Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about "Rigid pipes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

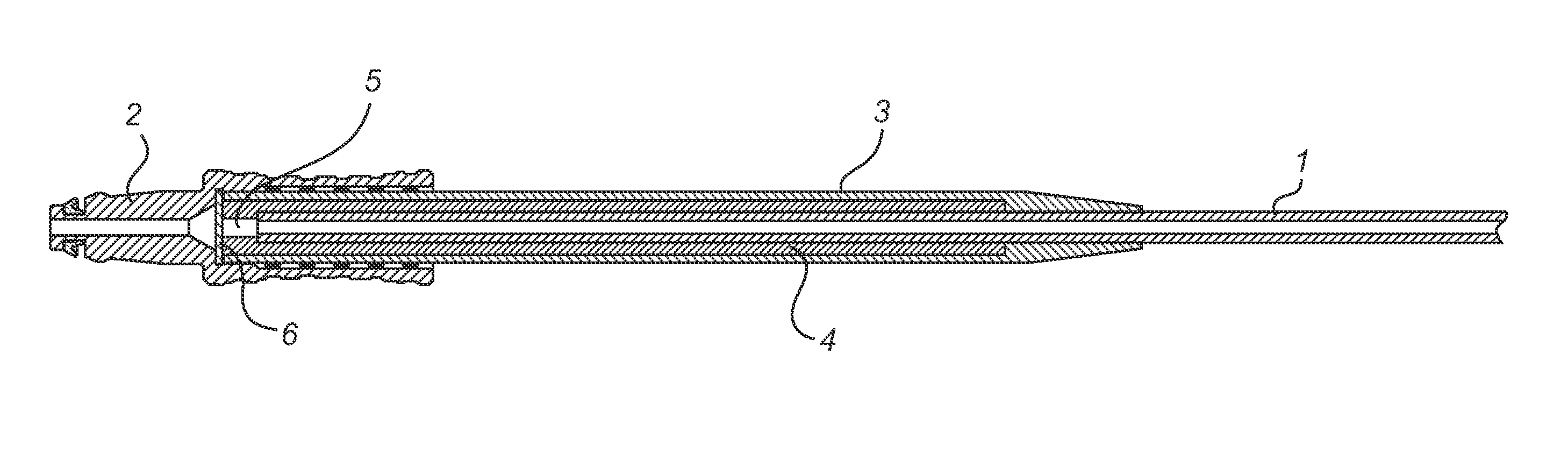

Gas sampling line

ActiveUS20110237969A1Improve accuracyReduce distortion problemsDispersed particle separationRespiratory organ evaluationGas analysisPolyethylene oxide

Owner:JPMORGAN CHASE BANK NA

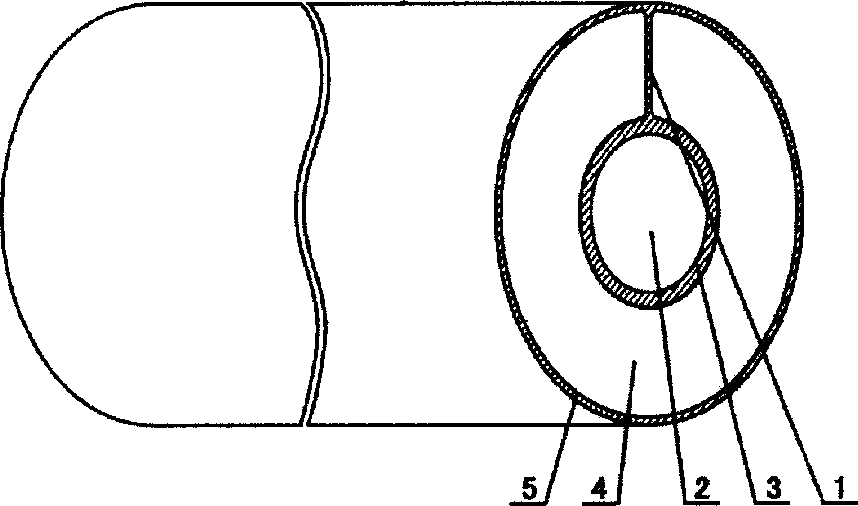

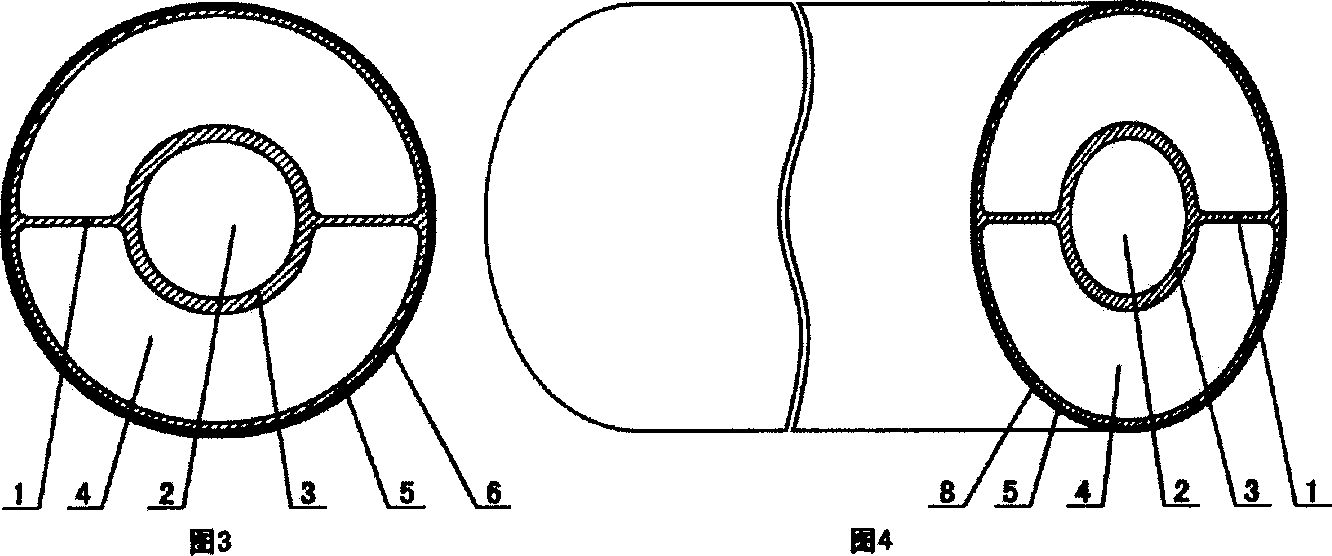

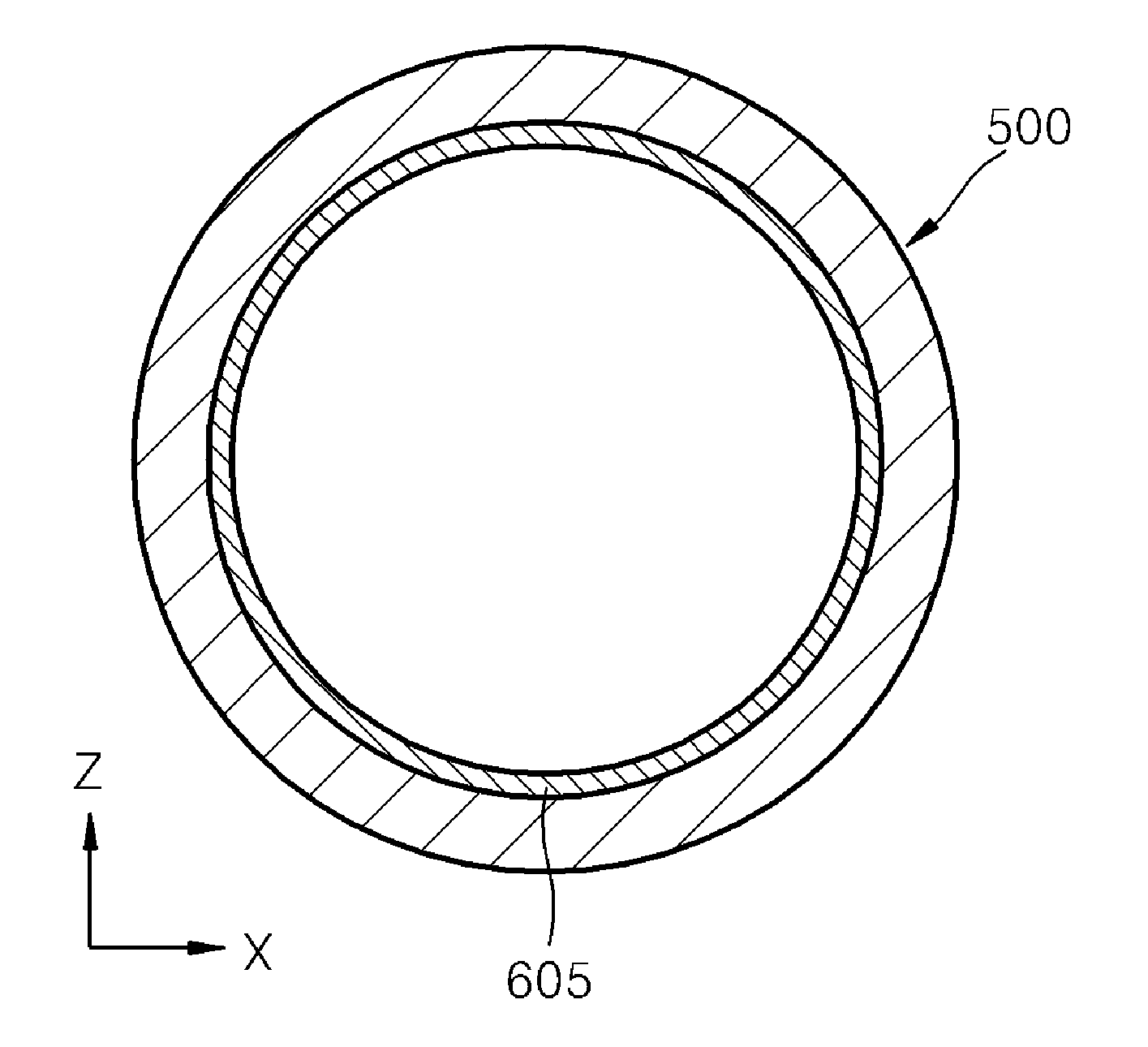

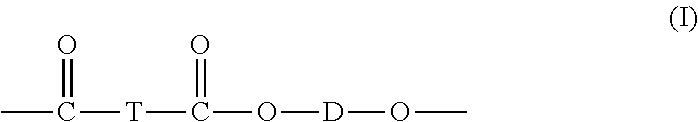

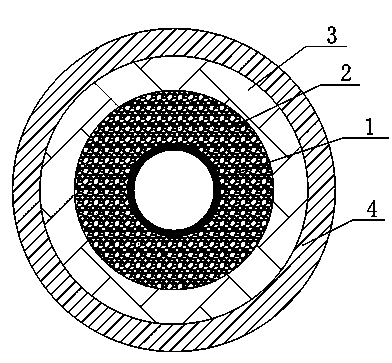

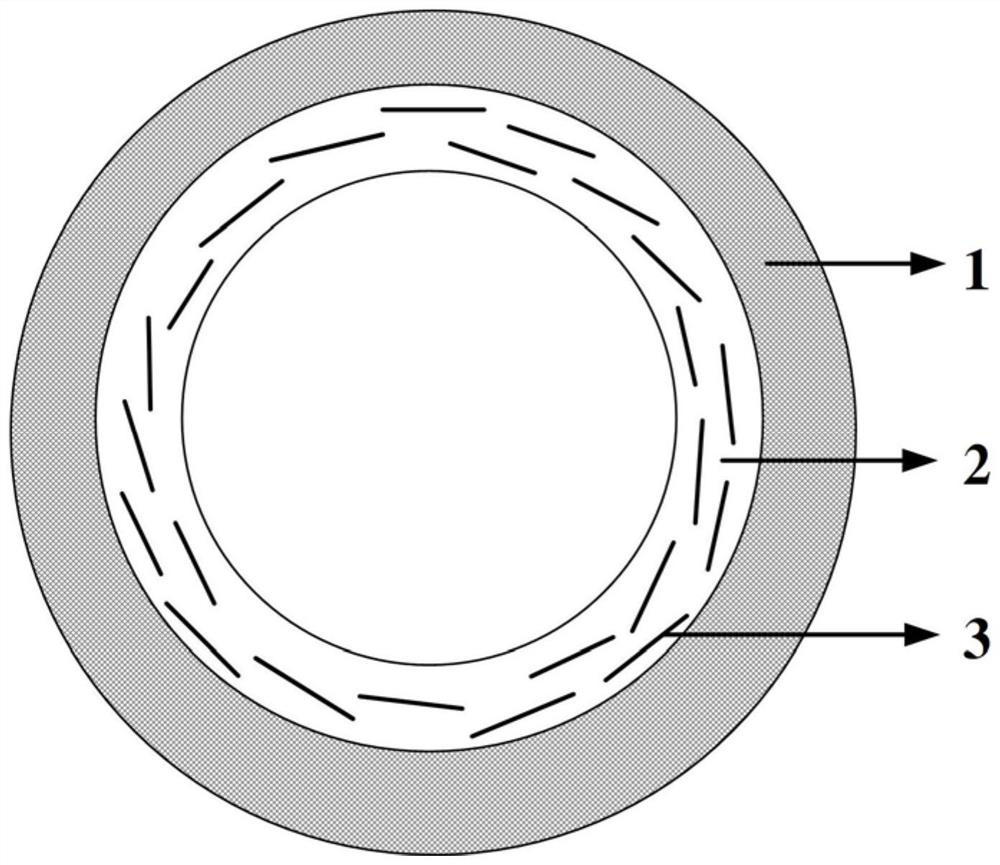

Ceramics particle strengthened composite material lining metal tube and manufacturing method thereof

InactiveCN101900227AExtended service lifeImprove wear resistanceCorrosion preventionPipe protection against corrosion/incrustationPolyesterManufacturing technology

The invention discloses a ceramics particle strengthened composite material lining metal tube and a manufacturing method thereof, belonging to the field of composite wear-resistant tubes. 4,4-Diphenylmethane diisocyanate (MDI), polyester glycol, 1,4-butanediol (BD), ceramics particles and the like serve as raw materials to prepare composite material liquid castables, and a centrifugal casting technology is adopted to cast polyurethane base ceramics particle strengthened composite material lining layers on the inner wall of an outer thimble. The invention has the beneficial effect that the prepared ceramics particle strengthened composite material lining metal tube has excellent abrasive resistance and corrosion-resistance and greatly improves service life. The raw materials of the invention are easy to be obtained, manufacturing technology is simple, cost is low and economic benefit is obvious and practical application and mass production are beneficial for factories.

Owner:XUZHOU SHENGHAI MACHINERY MFG TECH

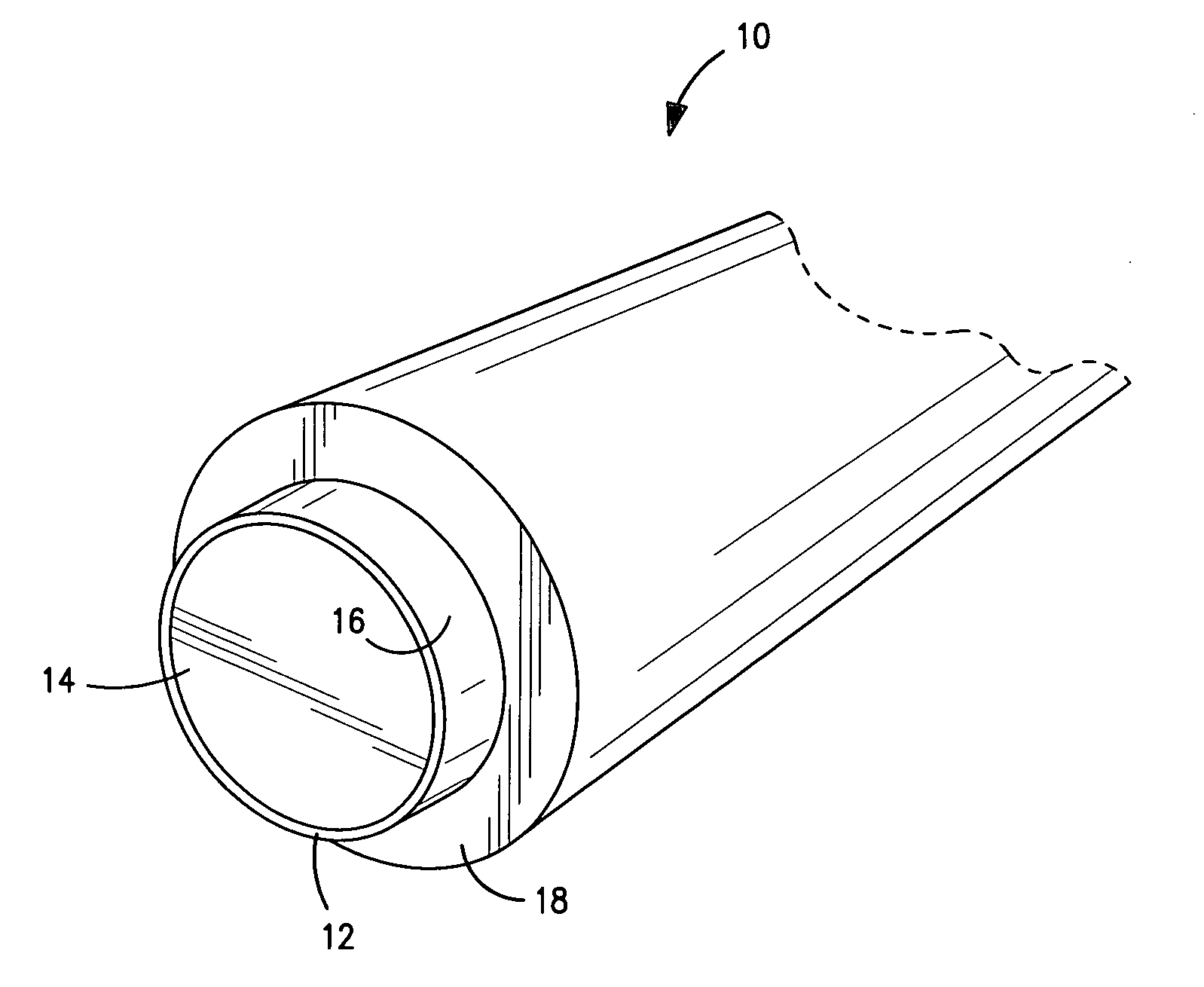

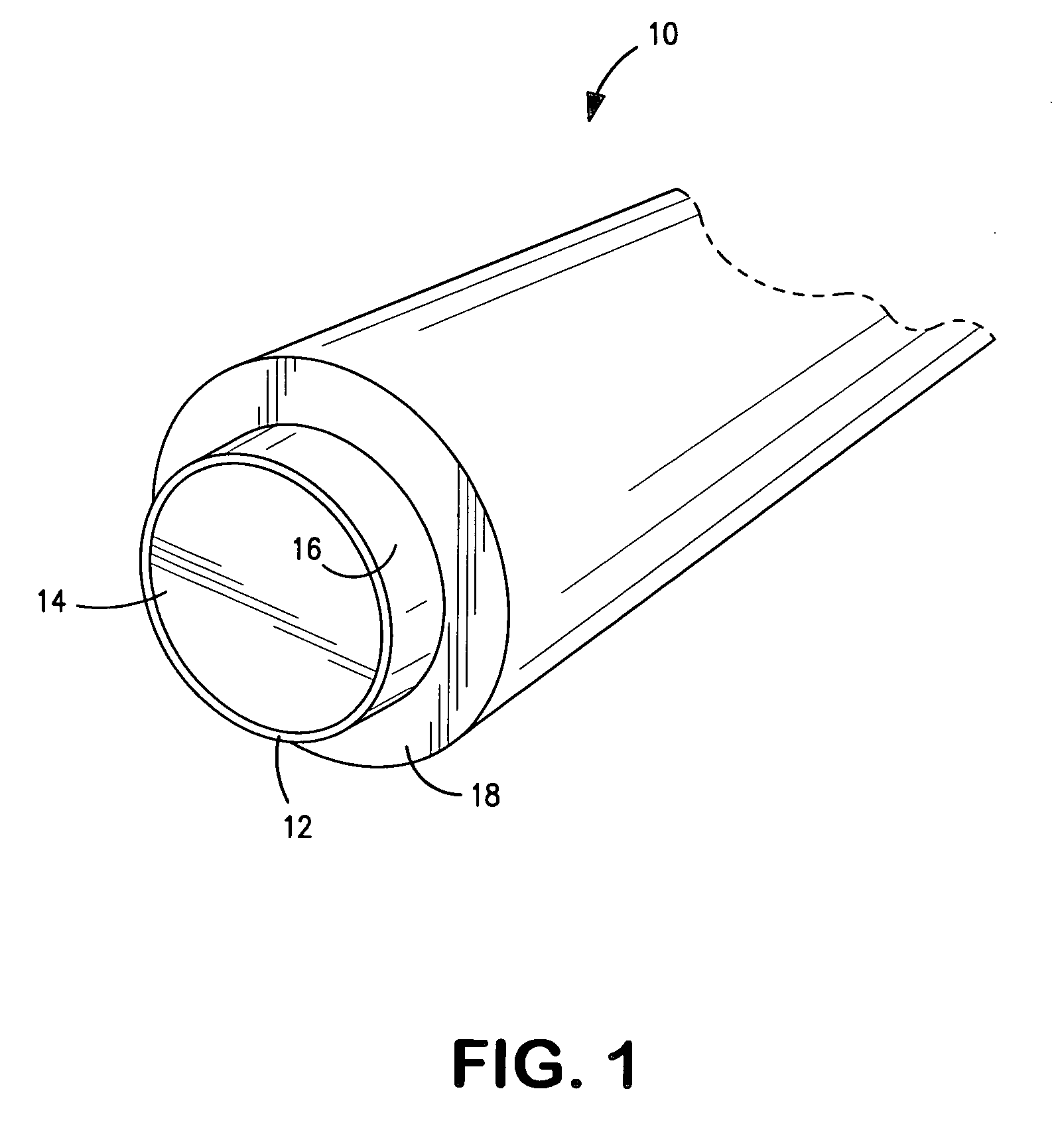

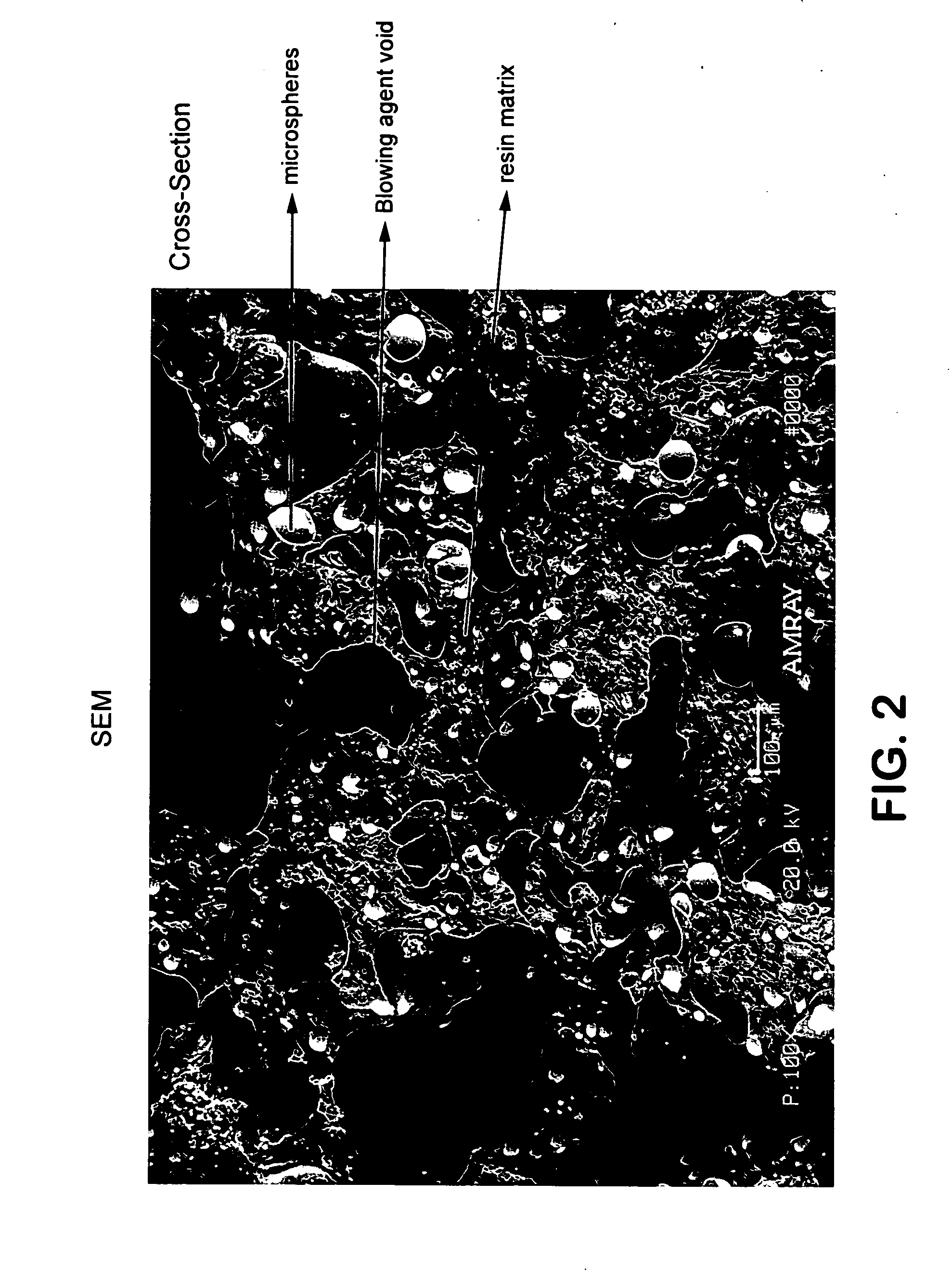

Syntactic Foam Compositions, Pipelines Insulated with Same, and Method

InactiveUS20110017340A1Improve thermal insulation propertiesIncrease buoyancyThermal insulationSolid waste managementEpoxyFoaming agent

Owner:CABOT CORP

Mineral methane gas drainage pipe and production method thereof

ActiveCN103195988AReduce weightImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationHigh pressureMethane gas

Owner:河北拓安管业有限公司

Anti-corrosion tube and its manufacturing process

Owner:大庆油田庆新工程材料有限公司

Laminated heat-preserving plastic composite pipe

InactiveCN1837667AFlexibleSimple structureThermal insulationPipe protection by thermal insulationSurface layerPliability

Owner:徐宝安

Steel pipe with bell and spigot joints

Owner:JILING YULINGLONG STEEL PIPE STEEL STRUCTURE MFG

Super-cold-resistant impact-resistant high-toughness PP-R pipe material and preparation method thereof

InactiveCN104910521AImprove low temperature resistanceSolve the problem of water deliveryRigid pipesWater deliveryInjection molding machine

The invention relates to a super-cold-resistant impact-resistant high-toughness PP-R pipe material and a preparation method thereof, belonging to the field of macromolecules. The method comprises the following steps: preparing materials by virtue of a PP-R resin and a cold-resistant toughened color master batch; adding the prepared raw materials into a twin-screw extruder, mixing, molding, cooling, and performing grain-sized dicing, thereby obtaining a modified material A; drying the modified material A in a drying box, thereby obtaining a modified material B; and finally, putting the modified material B on an injection molding machine, and performing injection molding to obtain the PP-R pipe. The PP-R pipe disclosed by the invention can be used at the temperature of 50 DEG C below zero to 30 DEG C below zero, the low temperature resistance of the pipe is enhanced, the water delivery problem in the northern area in winter is solved, the toughness and impact resistance of the PP-R pipe are enhanced, the PP-R pipe is difficult to age, and the service life is prolonged.

Owner:CHANGZHOU UNIV

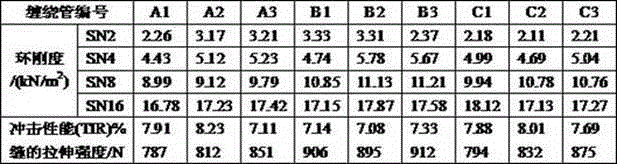

Super large caliber and non-excavation-use PE pollution discharge tubular product and manufacturing method thereof

The invention relates to a super large caliber and non-excavation-use PE pollution discharge tubular product and a manufacturing method thereof, wherein, the tubular product are manufactured by the following materials which are arranged according to the following mass percentage after the steps of pelleting and extrusion molding: 60-85% of PE100 pipeline special material; 5-15% of calcium carbonate superfine powder; 7-22% of unit triplet blending modified resin; 1-3% of high molecular weight polyethylene; and 0.2-2% of fluoropolymer. The method comprises the following steps: mixing PE100 pipeline special material accounting for 20-30% of total volume of addition evenly with other components according to proportion and obtaining master batch by extrusion and pelleting; mixing the excess PE100 pipeline special material evenly with the master batch and colorant and drying the mixture for 2-4 hours at the temperature of 0-80 DEG C; and then obtaining fixed-length tubular products after the steps of extrusion, vacuum sizing, cooling and cutting. The tubular products has the characteristic of integration; hot welding is carried out on the pipelines; the pipelines have fine flexibility and scratching-and-cracking-resisting capcacity; in addition, the pipelines has more unique technological and economic advantages when applied to drag construction of non-excavation works.

Owner:ANHUI YOUYI PIPES

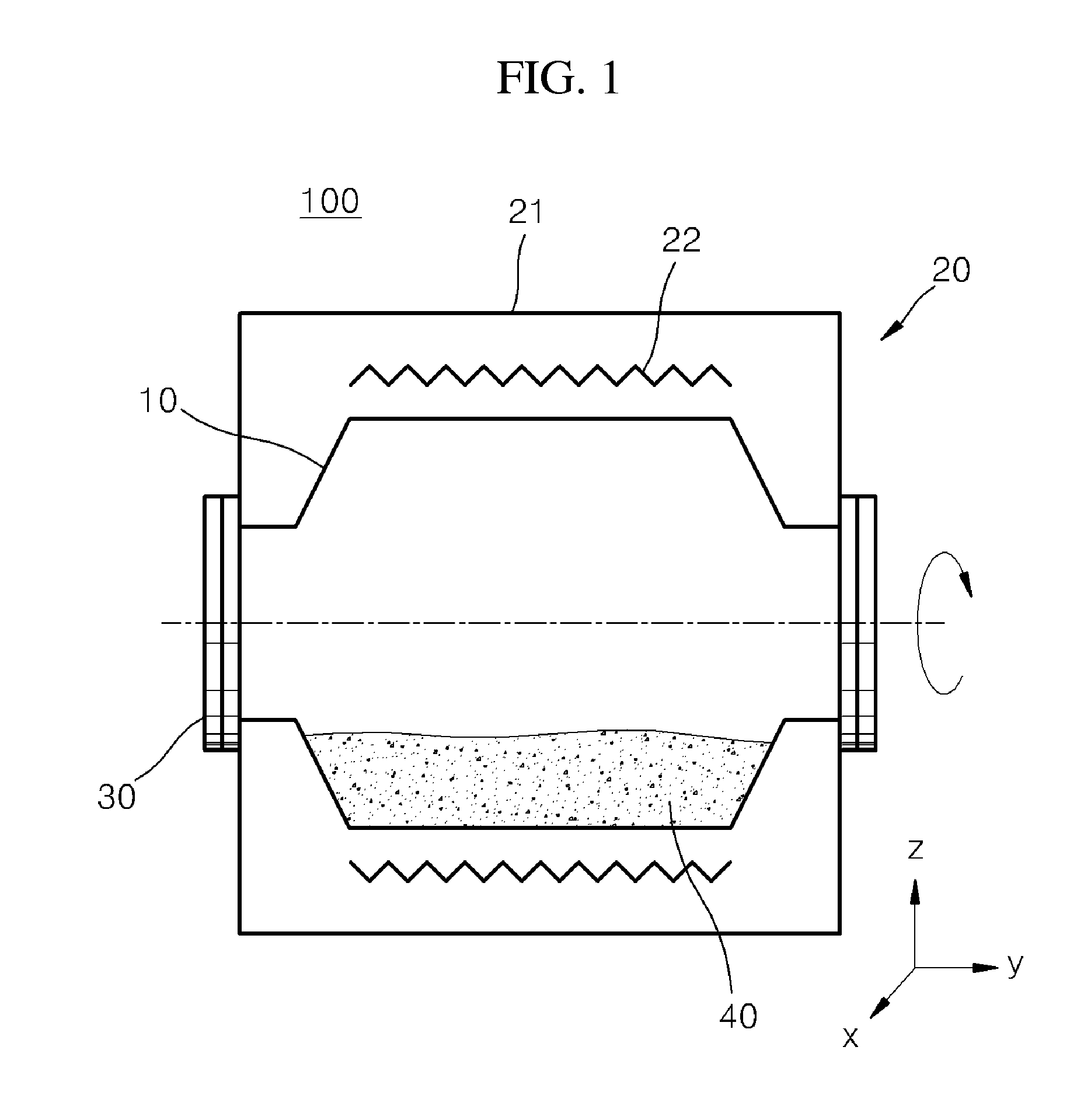

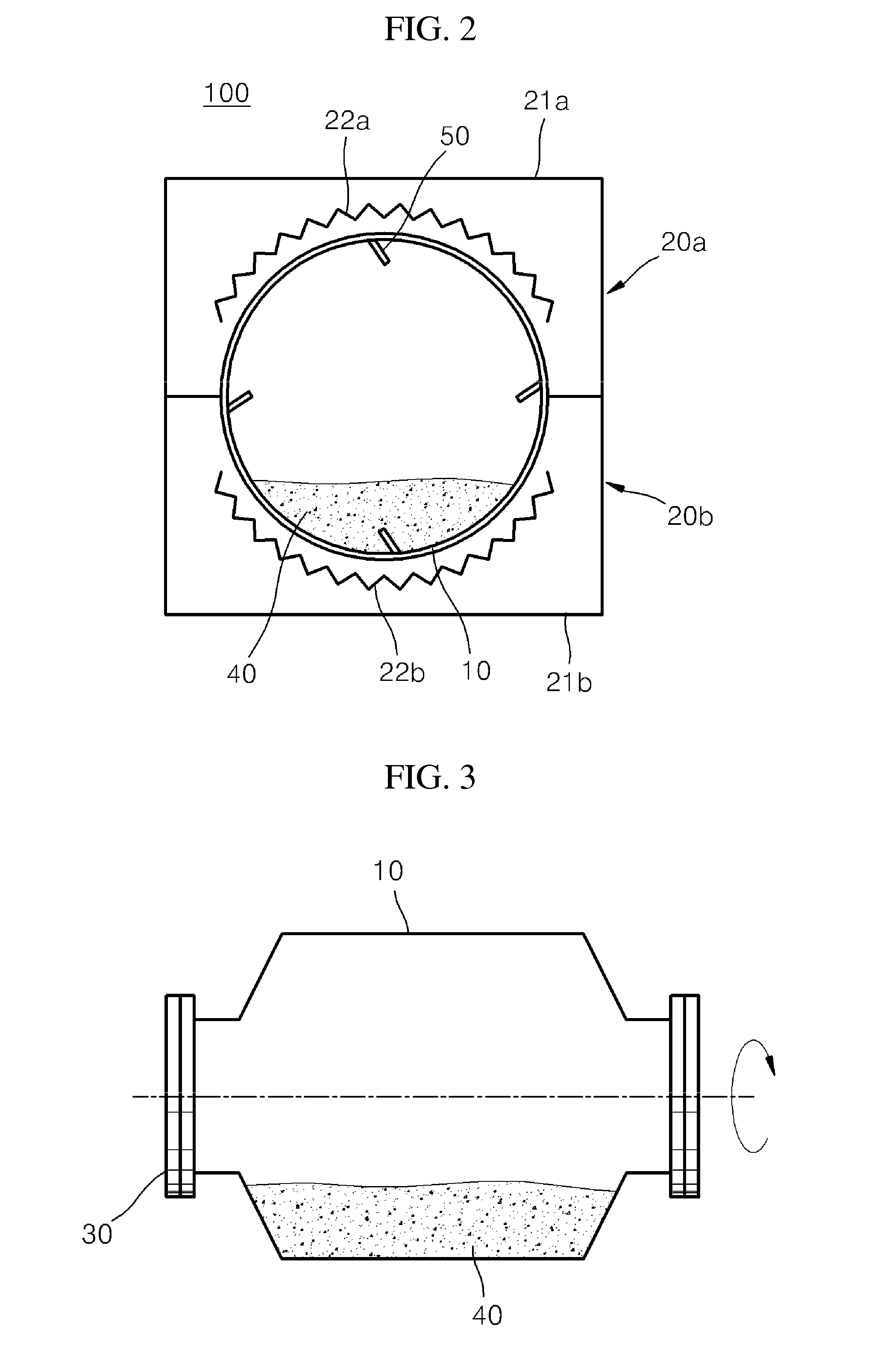

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS20140096858A1High hardnessLow melting pointHeat treatmentsLiquid surface applicatorsPowder mixtureAlloy

Owner:KMT CO LTD

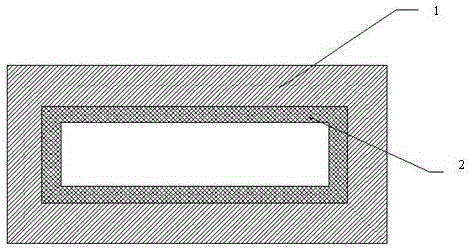

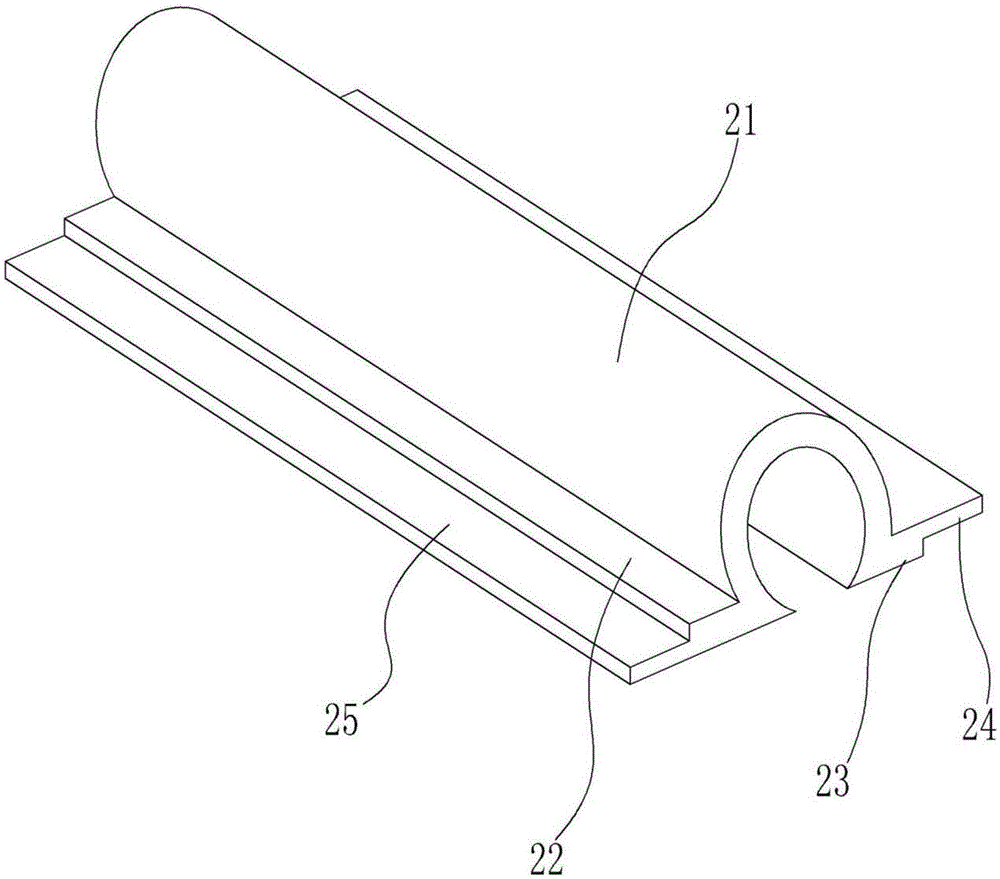

Winding pipe with fiber reinforced polypropylene (FRPP) reinforced hollow-structure wall and machining process for winding pipe

Owner:HUBEI KINGBULL PIPE IND

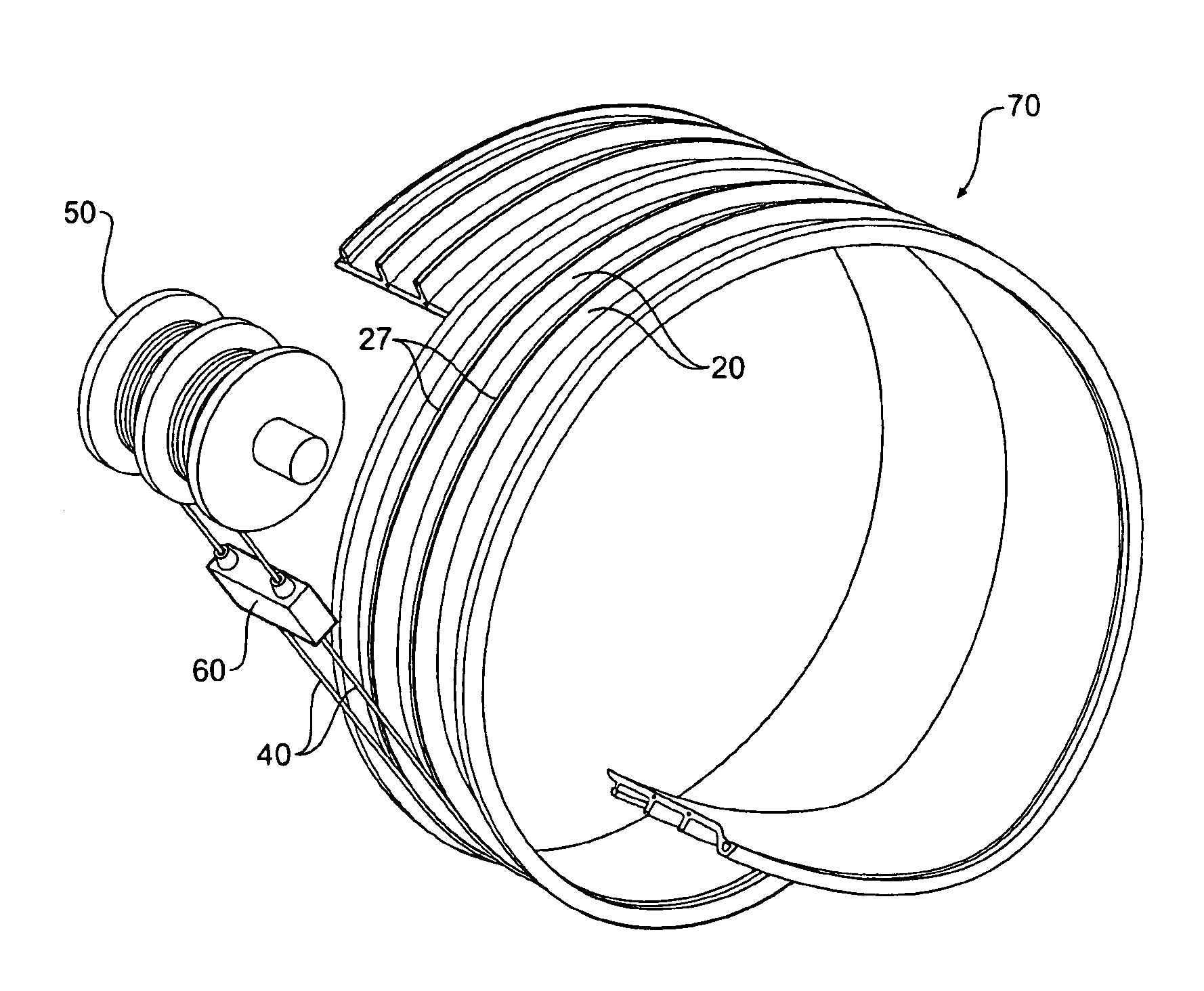

Composite reinforced strip windable to form a helical pipe and method therefor

Owner:SEKISUI RIB LOC AUSTRALIA

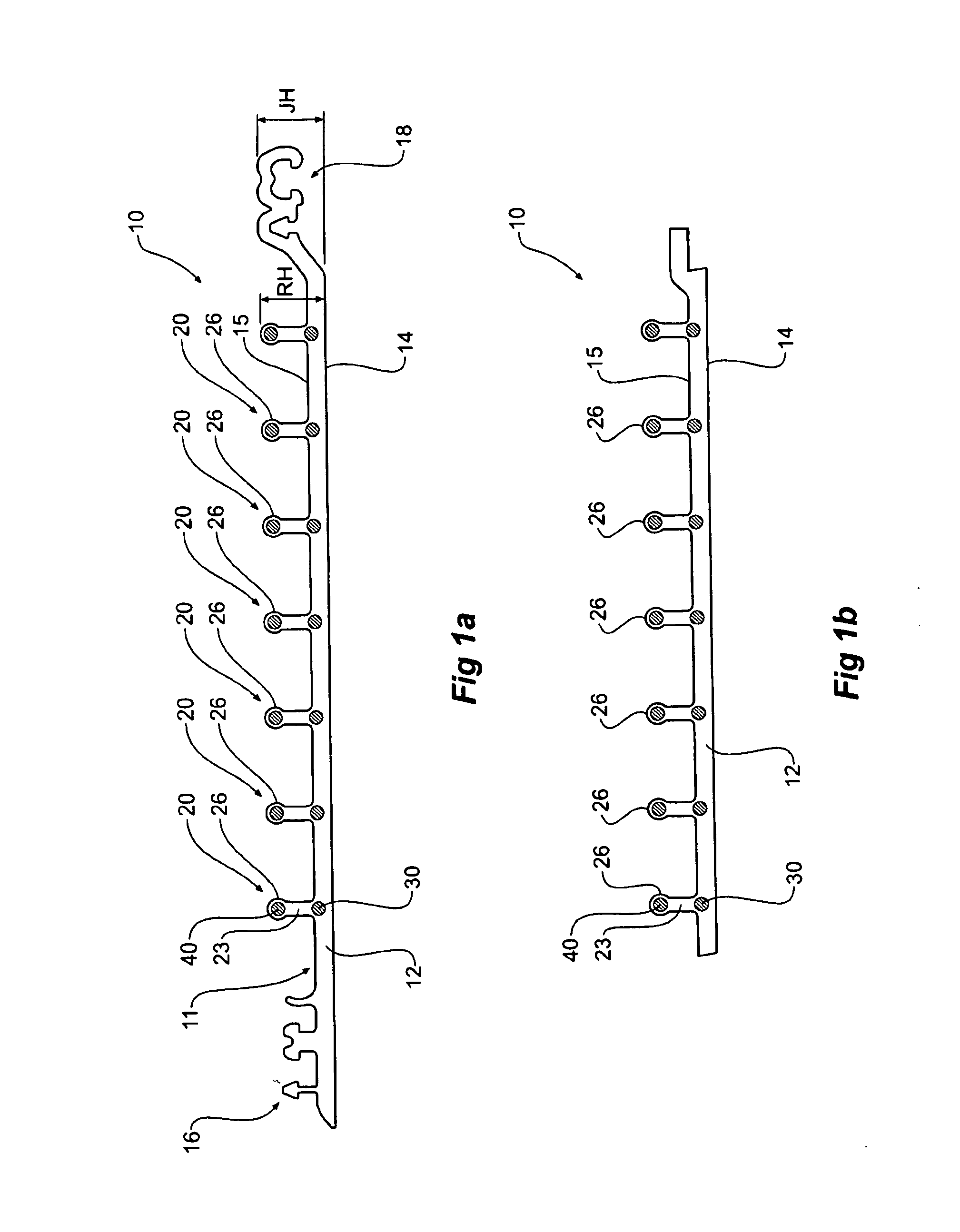

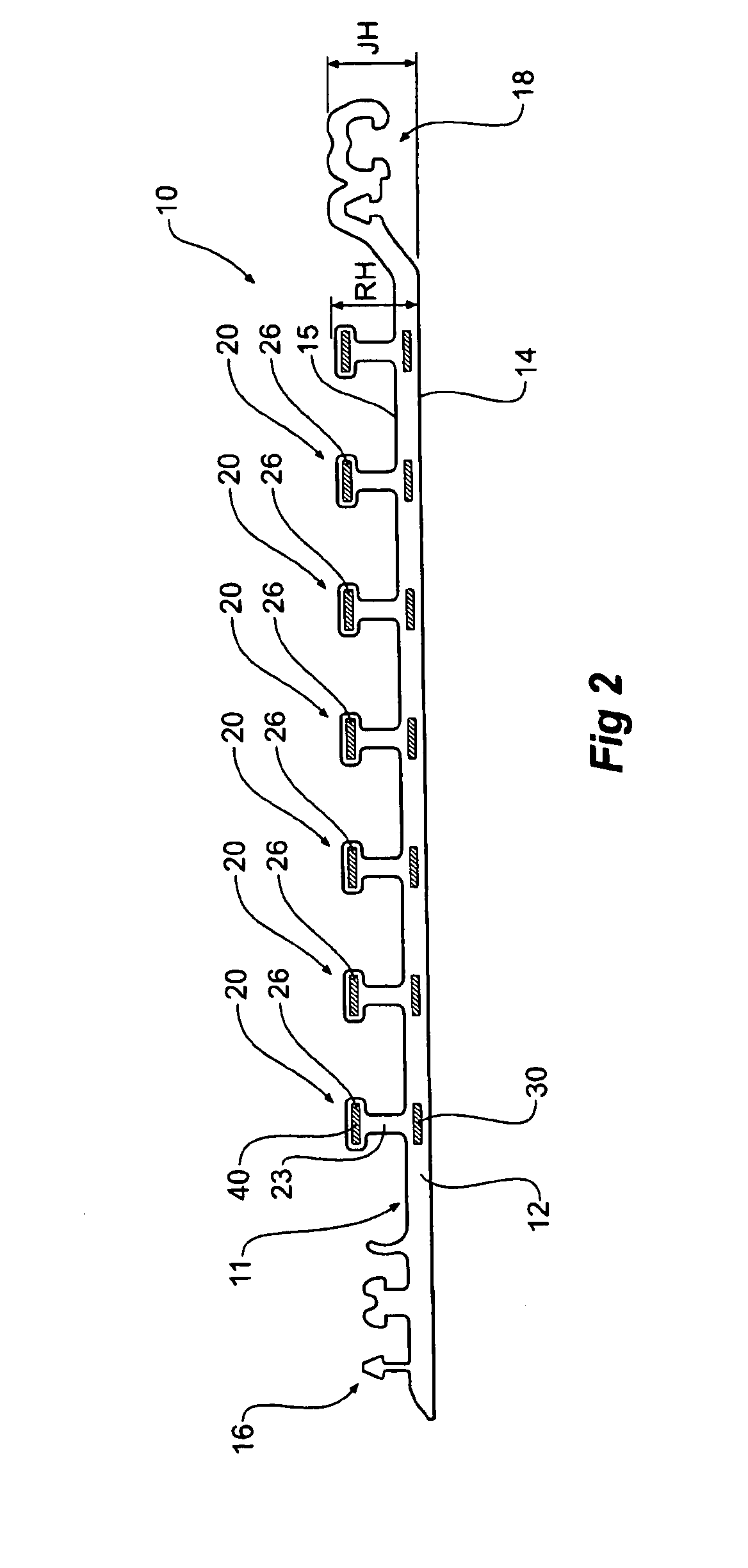

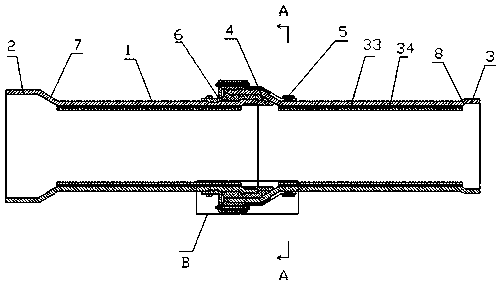

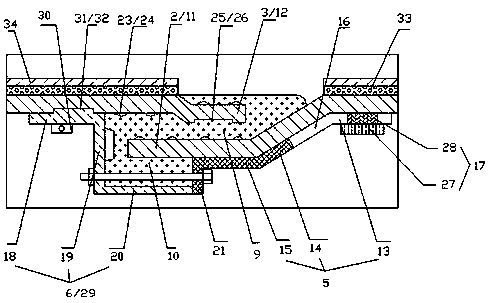

Exhaust manifold

ActiveUS20100126158A1Avoid damageRelieve pressureExhaust apparatusSilencing apparatusEngineeringExhaust manifold

An exhaust manifold includes: a double collecting pipe having an inner pipe, including a collecting pipe portion and branch pipe portions, and an outer pipe, covering the collecting and branch pipe portions and thicker than the inner pipe; and an inner pipe retainer having semi-circular portions and a connecting portion, and thicker than the inner pipe and thinner than the outer pipe. The inner pipe retainer connects the inner and outer pipes with a gap therebetween. Exhaust gas from exhaust ports of a set of cylinders is introduced into the collecting pipe portion through the branch pipe portions. The total spot-welded area of the outer peripheral portions of the branch pipe portions and the inner peripheral portions of the semi-circular portions is larger than that of the inner peripheral portion of the outer pipe and the outer peripheral portions of the semi-circular portions.

Owner:TOYOTA JIDOSHA KK

Hollow articles comprising fiber-filled polyester compositions, methods of manufacture, and uses thereof

Owner:SABIC GLOBAL TECH BV

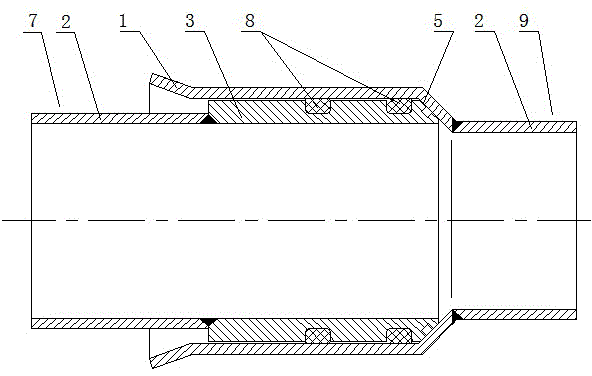

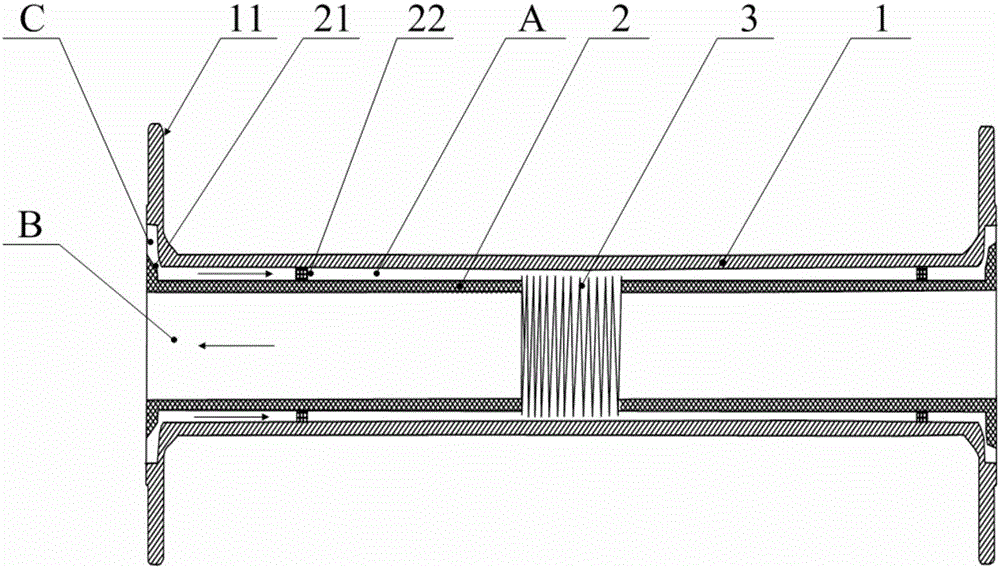

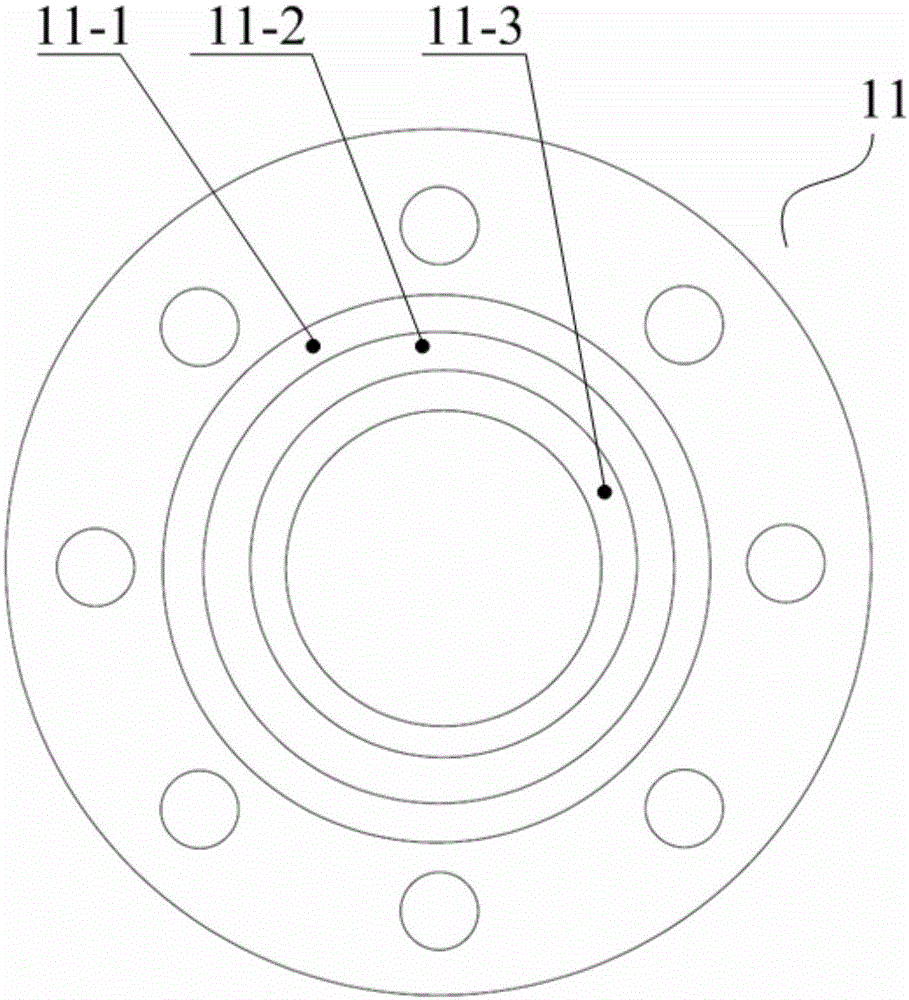

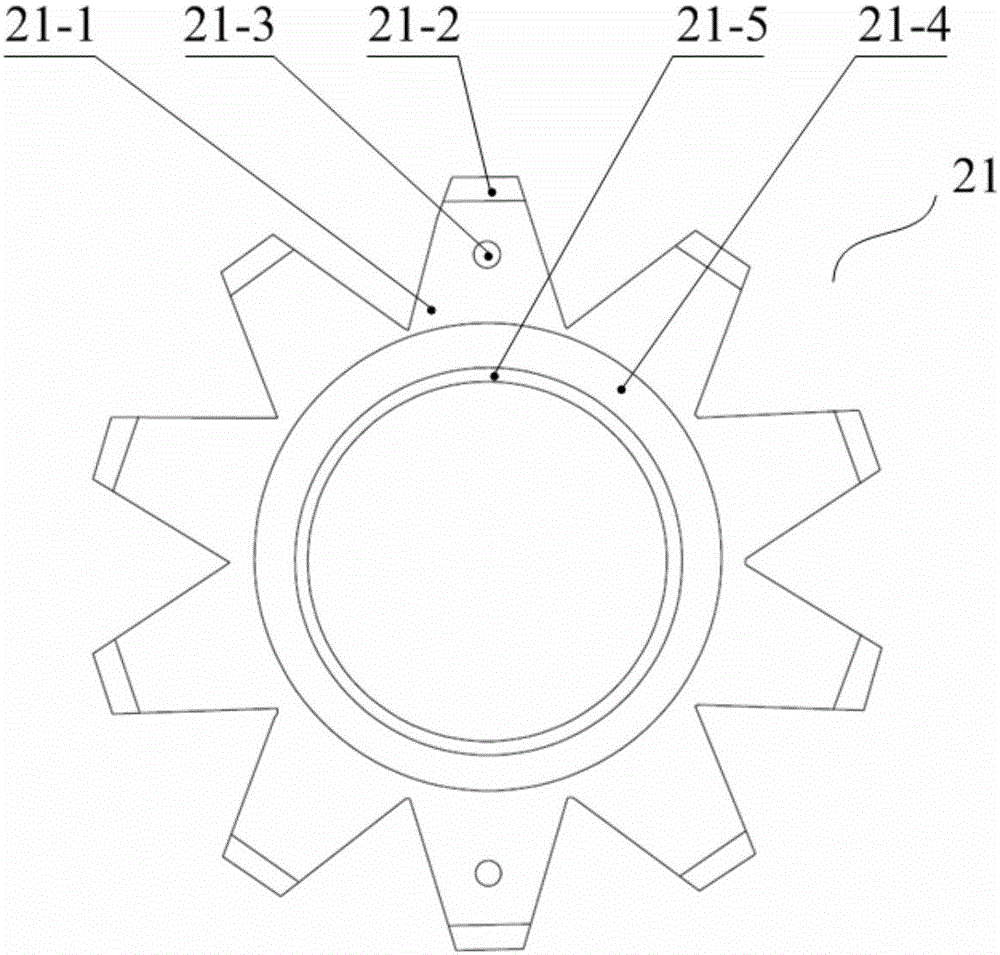

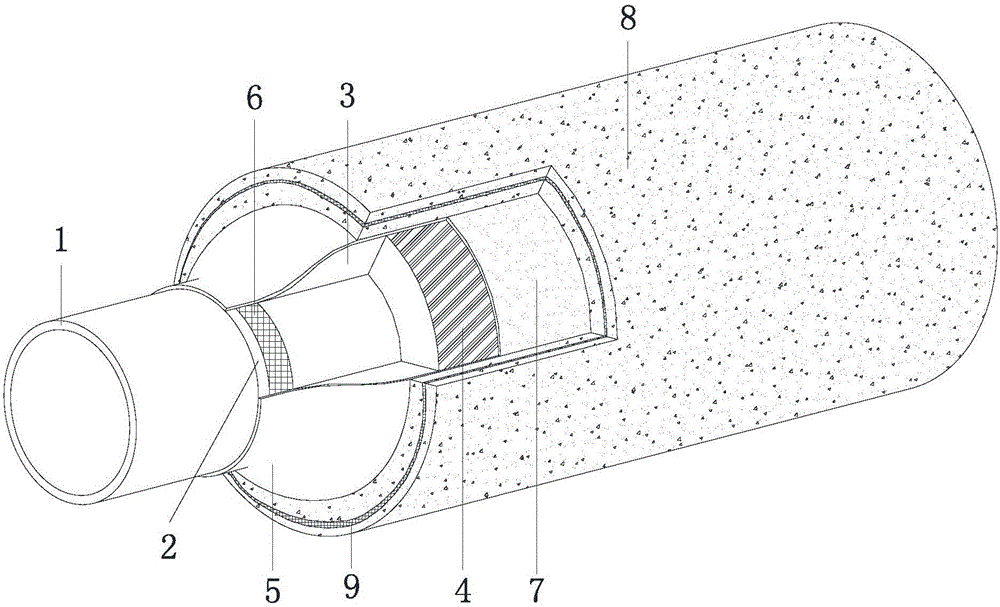

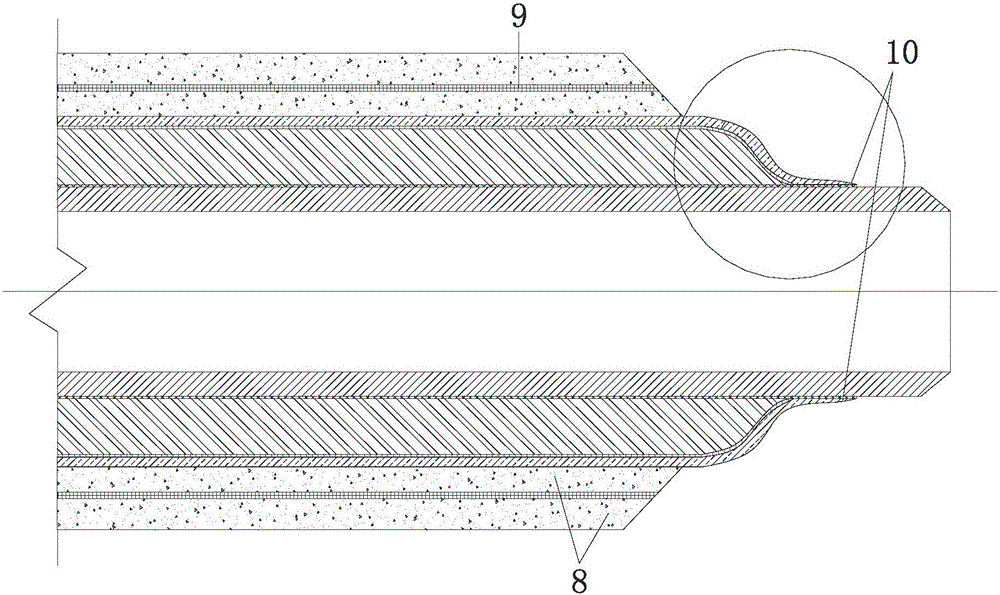

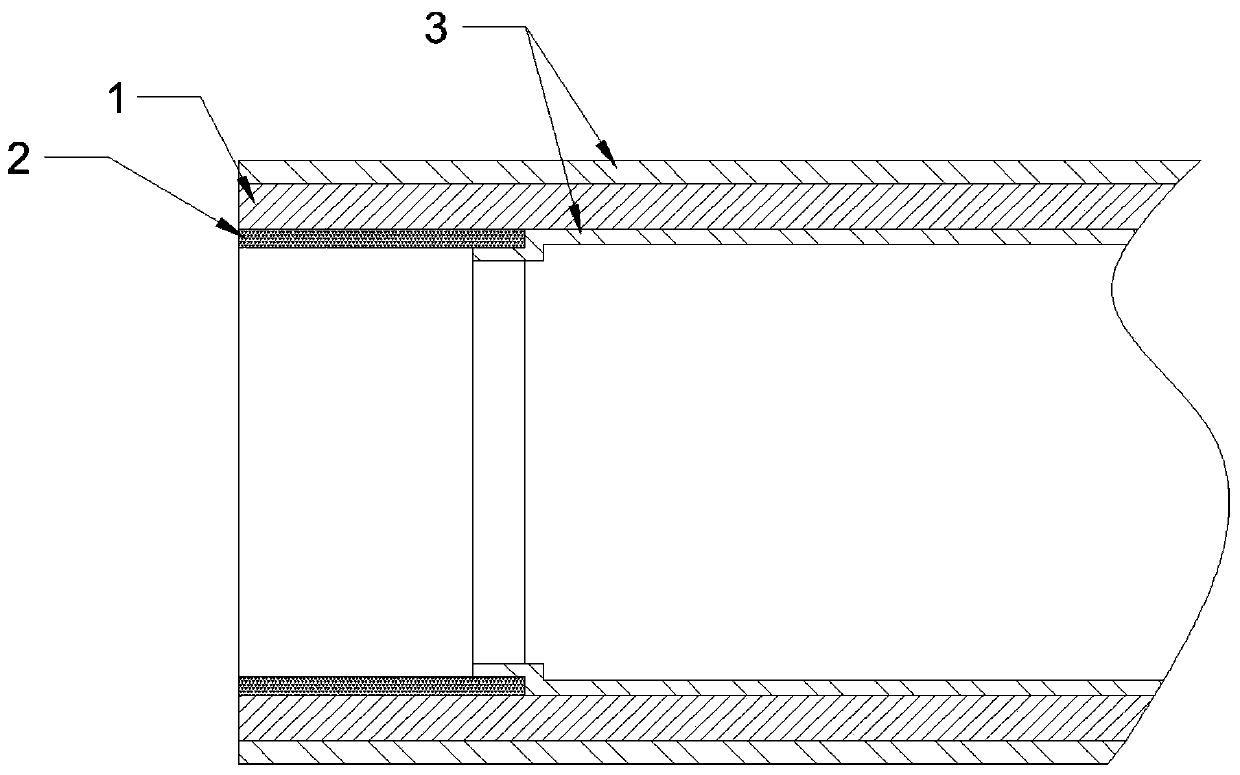

Straight pipeline for LNG return and liquid inlet

InactiveCN106322001AReduce generationImprove insulation effectFlanged jointsPipeline expansion-compensationEngineeringWorkload

Owner:TIANJIN BAIYAN TECH CO LTD

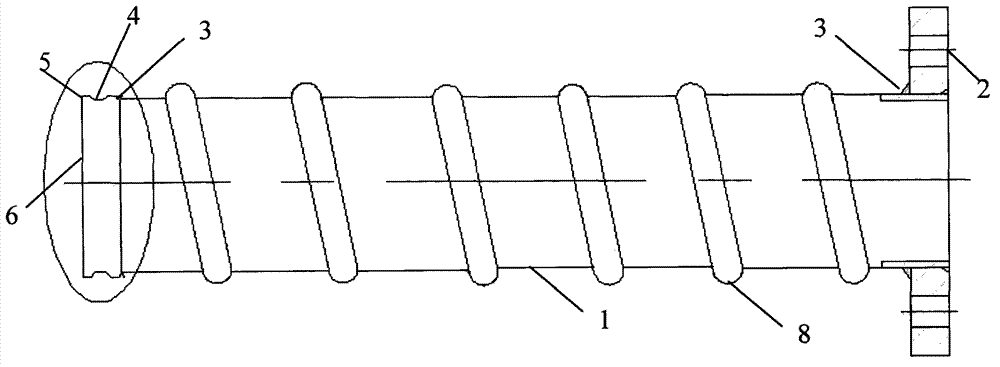

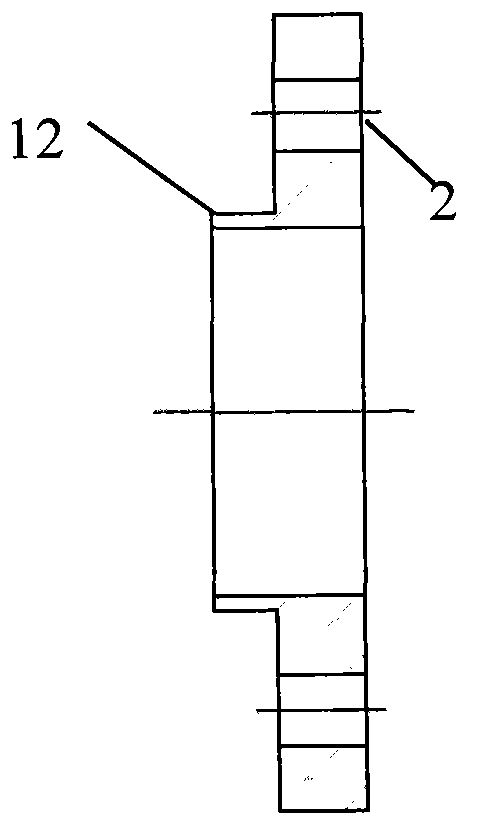

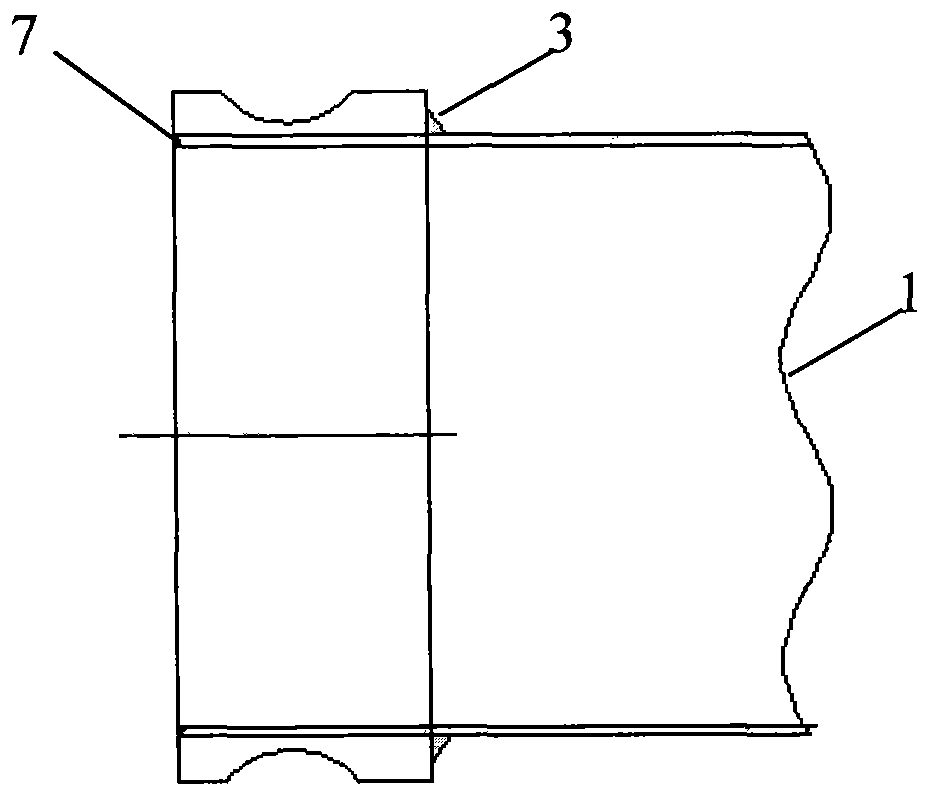

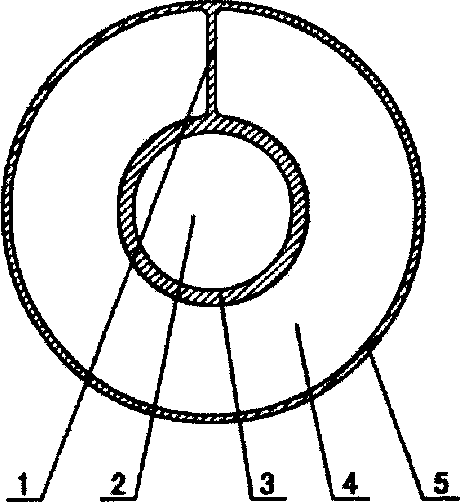

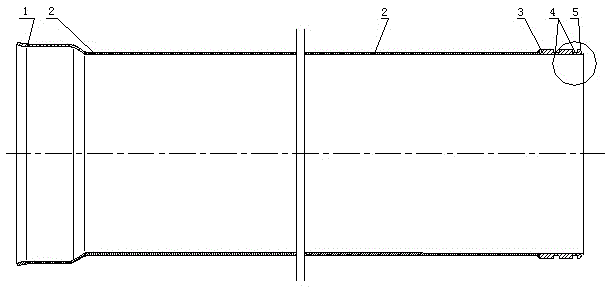

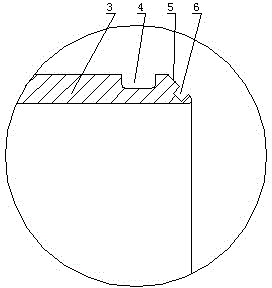

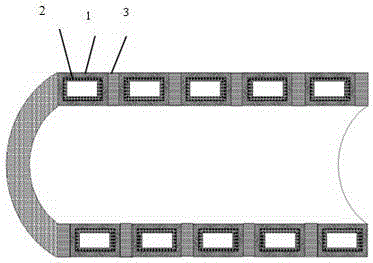

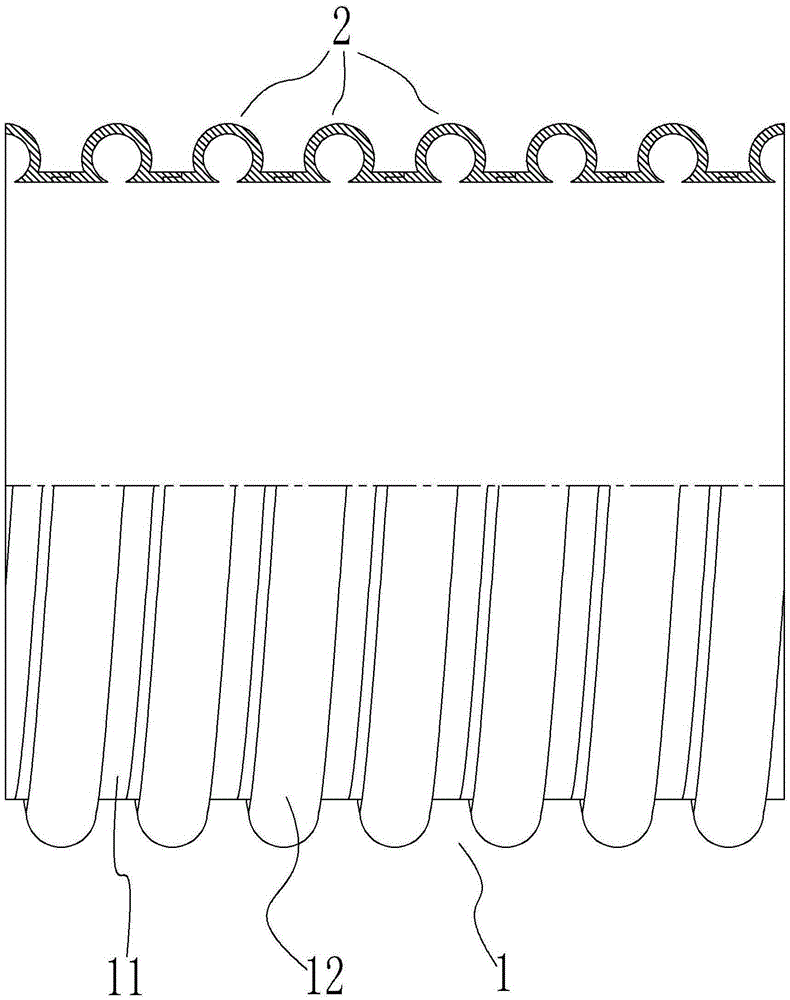

Steel strip reinforced polyethylene helically corrugated tube and production method thereof

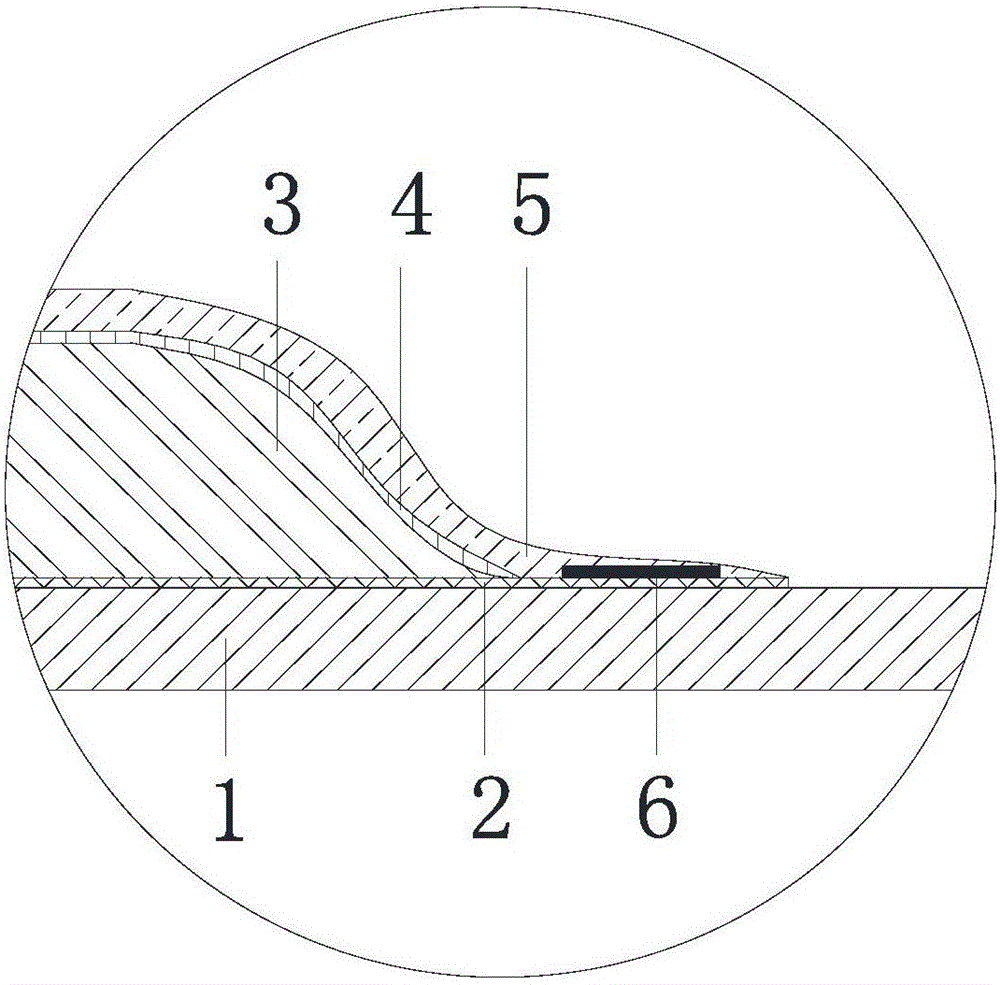

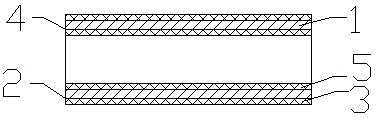

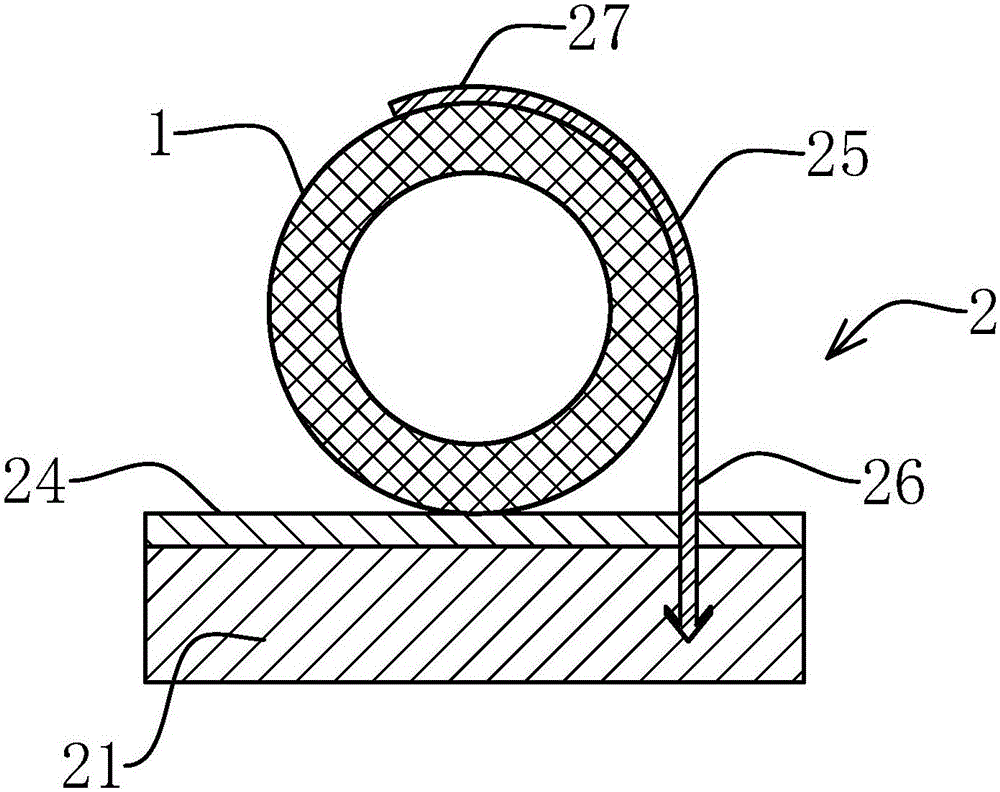

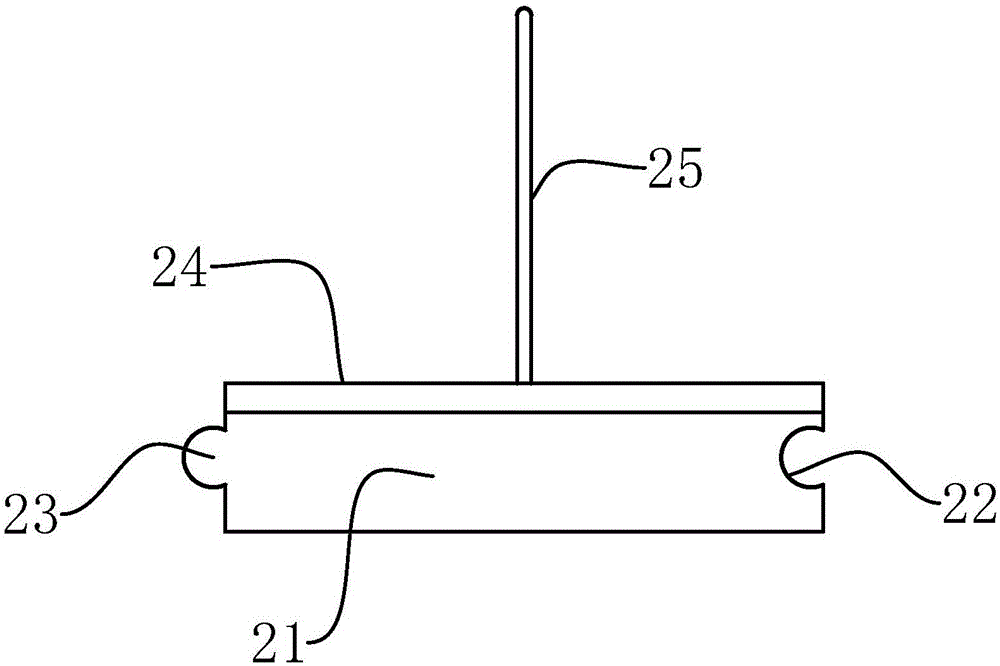

InactiveCN103697250AIncrease contact surfaceHigh bonding strengthRigid pipesBack stressCompression molding

The invention relates to a steel strip reinforced polyethylene helically corrugated tube and a production method thereof. A steel screen is welded at the feet of a V-shaped steel strip, a polyethylene layer is wound and coated with the bent steel strip, and the outer part of the steel strip is coated with the polyethylene layer. The production method comprises the steps of (1) molding of an inner layer, (2) compression molding of the steel strip, (3) welding of the steel screen through the steel strip, (4) bending and winding of the steel strip with a steel wire screen, and (5) molding of an outer layer. The steel strip reinforced polyethylene helically corrugated tube has the beneficial effects that the steel strip has certain spring-back stress in the compression process, so that after the steel screen is welded to the steel strip, the contact area of the steel strip and the outer side of a polyethylene tube is increased, the adhesion strength is improved, the product yield is improved, the shape and quality of a product are stabilized, and the safety of the product is ensured.

Owner:TIANJIN SHENGXIANG PLASTIC PIPE IND

Marine polyurethane spraying prefabricated thermal insulation balance weight pipe and preparation method thereof

InactiveCN105909883AEnsure consistencyAvoid your own flawsThermal insulationPipe protection by thermal insulationPolyolefinAdhesive

Owner:CHINA NAT OFFSHORE OIL CORP +1

Plastic-coated composite steel tube

Owner:丁春英

Floor heating pipe easy to install

InactiveCN105805812AStable supportEfficient use ofLighting and heating apparatusRigid pipesPipe fittingAluminum foil

Owner:叶君芝

Nickel-copper alloy seamless tube

The invention discloses a nickel-copper alloy seamless tube. The nickel-copper alloy seamless tube comprises the following components: copper, iron, manganese, silicon, silicon, sulfur and the balance of nickel; the manufacturing steps of the nickel-copper alloy seamless tube comprise the following steps of: (1), preparing blank and checking the performances of the blank; (2), heating up the ingredients and punching; (3), polishing the blank; (4), carrying out thermal expansion molding treatment on the blank; (5), heating up the blank; (6), carrying out straightening, internal grinding, external grinding and flaw detection on the blank; and (7), carrying out checking, spraying, packaging, weighing and stock removal on the finished product. According to the nickel-copper alloy seamless tube disclosed by the invention, the surface corrosion performances of the product are improved, the performance standards are better, and the manufacturing cost is lowered; and moreover, the production process is simple.

Owner:SUZHOU BEST METAL PROD

Improved splicing type aluminum alloy profile

ActiveCN113531231ANot easy to shake offEasy to turn and adjustSleeve/socket jointsPipe supportsAluminium alloy

The invention relates to the field of aluminum alloy sections, in particular to an improved splicing aluminum alloy profile. The improved splicing aluminum alloy profile comprises an aluminum alloy pipe, an inner pipe is arranged in the aluminum alloy pipe in a sleeve mode, a plurality of bearing plates are connected between the outer wall of the inner pipe and the inner wall of the aluminum alloy pipe, a bearing mechanism is further installed between every two adjacent bearing plates in the inner pipe and the aluminum alloy pipe. Abutting plates are converted into a vertical state from an inclined state and can abut against the inner wall of the aluminum alloy pipe, so that the sunken position of the aluminum alloy pipe is abutted and smoothed, the exterior of the aluminum alloy pipe can be rapidly repaired, repairing is simple and rapid, the attractiveness of the exterior of the aluminum alloy pipe can be kept, and the follow-up bearing capacity of the aluminum alloy pipe is improved.

Owner:YINGHE ALUMINUM IND (DONGGUAN) CO LTD

Halogen-free metal insulating tube and preparation method thereof

InactiveCN107573573AAchieve low smokeNot easy to catch fireThermal insulationCorrosion preventionCrack resistancePolyolefin

Owner:佛山市恒合信管业有限公司

Pipe for irrigation, water delivery and drainage in farmland water conservancy

The invention discloses a pipe for irrigation, water delivery and drainage in farmland water conservancy. The pipe is characterized by being composed of the following raw materials in parts by weight: 90-97 parts of high-density polyethylene, 0.7-1 part of dodecyl trimethyl ammonium chloride, 1-2 parts of zinc oxide, 2-3 parts of dimethacrylic acid glycol ester, 0.6-1 part of pyromellitic dianhydride, 2-3 parts of glycerin, 2-3 parts of maleic anhydride grafted polypropylene, 1-2 parts of zirconia, 1-2 parts of sodium antimonite, 2-3 parts of sillimanite, 0.1-0.4 part of butylmercaptooxo-stannane, 0.6-1 part of antioxidant 1010 and 8-14 parts of composite filler. The corrugated pipe disclosed by the invention is good in circulation, smooth in inner wall, small in frictional resistance and favorable in deposition and blockage preventing capability.

Owner:SINOMACH GENERAL MACHINERY SCIENCE & TECHNOLOGY CO LTD

PVC pipe with fireproof function and use method thereof

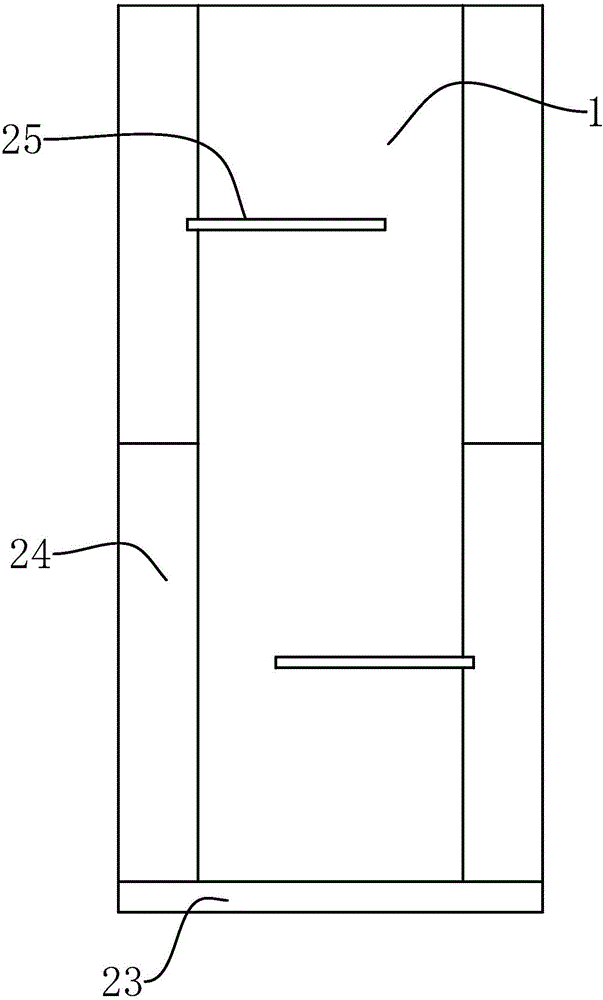

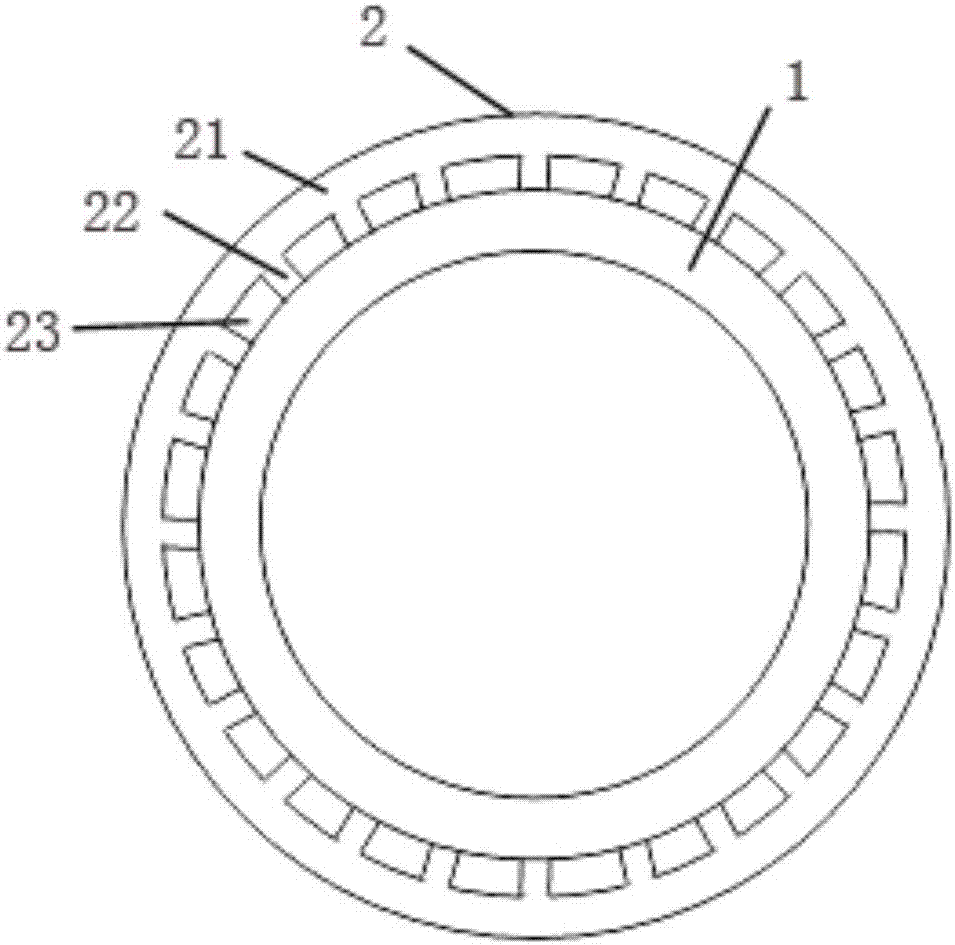

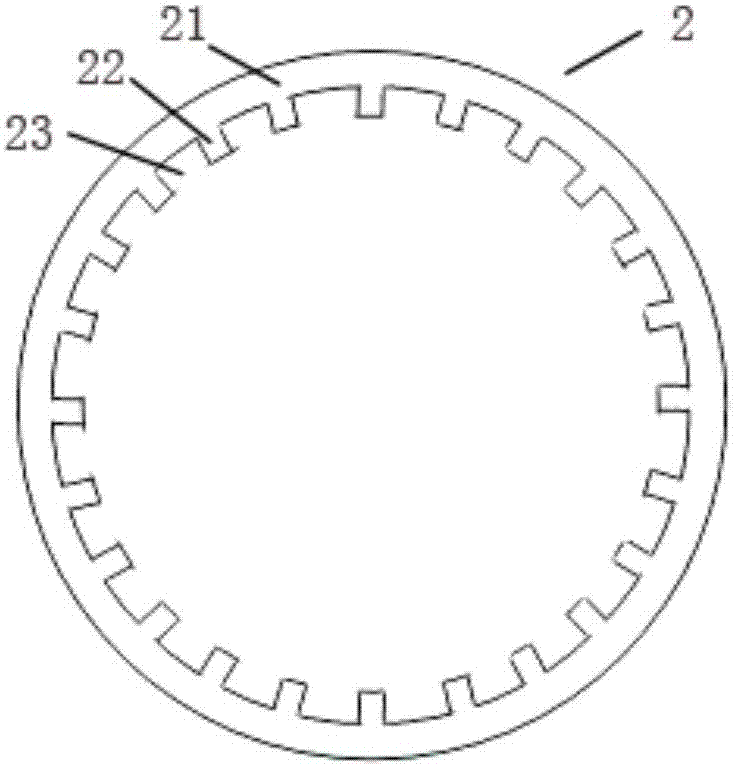

ActiveCN113063039AAchieve fire performanceHigh strengthRigid pipesPipe protection against damage/wearMechanical engineeringComposite material

The invention provides a PVC pipe with a fireproof function. The PVC pipe comprises a PVC pipe body and further comprises a fireproof outer pipe, wherein the PVC pipe body is sleeved with the fireproof outer pipe, a plurality of fixing blocks are arranged on the inner wall of the fireproof outer pipe in the circumferential direction of the fireproof outer pipe at equal intervals, clamping blocks are arranged at the ends, away from the inner wall of the fireproof outer pipe, of the fixing blocks, clamping bases with the same number as the fixing blocks are arranged on the outer wall of the PVC pipe body in the circumferential direction of the PVC pipe body at equal intervals, and clamping grooves used for being connected with the clamping blocks are formed in the clamping bases. By the adoption of the technical scheme, the clamping grooves of the clamping bases on the PVC pipe body are aligned with the clamping blocks in the fireproof outer pipe, the PVC pipe body is installed in the fireproof outer pipe, the fireproof effect on the PVC pipe body is achieved by means of the fireproof characteristic of the fireproof outer pipe, and when the outside of the fireproof outer pipe is stressed, supporting columns formed by connecting the clamping blocks and the clamping bases can support the inner wall of the fireproof outer pipe, and the strength of the fireproof outer pipe is improved.

Owner:BAILEY (FUJIAN) BUILDING MATERIALS CO LTD

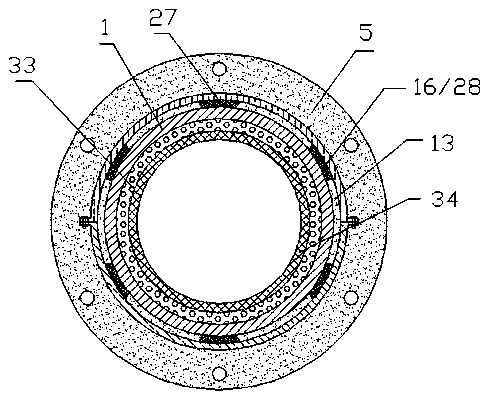

Pipeline with noise reduction and thermal insulation

InactiveCN104110535AImprove sealingHigh strengthThermal insulationPipe protection by thermal insulationThermal insulationEngineering

Owner:JIANGYIN HAILU HIGH PRESSURE PIPE

Bimetallic welding plastic coating composite steel pipe

Owner:重庆鼎久管道有限公司

Surface-treated steel plate, fuel pipe, cell can

ActiveCN103649362AImprove corrosion resistanceAvoid pittingCorrosion preventionJackets/cases materialsSheet steelNickel alloy

Provided is a surface-treated steel plate obtained by forming an iron-nickel alloy layer on the topmost surface, the surface-treated steel plate being characterized in that the Fe / Ni value obtained by Auger electron spectroscopy on the surface of the iron / nickel alloy layer is in the range of 0.3-2.0. In accordance with the present invention, there is provided a surface-treated steel plate having excellent corrosion resistance and in which the occurrence of pitting is effectively reduced when the surface-treated steel plate is exposed to various fuels such as automotive fuel oil.

Owner:TOYO KOHAN CO LTD

Nodular cast iron composite tube lined with epoxy ceramic and manufacturing method thereof

Owner:SHANDONG GUOMING DUCTILE IRON PIPES TECH CO LTD

Helical corrugated winding pipe

Owner:HUBEI SHUIZHIYI TECH CO LTD

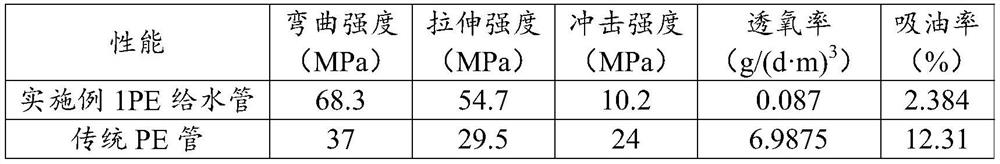

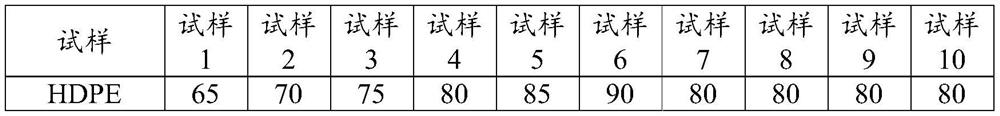

PE water supply pipe and preparation method thereof

Owner:FOSHAN RIFENG NEW PIPE +3

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap