Goods transfer equipment used in freight agency process

A technology of equipment and cargo, which is applied in the field of cargo transfer equipment, can solve the problem that the slide cannot be folded, and achieve the effect of easy loading, unloading, and easy placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

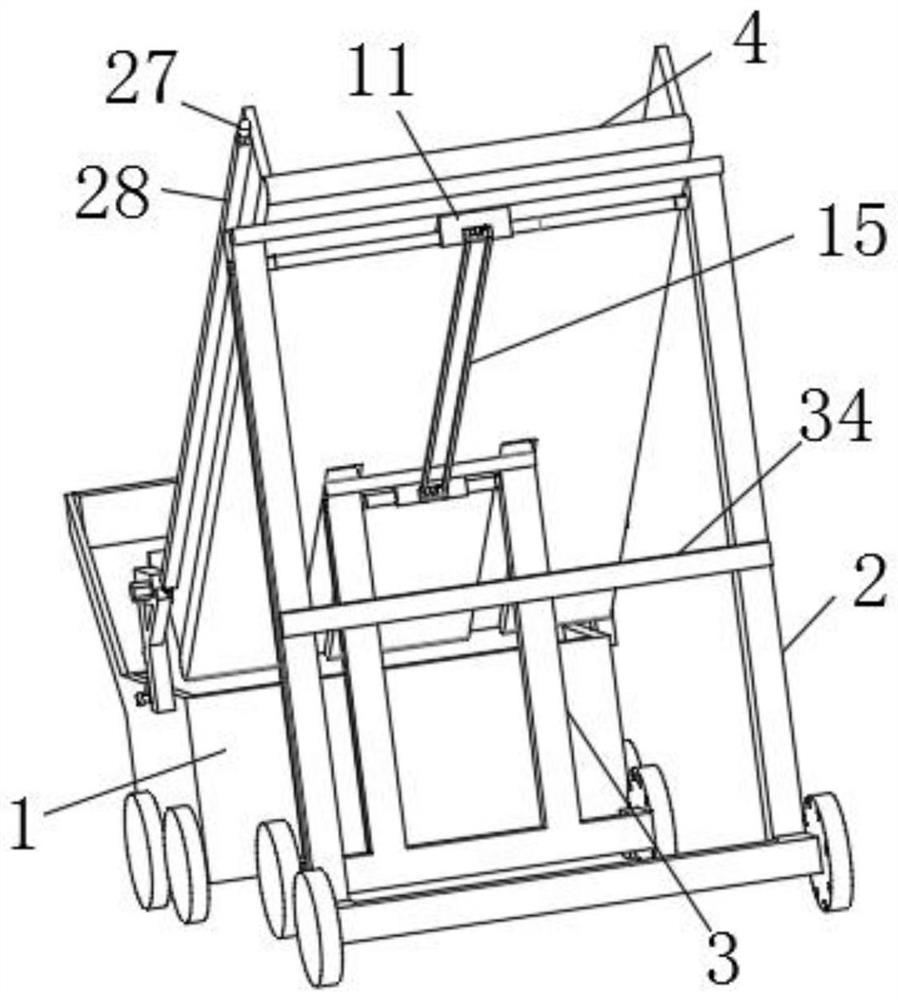

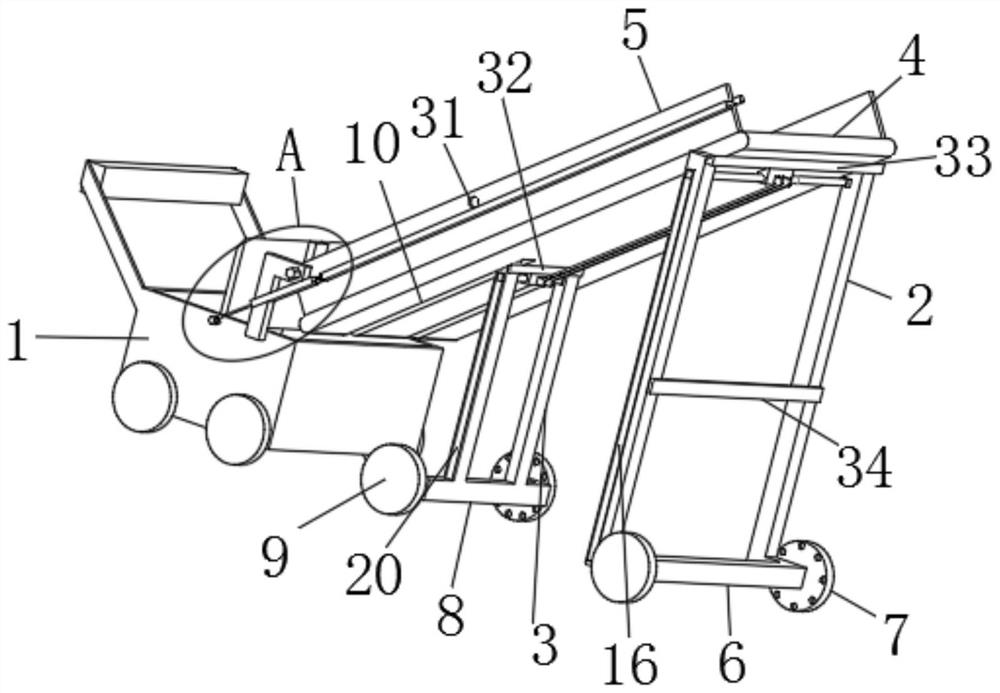

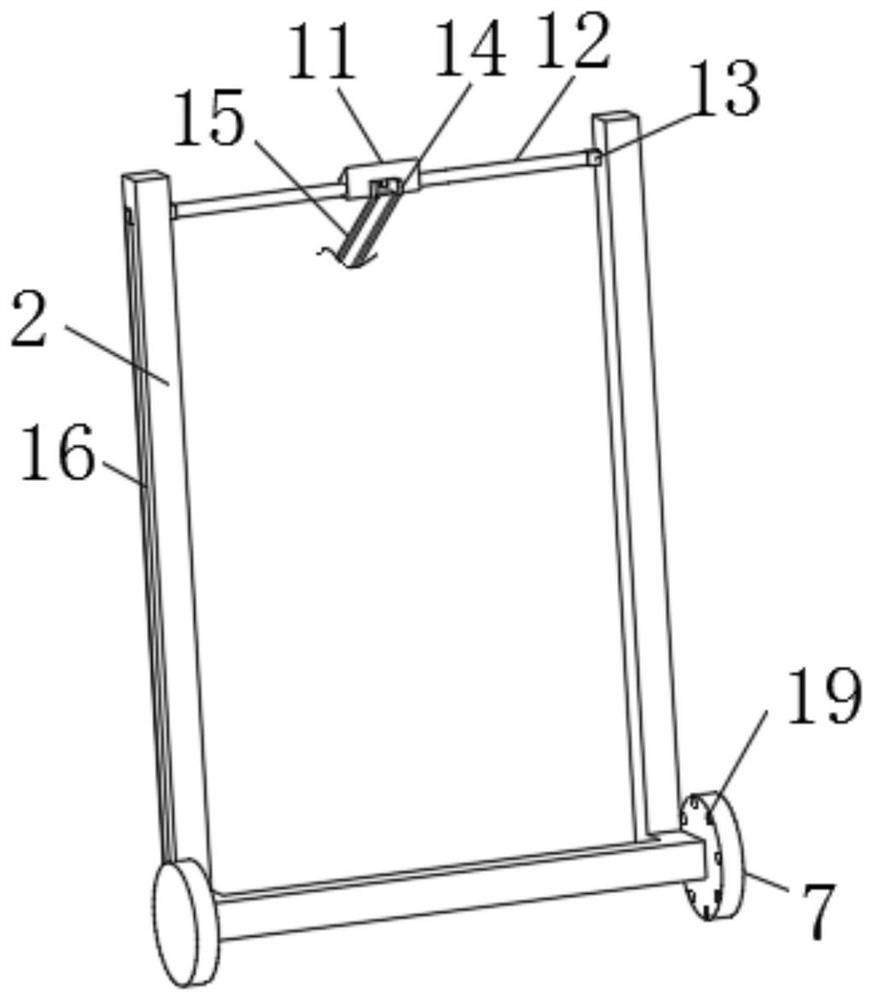

[0031] Example: Reference Figure 1-9 The cargo transportation equipment used in the fuelry proxy, including transport vehicles 1, and two long support rods 2 and two short-support rods 3, transport vehicles 1, long support rod 2 in the side of the transport vehicle 1. The short support rod 3 can be any of the prior art, and the long support rod 2 and the short-support rod 3 are disposed above the unloading plate 4, and two storage grooves 10 are opened at the bottom of the discharge plate 4, two short support. The top of the rod 3 is rotatably mounted to the two storage tank 10, respectively, and the two long support rods 2 are rotatably mounted on both sides of the unloading plate 4, and two anti-fall plates 5 are mounted. 5, unloading board 4, the anti-landing plate 5 can be any of the prior art, the transport vehicle 1 is connected to the side of the two flange 5 by the connecting mechanism, and the bottom end of the two long support rods 2 is mounted with a U-shaped connecting ro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap