Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Heat treating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat treating (or heat treatment) is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. It is noteworthy that while the term heat treatment applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding.

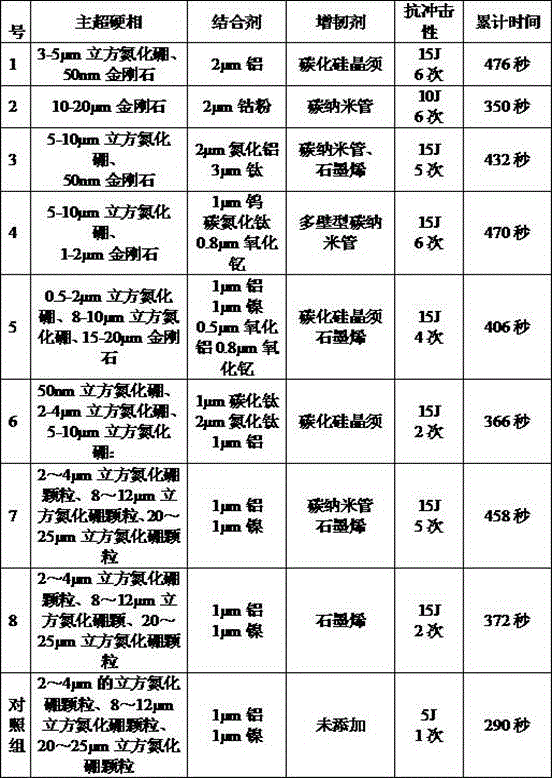

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

Method for preparing silicon carbide ceramic material with low residual silicon by adopting multi-step reaction sintering method

ActiveCN106478105ASolve the mechanical propertiesSolving Elasticity ProblemsHeat conductingYoung's modulus

Owner:咸阳瞪羚谷新材料科技有限公司

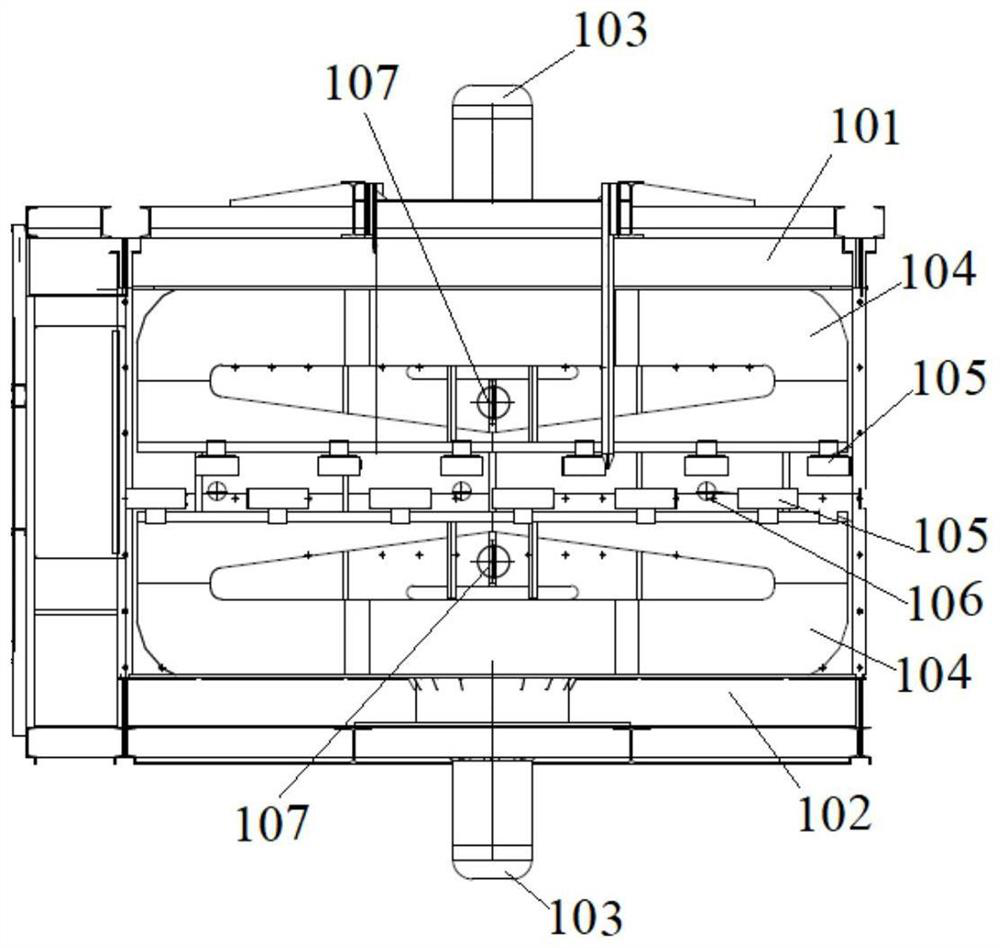

Au-Sn alloy sputtering target material and preparation method thereof

ActiveCN105132873ALow germanium contentVacuum evaporation coatingSputtering coatingIngotHeating furnace

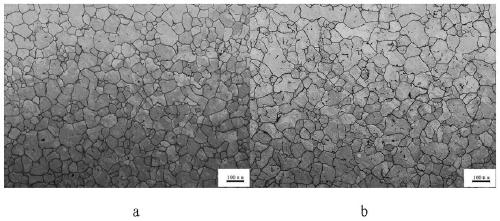

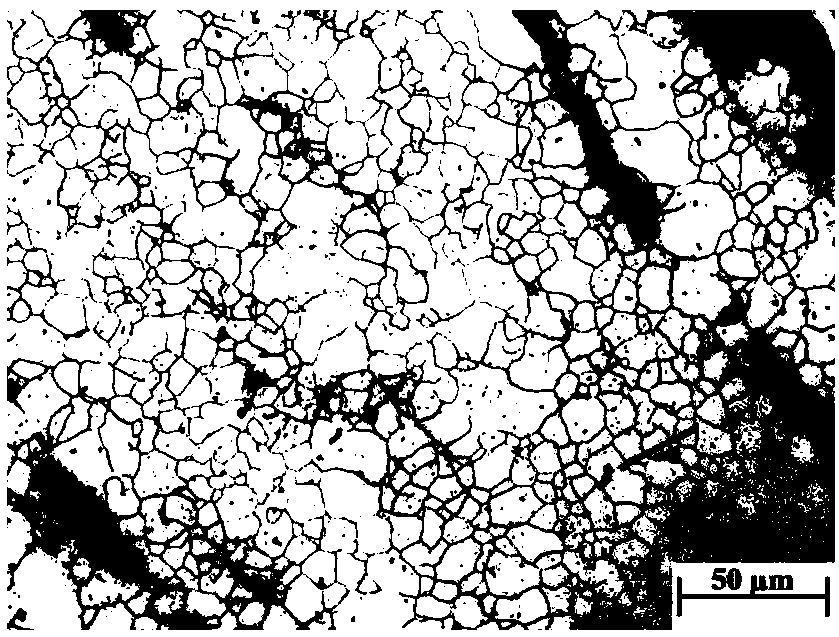

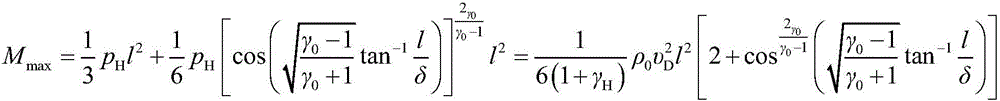

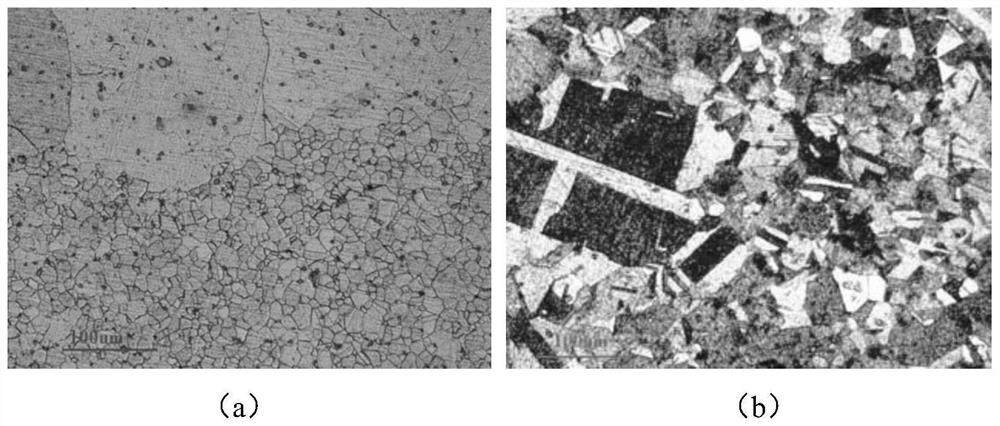

The invention relates to an Au-Sn alloy sputtering target material and a preparation method thereof. The method comprises the following steps: 1, Au and Sn are taken as raw materials, vacuum induction melting and vacuum casting are used for casting so as to obtain an eutectic or hypo eutectic Au-Sn alloy ingot, wherein the content of Ge in the alloy ingot accounts for 2 to 12.5 wt percent, and the content of Au serves as the balance; 2, a heating furnace is used for carrying out homogenization heat treatment on the alloy ingot obtained in the step 1; the temperature of the homogenization heat treatment is 270 to 340 DEG C, and the time is 50 to 65 minutes; 3, plastic working equipment is used for carrying out hot plastic processing to the ingot in the thickness direction; 4, the blank is placed inside the heating furnace for temper heat treatment after each 1 to 2 times of processing, the temperature is 270 to 340 DEG C, and the time is 10 to 30 minutes; and 5, the step 3 and the step 4 are repeated until the required target blank dimension is obtained. The Au-Sn alloy sputtering target material obtained through the method is even in components, and has a microscopic structure mainly composed of an Au solid solution and bulks of Ge distributed in a diffused manner.

Owner:GRIKIN ADVANCED MATERIALS

Novel process for precision forging of disc steering knuckle

InactiveCN102319866AAdvanced precision forging technologyIncrease productivityRailway componentsVehicle componentsNational standardForge

Owner:桂林福达重工锻造有限公司

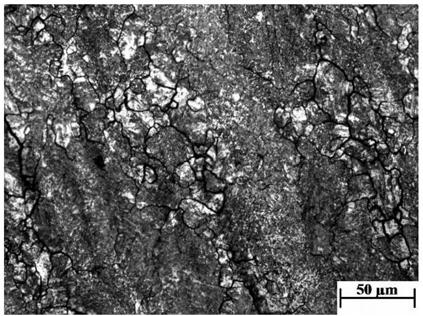

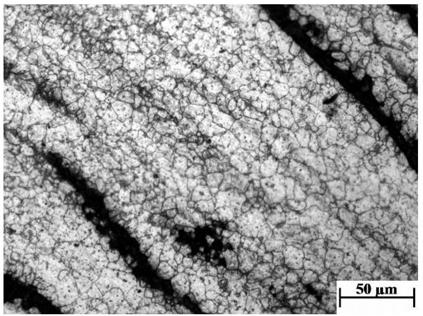

Copper/cerium-containing antimicrobial stainless steel and preparation method thereof

The invention discloses a copper / cerium-containing antimicrobial stainless steel and a preparation method thereof. The copper / cerium-containing antimicrobial stainless steel comprises the following chemical components in percentage by weight: at most 0.08% of C, at most 1% of Si, at most 2.00% of Mn, less than 0.045% of P, less than 0.030% of S, 17.5-20.0% of Cr, 8-11% of Ni, 0.5-2.8% of Cu, 0.01-0.45% of Ce, and the balance of Fe and inevitable impurities. The stainless steel is molten in an induction furnace after smelting, and is subjected to aging high-temperature diffusion heat treatment composed of 20-minute 1180 DEG C solid solution and 1-hour 685 DEG C thermal insulation so as to precipitate the antimicrobial phase epsilon-Cu and Ce, thereby endowing the stainless steel with antimicrobial property. The steel grade has stainless steel performance and broad-spectrum antibacterial property; the corrosion resistance, wear resistance, strength, toughness, oxidation resistance and other comprehensive properties of the stainless steel are improved; and the production technique is simple, has great utilization value in industry, and is suitable for industrial production.

Owner:SHANGHAI UNIV

Ferrierite molecular sieve, preparation method thereof and application

ActiveCN107010636AGood choiceImprove stabilityHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationCrystallinity

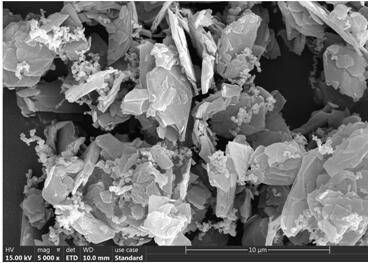

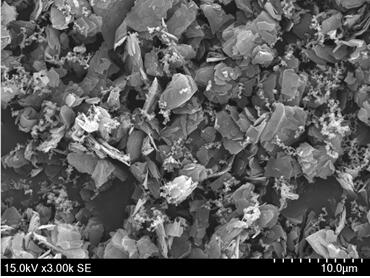

The invention provides a ferrierite molecular sieve, a preparation method thereof and an application. The preparation method includes the steps: mixing silicon sources, alkalinity conditioning agents, aluminum sources, template agents and water to form uniform sol; controlling the molar ratio of SiO2, Al2O3, R, Na2O to H2O to be 1.0:(0.005-0.10):(0.05-1.2):(0.03-0.50):(5.0-100.0), and enabling a pH (potential of hydrogen) value to be lower than 12.8; performing pre-crystallization, crystallization, drying and calcination to obtain molecular sieve raw powder; performing acid treatment on the obtained molecular sieve raw powder; mixing the molecular sieve raw powder, the template agents and the water or further mixing the molecular sieve raw powder, the template agents, the water and the silicon sources to form water solution; performing water-heat treatment, drying and calcination to obtain the ferrierite molecular sieve. R is the template agents. The prepared ferrierite molecular sieve is high in relative crystallinity and silica alumina ratio, large in specific surface area and crystal particle and adjustable in acidity and has excellent selectivity and stability when being applied to linear-chain olefin skeletal isomerization reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for improving durability of GH3536 alloy manufactured by selective laser melting technology

PendingCN111390180AAdditive manufacturing apparatusIncreasing energy efficiencyHeat treatingAnisotropy

Owner:南京国重新金属材料研究院有限公司

Special-steel-material flexible wheel of harmonic reducer, and cyclic heat treatment method thereof

InactiveCN109280851AImprove fatigue lifeImprove stabilityFurnace typesHeat treatment furnacesAustenite grainReduction drive

Owner:XINING SPECIAL STEEL +1

Method of producing magnesium fluoride coating, antireflection coating, and optical element

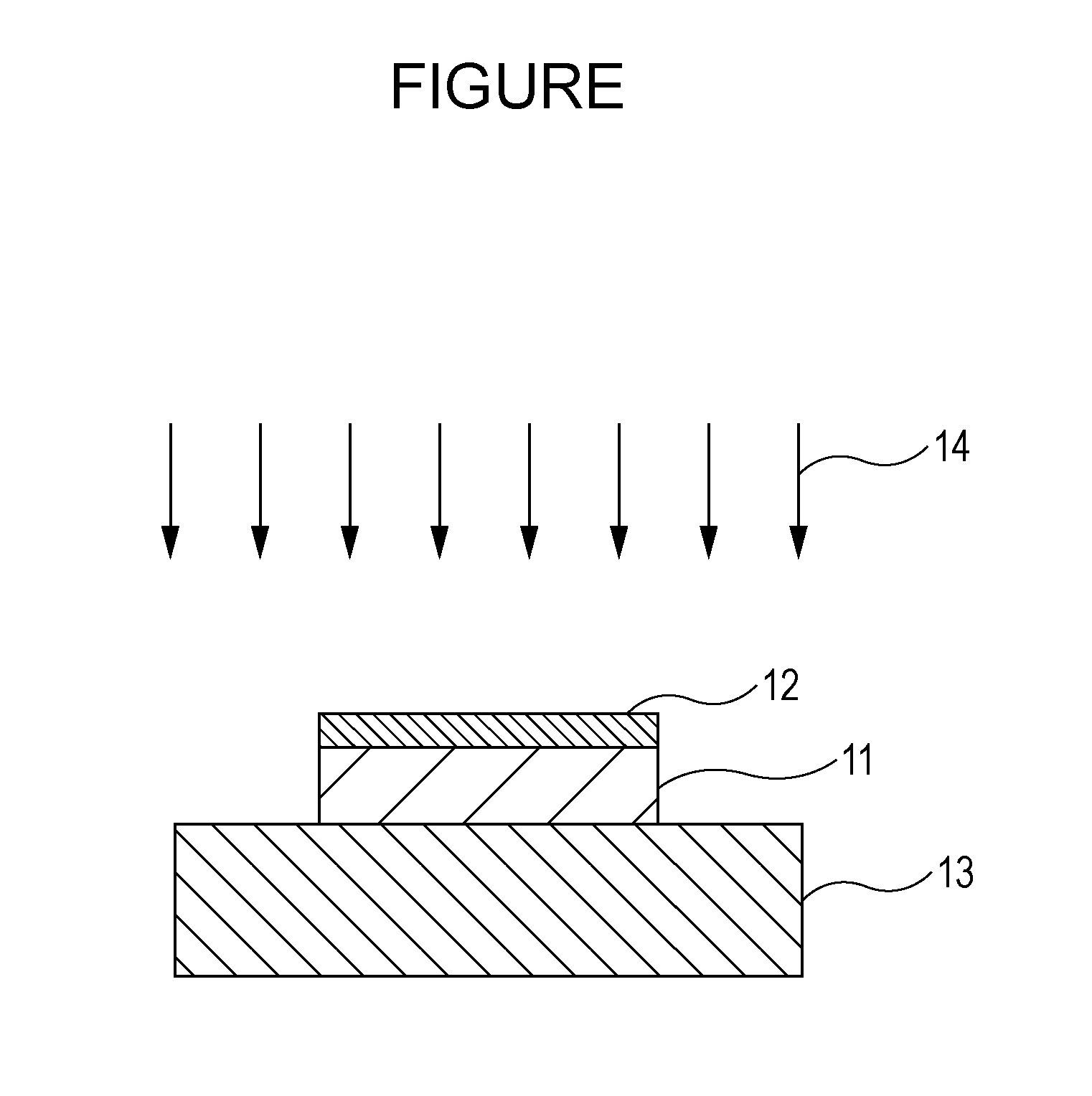

InactiveUS20110027577A1Improve anti-reflection effectLow refractive indexLayered productsRadiation applicationsMagnesium fluorideSingle bond

Owner:CANON KK

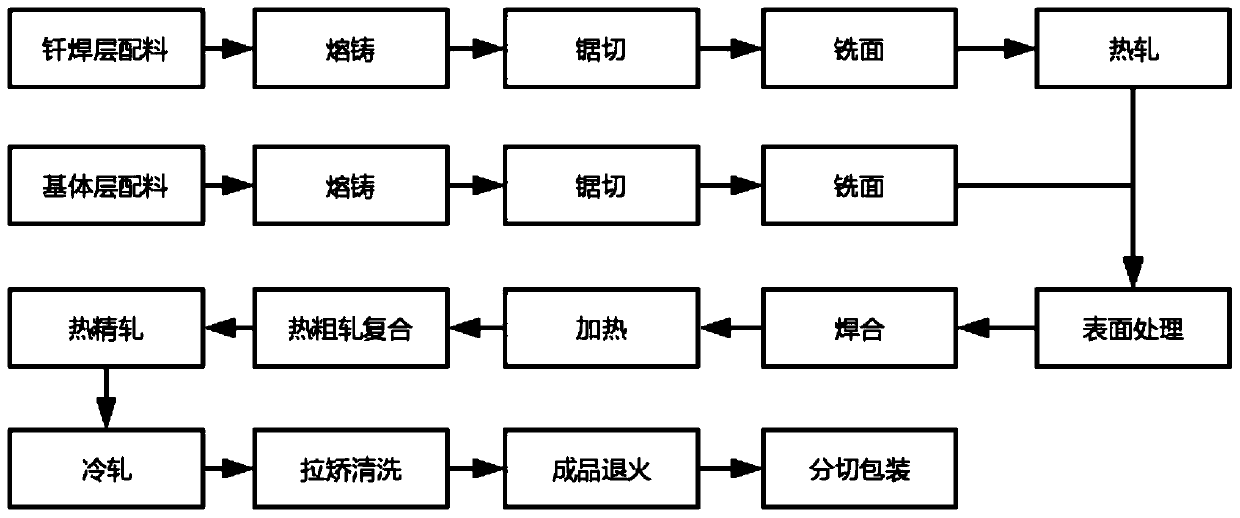

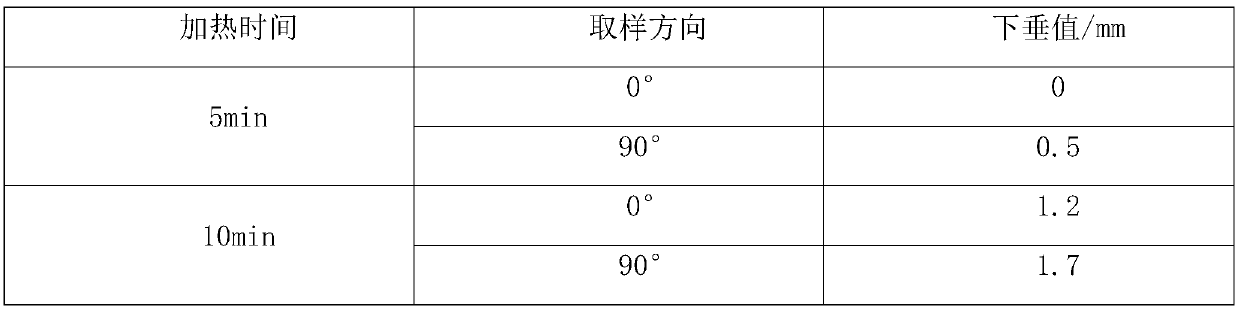

Manufacturing method of aluminum alloy three-layer composite material for brazing

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

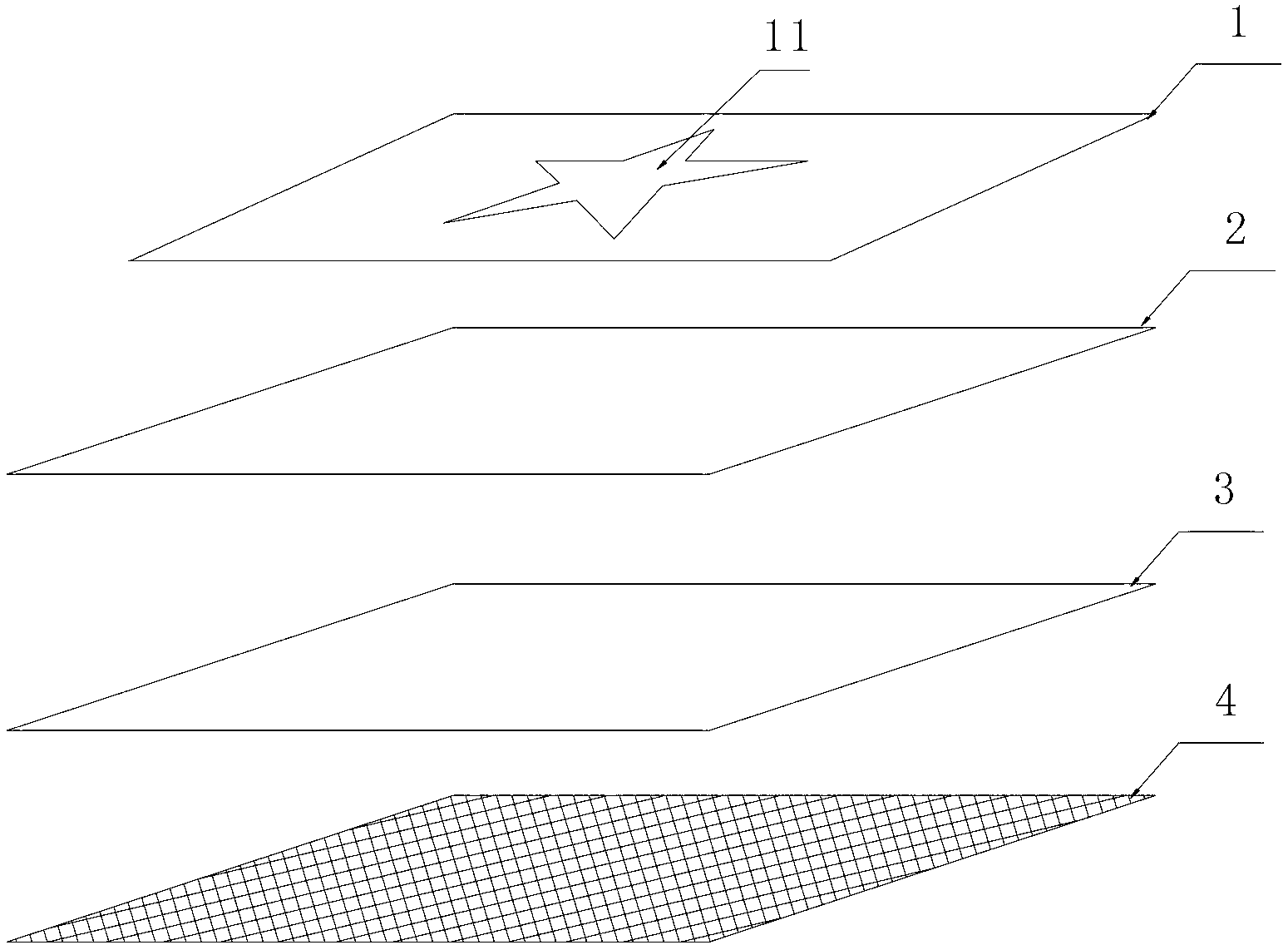

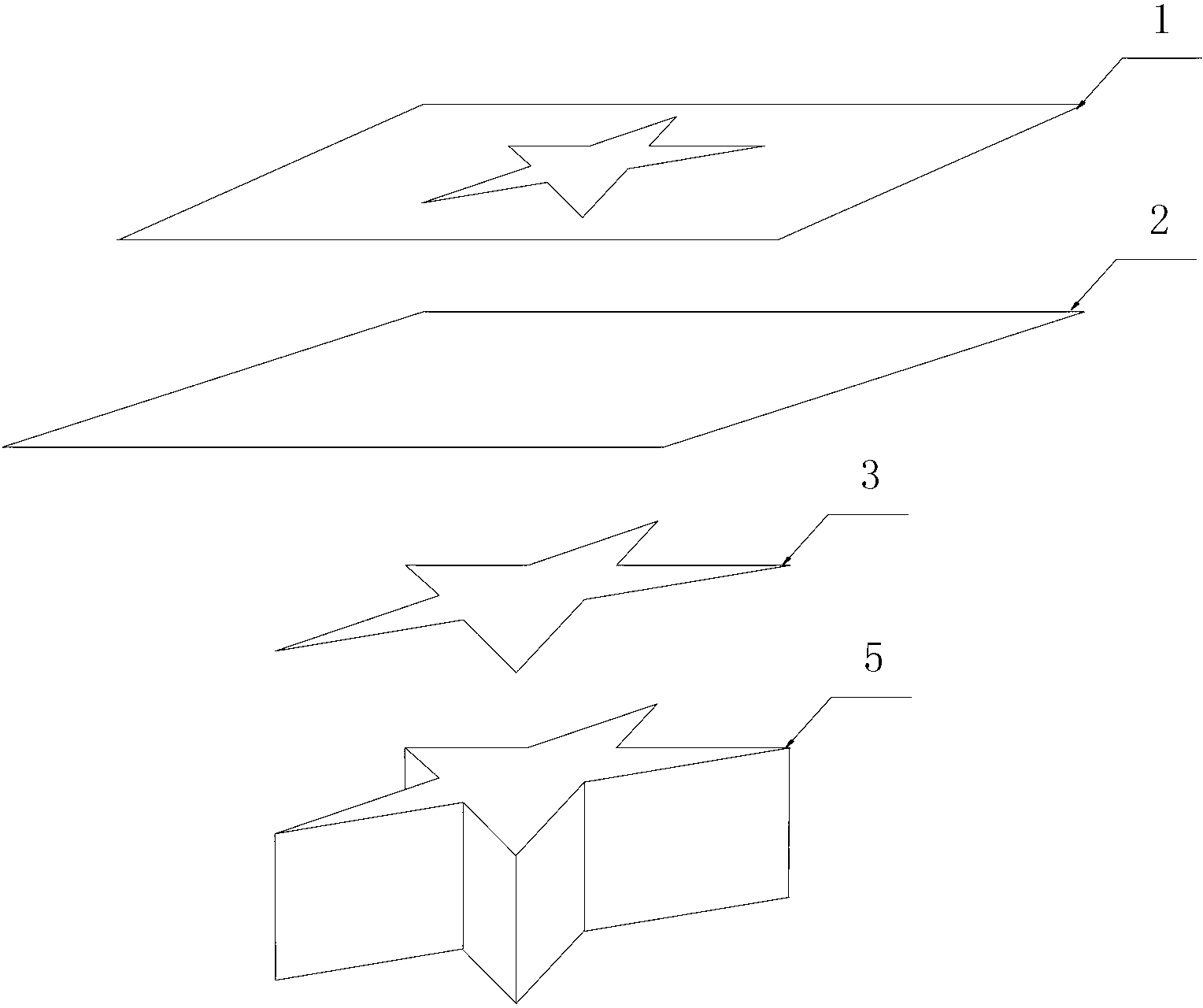

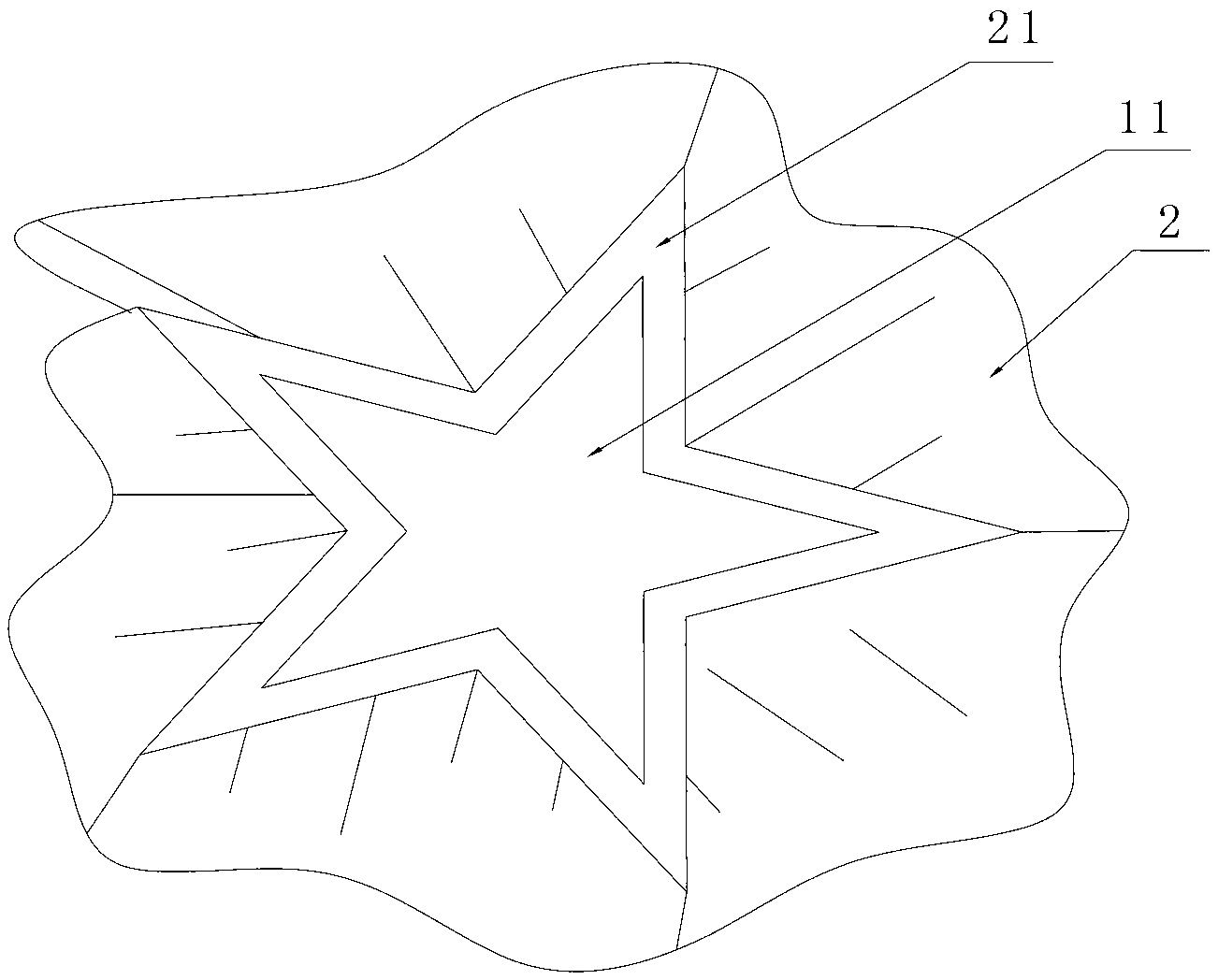

Method for applique on fabric

InactiveCN103266512AFast bondingCause sewing inconvenienceTextile decorationLaser cuttingBiomedical engineering

Owner:广州衍才烫花工艺有限公司

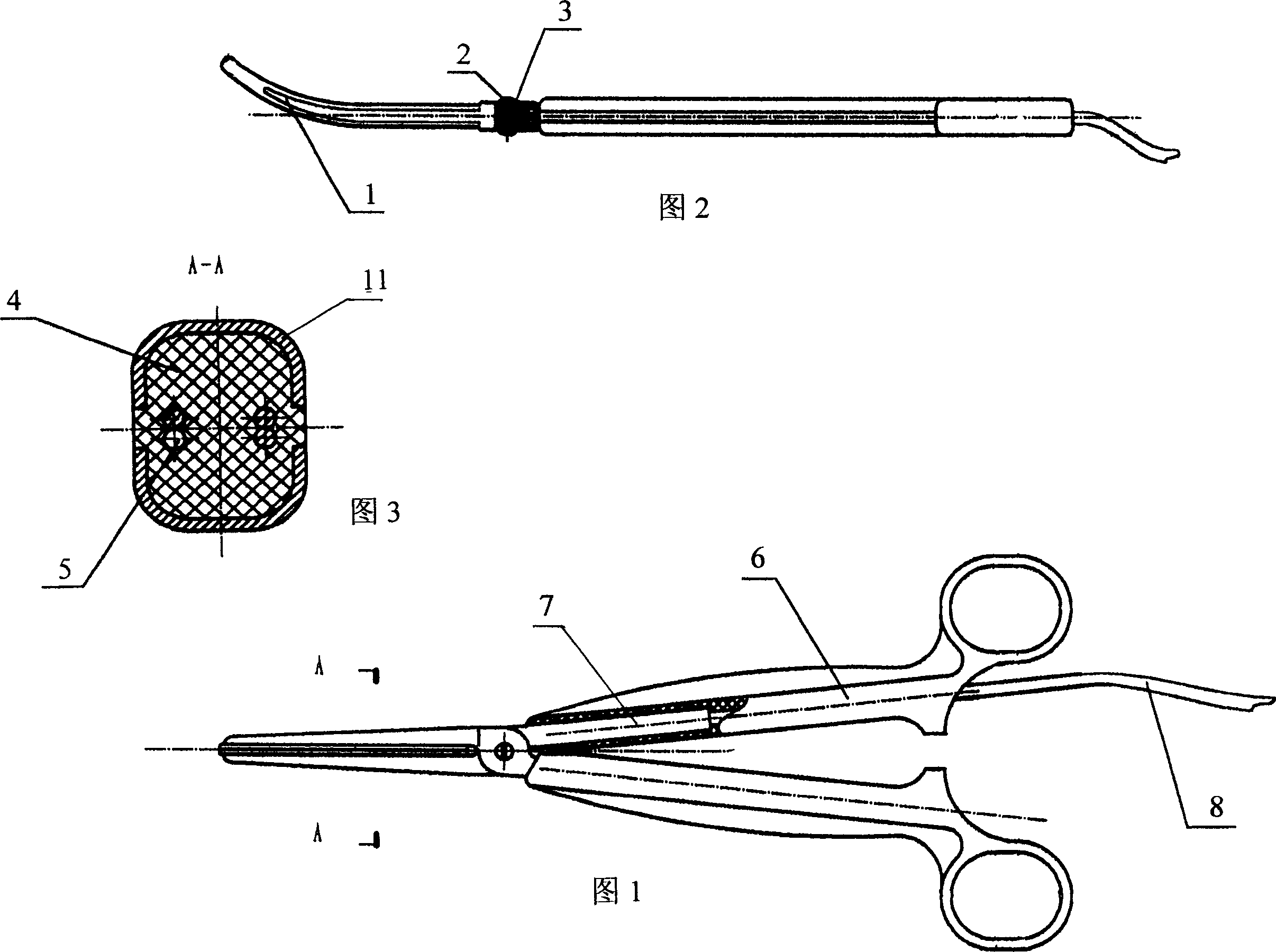

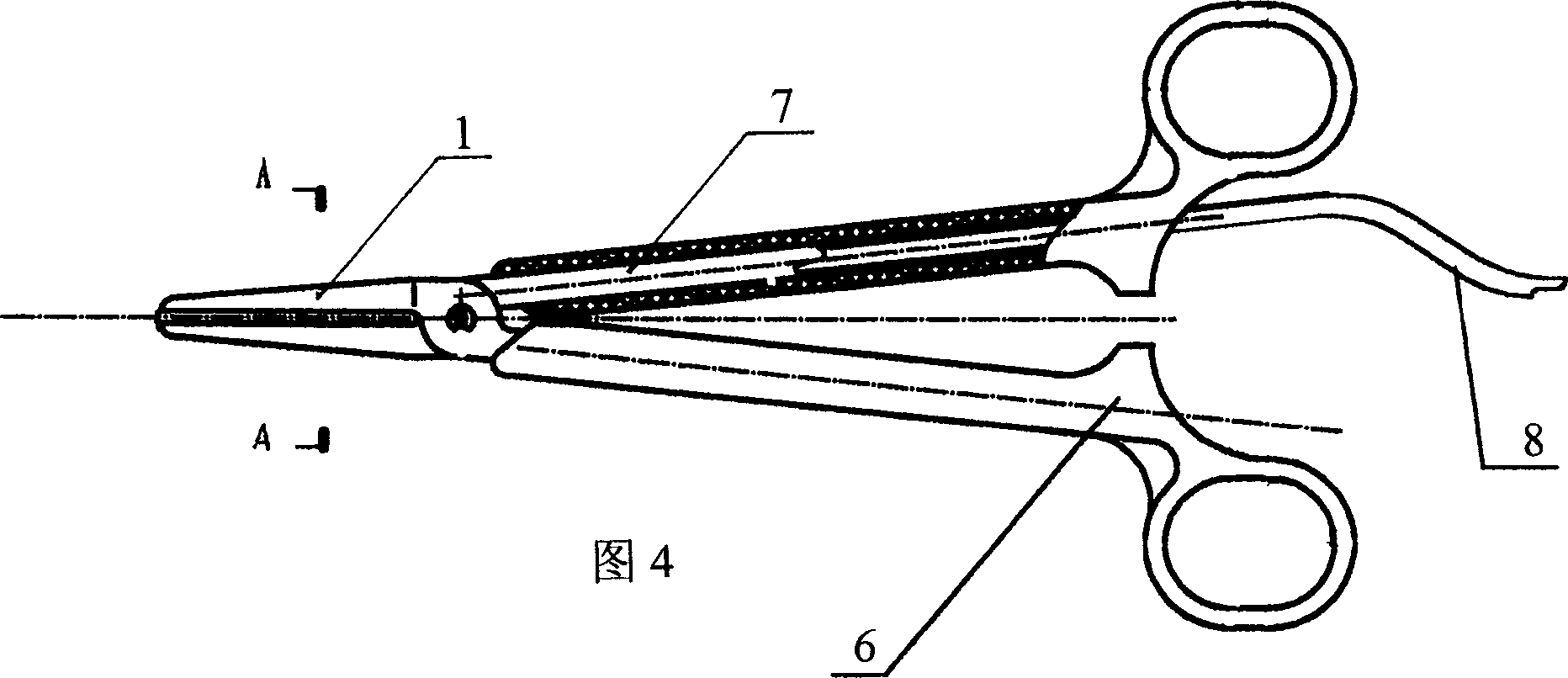

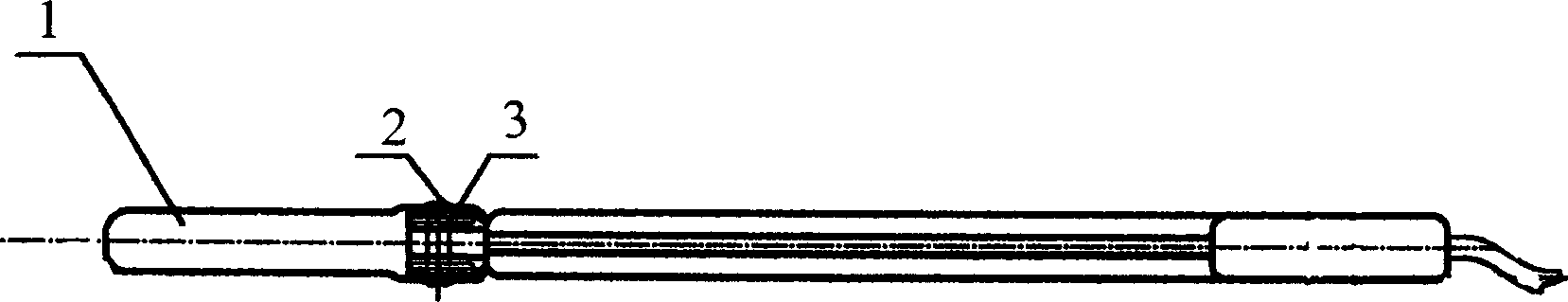

Fast ligaturing and closing electrical medical pliers and the making process

ActiveCN1608597AIncrease profitSimple and complicated processing procedureSurgical instruments for heatingCapacitancePunching

Owner:寿张根

Preparation method of hydrogenation catalyst

ActiveCN103769147AReasonable hole structureSurface acidity is suitableCatalyst carriersTreatment with hydrotreatment processesPore distributionCombined method

Owner:CHINA PETROLEUM & CHEM CORP +1

Heat treatment process for lowering yield ratio of ultra-high-strength marine steel

Owner:SUQIAN NANGANG JINXIN STEEL ROLLING CO LTD

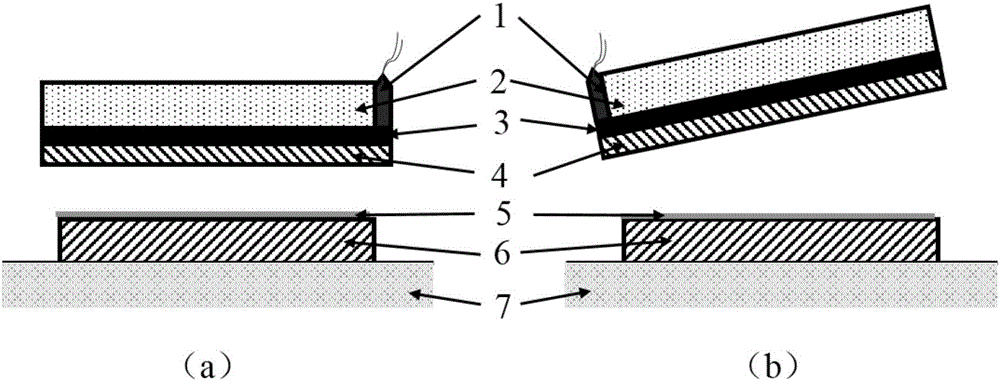

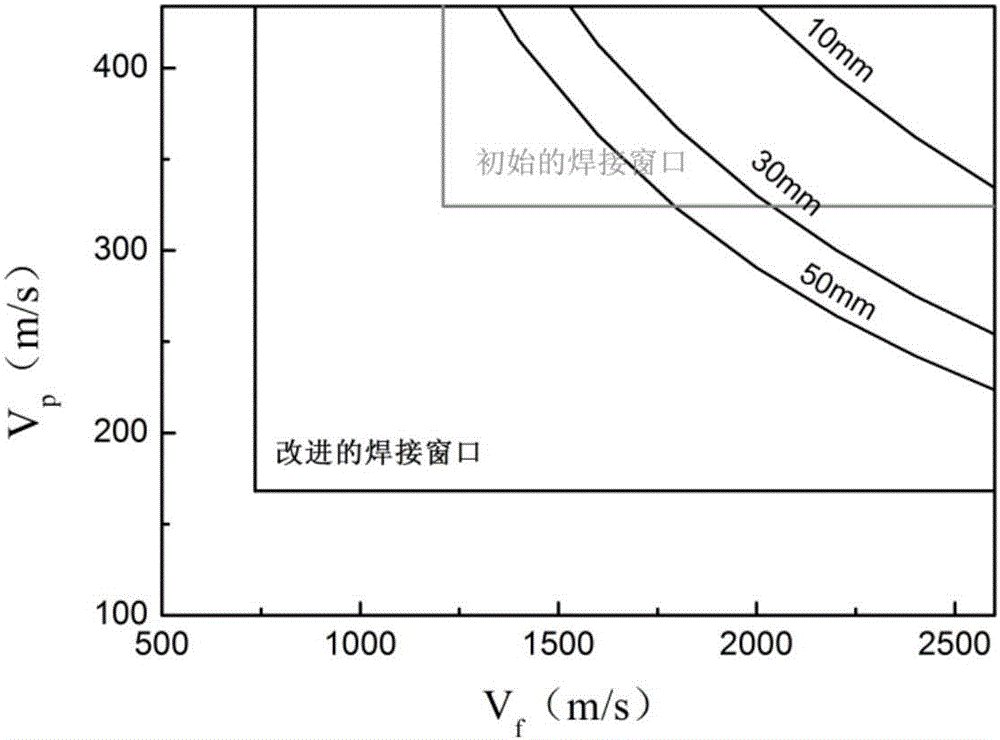

Method capable of improving explosive welding weldability of large-thickness high-strength alloy

Owner:XI AN JIAOTONG UNIV

Method for preparing wear-resistant plastic particles by using waste polystyrene

InactiveCN110760138AImprove wear resistanceSolve the defect of poor wear resistanceCyclohexanoneSilicic acid

The invention discloses a method for preparing wear-resistant plastic particles by using waste polystyrene. The method specifically includes the following steps that (1) the waste polystyrene and liquid paraffin are put into a reactor for heat treatment under the nitrogen environment, then cobalt powder is added for natural cooling, and pretreated polystyrene is obtained; (2) tetraethyl orthosilicate is added into a chitosan solution, hydrochloric acid is added and then placed in a water bath, glutaraldehyde is added, and chitosan / silica particles are obtained by reaction; (3) the pretreated polystyrene is added into cyclohexanone after being cut into granules and dried, and polyvinyl pyrrolidone is added, stirred and dissolved, and then dried particles are added to obtain a coating solution; and (4) after the coating solution is treated, a film is scraped on a substrate, removed after phase transfer, and melted and extruded with a plasticizer and a lubricant through a twin-screw extruder. According to the method, by increasing the bond strength between the polystyrene and silicon dioxide, significant improvement of the wear resistance of the polystyrene is realized, and the methodis suitable for large-scale and industrial production.

Owner:ANHUI GUANHONG PLASTIC IND

Continuous spheroidizing annealing method for high-carbon chromium bearing steel round steel

PendingCN114107626AImprove uniformityPromote the transformation of globularizationBrinellingHeat conservation

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Preparation method of glass ceramic

InactiveCN104355542AImprove insulation reliabilityImprove flexural strengthRare earth ionsHigh reflectivity

The invention relates to a preparation method of glass ceramic. The method comprises the following steps: (1) preparing the following raw materials by mass percent: 30%-40% of magnesia borosilicate glass powder, 30%-50% of aluminum oxide filler powder, 10%-30% of Y2O3 and 10%-15% of rare earth ions, wherein the magnesia borosilicate glass powder contains 40%-70% of SiO2, 8%-25% of B2O3, 5%-30% of Al2O3 and 20%-30% of MgO; (2) performing heat treatment for the first time at 650-750 DEG C and performing heat treatment for the second time at 700-750 DEG C. A glass ceramic substrate prepared by the method is high in reflection rate, low in glass phase crystallization rate and excellent in luminous performance.

Owner:华文蔚

Method for preparing lithium battery negative electrode by compounding silicon, carbon and silicon dioxide in extruder

ActiveCN112151767AImprove composite effectAchieve physical wrappingNegative electrodesSecondary cellsNano siliconSilicon monoxide

Owner:梧州市同创新能源材料有限公司

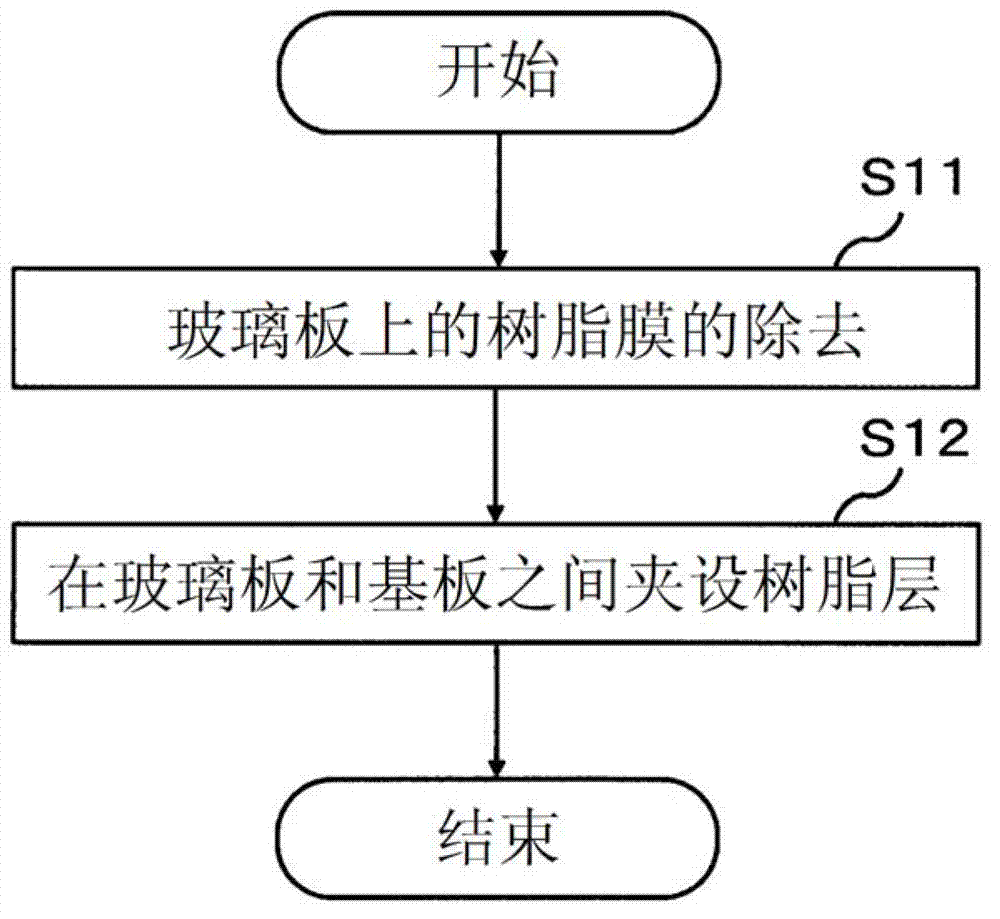

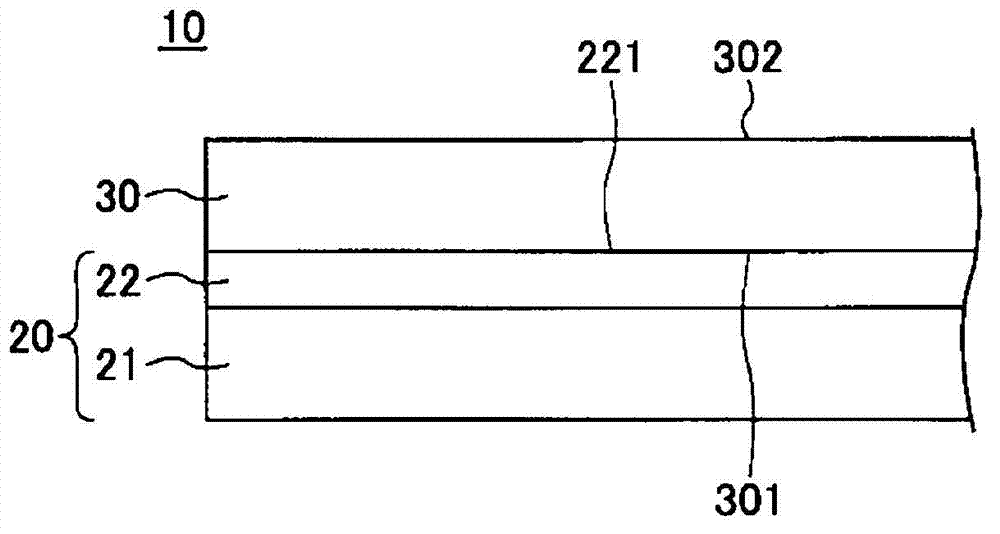

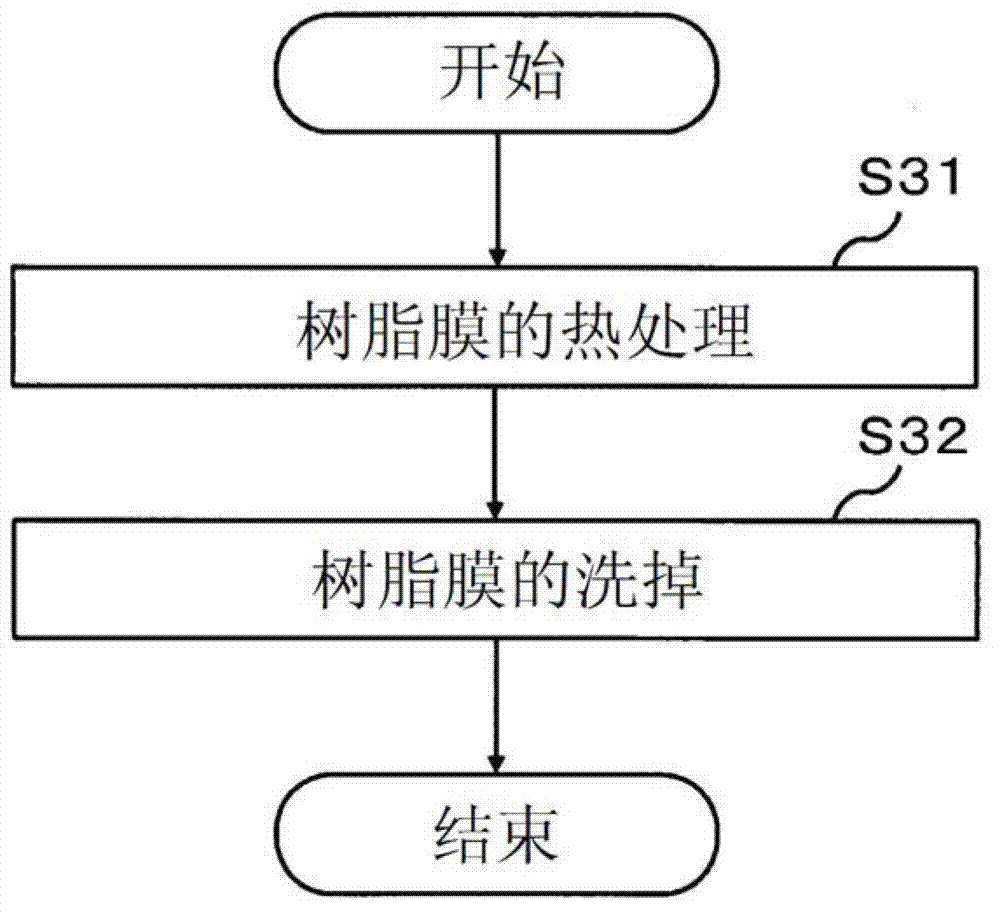

Method for eliminating resin film and method for producing laminate

Owner:ASAHI GLASS CO LTD

Nickel-copper alloy seamless tube

The invention discloses a nickel-copper alloy seamless tube. The nickel-copper alloy seamless tube comprises the following components: copper, iron, manganese, silicon, silicon, sulfur and the balance of nickel; the manufacturing steps of the nickel-copper alloy seamless tube comprise the following steps of: (1), preparing blank and checking the performances of the blank; (2), heating up the ingredients and punching; (3), polishing the blank; (4), carrying out thermal expansion molding treatment on the blank; (5), heating up the blank; (6), carrying out straightening, internal grinding, external grinding and flaw detection on the blank; and (7), carrying out checking, spraying, packaging, weighing and stock removal on the finished product. According to the nickel-copper alloy seamless tube disclosed by the invention, the surface corrosion performances of the product are improved, the performance standards are better, and the manufacturing cost is lowered; and moreover, the production process is simple.

Owner:SUZHOU BEST METAL PROD

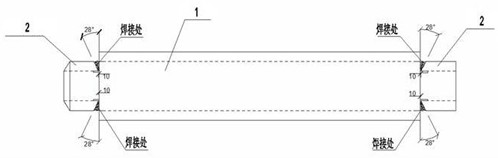

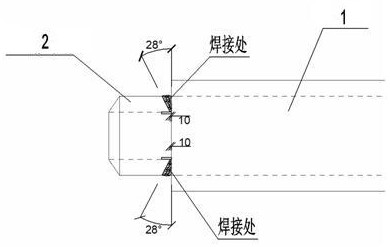

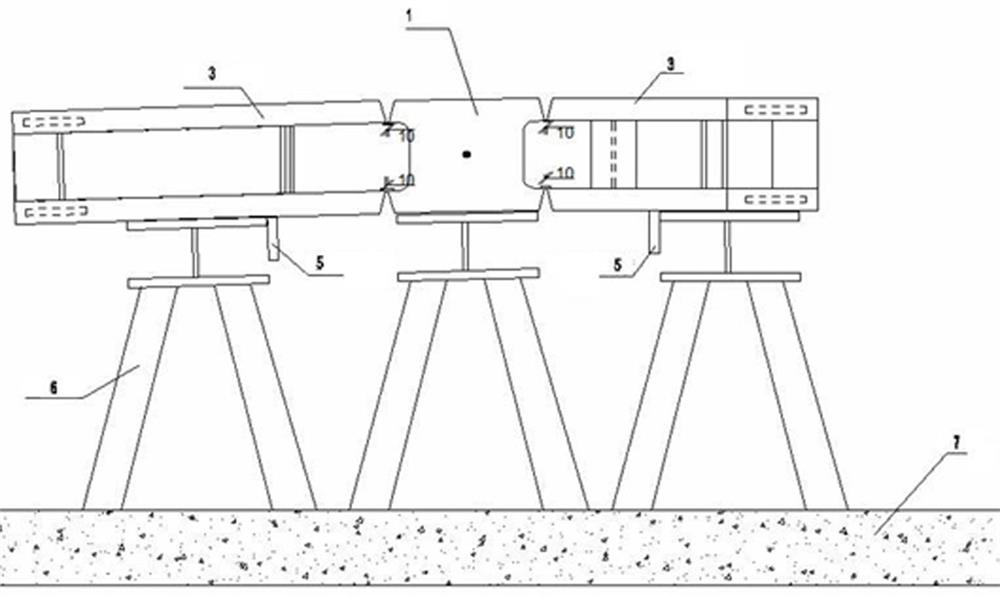

Assembling and welding method for truss layer corner column

PendingCN114515917AImprove securityReduce the amount of weldingFurnace typesWelding/soldering/cutting articlesStructural engineeringWeld seam

Owner:中冶(上海)钢结构科技有限公司

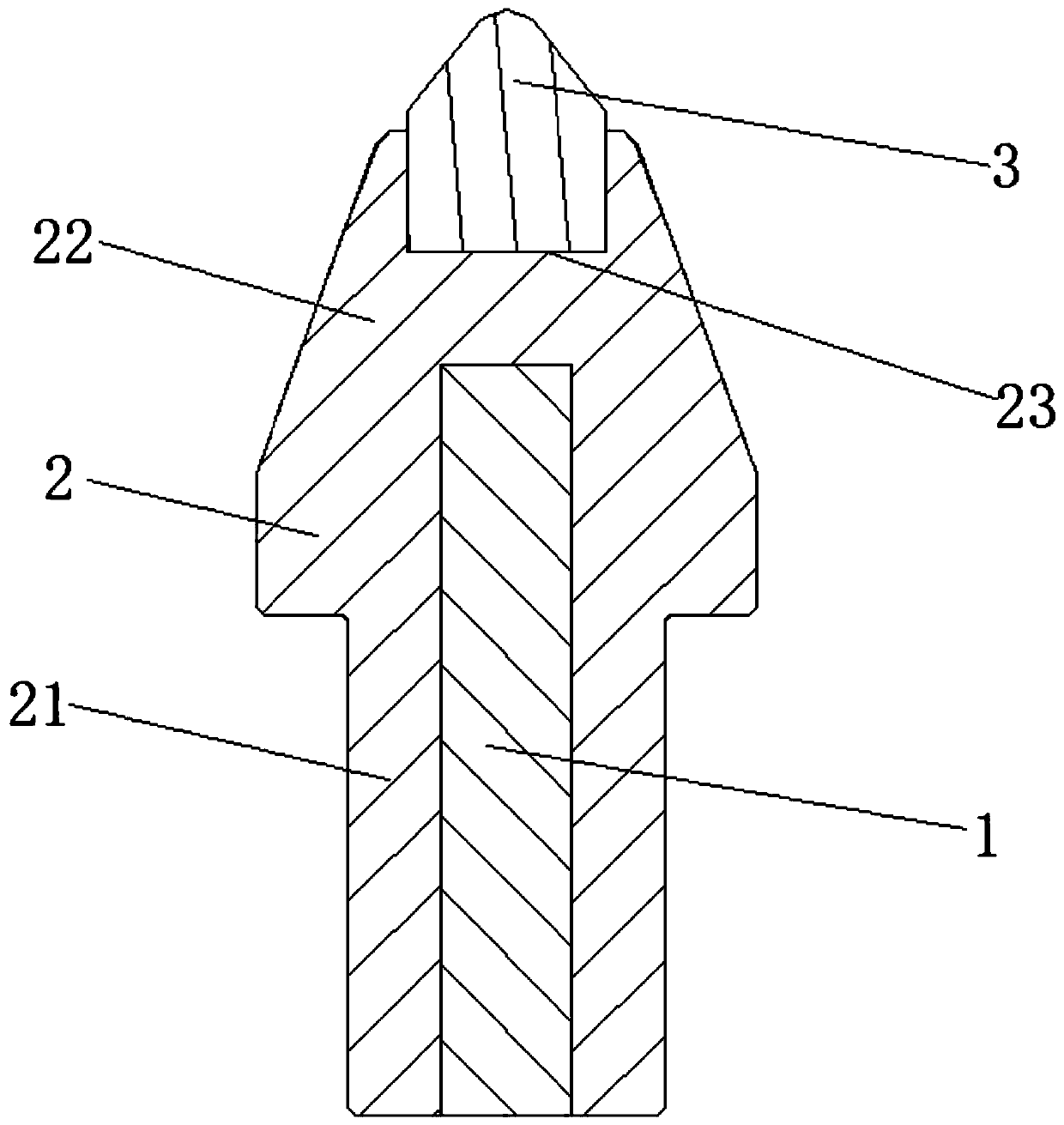

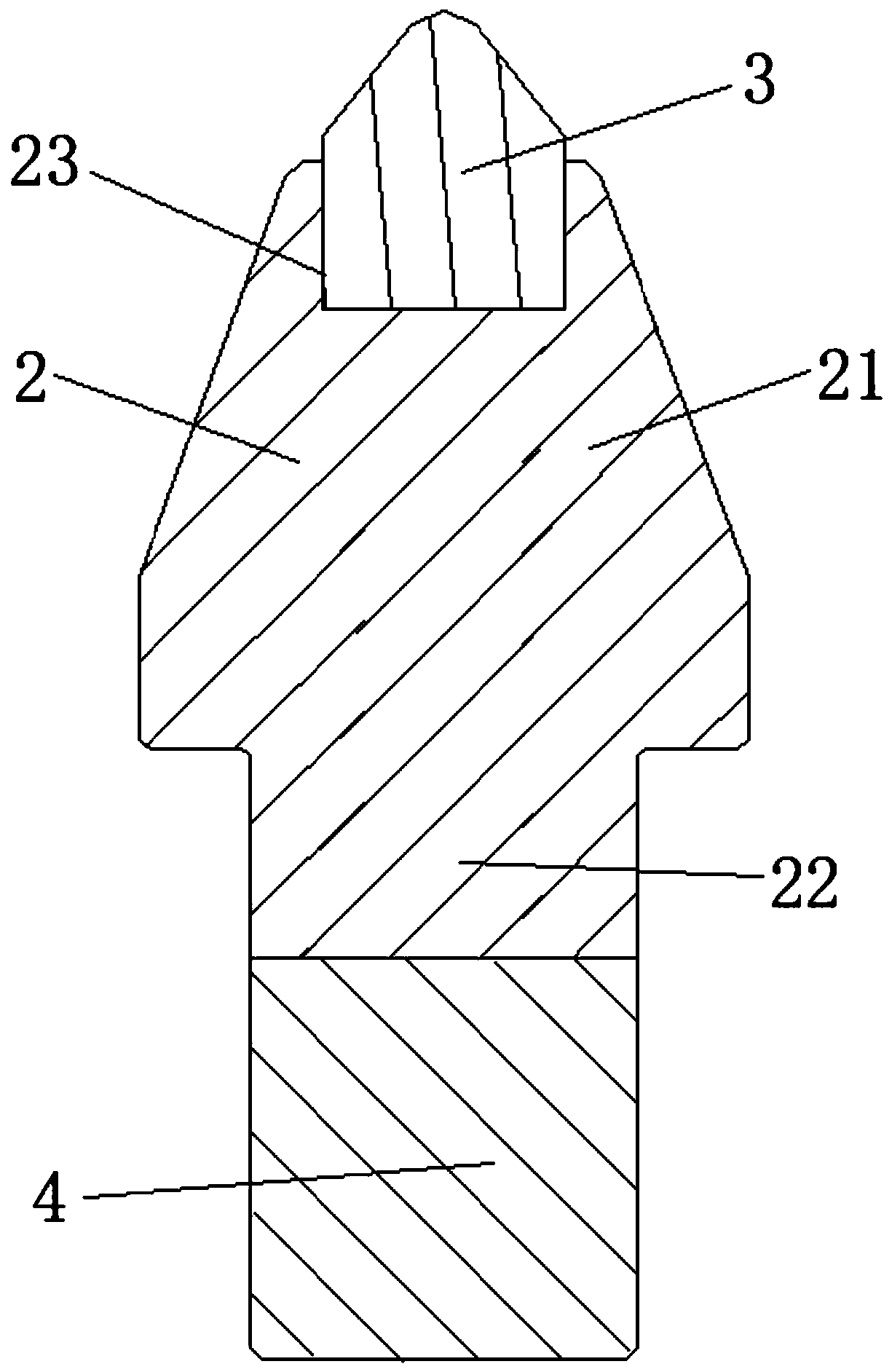

Manufacturing method of composite cutter bits and composite cutter bits

ActiveCN111360232AHigh hardnessImprove wear resistanceSlitting machinesFurnace typesMetallic materialsAlloy

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

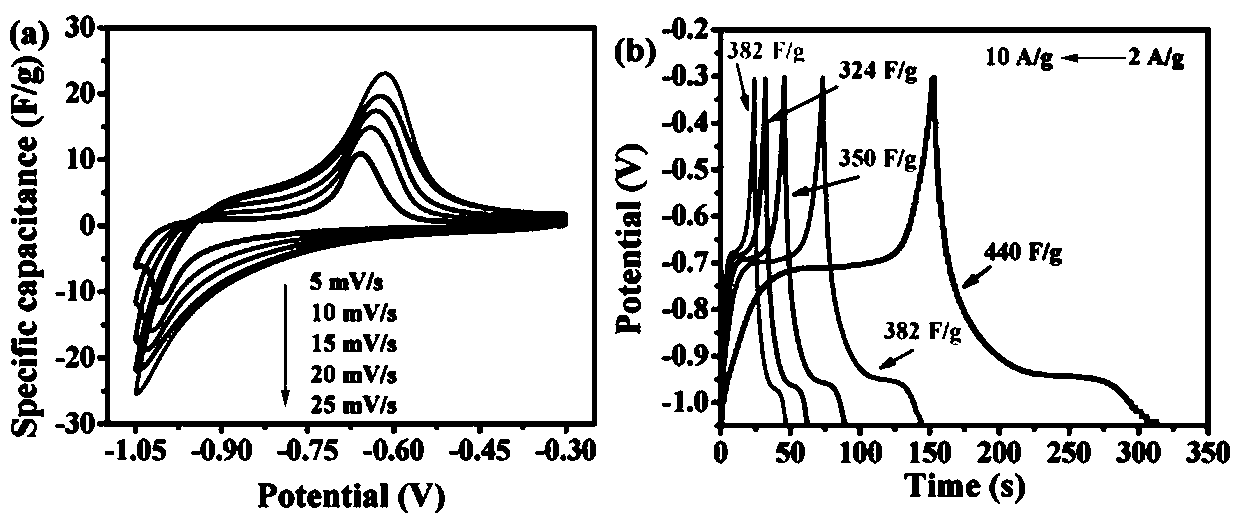

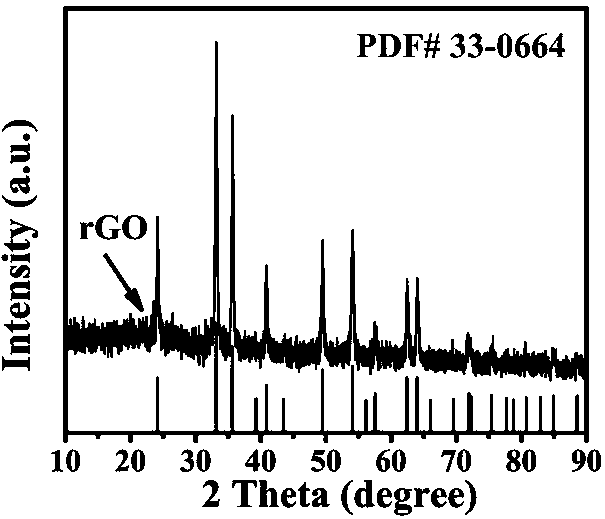

Reduced graphene/alpha-Fe2O3 supercapacitor material and preparation method and application thereof

ActiveCN110136978ALight in massQuality improvementHybrid capacitor electrodesHybrid/EDL manufactureThioureaSupercapacitor

Owner:ZHOUKOU NORMAL UNIV

Heat treatment method of quartz glass

PendingCN110655305ALow stress birefringenceShort holding timeGlass shaping apparatusGlass productionVitrificationThermal insulation

The invention provides a heat treatment method of quartz glass. The heat treatment method adopts a vitrification molding and heat treatment integrated process, and comprises: (1) vitrifying a silicondioxide raw material to obtain a transparent quartz glass; (2) directly cooling the vitrified high-temperature transparent quartz glass to a heat treatment temperature, and carrying out thermal insulation; and (3) cooling the obtained quartz glass to a room temperature at a certain annealing rate to obtain the transparent quartz glass with low stress birefringence. According to the method of the invention, vitrification forming and heat treatment are carried out in the same sintering furnace, the temperature after vitrification forming is directly reduced to the heat treatment temperature, andthermal insulation is carried out, so that the heat treatment thermal insulation time is effectively shortened, the pollution risk is reduced, the production efficiency is improved, and the stress birefringence of the prepared quartz glass is smaller than 1.8 nm / cm.

Owner:ZHONGTIAN TECH

Heat treatment method for engine valve

PendingCN113981199AImprove mechanical propertiesEasy to processFurnace typesHeat treatment furnacesThermodynamicsProcess engineering

Owner:HUAI JI DENG YUE VALVE CO LTD

Watch dial embellishing and flash sand pressing treatment method

InactiveCN113211328AImprove surface oxidation resistanceRealize heat treatment rust removalElectrophoretic coatingsCleaning using liquidsIndustrial engineeringCorrosion resistant

The invention discloses a watch dial embellishing and flash sand pressing treatment method, and belongs to the technical field of watch dial embellishing and flash sand pressing treatment. The method comprises the steps of flash sand preparation, watch dial preparation, sand pressing pretreatment on a watch dial, arc-shaped sand treatment and electrophoretic coating treatment, the watch dial is stamped and formed into a required shape, and then mirror polishing is conducted on the stamped watch dial to achieve a bright mirror effect. By conducting heat treatment on a workpiece at different temperature and different time, the workpiece presents different colors on the basis of different lines, so that the ornamental value and the corrosion resistance are improved; and flash sand is pressed on the dial by utilizing an arc-shaped sand process, and the dial is subjected to electrophoretic coating, so that the product has metal luster, the dial has both a sand surface effect and the mirror effect, and the corrosion resistance is also improved.

Owner:DONGGUAN BAIXING PRECISION HARDWARE CO LTD

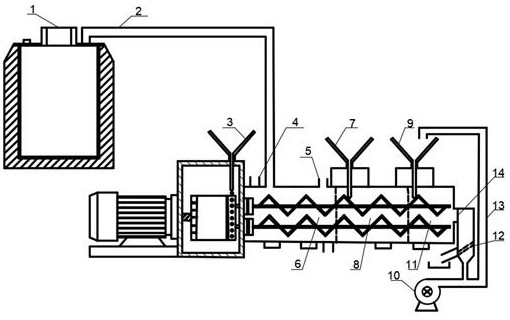

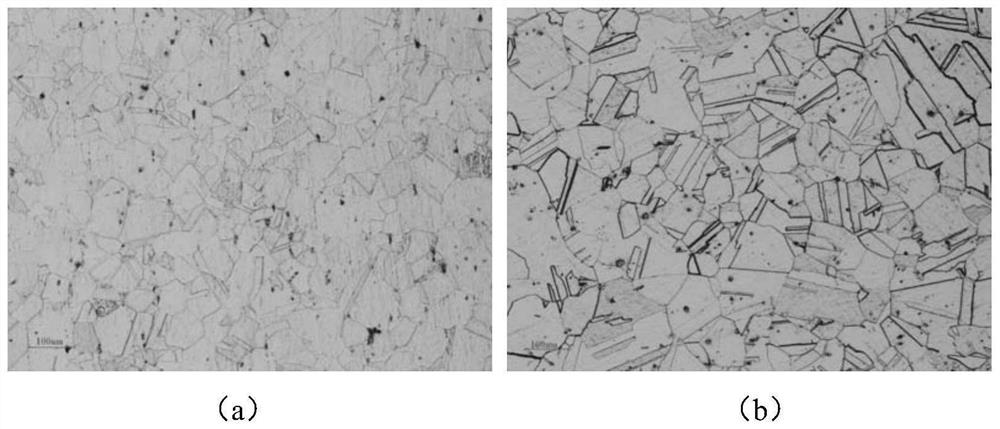

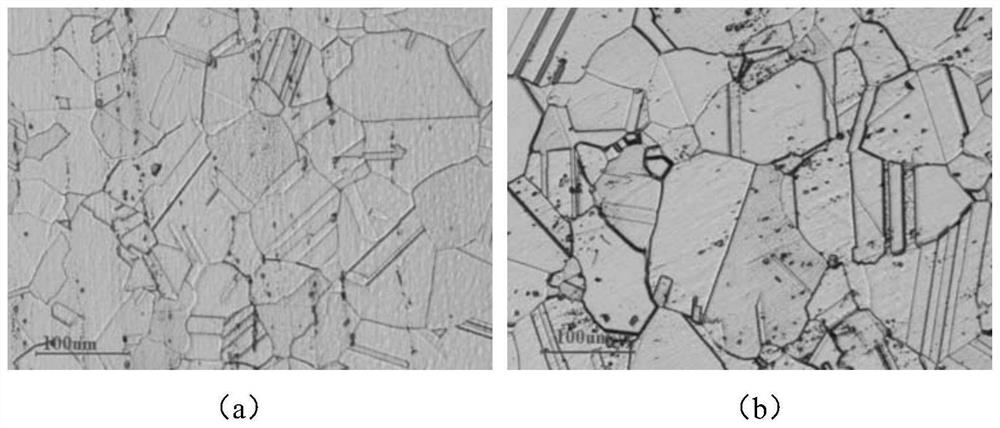

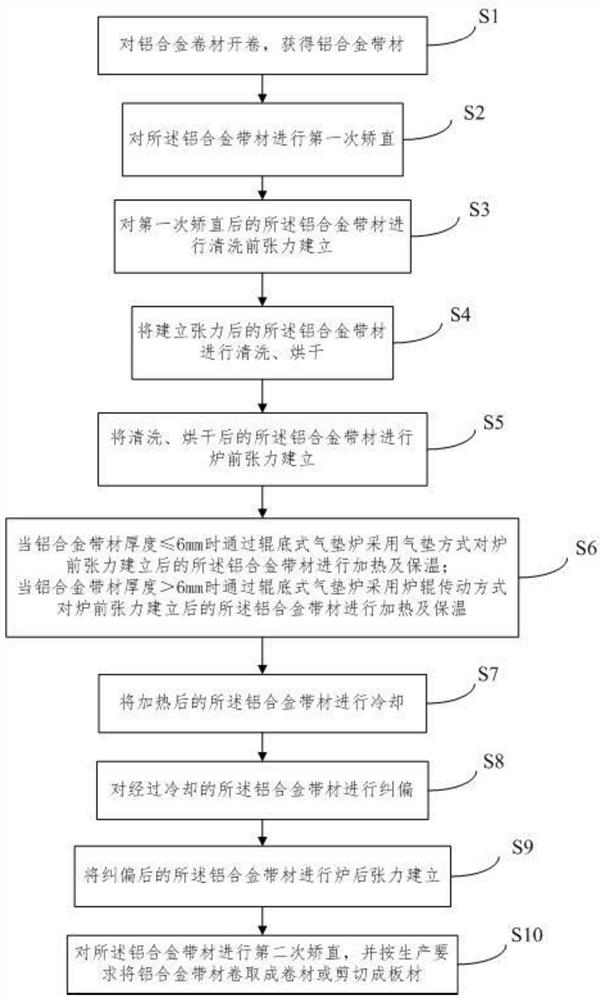

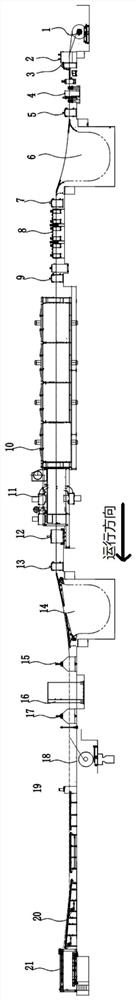

Production method and system of aluminum alloy coiled material/plate

ActiveCN111673378AIncrease productivityRapid solid solutionFurnace typesGas emission reductionMachiningManufacturing line

Owner:广西先进铝加工创新中心有限责任公司 +1

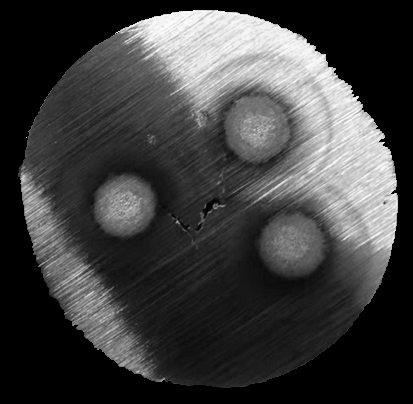

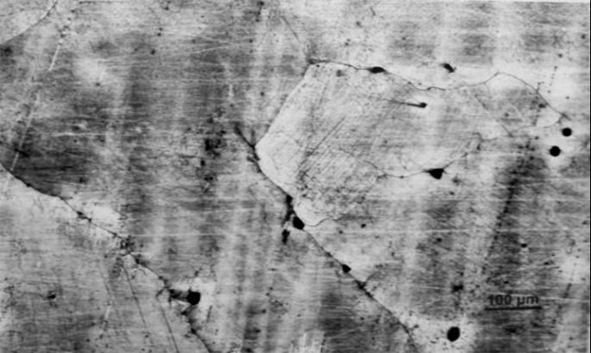

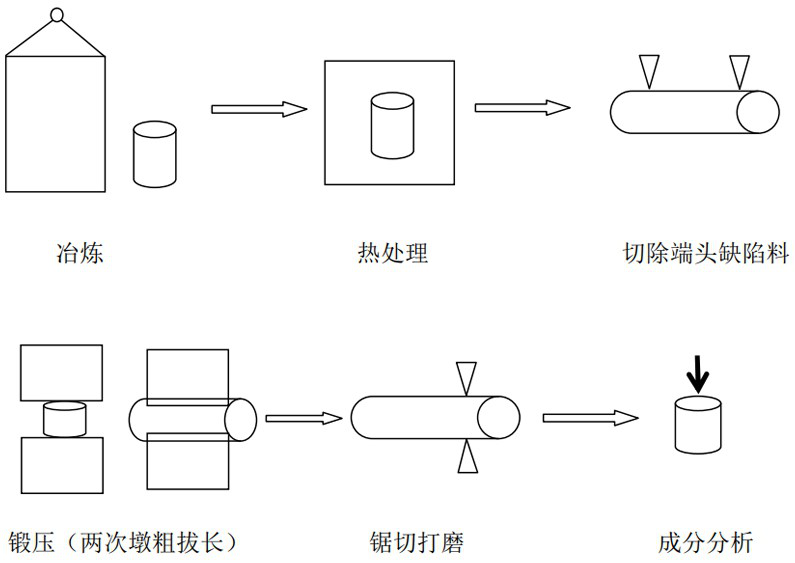

Manufacturing method of high manganese steel spectrum standard sample

PendingCN114689402AImprove economyReduce procurement costsPreparing sample for investigationManganeseStandard samples

Owner:TAIYUAN UNIV OF TECH

Preparation method of rare earth doped ZnAl2O4 nanocrystalline glass

The invention provides a preparation method of rare earth doped ZnAl2O4 nanocrystalline glass. The preparation method comprises the following steps: preparing base glass of the ZnAl2O4 nanocrystalline glass; the base glass is subjected to thermoelectric coupling, and in the thermoelectric coupling process, heating is conducted till glass nucleation is conducted, and then an electric field is applied in the devitrification stage. Aiming at the problem of difficulty in crystal regulation in thermodynamic treatment of glass crystals, an electric field is introduced to obtain spinel glass with different properties; on the basis of heat treatment, the size of nanoscale crystals in spinel is regulated and controlled through a thermoelectric coupling effect, and the light transmittance and the mechanical strength of the glass are regulated and controlled.

Owner:HAINAN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap