Production method of L80-1 steel-grade oil casings with low cost

A technology of oil casing and production method, applied in the direction of furnace type, furnace, quenching agent, etc., can solve the problems of lack of competitiveness and high cost, and achieve the effects of low cost, improved plasticity, and reasonable material composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

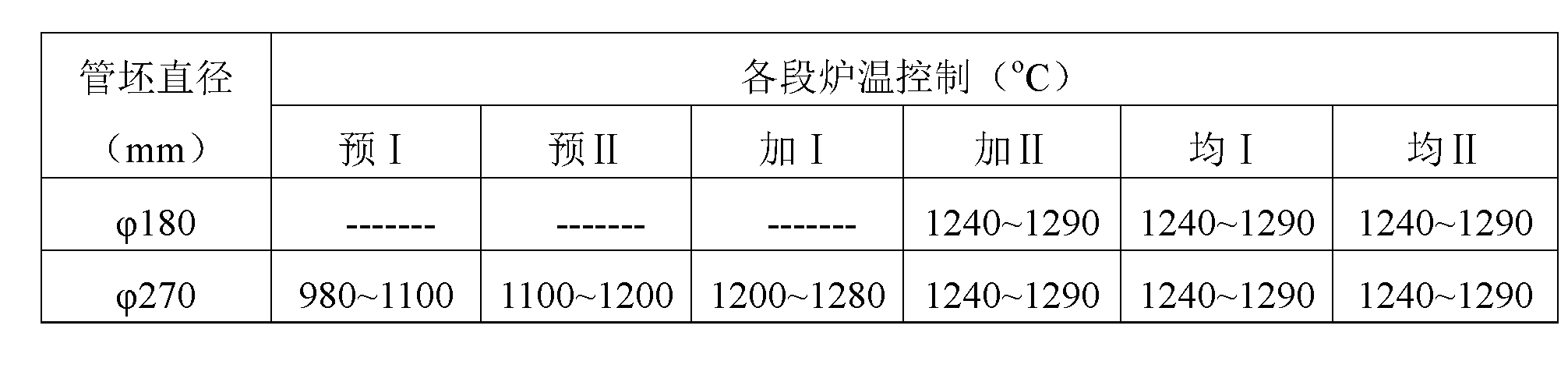

Image

Examples

Embodiment 1

[0028] 1. Composition of smelting products and sulfur printing results

[0029] The composition of the smelted finished product is shown in Table 2, and the test results of the slab sulfur marks are listed in Table 3. Most of the central cracks and inclusions are grade one, and most of the middle cracks and subcutaneous cracks are zero grade. The quality of the billet is in good condition.

[0030] Table 2 Composition of 30MnCr22 continuous casting finished products (%)

[0031] C Si mn P S Cr Al scope 0.27~0.33 0.20~0.36 1.28~1.54 ≤0.030 ≤0.025 0.14~0.31 0.012~0.038 average value 0.29 0.30 1.41 0.021 0.015 0.24 0.034 standard 0.26~0.34 0.18~0.38 1.25~1.55 ≤0.030 ≤0.025 0.12~0.32 0.01~0.04

[0032] Table 3 Sulfur print inspection results of billets

[0033] Center crack (level) Middle crack (grade) Subcutaneous crack (grade) Inclusions (level) Number of zero levels 2 55 58 0 first level n

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap