System and method for modular repair of pipe leaks

a modular and pipe technology, applied in the direction of pipes/joints/fittings, pipe elements, mechanical devices, etc., can solve the problems of pipeline shutdown, pipe leakage, deterioration and leakage along the pipe,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

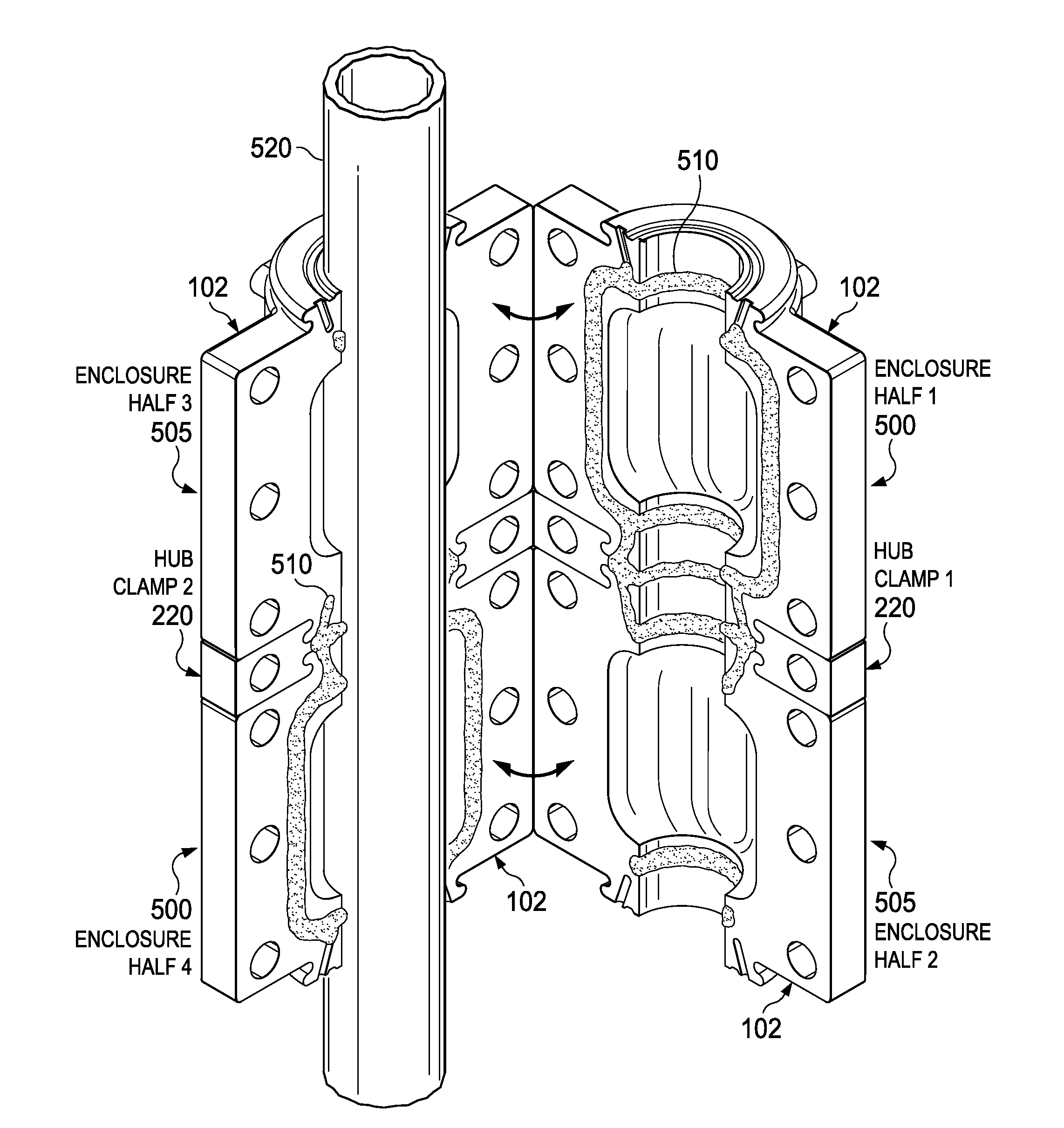

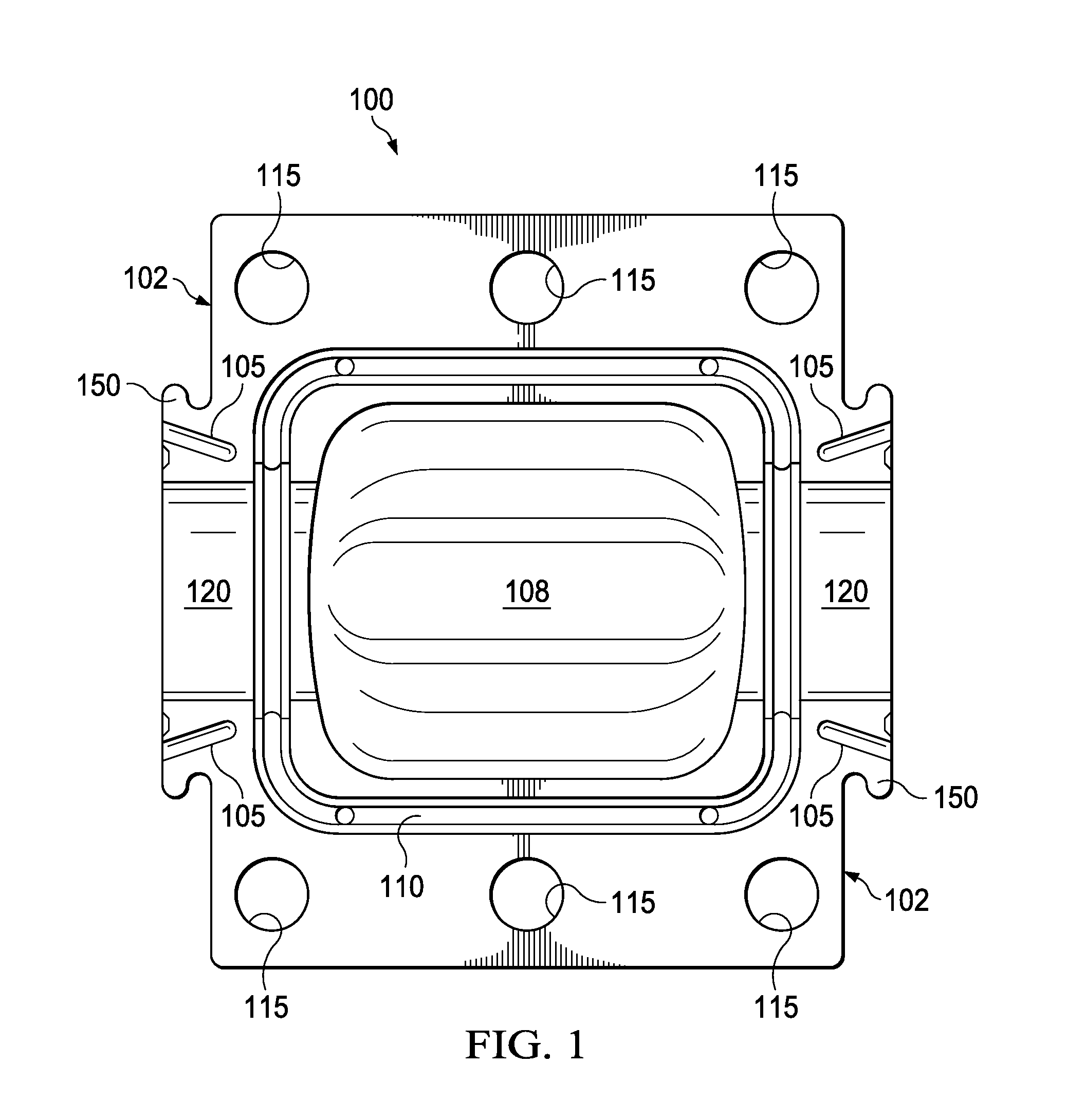

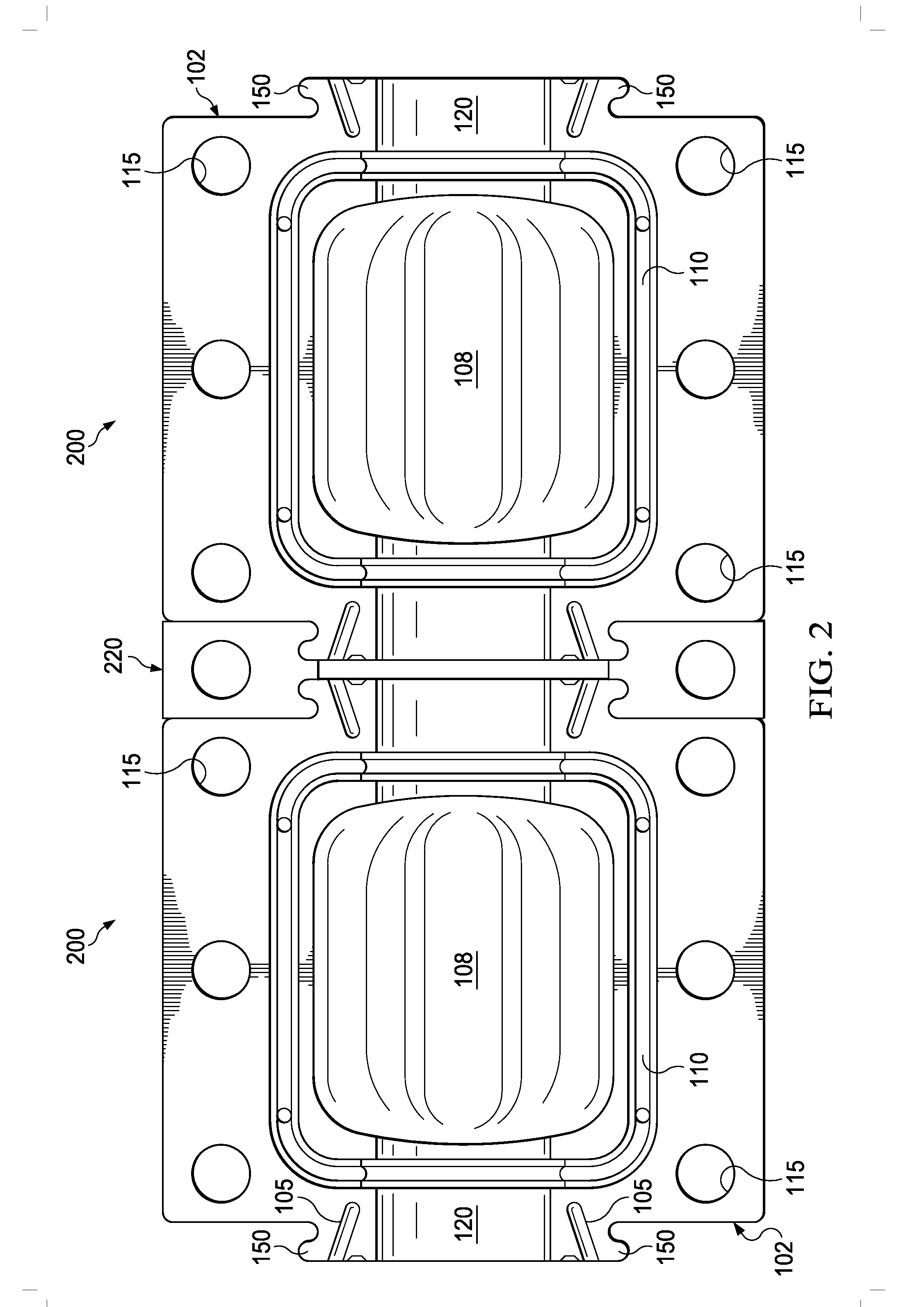

[0005]One or more of the problems outlined above may be solved by the various embodiments of the invention. Broadly speaking, the invention includes systems and methods for repair and sealing of leaks in pipelines under pressure. In one aspect, disclosed is a method for modular pipe repair, comprising: attaching two enclosure halves over a leak in a pipe to assemble a first repair enclosure; attaching enclosure attachment devices to the assembled repair enclosure, wherein each of the enclosure attachment devices is fastener such as a clamping bolt or clamping stud; determining if another repair enclosure is needed for another leak in the pipe, wherein if another repair enclosure is needed: drilling in the first repair enclosure a drill hole passage in each of selected ones of a plurality of angled grooves to connect to a primary groove in the enclosure; attaching a second repair enclosure to pipe; attaching enclosure attachment devices to the assembled second repair enclosure, wherein

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap