Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "Steel tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

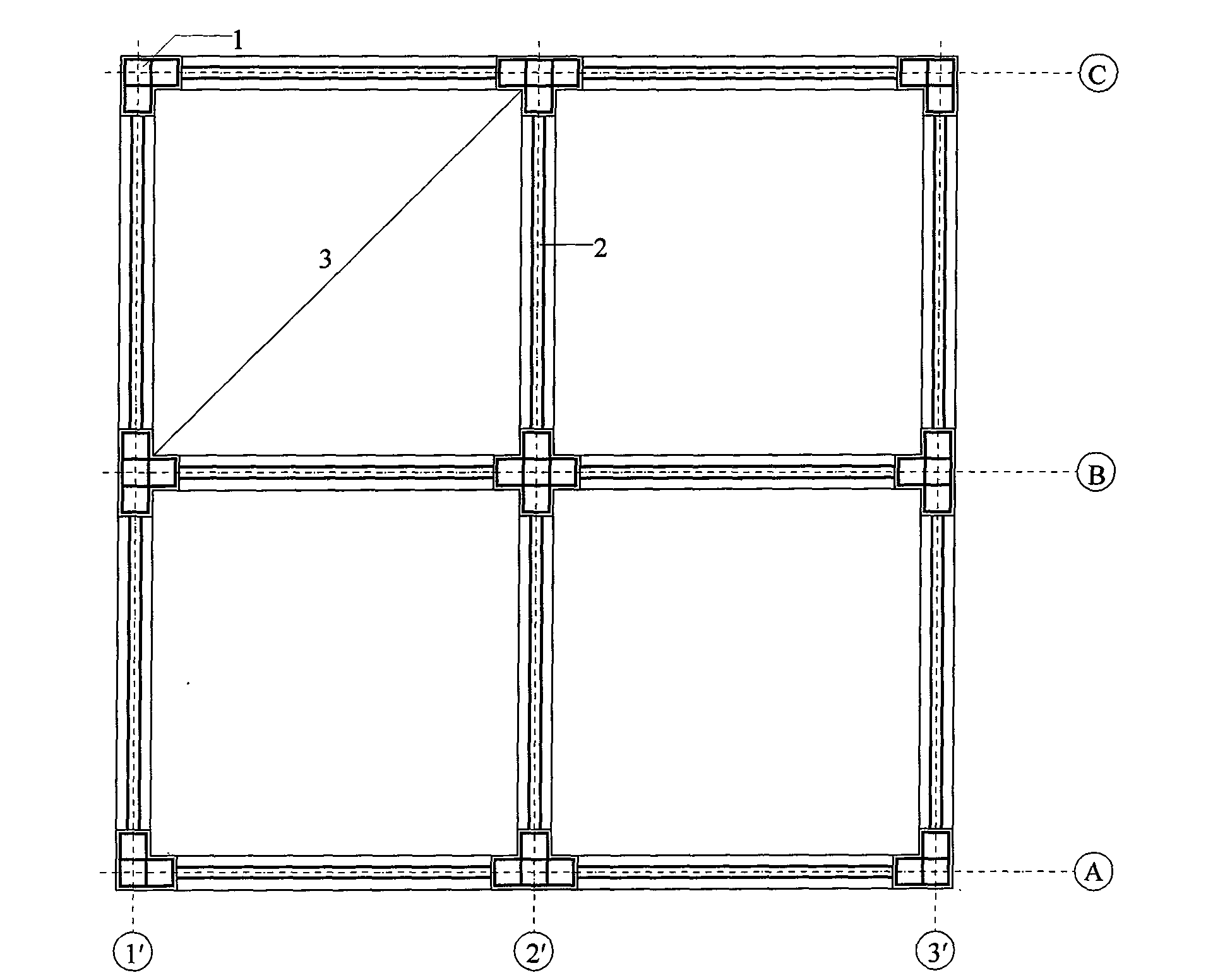

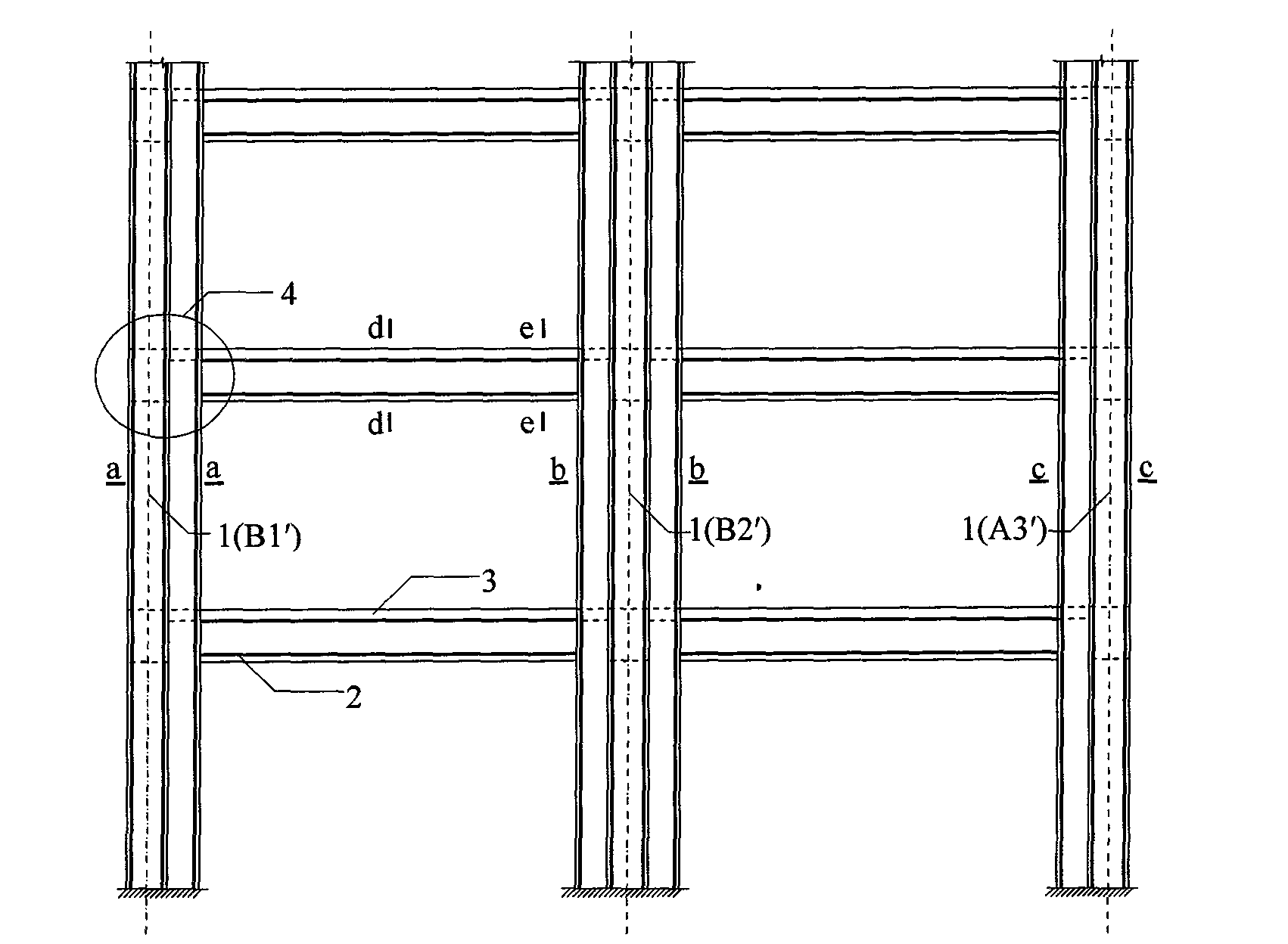

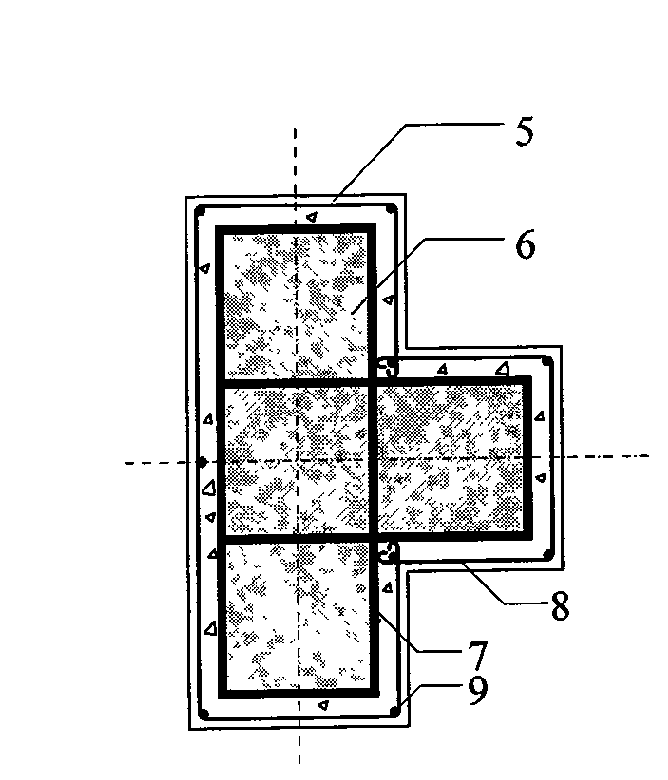

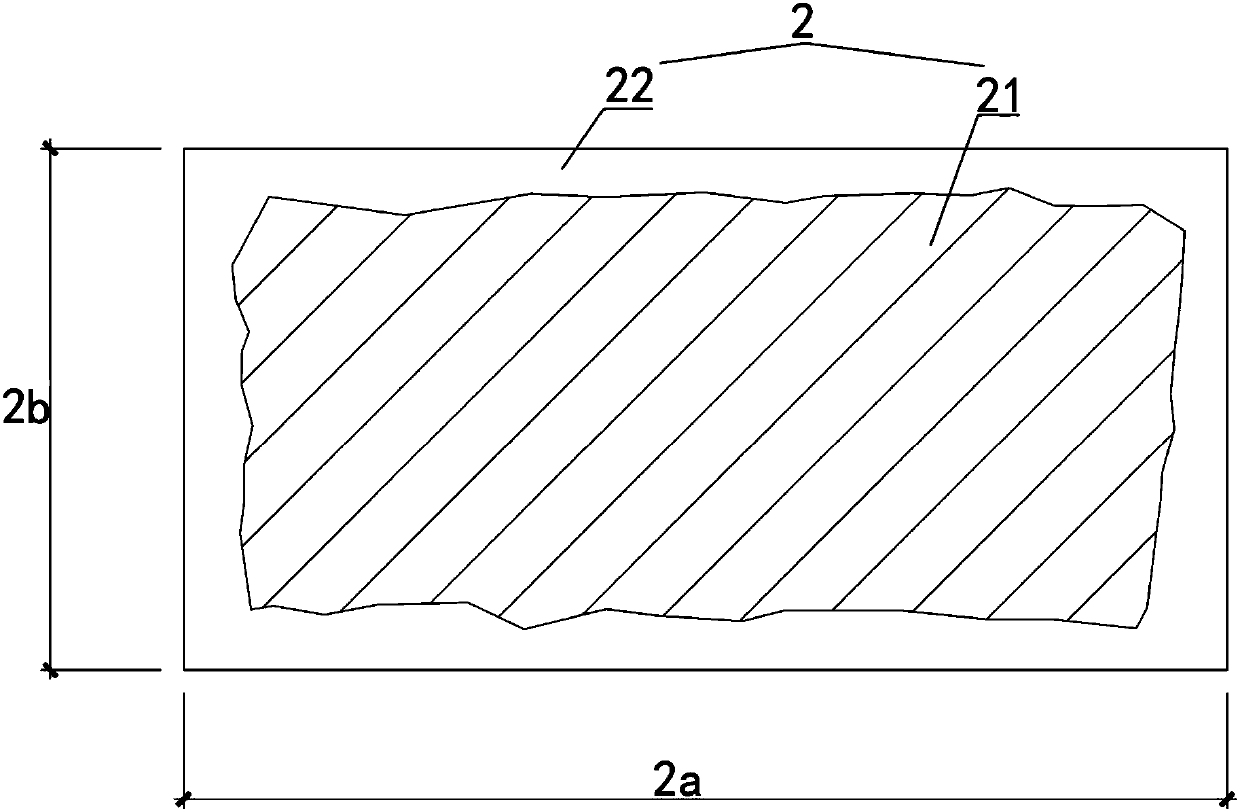

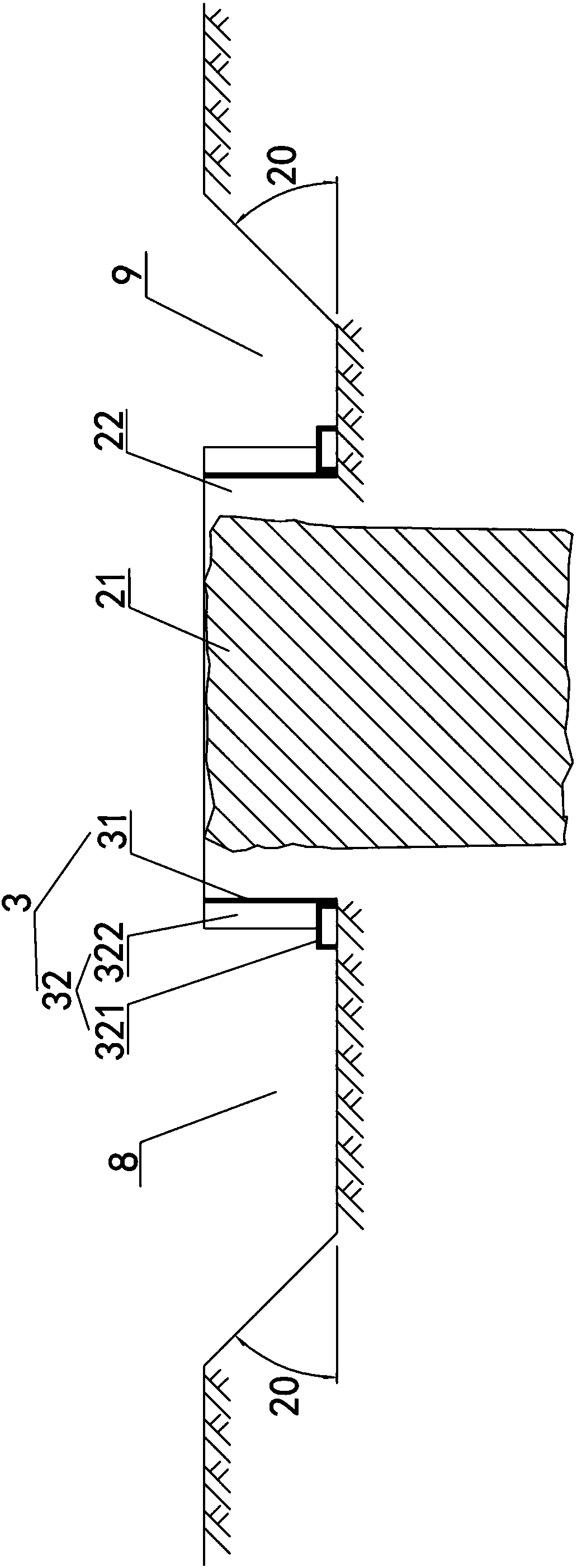

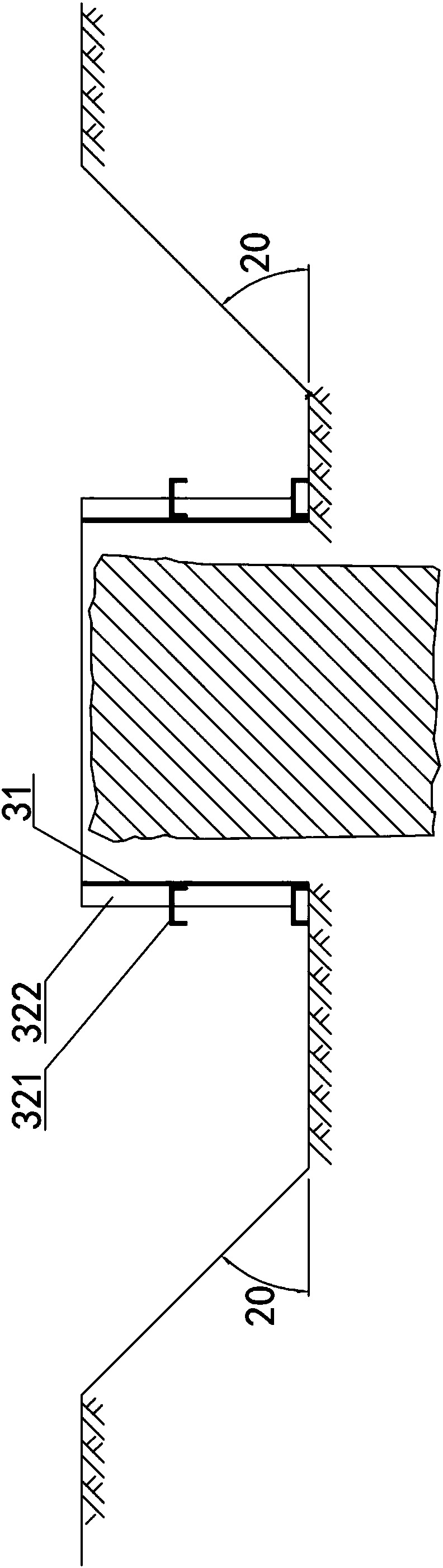

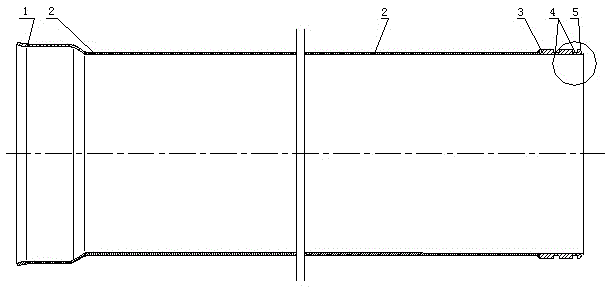

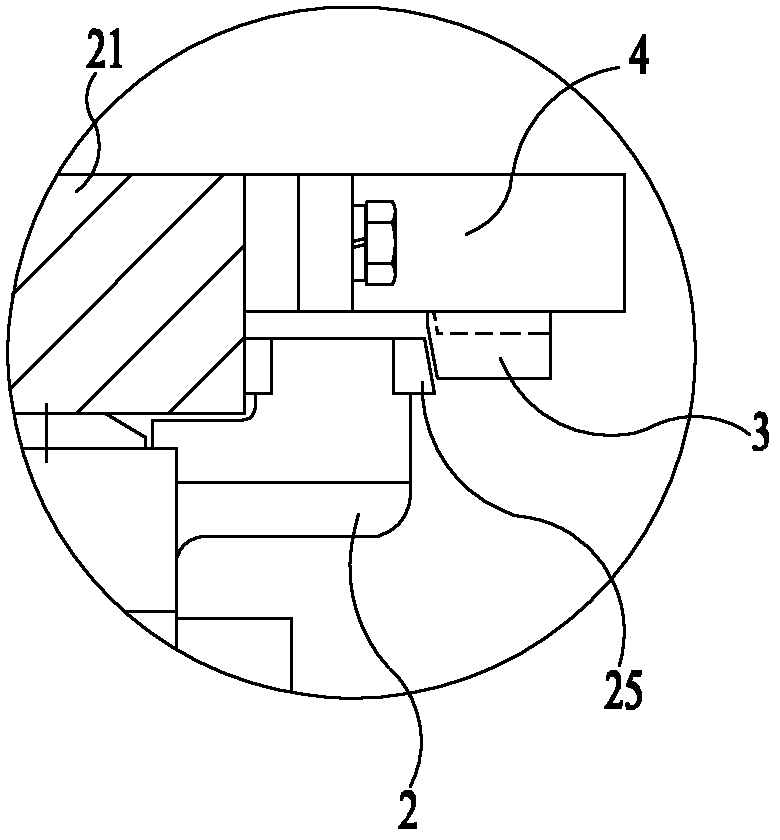

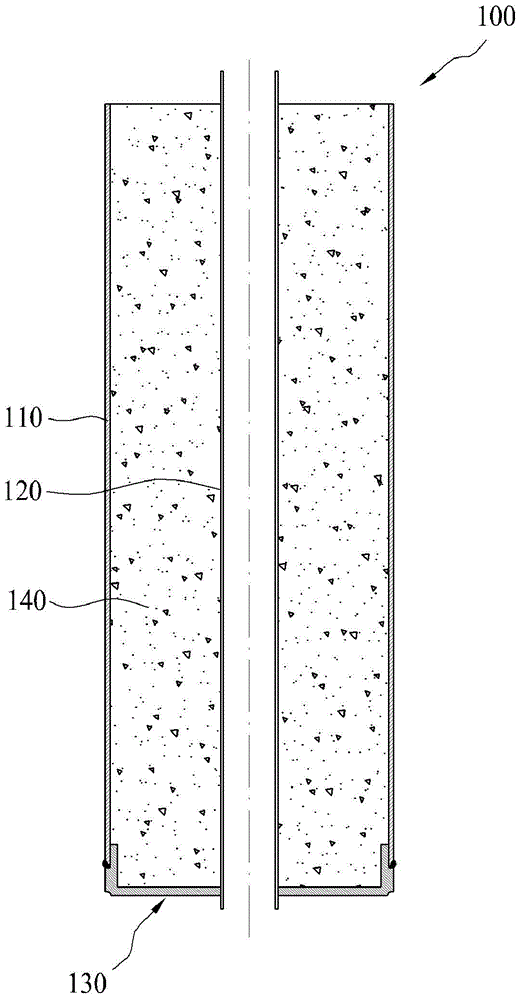

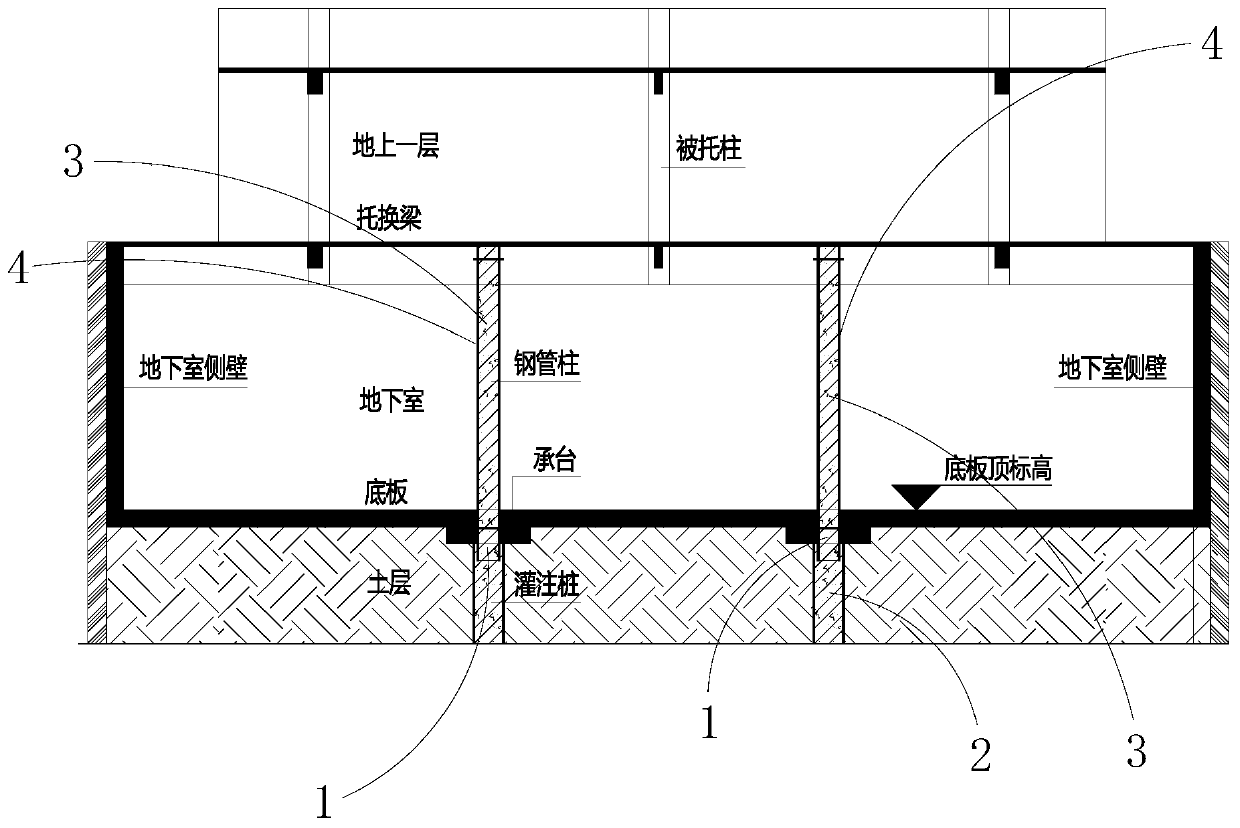

Mixed steel-concrete composite frame structure

ActiveCN101581115AEfficient use ofImprove structural fire resistanceBuilding constructionsFloor slabReinforced concrete

Owner:TSINGHUA UNIV

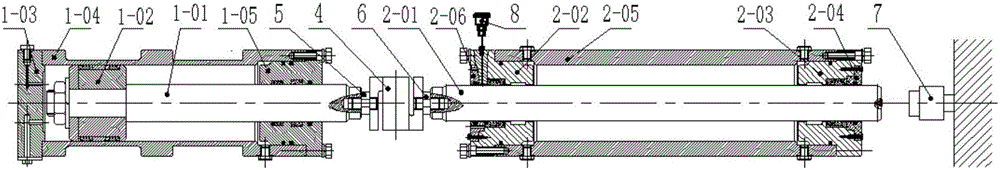

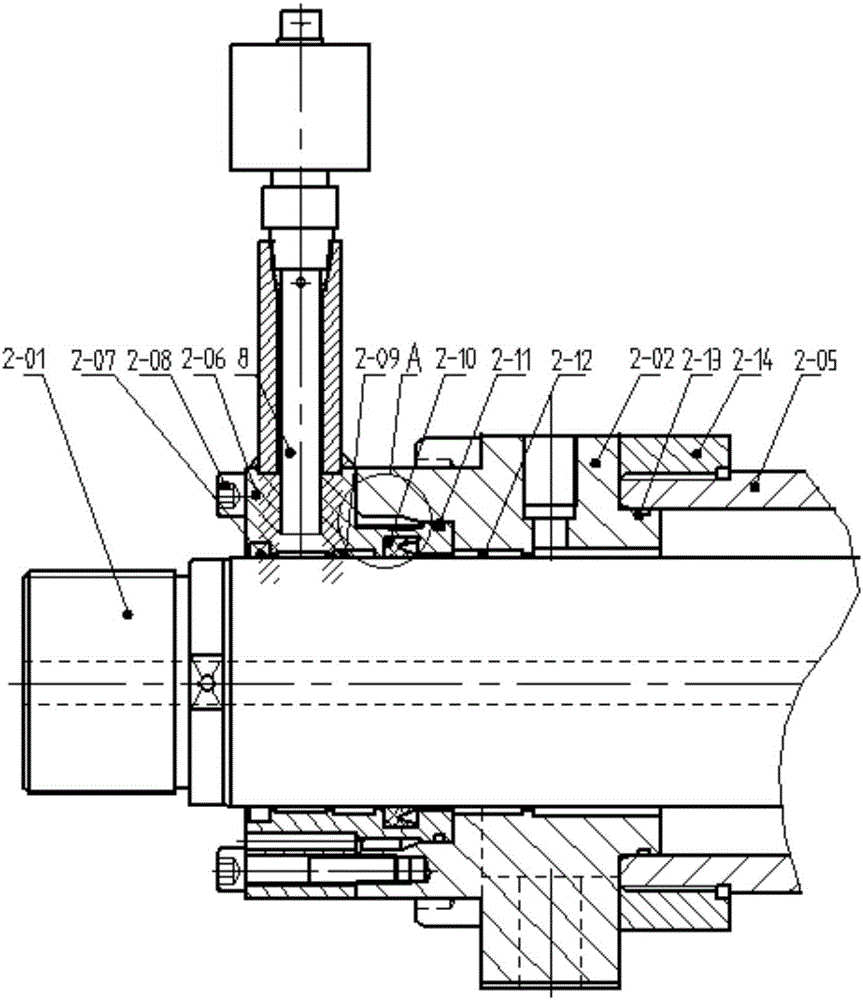

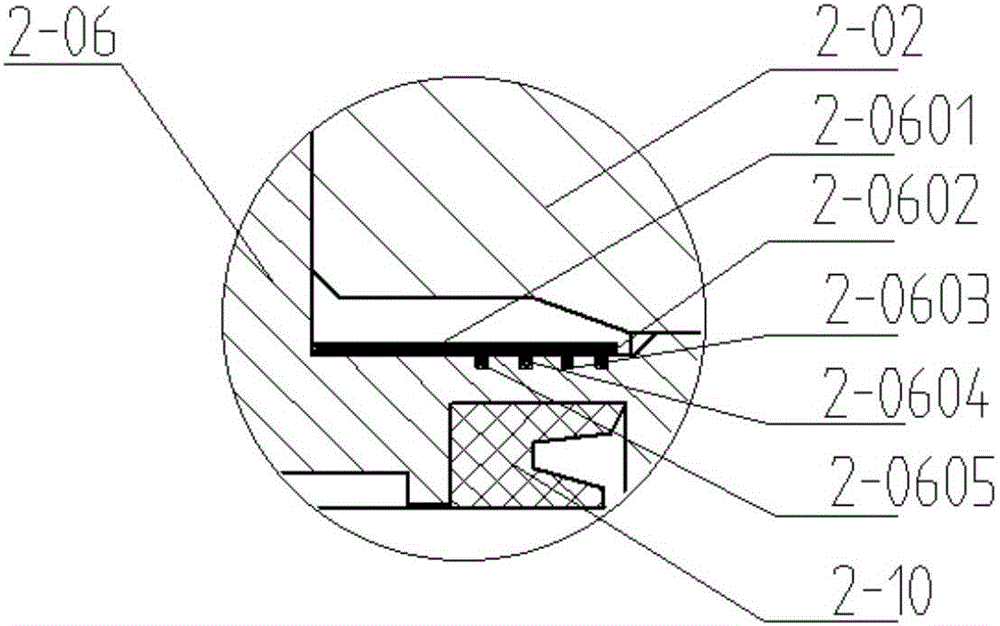

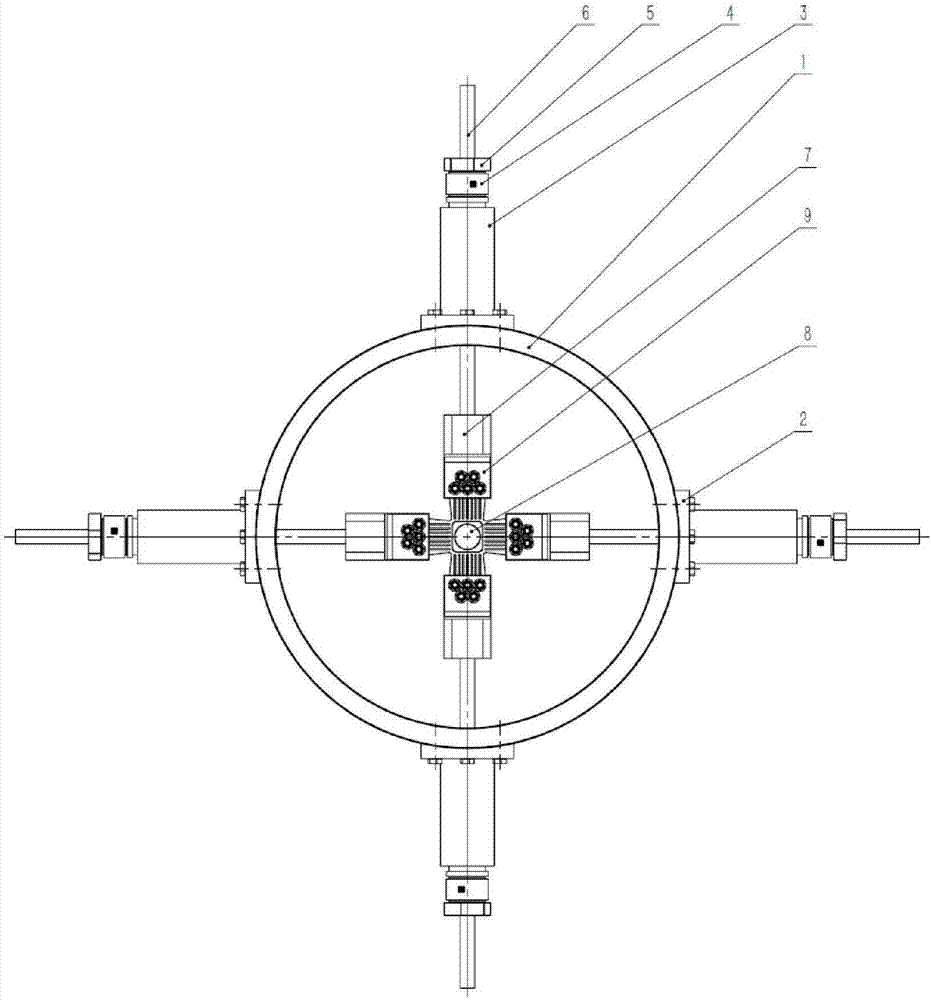

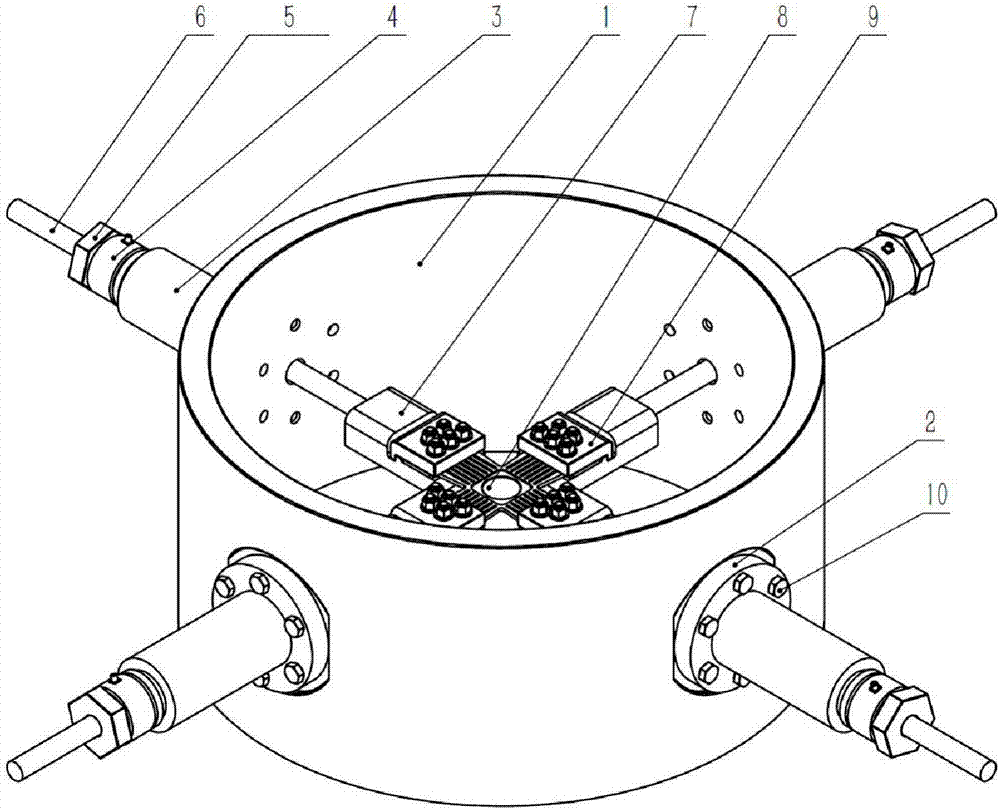

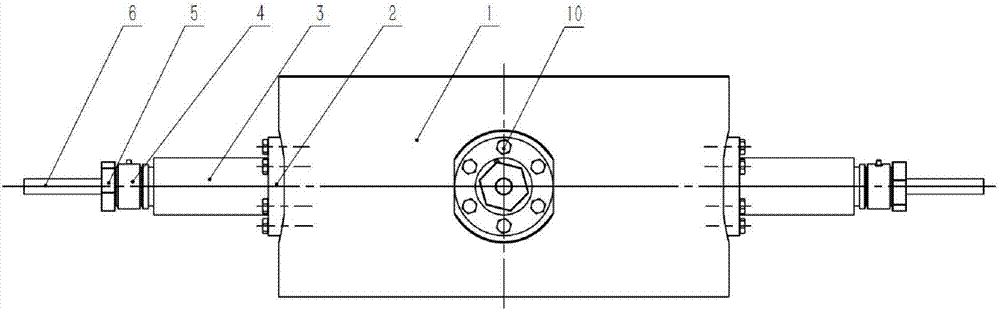

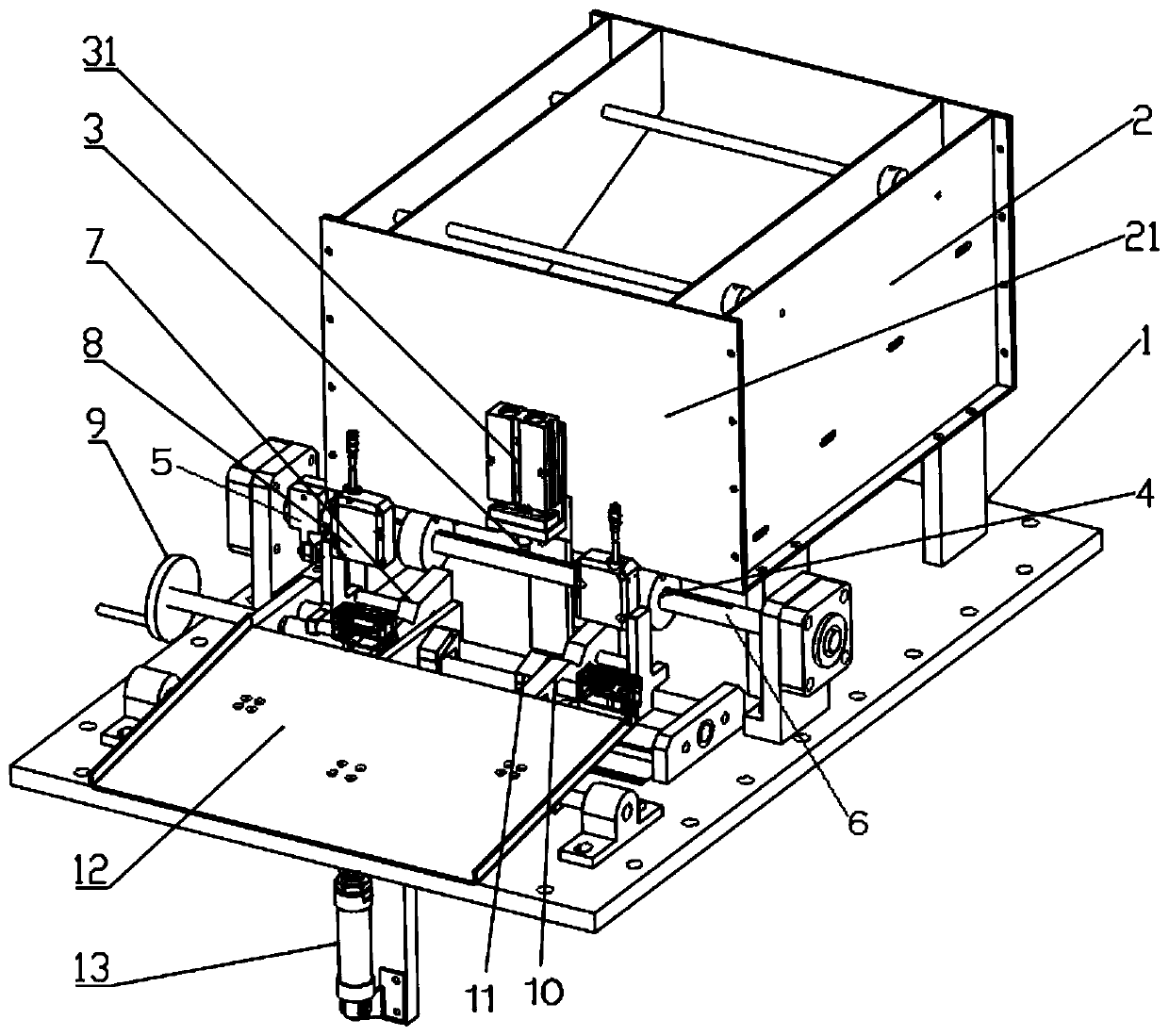

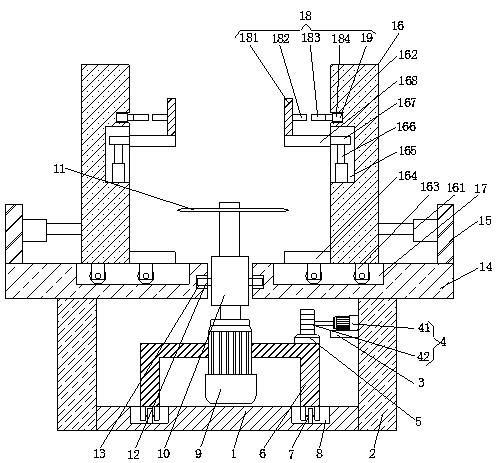

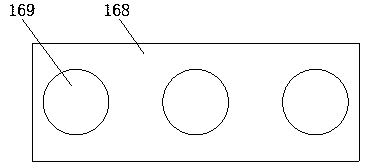

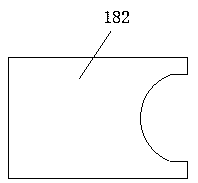

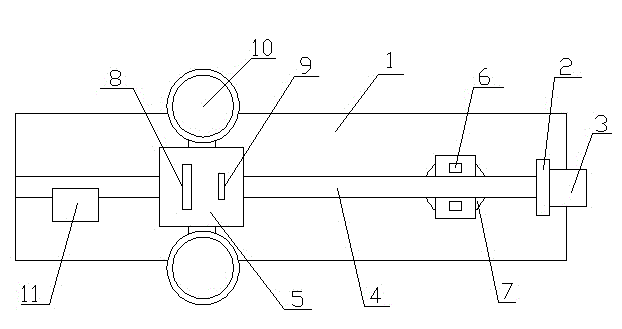

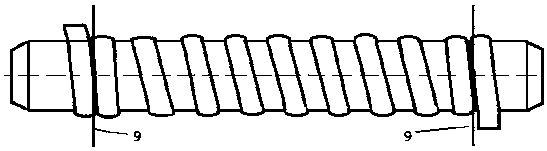

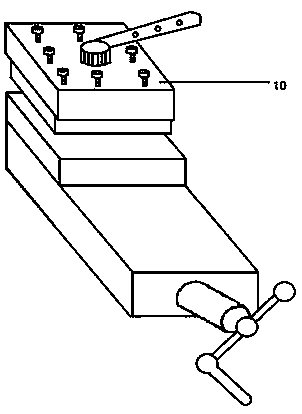

Hydraulic reciprocating seal dynamic property detection device and design

Owner:WUHAN UNIV OF TECH

High-strength pipeline steel, steel pipe and manufacture method thereof

ActiveCN102953018AHigh elongationHigh uniform elongationTemperature control deviceCooling temperatureSteel tube

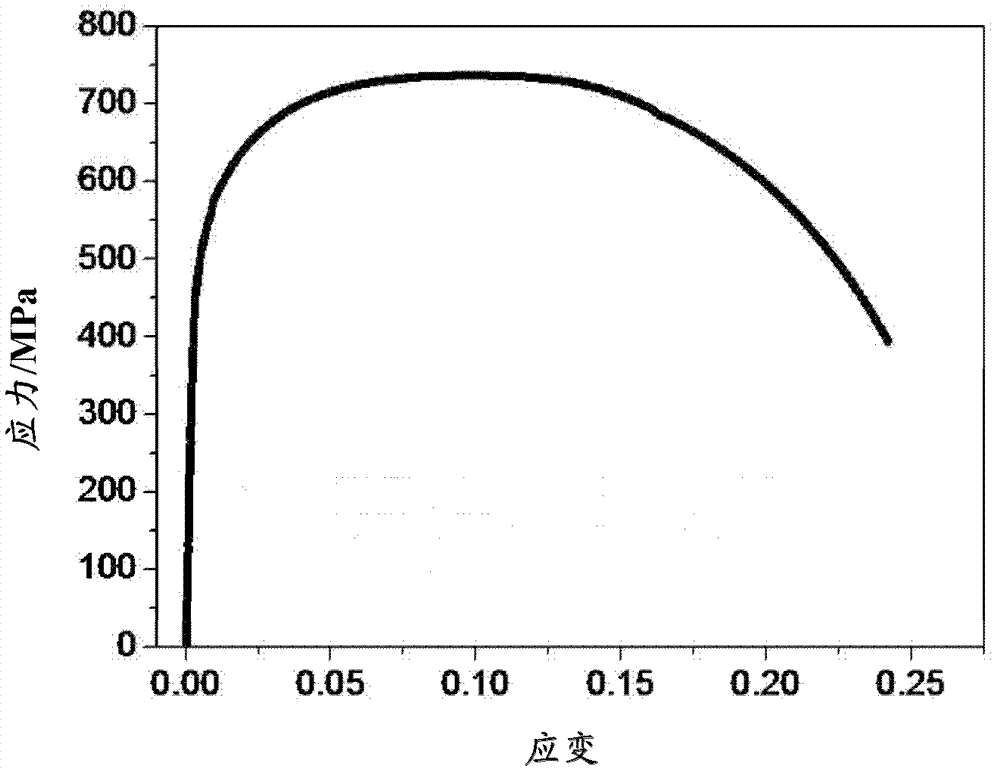

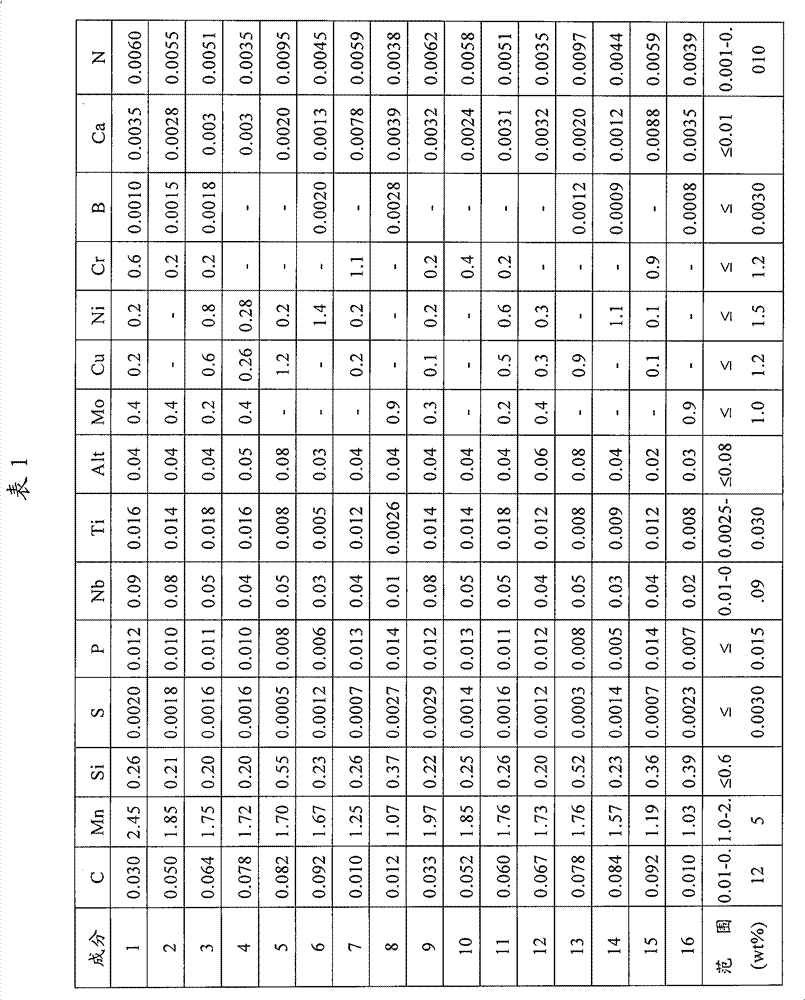

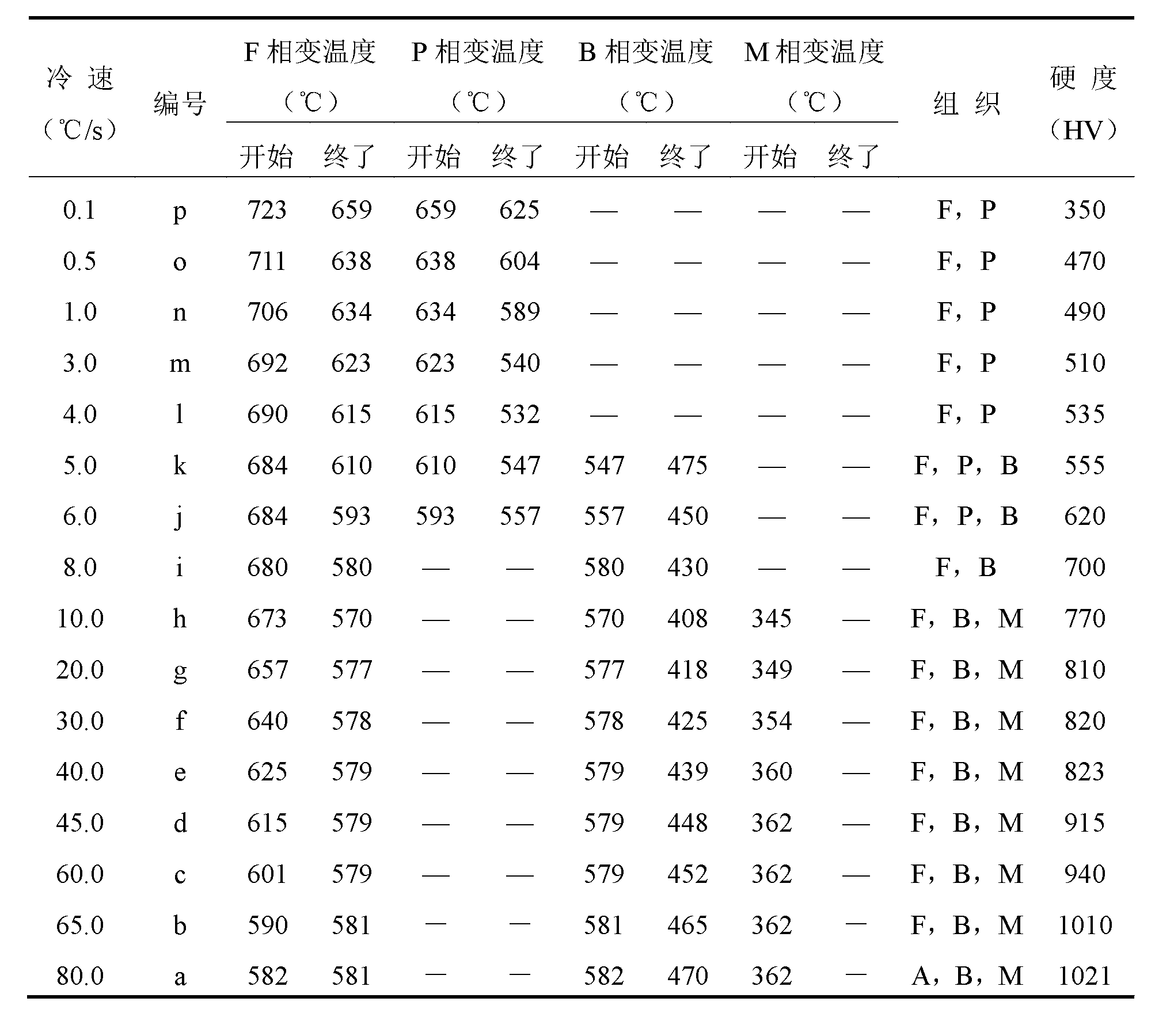

The invention relates to a high-strength pipeline steel which comprises the following chemical components by weight percent: 0.01-0.12 % of C, 1.0-2.5 % of Mn, less than or equal to 0.6 % of Si, less than or equal to 0.0030 % of S, less than or equal to 0.015 % of P, 0.01-0.09 % of Nb, 0.0025-0.030 % of Ti, less than or equal to 0.08 % of Alt, less than or equal to 1.0 % of Mo, less than or equal to 1.2 % of Cu, less than or equal to 1.5 % of Ni, less than or equal to 1.2 % of Cr, less than or equal to 0.0030 % of B, less than or equal to 0.01 % of Ca, 0.001-0.010 % of N, and the balance being iron and unavoidable impurities. The steel is polygonal ferrite and bainite duplex structure. A manufacture method of the high-strength steel pipe comprises heating slab with a temperature of 1100 to 1250 DEG C, rolling a non-recrystallization region with a starting temperature of 750 to 920 DEG C and a terminating temperature of 720 to 840 DEG C, two-stage cooling under control with an ACC terminating cooling temperature of 200 to 580 DEG C and a cooling rate of 5 to 30 DEG C per second, and manufacturing the pipe by using a UOE technology with a compression rate of 0.1 to 0.5 % and a diameter-expanding rate of 0.5 to 1.5 %. The obtained steel pipe can meet demands of low yield ratio and high uniform elongation.

Owner:BAOSHAN IRON & STEEL CO LTD

Efficient cutting device of hardware steel pipe

ActiveCN106180867AHigh hardnessAnti-crackTube shearing machinesDriving apparatusEconomic benefitsEngineering

Owner:开平力蒲卫浴有限公司

Efficient steel pipe cleaning device

Owner:上海申第实业有限公司

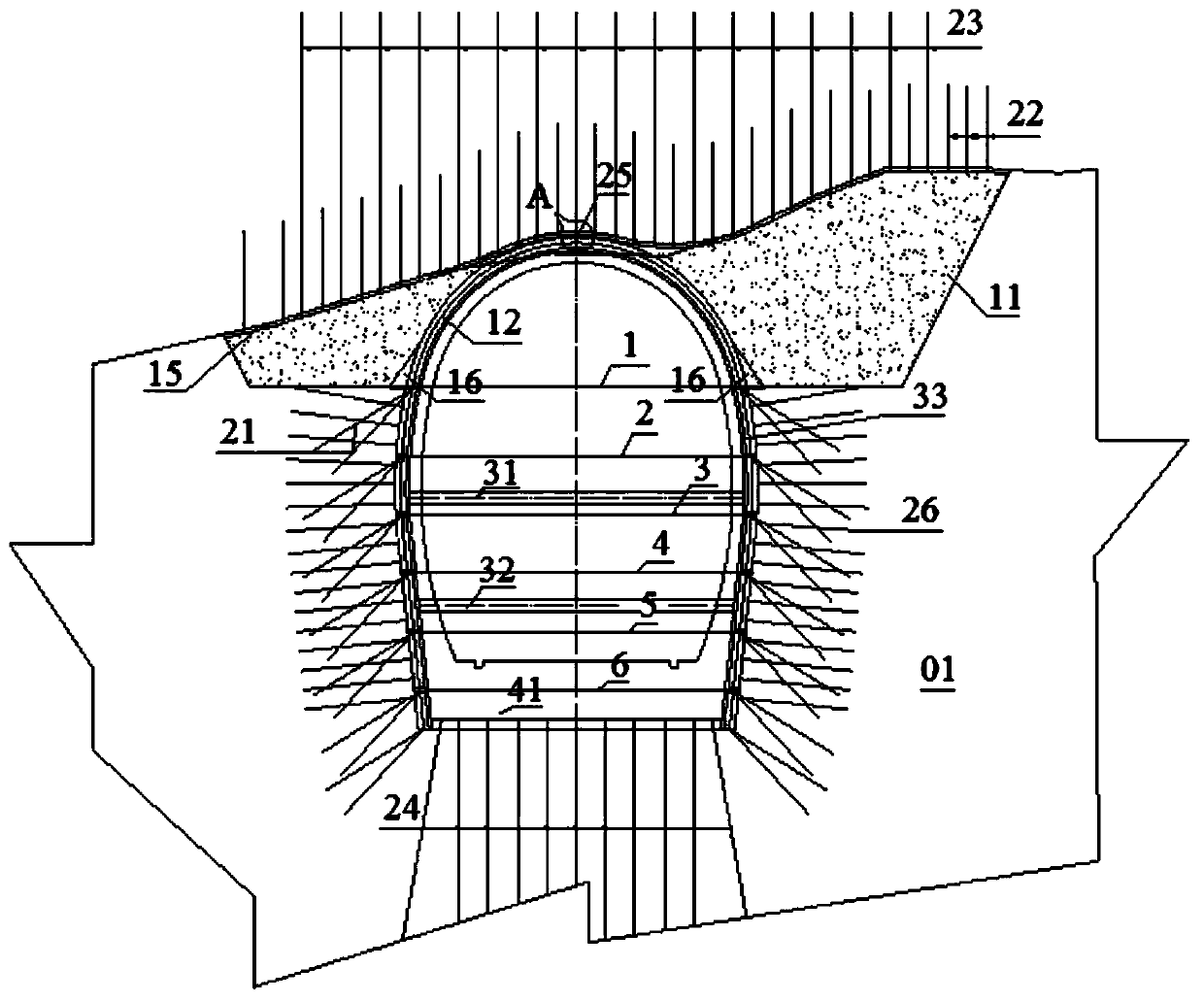

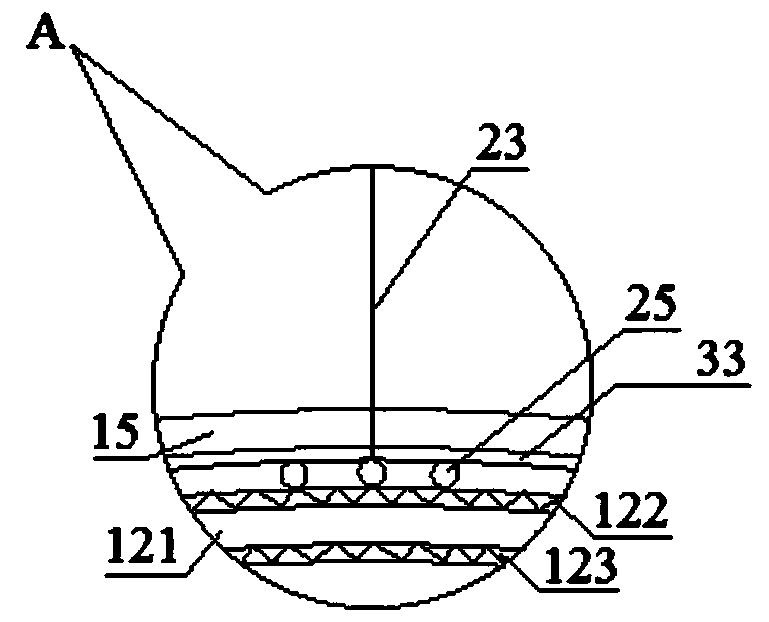

Large-section tunnel supporting system penetrating through giant karst cave hall and construction method thereof

PendingCN111411993AAvoid delayAvoid economic lossUnderground chambersMaterial fill-upSupporting systemArchitectural engineering

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

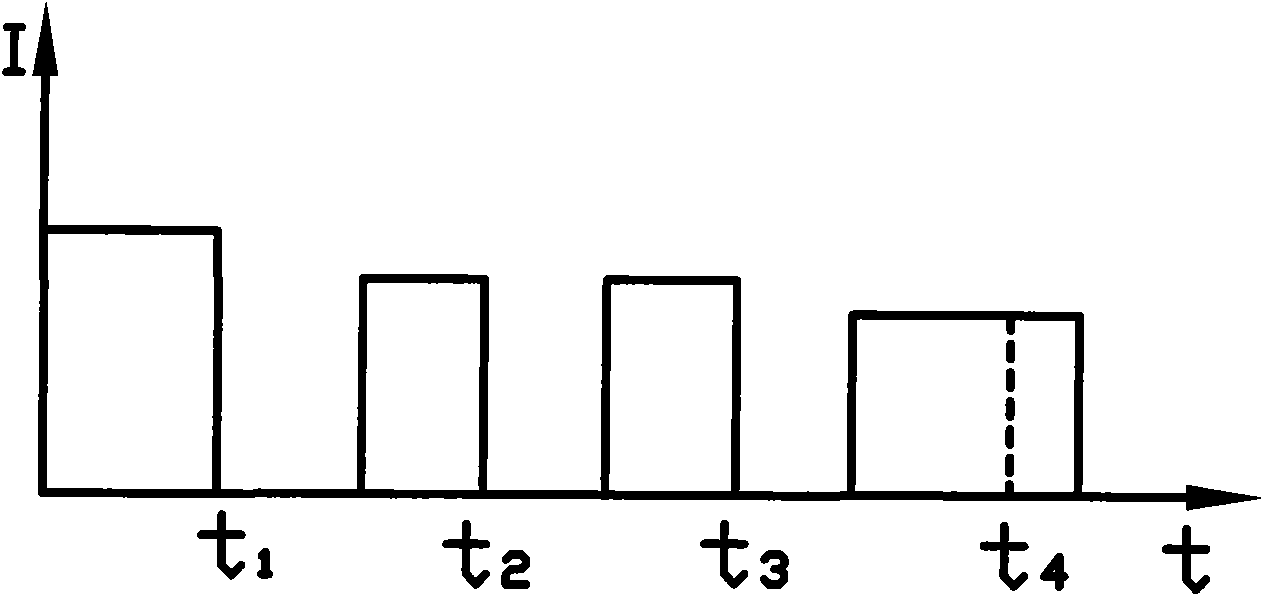

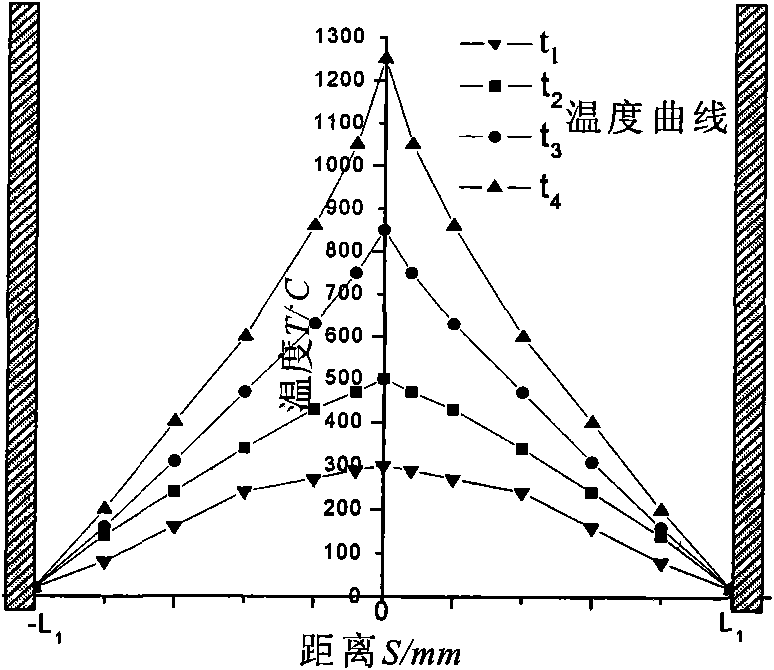

Butt welding method of small caliber metallic resistances

ActiveCN101596643ALess heat productionReduce the impactResistance welding apparatusButt weldingEngineering

Owner:BEIJING UNIV OF TECH

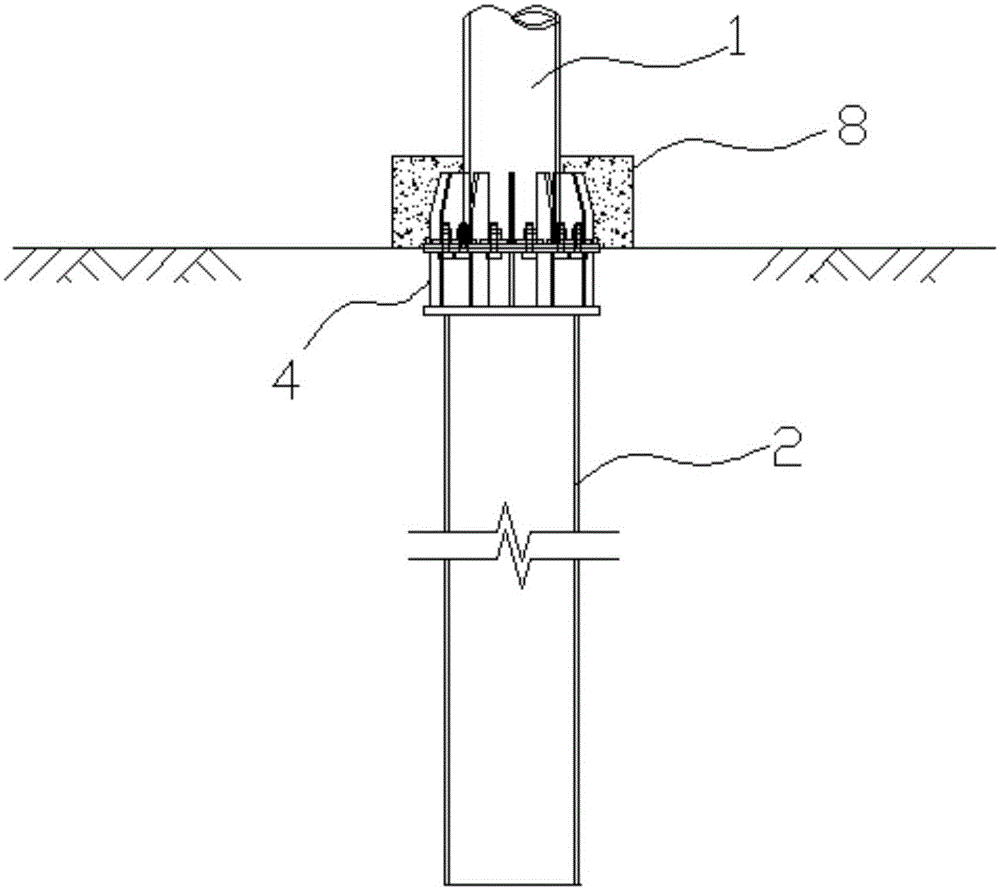

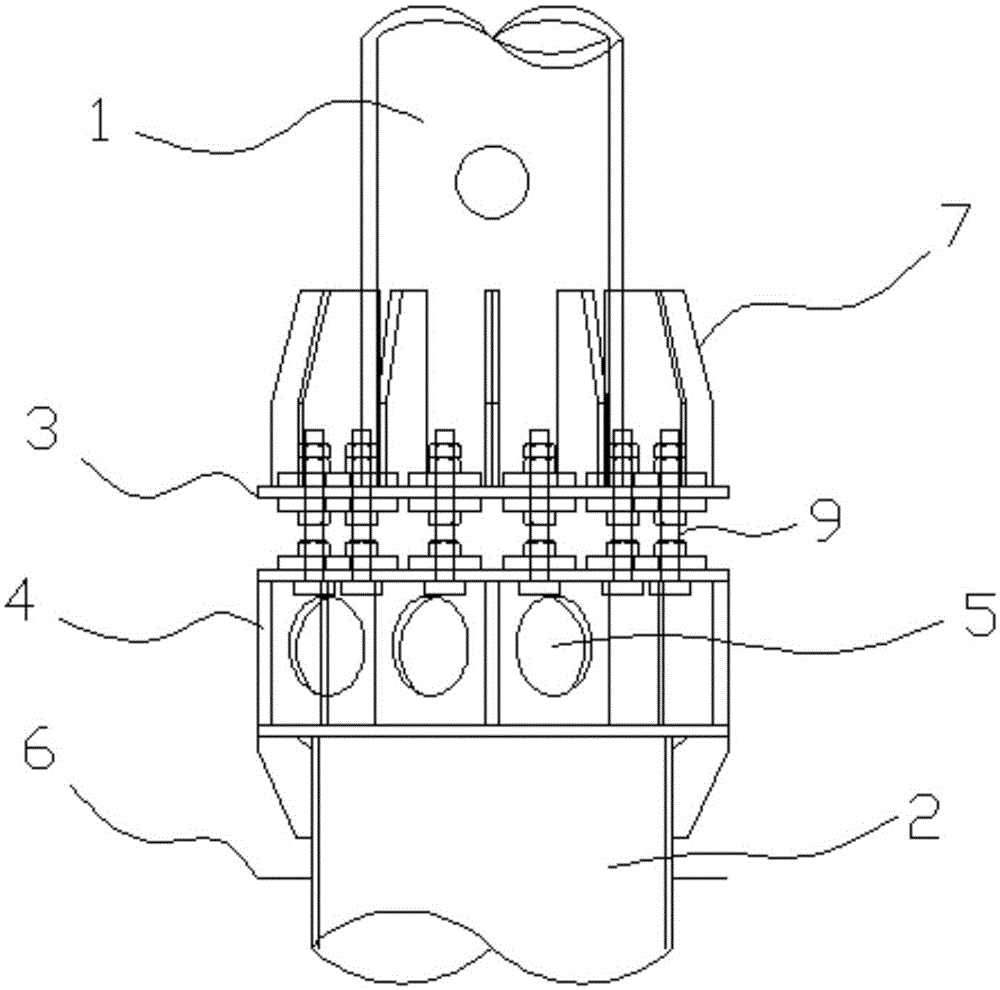

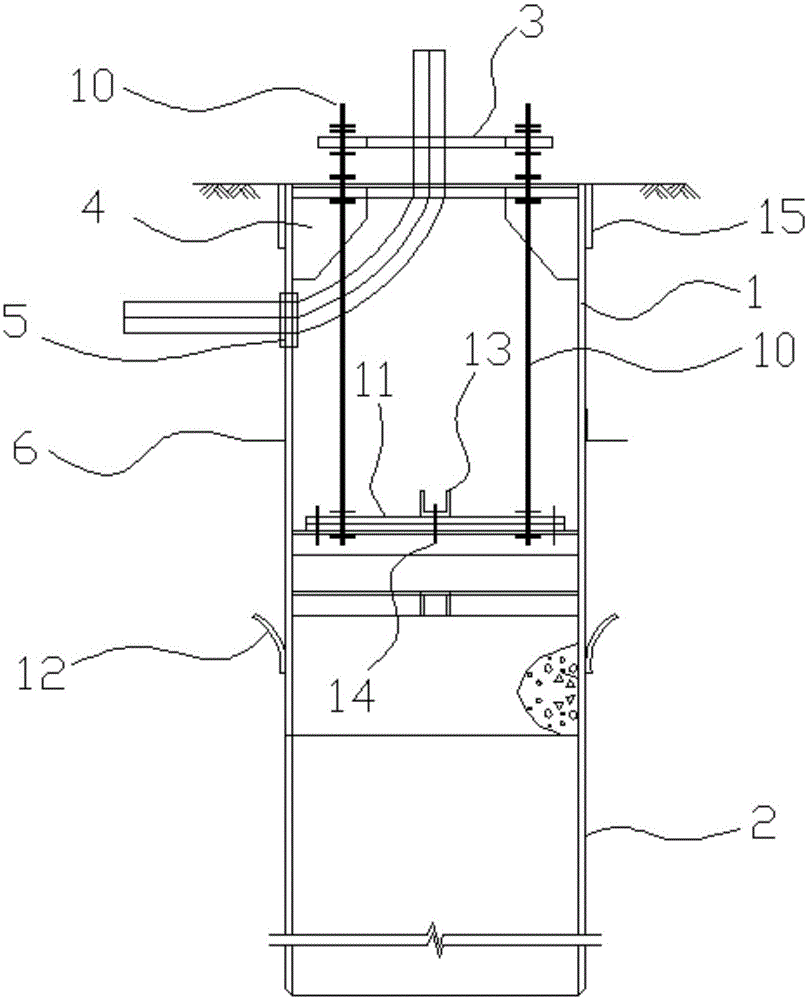

Communication pole tower with steel tube pile as foundation

Owner:HUAXIN CONSULTATING CO LTD

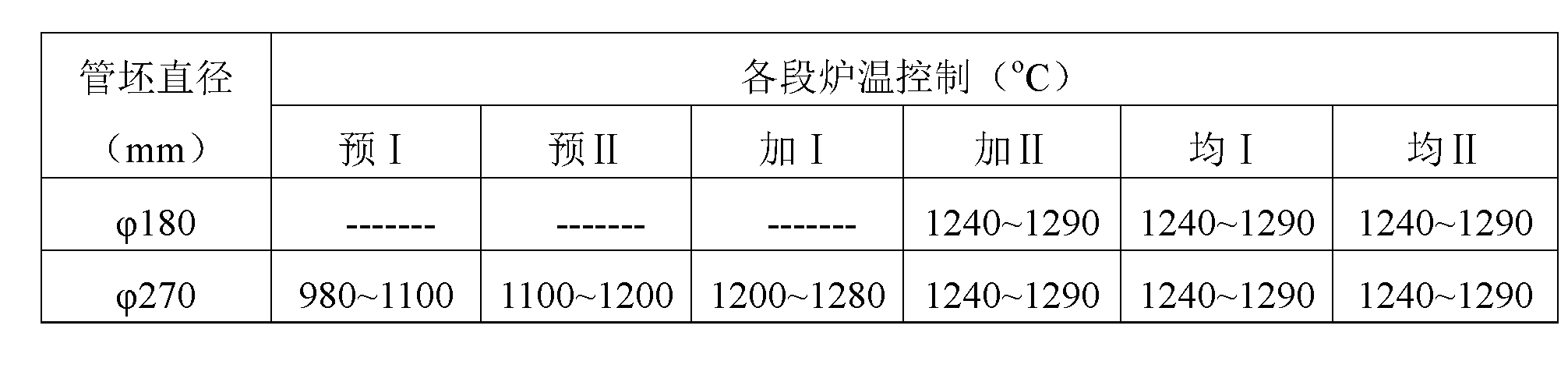

Ultra-low carbon martensitic stainless steel seamless tube and manufacturing method thereof

InactiveCN108277438AHigh tensile strengthHigh yield strengthFurnace typesHeat treatment furnacesMartensitic stainless steelHigh pressure

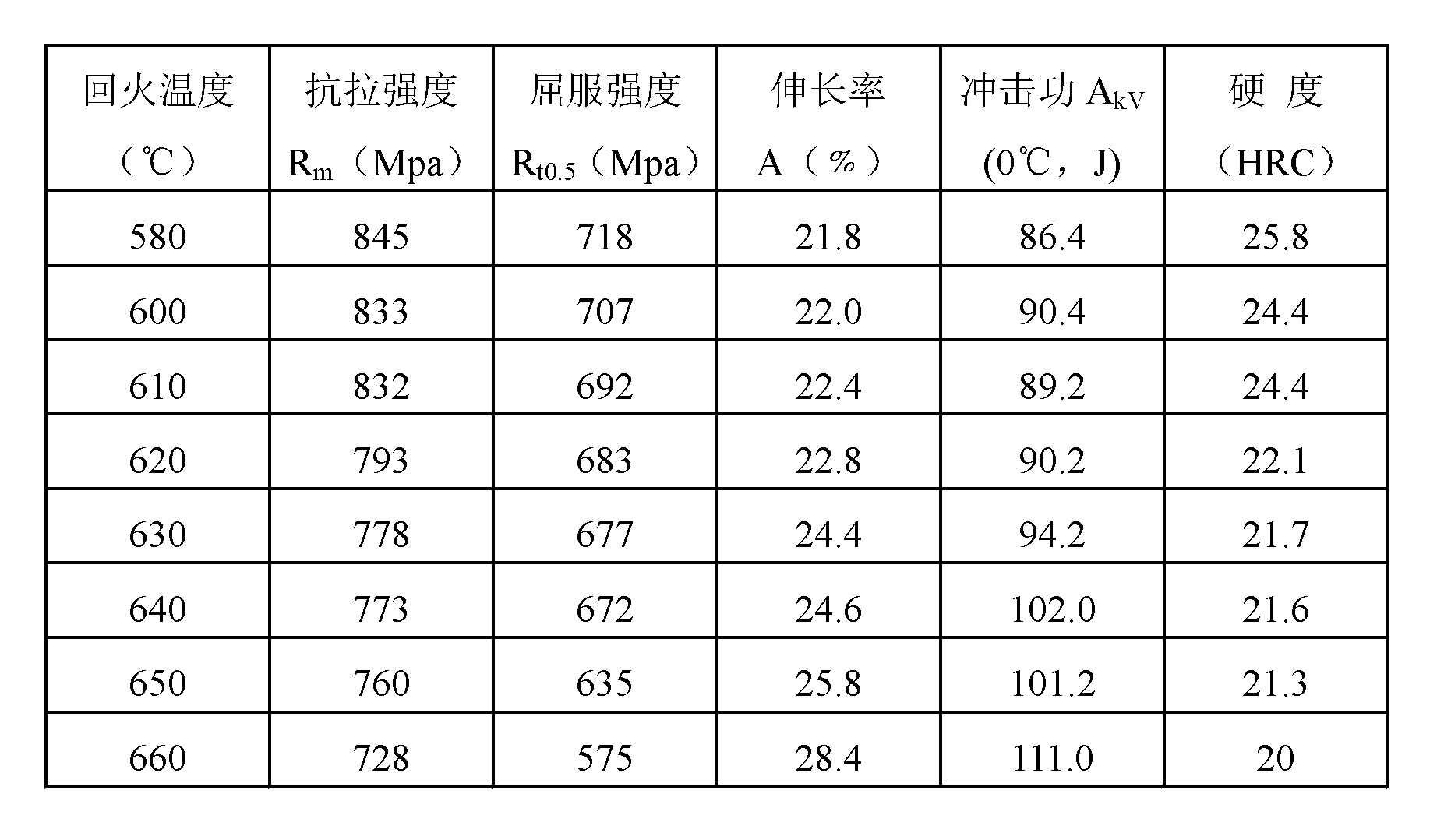

The invention discloses an ultra-low carbon martensitic stainless steel seamless tube. The ultra-low carbon martensitic stainless steel seamless tube is prepared from ultra-low carbon martensitic stainless steel. The ultra-low carbon martensitic stainless steel is prepared from the following components in percentage by mass: less than or equal to 0.03% of C, 0.1-0.5% of Si, 0.2-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 12.2-13.2% of Cr, 5.2-5.7% of Ni, 1.9-2.1% of Mo, 0.1-1.6% of Cu and the balance of Fe and other impurities. The seamless tube can be suitable for oil and gas fields. The invention also provides a manufacturing method of the seamless tube. The manufacturing method comprises the following steps: smelting; tube blank thermal processing;steel tube thermal processing; and thermal treatment, wherein the heating temperature of tube blank thermal processing is 1200-1280 DEG C, the heating temperature of tube manufacturing by means of anextruding method is 1150-1250 DEG C, the heating temperature of tube manufacturing by means of a perforating cold rolling method is 1200-1280 DEG C, and the temperatures for thermal treatment are as follows: quenching at 900-1050 DEG C and tempering at 550-680 DEG C. The seamless tube provided by the invention has excellent strength and corrosion resistance in a CO2 and Cl<-> coexisting corrosionenvironment and in high-temperature and high pressure conditions.

Owner:TAIYUAN IRON & STEEL (GRP) CO LTD

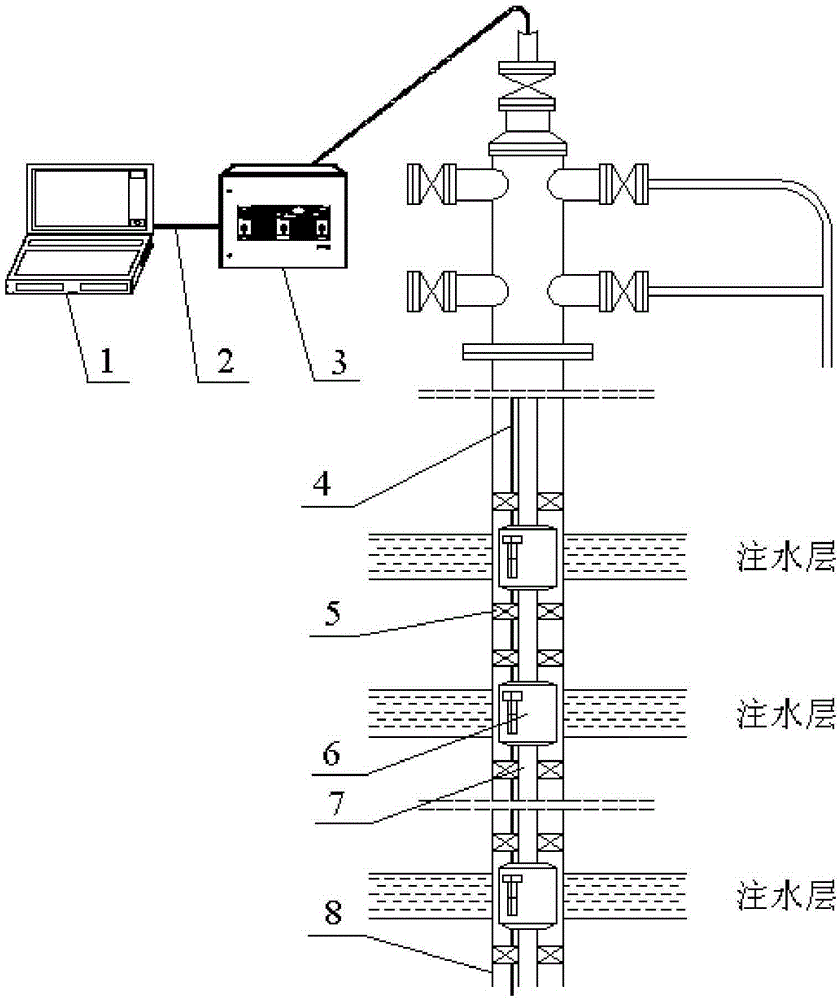

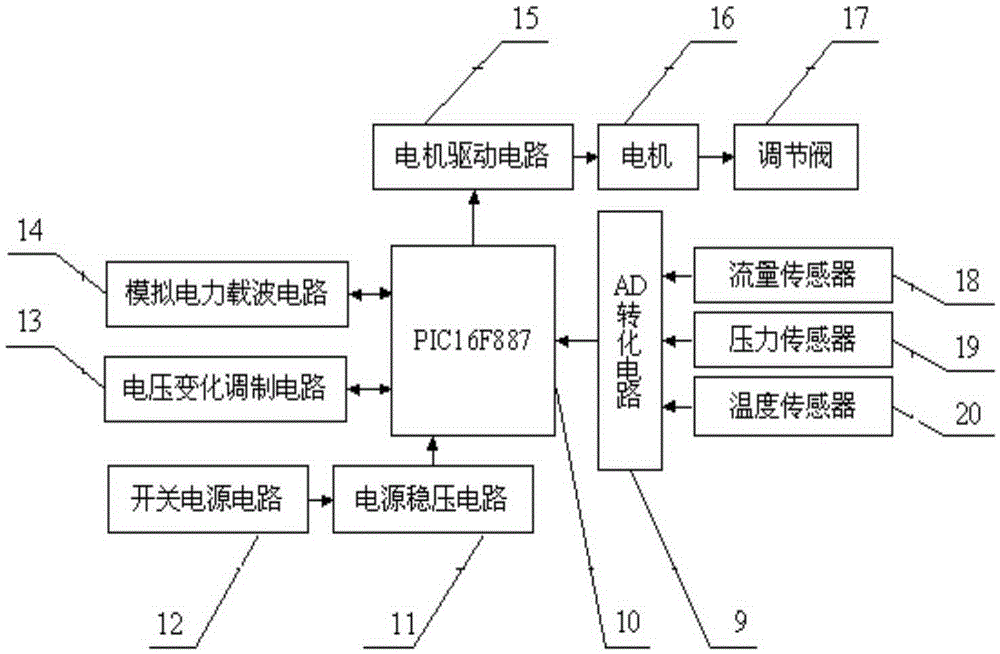

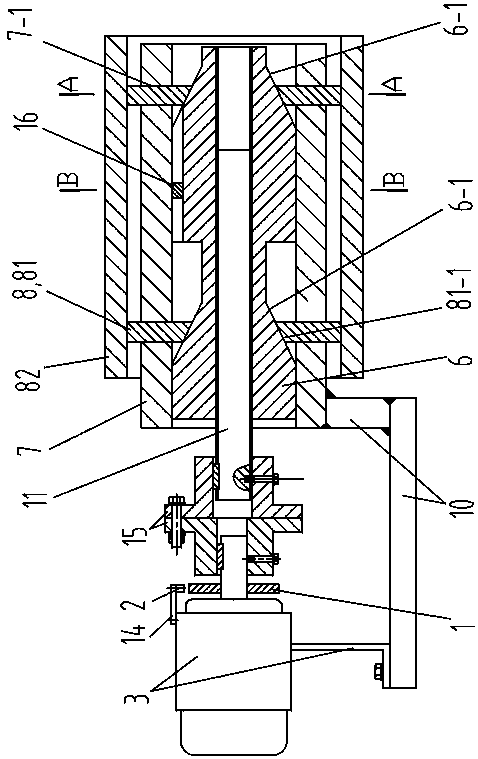

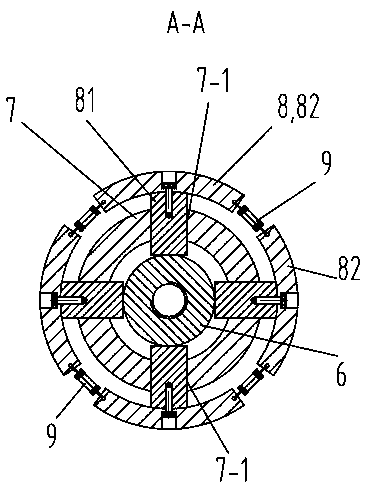

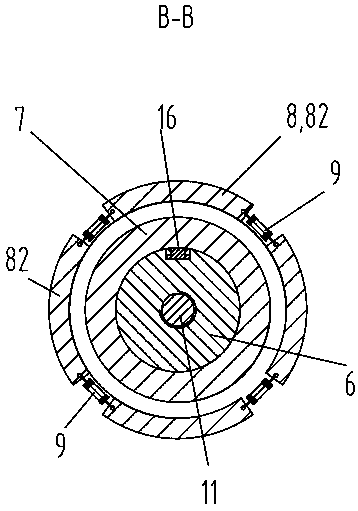

Monitoring system for water injection state of each layer of multi-layer water injection well

Owner:PETROCHINA CO LTD

Pipe fitting clamping device

Owner:刘剑

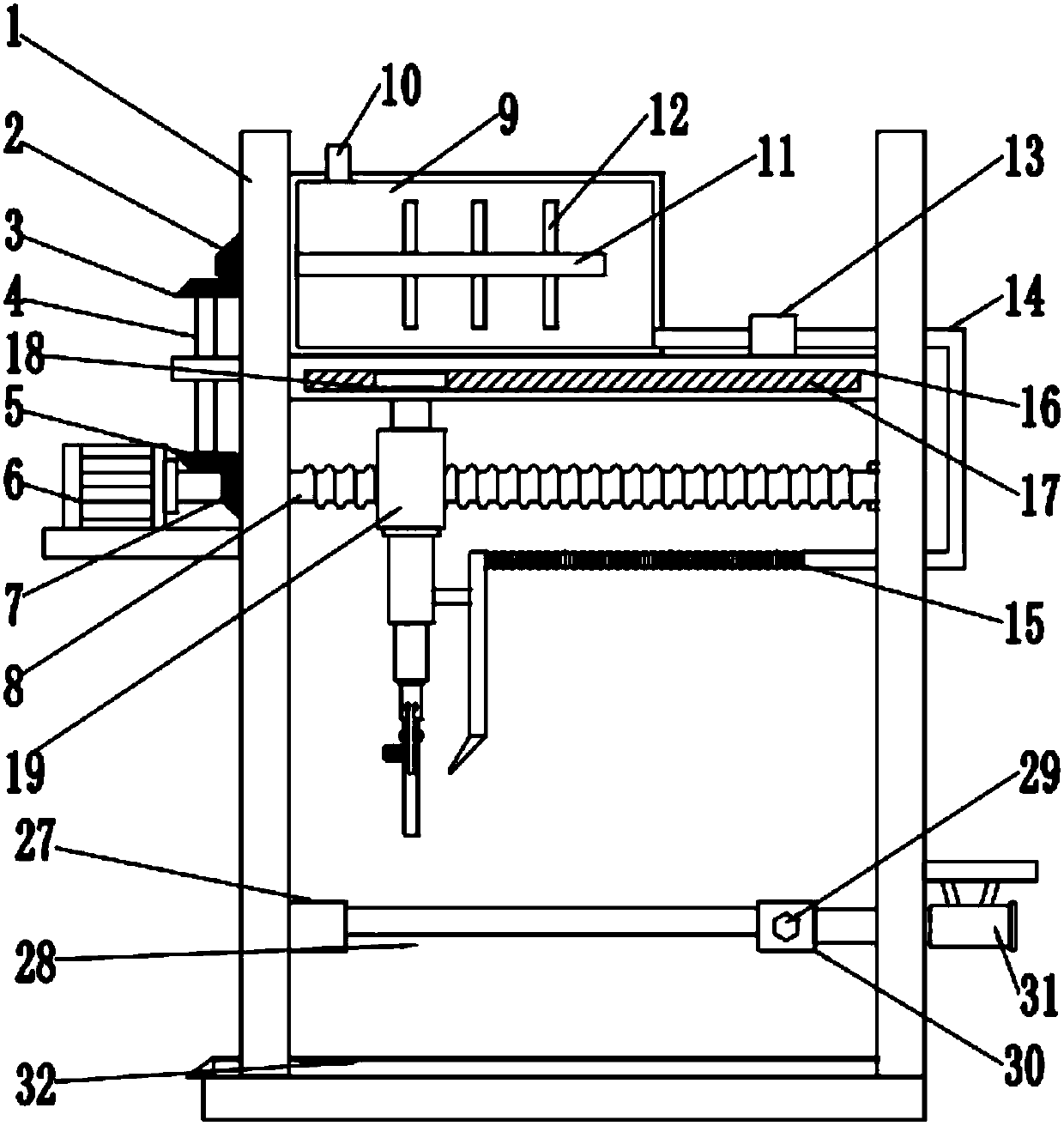

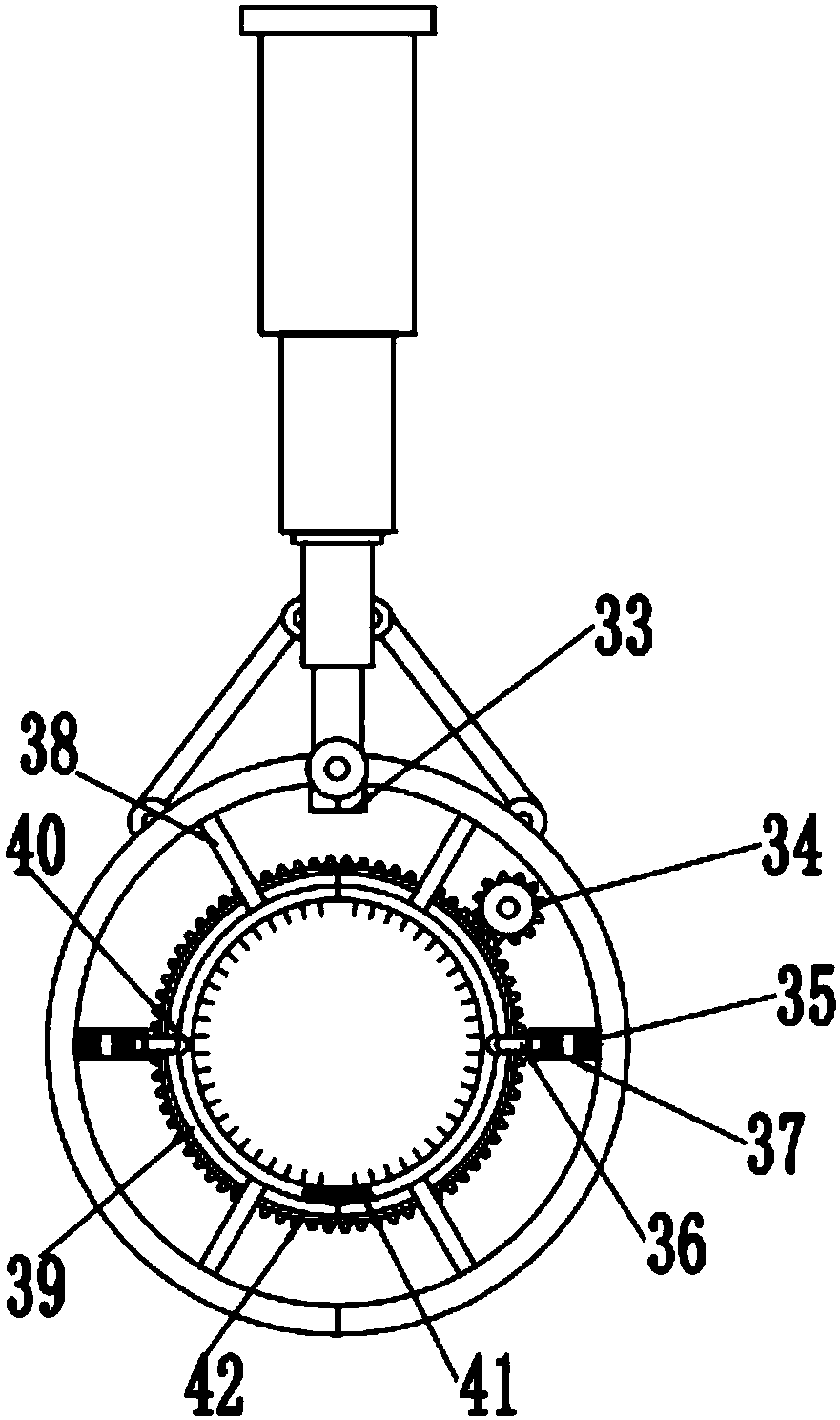

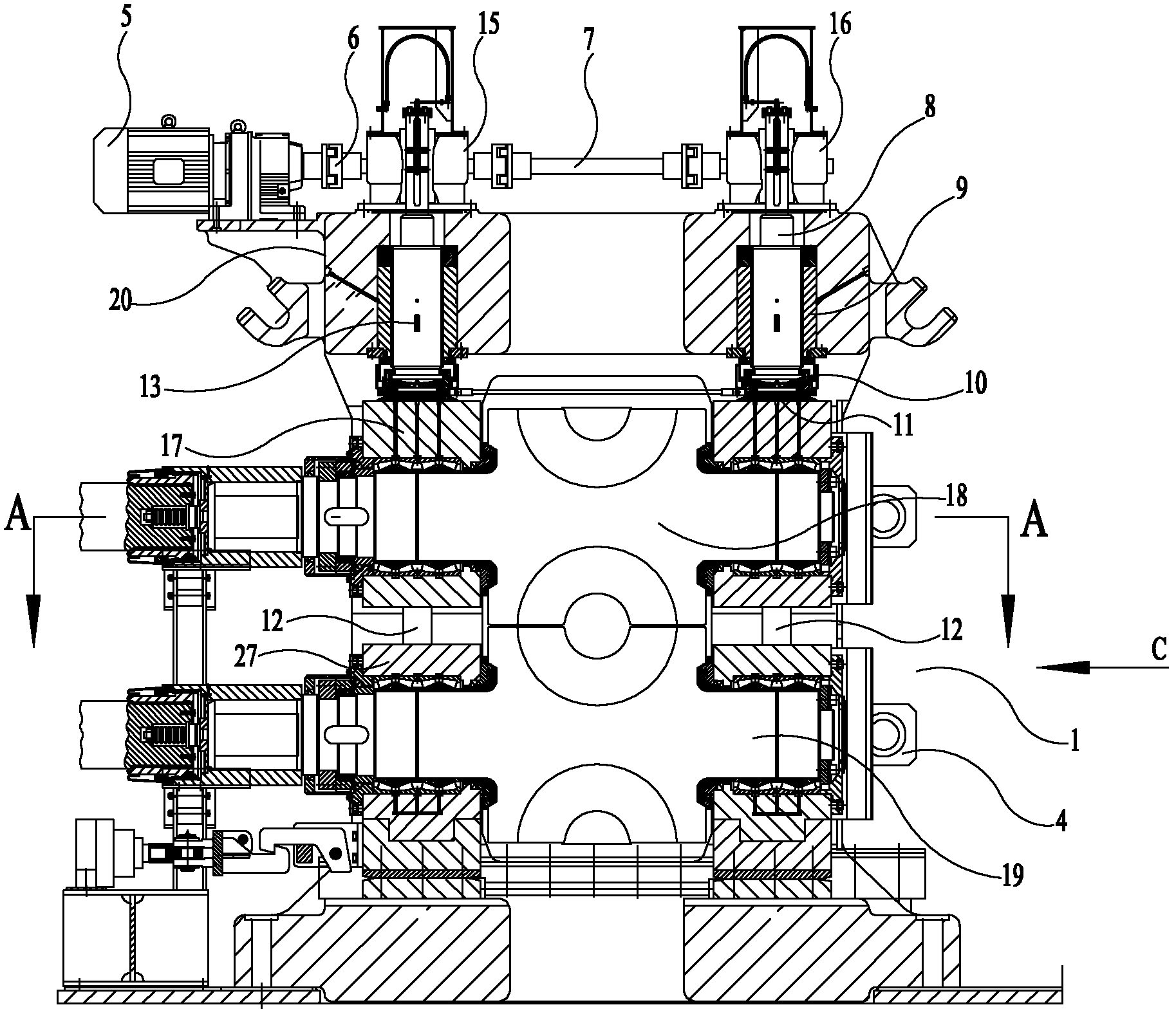

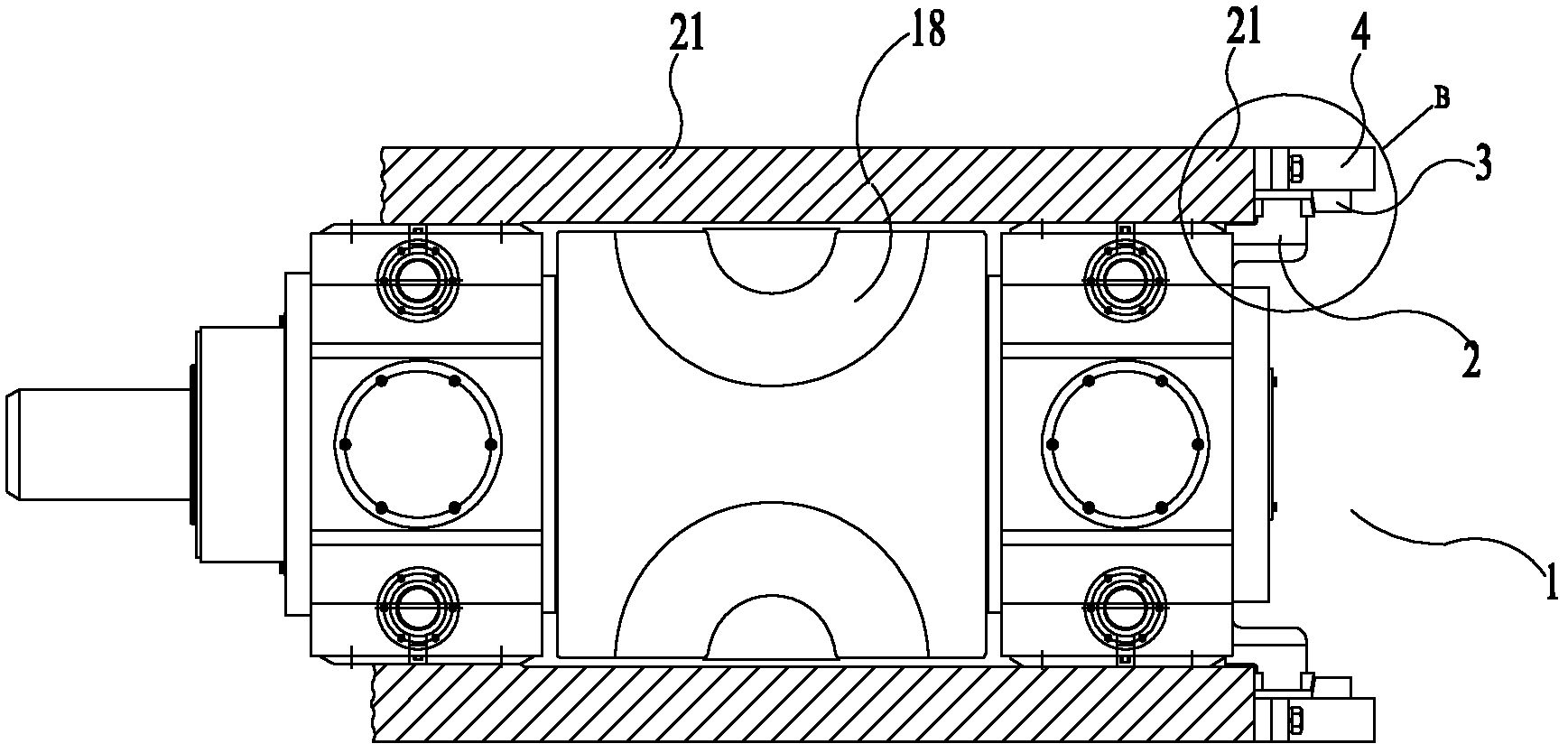

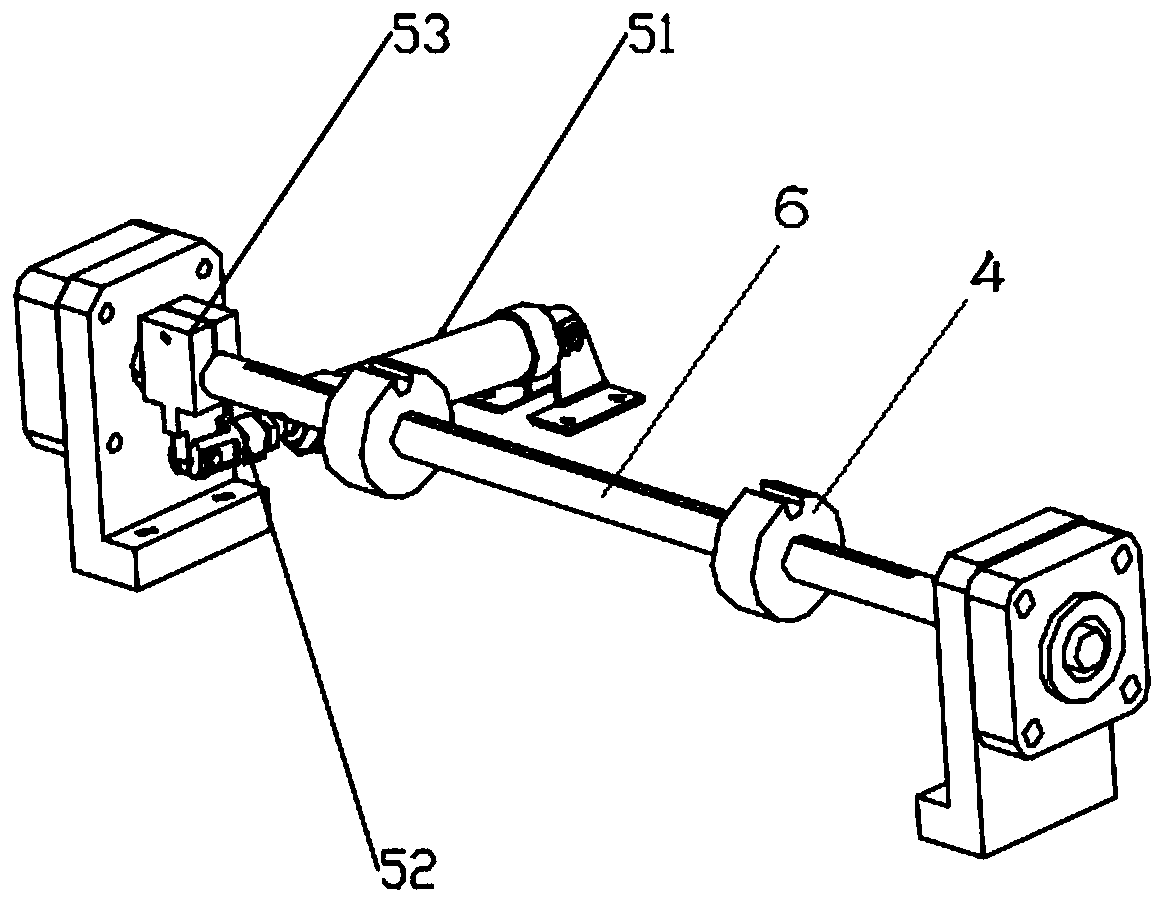

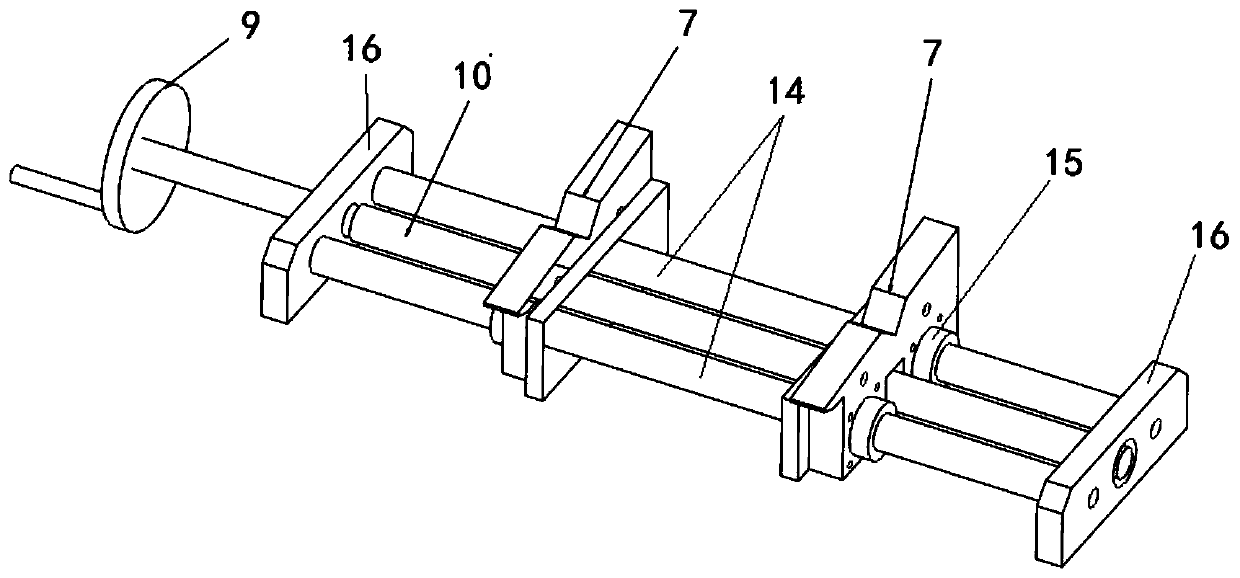

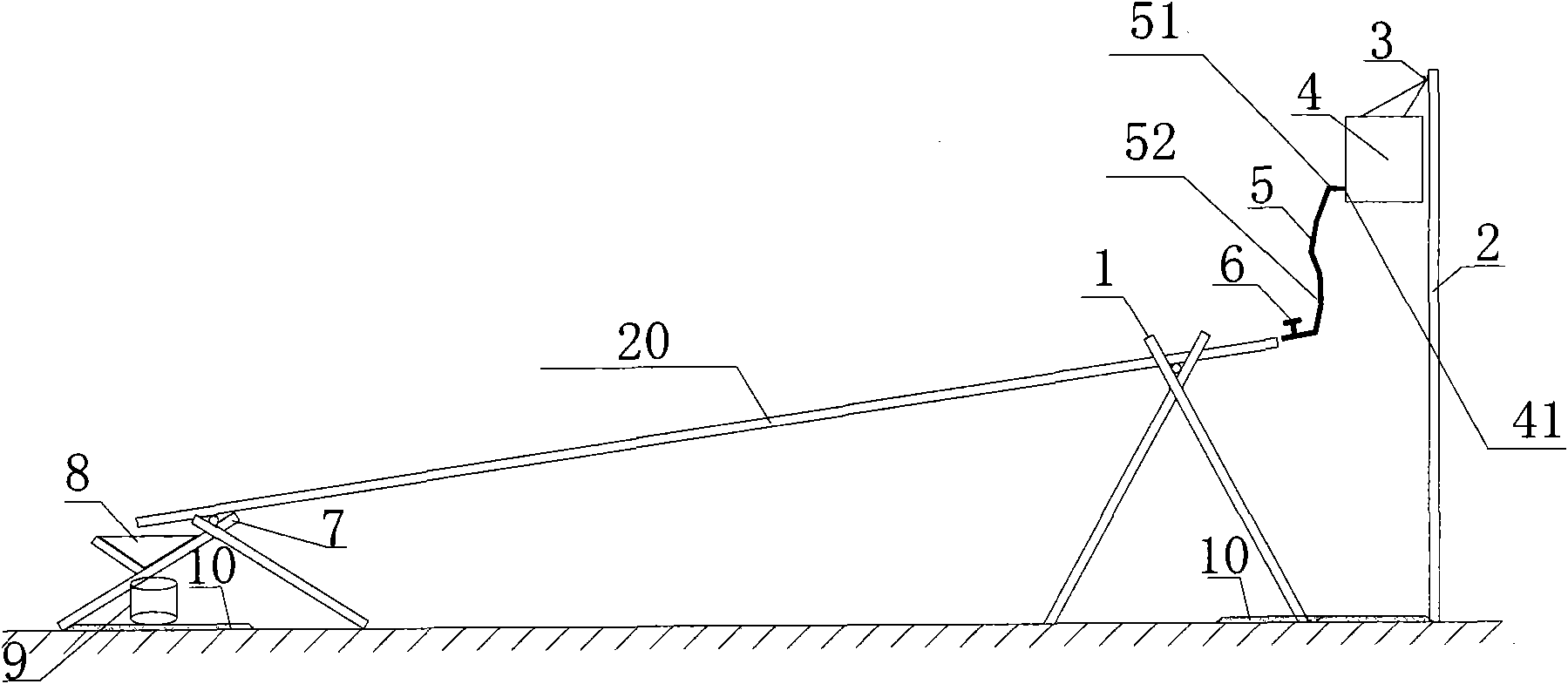

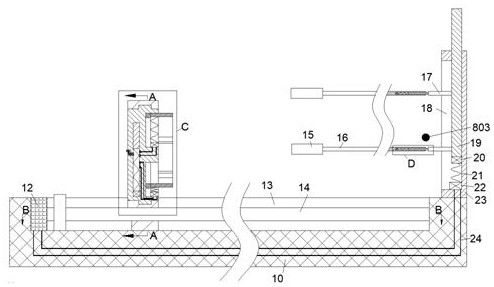

Dual-purpose polishing machine for inner and outer walls of steel tube

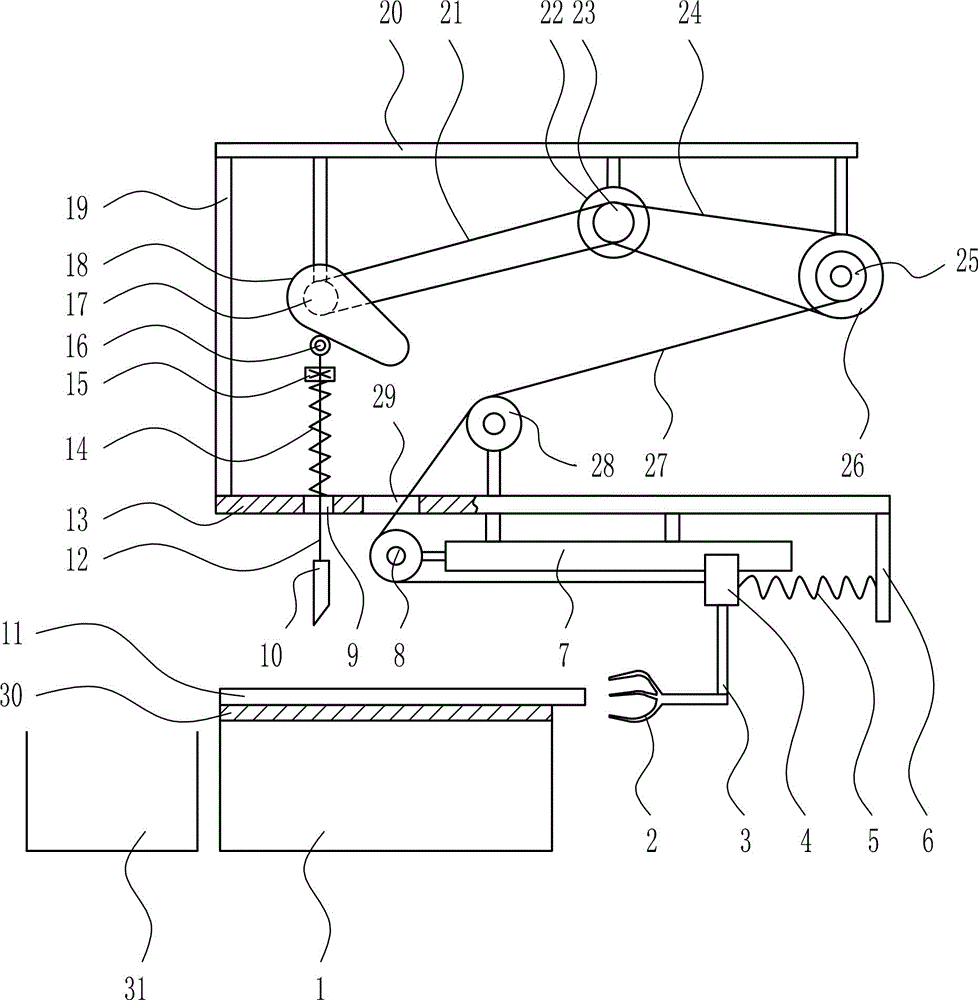

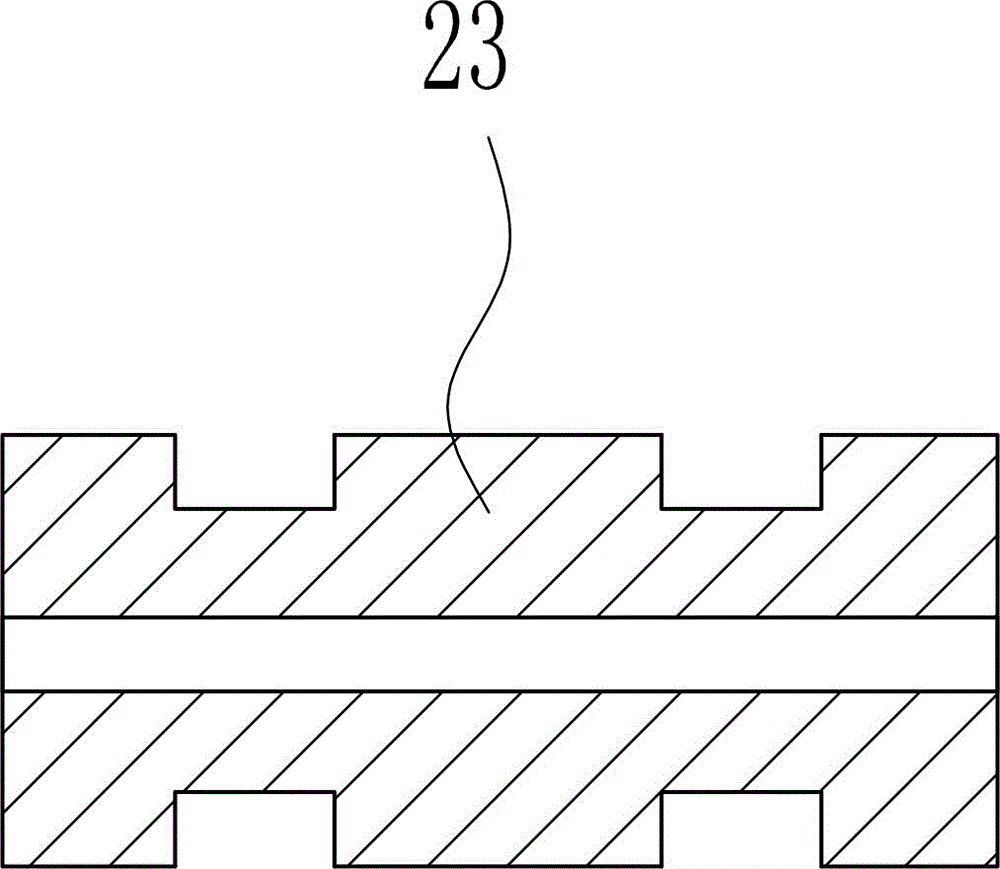

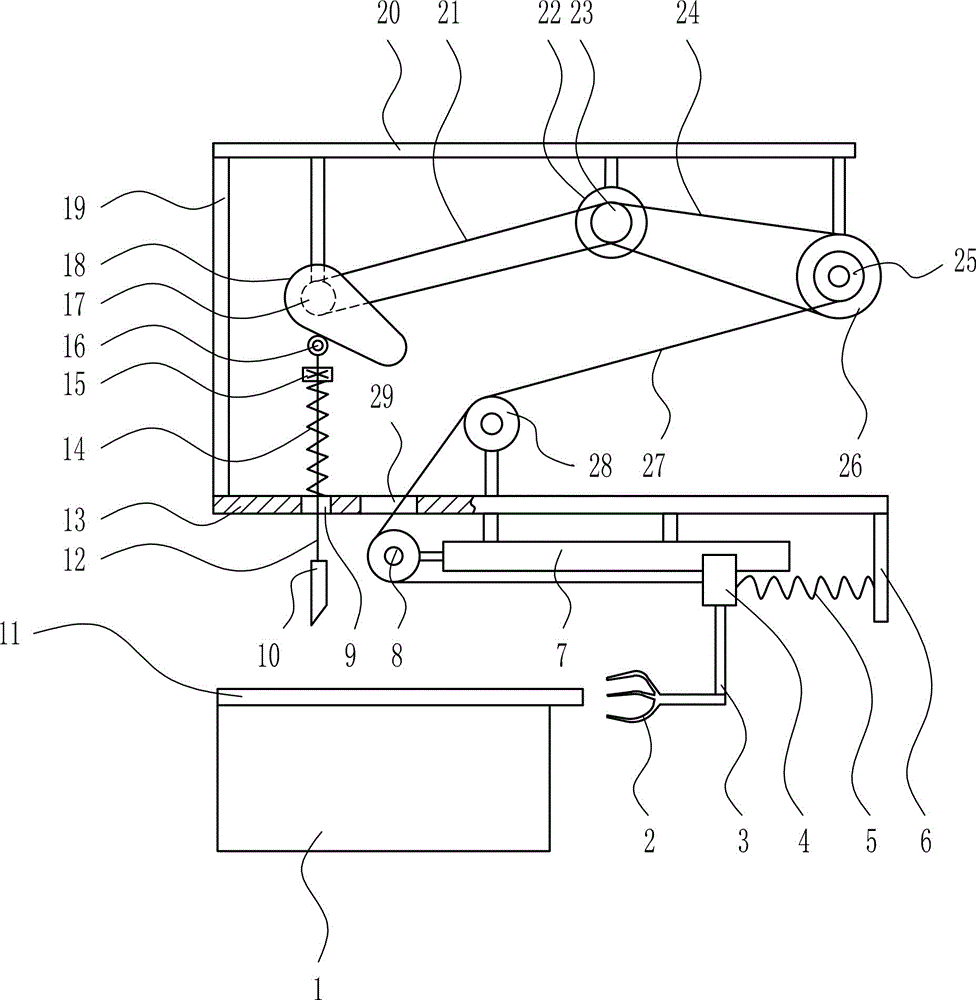

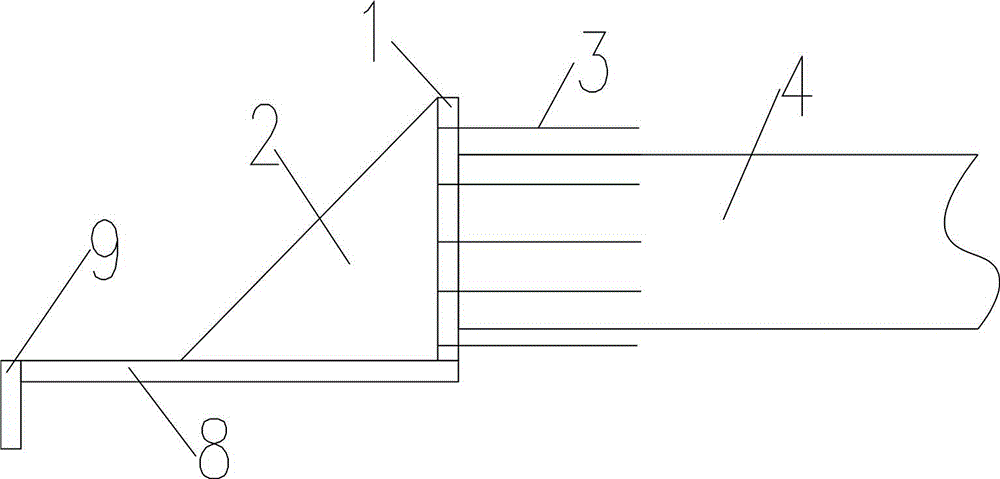

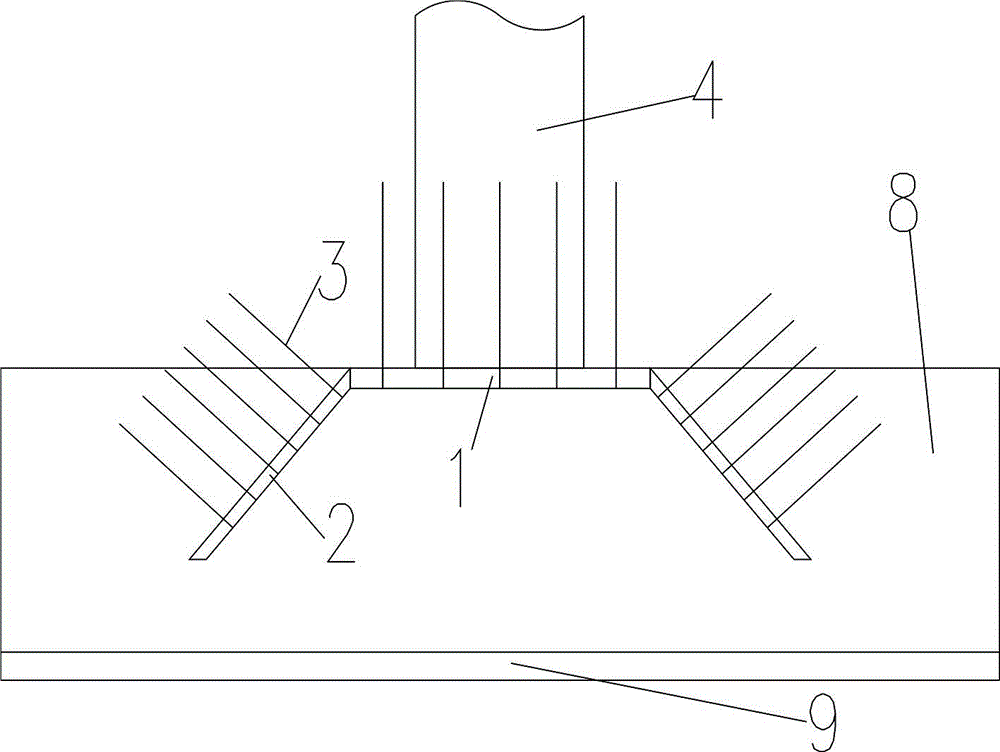

InactiveCN102632451AEasy to processRealize the purpose of one machine with two usesPolishing machinesDual purposeElectric control

The invention relates to a dual-purpose polishing machine for inner and outer walls of a steel tube, comprising a rotary feed mechanism, a supporting mechanism and an electric control cabinet for controlling the rotary feed mechanism and the supporting mechanism, wherein the rotary feed mechanism comprises a motor base and a first motor fixed on the motor base; the supporting mechanism comprises a plurality of supporting wheel sets and a second motor for controlling the rotation of the supporting wheel sets; a grinding bar is in driving connection on an output shaft of the first motor; a grinding head is fixedly connected at the other end of the grinding bar; and the supporting wheel set for rotating the steel tube is arranged at the front end of the grinding head. According to the invention, the rotary feed mechanism is designed to be of a structure capable of adjusting up and down to ensure that processing of the steel tubes with different models is convenient; meanwhile, the outer circle of the steel tube can also be polished through adjusting the up-and-down positions of the rotary feed mechanism to ensure that the purpose of one machine with dual purposes is realized and the cost is saved; and the dual-purpose polishing machine is compact in structure and simple in operation.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

Jacking pipe cutting protective structure for building remains and construction method thereof

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

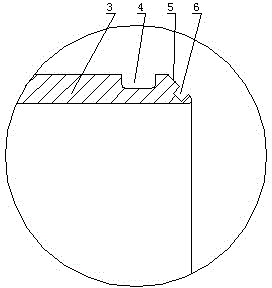

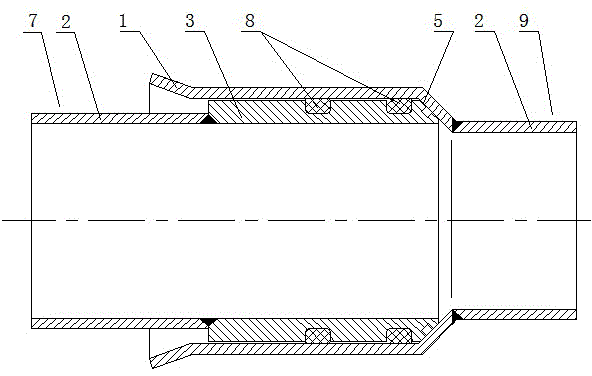

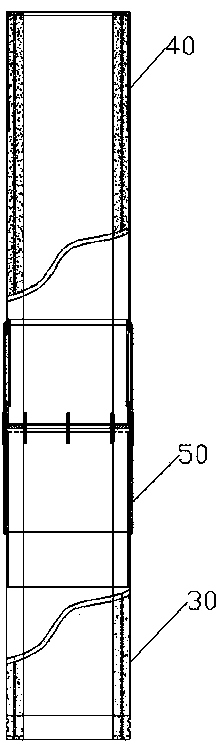

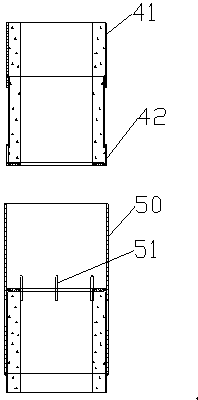

Steel pipe with bell and spigot joints

Owner:JILING YULINGLONG STEEL PIPE STEEL STRUCTURE MFG

Two-roll tandem pipe mill and roll framework locking device thereof

Owner:TAIYUAN HEAVY IND

Combined splicing tubular pile and pile splicing method

Owner:国鼎(南通)管桩有限公司

Horizontal biaxial extension testing machine and tension testing method thereof

Owner:SOUTHEAST UNIV

Culvert mouth of corrugated steel pipe culvert

Owner:CHINA THREE GORGES UNIV

Device and method for decreasing columns and reinforcing girders of reinforced concrete members

ActiveCN103452328AImprove efficiencyLow costBuilding repairsReinforced concrete columnSocial benefits

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

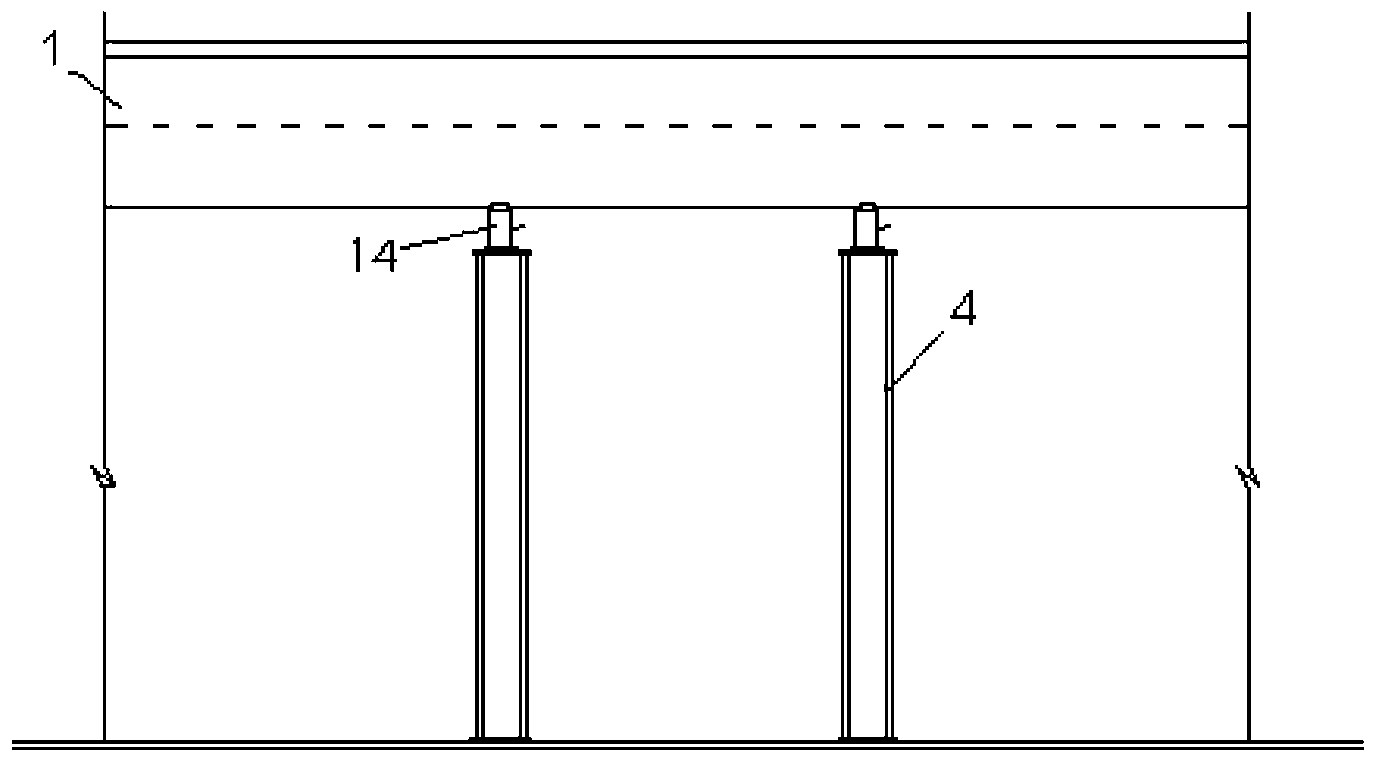

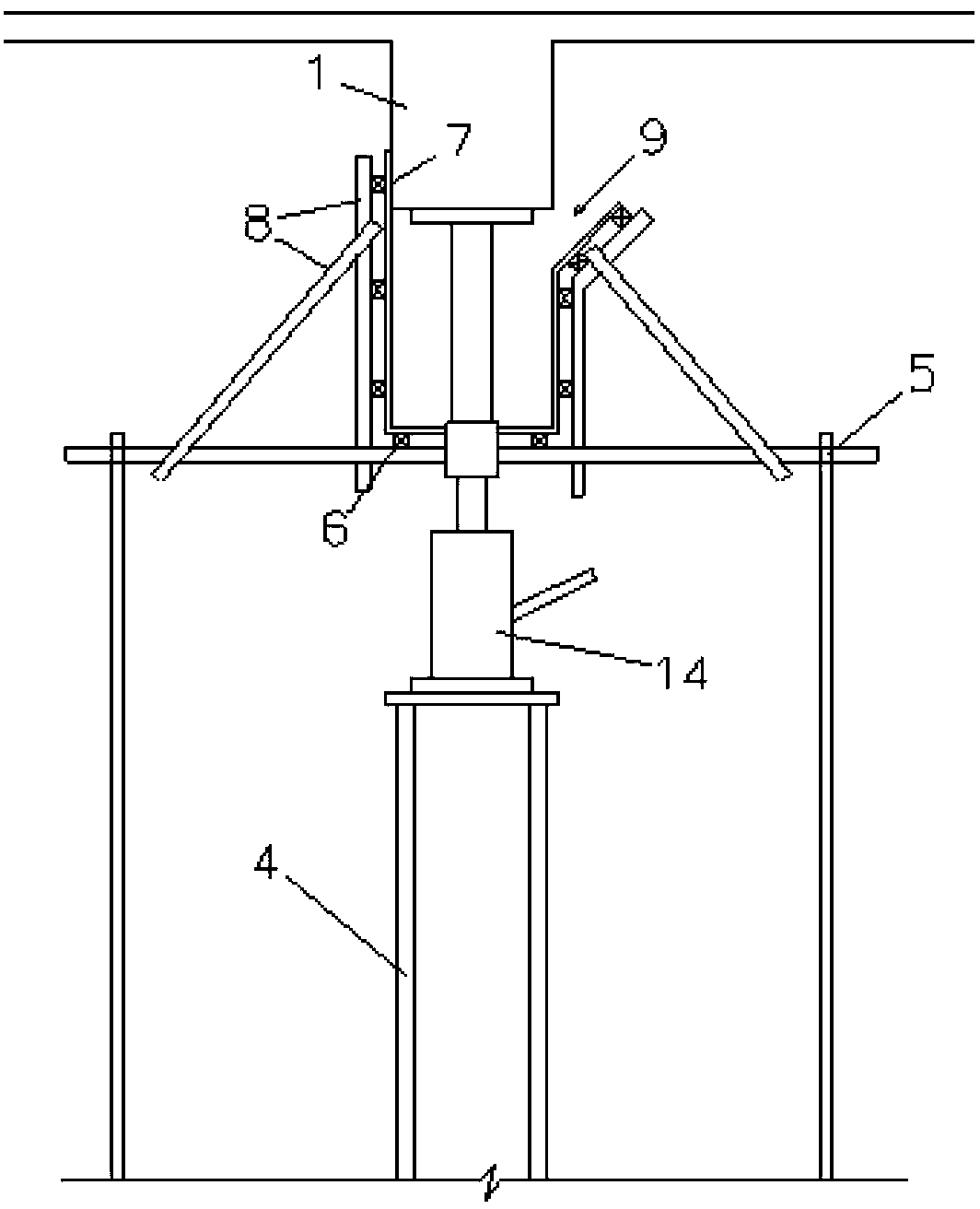

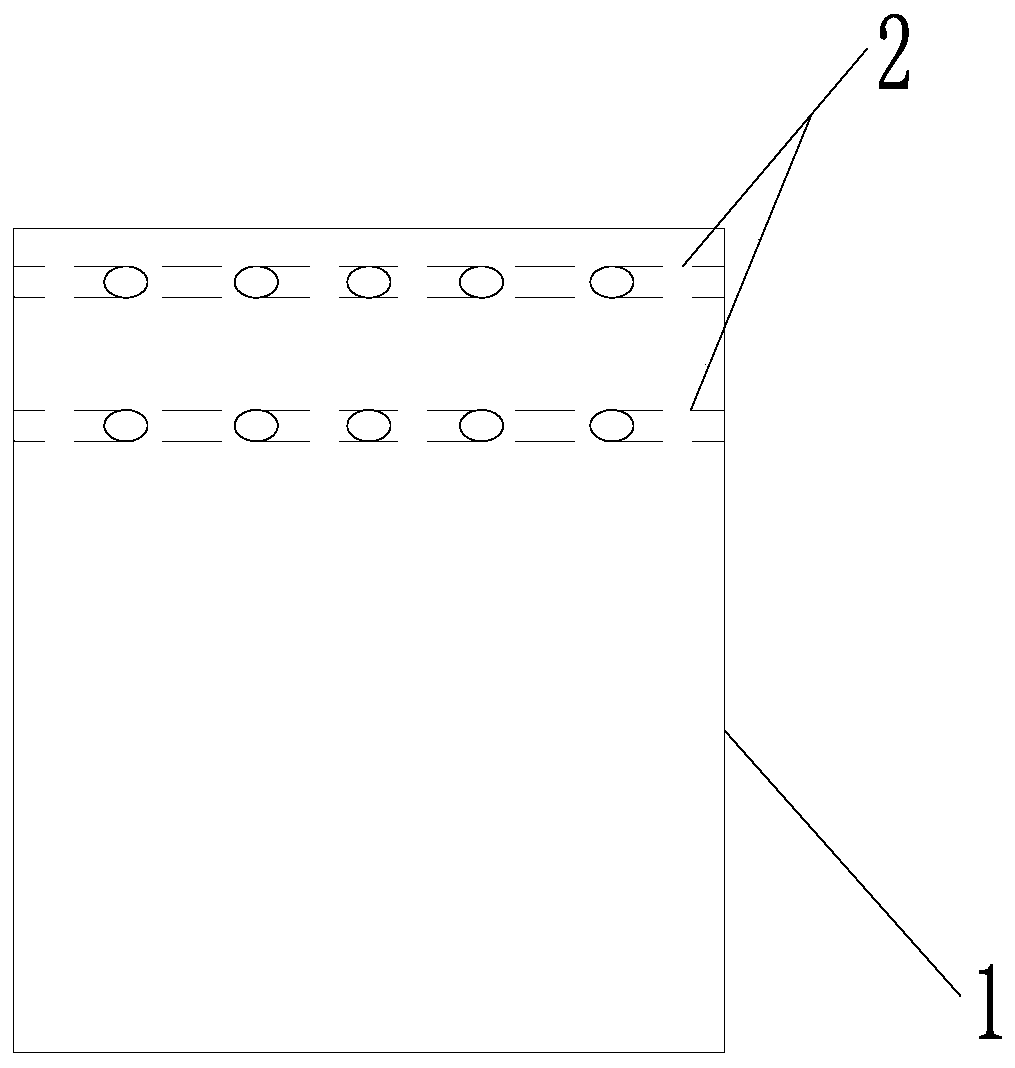

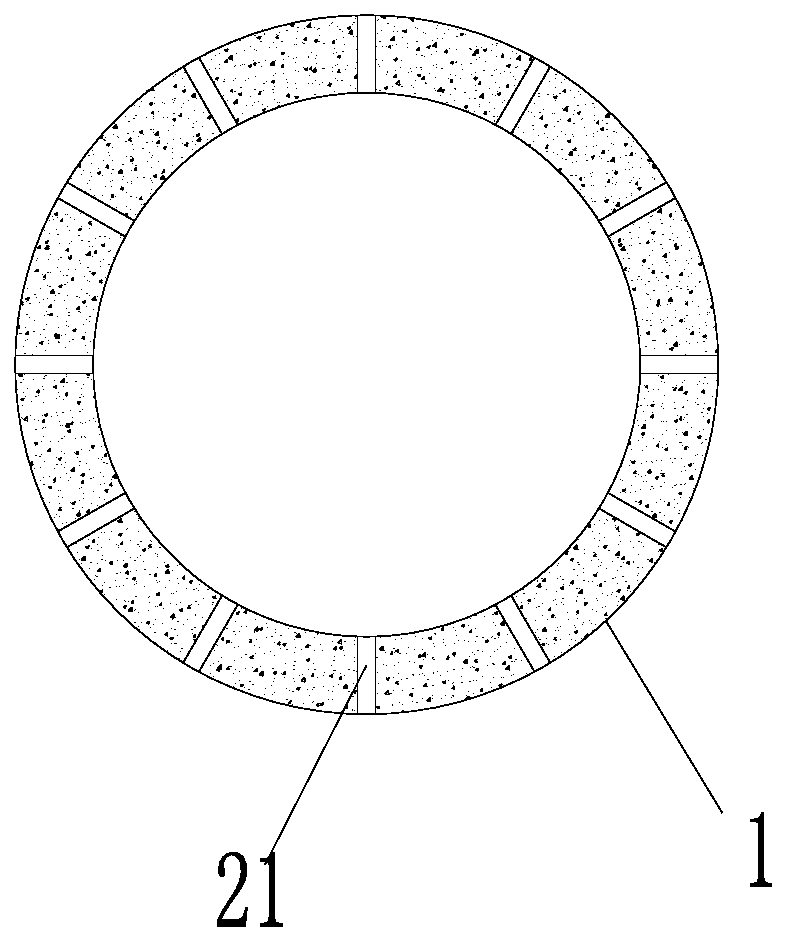

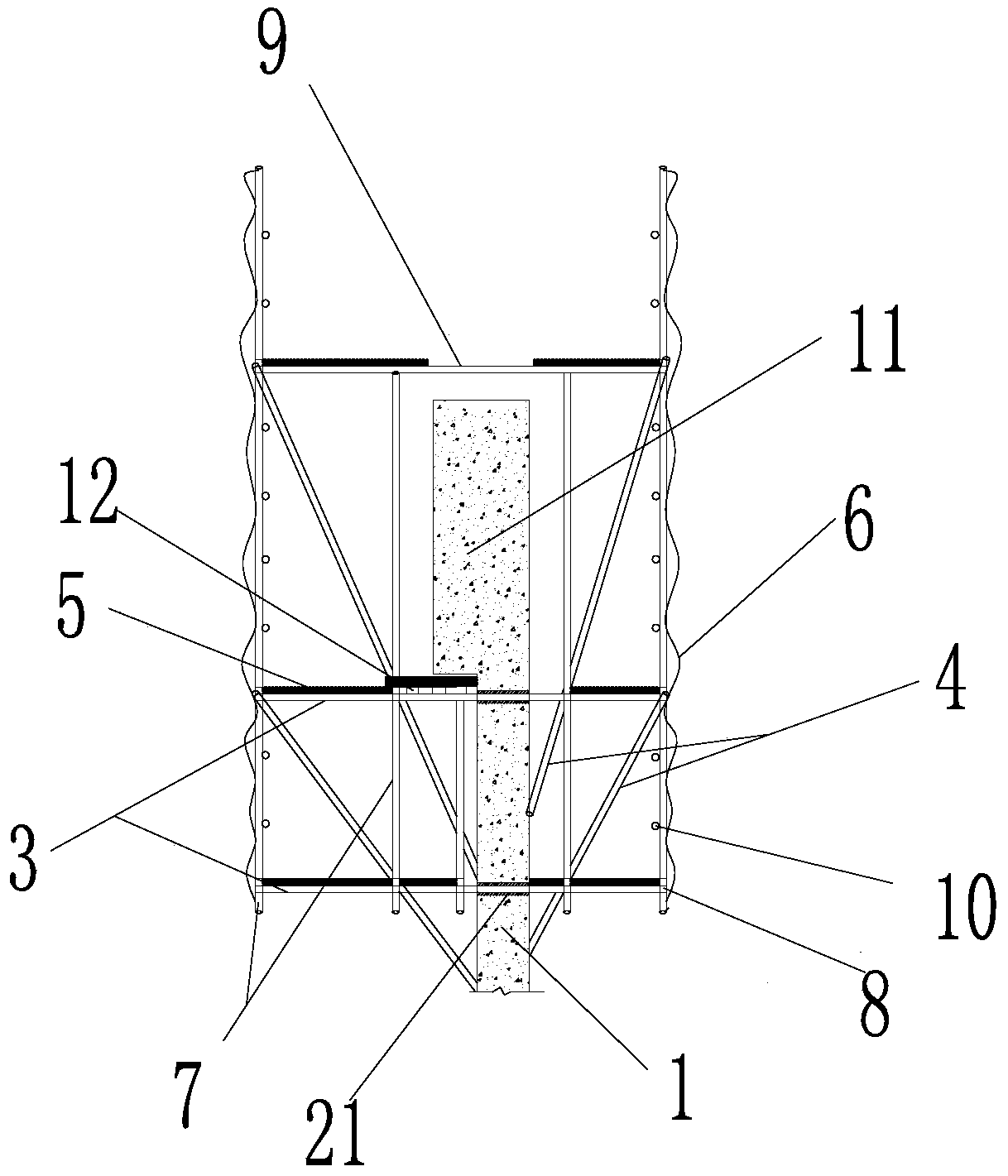

Erecting structure and erecting method for top ring beam construction platform of concrete silo

InactiveCN110725597ALess materialSimple structureBulk storage containerBuilding support scaffoldsArchitectural engineeringPipe layer

Owner:CHINA 19TH METALLURGICAL CORP

Steel pipe length measuring device

Owner:江苏统联科技股份有限公司

Production method of L80-1 steel-grade oil casings with low cost

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Device for brushing paint on inner wall of steel tubes

Owner:中建五局安装工程有限公司

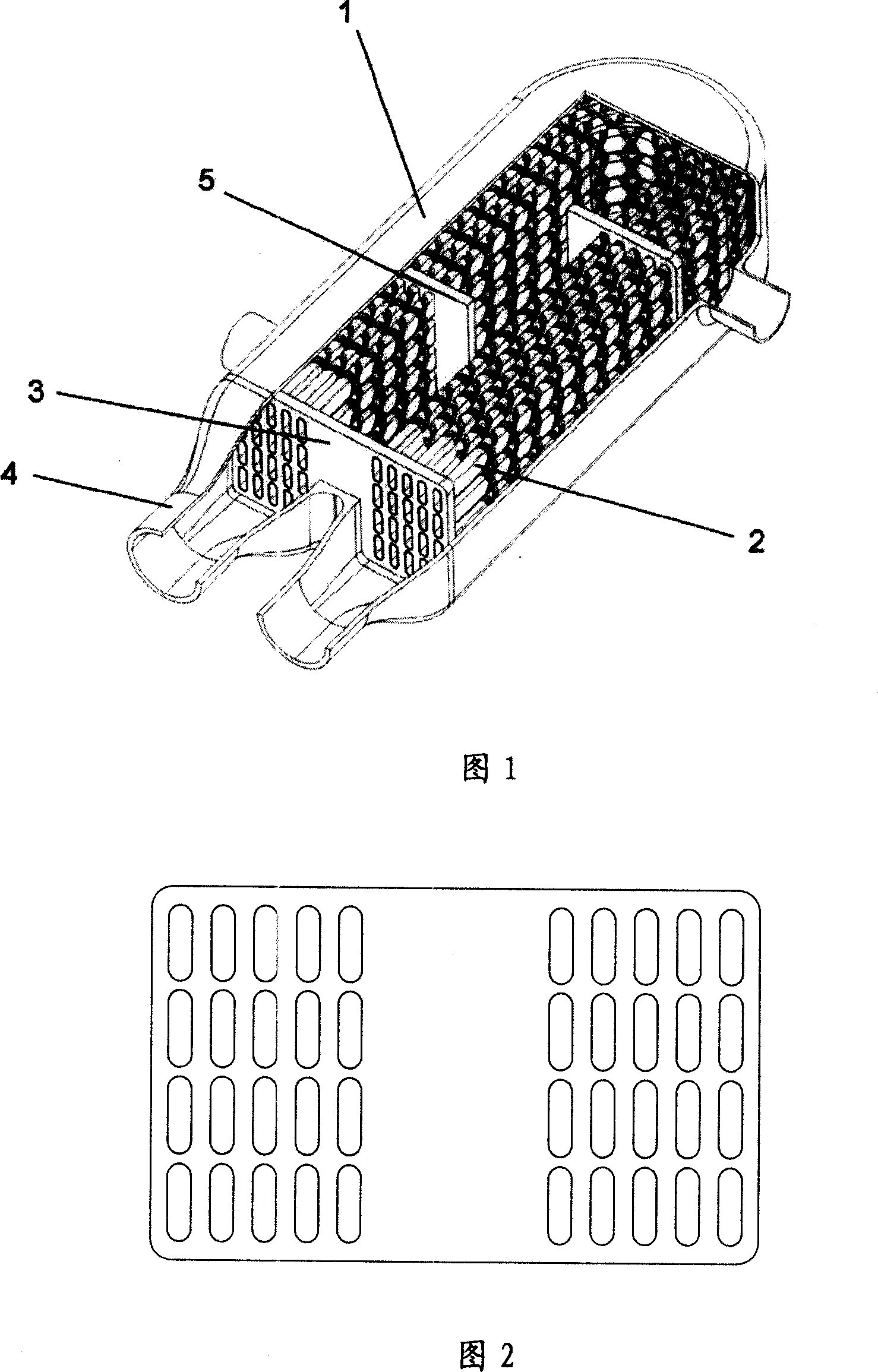

Shell-and-tube type heat exchanger employing crossed spiral tube

ActiveCN101101186ACompact layoutRapid coolingStationary conduit assembliesTubular elementsSiphonEngineering

Owner:BEIJING U BRIDGE CHAOYANG +1

Steel pipe cutting machine capable of cutting multiple steel pipes simultaneously

InactiveCN108705136ASolve cutting problemsAvoid the problem of too slow cutting speedTube shearing machinesShearing machine accessoriesArchitectural engineeringSteel tube

Owner:裴彬

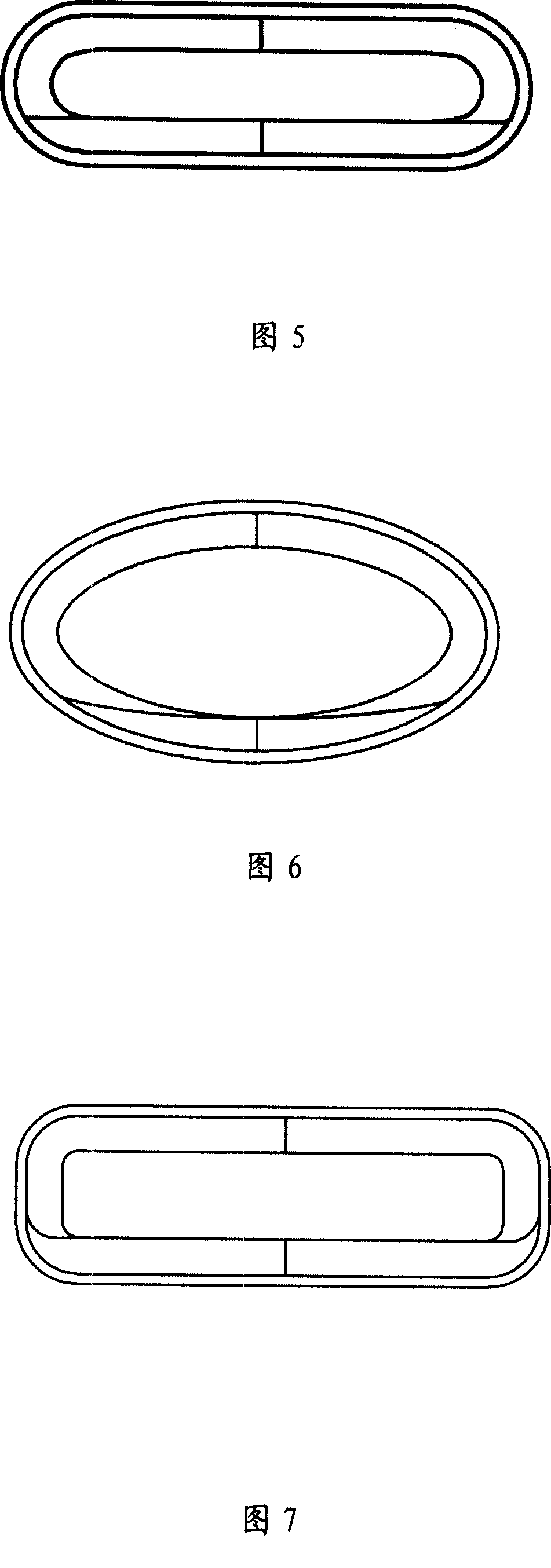

Steel tube sheet winding machine

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

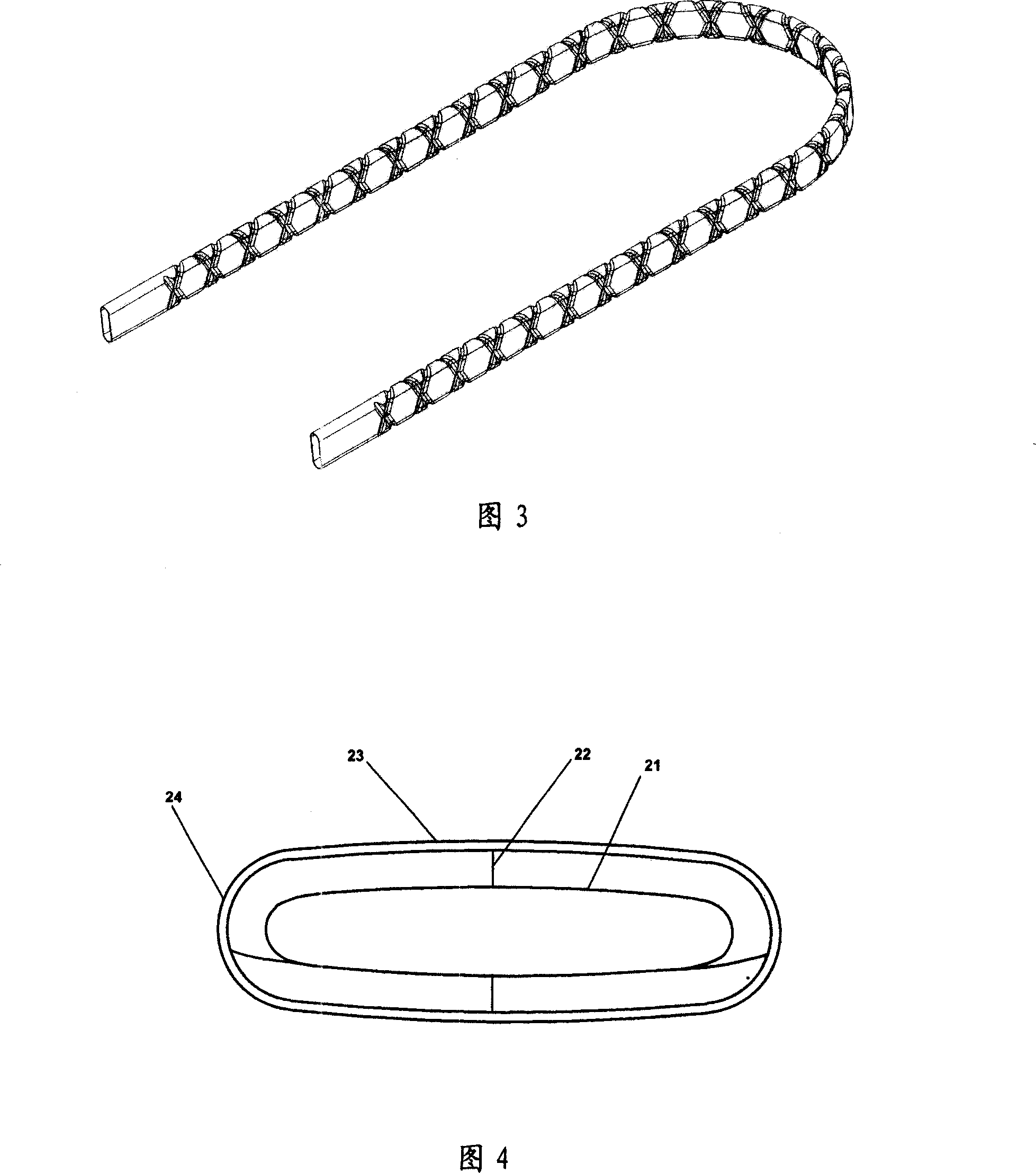

Manufacturing method of bamboo spring bracket and application thereof

InactiveCN109227826AReduce usageReduce production processWood working apparatusCane mechanical workingCarbonizationEngineering

Owner:NANJING FORESTRY UNIV

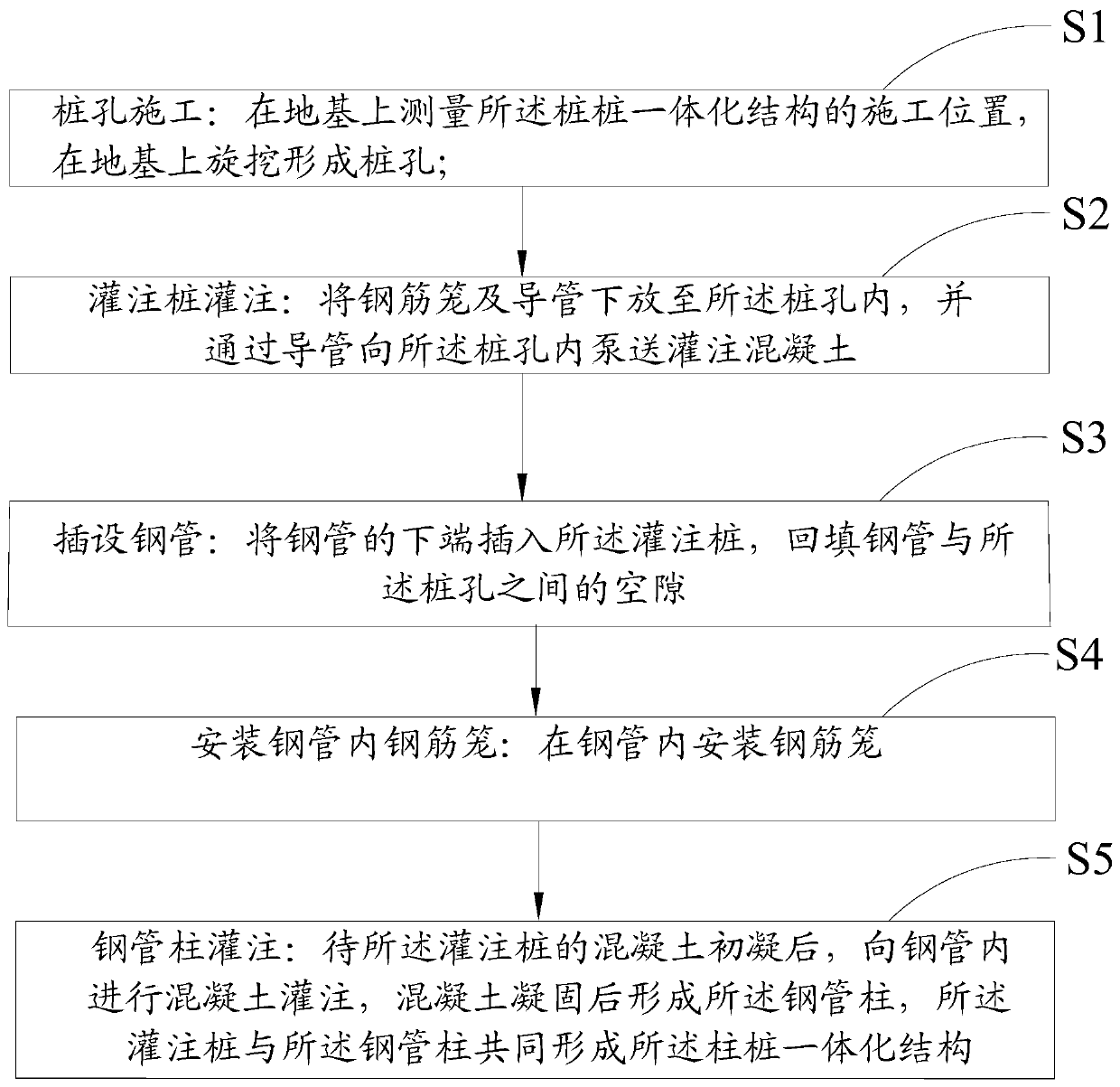

Construction method of pile-column integrated structure

Owner:SHENZHEN MUNICIPAL ENG +1

Friction rust removal device for inner wall and outer wall of steel pipe

Owner:浦江县旭星机械科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap