Composite reinforced strip windable to form a helical pipe and method therefor

a technology of helical pipes and reinforced strips, which is applied in the direction of pipes, pipe protection against damage/wear, mechanical equipment, etc., can solve the problems of requiring considerable force during the rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072]Embodiments of the invention are illustrated in the accompanying representations in which:

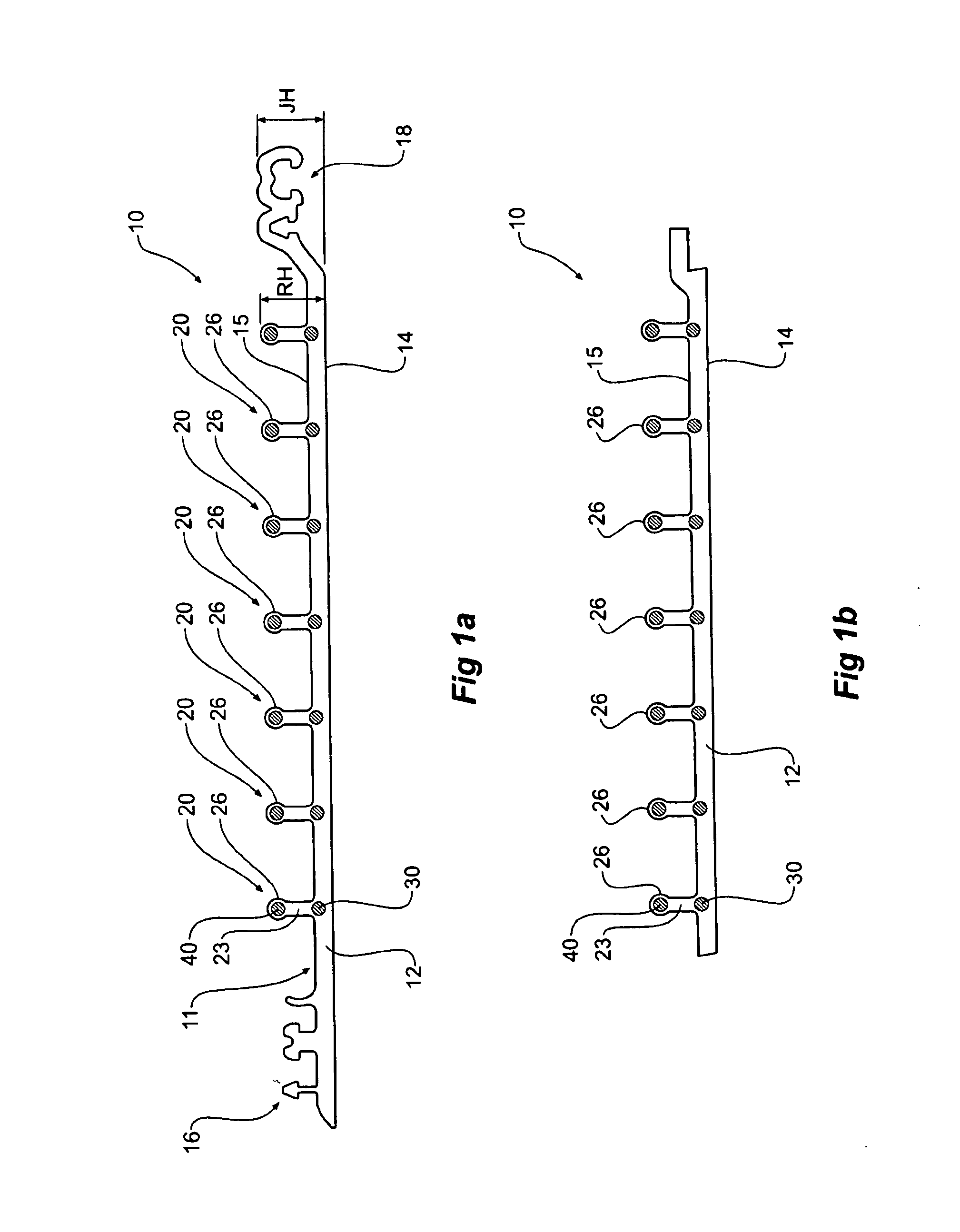

[0073]FIG. 1a shows a cross-sectional view of a composite strip according to an embodiment of the invention.

[0074]FIG. 1b is a similar view to that of FIG. 1a but shows alternative edge arrangements for joining adjacent convolutions of the strip.

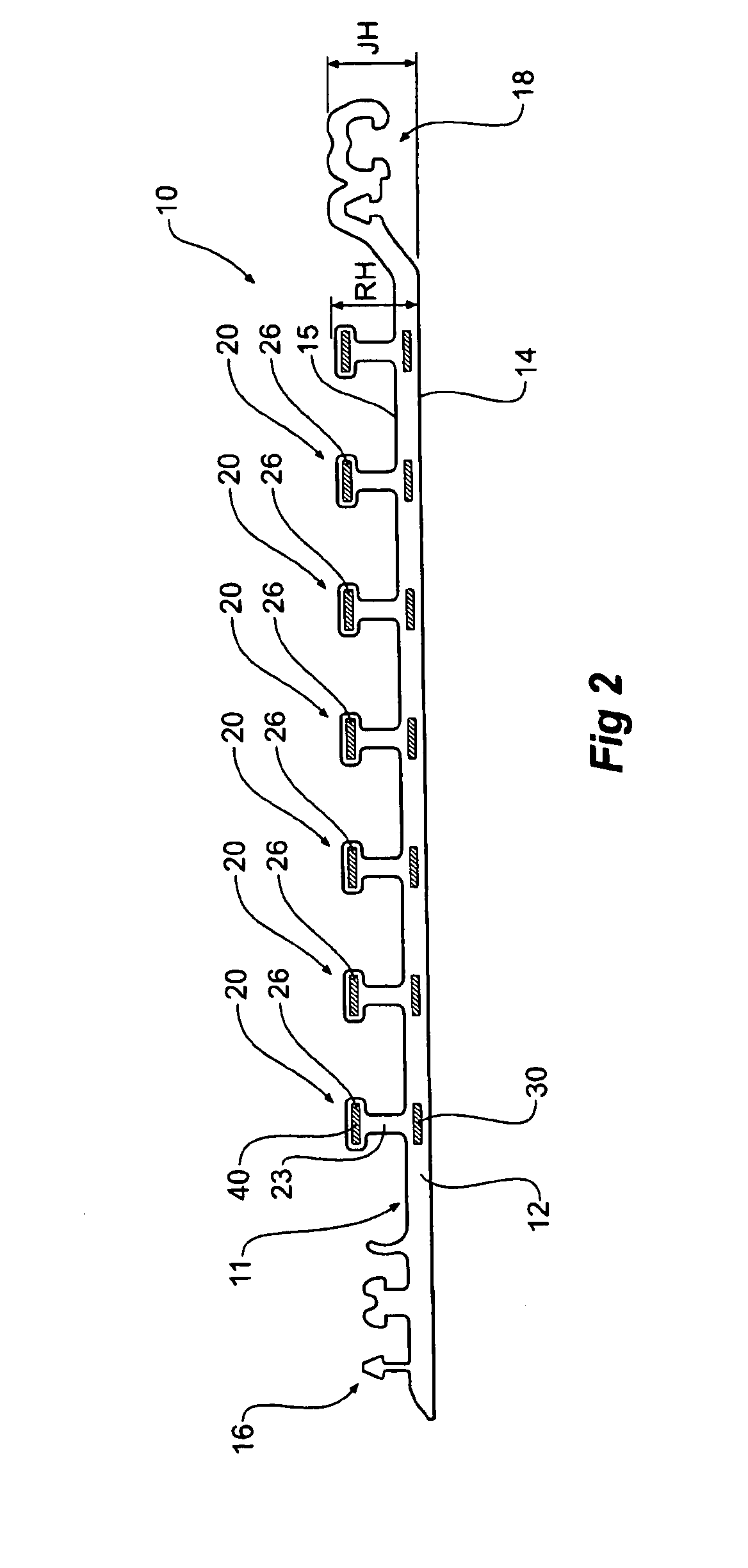

[0075]FIG. 2 shows an alternative embodiment of the invention.

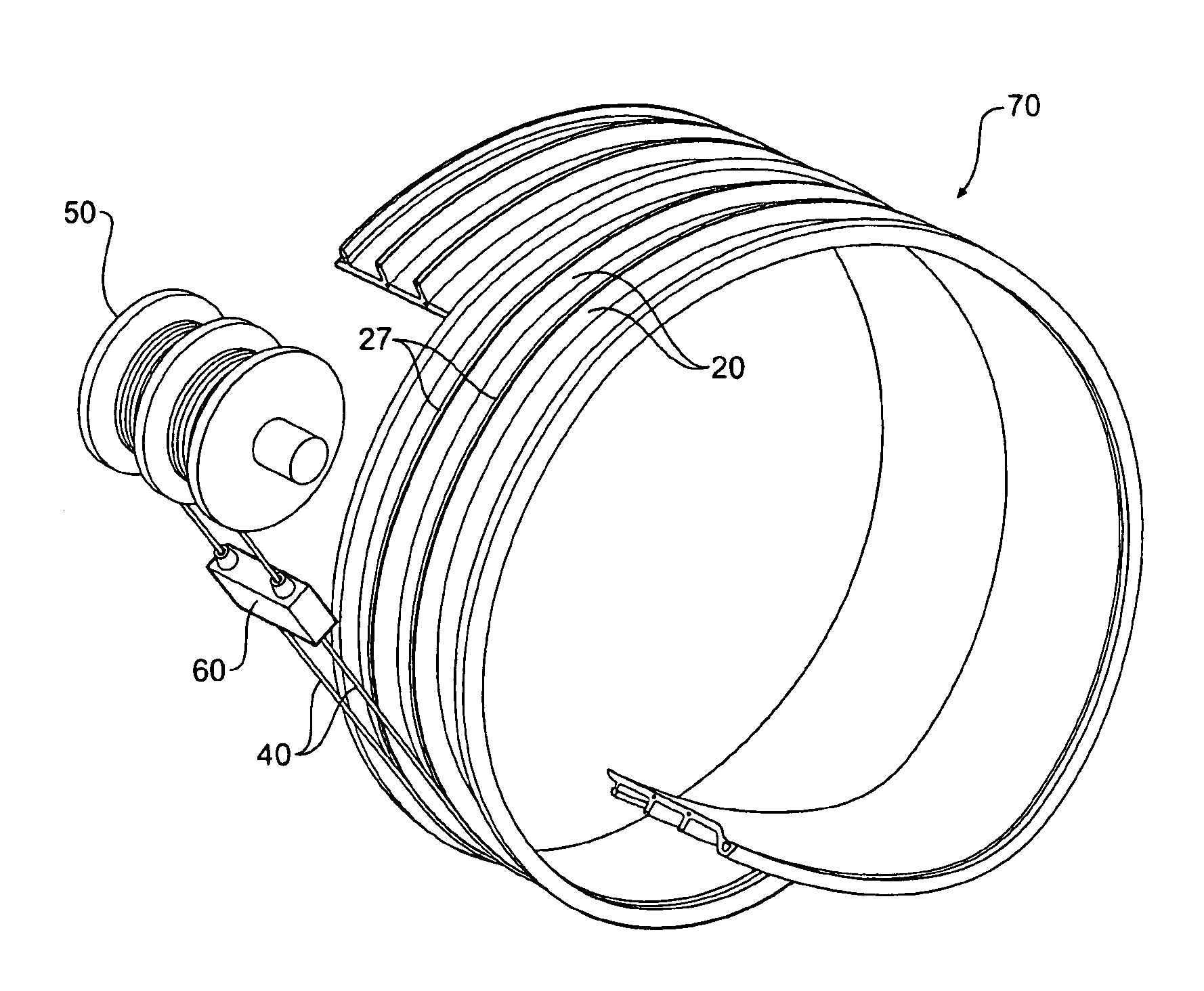

[0076]FIGS. 3a and 3b are isometric views of the profiles of FIGS. 1 and 1b respectively.

[0077]FIG. 4 is an isometric view of a pipe wound from the profile of FIG. 1b.

[0078]FIG. 5 is a cross-sectional view of a composite strip according to a further alternative embodiment of the invention, of the strip having a base reinforcing the portion.

[0079]FIG. 6 is similar view to that of FIG. 5 but shows adjacent profiles interlocking.

[0080]FIG. 7a shows a cross-sectional view of a composite strip according to a further embodiment of the invention. Included within FIG. 7a is an enlarged view of th

PUM

| Property | Measurement | Unit |

|---|---|---|

| Distance | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap