Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Pipe elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

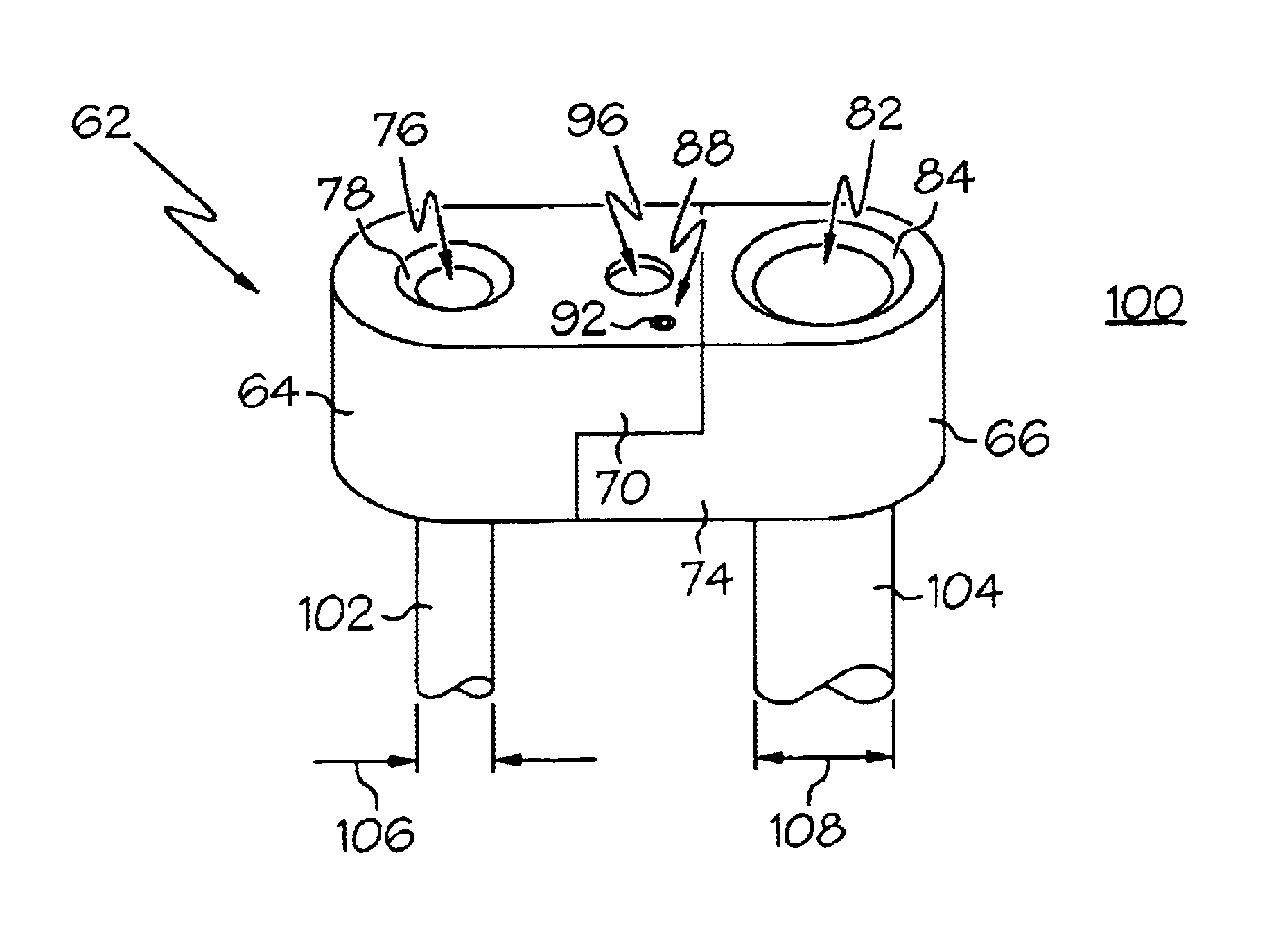

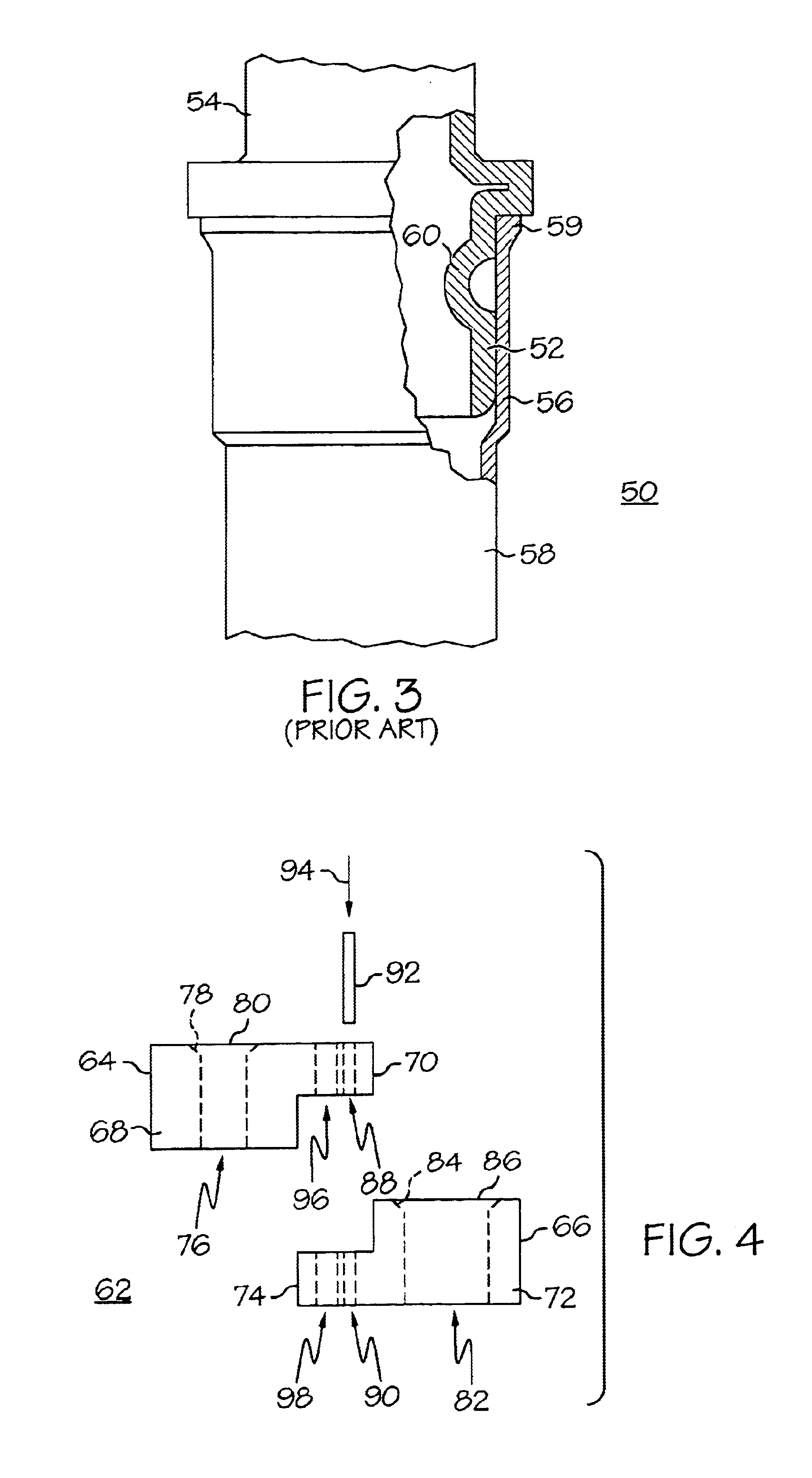

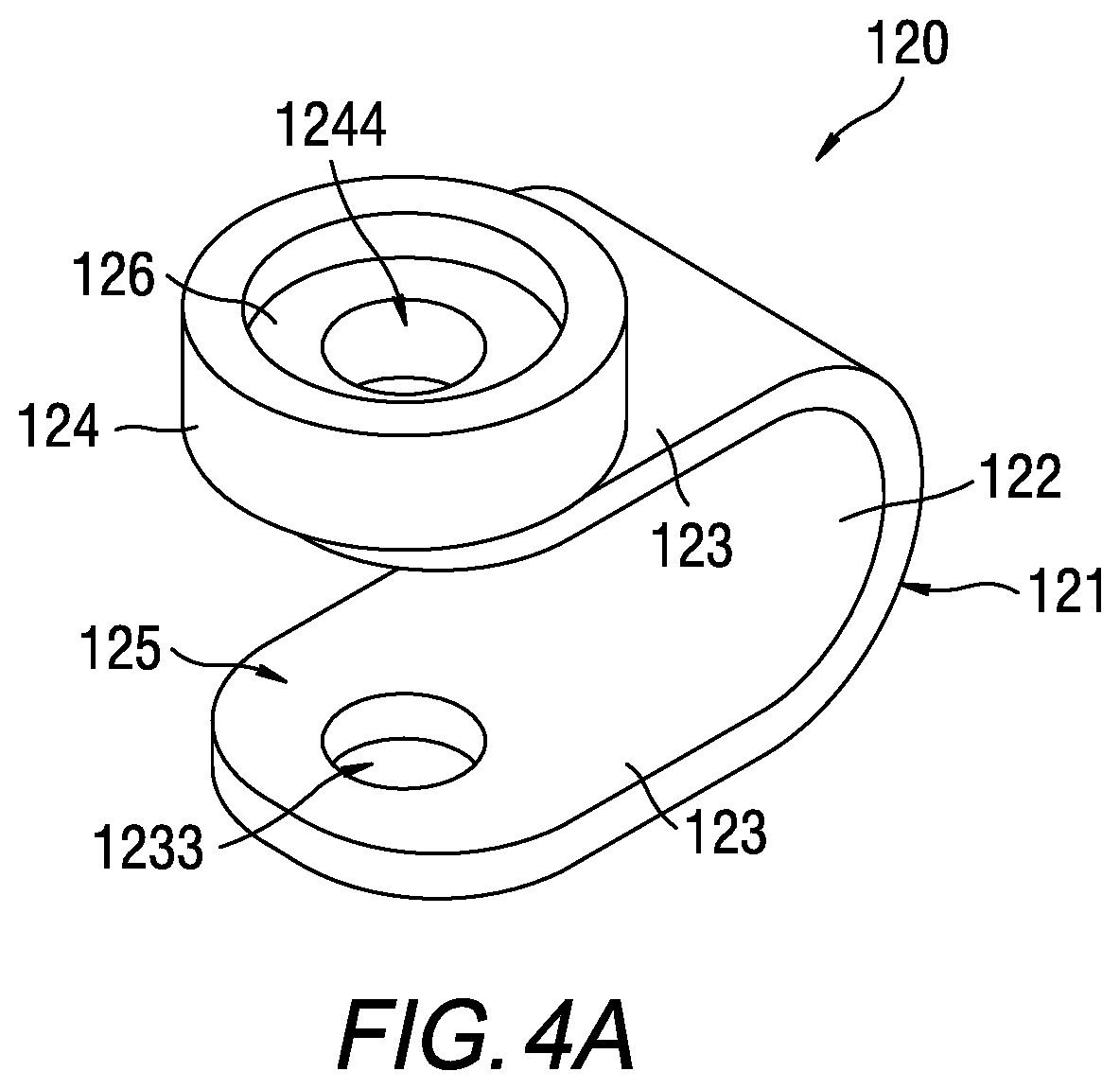

Dual flange for a tube joint assembly

InactiveUS6866300B2Improves Structural IntegritySignificant achievement in manufacturing flexibilityPipe elementsBranching pipesEngineeringFlange

Owner:CALSONICKANSEI NORTH AMERICA

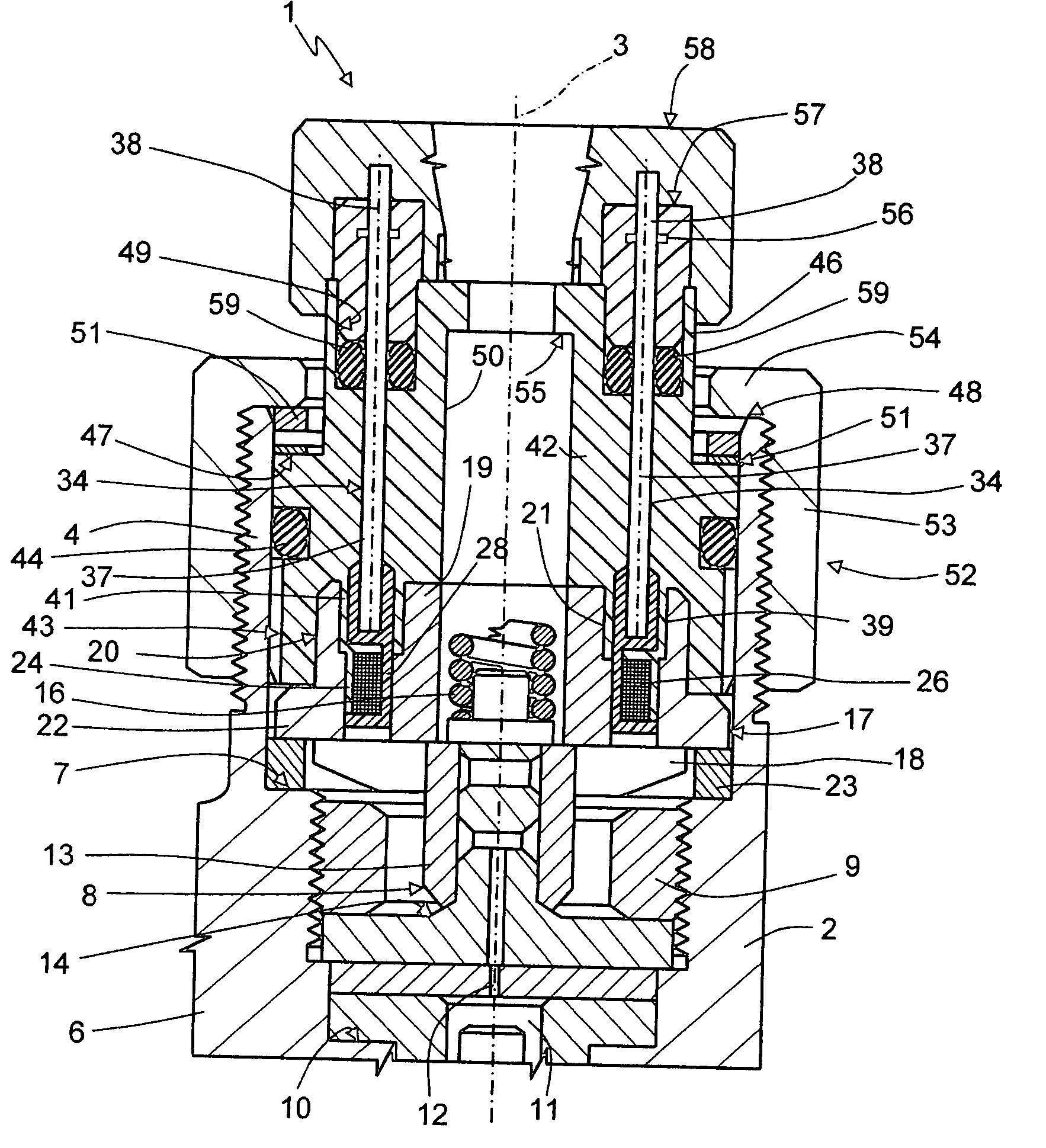

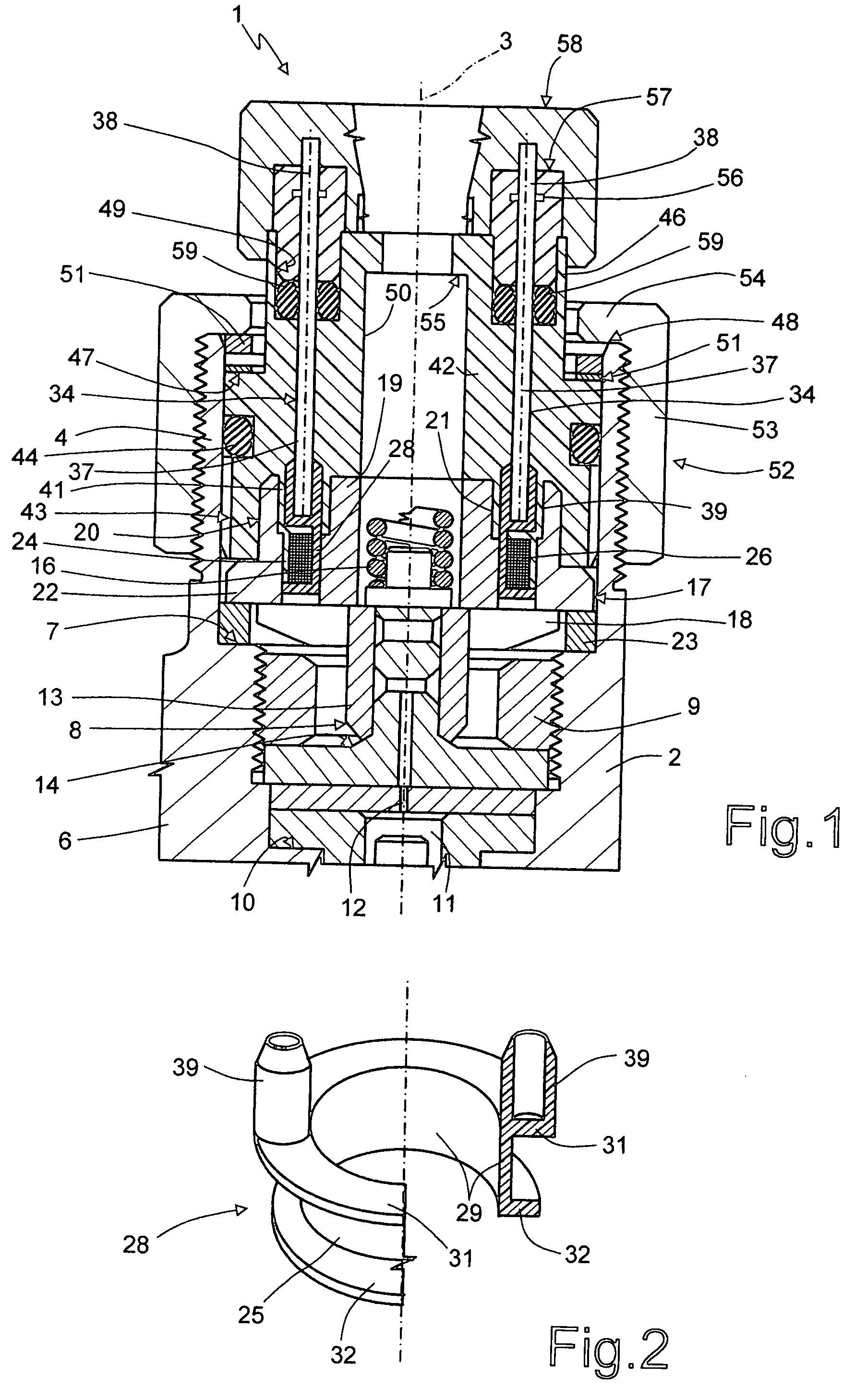

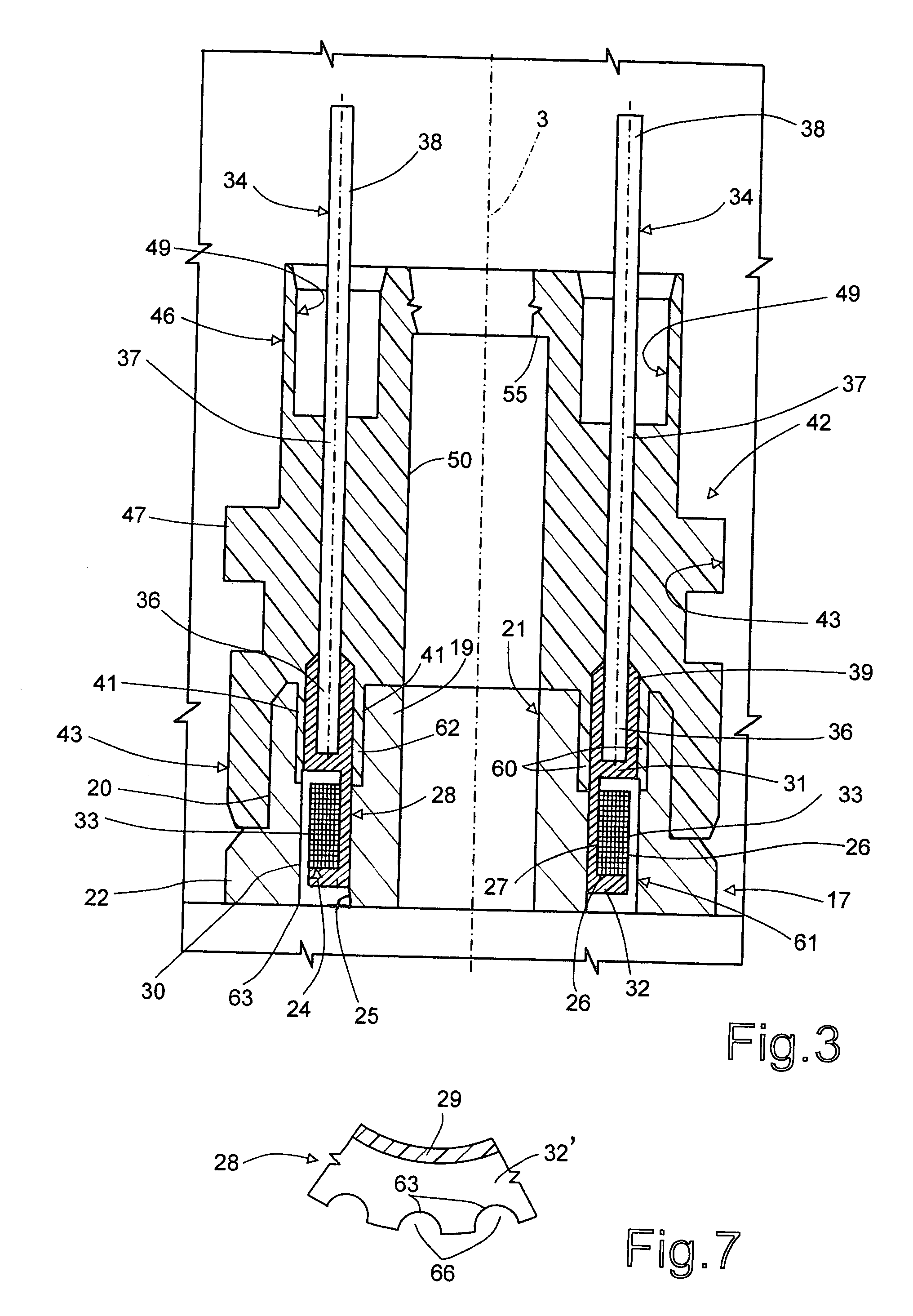

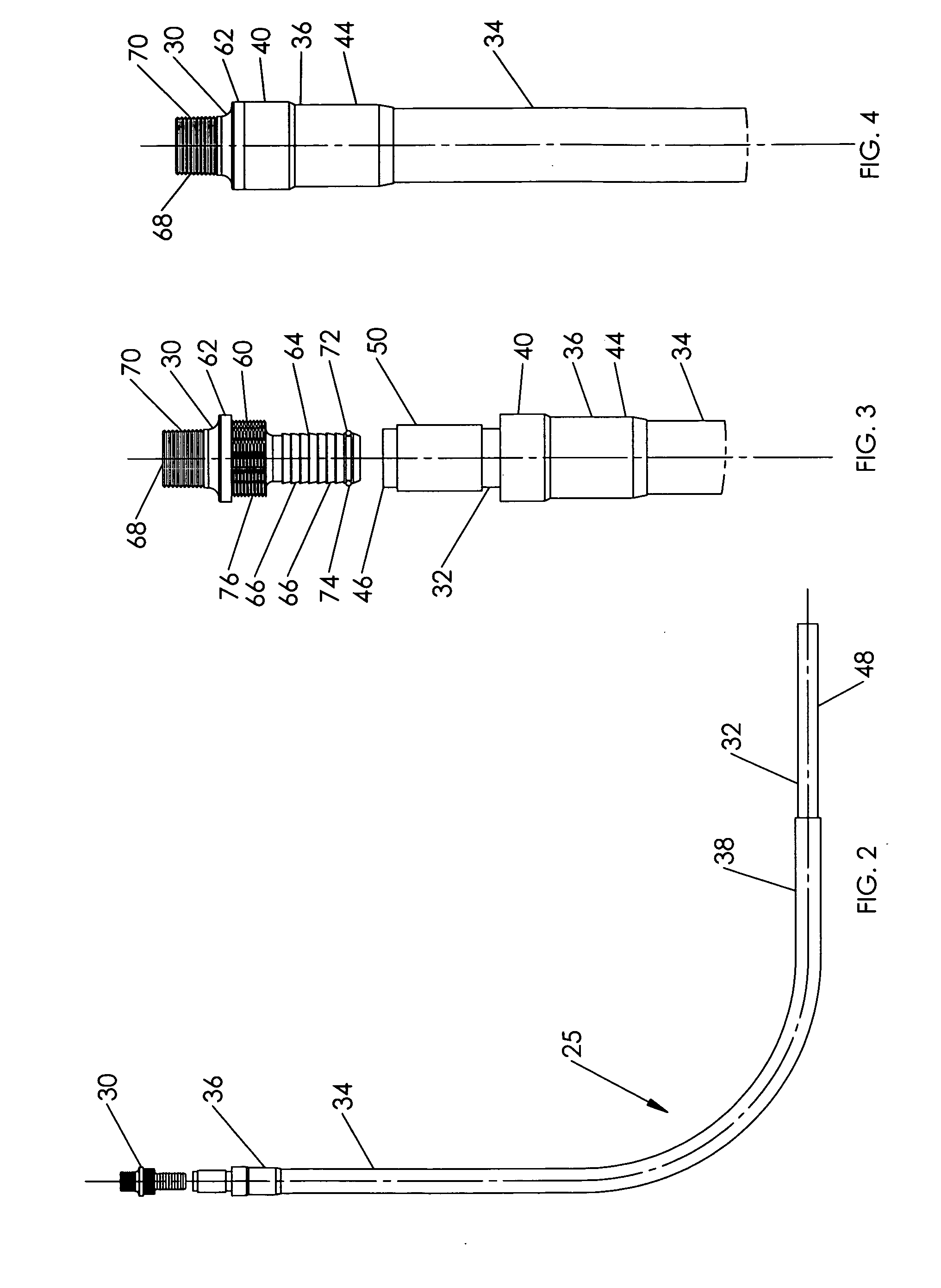

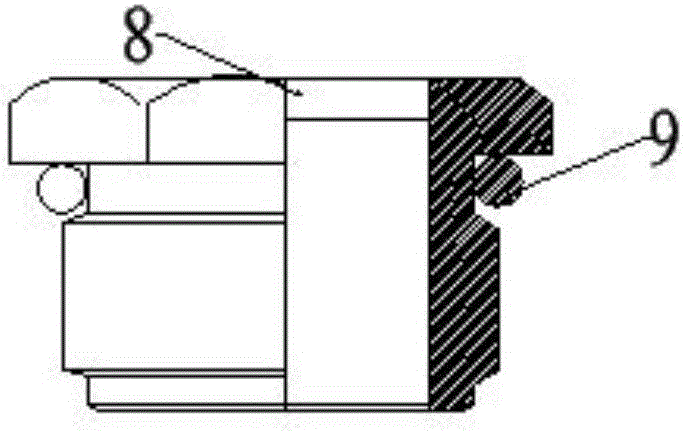

Connecting structure with quick connector for piping

First, second and third O-rings are disposed in an inner peripheral surface of a resin tube connecting portion of a connector housing. A resin tube is connected to the resin tube connecting portion while fitted thereon such that an opposite axial end of a fit-on portion of the resin tube reaches an opposite axial end of the resin tube connecting portion and the opposite axial end of the fit-on portion of the resin tube is located substantially on an axial position of the third O-ring. The tubular connector housing is made of resin and the resin tube has a barrier layer against gasoline fuel or the like.

Owner:SUMITOMO RIKO CO LTD

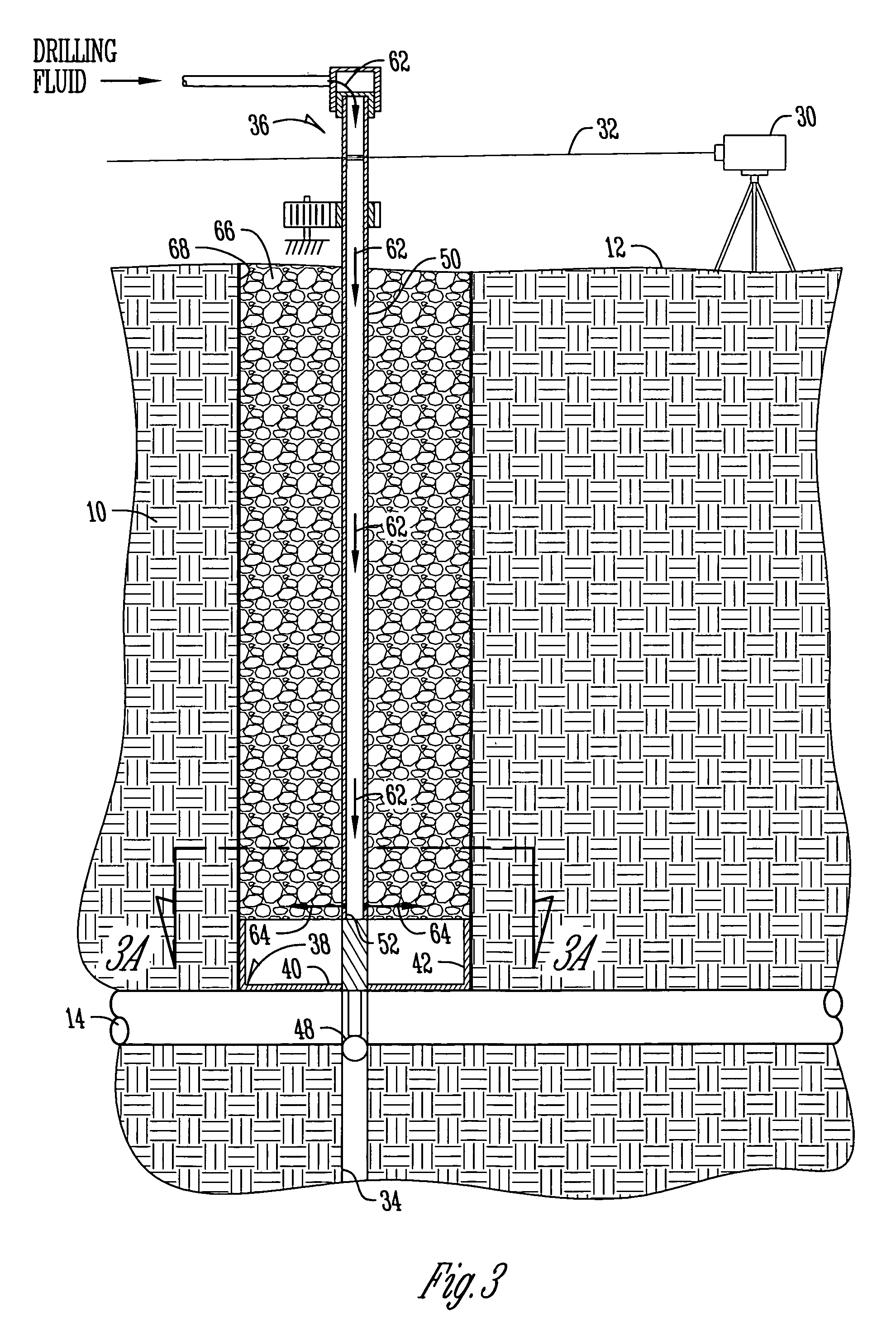

Composite pipe lining, method and apparatus for installing composite lining

Owner:诺曼·怀斯特·贝拉米 +1

Connection between a lateral and main pipe and method for making same

Owner:SHOOK WILLIAM E +1

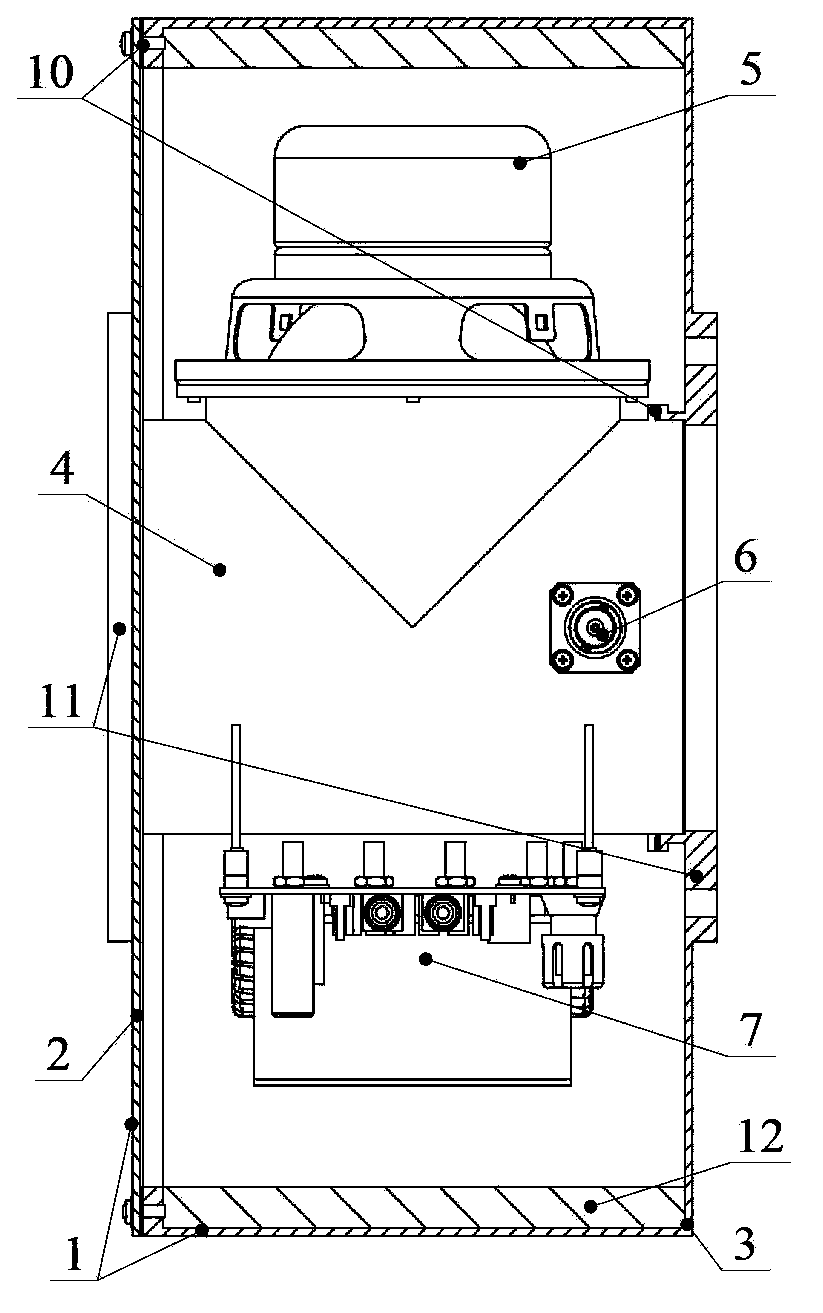

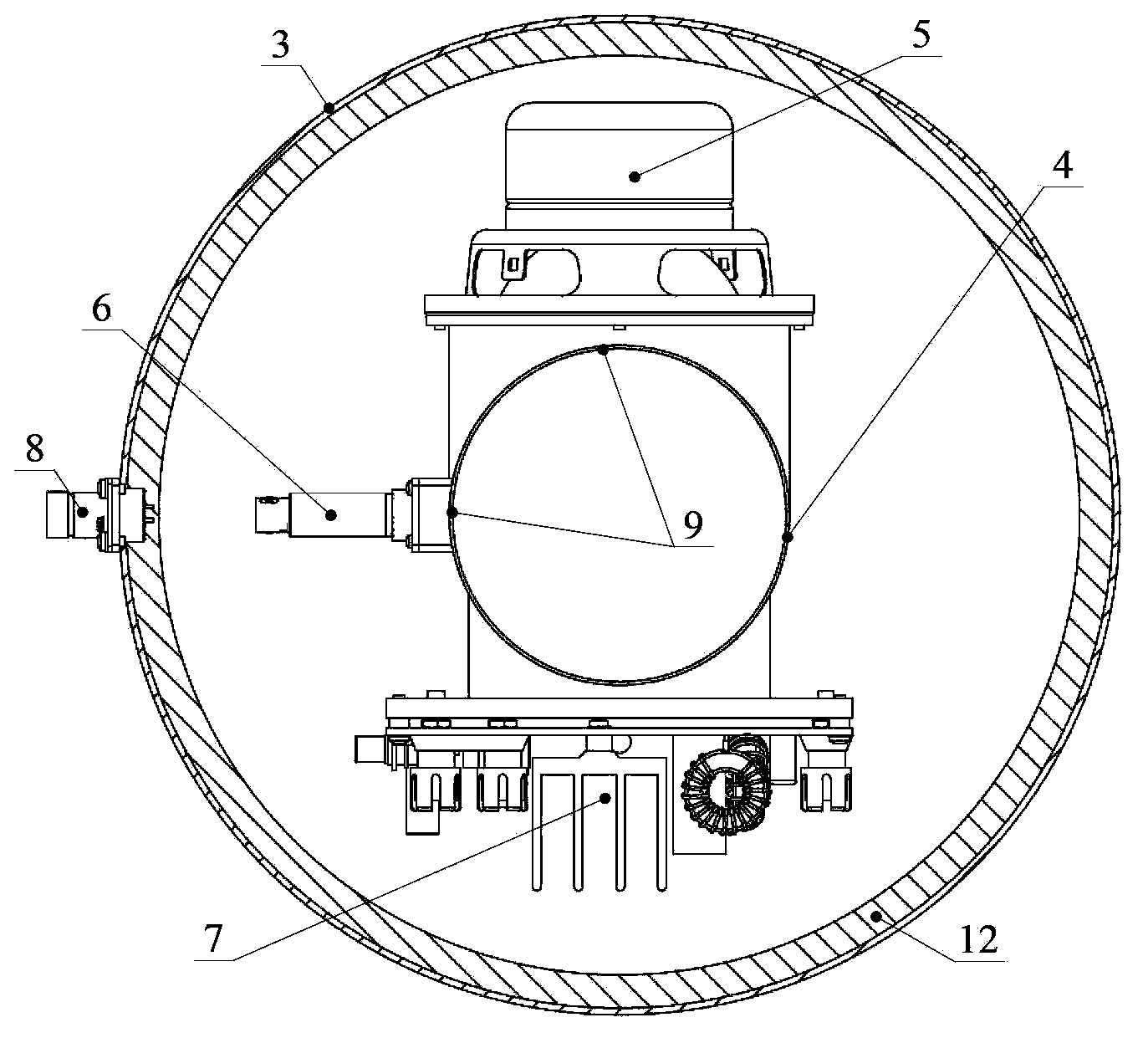

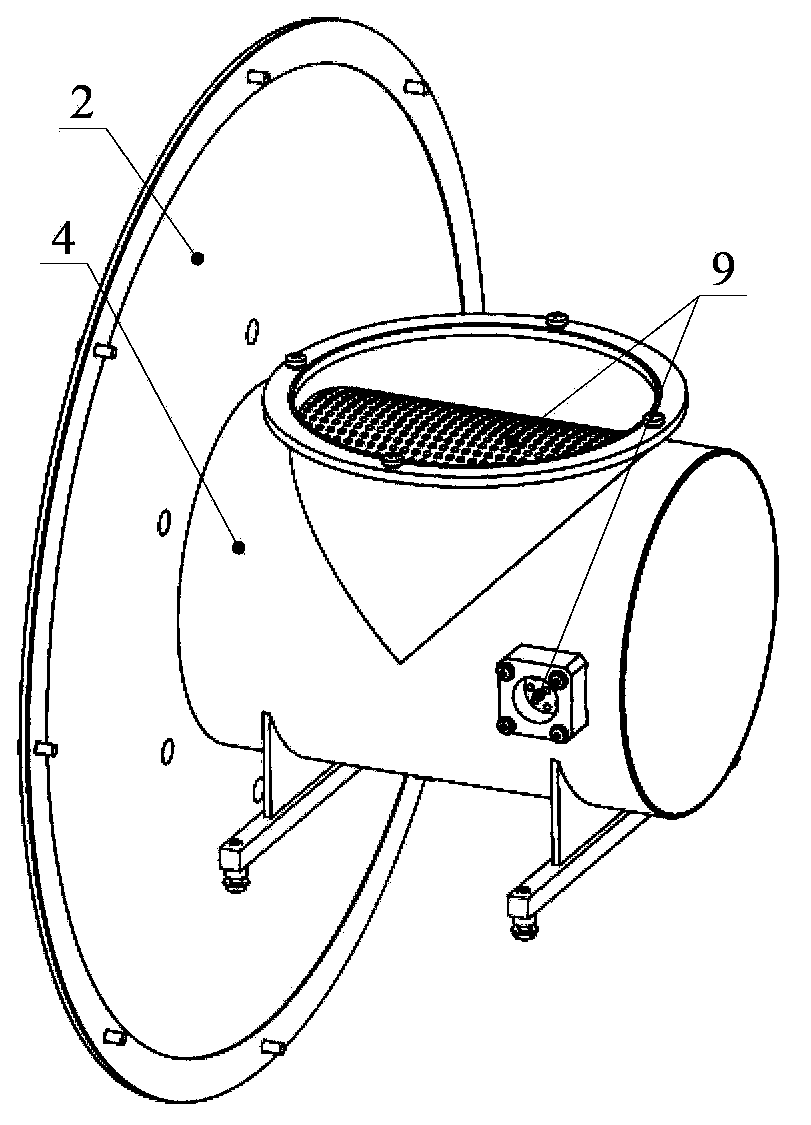

Active sound eliminator for ventilation pipeline system

Owner:IOASONIC SU ZHOU TECH CO LTD

Fuel injector for internal combustion engine and corresponding method of manufacture

ActiveUS20070289578A1Contained costDrawback can be obviatedOperating means/releasing devices for valvesSpray nozzlesComing outBobbin

Owner:C R F SOC CONSORLILE PER AZIONI

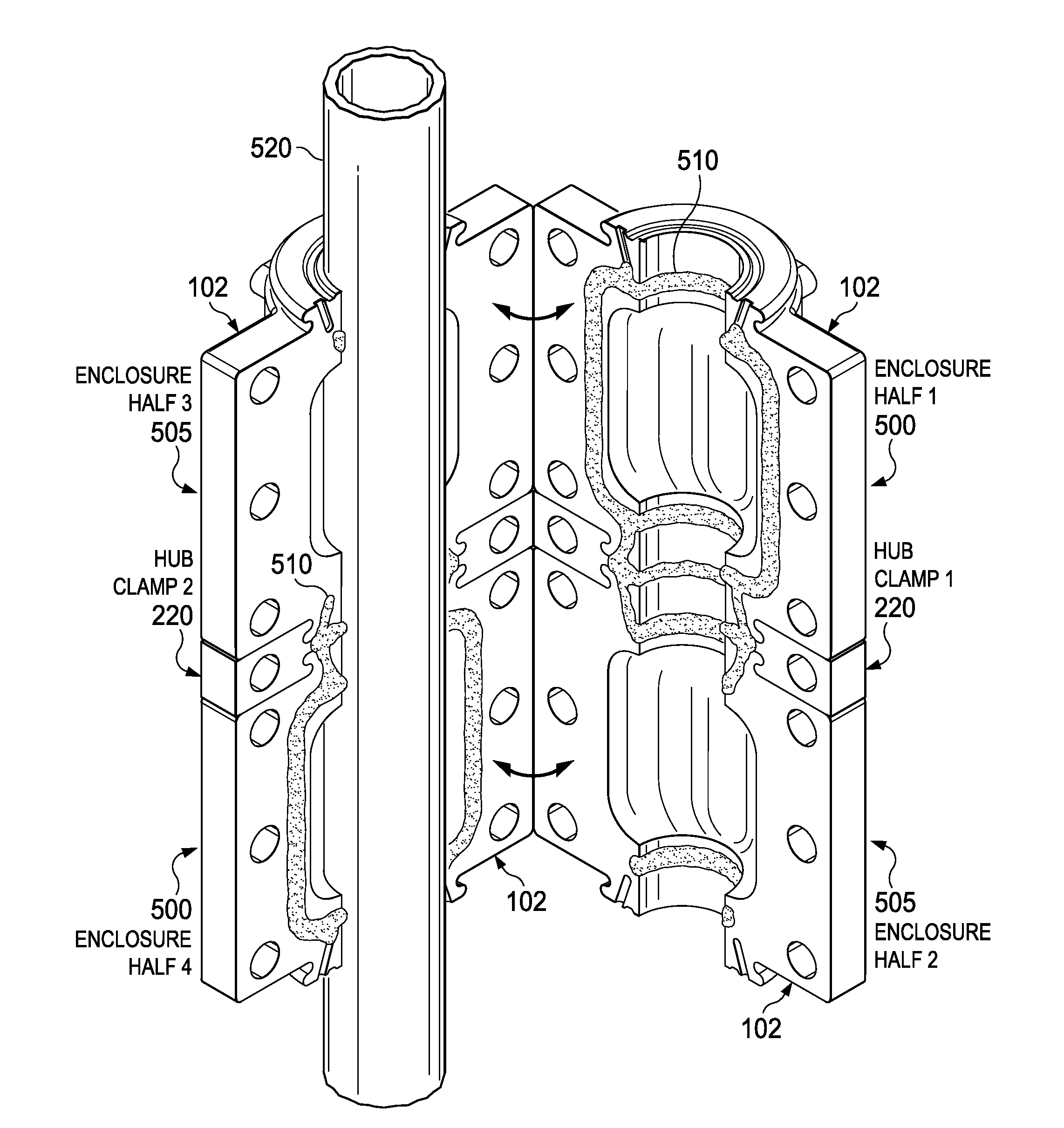

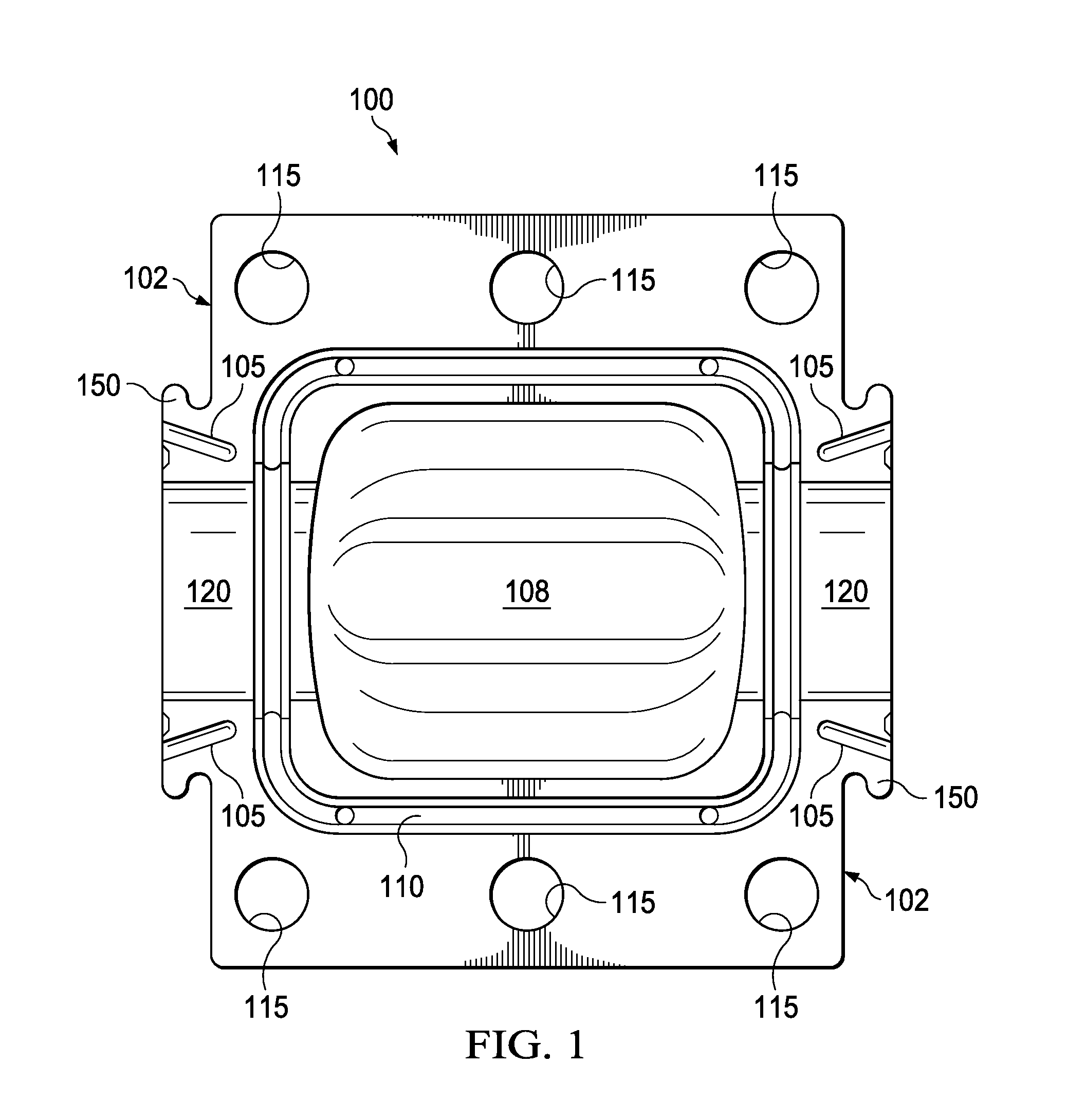

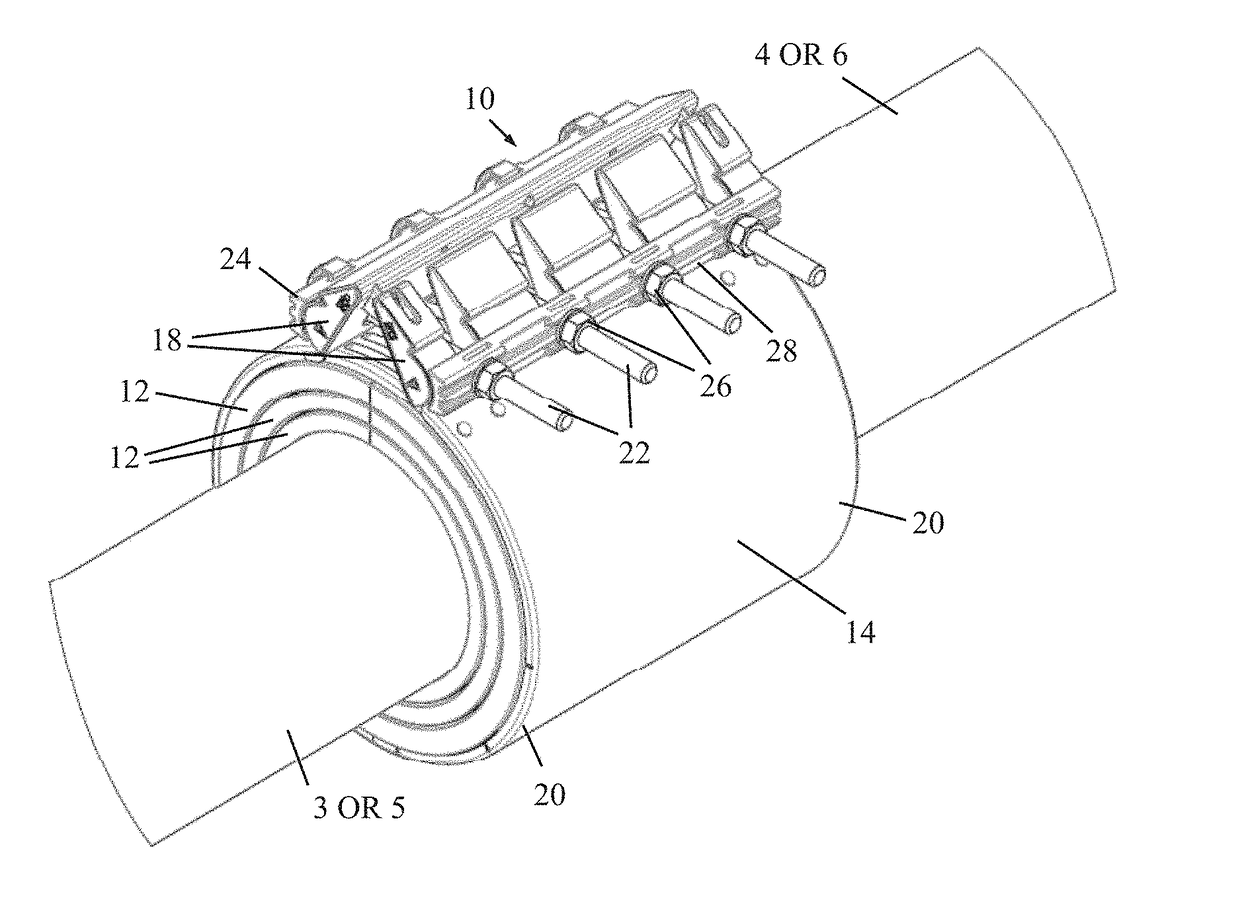

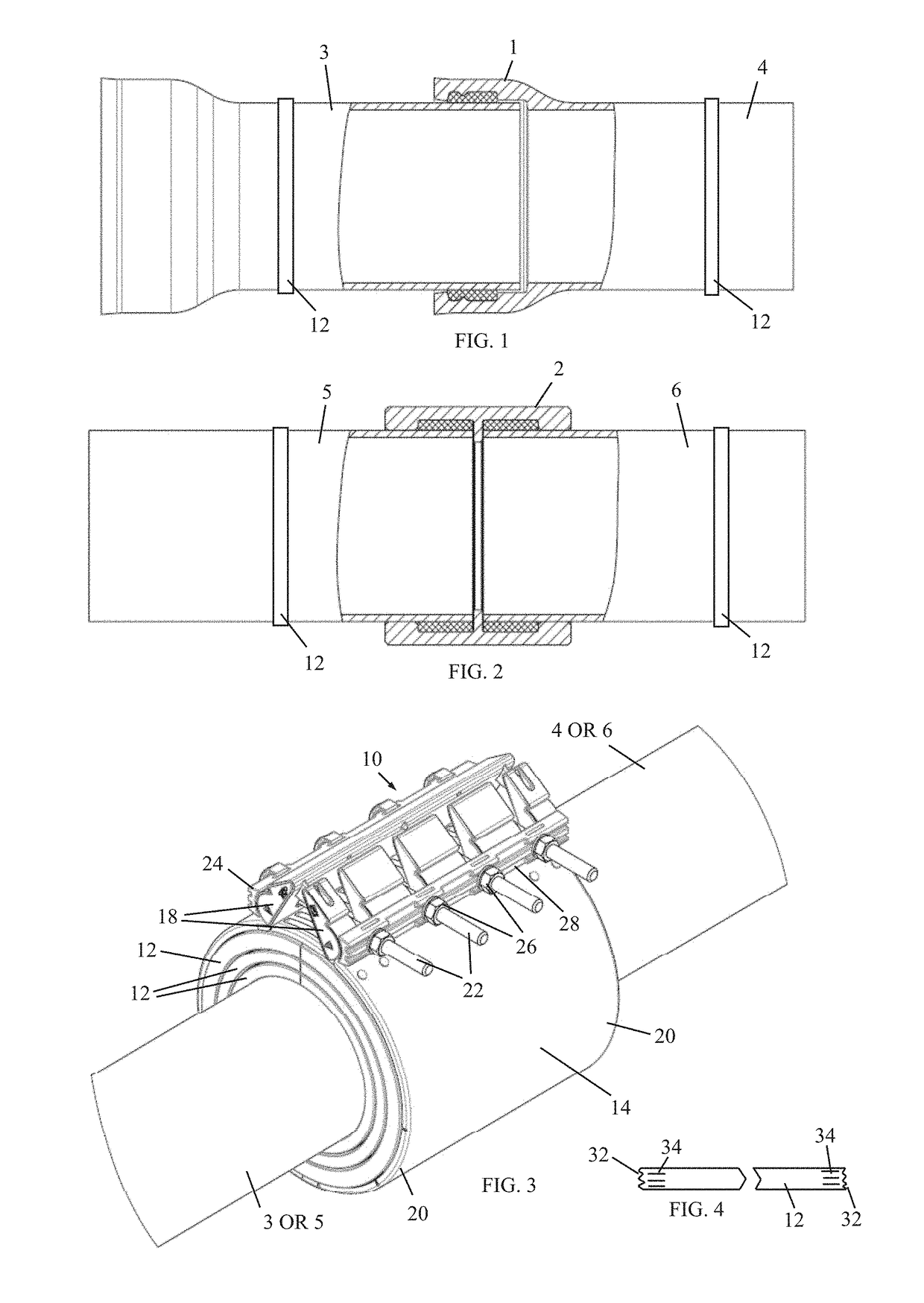

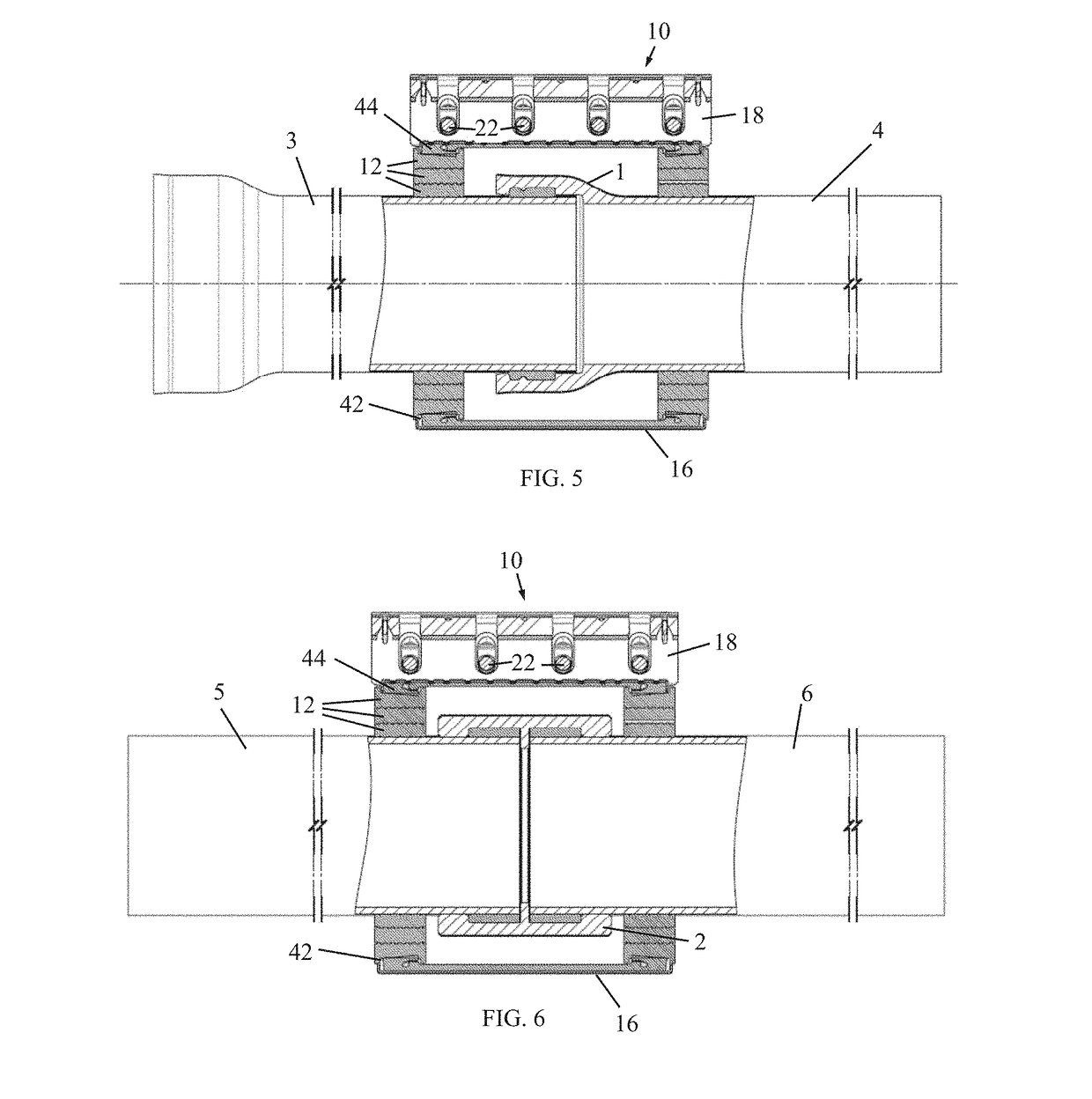

System and method for modular repair of pipe leaks

Owner:COLT SERVICES LP DE

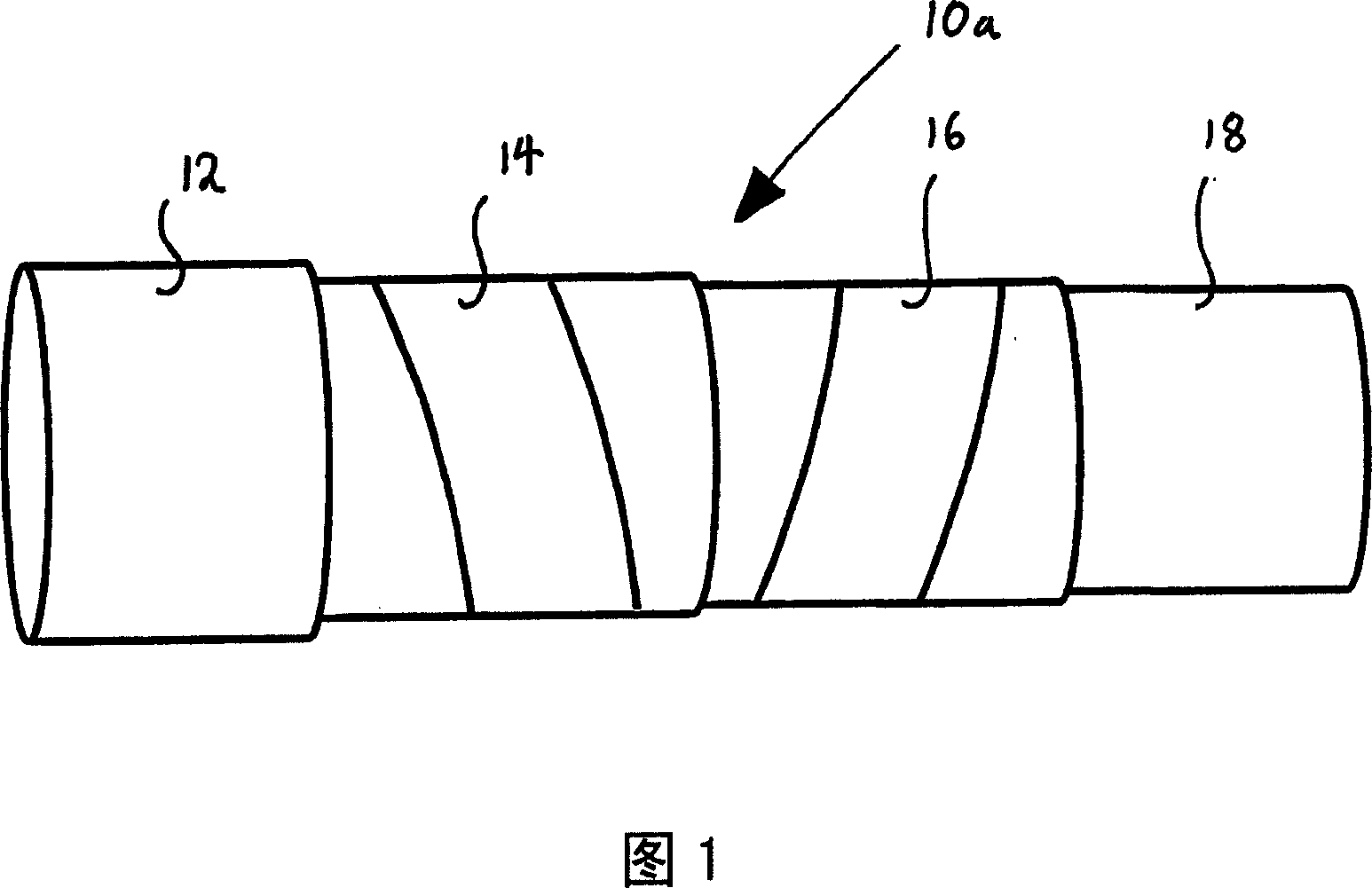

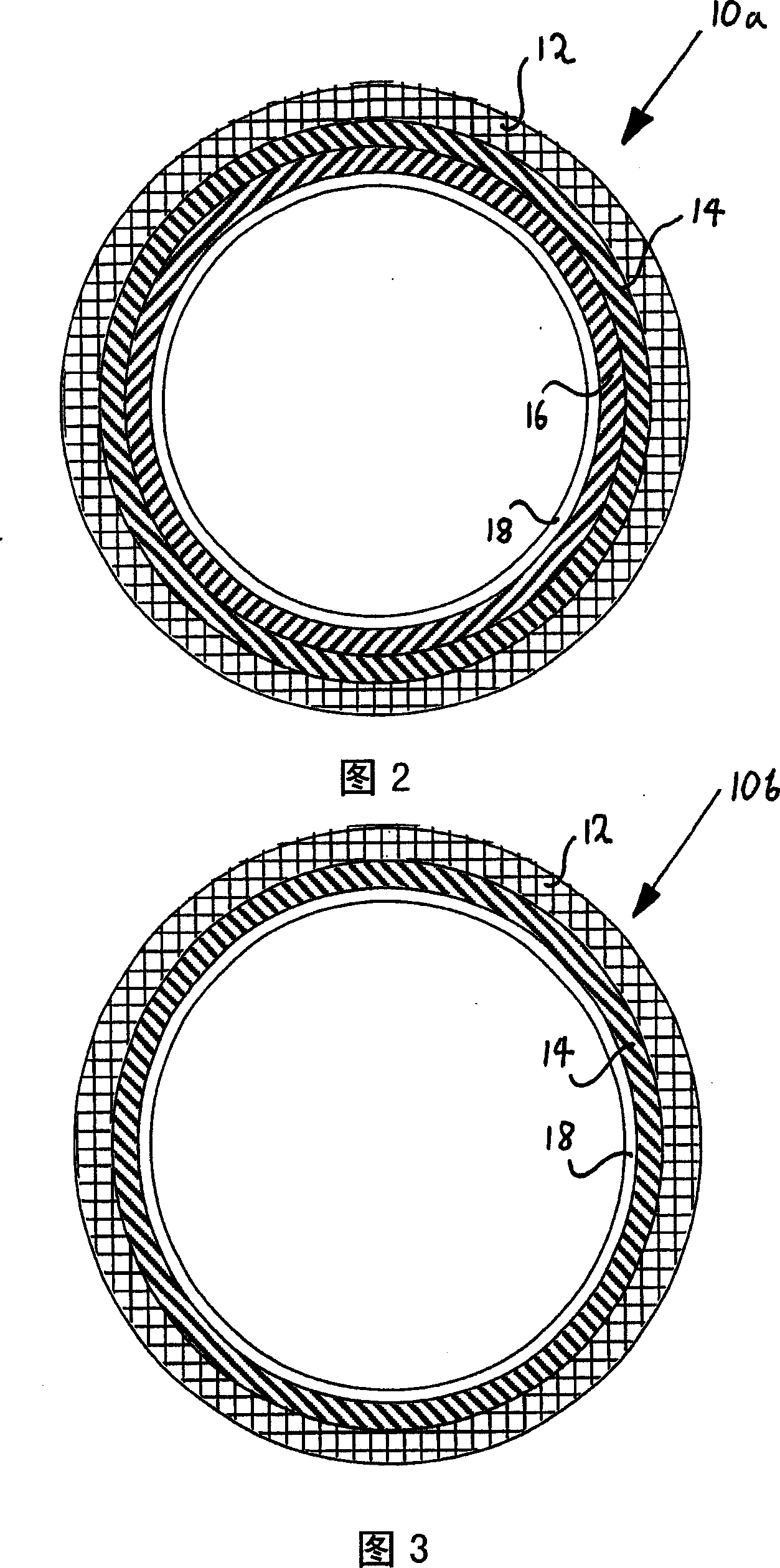

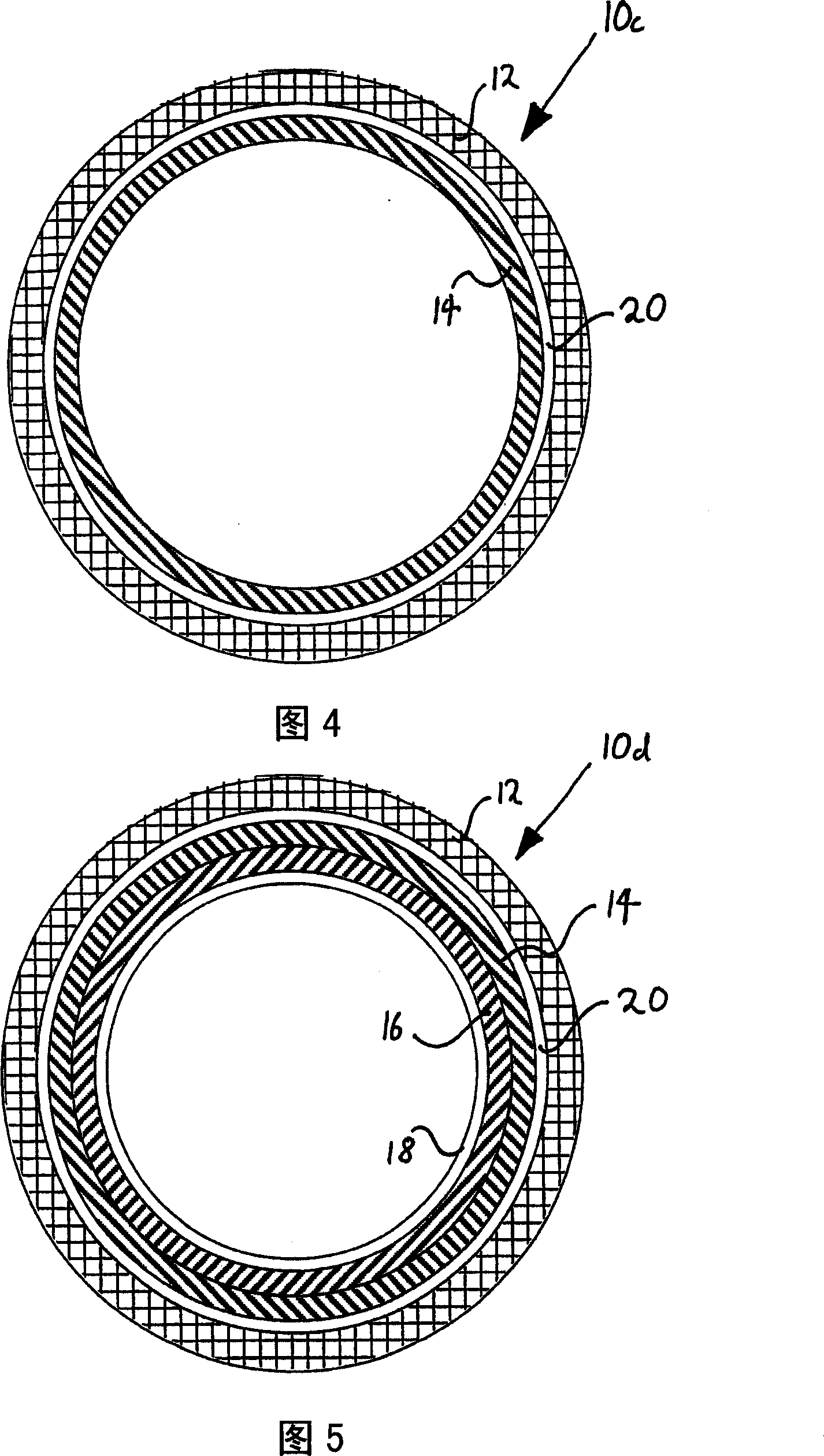

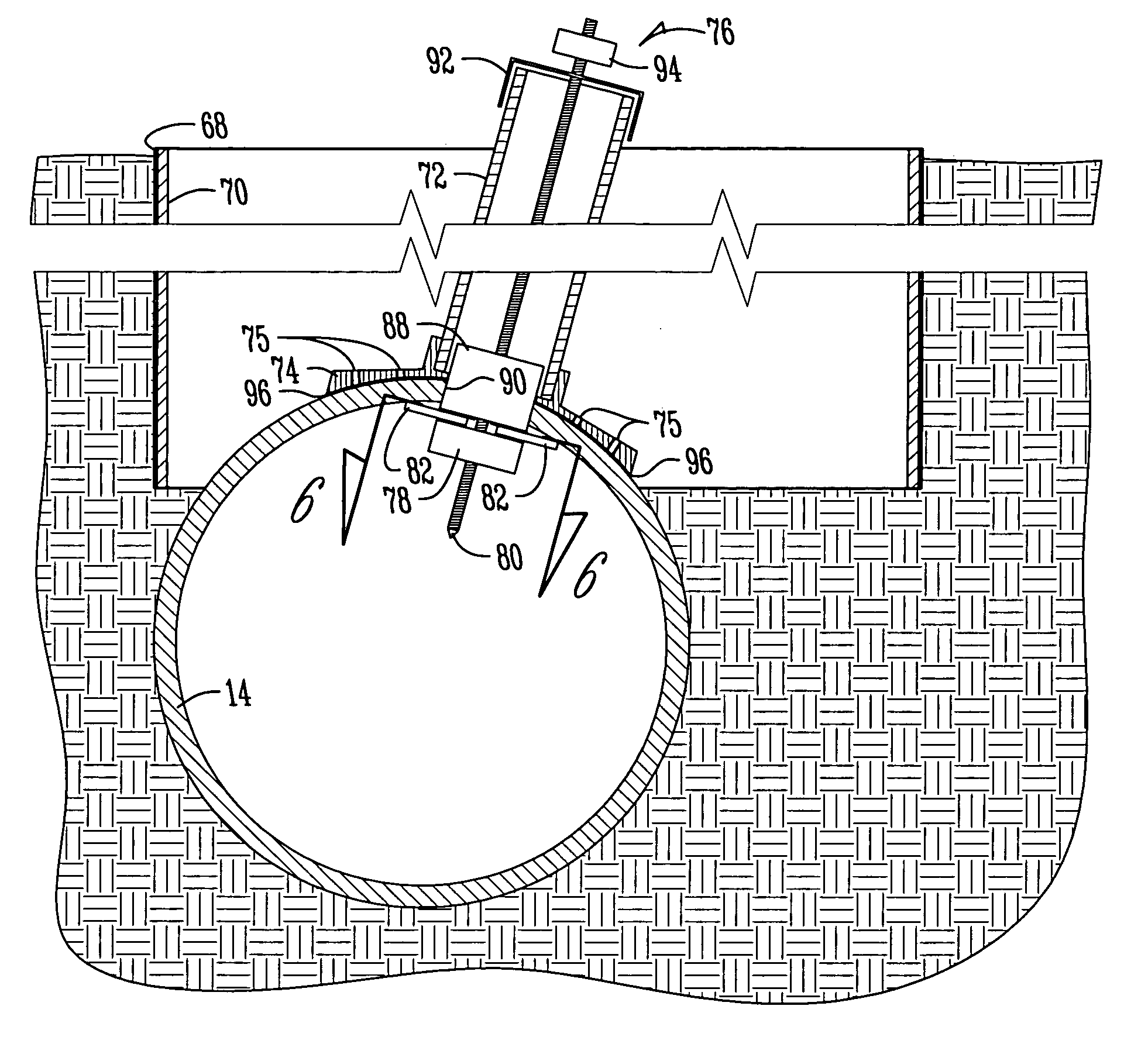

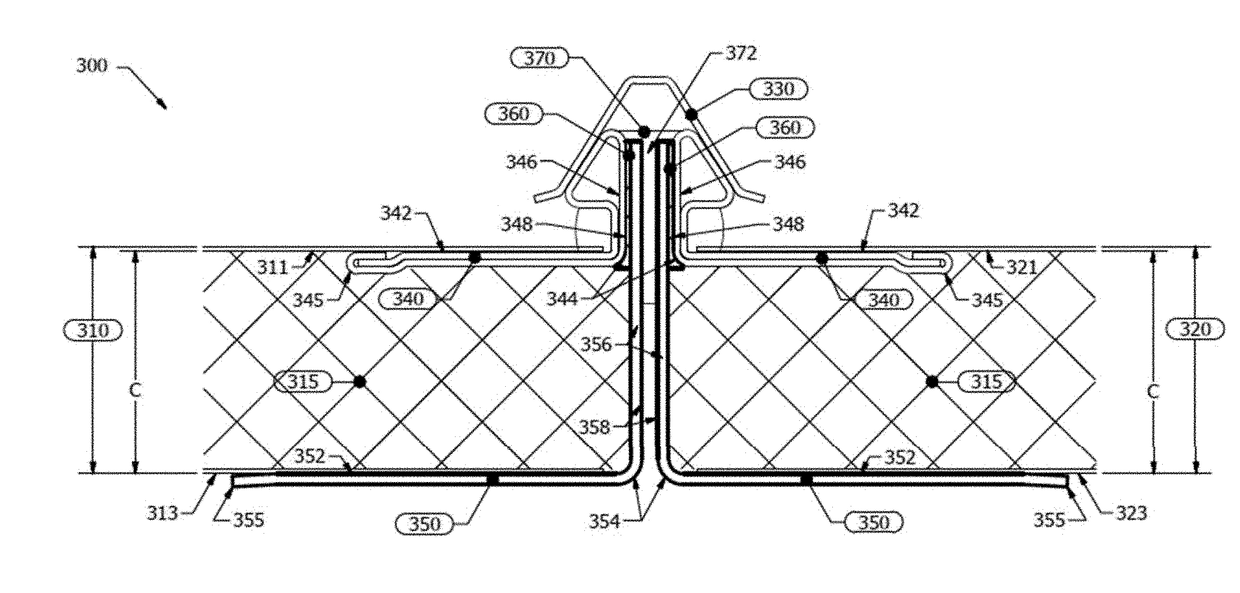

Cured In Place Pipe Liner With Styrene Barrier

InactiveUS20100243154A1Promote migrationHigh hardnessPipe elementsRecord information storageEngineeringCured-in-place pipe

A liner for repairing damaged pipes, such as underground sewer or gas pipes is disclosed. The liner comprises a TPU coating on fibrous mat of non-woven fabric. The TPU coating contains a barrier layer to retard the migration of styrene from the liner to the media used to force the liner against the damaged pipe and to activate the thermoset resin. The thermoset resin converts the liner from a flexible state to a rigid state as the liner is cured in place inside the pipe.

Owner:LUBRIZOL ADVANCED MATERIALS INC

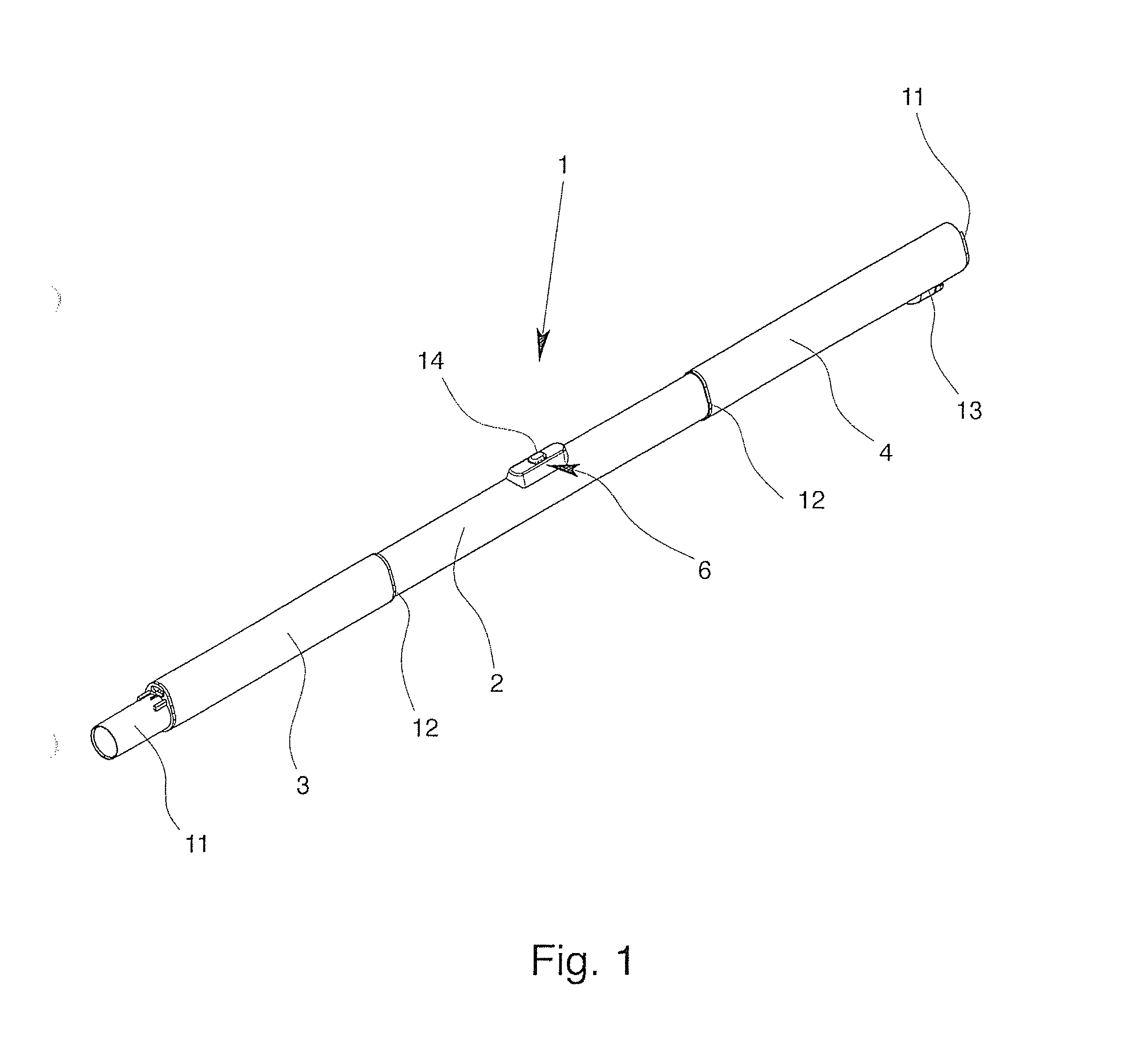

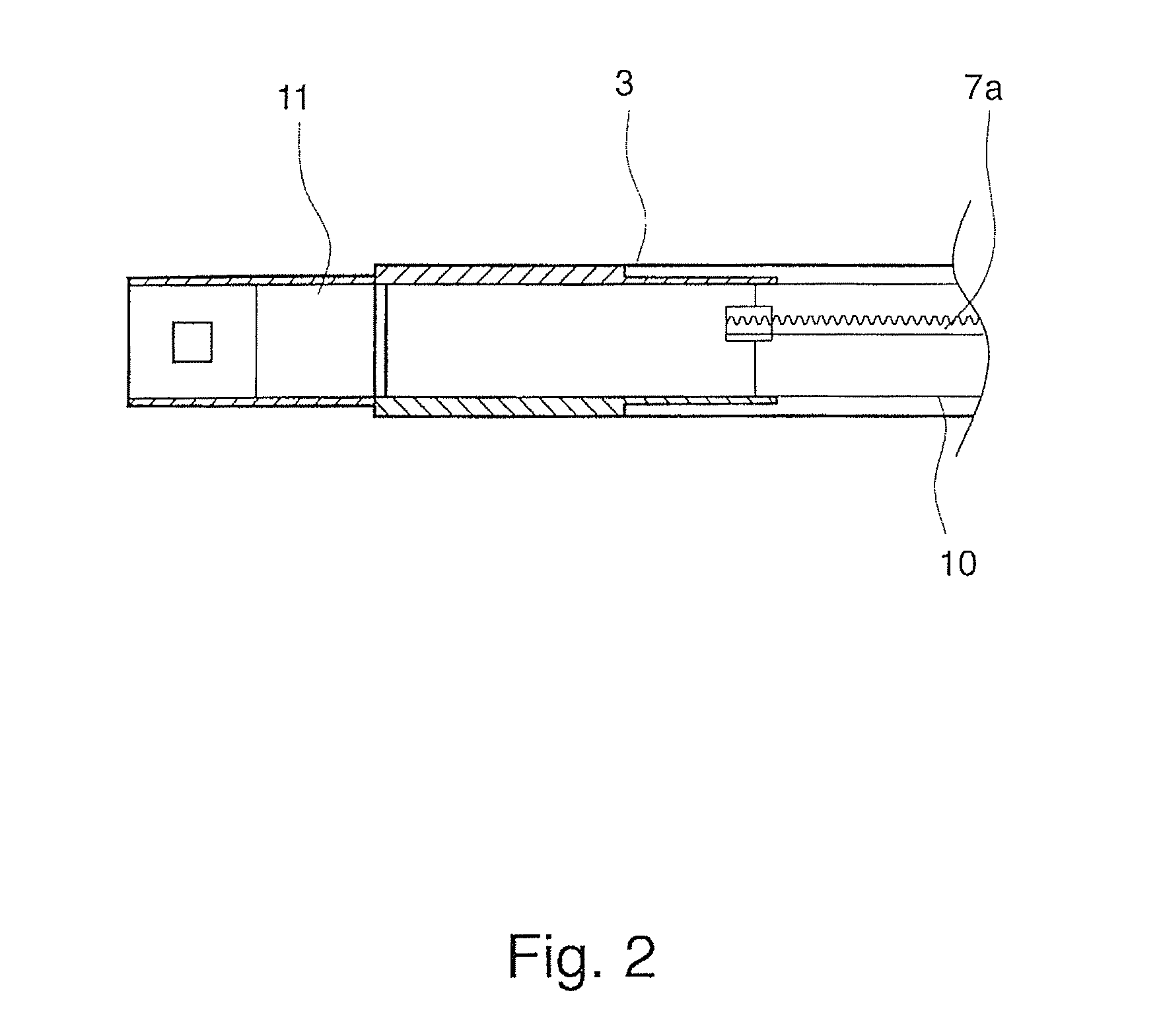

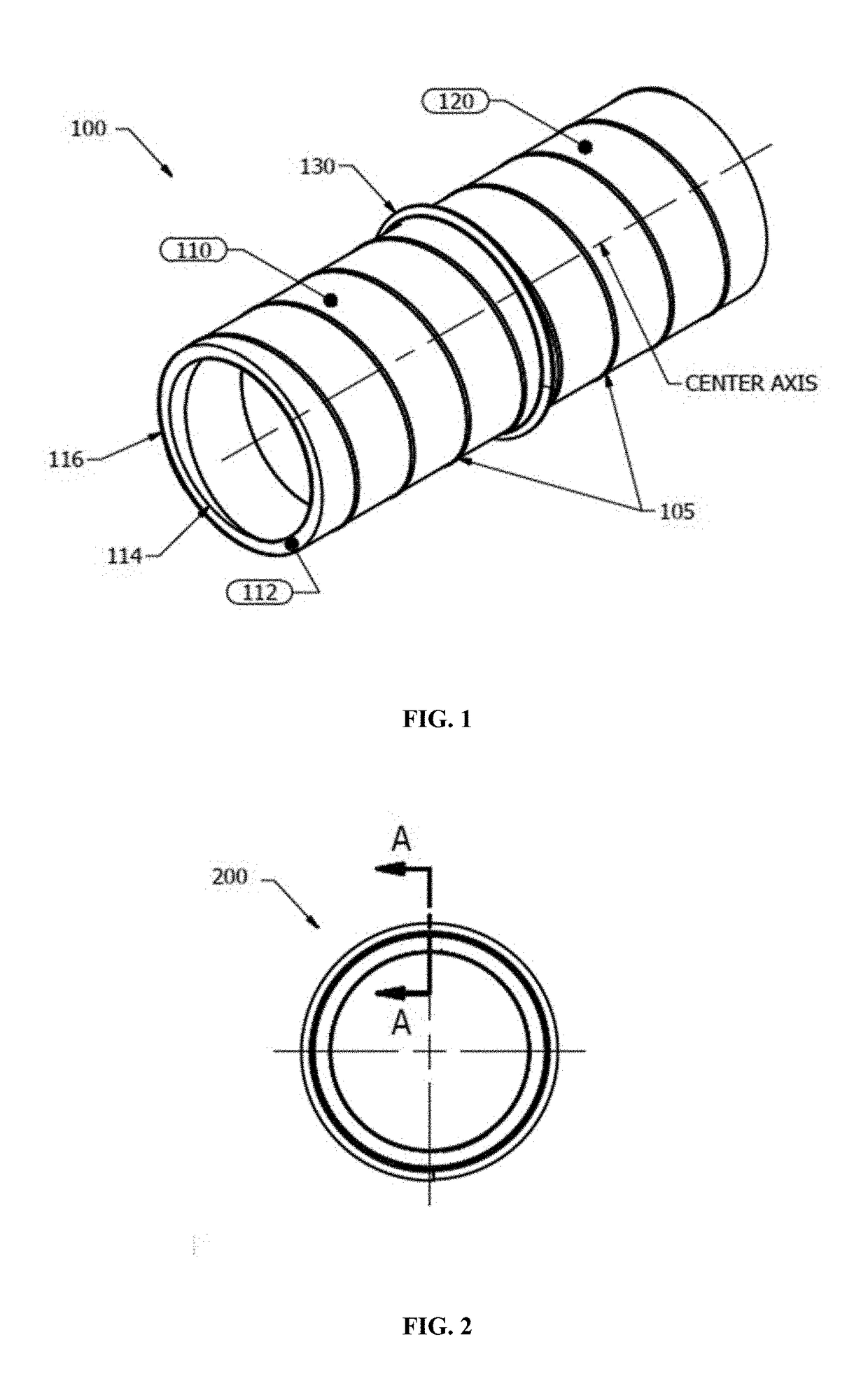

Vacuum cleaner suction pipe

Owner:FISCHER ROHRTECHN

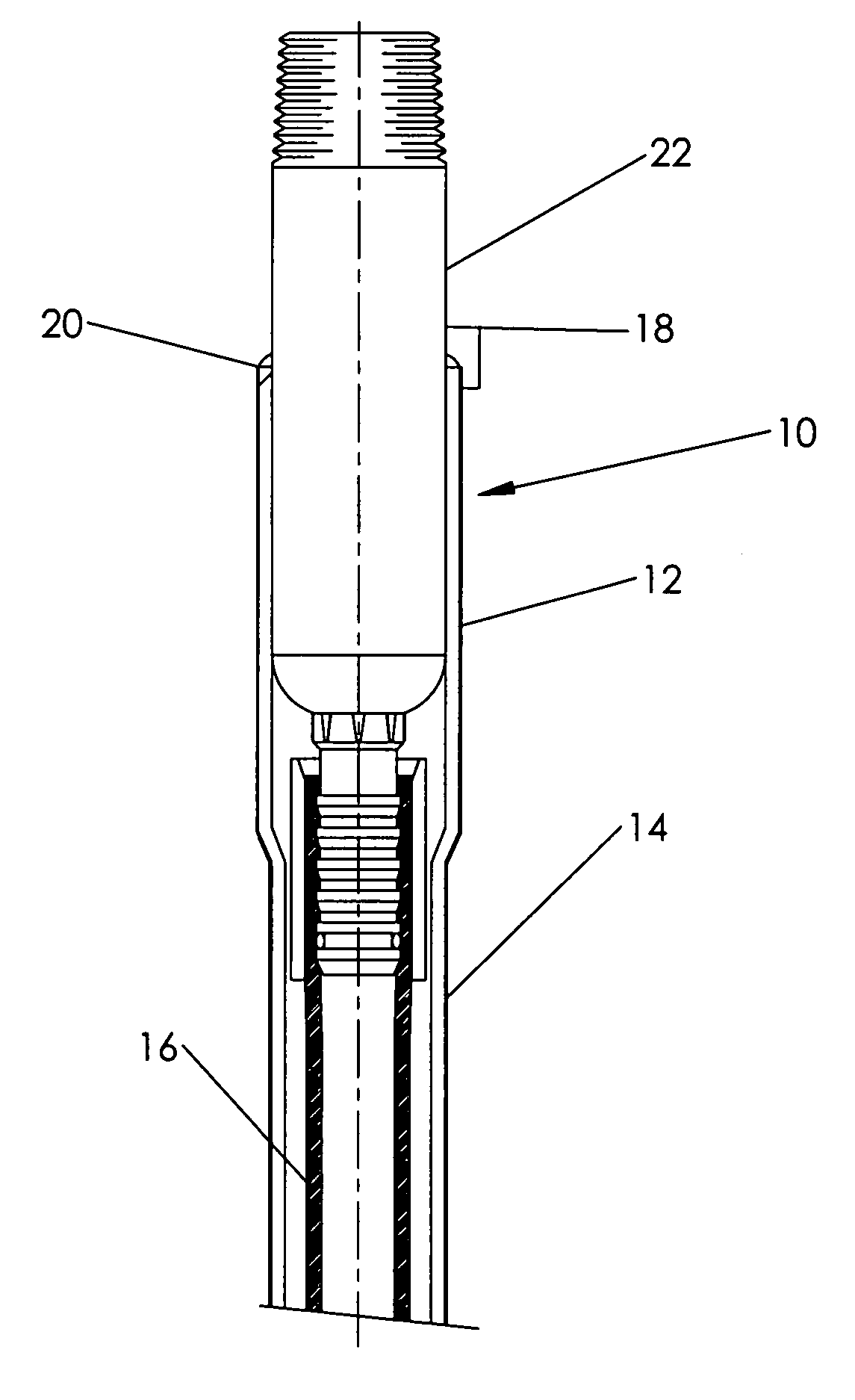

Corrosion resistant gas service riser assembly

Owner:GEORG FISCHER CENT PLASTICS

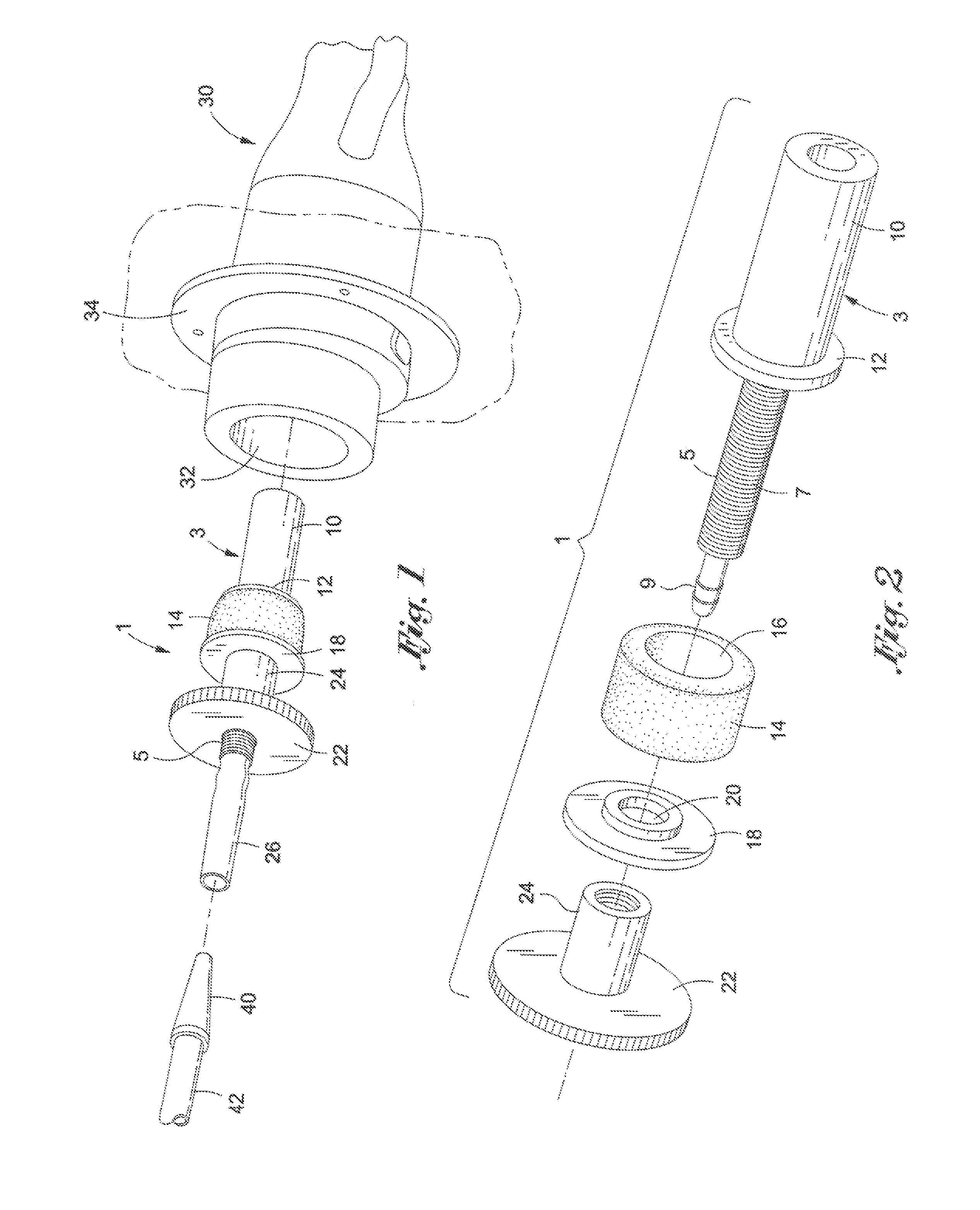

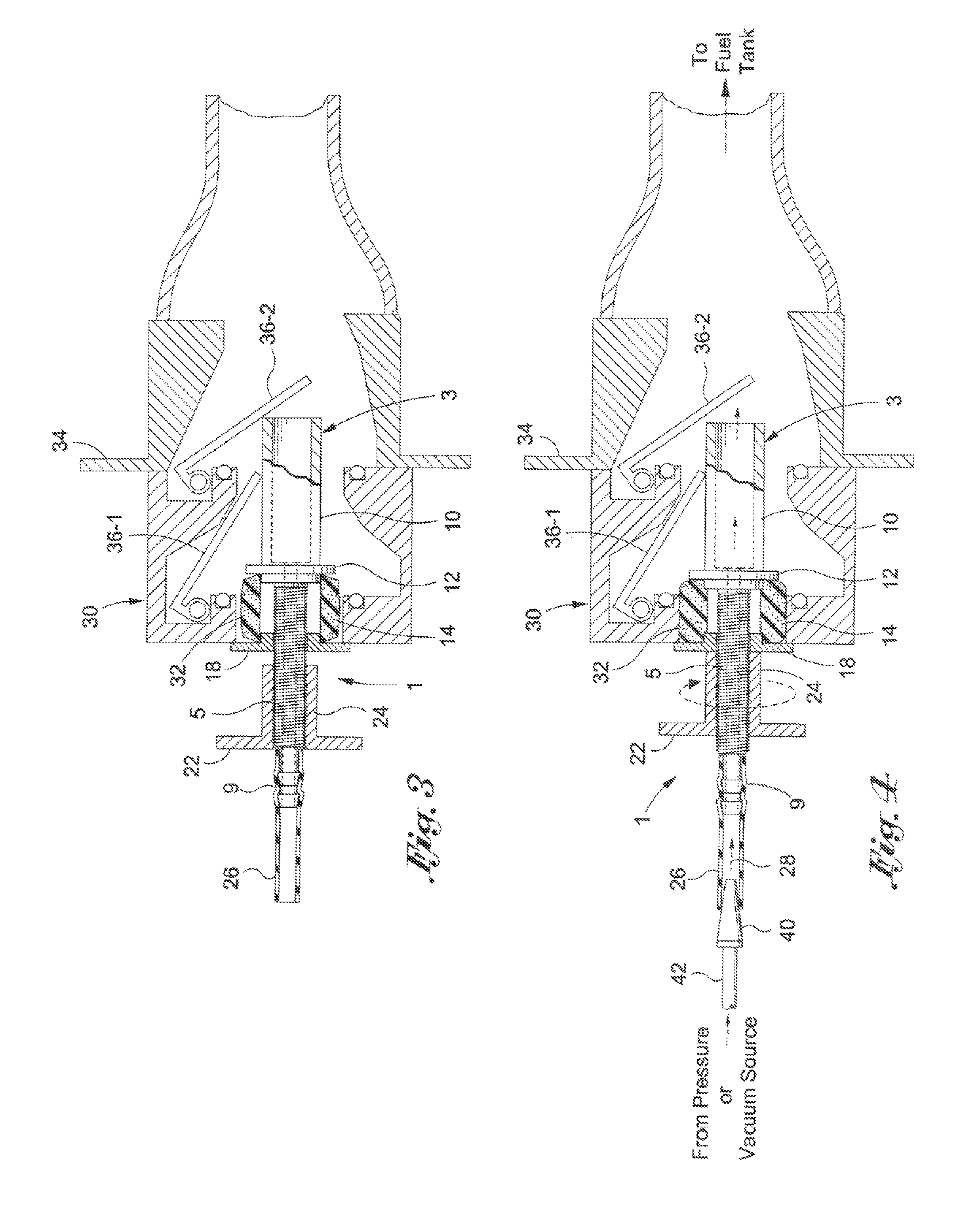

Foamable filling device

ActiveUS20140000739A1Suitable propertyEasily formedCheck valvesPipe elementsEngineeringMechanical engineering

Owner:IIDA IND CO LTD +1

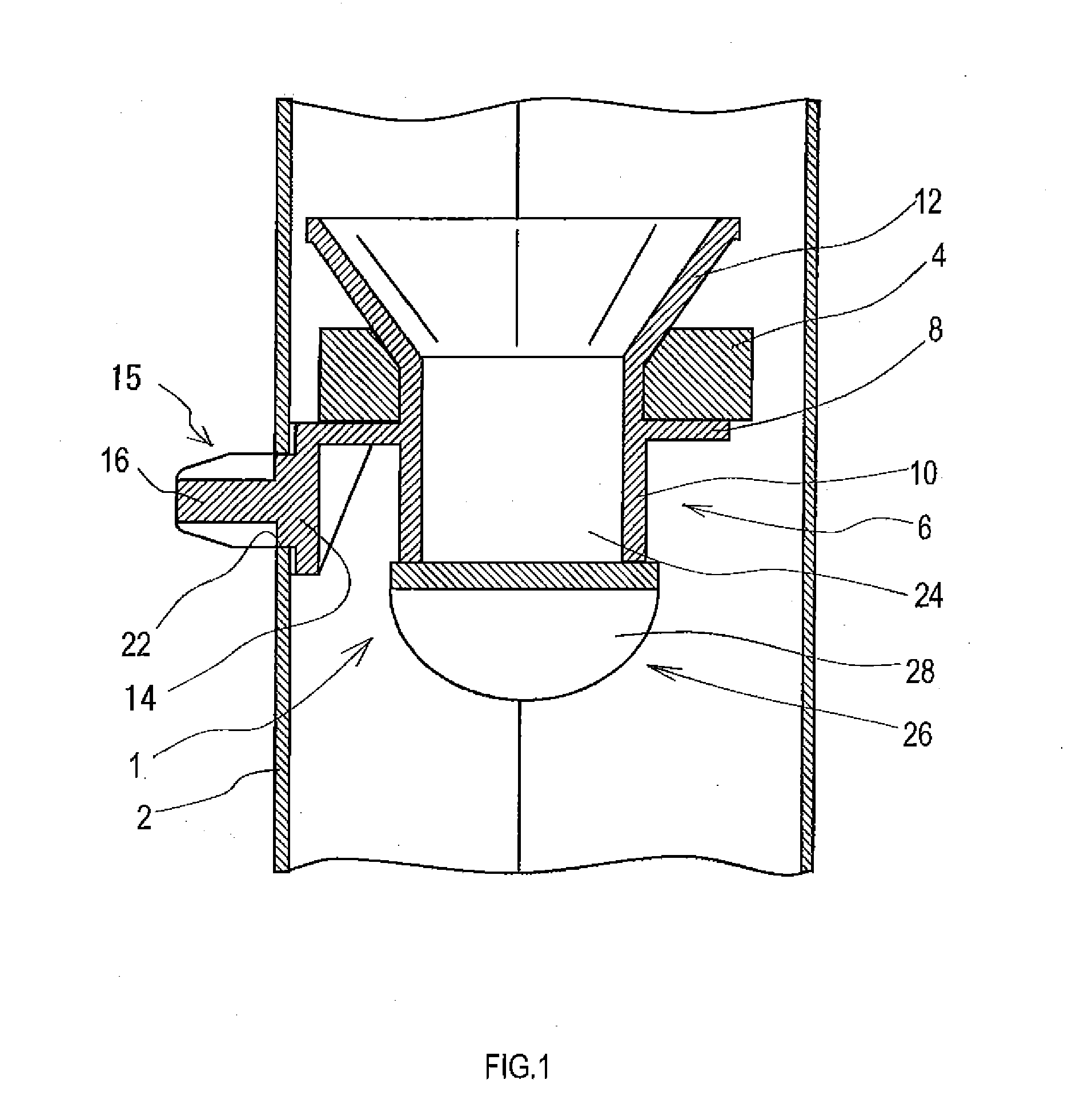

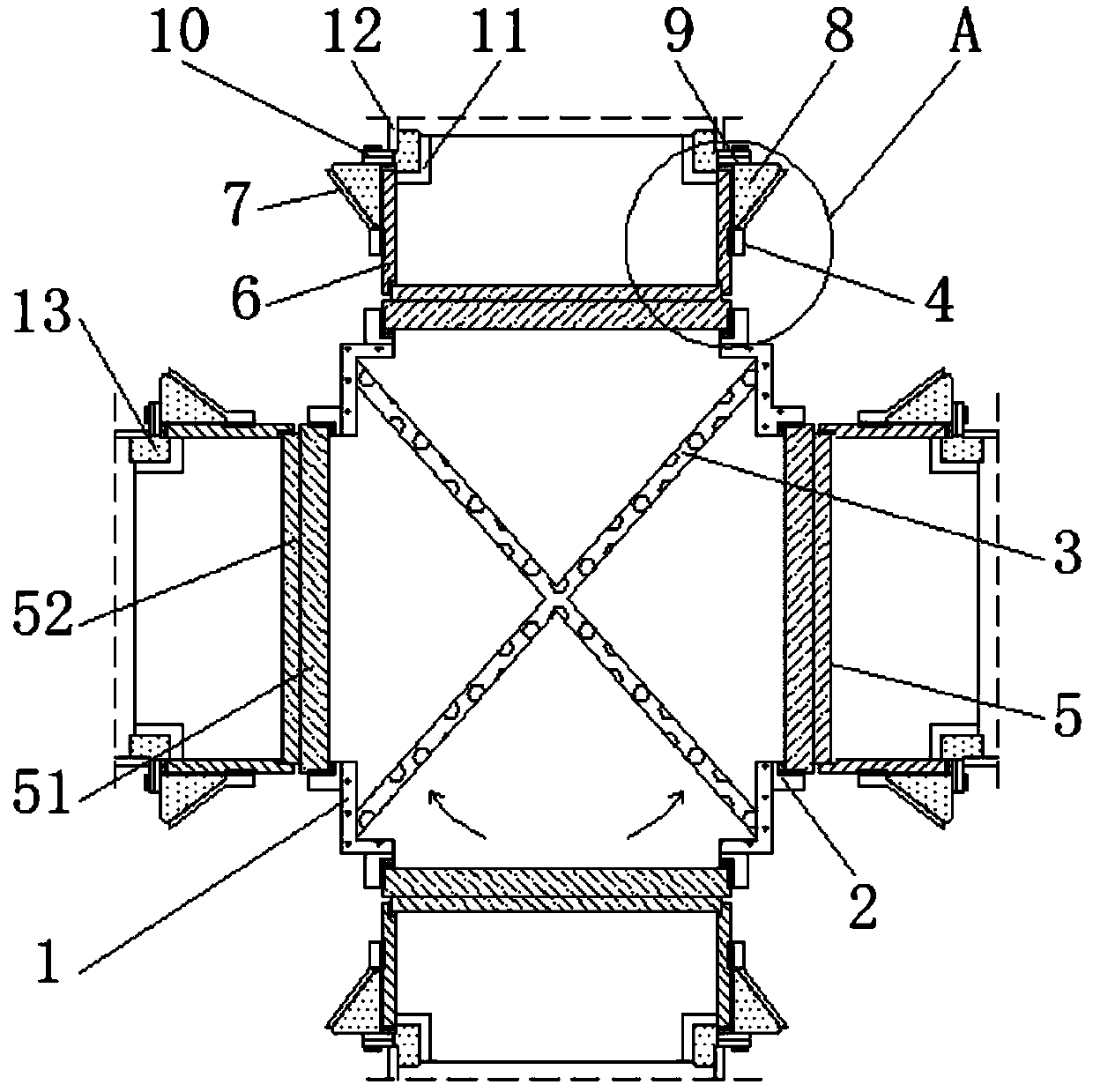

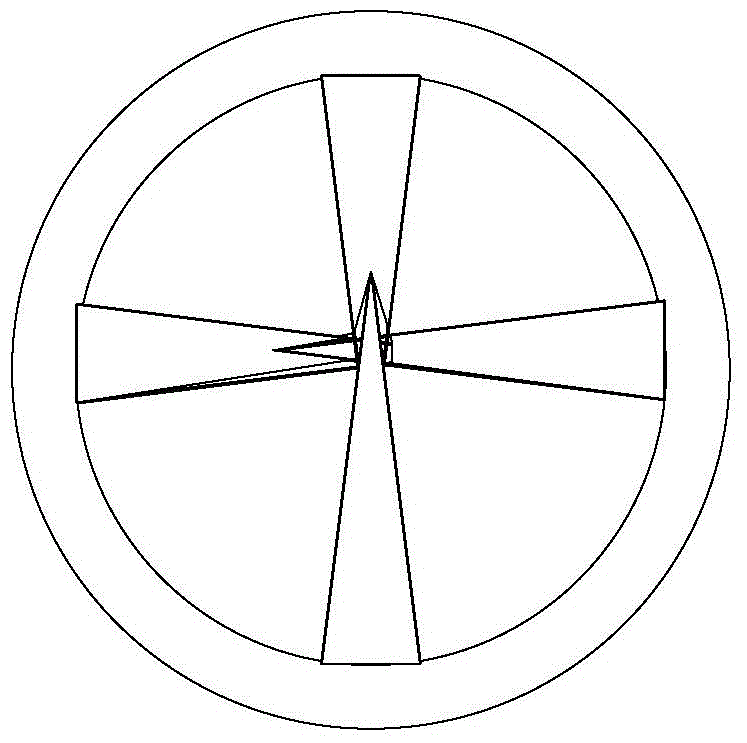

Self-adaptive irrigation system pipeline water hammer impact reducing device

ActiveCN110220043AImprove production efficiencyImprove reliabilityValve members for absorbing fluid energyPipe elementsWater dischargeDistribution system

The invention discloses a self-adaptive irrigation system pipeline water hammer impact reducing device. The self-adaptive irrigation system pipeline water hammer impact reducing device comprises a valve inlet pipeline, a reducer and a water hammer response channel; the reducer and the outer wall of the valve inlet pipeline form a closed annular cavity; the edge of an isolating reinforcement plateis connected with the inner wall of the reducer and the outer wall of the valve inlet pipeline separately; a pressure relief action block is fit with the inner wall of the reducer and the outer wall of the pipeline; the isolating reinforcement plate and the first end face of the pressure relief action block form a pressure relief cavity; a water discharging port is formed in the pressure relief cavity; the isolating reinforcement plate and the second end face of the pressure relief action block form an action cavity; the water hammer response channel communicates with the action cavity and aninner cavity of the valve inlet pipeline; a pressure relief hole and a pipeline hole are completely staggered under the normal water conveying state, and the pressure relief hole communicates with thepipeline hole under the pressure relief state; and the self-adaptive irrigation system pipeline water hammer impact reducing device can actively respond the water hammer impact of the valve in an irrigation distribution network, effectively reduce the water hammer impact, guarantee the safety of a key part of an irrigation water distribution network and improve the stability of an irrigation water distribution system, and is suitable for the multi-user random irrigation water distribution network working condition.

Owner:XI AN JIAOTONG UNIV

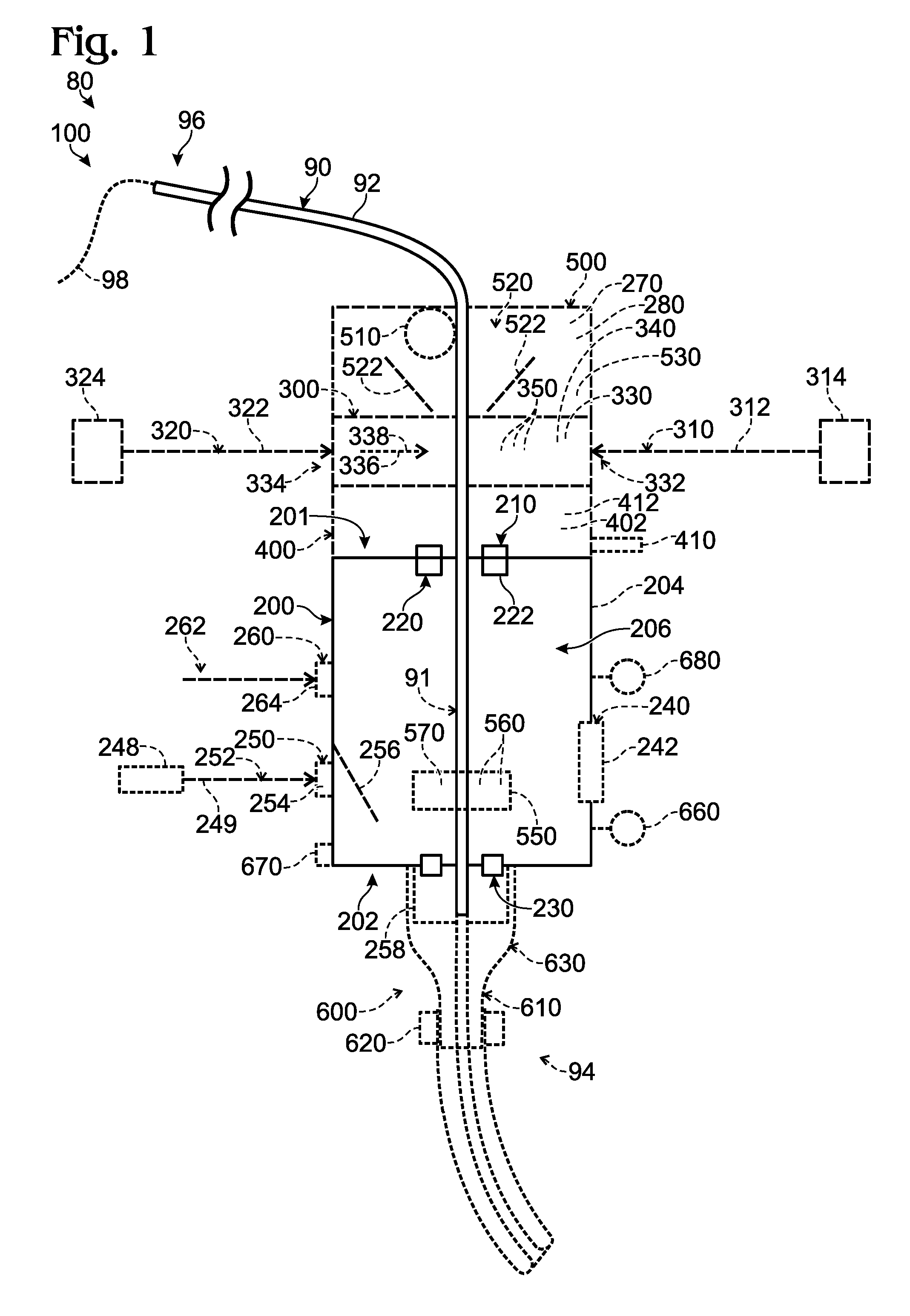

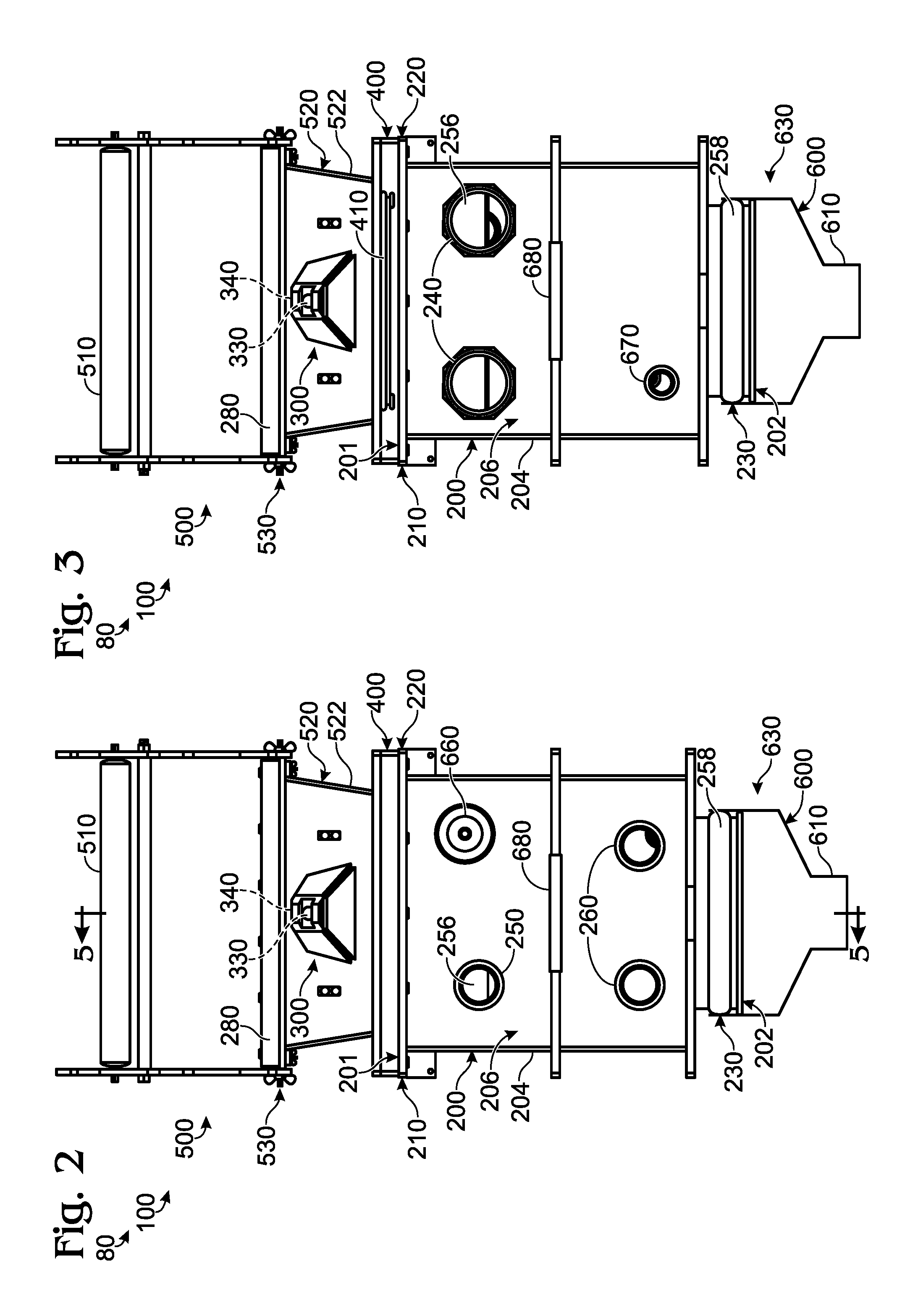

Tubing everting apparatus, assemblies, and methods

Owner:EMAGINEERED SOLUTIONS INC

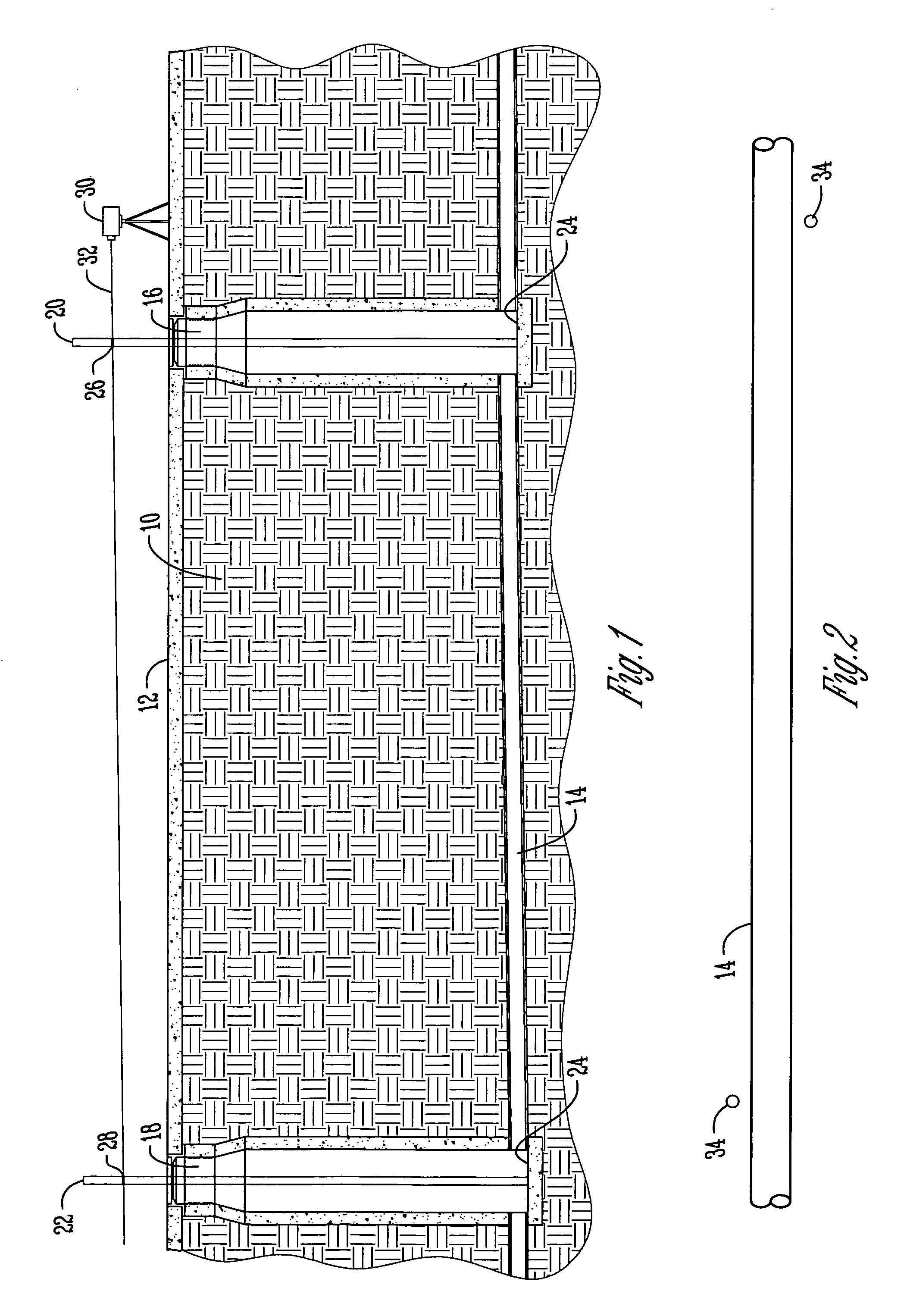

Method of Laying Lined Pipeline

ActiveUS20180073666A1Good continuityMaintain continuityPipe laying and repairPipe elementsEngineeringMechanical engineering

A method lays lined pipeline which actively and successfully removes air pockets which night be trapped in the annulus between the liner and the host pipe by progressively flooding the lined pipeline. Further, the liner is brought into closer contact and engagement with the host pipe. The removal of air in the annulus enables the pipeline test pressure to stabilize more quickly and avoids the risk of potential collapse during operational service life in the event the pipeline pressures fluctuate or a vacuum is created during an emergency shutdown.

Owner:PIONEER LINING TECH

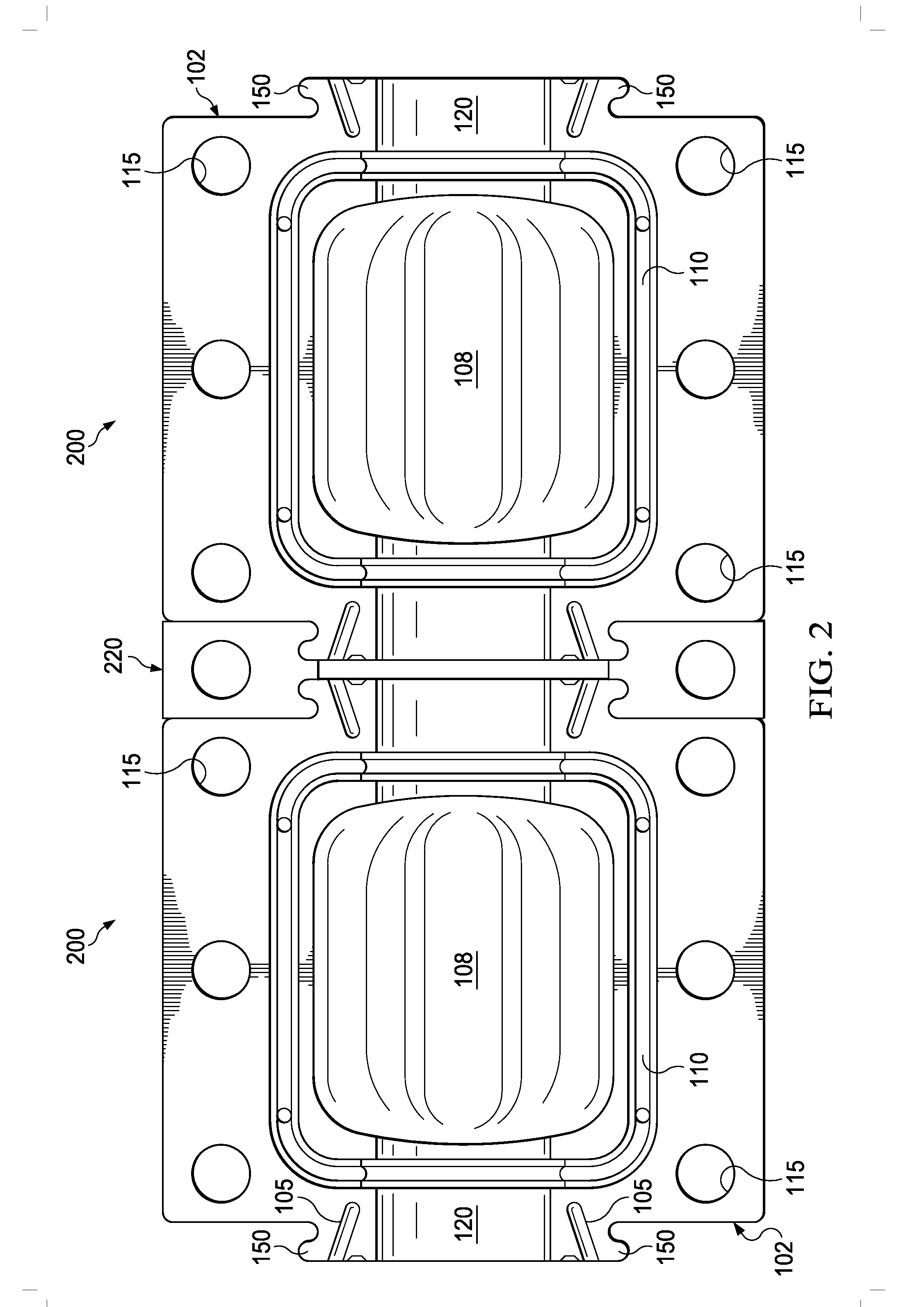

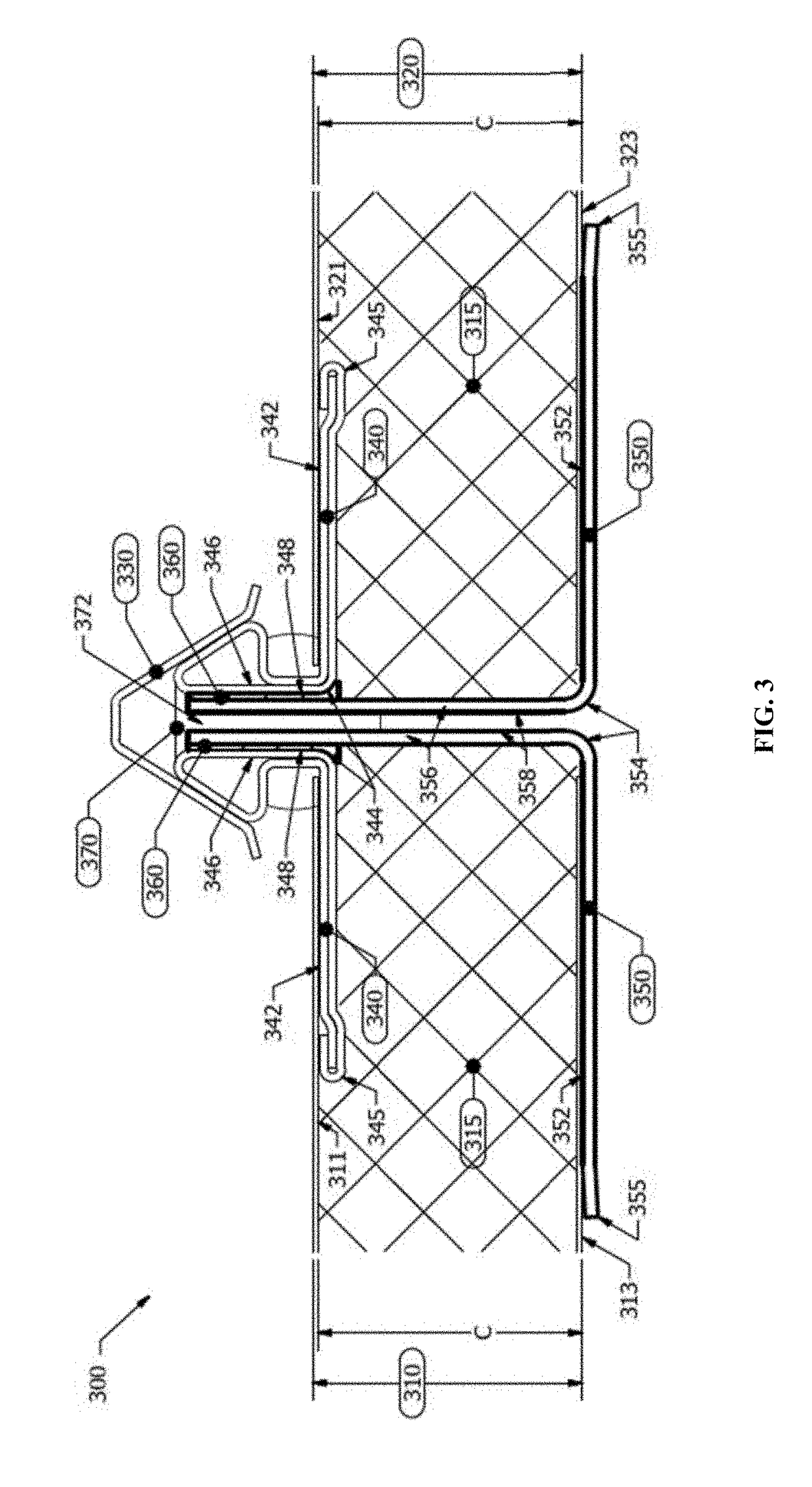

Double Wall Duct Connector

ActiveUS20180087700A1Easy to useAvoid missed connectionsFlanged jointsLighting and heating apparatusEngineeringDouble walled

Owner:DMI CO INC

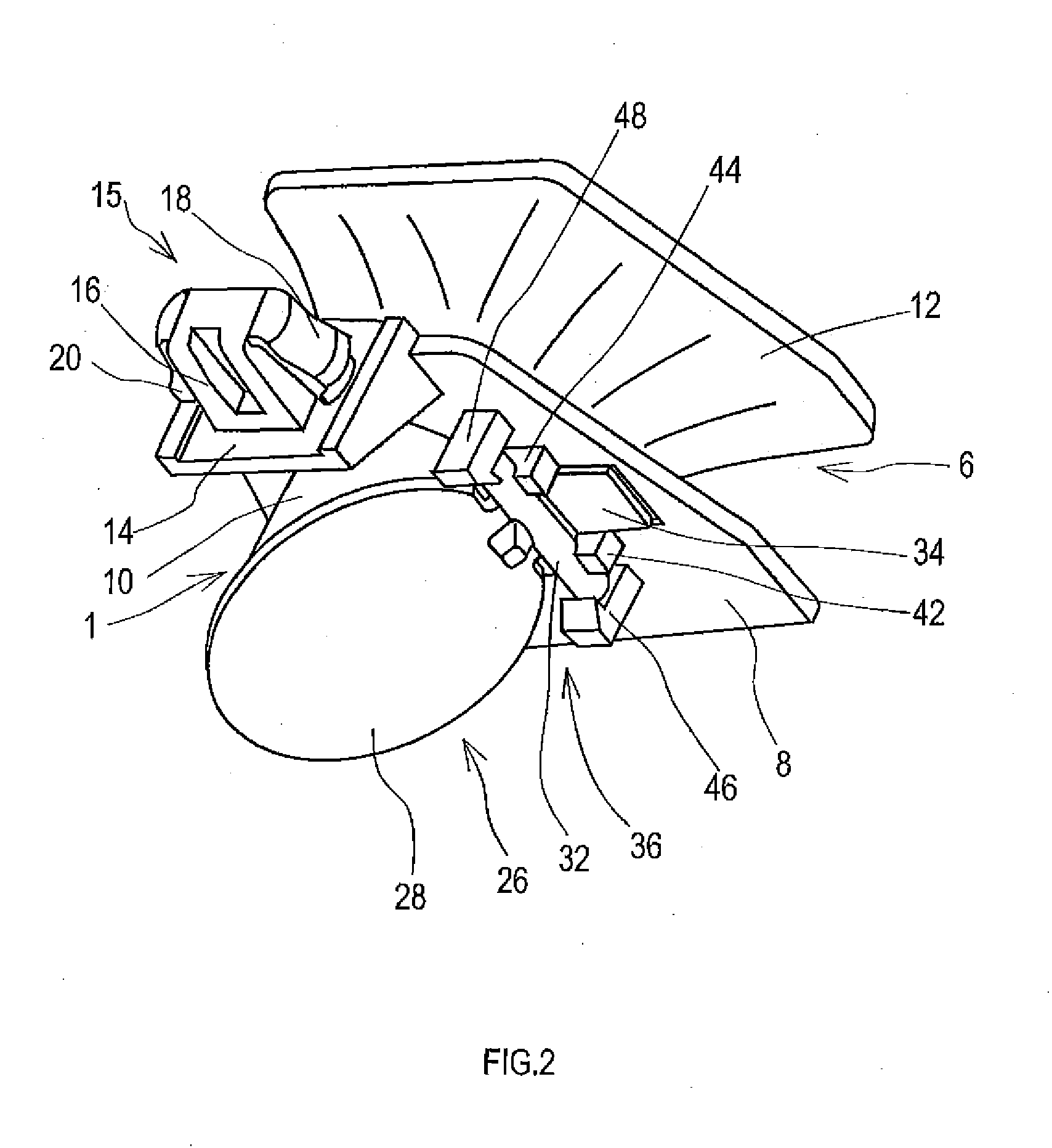

Nylon pipe clamp structure based on automobile air conditioning pipeline

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

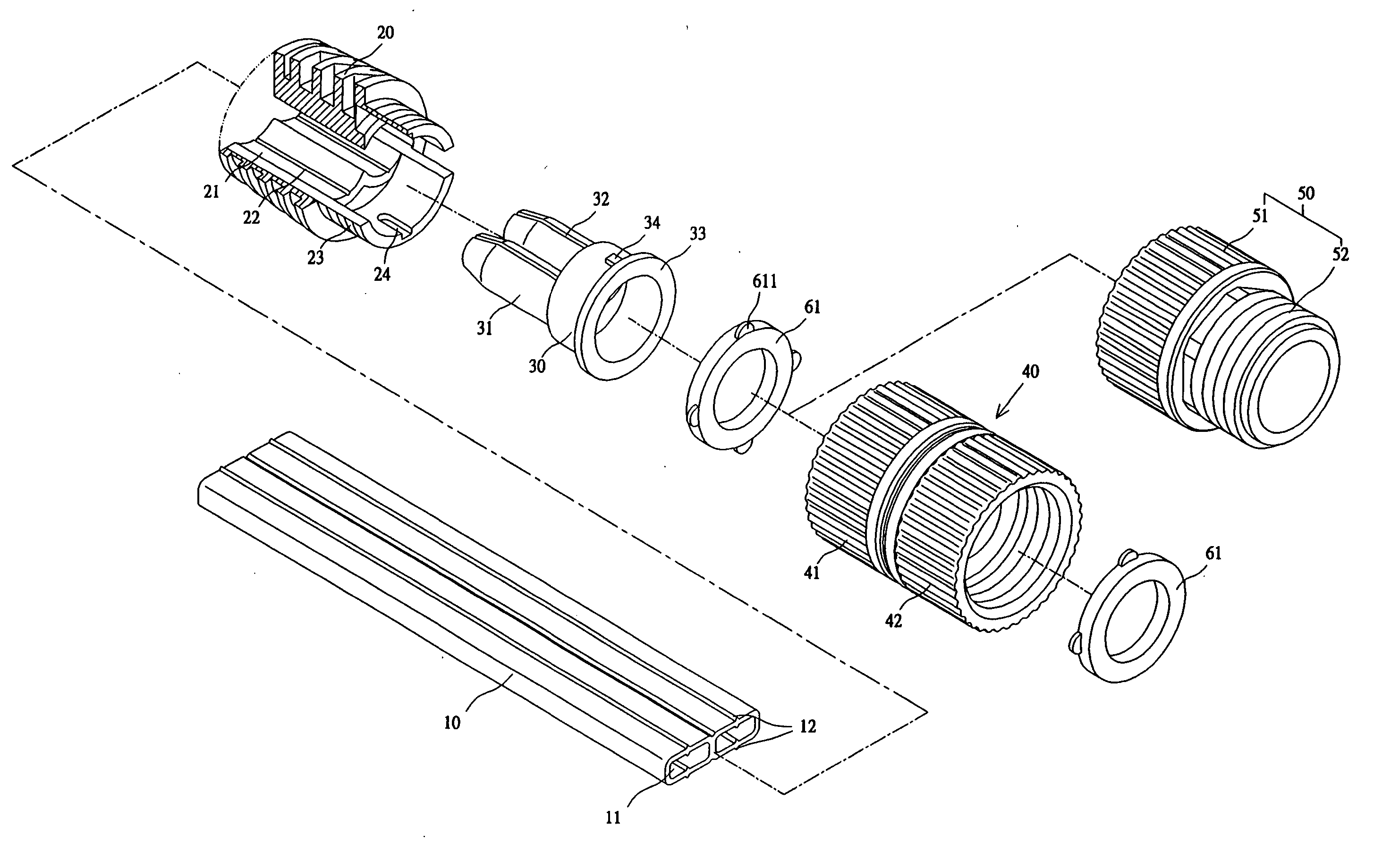

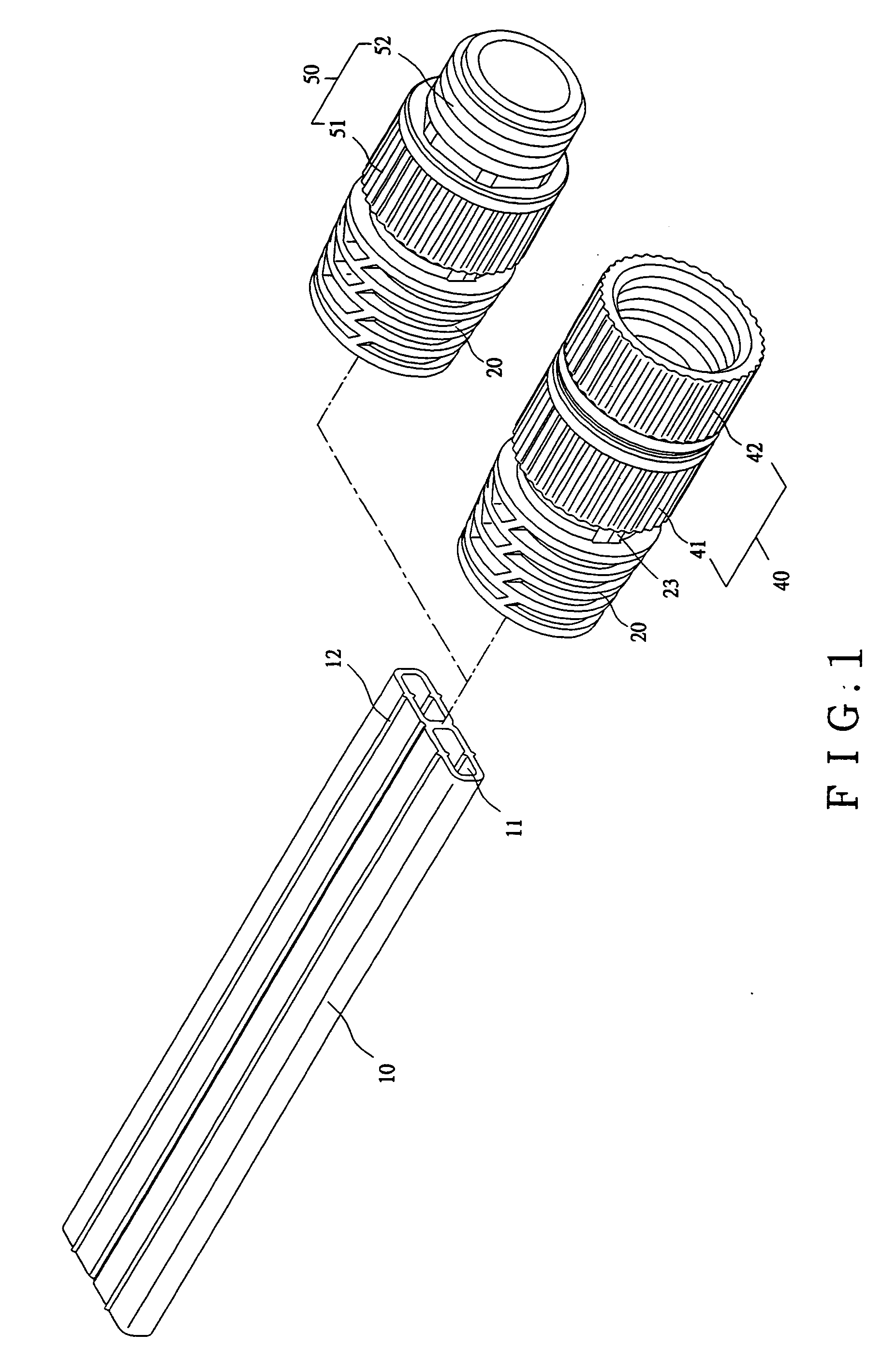

Combination of hose and hose connector

Owner:CHUAN YI PLASTIC

Composite conical sleeve

ActiveUS20190040989A1Improve performance reliabilityPipe elementsCorrosion preventionEngineeringMechanical engineering

A device for repairing pipelines comprises a sleeve adhered to a pipeline, said sleeve being made of a cured composite material in the form of a truncated cone with a cylindrical passage passing along an axis, the diameter of the passage being equal to the outer diameter of the pipeline being repaired, and a side wall, the inner surface of the side wall corresponding to the outer surface of the sleeve, wherein the side wall is made of a cured composite material. The invention provides improvement of performance reliability of the repaired pipeline.

Owner:VINOKUROV VALERIY IVANOVICH +2

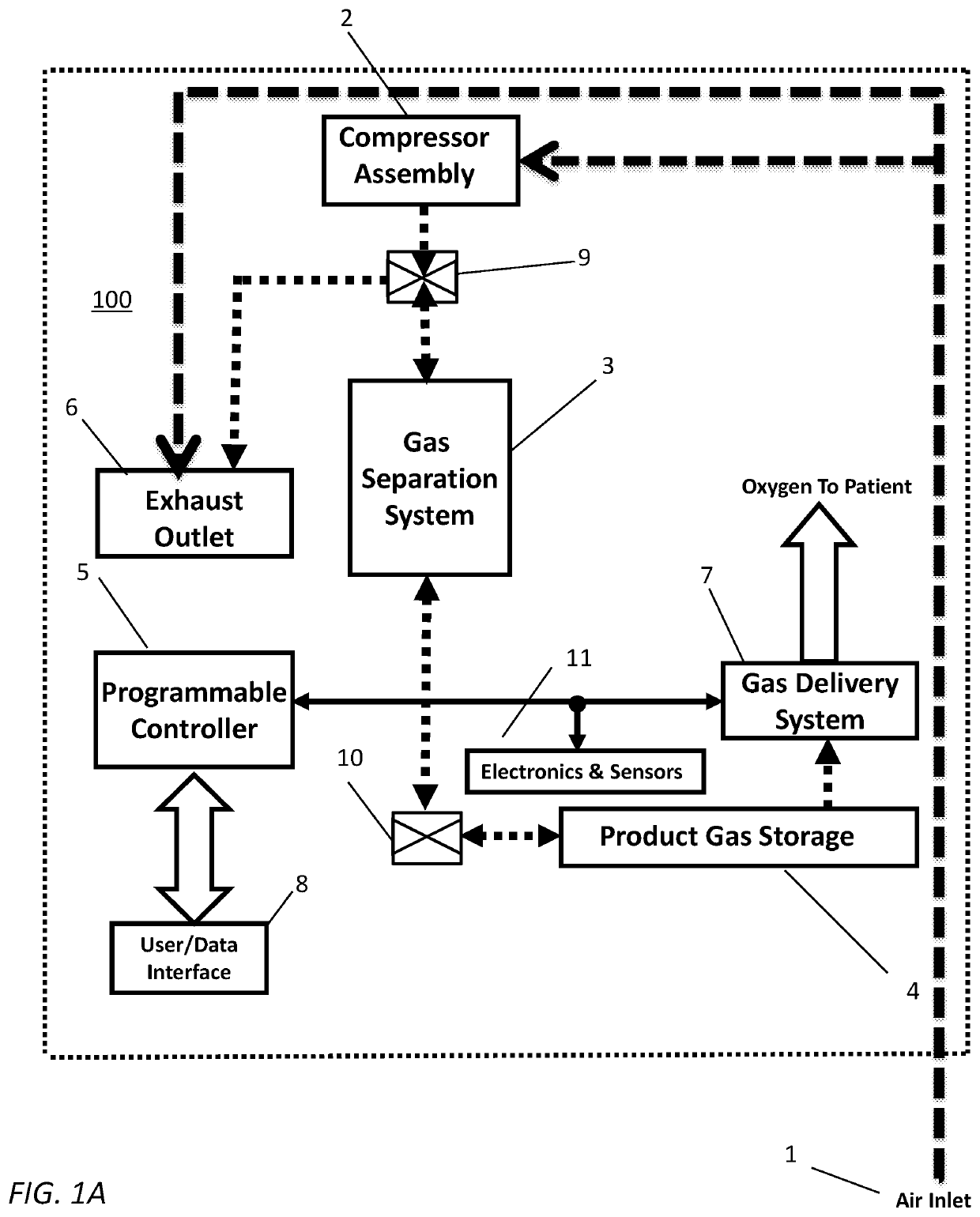

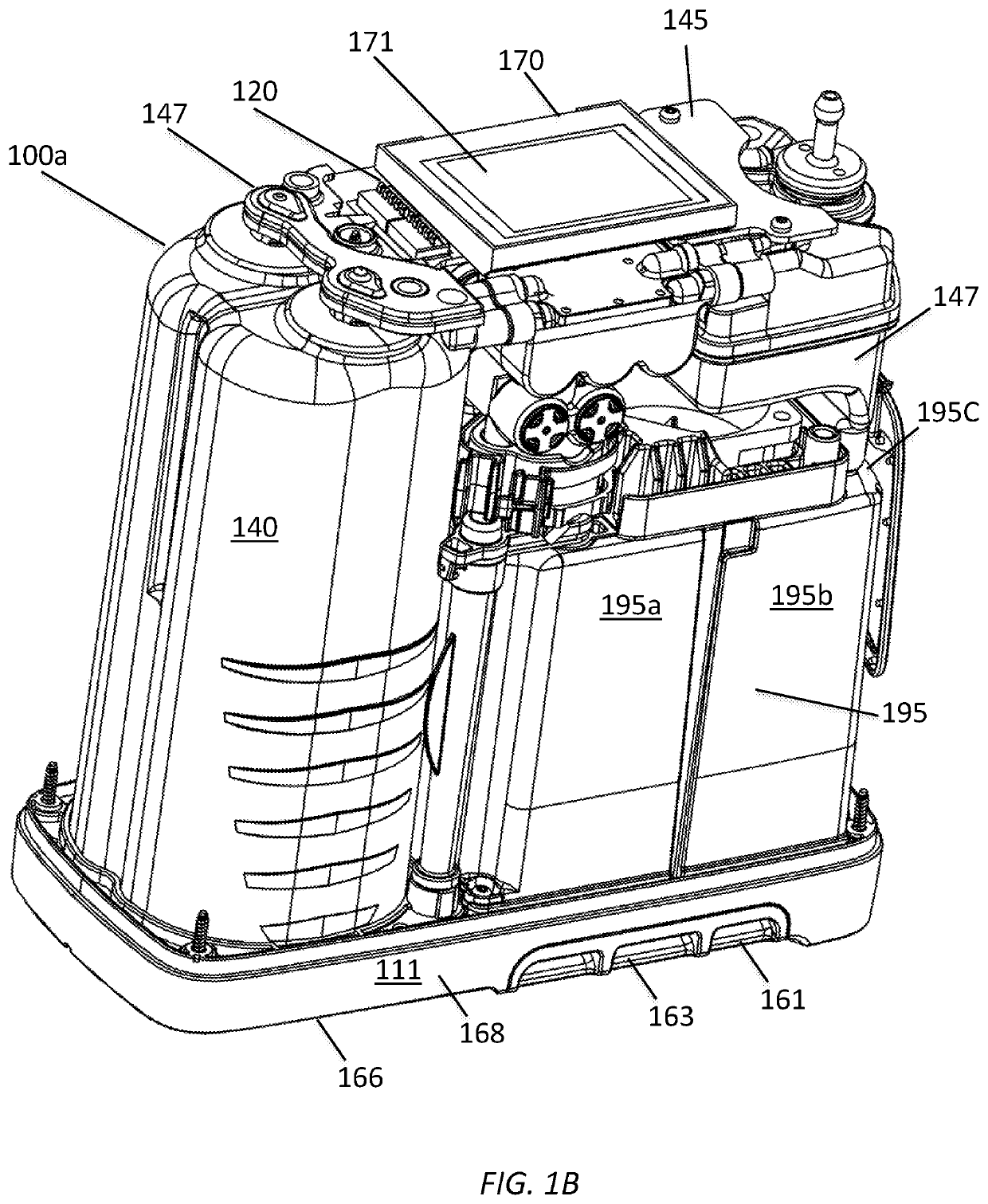

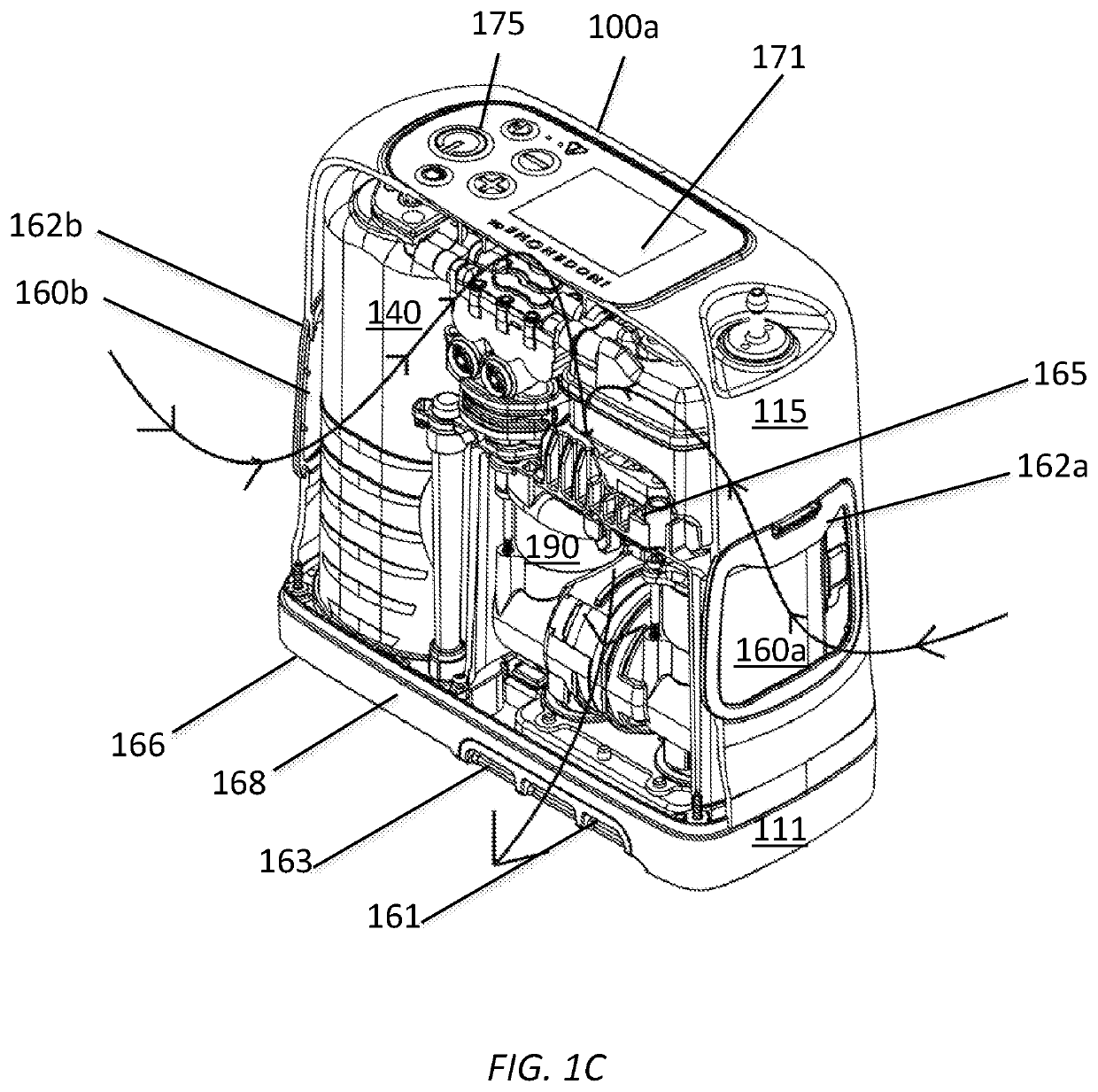

Compact portable oxygen concentrator

ActiveUS20200309115A1Improve efficiencyReduce switching lossesMedical devicesPipe elementsPhysicsMotor efficiency

Owner:INOGEN INC

Pipeline connection mechanism used for chemical waste water transportation and capable of preventing leakage

Owner:温州普奈机械科技有限公司

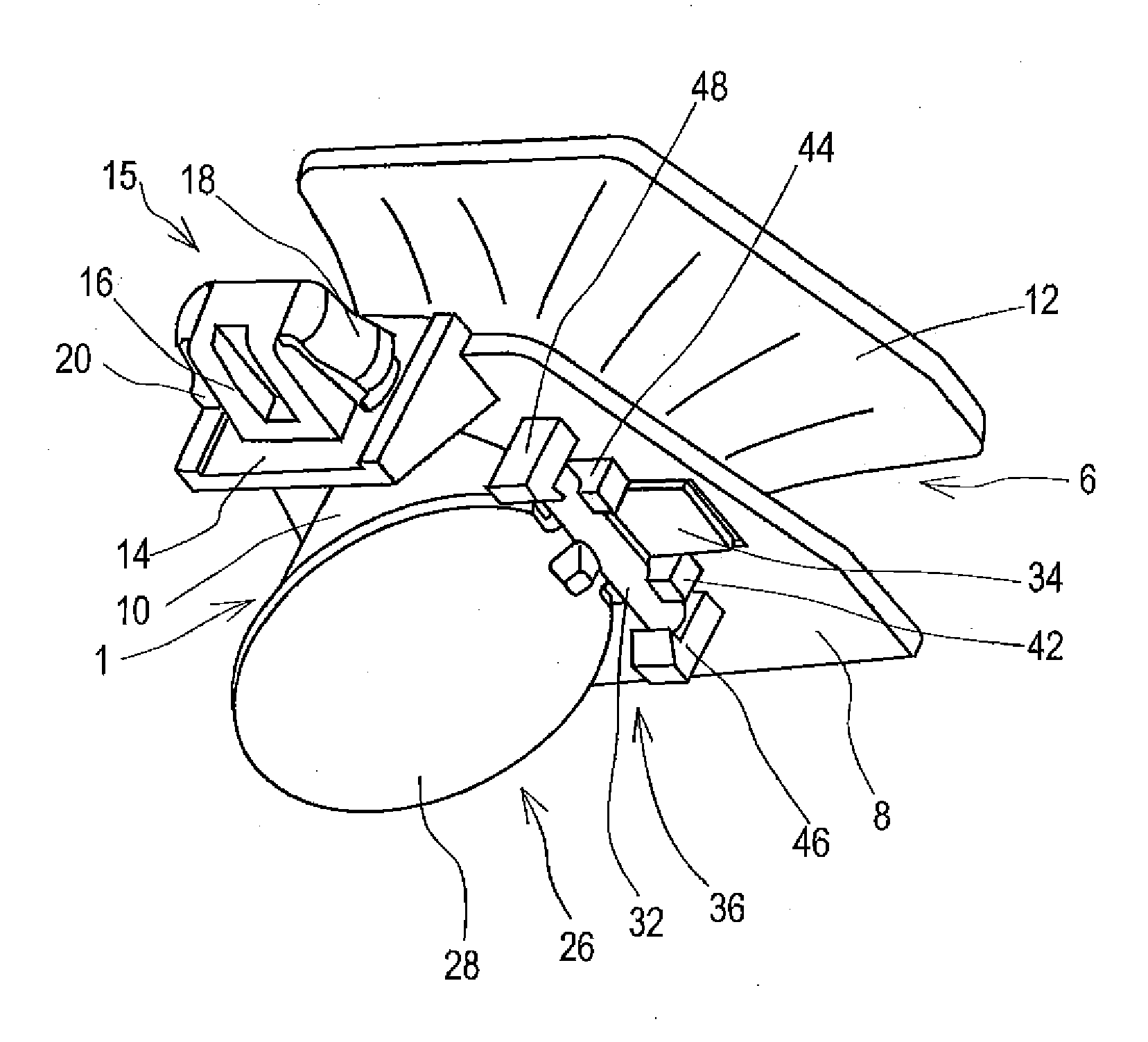

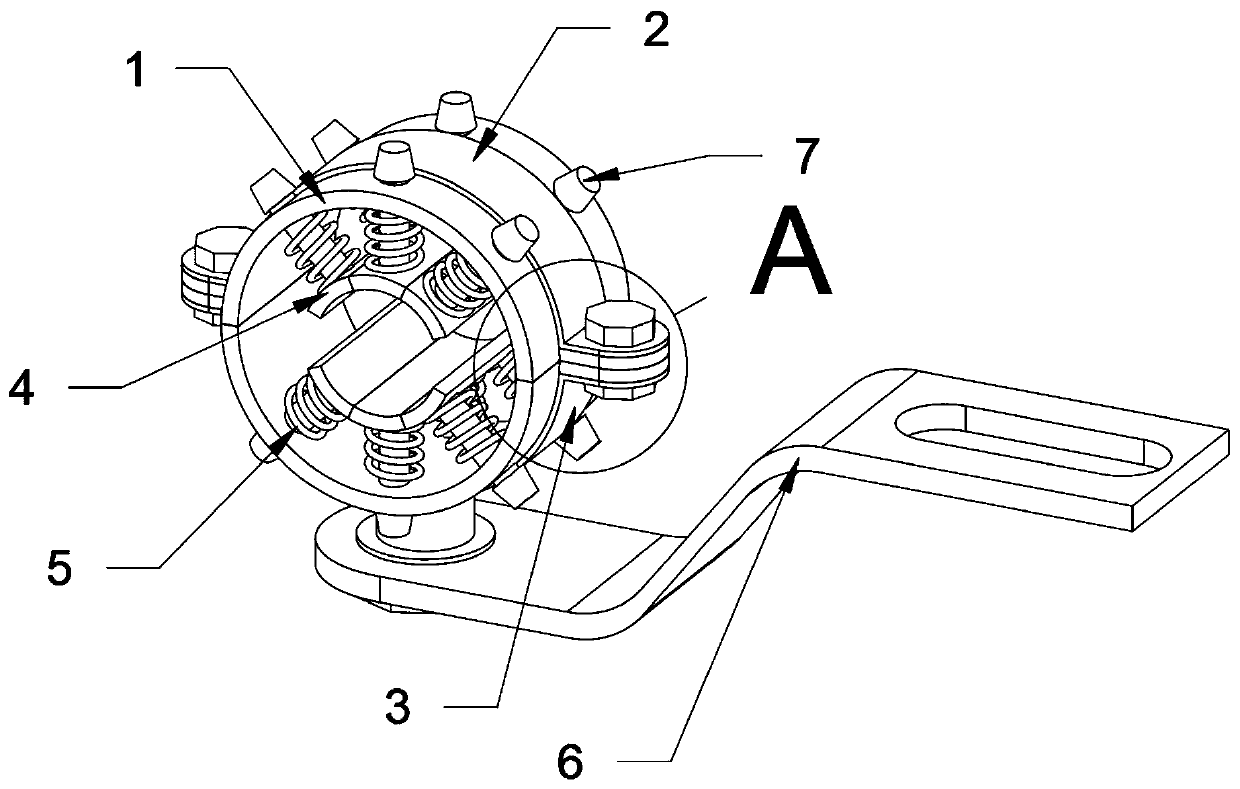

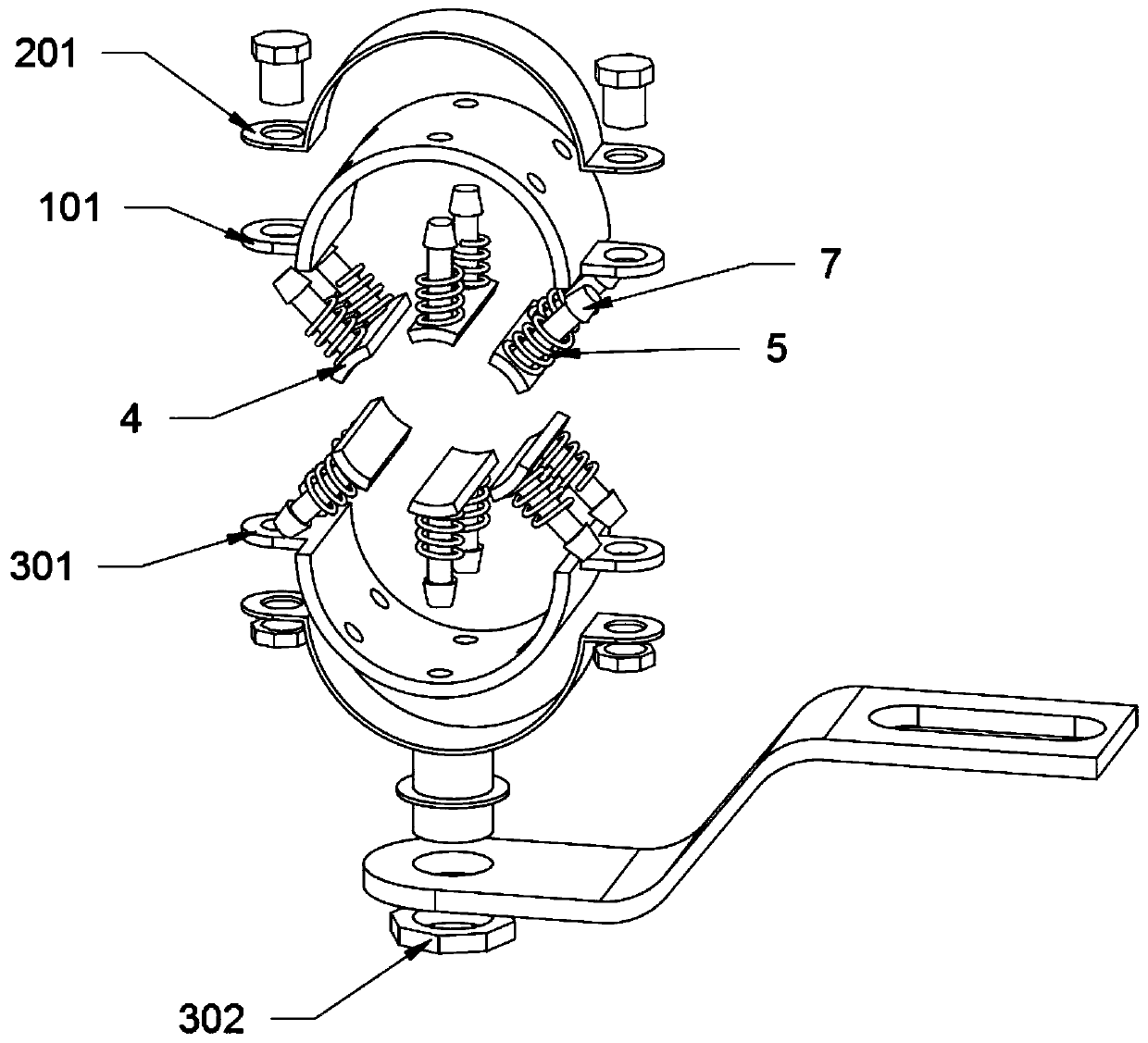

Leaking stoppage pipe clamp device and locking device for leaking stoppage pipe clamp

ActiveCN110541994AHigh degree of automationImprove installation efficiencyPipe elementsEngineeringAutomation

The invention relates to a leaking stoppage pipe clamp device and a locking device for a leaking stoppage pipe clamp. The locking device comprises at least one locking unit. The locking units are arranged on an opening in one side or openings in two opposite sides of the leaking stoppage pipe clamp. Each locking unit comprises a first locking module and a second locking module which are arranged in a spaced manner and can move in the opposite direction. Each first locking module comprises a first clamping groove. Each second locking module comprises a second clamping groove. Each second clamping groove and the corresponding first clamping groove cooperate mutually to be arranged on the leaking stoppage pipe clamp in a clamped manner. A first locking and connecting part arranged in a wedgeshape is arranged on at least one side wall, arranged in the moving direction, of each first clamping groove. A second locking and connecting part arranged in a wedge shape and arranged in the direction opposite to the corresponding first locking and connecting part is arranged on at least one side wall, arranged in the moving direction, of each second clamping groove. The first locking and connecting parts and the second locking and connecting parts cooperate with the leaking stoppage pipe clamp for locking. The locking device has the advantages of being high in automation degree, simple in structure, easy to operate, high in installing efficiency and high in success possibility.

Owner:SHENZHEN OFFSHORE OIL ENG UNDERWATER TECH CO LTD

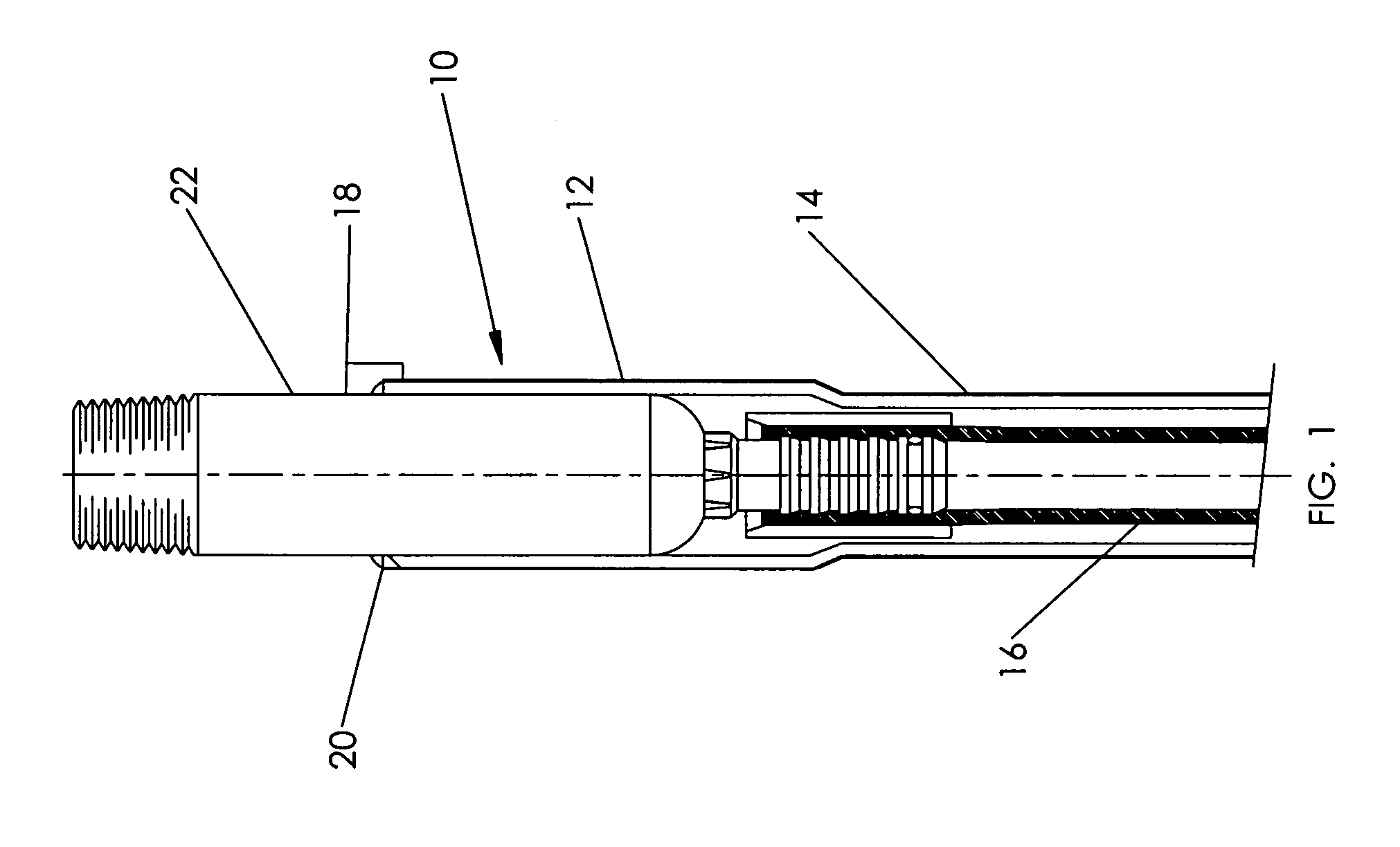

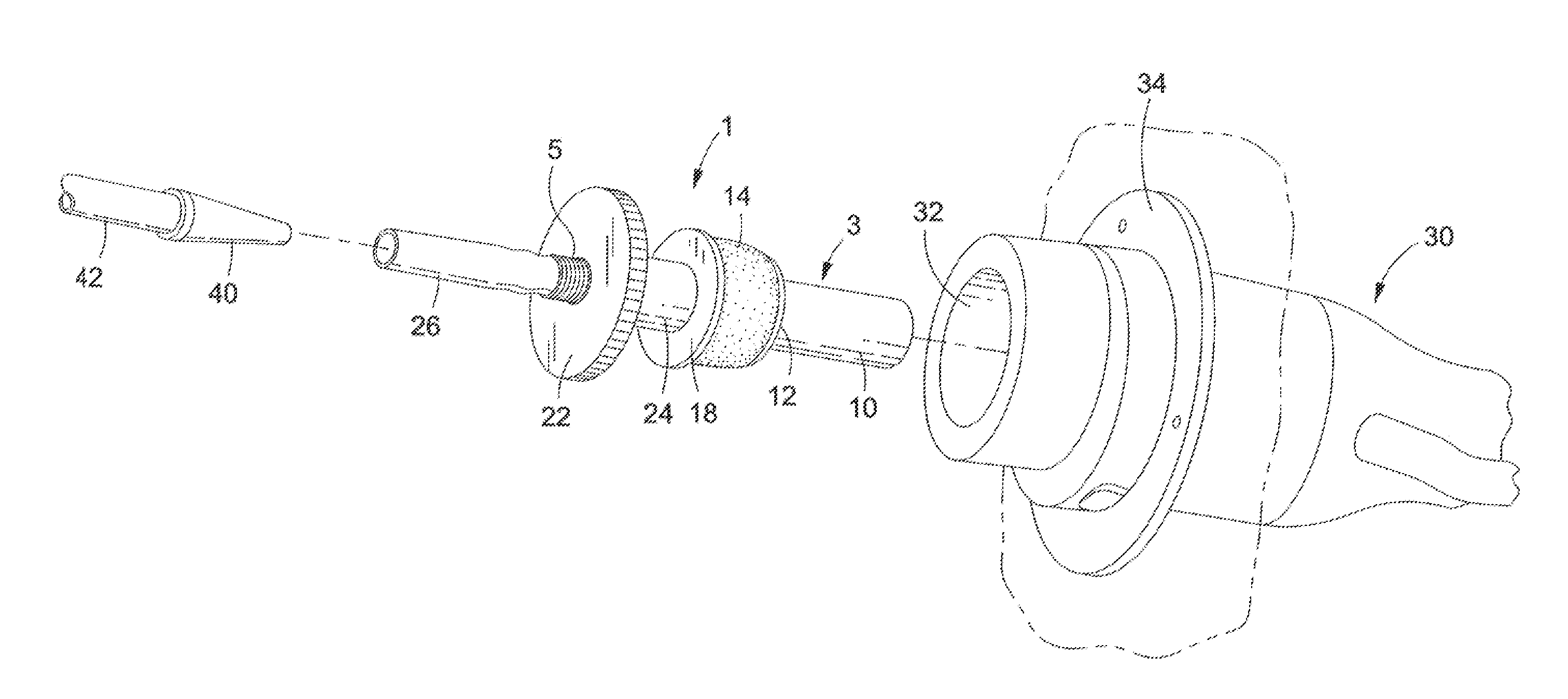

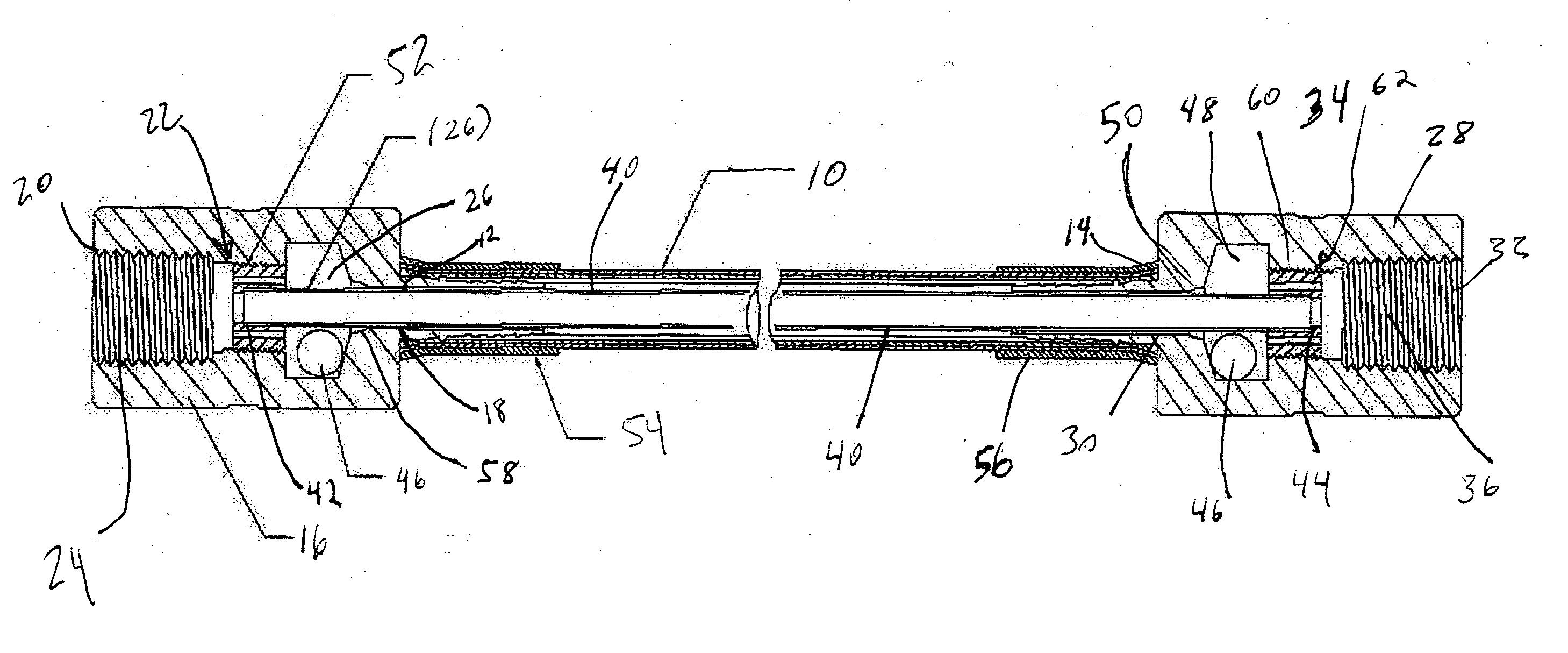

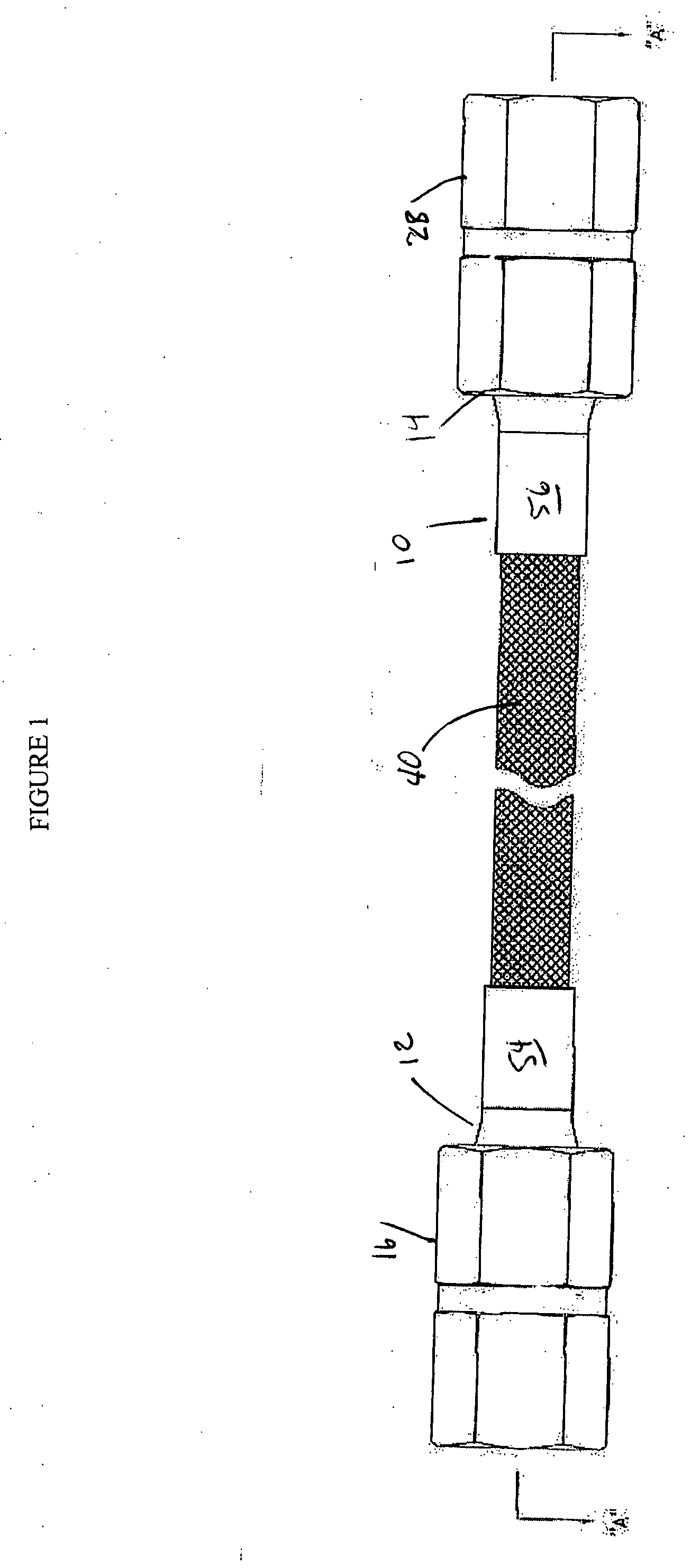

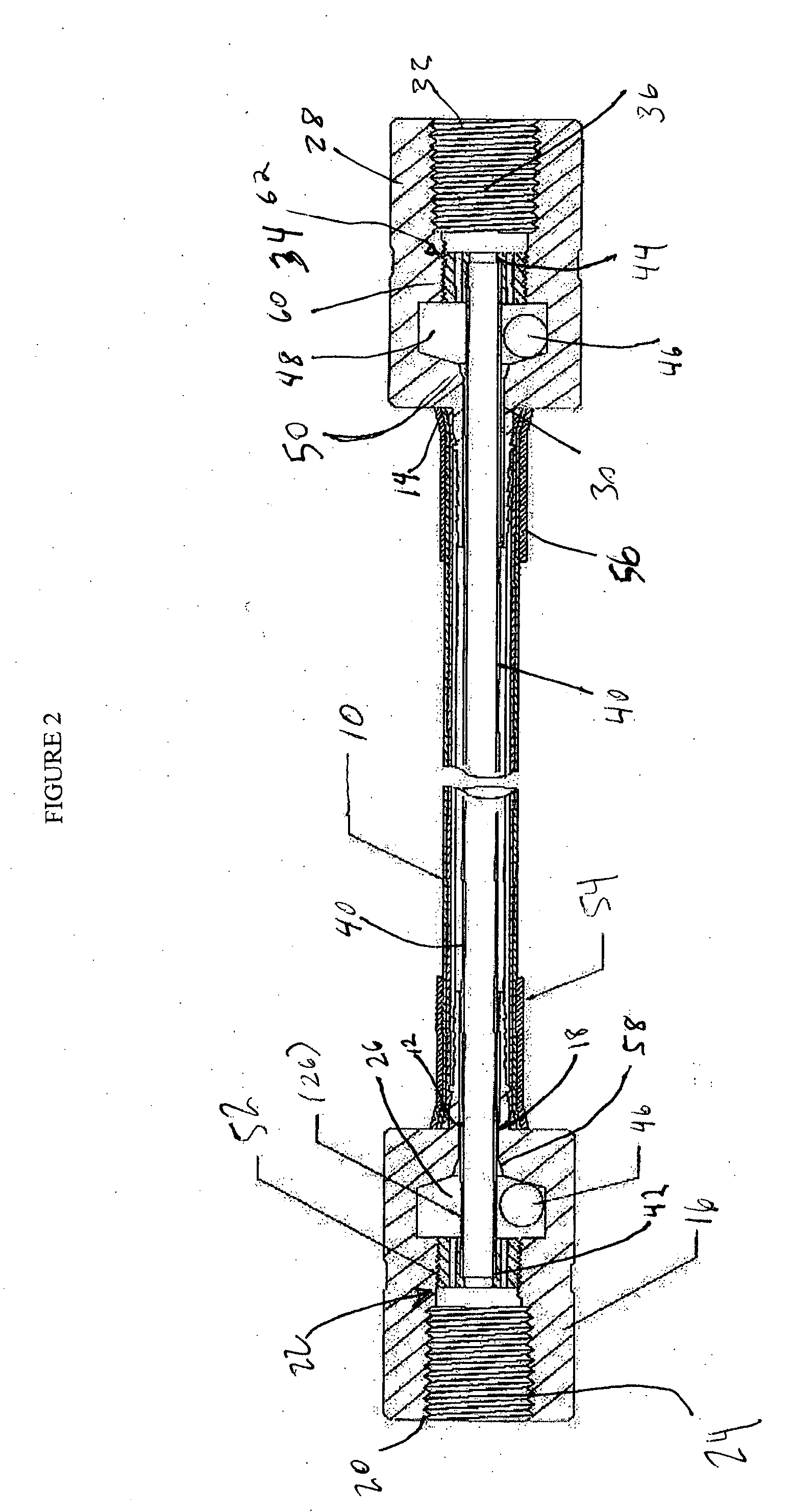

Safety system hose

A safety system for a fluid conduit having: a hose; a first housing connected to the hose with an internal cavity having a first connection point and a first check ball opening cavity; a second housing connected to the hose with an internal cavity having a second connection point and a second check ball opening cavity; a perforated retention tube positioned longitudinally within the hose and in communication with the first connection point and the second connection point; a first check device contained within the first check ball opening cavity and interposed between the perforated retention tube and the first check ball opening cavity; and a second check device contained within the second check ball opening cavity and interposed between the perforated retention tube and the second check ball opening cavity.

Owner:GOLDSTEIN JEFFREY

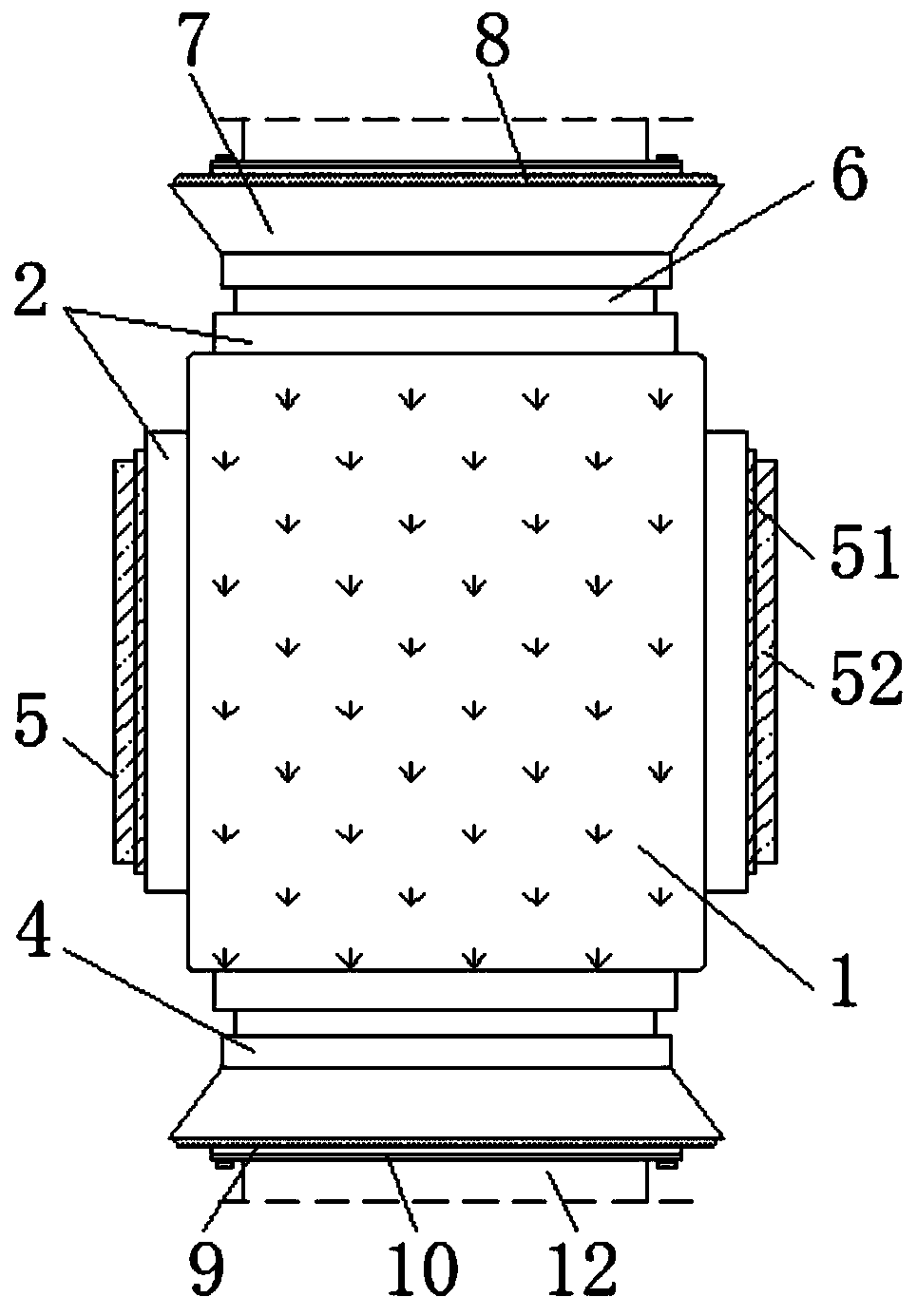

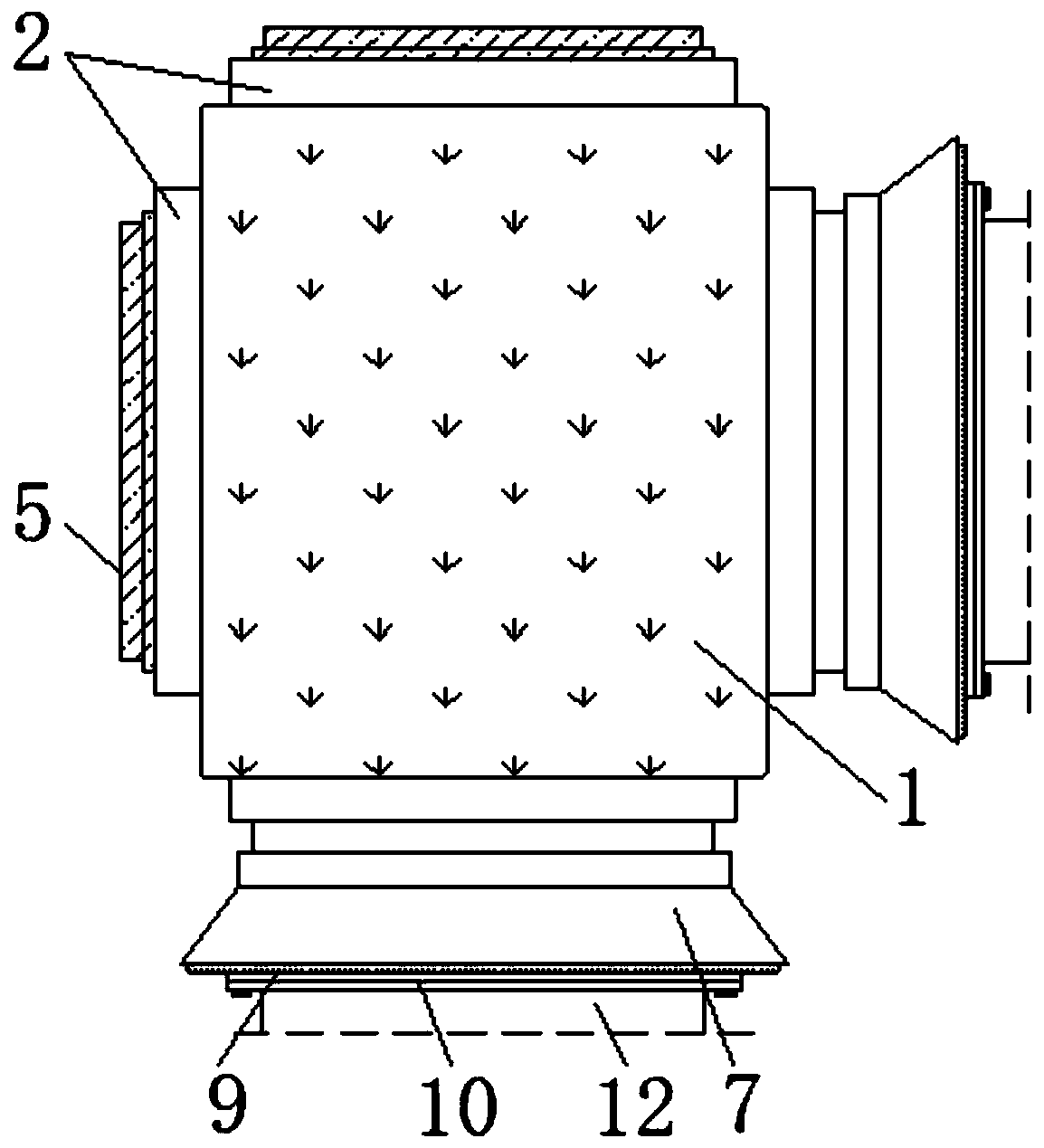

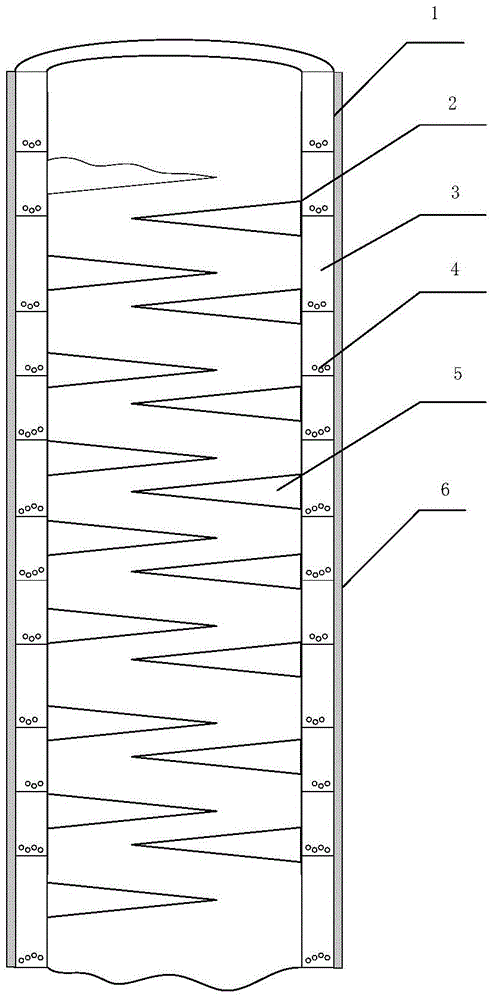

Rainwater flow guiding pipe with inner wall noise elimination function

The invention discloses a rainwater flow guiding pipe with the inner wall noise elimination function. The portion between two layers of pipe walls is divided into a plurality of small closed spaces. Noise generated when the pipe walls are washed by rainwater can be preliminarily blocked; in addition, the small spaces are filled with energy absorption balls; when sound is transmitted into the small spaces, energy of sound wave vibration is absorbed, and noise is further eliminated; fang-type staggered protrusions are arranged on the inner side of the inner pipe wall in the radial direction. After downward rainwater wash is performed, rainwater flows along a convolution-shaped path formed by the staggered protrusions, the rainwater wash speed is greatly decreased, the pipe wall impacting sound is greatly lowered, and the effect of eliminating noise is achieved; the upper surfaces of the protrusions are provided with wave-shaped protrusions, during rainwater washing, the water flow speed can be further decreased, the outer side of the outer pipe wall is coated with noise elimination cotton, and the effect of eliminating noise is further achieved.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Method for pipe coupling encapsulation

A method for pipe coupling encapsulation includes placing two elastomeric partial rings around pipes on opposite sides of a leaking joint coupling, taking a repair coupling, which includes a band and opposing clamp members extending outwards from ends of the band, and placing the band around the leaking joint coupling such that opposite end portions of the band overlie the elastomeric partial rings, and tightening the opposing clamp members towards each other with one or more tightening elements.

Owner:KRAUSZ IND

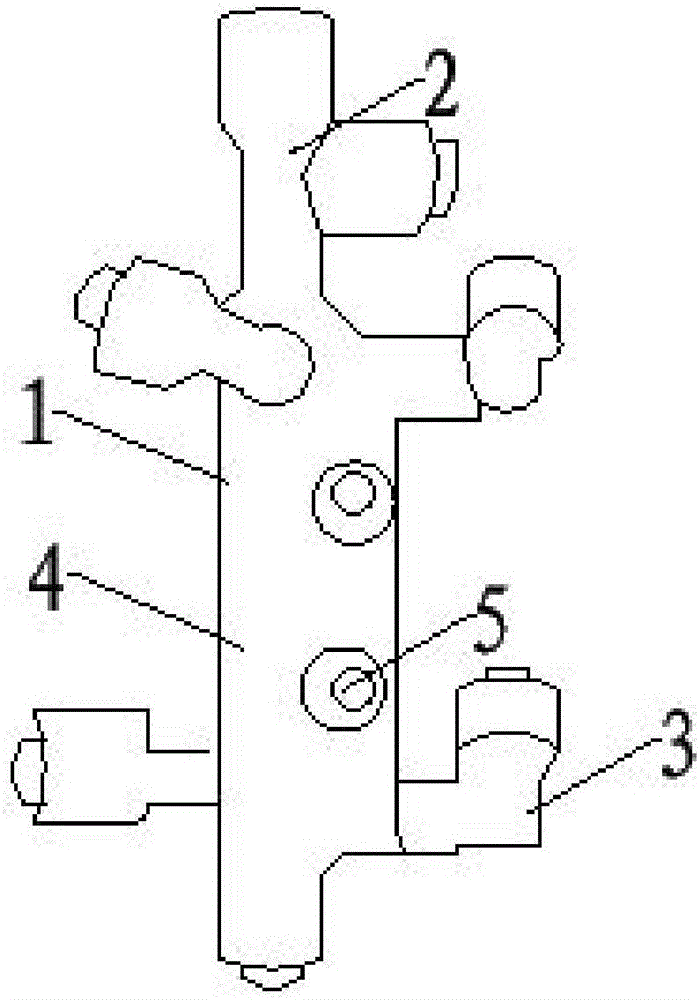

Multipurpose vehicle pipe set quick insertion joint

InactiveCN106439340AEasy connectionImprove sealing connection performancePipe elementsBranching pipesCarbon steelEngineering

The invention discloses a multipurpose vehicle pipe set quick insertion joint. The multipurpose vehicle pipe set quick insertion joint comprises a pipe set assembly; the top end of the pipe set assembly is rotationally connected with an eccentric three-way joint; bend passing joints are uniformly spaced on a main body of the pipe set assembly; the pipe set assembly includes a nylon pipe; valve bodies are uniformly drilled in a pipe body of the nylon pipe; the eccentric three-way joint and the bend passing joints consist of nut assemblies and plug assemblies; the nut assemblies include nut bases; standard threads are carved at the bottom ends of the nut bases; a rubber dustproof ring is sleeved below a nut cap at the top end; the plug assemblies include carbon steel plugs; plastic clamping rings coat grooves at the tail ends of the carbon steel plugs; the tail ends of the carbon steel plugs are coated with rubber gaskets; the plug assemblies penetrate out from the nut bases; and the nut assemblies and the valve bodies are spirally connected to form an integral structure. The multipurpose vehicle pipe set quick insertion joint can quickly realize the vehicle route connection, can satisfy various connecting demands, and is convenient and fast.

Owner:十堰派尔汽车管业有限公司

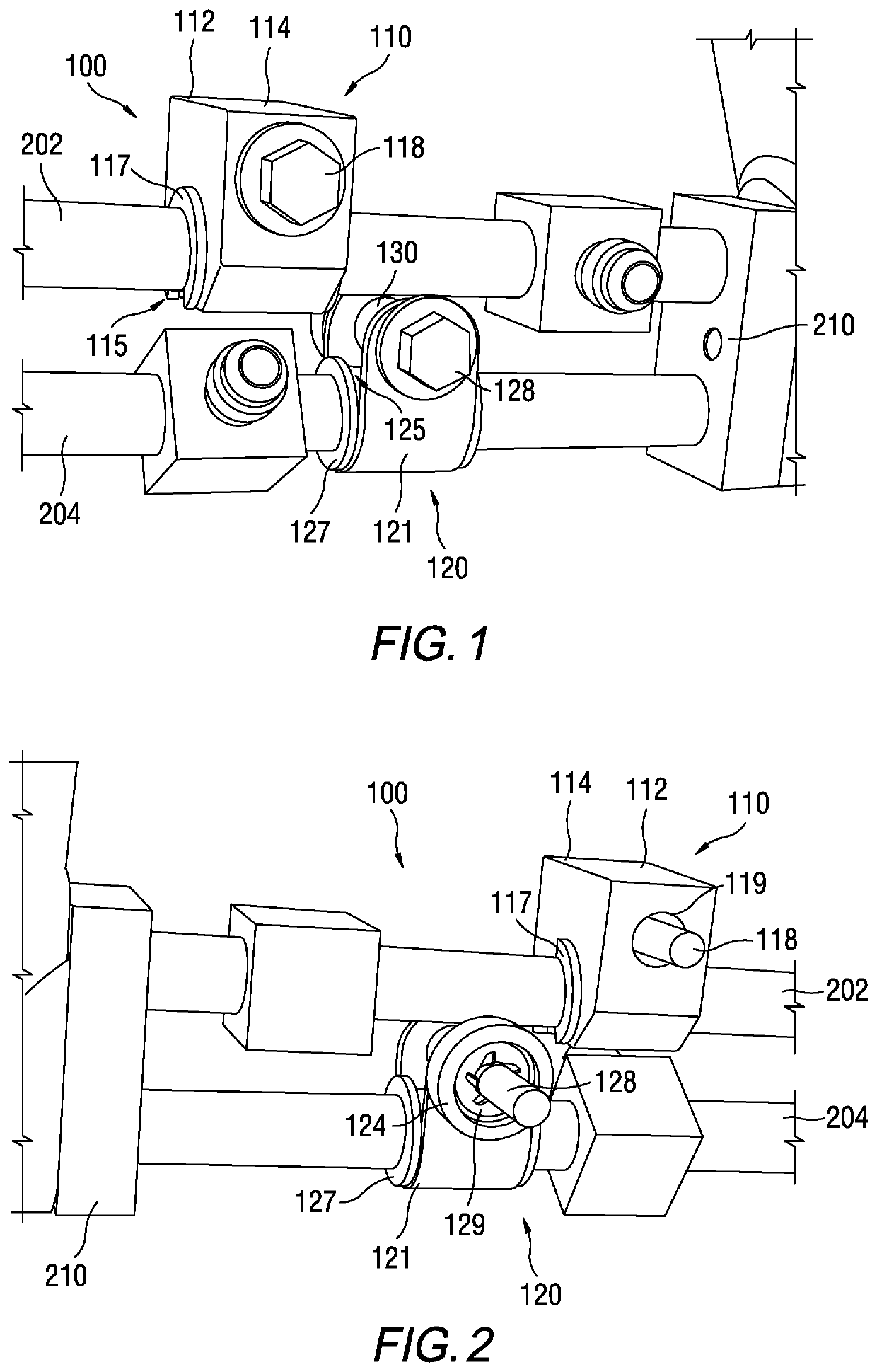

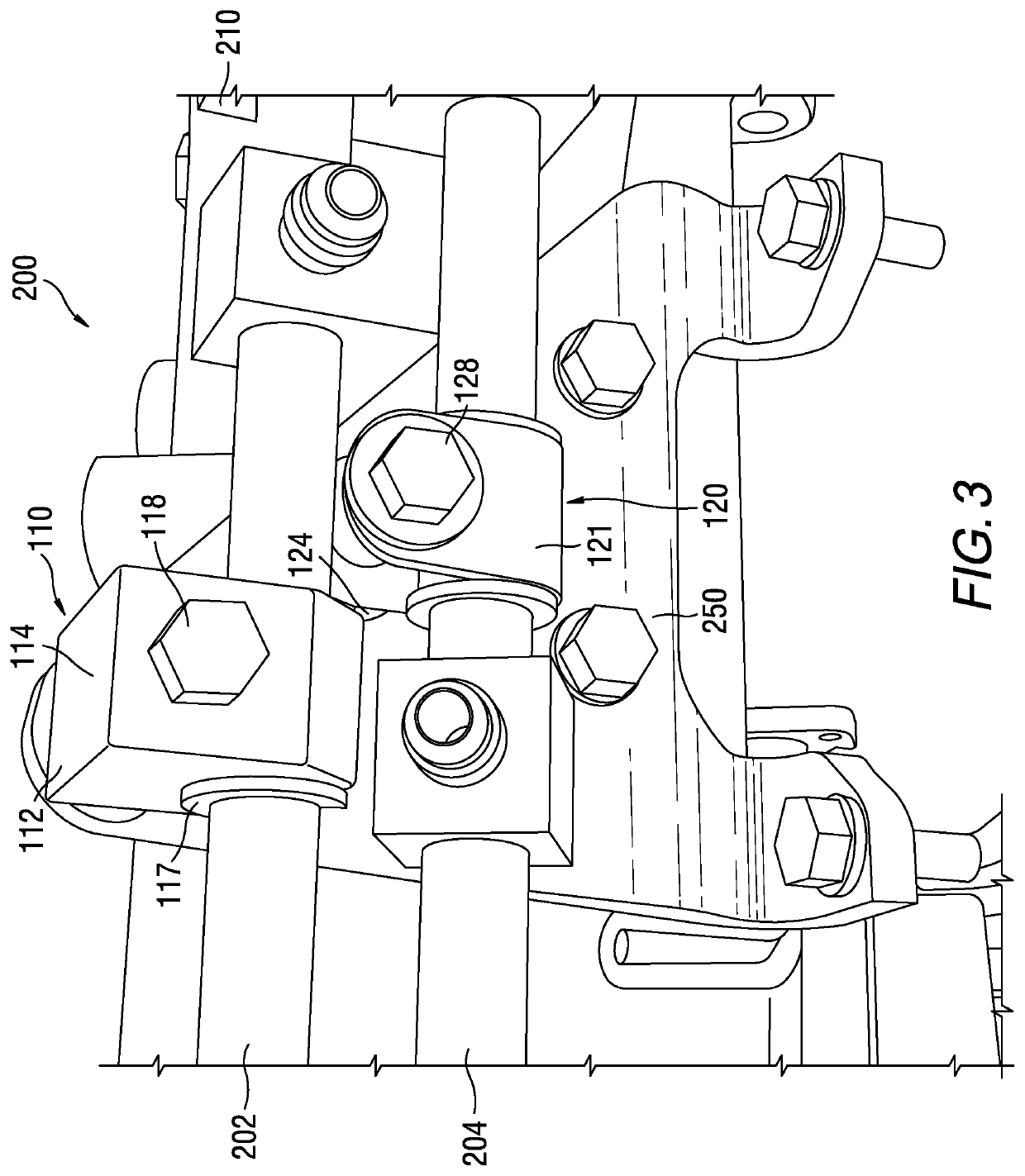

Clamping assembly for a pair of fuel lines and components, systems, and methods thereof

Owner:CATERPILLAR INC

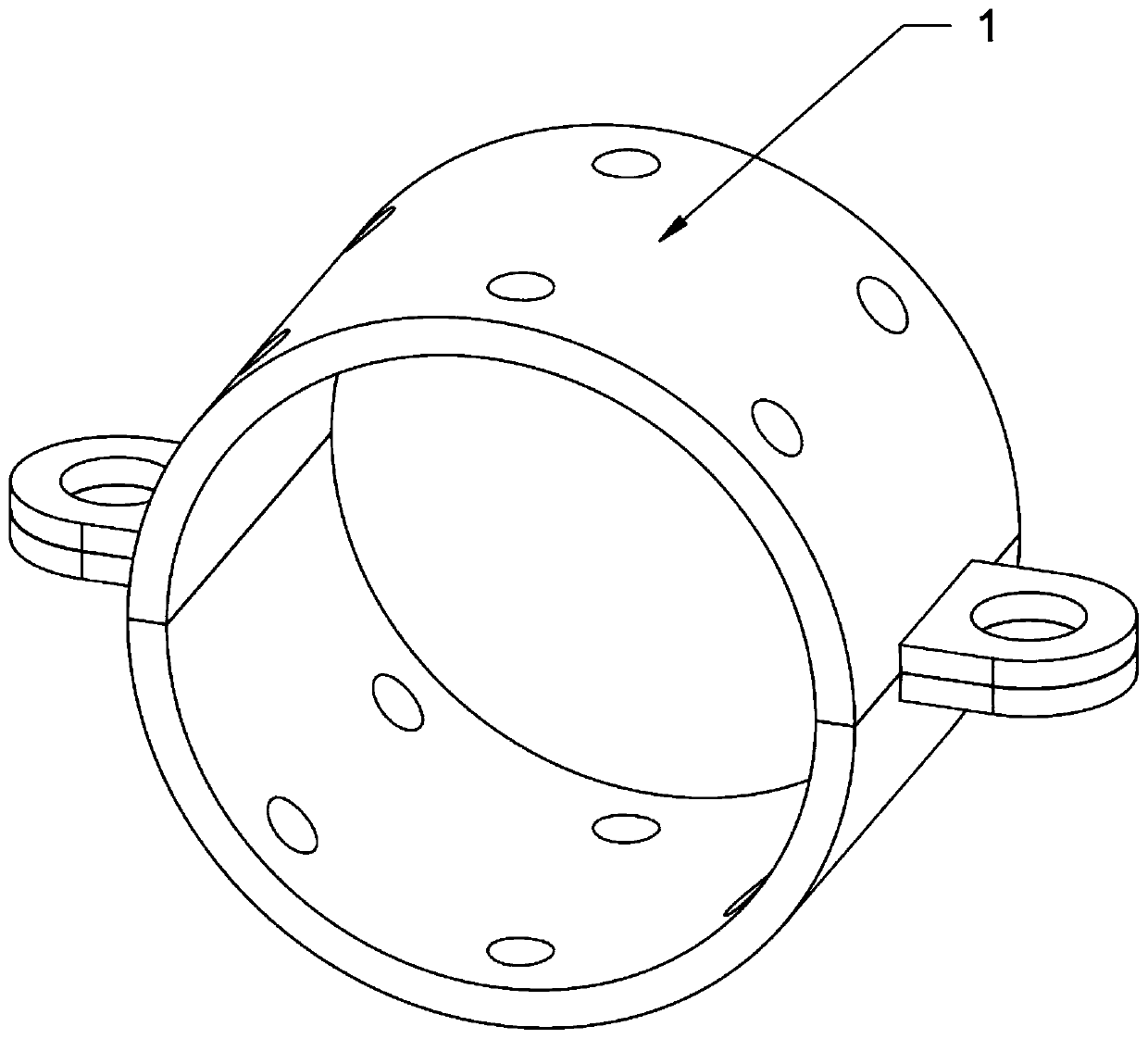

Underground pipeline anti-seepage structure and mounting method thereof

ActiveCN114458860ASlow down the leak rateReduce lossesLiquid surface applicatorsPipe elementsLine tubingAdhesive glue

The invention relates to an underground pipeline anti-seepage structure and a mounting method thereof, and belongs to the technical field of underground pipeline construction, the underground pipeline anti-seepage structure comprises a mounting ring used for sleeving the joint of adjacent pipelines, a mounting groove is formed in the surface, facing the pipelines, of the mounting ring, the head and the tail of the mounting groove are connected to form a ring, and an abutting pad is slidably arranged in the mounting groove; the abutting pad slides in the annular direction of the mounting groove, and a first driving piece used for driving the abutting pad to slide is arranged in the mounting groove; the abutting pad slides in the direction parallel to the diameter of the pipeline, and the second driving piece is used for driving the abutting pad to slide and abut against the damaged position of pipeline connection; a drainage hole is formed in the mounting ring, and a first conveying pump for pumping conveyed materials in the mounting groove to be discharged through the drainage hole is arranged on the mounting ring; a glue storage box is arranged in the mounting groove, glue used for adhering the abutting pad to the damaged position of pipeline connection is stored in the glue storage box, and the device further comprises a gluing device used for smearing the glue to enable the abutting pad to be adhered to the damaged position. The conveying device has the effect of reducing the loss of conveyed objects.

Owner:CHENGDU KAWAGOE FIRE ENG CO LTD

Pipeline opening sealing and storing device for pre-buried pipeline

PendingCN114811255ANot easy to blockEasy to assemble and disassemblePipe elementsWater-power plantsComputer hardwareEngineering

The invention relates to the technical field of embedded pipelines, in particular to a pipeline opening sealing device of an embedded pipeline, which comprises a plugging seat, a fixing mechanism and a coding mechanism, the fixing mechanism comprises a supporting assembly used for being matched with the inner wall of the pipeline in an abutting mode and a locking assembly used for fixing the supporting assembly. The encoding mechanism is arranged on the side, away from the fixing mechanism, of the plugging base and comprises a universal encoding disc used for displaying the pipeline model and an adjusting assembly used for adjusting encoding information of the universal encoding disc and controlling the locking assembly. By means of the pipeline opening sealing device of the embedded pipeline, impurities are not prone to entering the embedded pipeline to cause blocking before the embedded pipeline is used, and disassembly and assembly are very convenient; and meanwhile, the universal coding disc is arranged, so that workers can conveniently and visually know the model of the pre-buried pipeline, and follow-up operation is facilitated.

Owner:SICHUAN DATANG INT GANZI HYDROELECTRIC DEV CO LTD

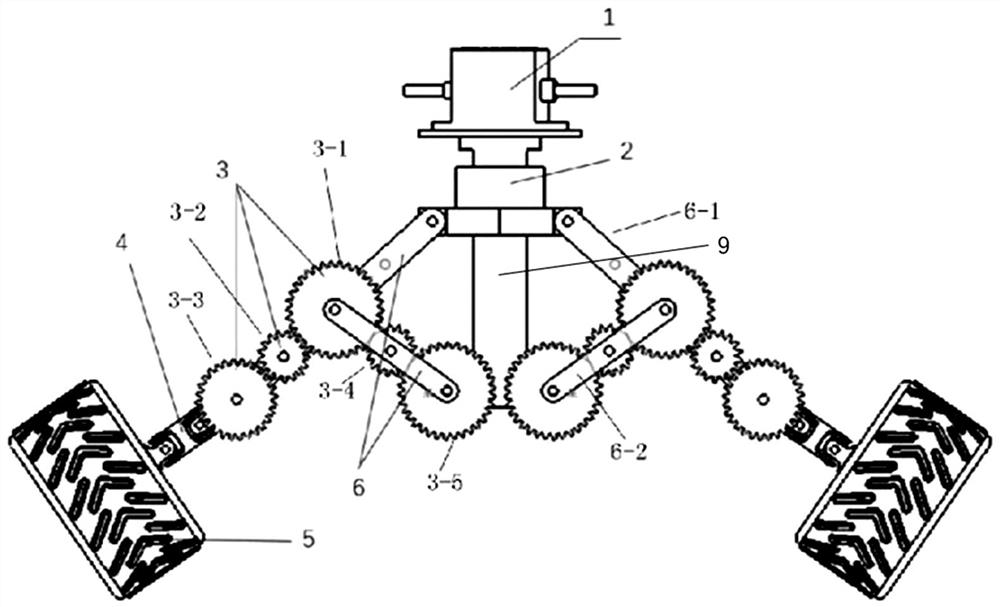

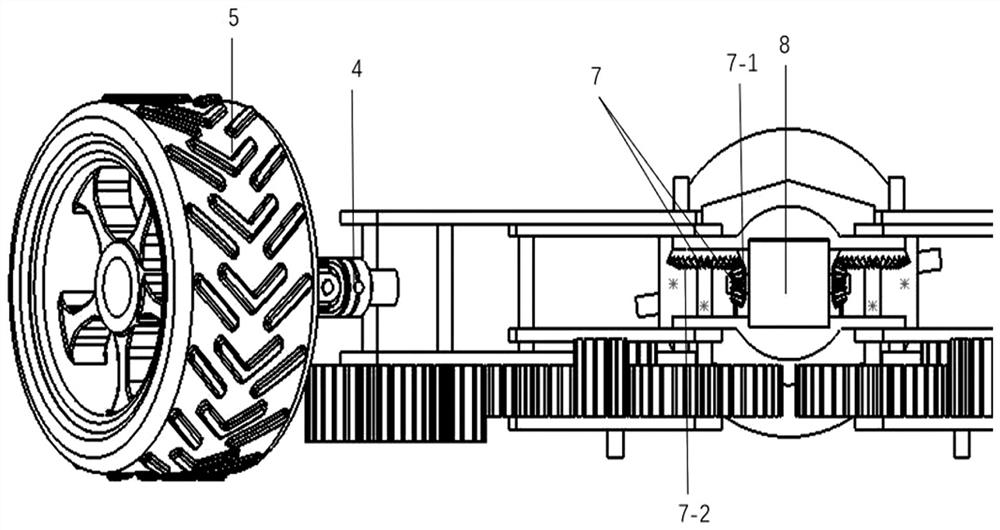

Pipeline robot with self-adaptive reducing mechanism

PendingCN113108157AQuick stop brakeImprove adaptabilityPipe elementsMechanical energy handlingGear wheelCoupling

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap