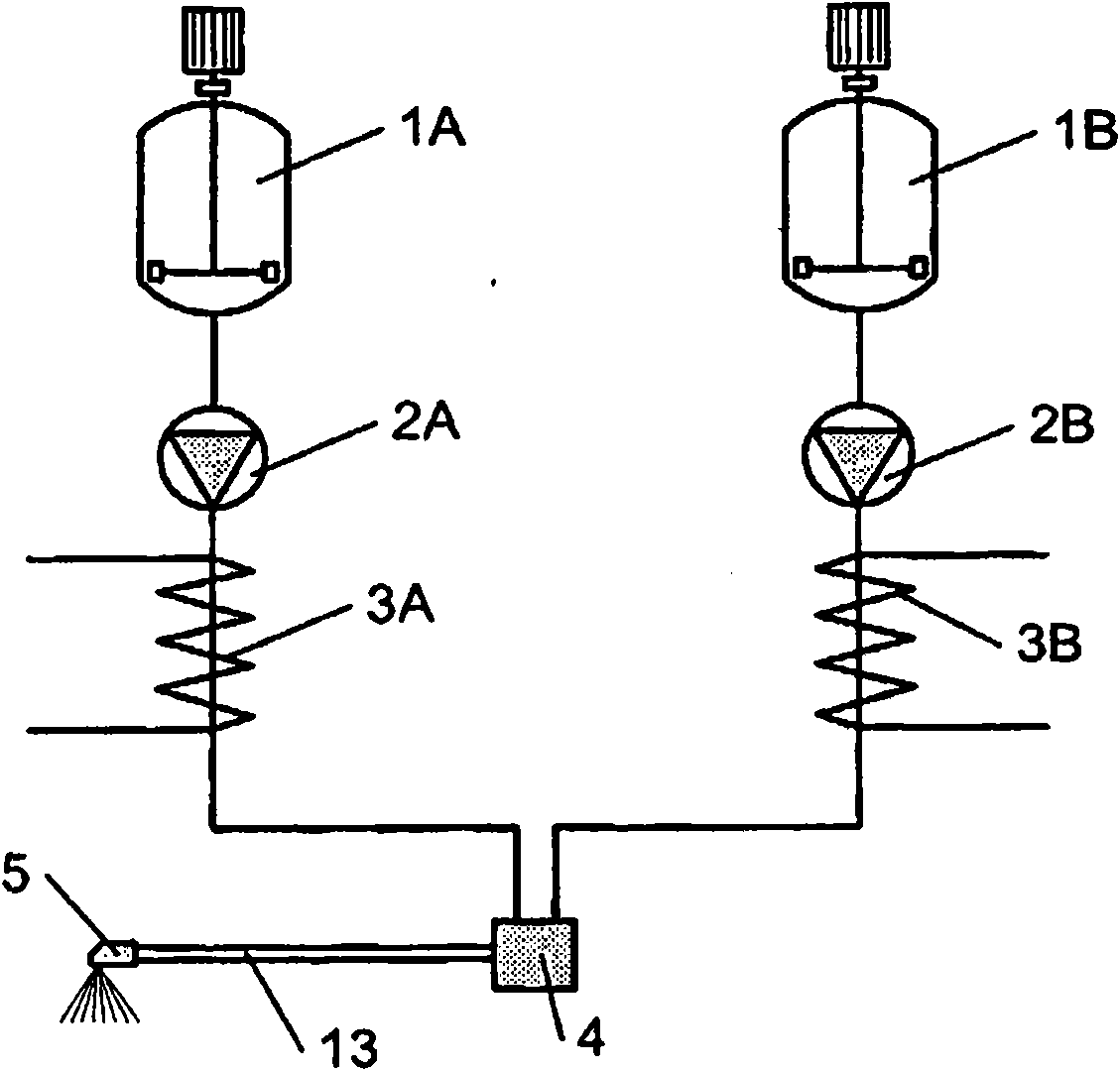

Snow-gun

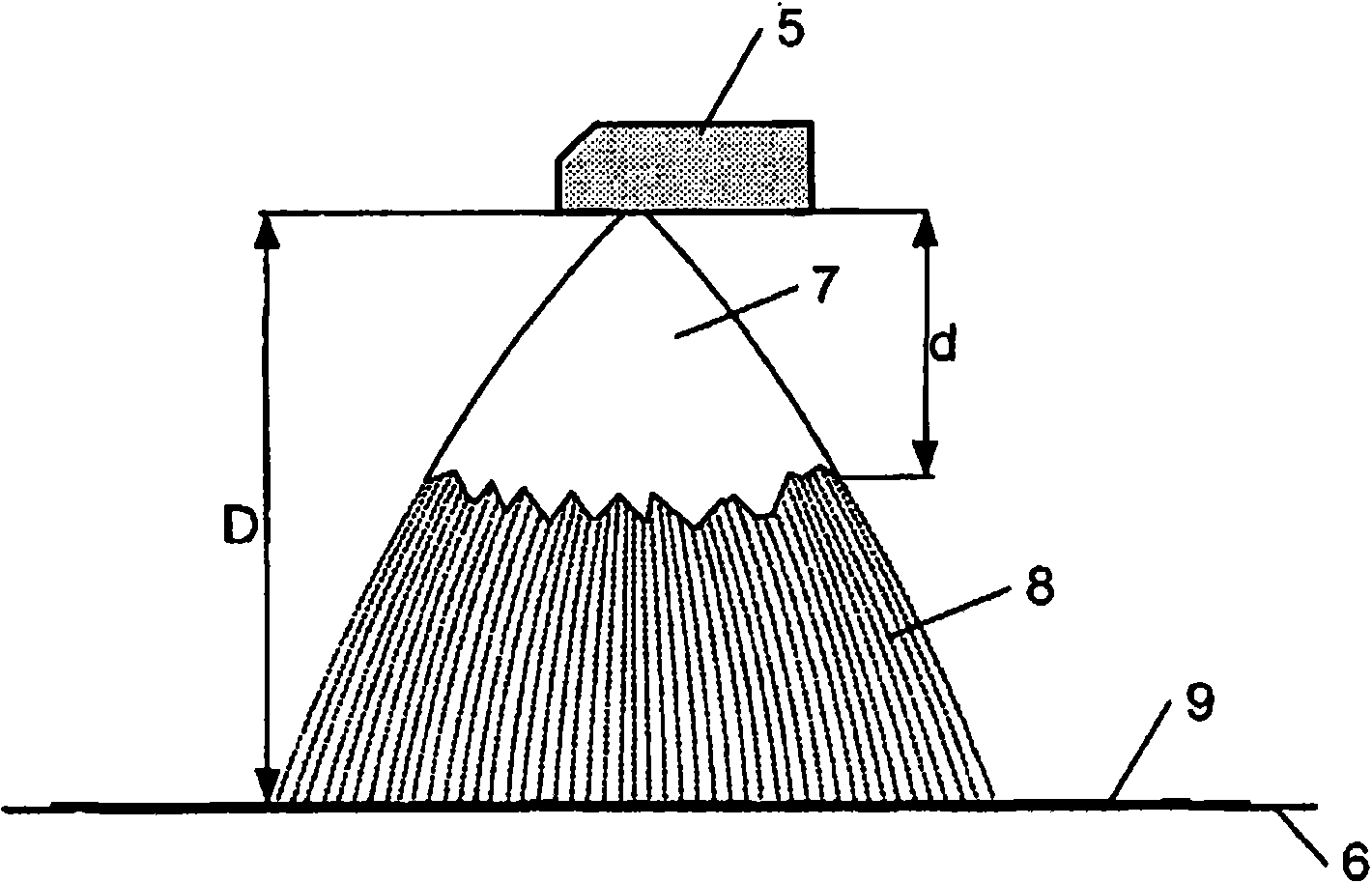

ActiveUS20060071091A1Improve efficiencyRecreational ice productionSpray nozzlesWater featureWater particle

Owner:RATNIK IND

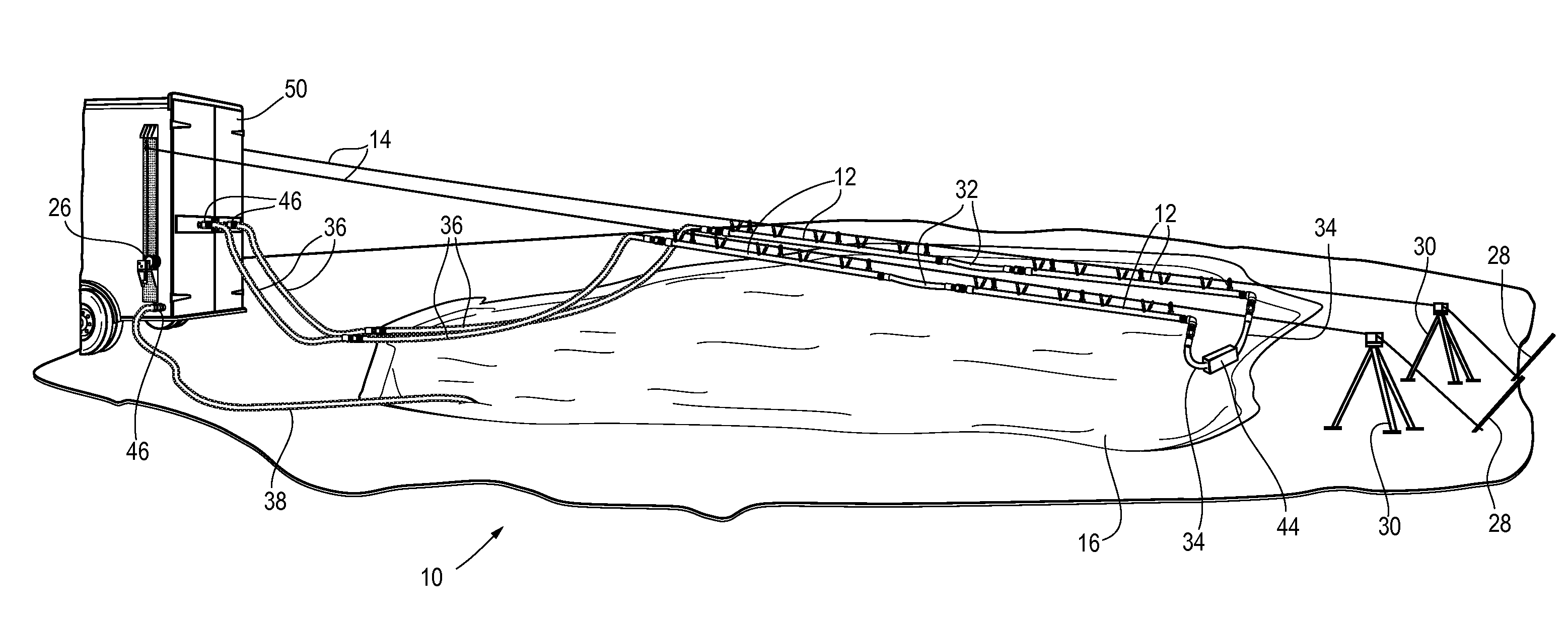

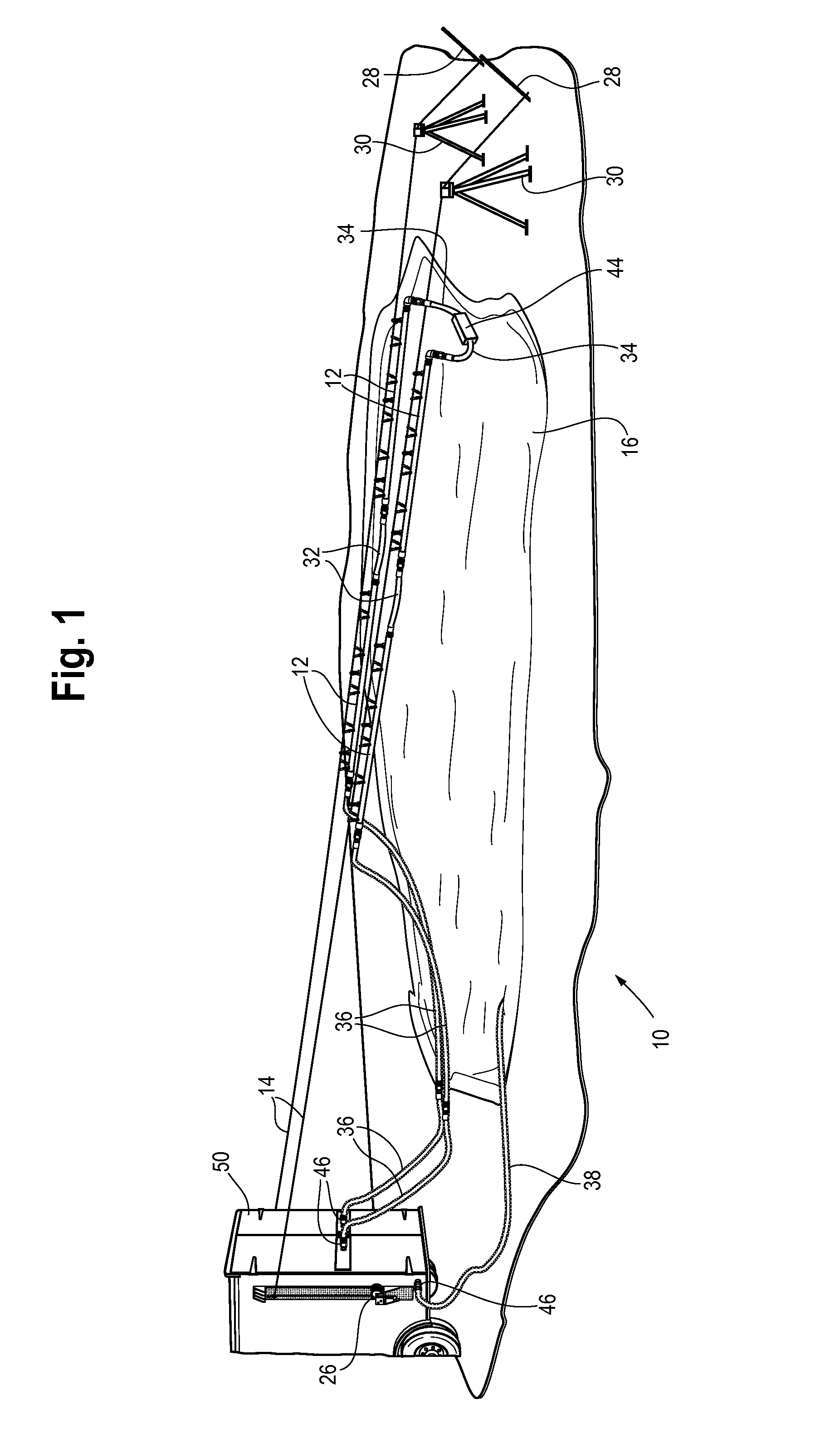

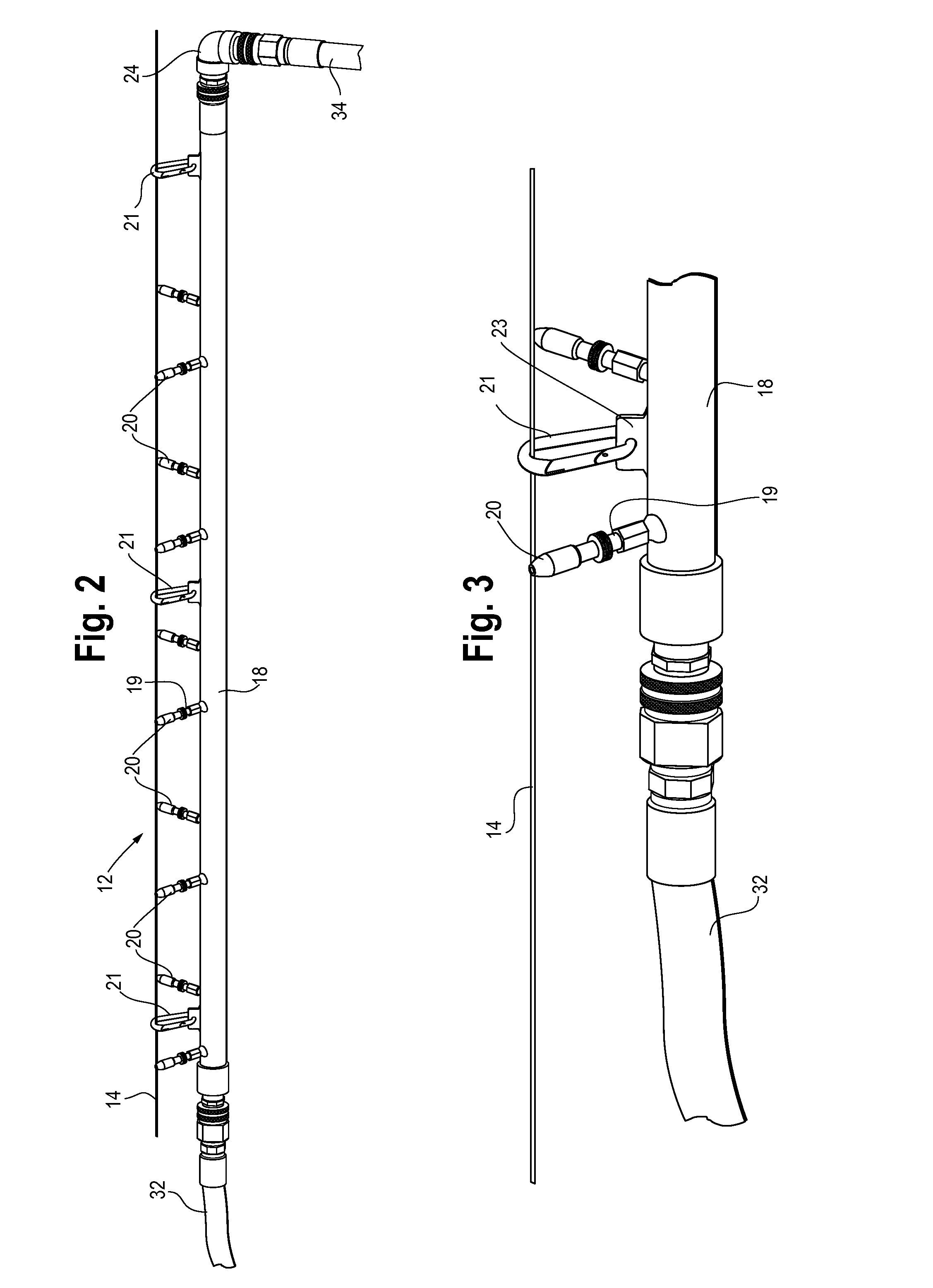

Water evaporation system using nozzles attached to a suspended cable

Owner:EVAPORITE SYST

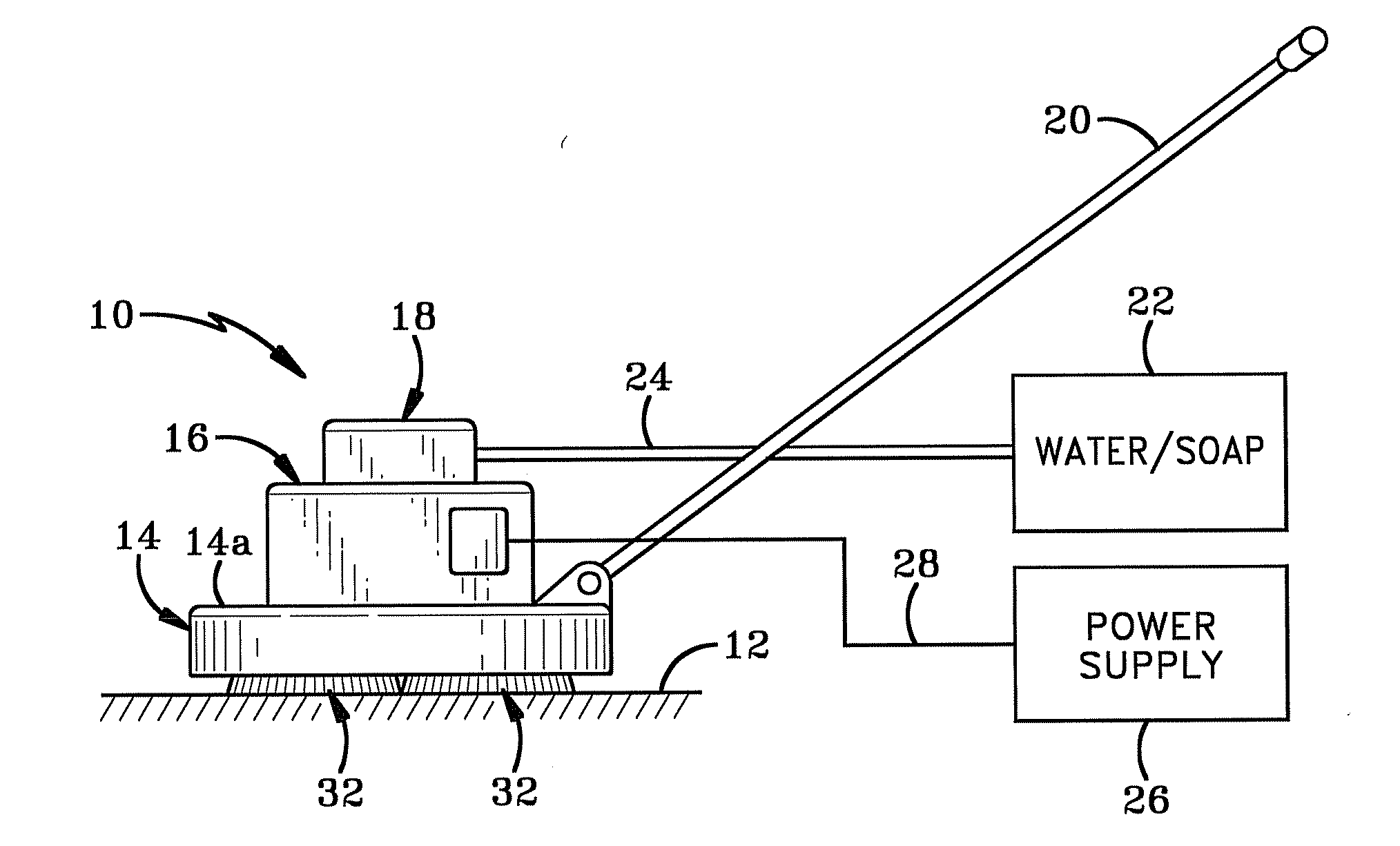

Liquid dispensing brush assembly for a floor scrubber

Owner:JORDAN POWER & EQUIP

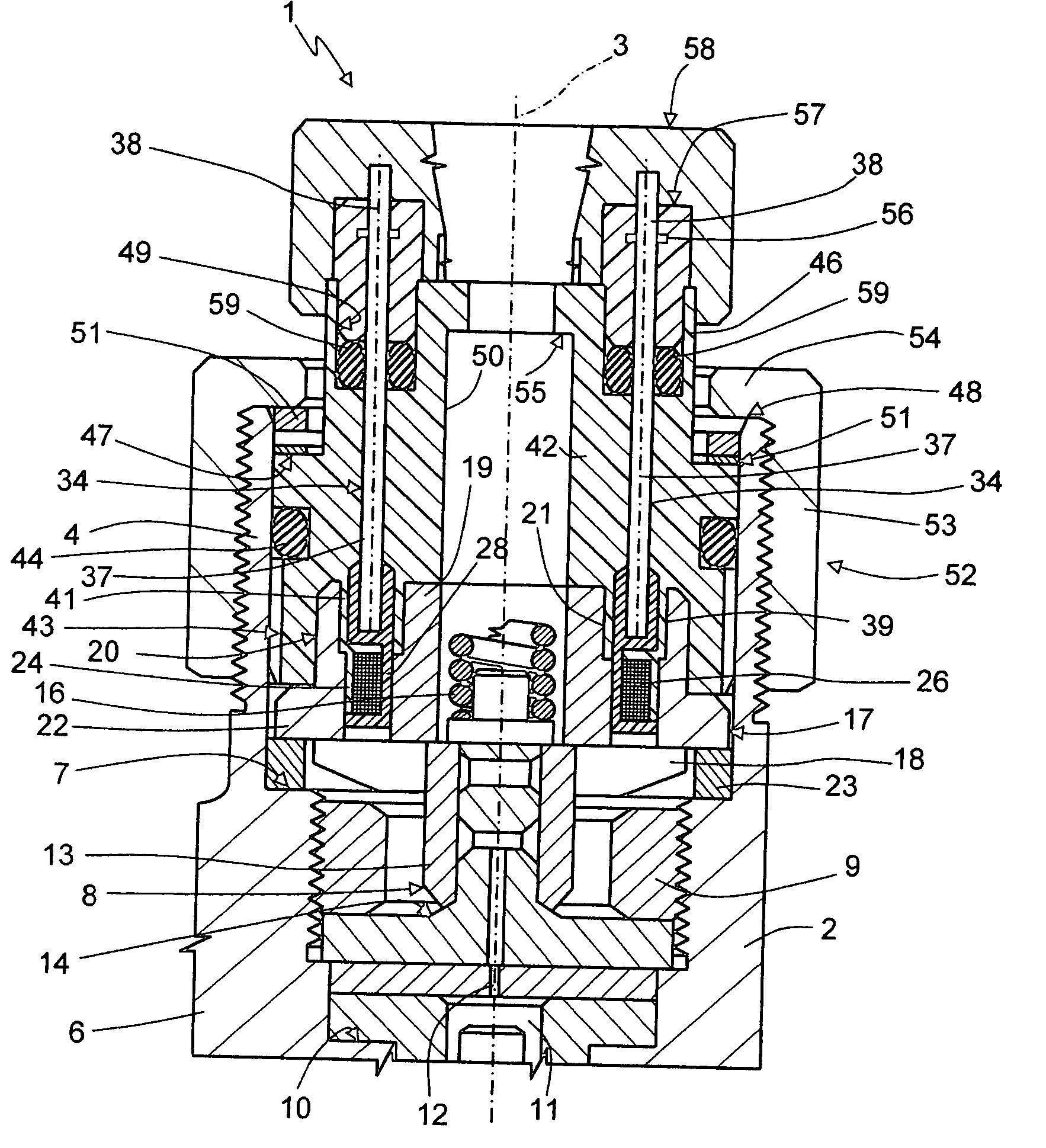

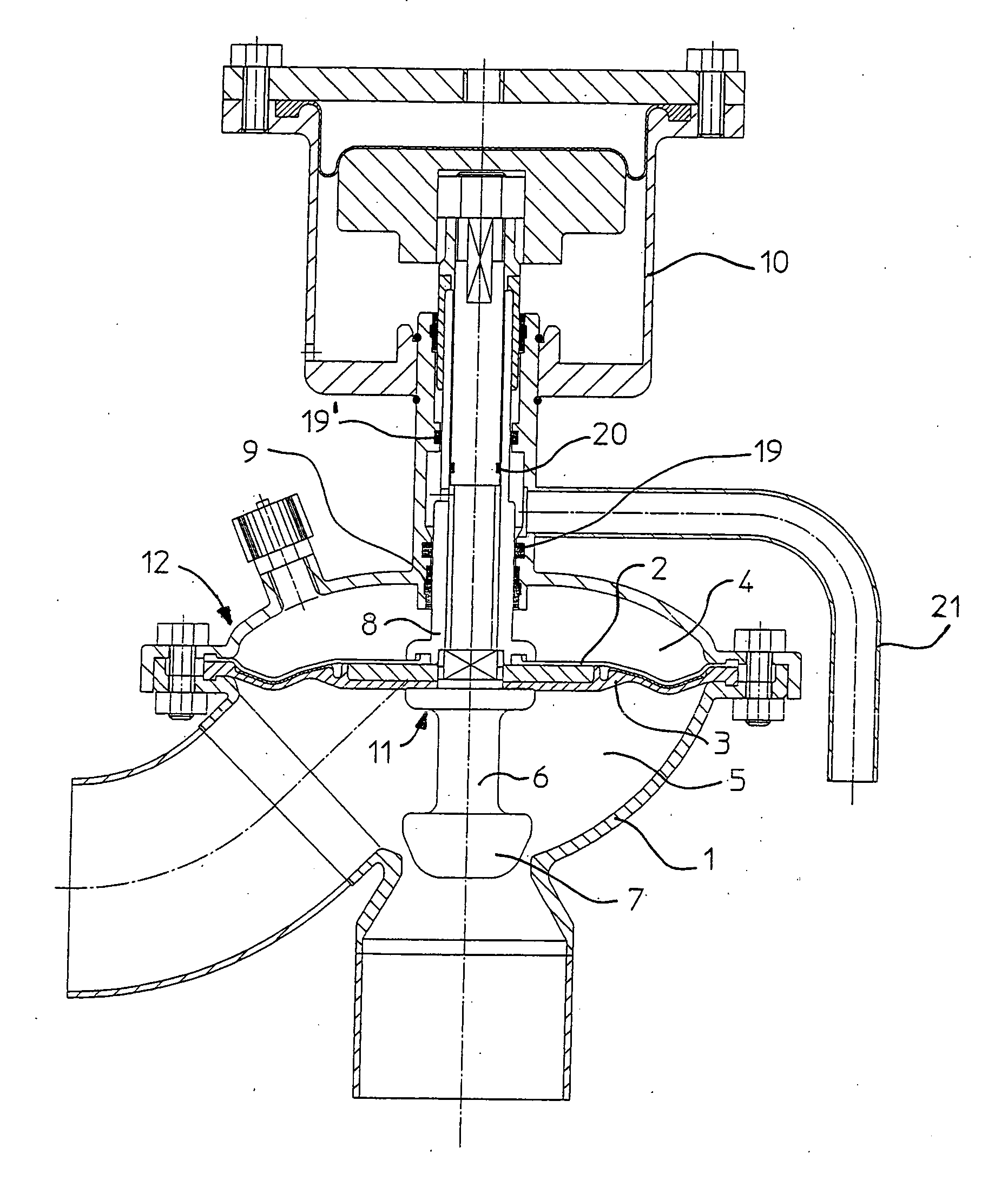

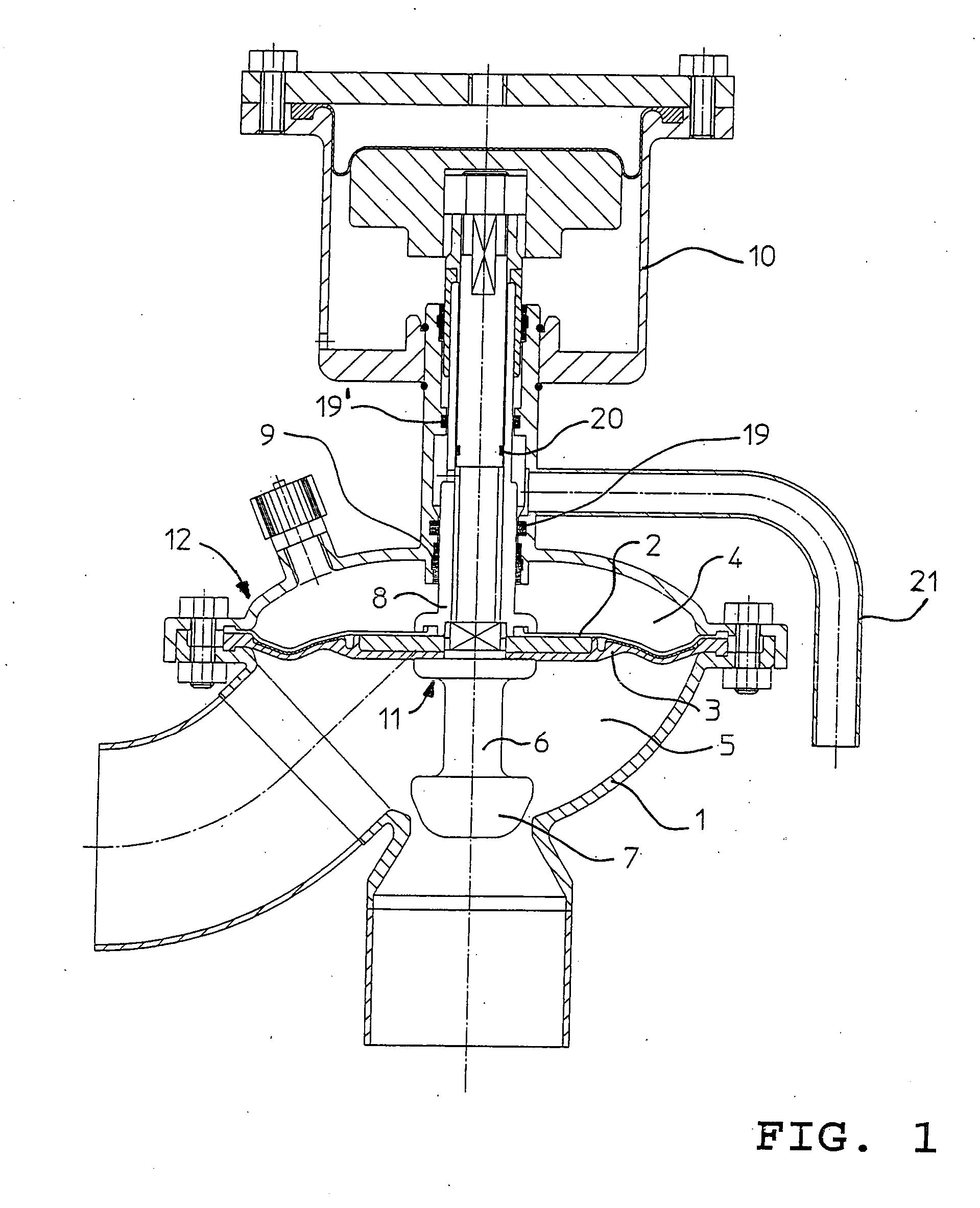

Fuel injector for internal combustion engine and corresponding method of manufacture

ActiveUS20070289578A1Contained costDrawback can be obviatedOperating means/releasing devices for valvesSpray nozzlesComing outBobbin

Owner:C R F SOC CONSORLILE PER AZIONI

Food and beverage industry membrane valve structure

ActiveUS20060273206A1Easy constructionReduce the numberSpindle sealingsOperating means/releasing devices for valvesTrademarkEngineering

Owner:APV ROSISTA

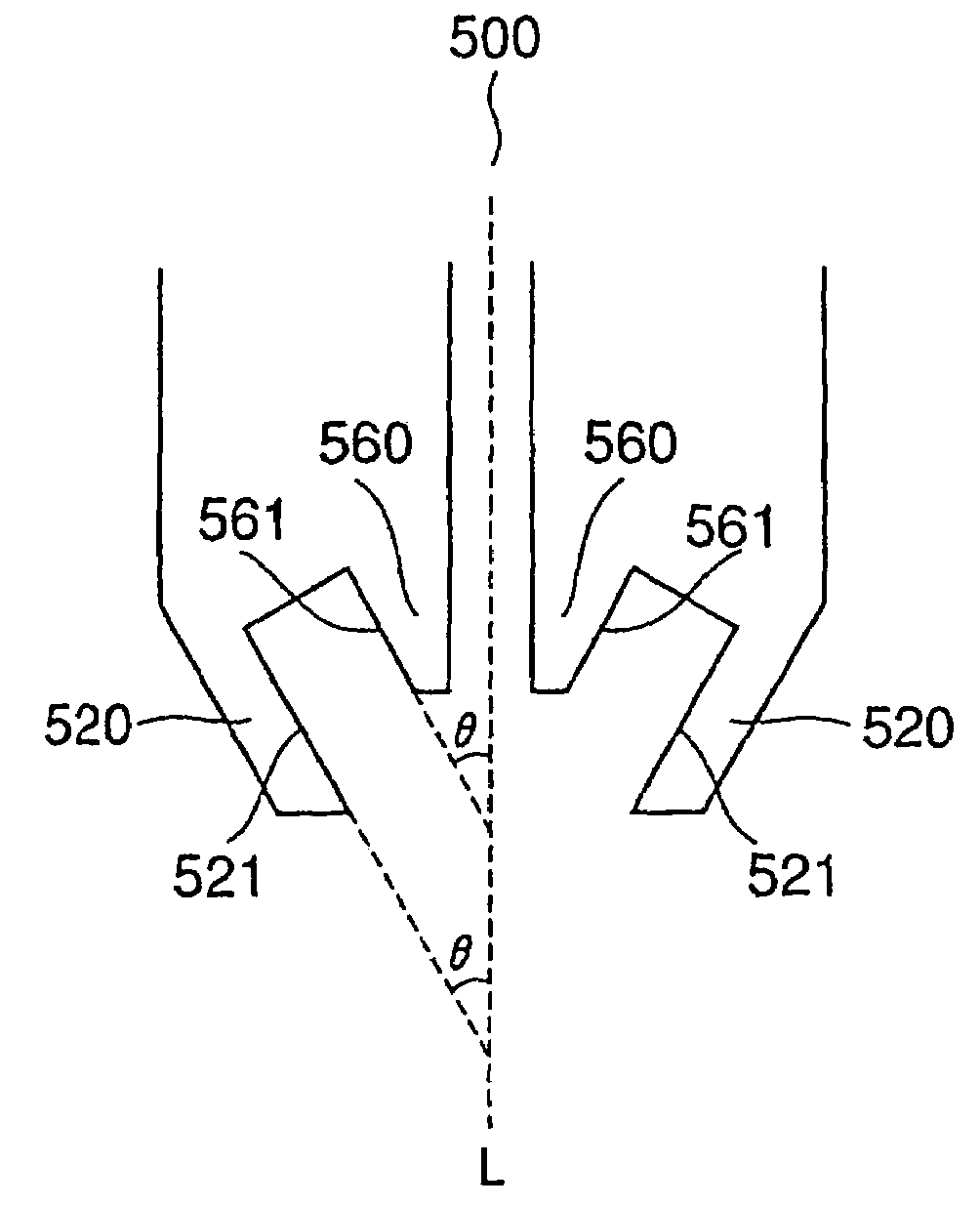

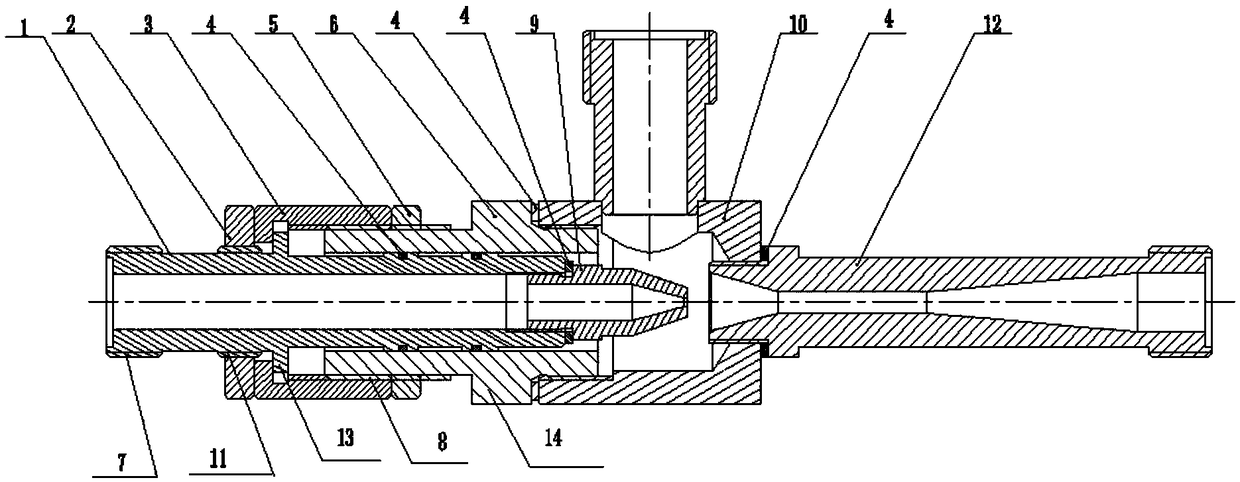

Fuel injection valve

InactiveUS20040069863A1Spray nozzlesFuel injection with piezoelectric/magnetostrictive elementsEngineeringInternal combustion engine

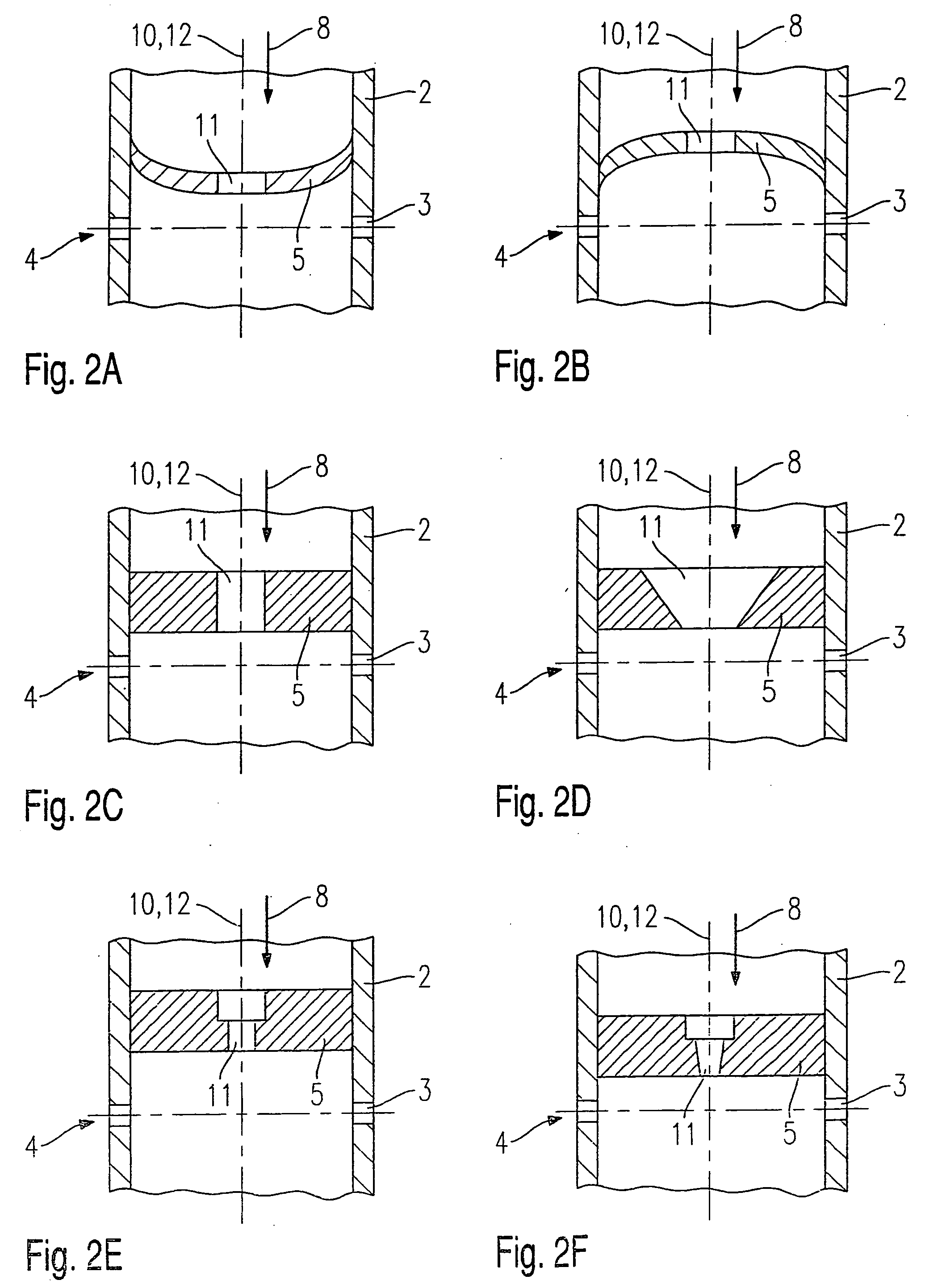

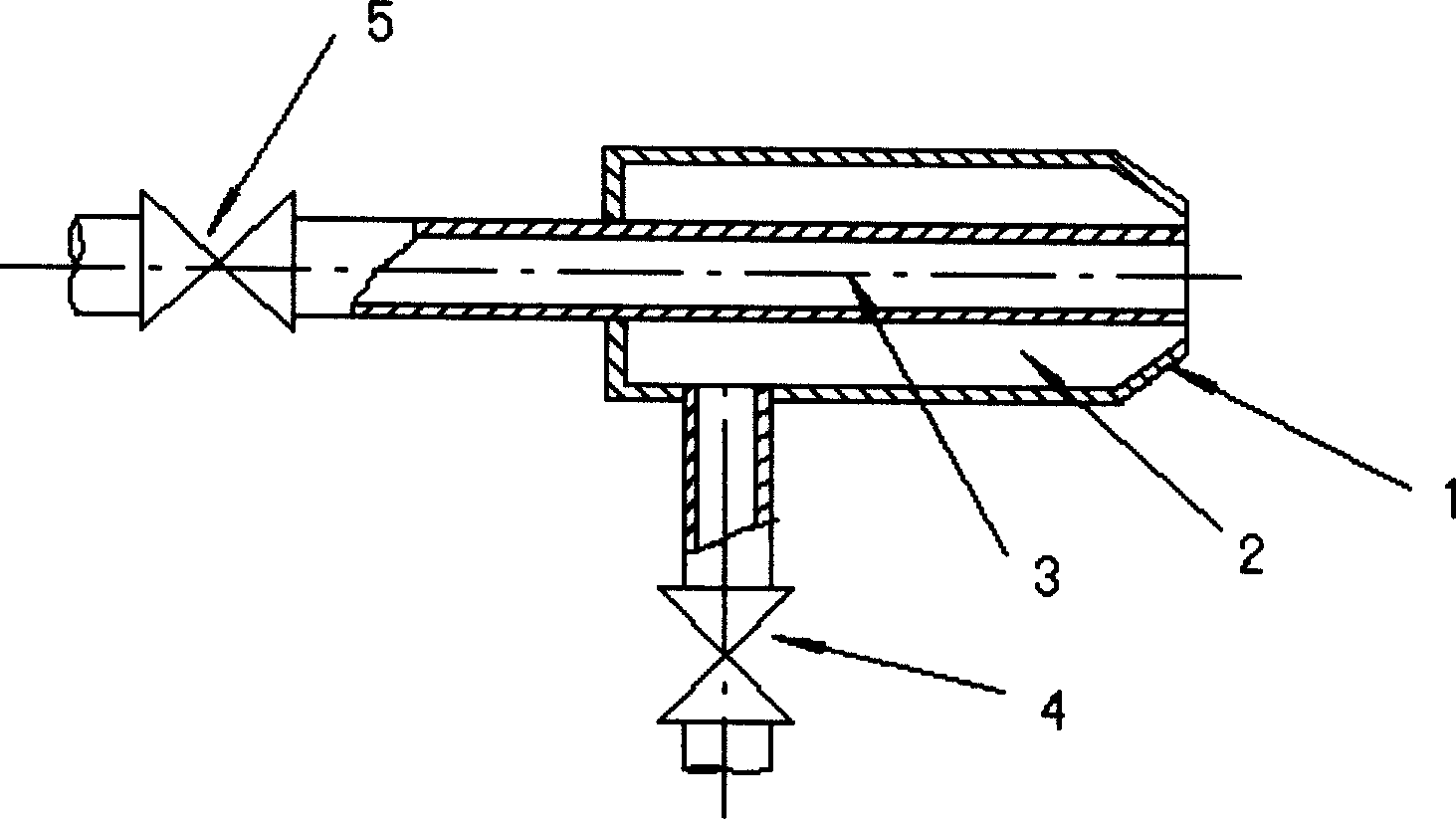

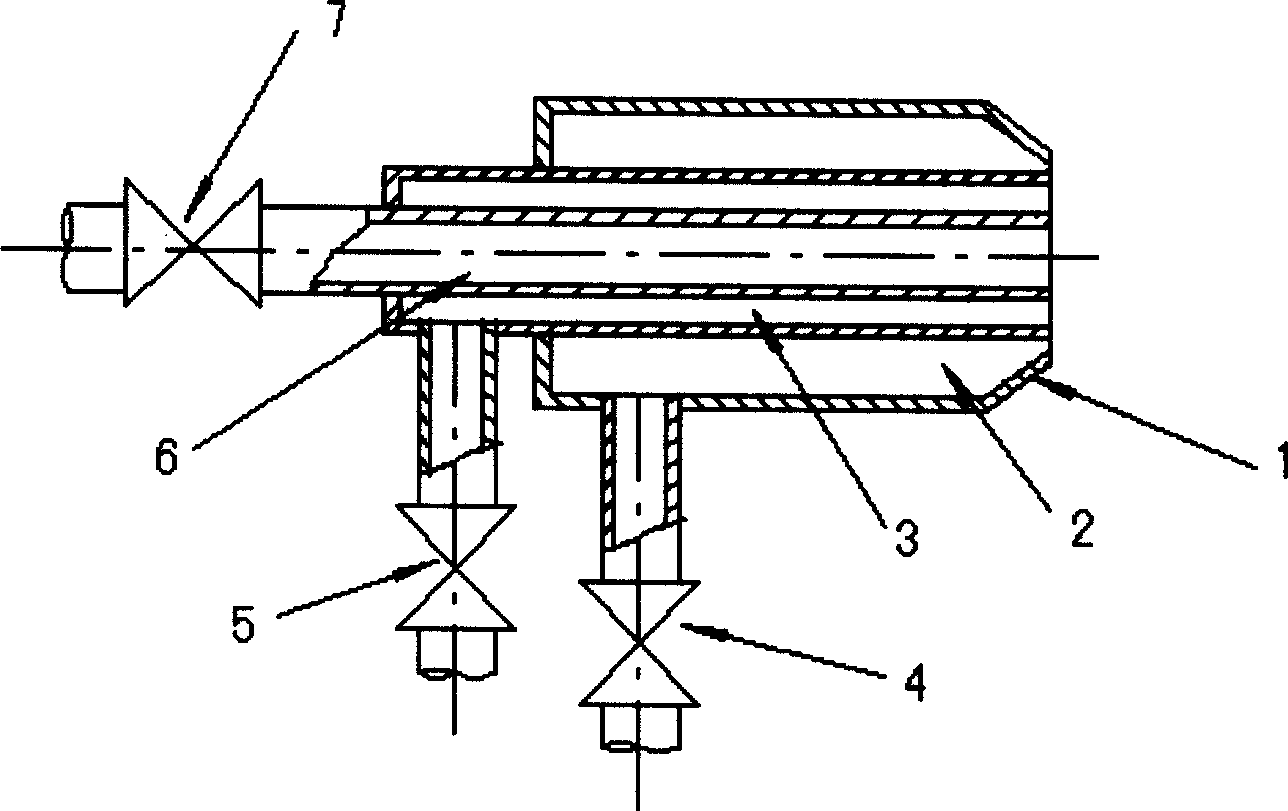

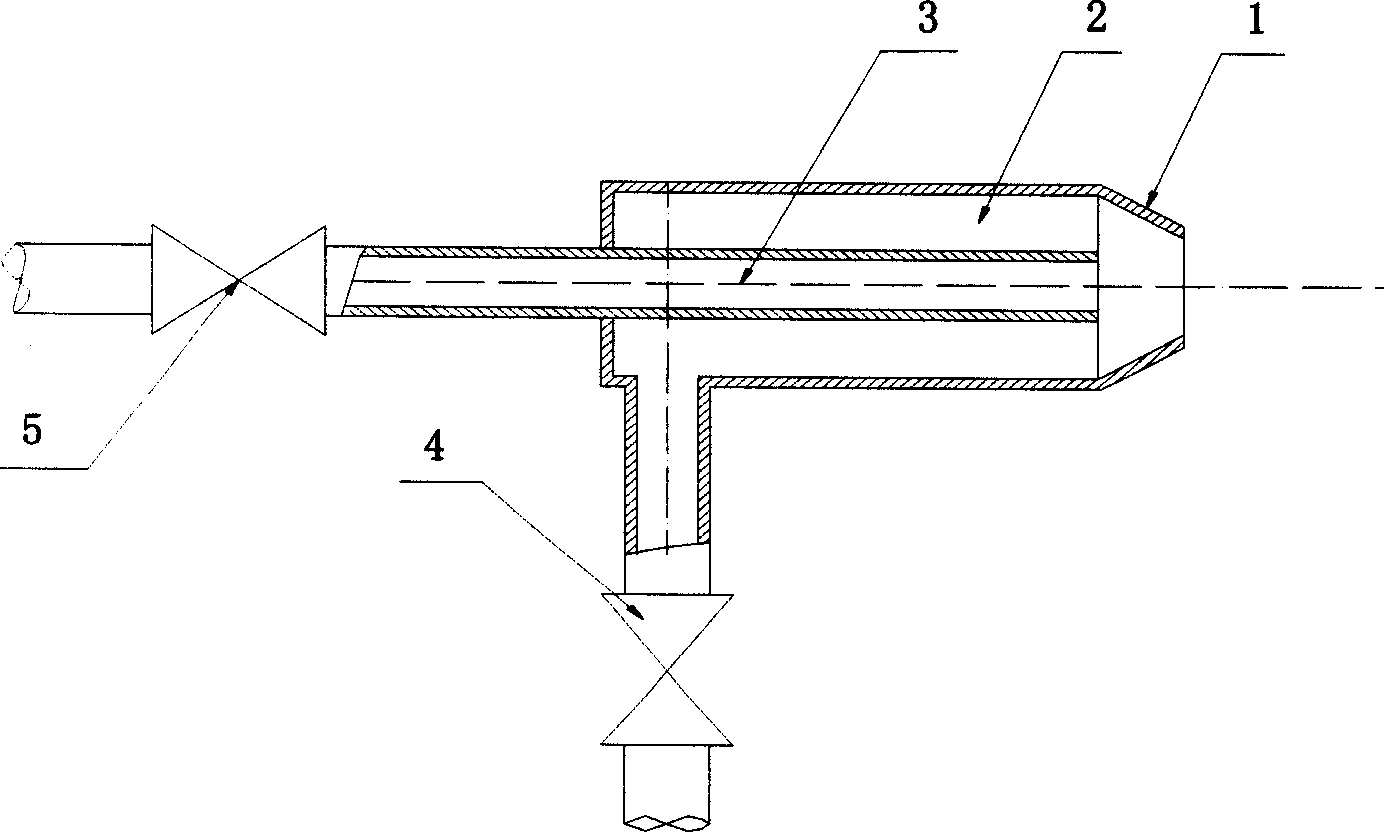

In a fuel injection valve for internal combustion engines, having a valve housing, having an axially movable valve member for opening and closing an injection opening of the injection valve, and having a part, which acts in the closing direction of the valve member, which is guided with its end remote from the injection opening in a bore of a first valve piece inserted into the valve housing and with this end, encloses a control pressure chamber in the first valve piece, which control pressure chamber can be connected to a high-pressure fuel connection via an inlet conduit, which is provided with at least one inlet throttle, and can be connected to a low-pressure fuel connection via an outlet conduit, which has an outlet throttle and can be closed by a movable control valve member, where the injection process can be controlled by means of the fuel pressure in the control pressure chamber, the proposal is made that at least the section of the inlet conduit provided with the inlet throttle be disposed in a second valve piece inserted into the valve housing, which second valve piece is connected to an opening embodied in the first valve piece in such a way that the section of the inlet conduit of the second valve piece provided with the inlet throttle feeds into the control pressure chamber of the first valve piece.

Owner:ROBERT BOSCH GMBH

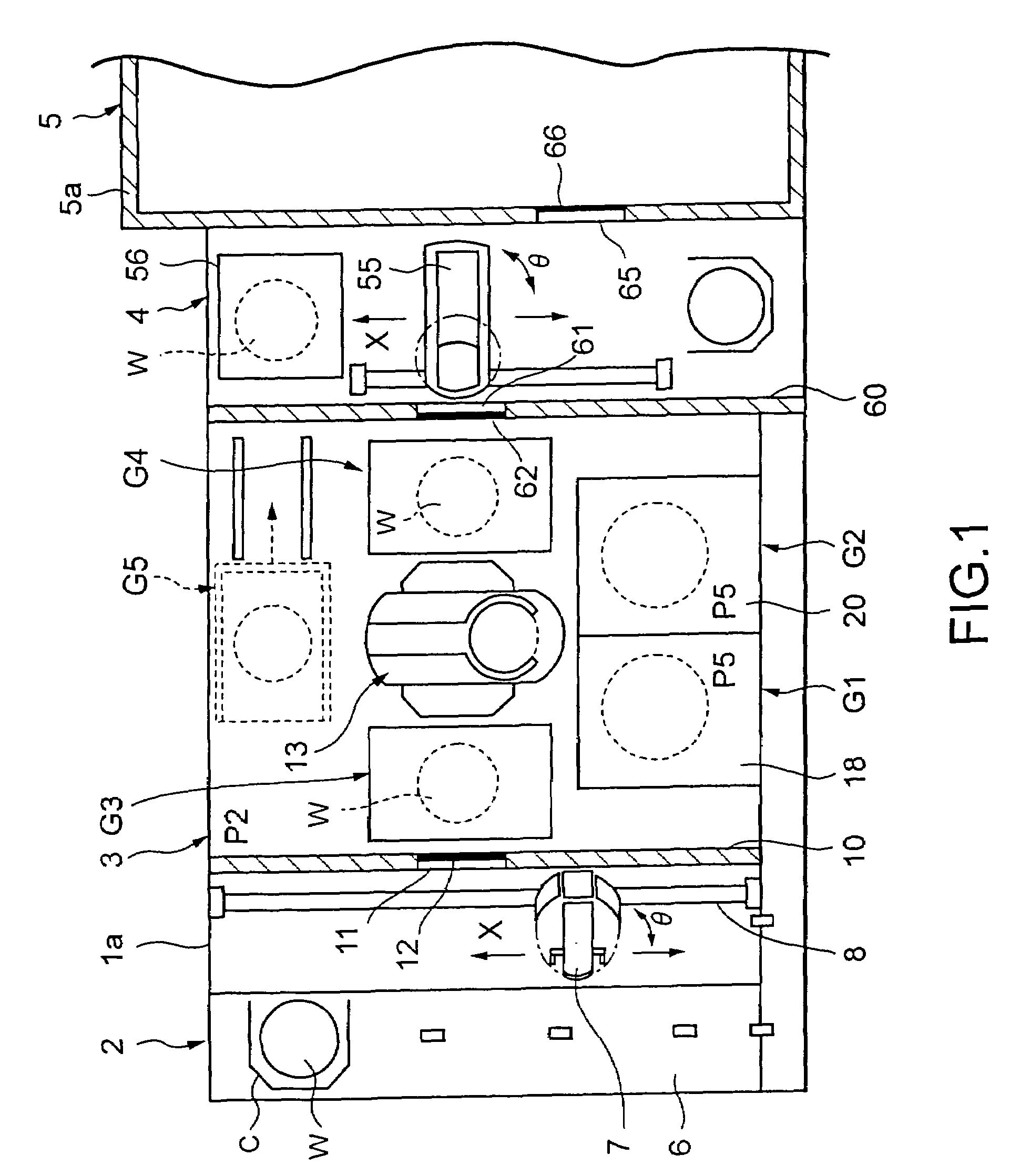

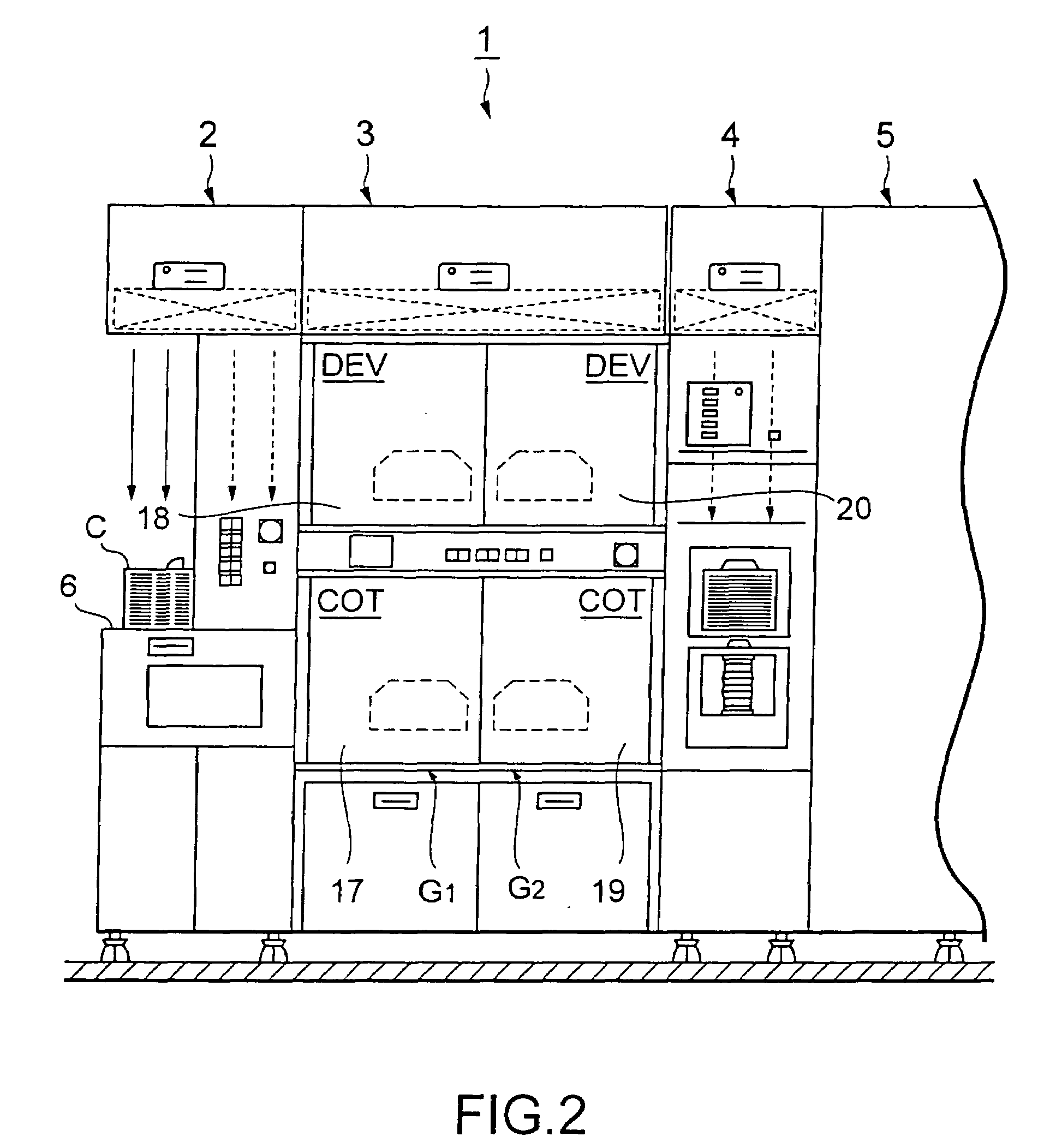

Substrate processing apparatus and substrate processing method

InactiveUS7208066B2Avoid levelingLiquid surface applicatorsPhotomechanical apparatusAtmospheric airEngineering

Owner:TOKYO ELECTRON LTD

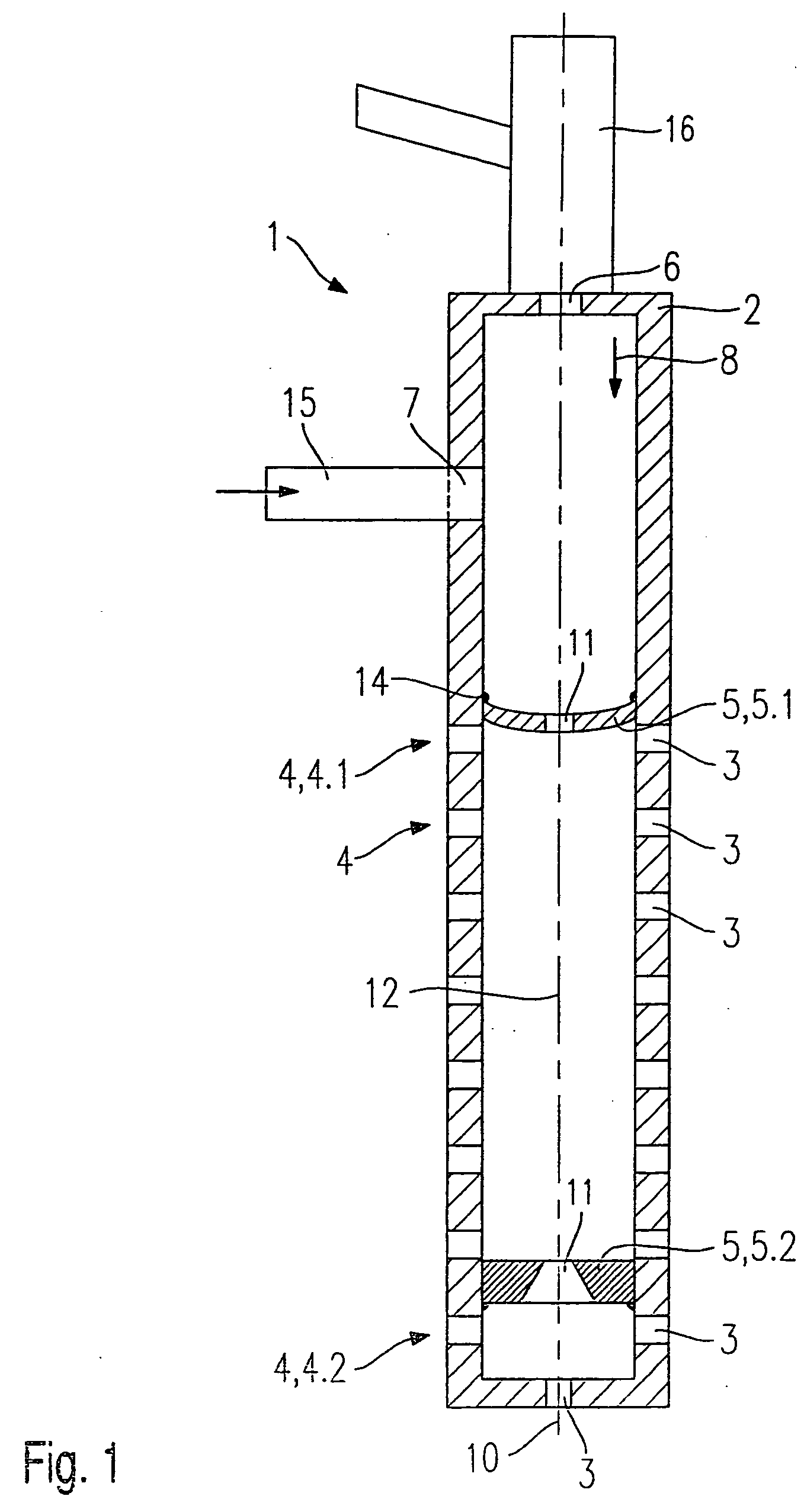

Atomising nozzle

InactiveUS20060144966A1Simple processImprove business performanceBurnersSpray nozzlesHydrogenAtomizer nozzle

Owner:ROBERT BOSCH GMBH

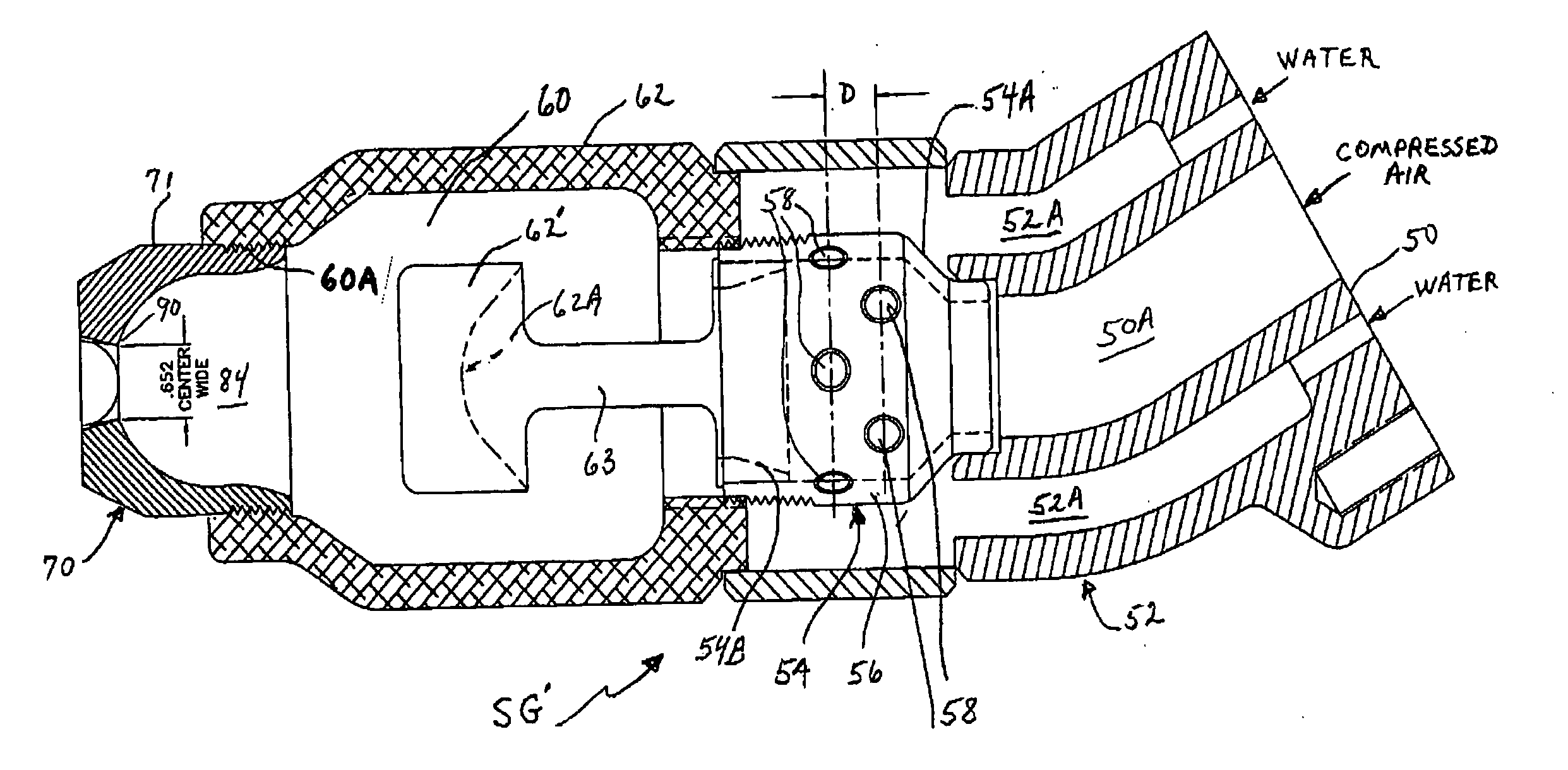

Sensitizing method of emulsified explosive and gas flow nozzle used

InactiveCN1453253AEasy to storeImprove efficiencySpray nozzlesExplosive working-up apparatusAirflowEmulsion explosive

Compressed air flowing through airflow nozzle is used to atomize emulsified explosive matrix, and during atomizing, the emulsified explosive matrix is inflated with air and thus sensitized. One kindof nozzle for the said process is also provided and includes nozzle body with compressed air passage and emulsified matrix passage inside it. The present invention can complete the sensitization of emulsified explosive matrix without using any sensitizing material and in high efficiency and yield. The present invention can complete the cooling and sensitizing of high temperature emulsified explosive matrix, the density of the emulsified explosive may be regulated via regulating the pressure of compressed air and the yield via regulating the flow rate of emulsified explosive matrix. Withoutany mechanical stirring, the present invention is favorable to the storage of explosive.

Owner:倪欧琪 +1

Micro-irrigation emitter

InactiveCN101791596AWater/sewage treatment by irradiationSpray nozzlesDecompositionFilm-coated tablet

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

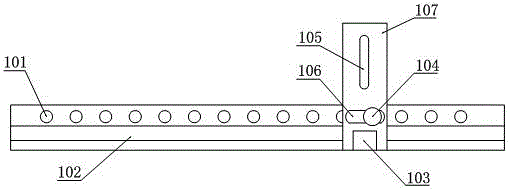

Spray hole number selection platform

Owner:余姚市腾翔电子科技有限公司

Water spreading in evaporative coolers

Owner:F F SEELEY NOMINEES

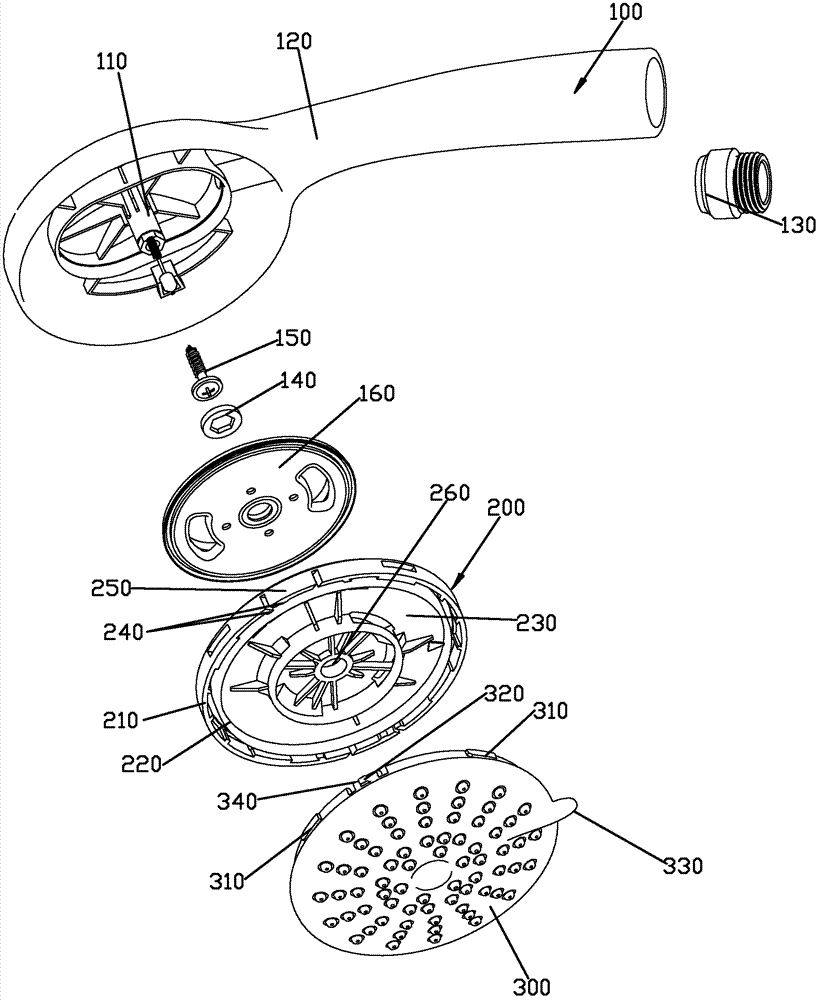

Nozzle device and sanitary washing device using the same

ActiveCN102518196AThere is no need to increase the cross-sectional areaSmall pulsationSpray nozzlesLavatory sanitoryWash waterBuffer tank

A nozzle and a sanitary washing device using the same are provided. The nozzle device has a nozzle port arranged on a nozzle body, a flow passage supplies washing water to the nozzle port from a rear end of the nozzle body and a buffer tank which is connected through a communication path from the halfway of the flow channel.

Owner:PANASONIC CORP

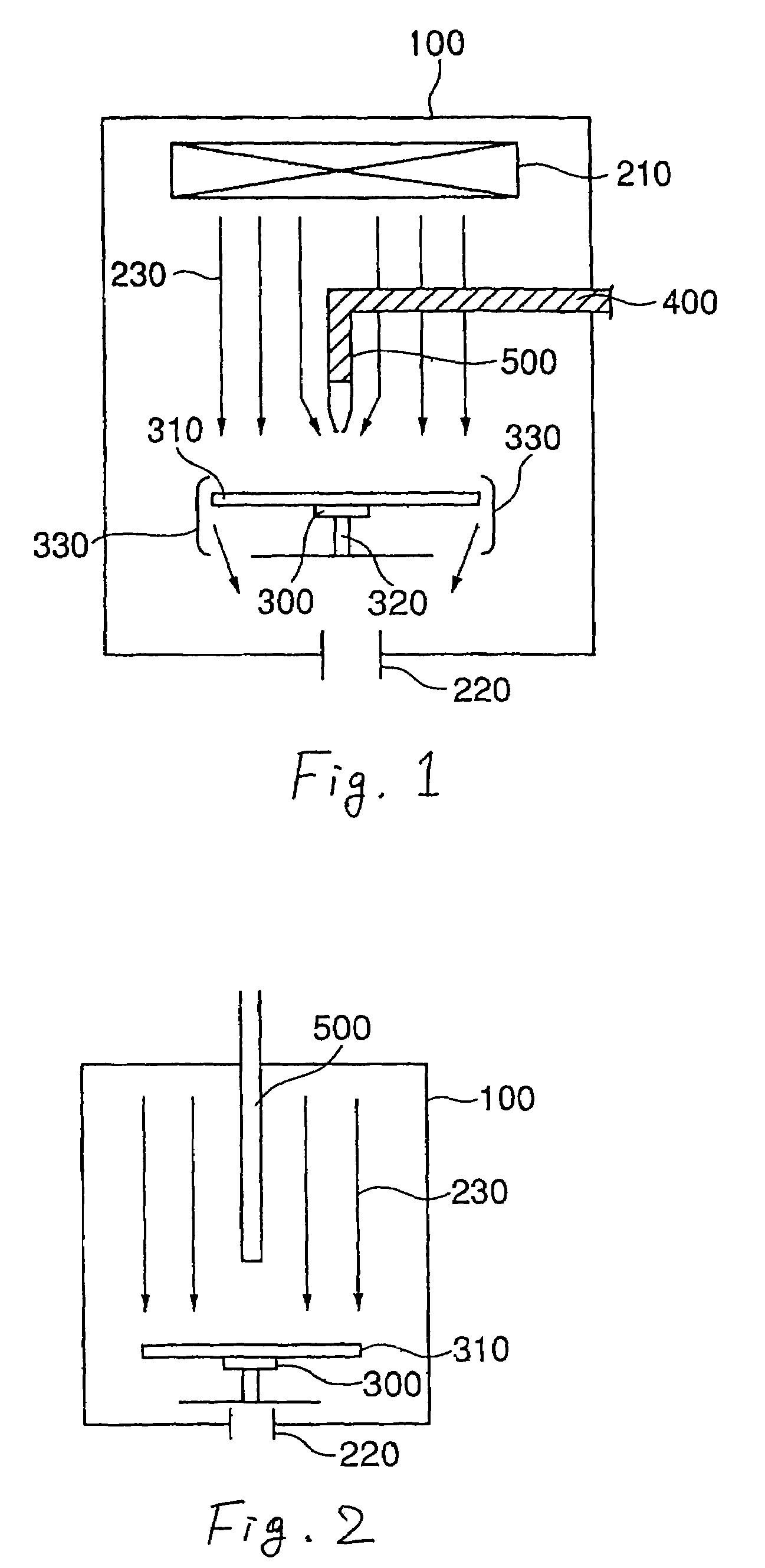

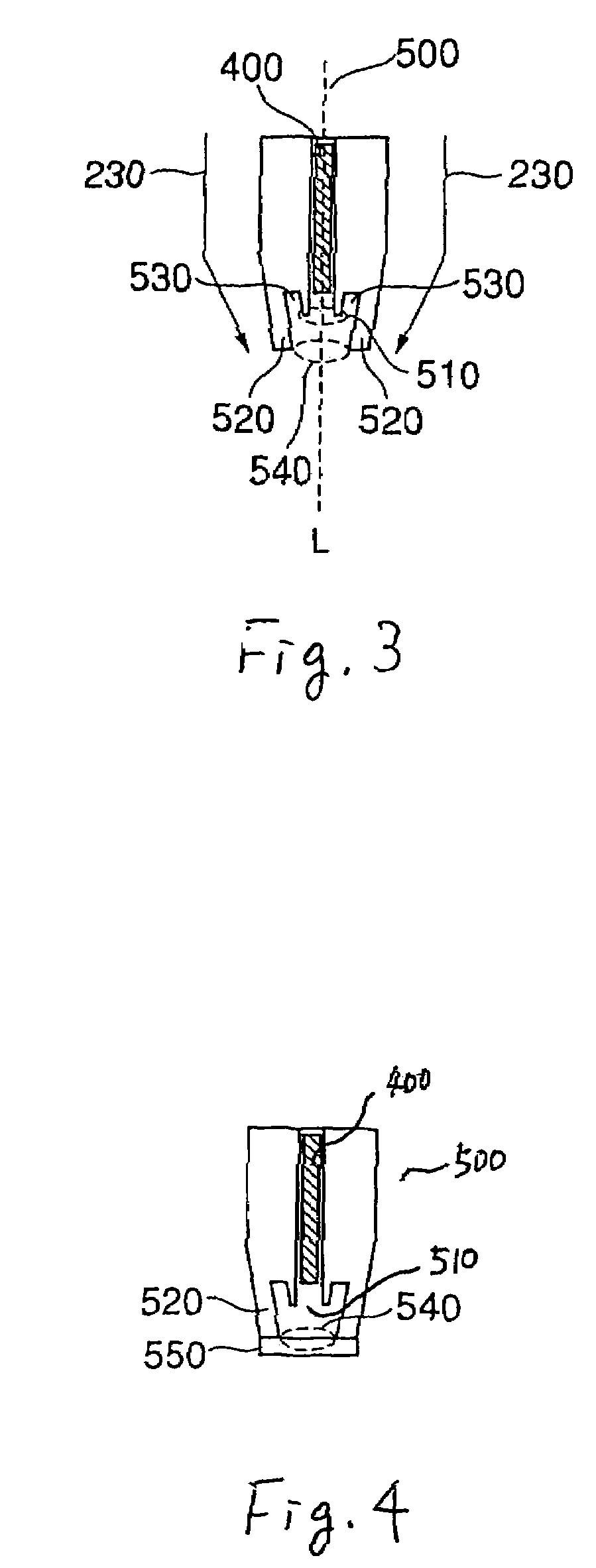

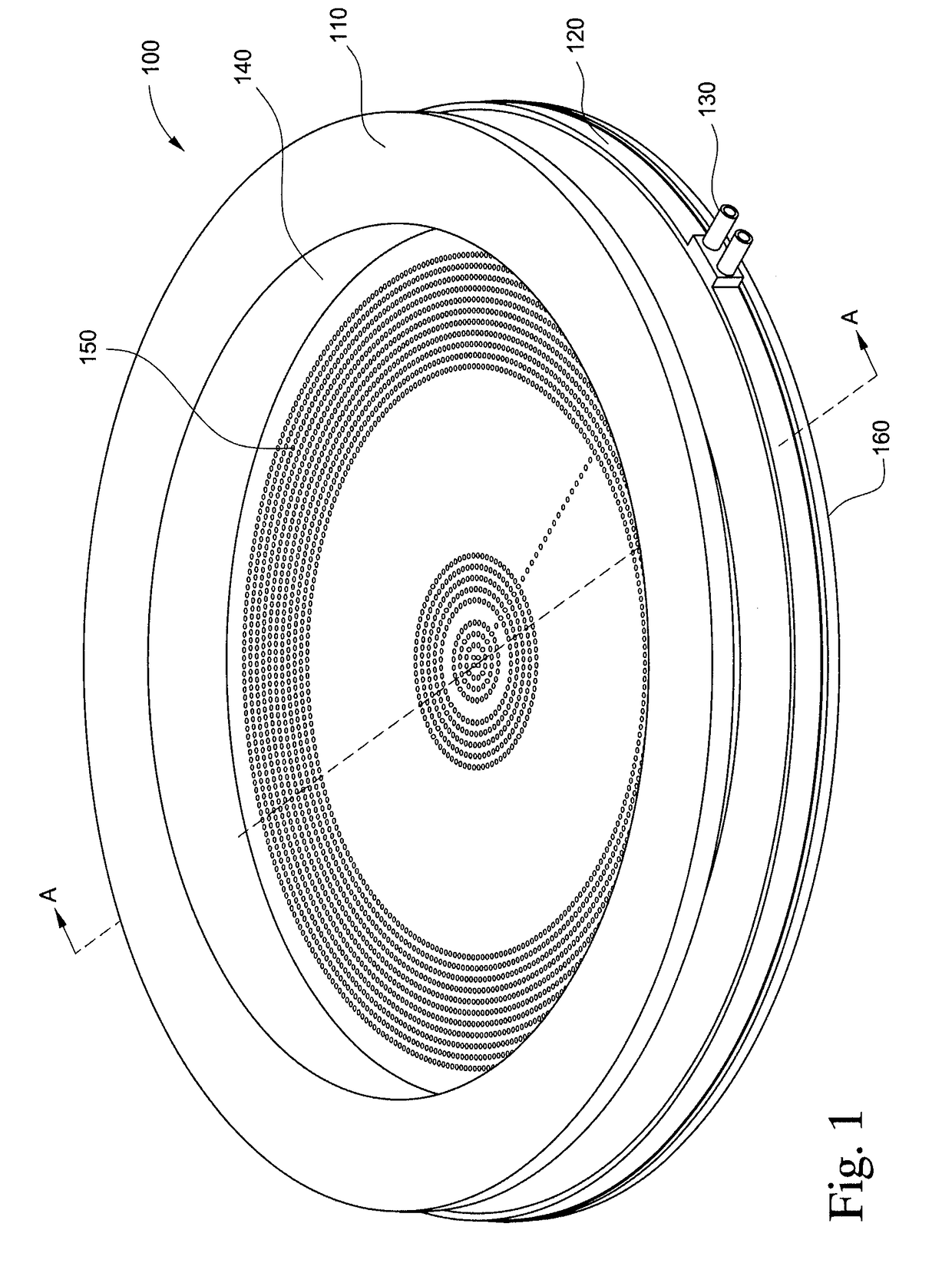

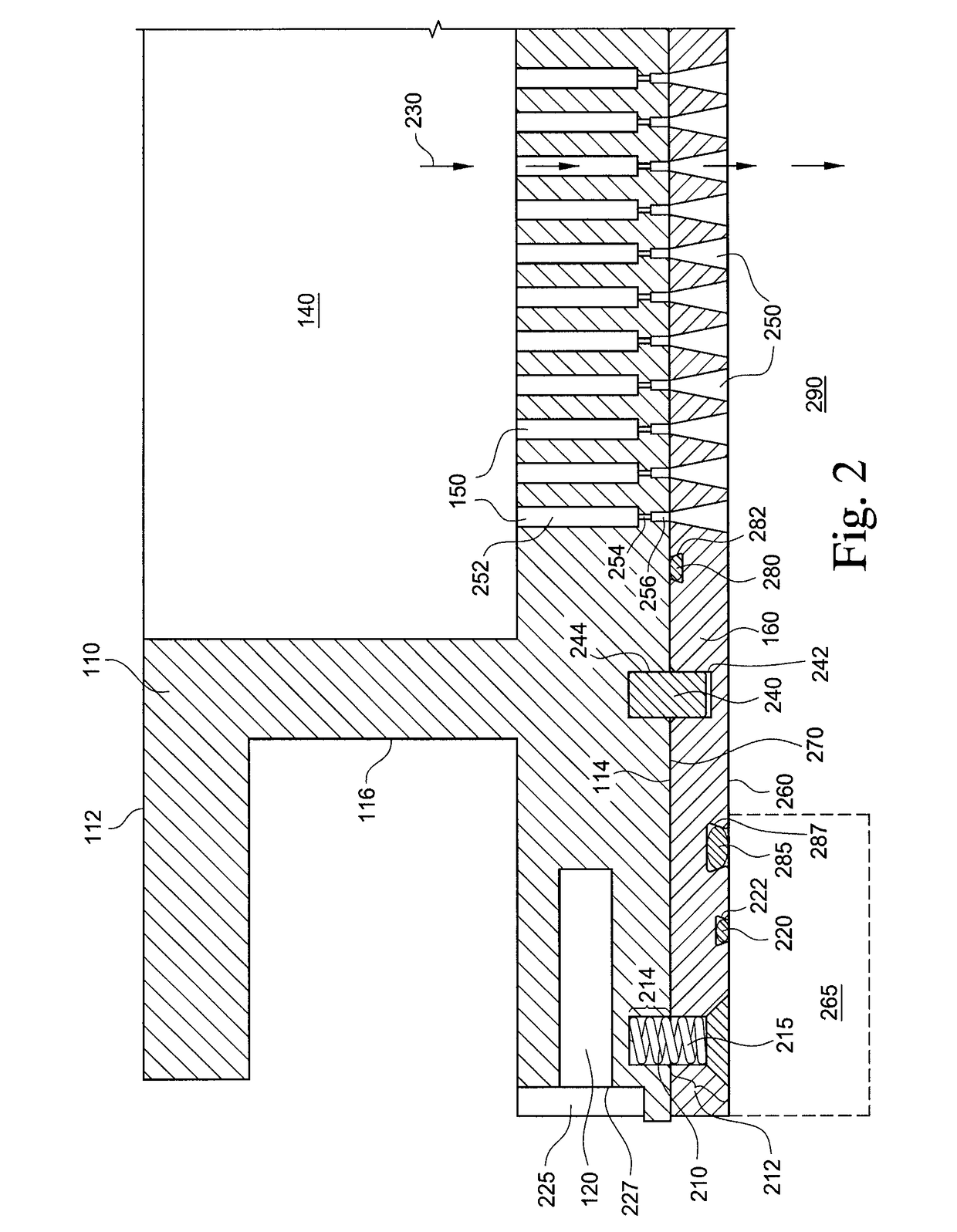

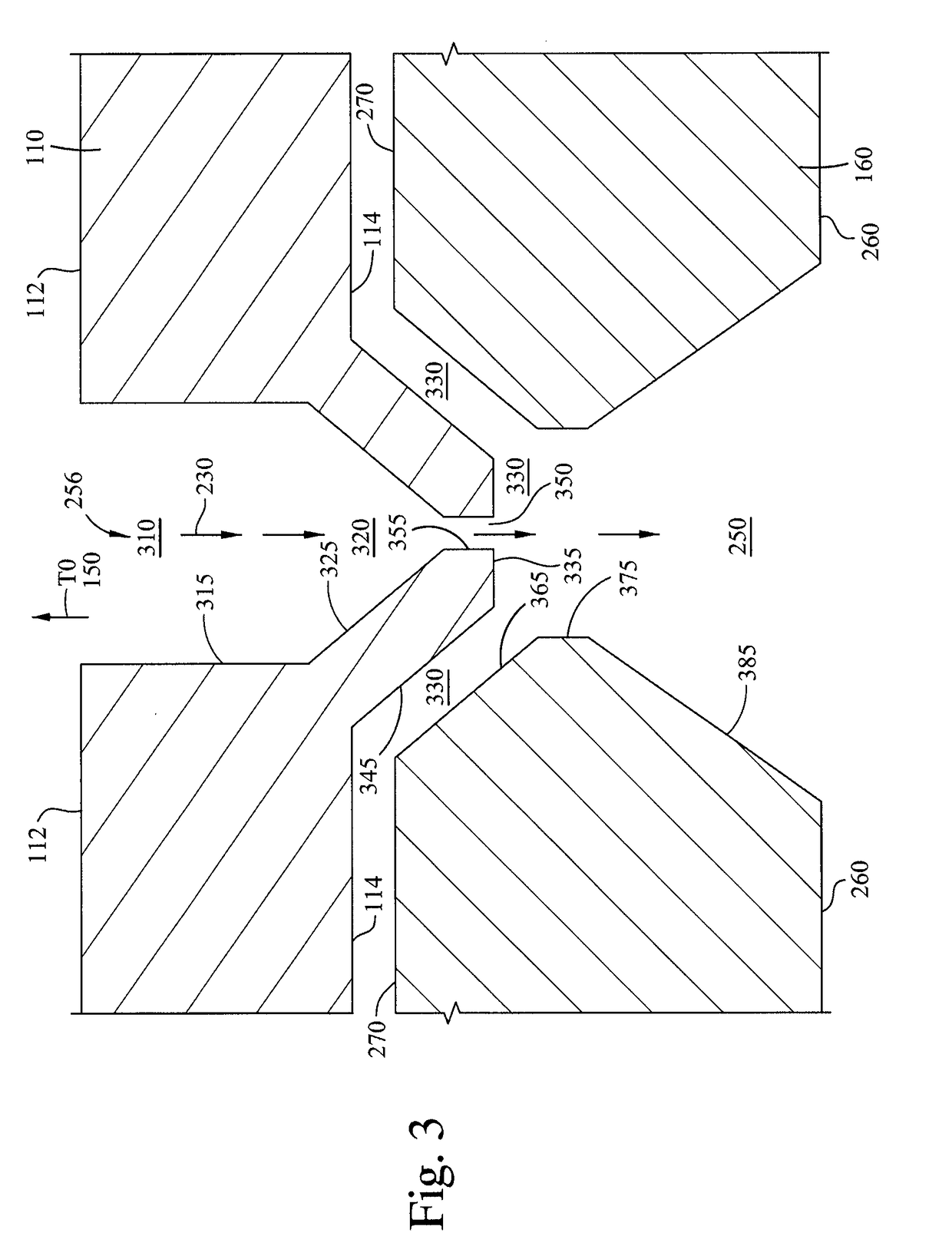

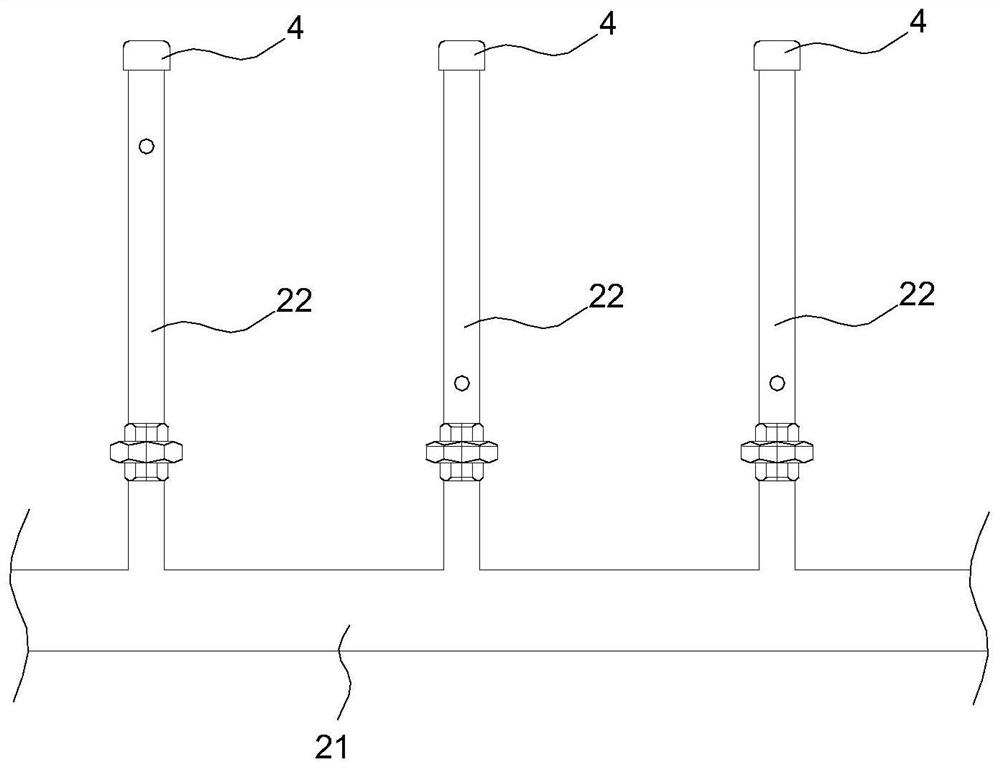

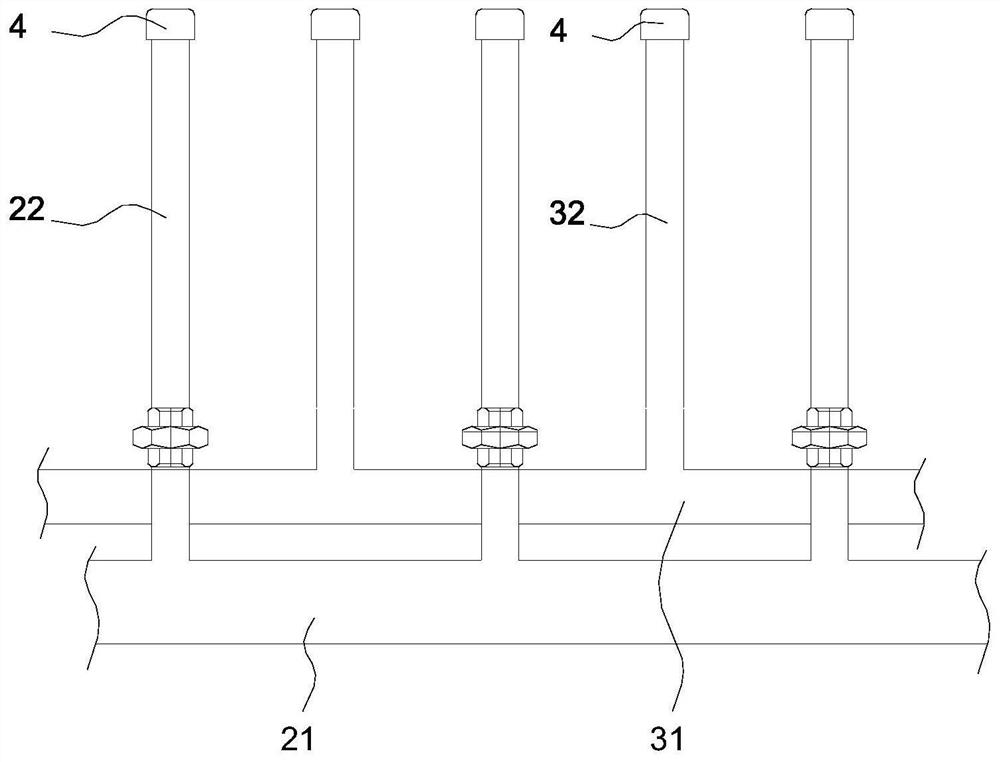

Thermal repeatability and in-situ showerhead temperature monitoring

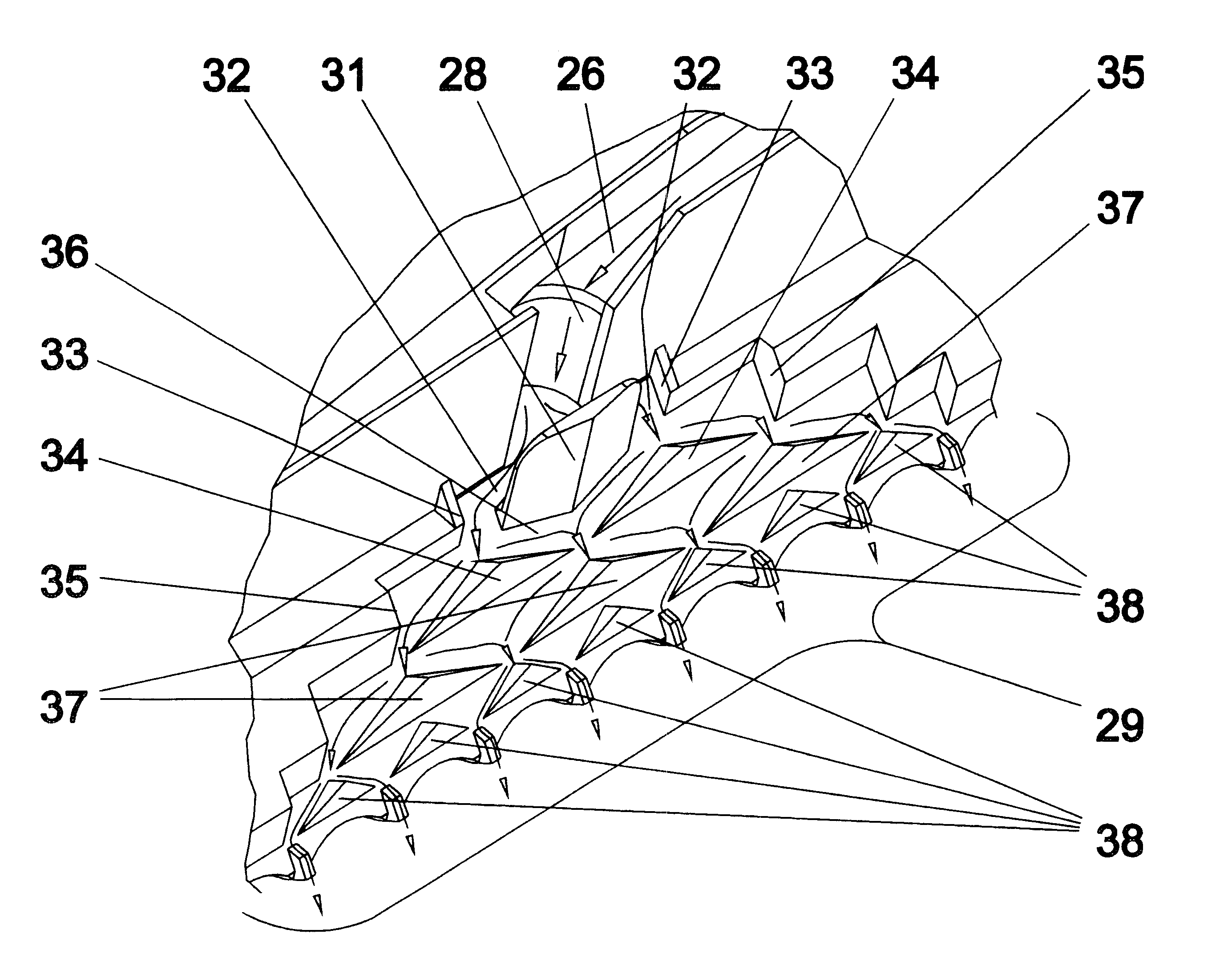

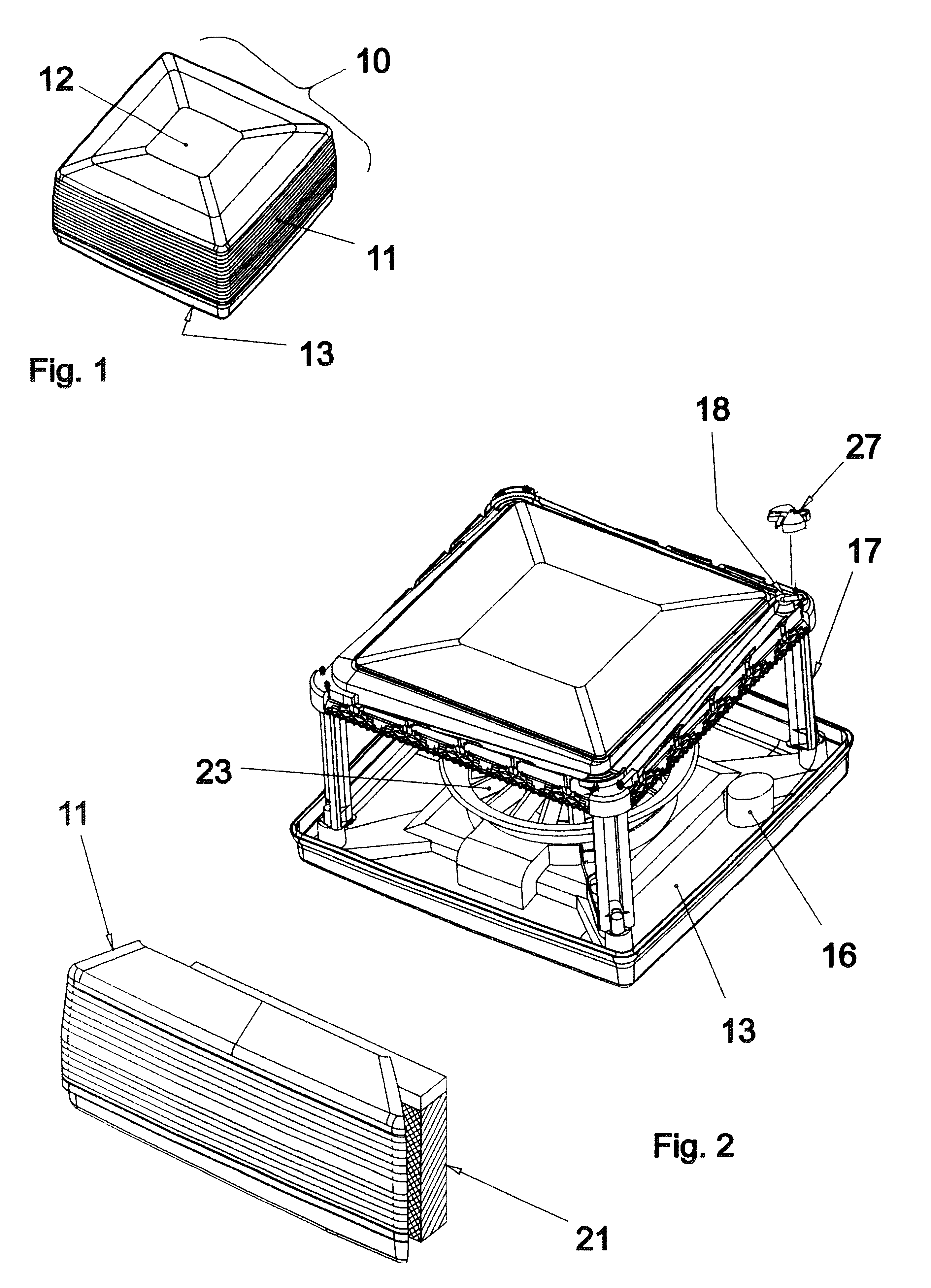

Embodiments described herein generally related to a substrate processing apparatus, and more specifically to an improved showerhead assembly for a substrate processing apparatus. The showerhead assembly includes a gas distribution plate and one or more temperature detection assemblies. The gas distribution plate includes a body having a top surface and a bottom surface. The one or more temperature detection assemblies are interfaced with the top surface of the gas distribution plate such that a thermal bond is formed between the gas distribution plate and each of the one or more temperature detection assemblies. Each temperature detection assembly includes a protruded feature and a temperature probe. The protruded feature is interfaced with the top surface of the gas distribution plate such that an axial load is placed on the gas distribution plate along an axis of the protruded feature. The temperature probe is positioned in a body of the protruded feature.

Owner:APPLIED MATERIALS INC

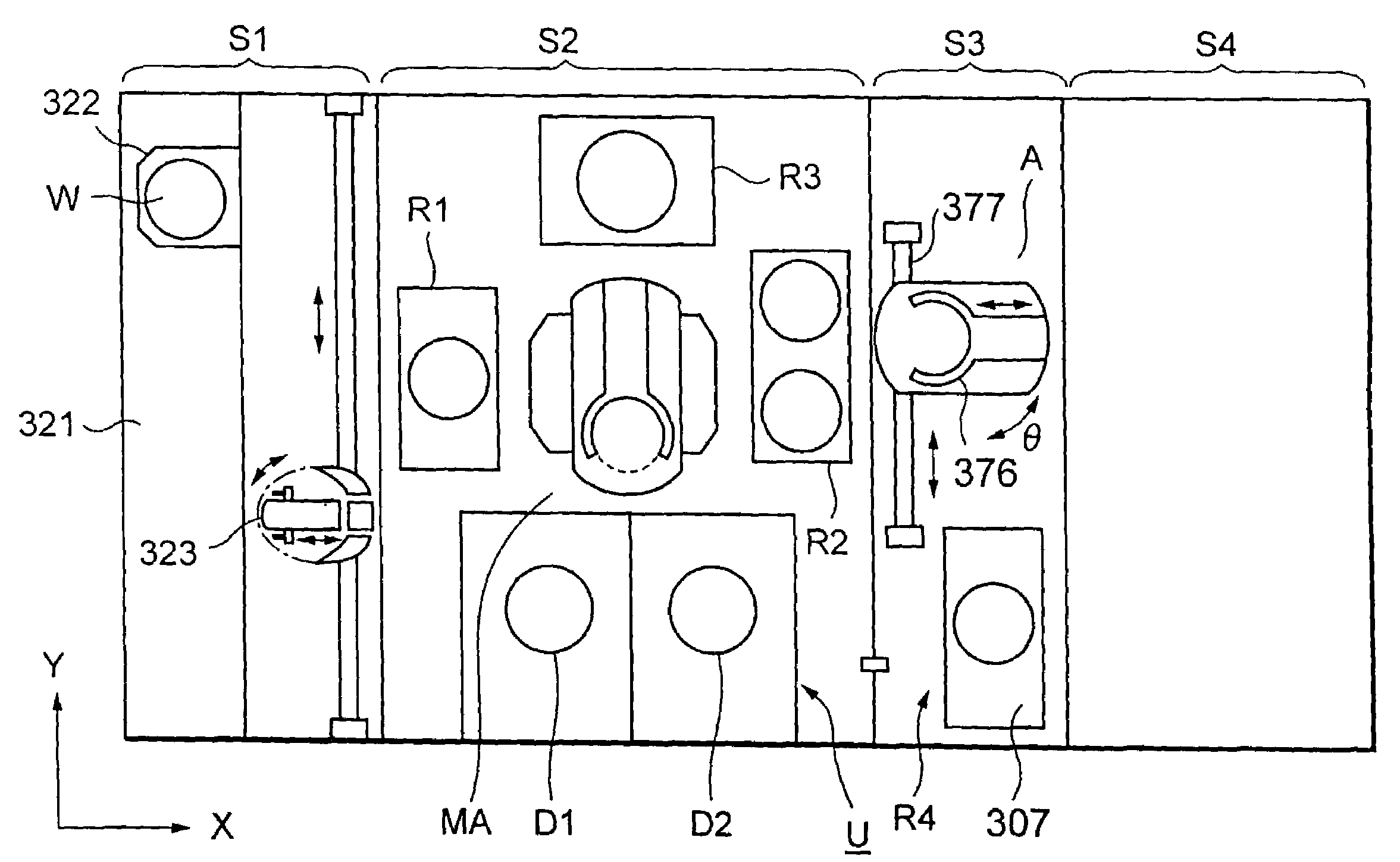

Processing equipment

Owner:LAPIS SEMICON CO LTD

Adjustable jet device

Owner:TIANJIN JIEQIANG POWER EQUIP

Paint spraying technology for water screen vortex roll spray room

InactiveCN104174519AImprove purification efficiencySimple structureSpray nozzlesLacquerVolumetric Mass Density

The invention discloses a paint spraying technology for a water screen vortex roll spray room. The technology comprises the following processes: a conveying fixture carrying a paint spraying product travels along a conveying track and the paint spraying product is then sprayed with paint by an automatic spray gun on one side of the conveying fixture; paint mist generated in the paint spraying process flows to a serration plate along with the air flow under the action of a suction groove; high-speed air flow and negative pressure are formed at notches of the serration plate due to the fact that the ventilation section area is suddenly decreased, so that water at the notches is atomized and the high-speed air flow passes through the serration plate and then enters a vortex roll plate; paint grains with greater density is in full contact with water under the action of centrifugal force and then collected and taken down by water; the rest of paint mist collides and in contact with atomized water repeatedly for many times in the vortex roll along with the air flow, condenses into water droplets containing paint mist and enters a circulating water pool. The paint spraying technology is good in paint mist capturing effect, and besides, the water screen vortex roll spray room is simple in structure, pipelines are less prone to blockage, and the purification efficiency is high.

Owner:CHANGXING HUARUI MACHINERY EQUIP

Gapless air curtain blow nozzle and air blowing method

InactiveCN103423832AAvoid enteringImprove stress resistanceLighting and heating apparatusSpray nozzlesEngineeringMechanics

The invention relates to a gapless air curtain blow nozzle and an air blowing method. The air outlet hole of the existing air curtain blowing and flushing pipe is the circular hole, the spraying area for air blowing is very small and belongs to the dot spraying, and the harmful gas cannot be completely blocked from entering, so the air purity in the escape capsule and the refuge chamber cannot be ensured, and the safety of refugees cannot be ensured. The gapless air curtain blow nozzle consists of a base (2) and a press cover (3), wherein the base (2) and the press cover (3) are connected through a screw (1), the base is provided with an air inlet pipe groove (4), the air inlet pipe groove is connected with an air outlet groove (5), the air outlet groove is connected with a lower air spraying curtain port (7), the press cover is provided with an upper air spraying curtain port (8), the base is connected with the press cover, and the upper air spraying curtain port and the lower air spraying curtain port form an air spraying curtain port (6). The gapless air curtain blow nozzle is used for blocking the harmful air from entering the refugee chamber.

Owner:HEILONGJIANG YUXI MACHINERY MFG

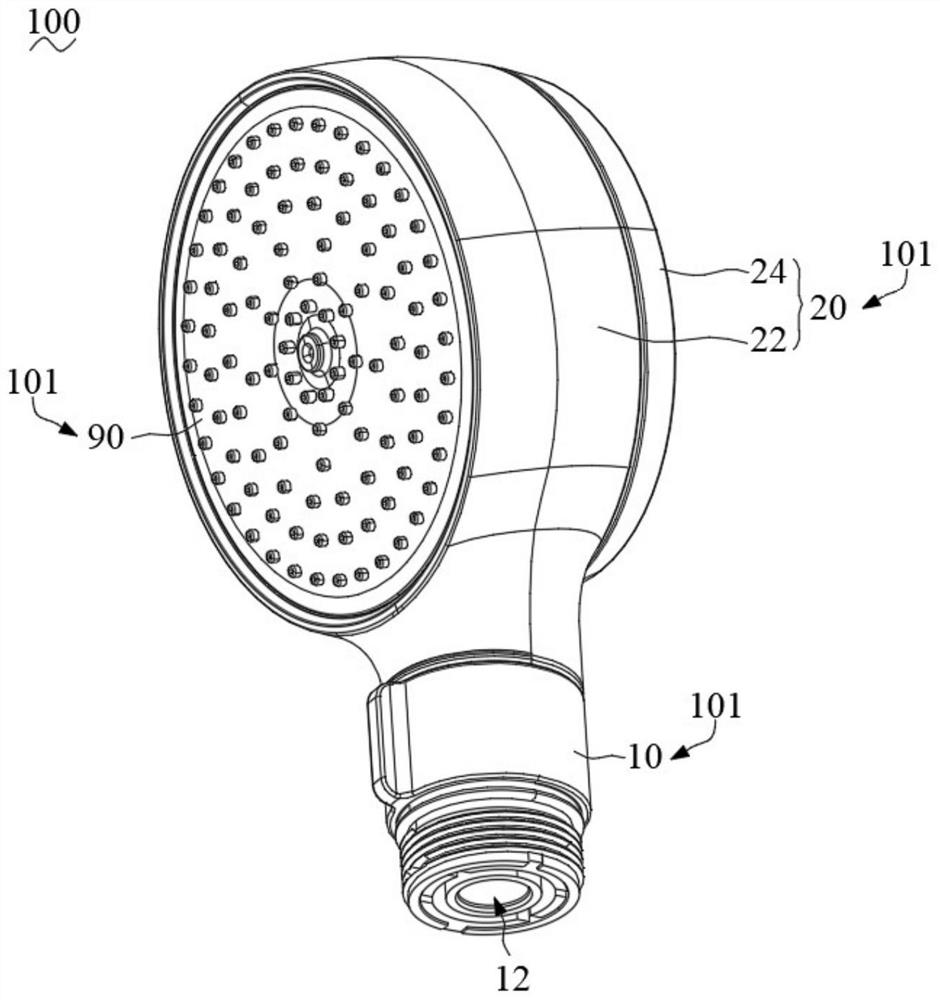

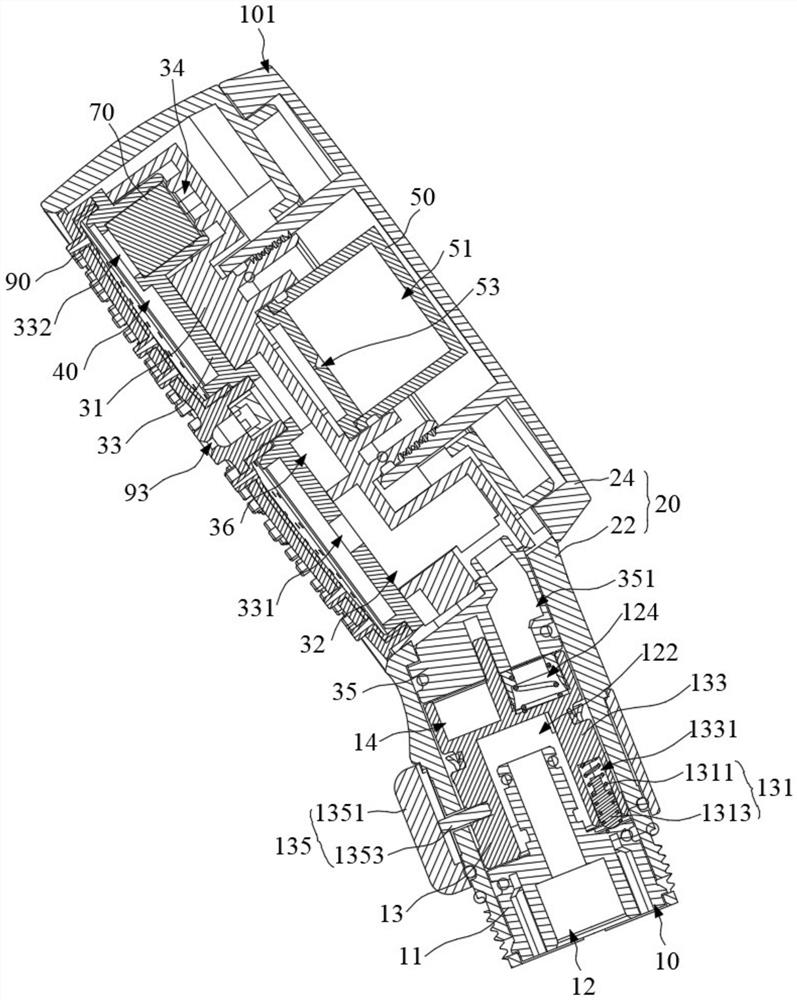

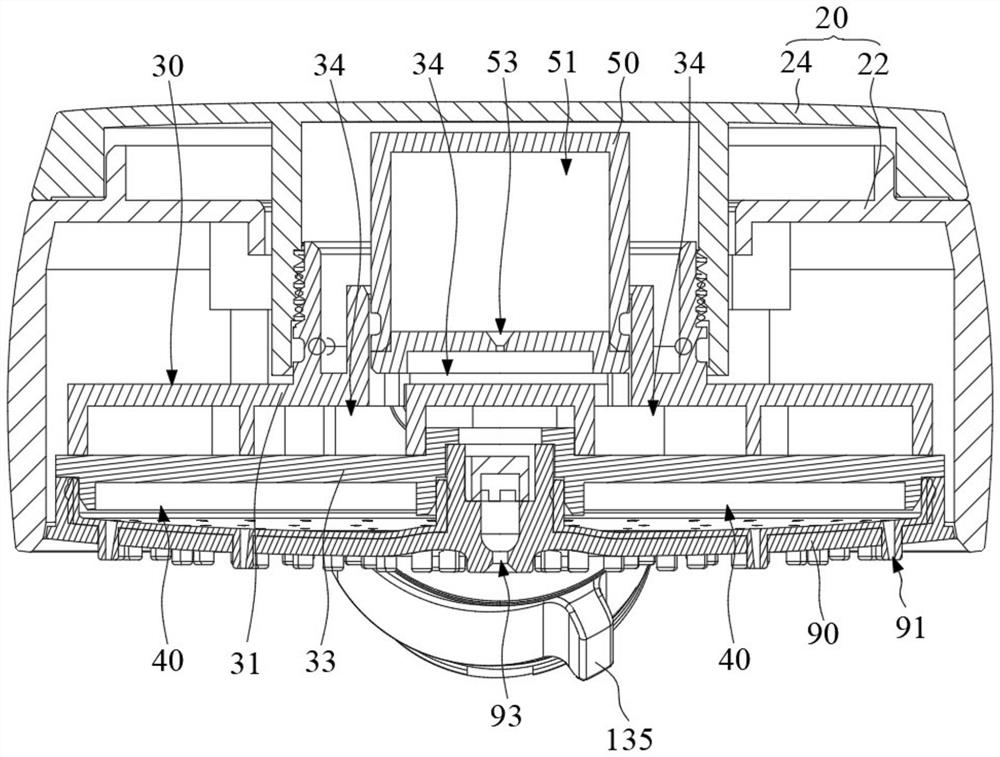

Sprinkler with detachable surface cover

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

Pressure swirl atomizing nozzle for spraying a curable composition and associated method and use

Owner:雷克蒂塞尔汽车配件有限公司

Shower nozzle

Owner:HEGII SANITARY WARE CO LTD +1

Multi-plate faceplate for a processing chamber

Owner:APPLIED MATERIALS INC

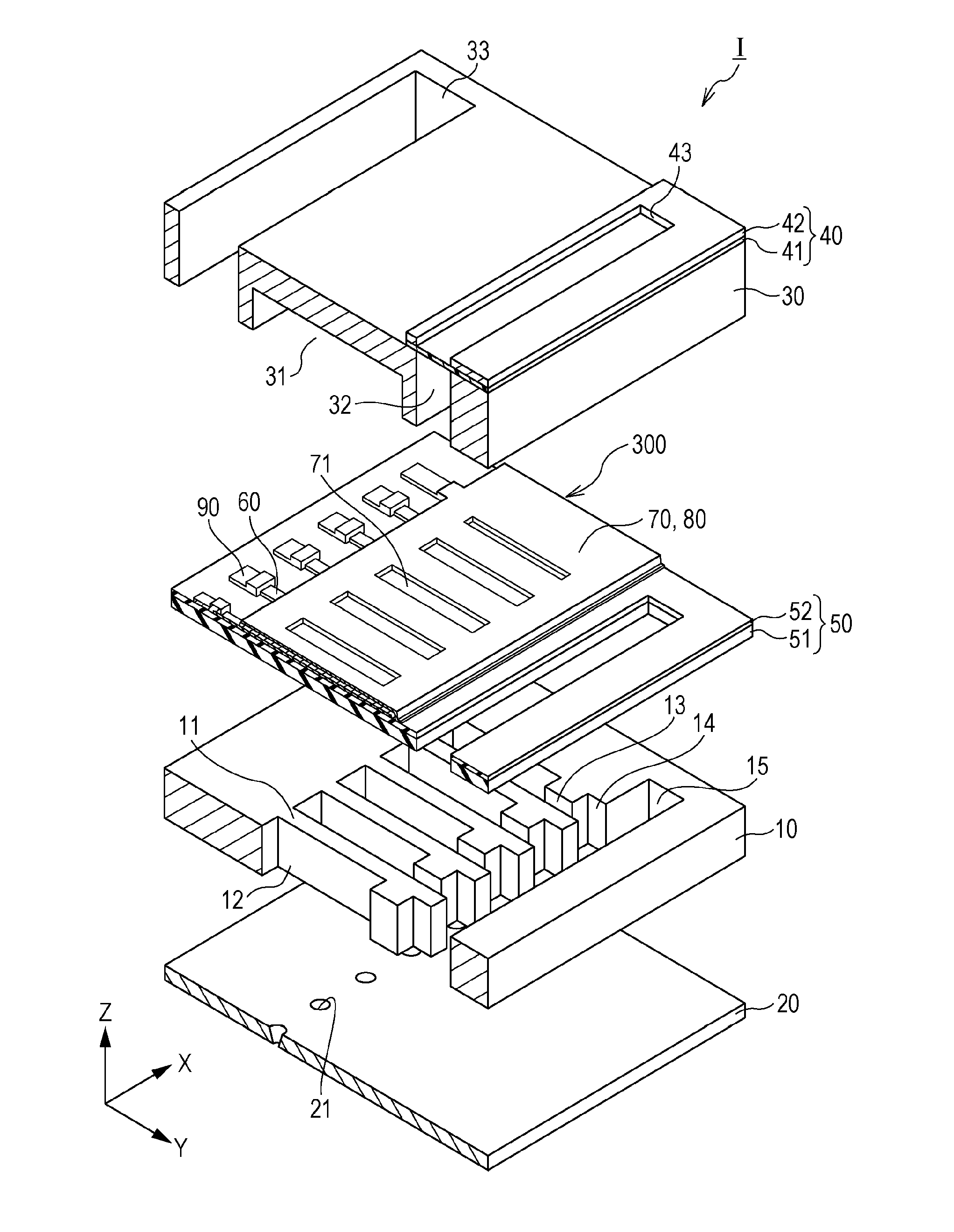

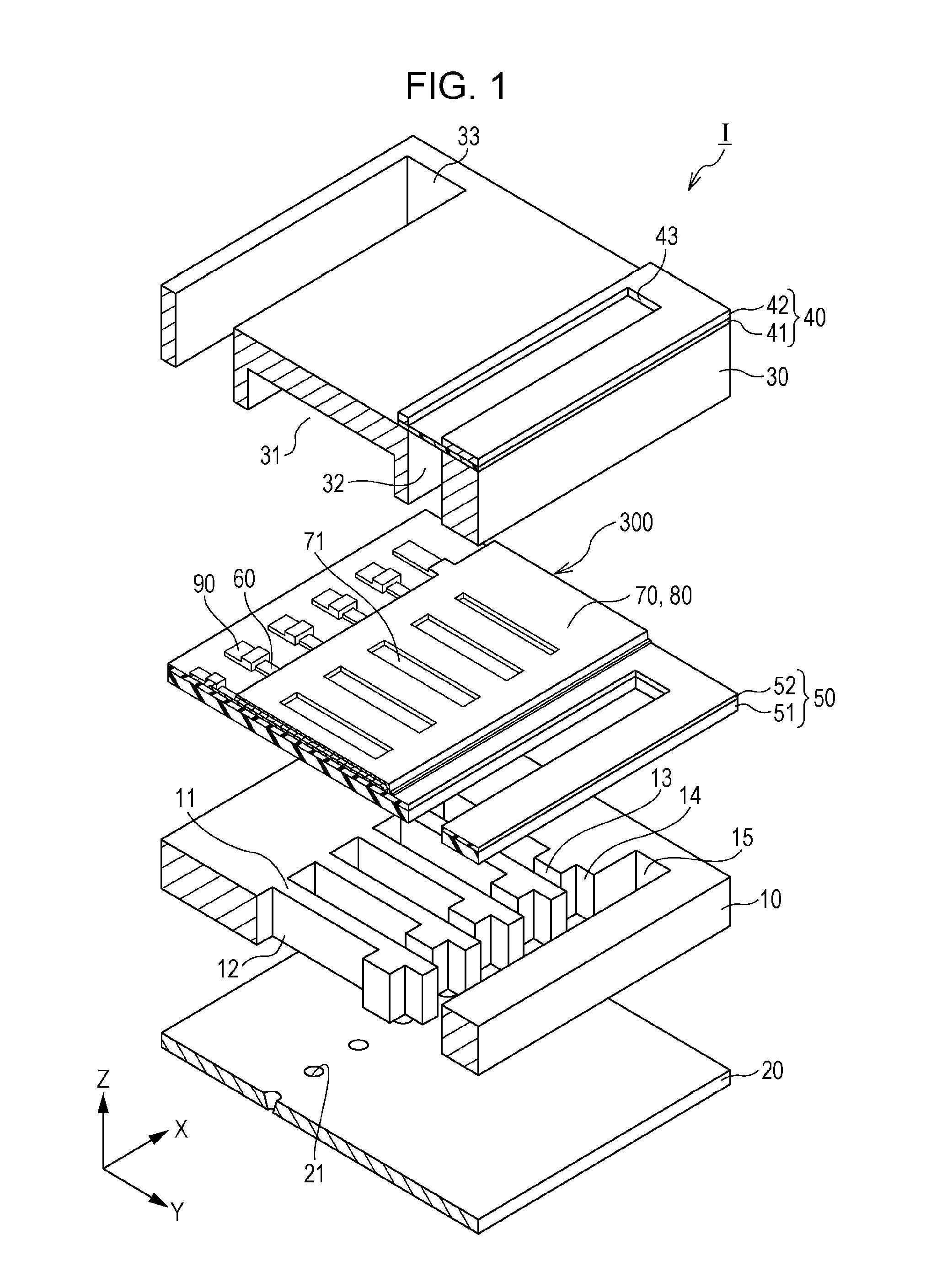

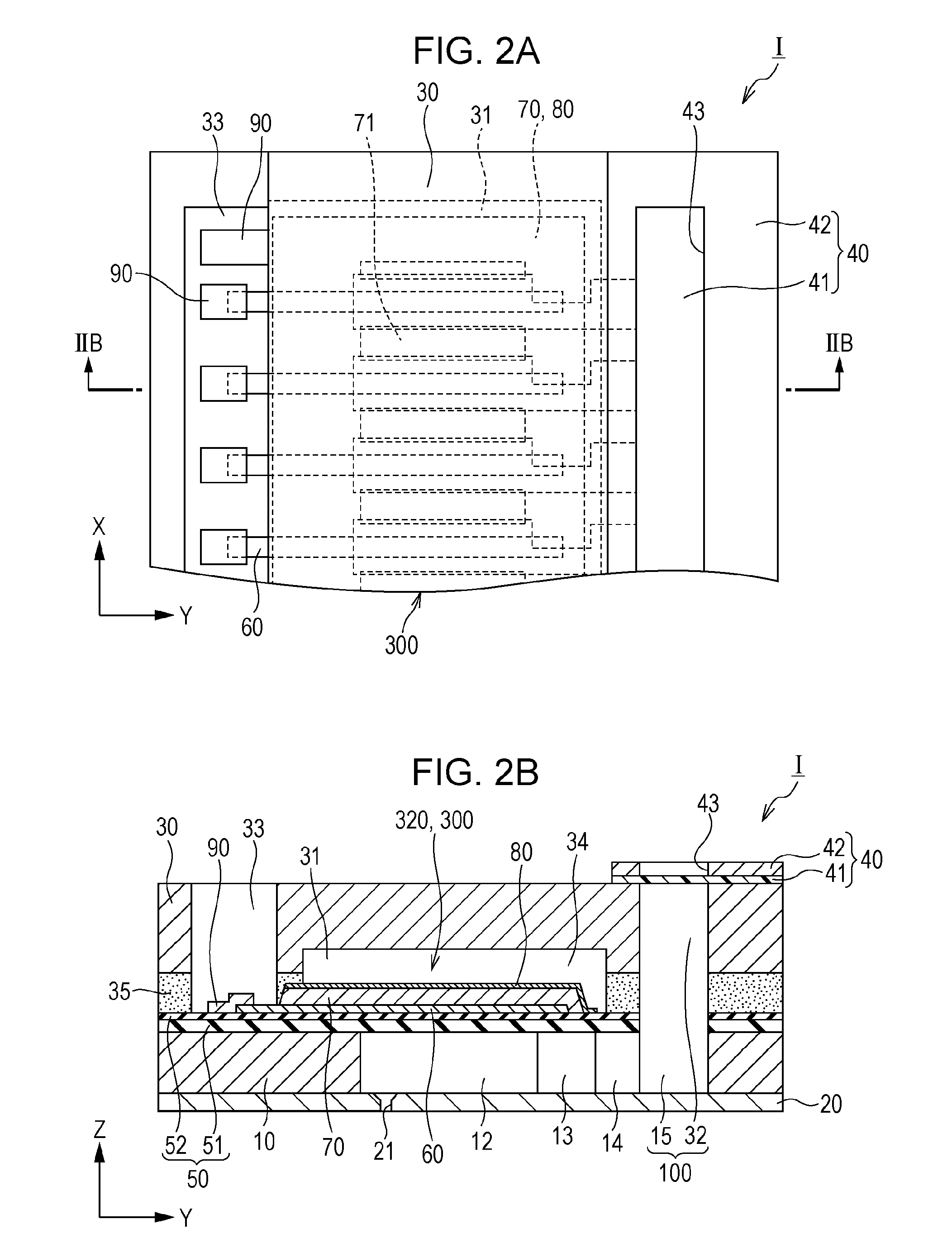

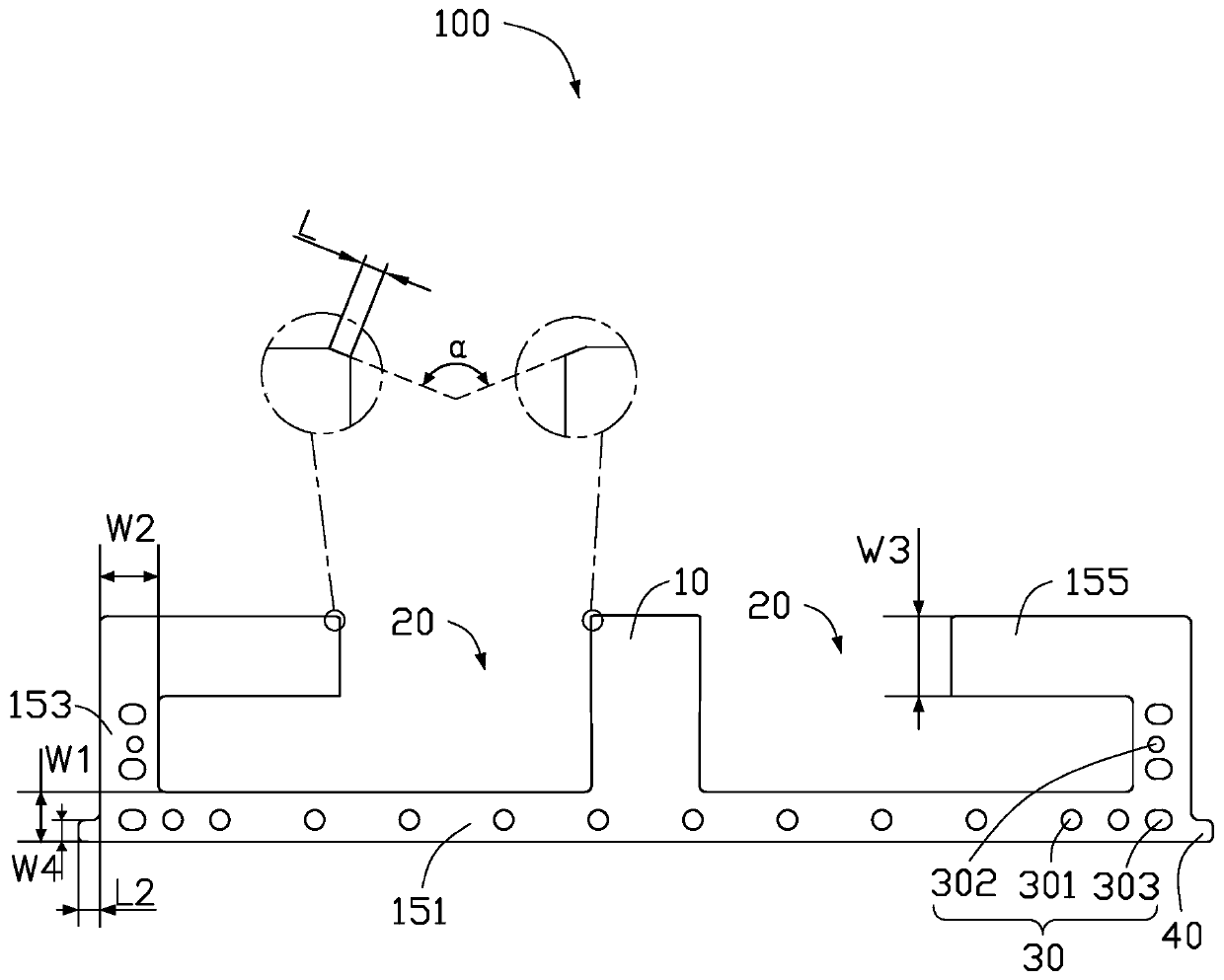

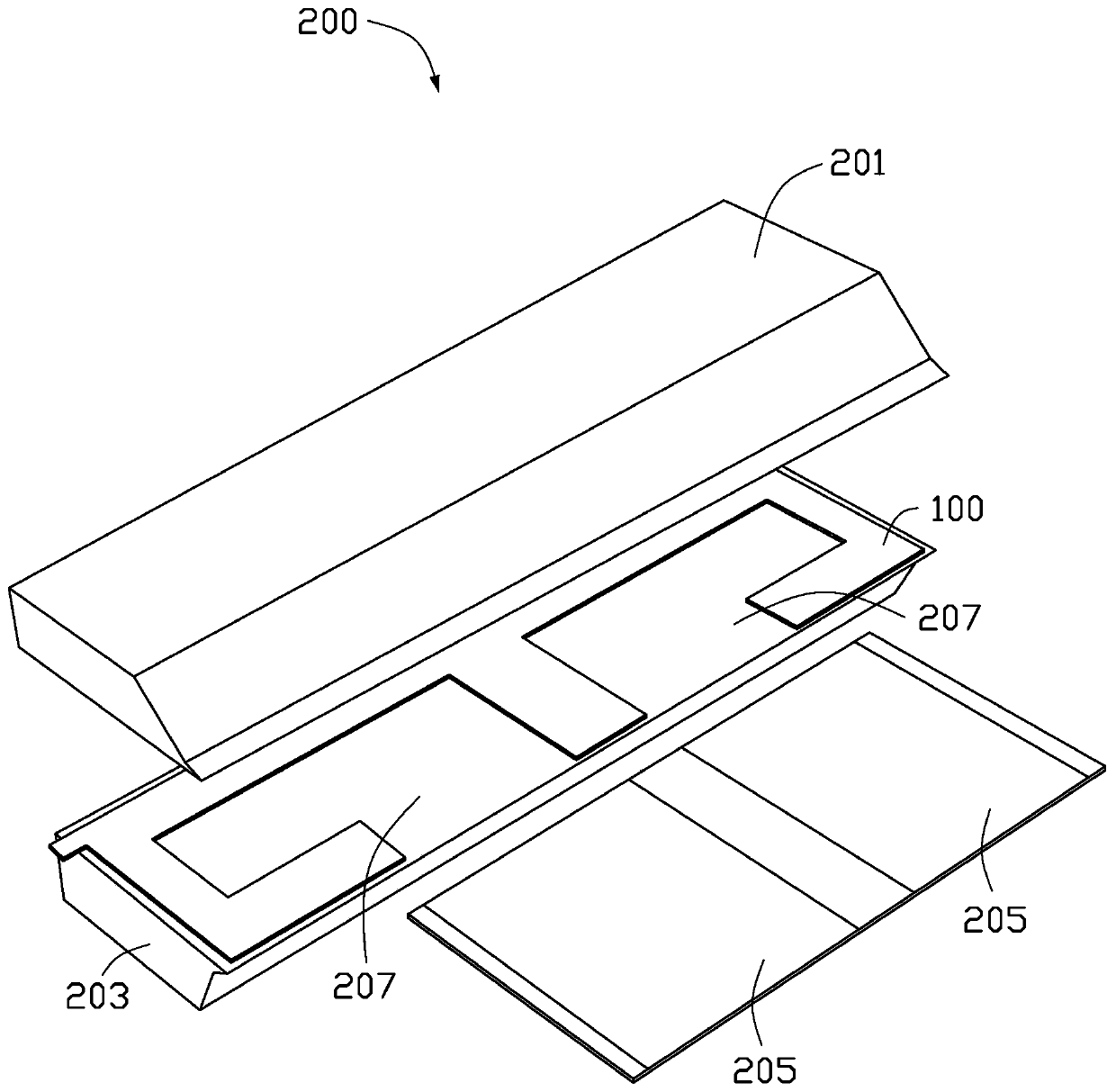

Liquid ejecting head and liquid ejecting apparatus

ActiveUS20140263727A1Highly-efficient discharging propertyHighly-efficient liquid discharging propertiesMovable spraying apparatusSpray nozzlesMechanical engineeringNozzle

A liquid ejecting head includes a flow-path forming substrate including pressure generation chambers that communicate with nozzle openings through which ink is ejected, a piezoelectric element that applies a pressure to the pressure generation chambers via a diaphragm, and a protection substrate that forms a sealed space for sealing the piezoelectric element, in which a pressure in the sealed space is adjusted such that the diaphragm is drawn up to the piezoelectric element side and an initial bent position of the diaphragm is adjusted.

Owner:SEIKO EPSON CORP

Coating gasket, coating machine and pole piece coating process

Owner:ZHONGTIAN ENERGY STORAGE TECH

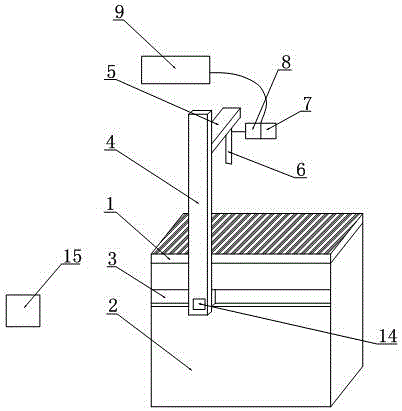

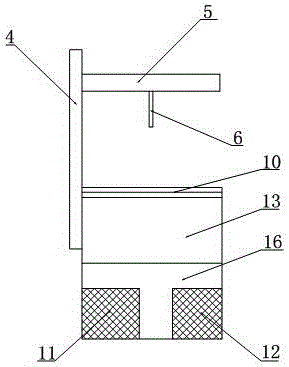

Automatic spraying device applied to SPE film and achieving method of automatic spraying device

ActiveCN105772252AImprove permeabilityAvoid deformationSpray nozzlesTemperature controlControl system

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

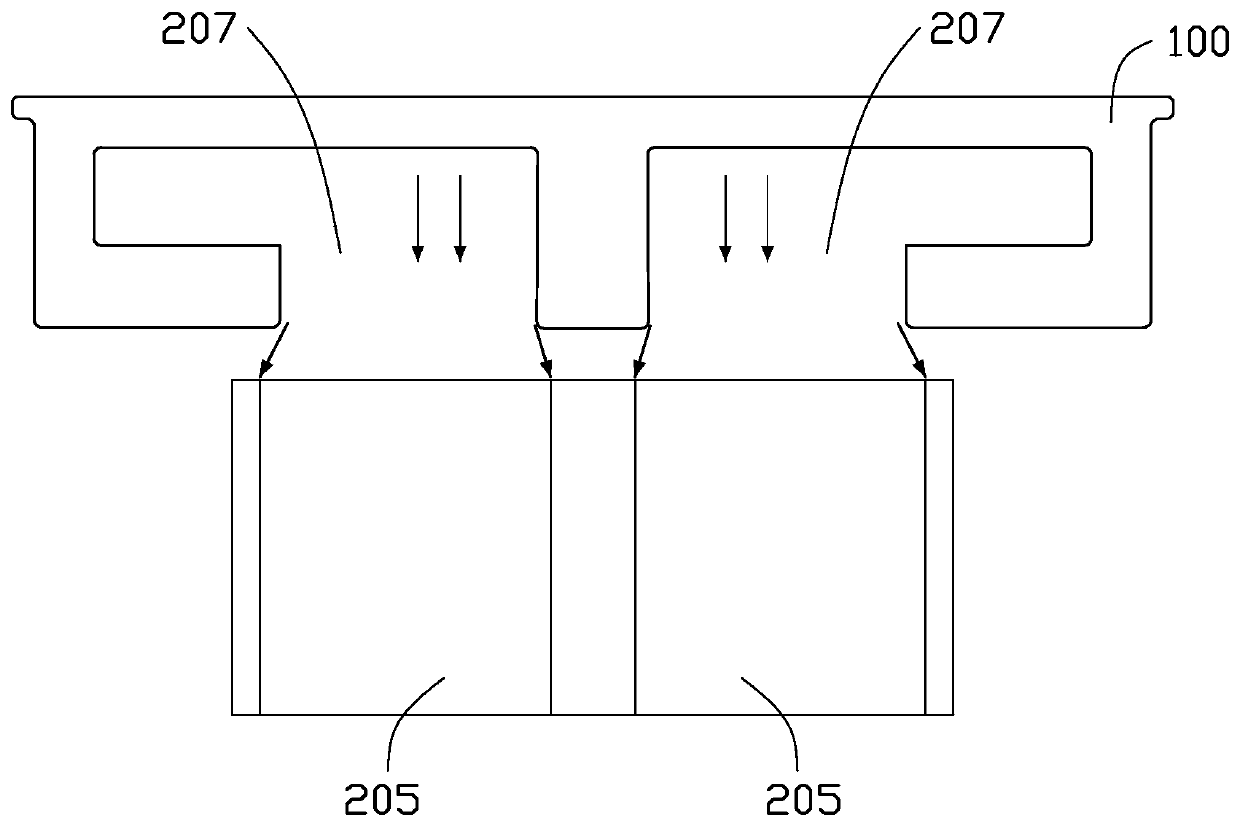

Nonpolar atomizing water outlet structure

Owner:XIAMEN LOTA INT CO LTD

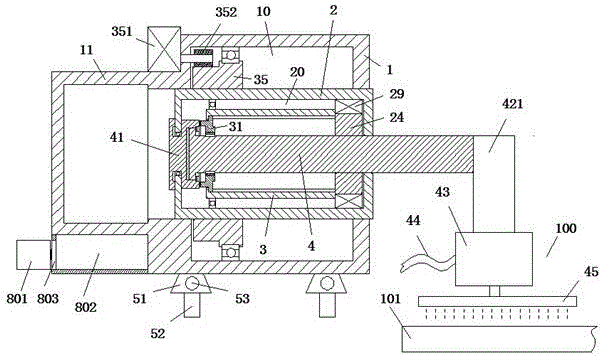

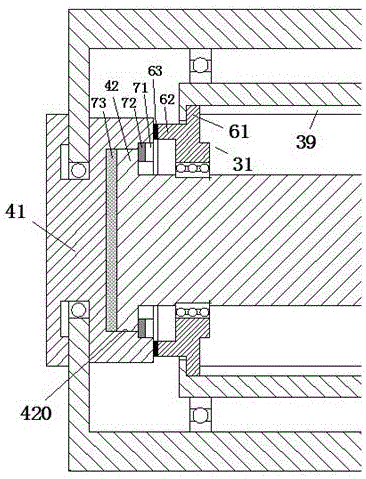

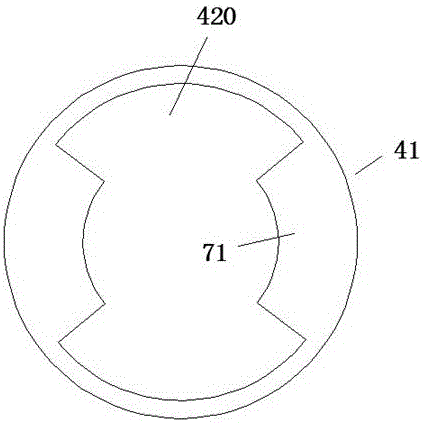

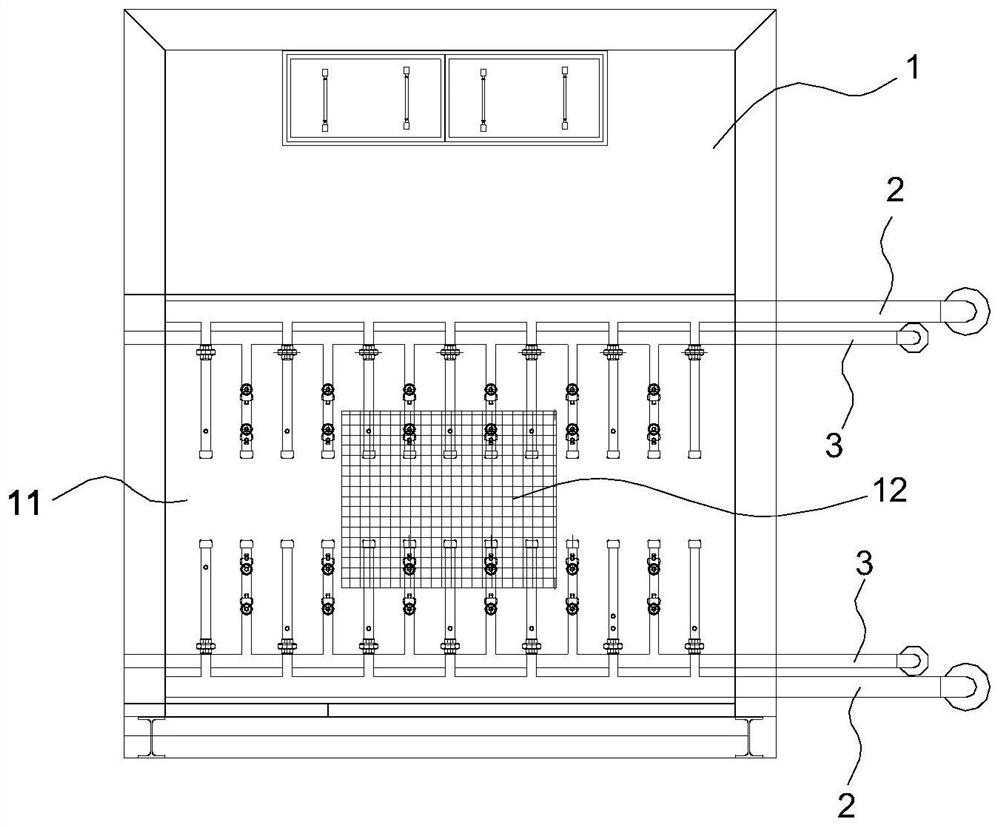

Spraying device and working method thereof

ActiveCN113083534ADensity adjustmentLarge pressure rangeSpray nozzlesElectrophoretic coatingsEngineeringPhysics

Owner:昆山田盛汽车配件有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap