Active sound eliminator for ventilation pipeline system

A ventilation pipeline and muffler technology, which is applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as poor low-frequency effects, and achieve low pressure loss, high air velocity, and low-frequency noise reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described now in conjunction with accompanying drawing.

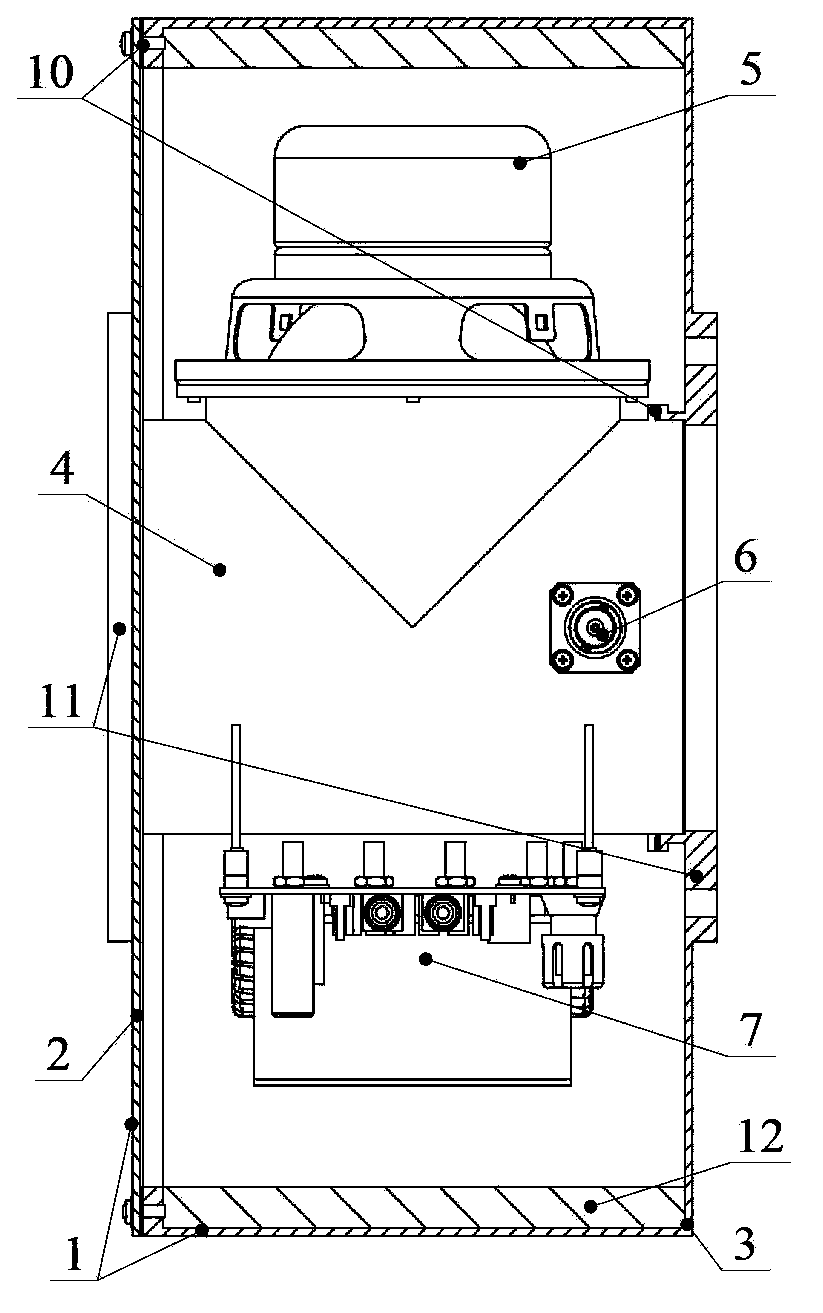

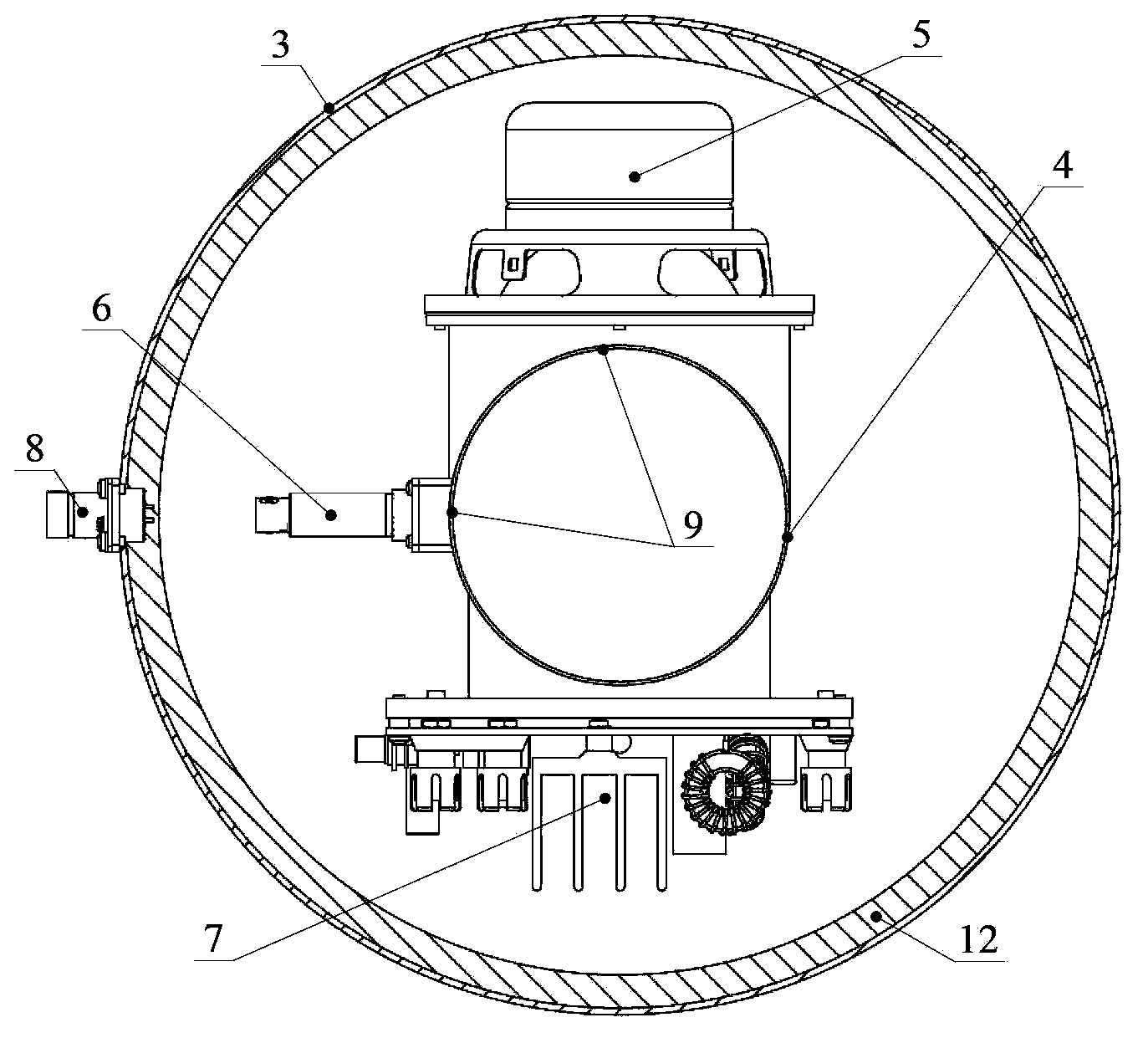

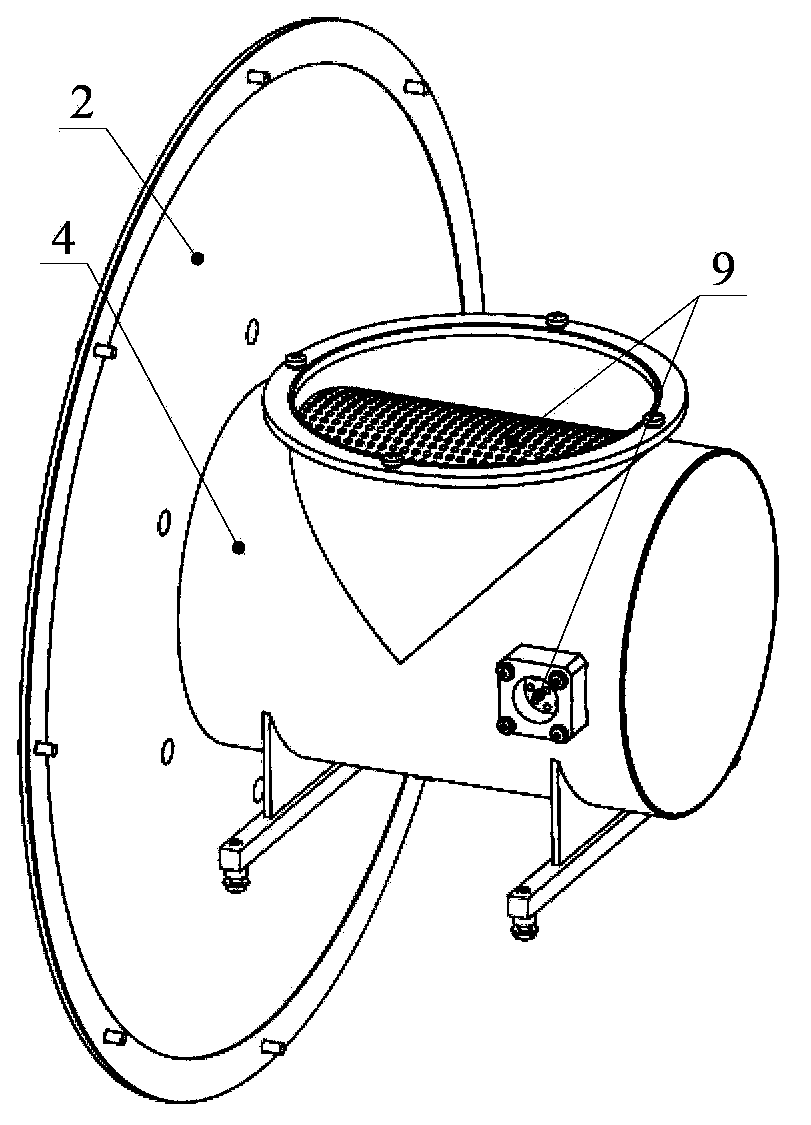

[0029] refer to figure 1 and figure 2 , the active muffler for the ventilation pipeline system provided by the present invention includes a shell 1, an inner pipe section 4, a speaker unit 5, an error microphone 6 and a speaker power amplifier board 7; wherein, the shell 1 includes a cover 2 and a shell body 3; the cover 2 is a plate-shaped structure with a hole in the center, the housing 3 is a barrel-shaped structure with a hole in the center of the bottom, and one end of the inner pipe section 4 passes through the hole in the center of the cover 2 And fixed on the cover 2, the other end of the inner pipe section 4 is embedded in the hole at the center of the housing 3, the cover 2 is installed on the top of the housing 3; the inner pipe section Around 4, described loudspeaker unit 5, error microphone 6 and loudspeaker power amplifier board 7 are installed respectively, whe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap