Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Assembly line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An assembly line is a manufacturing process (often called a progressive assembly) in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is produced.By mechanically moving the parts to the assembly work and moving the semi-finished assembly from work station to ...

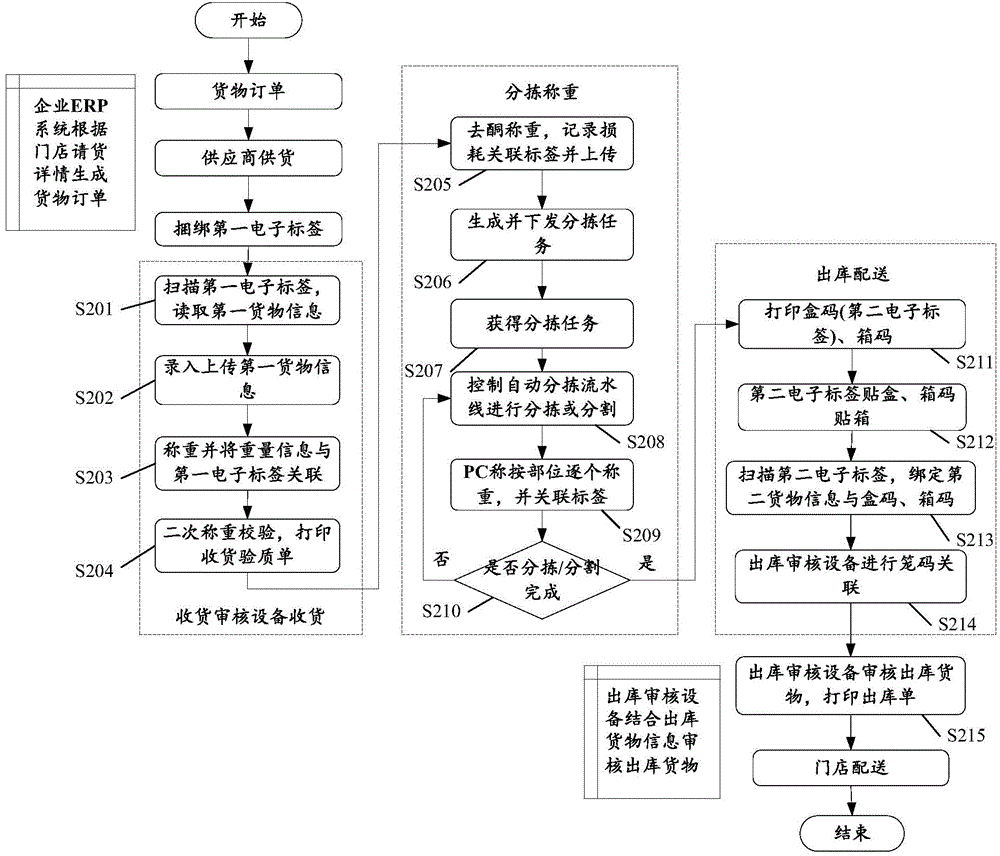

Internet of Things system for supply chain management

ActiveCN104463549AResolve accuracySolve efficiency problemsLogisticsLogistics managementAssembly line

Owner:武汉华工赛百数据系统有限公司

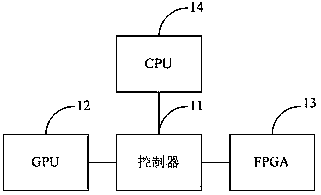

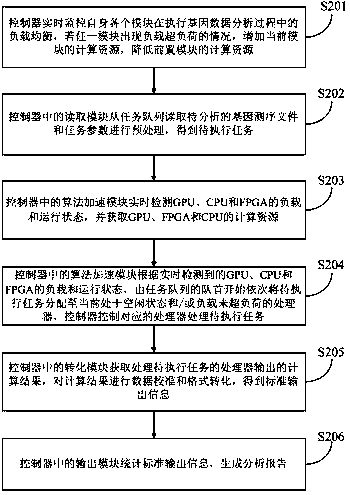

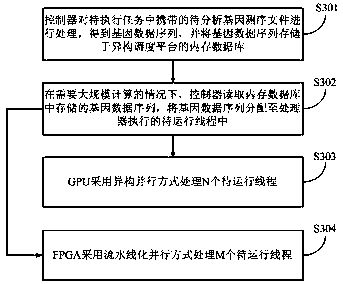

Gene data analysis method and heterogeneous scheduling platform

Owner:BGI TECH SOLUTIONS

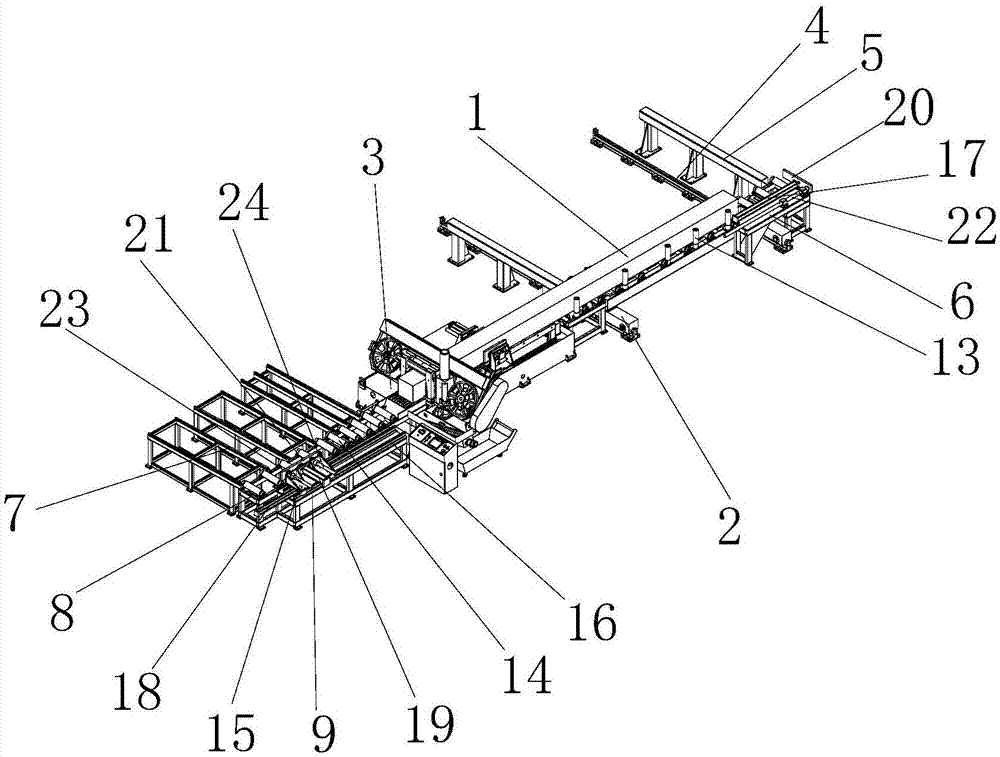

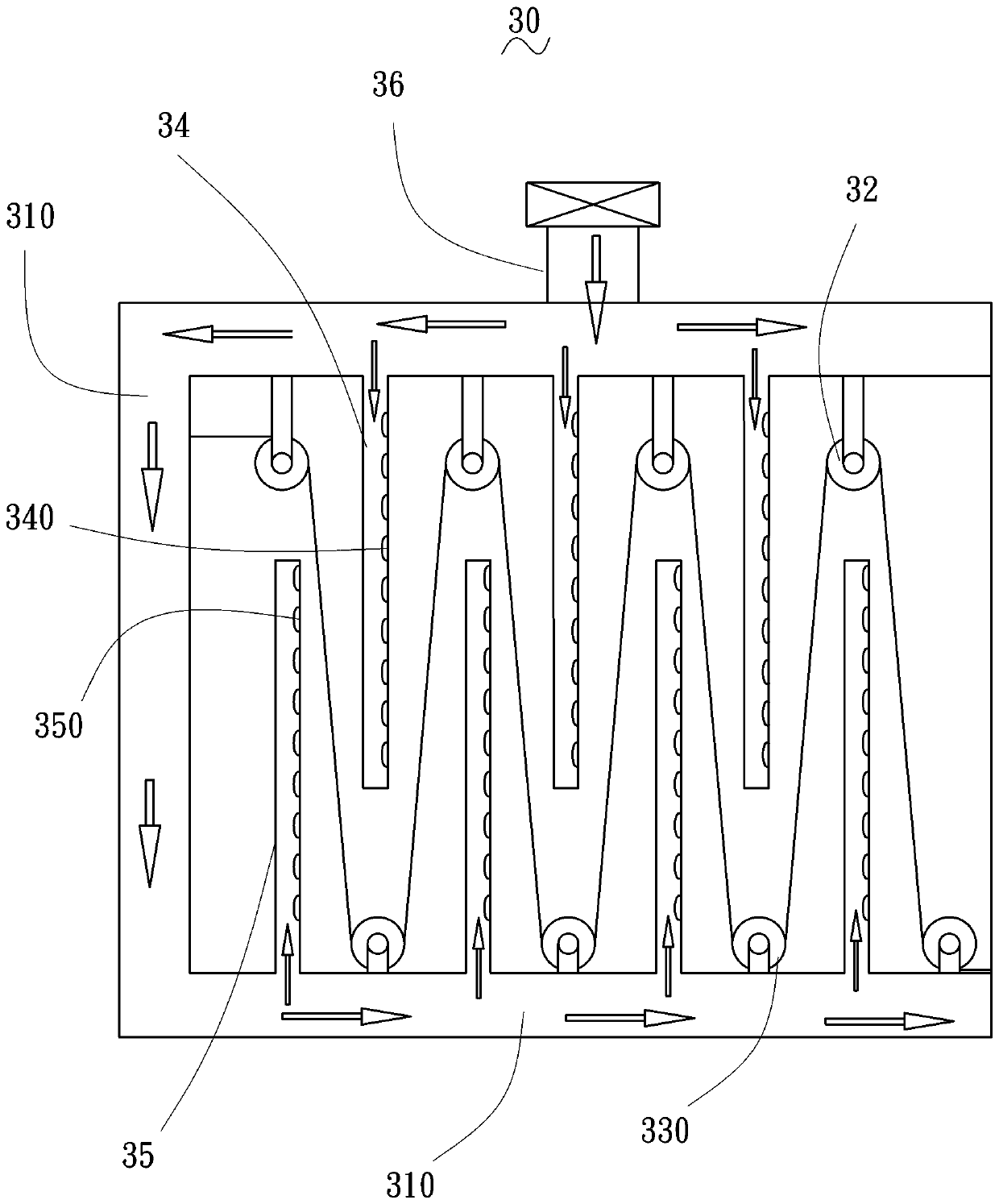

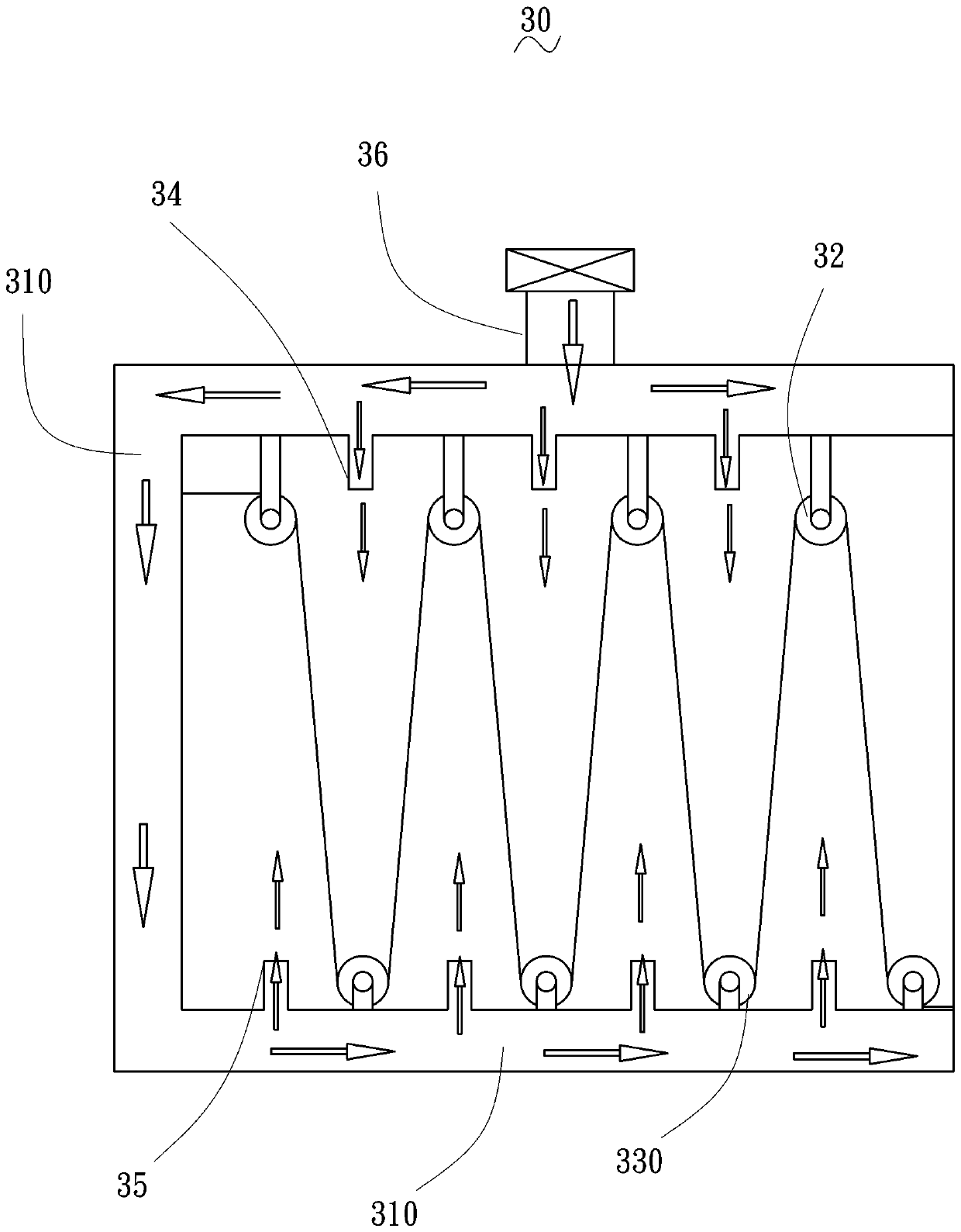

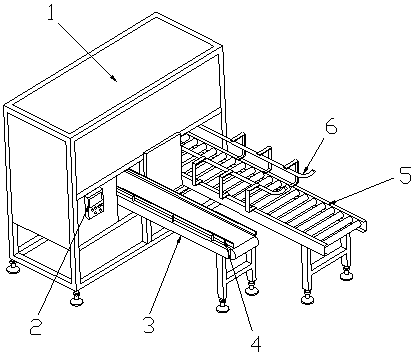

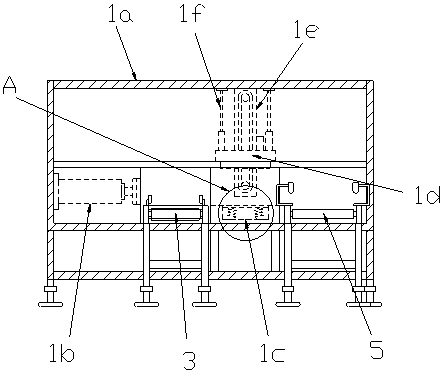

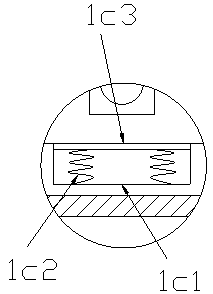

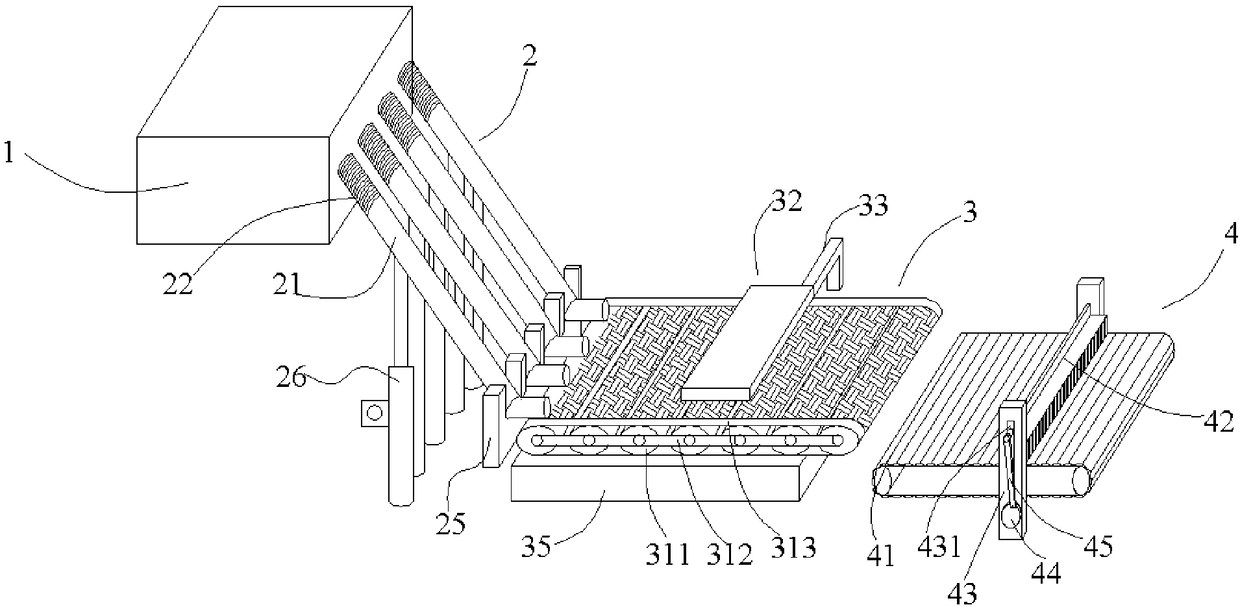

Automatic sorting and processing assembly line of logistics warehouse

ActiveCN111545477AImprove work efficiencyIncrease sliding forceStacking articlesSortingLogistics managementProcess engineering

The invention relates to an automatic sorting and processing assembly line of a logistics warehouse. The automatic sorting and processing assembly line of the logistics warehouse comprises a sorting device and conveying and stacking devices, wherein the conveying and stacking devices are symmetrically arranged front and back on the left side of the sorting device, and the lower ends of the sortingdevice and the conveying and stacking devices are arranged on the existing working ground. According to the design concept of the sorting-stacking integrated structure, automatic sorting of goods inthe logistics warehouse is carried out, the adopted sorting device can be used for screening different specification types of packages in a uniform shape integrally, the screened goods can be rapidlytransported and stacked by the aid of the arranged conveying and stacking devices, and compared with a traditional manual sorting and arranging mode, the automatic cooperation operation mode between the sorting device and the conveying and stacking devices greatly improves working efficiency.

Owner:ZHEJIANG YIXINGDA WISDOM TECH CO LTD

Automatic lamination, detection and boxing production line of stator and rotor

PendingCN108526375AReduce in quantityReduce labor intensityManufacturing stator/rotor bodiesSortingProduction lineMechanical equipment

Owner:浙江钜丰科技有限公司

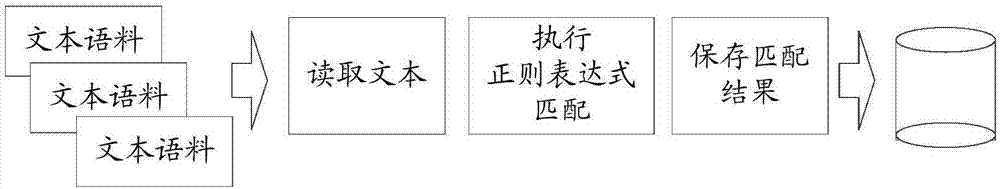

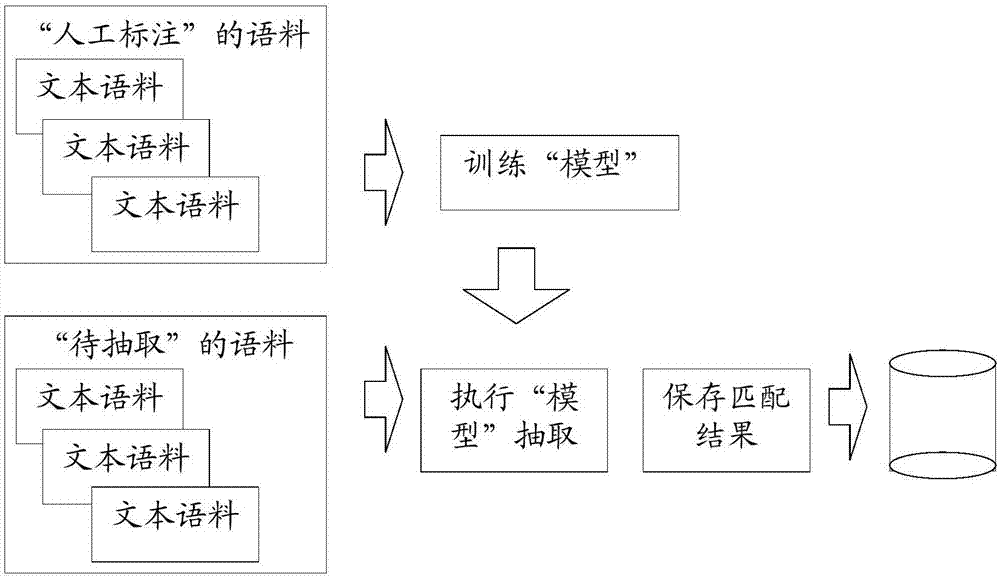

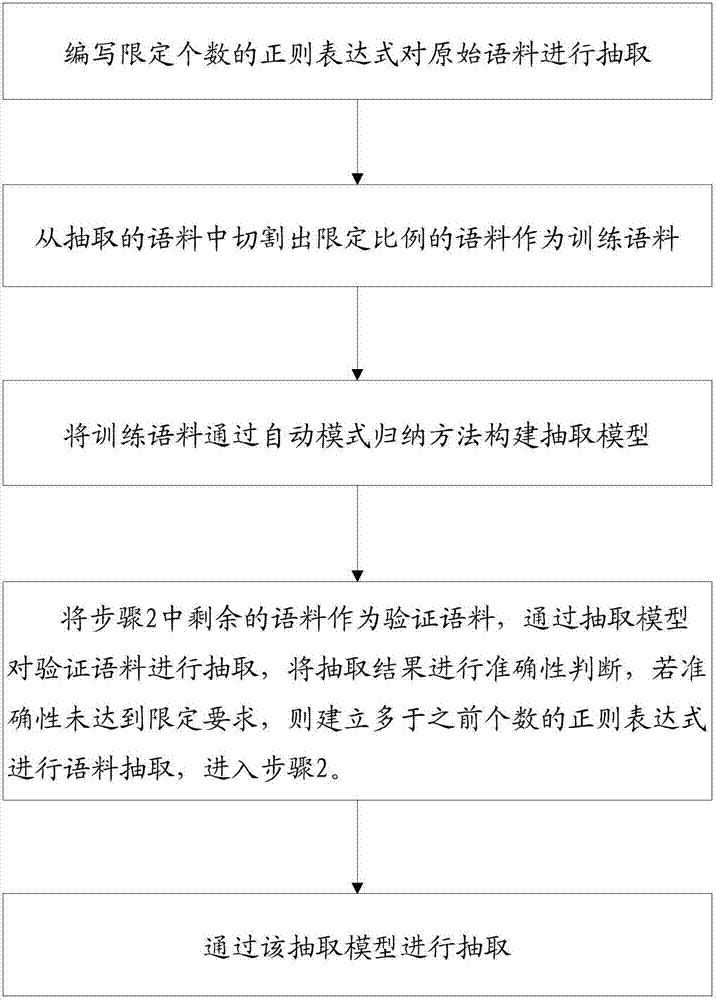

General text information extraction method and system

PendingCN107977345ANatural language data processingSpecial data processing applicationsInformation extractionAssembly line

Owner:FUJIAN YIRONG INFORMATION TECH +3

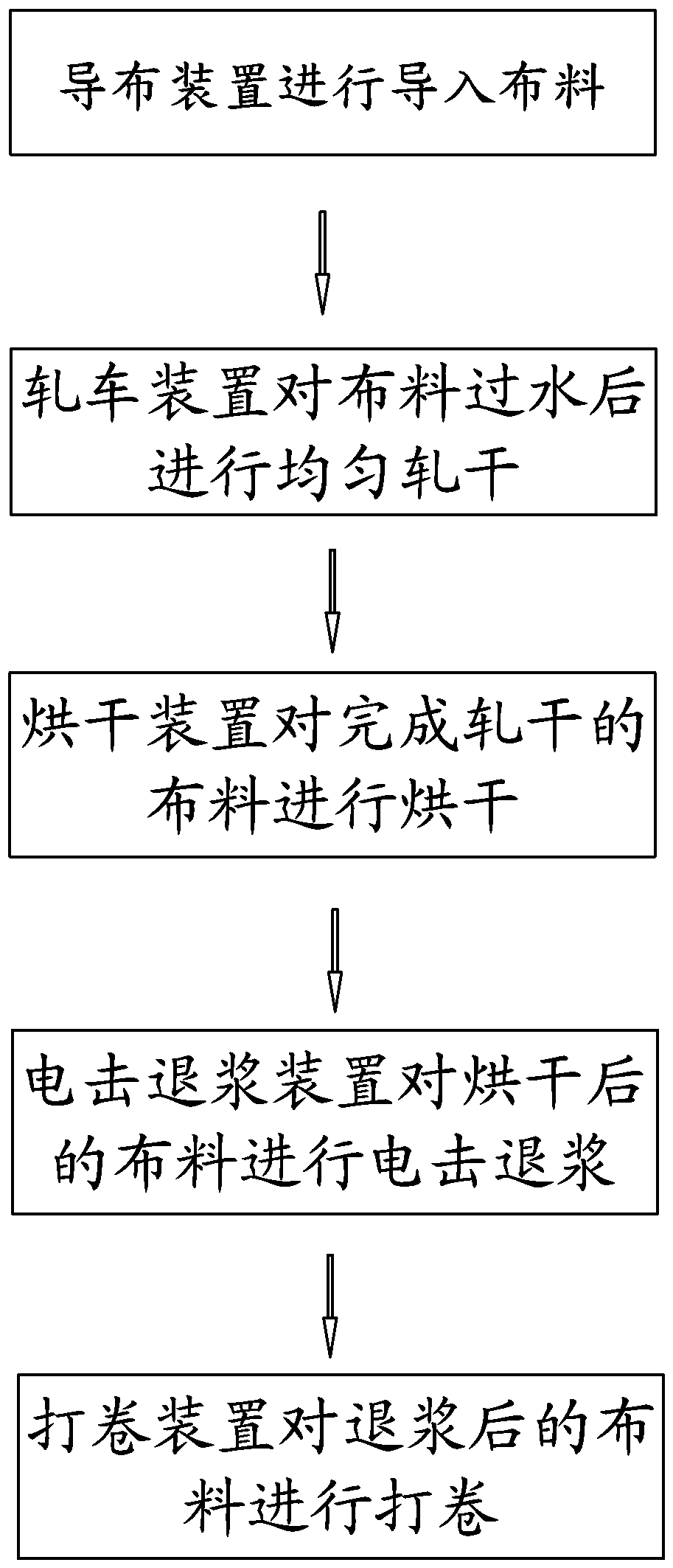

Cloth dyeing pretreatment assembly line and treatment method thereof

PendingCN107841840AHigh color fastnessHigh lusterLiquid/gas/vapor removal by squeezing rollersUltrasonic/sonic fibre treatmentAssembly linePulp and paper industry

Owner:浙江佳茂环保科技有限公司

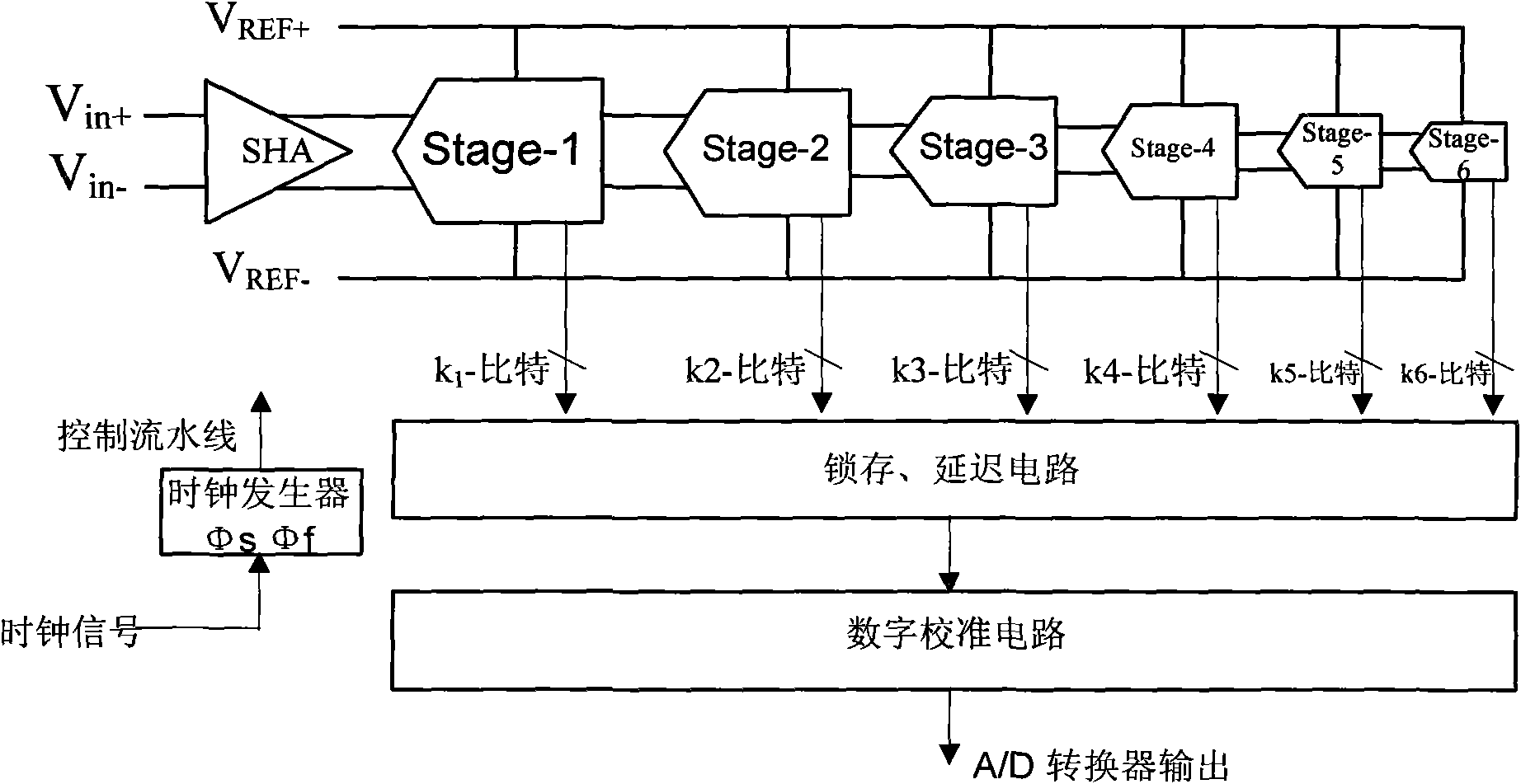

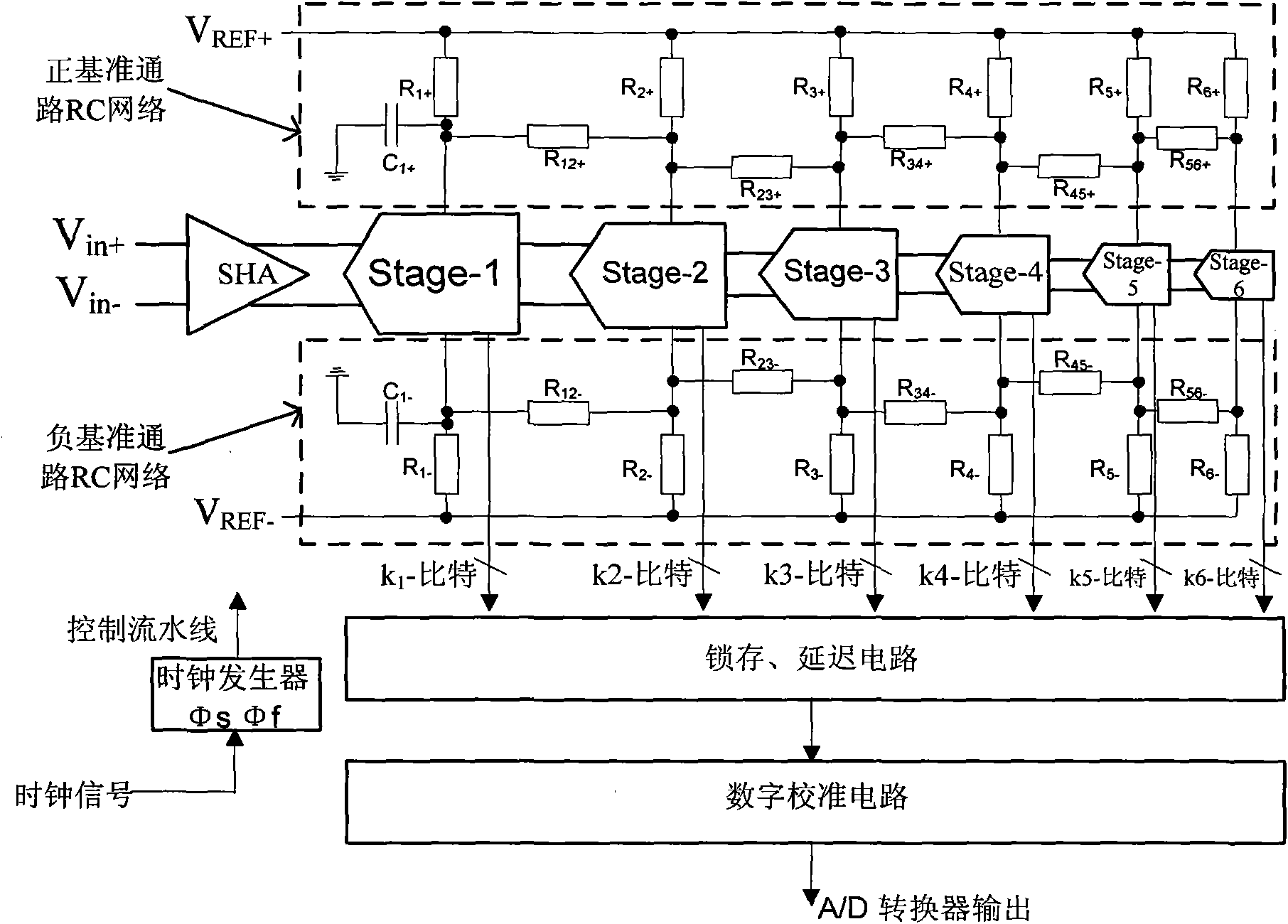

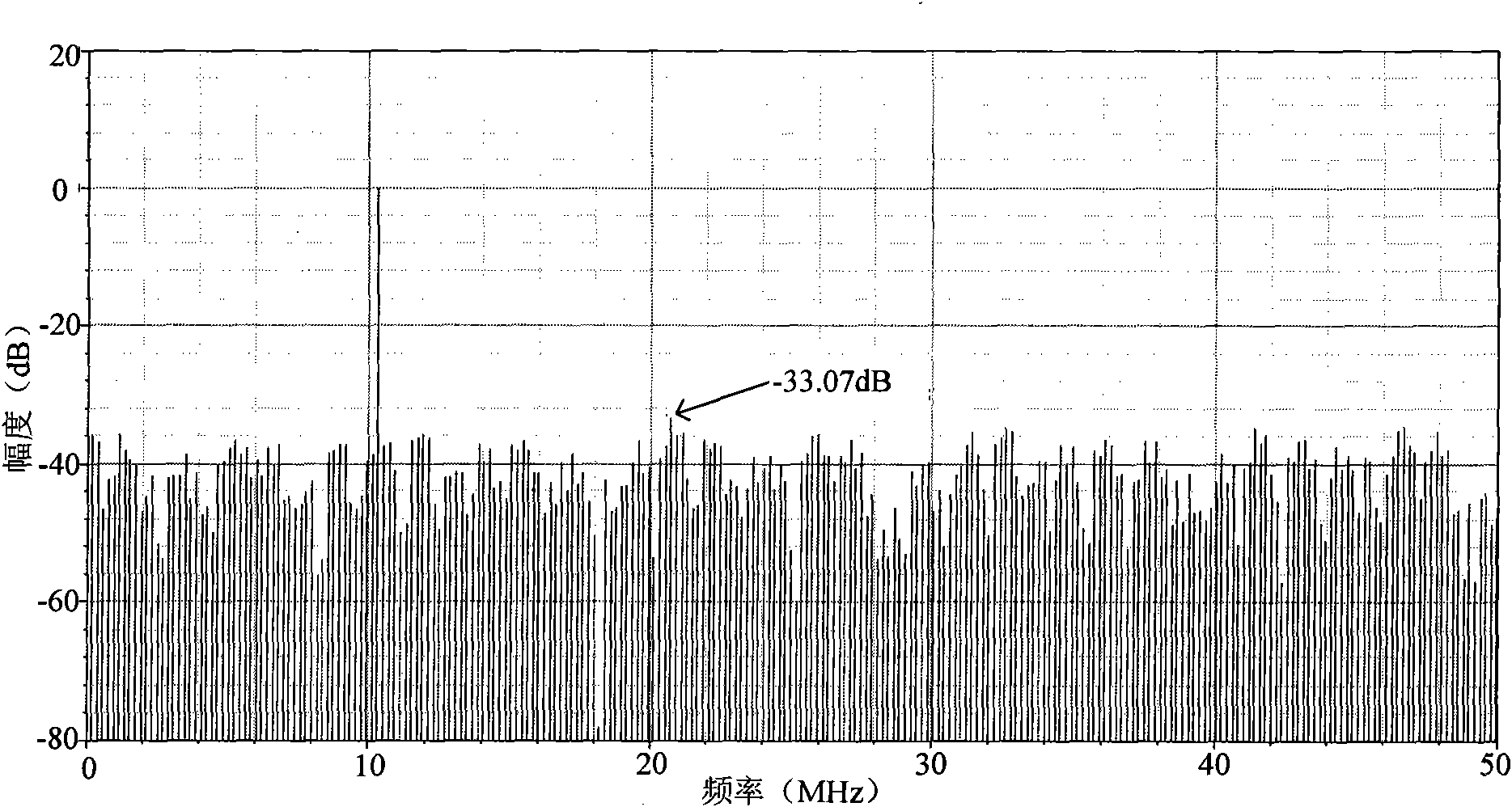

Switching noise suppression circuit integrated on A/D (analog/digital) converter chip

InactiveCN102064808AImprove dynamic performanceSuppression of SSN noiseElectronic switchingElectrical resistance and conductanceCapacitance

Owner:NO 24 RES INST OF CETC

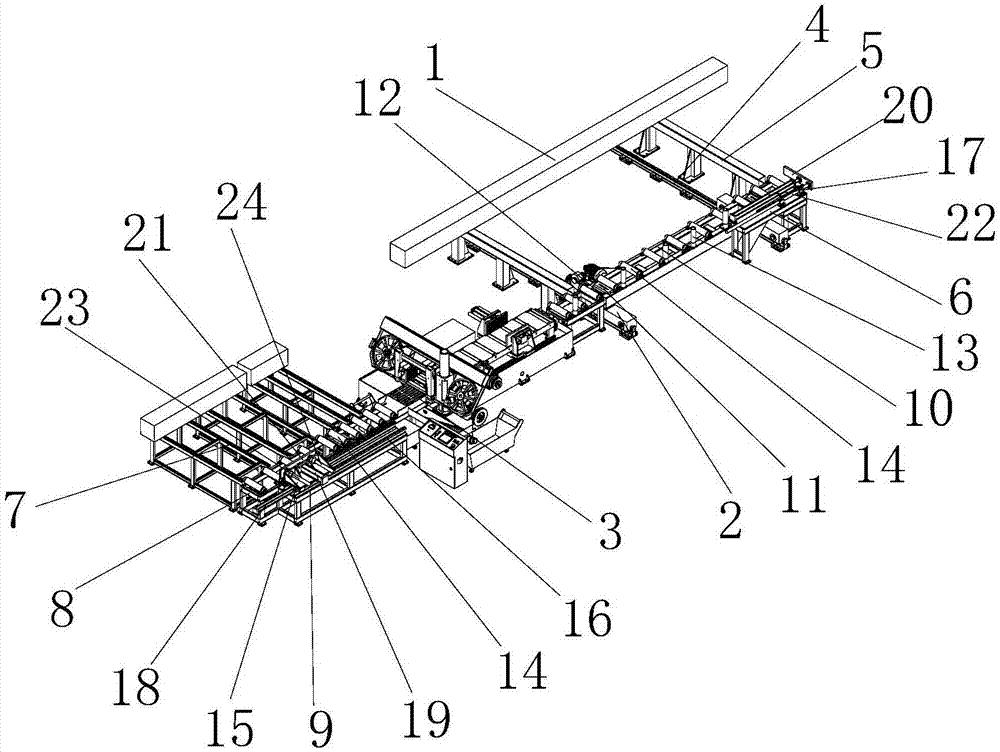

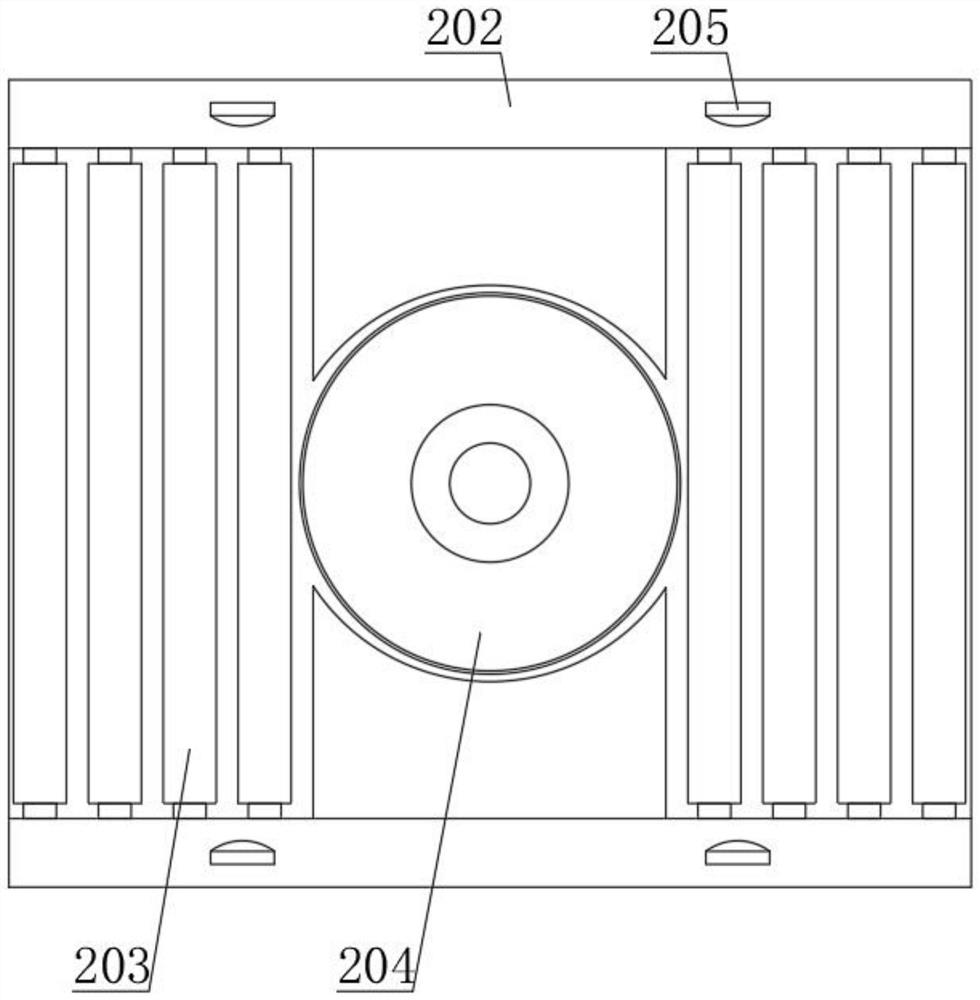

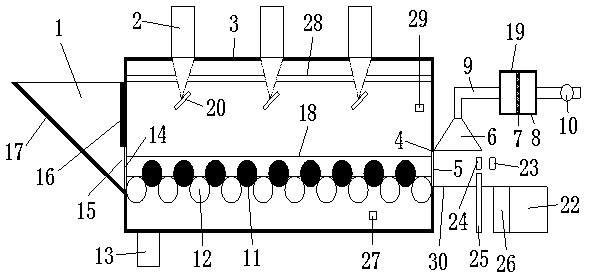

Full-automatic colored stone metal tile glue spraying and sand spraying assembly line

InactiveCN112854615AAvoid pollutionIncrease production capacityRoof covering using tiles/slatesLiquid surface applicatorsAssembly lineColor Stone

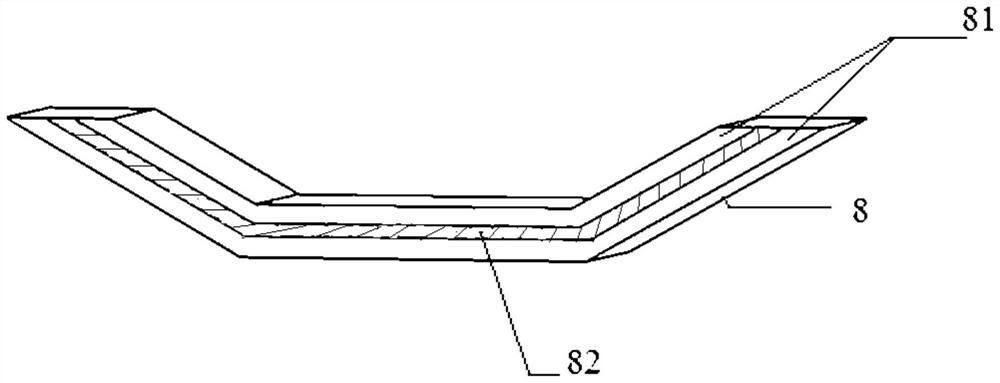

The invention discloses a full-automatic colored stone metal tile glue spraying and sand spraying assembly line, and relates to the technical field of colored stone metal tile production. The full-automatic colored stone metal tile glue spraying and sand spraying assembly line involves conveying equipment, wherein a glue spraying machine, a sand spraying machine, a sand blowing machine, a surface glue machine and a tile receiving machine are installed on the top of the conveying equipment from left to right. According to the full-automatic colored stone metal tile glue spraying and sand spraying assembly line, two fans and eight air outlets are arranged, sufficient wind power is provided for sand blowing, floating sand is thoroughly cleaned, the productivity is improved, a first conveying belt is adopted for feeding, the triangular shape of a traditional first conveying belt is changed into an irregular shape, the first conveying belt cannot be attached by primer, and pollution to raw material metal tiles is avoided. When the backflow sand is collected, the concave conveying belt is adopted for recycling, the color sand cannot be leaked from the edge, raw materials are saved, cost is reduced, pollution caused by the floating sand can be prevented as well, after production of raw material metal tiles is completed, the stone metal tiles are collected through a tile receiving machine, a traditional manual collection mode is changed, the product quality is improved, and the defective rate is reduced.

Owner:SHANDONG MINGSHENG MASCH CO LTD

Paper box packaging assembly line

ActiveCN110978619AReduce wasteLight in massPaper-makingBox making operationsMolding machineAdhesive glue

Owner:ZHEJIANG JUCHENG PRINTING CO LTD

Simulation teaching system for simulating classified storage

InactiveCN111681487ASolve problems such as packet loss and delayCosmonautic condition simulationsProgramme control in sequence/logic controllersProduction lineControl signal

The invention discloses a simulation teaching system for simulating classified storage. The system comprises a classified storage simulation module and a programmable control module, the programmablecontrol module is a programmable controller and a computer provided with PLC programming software and is mainly used for transmitting PLC control signals to the classified storage simulation module end, the classified storage simulation module is connected with a PLC in the programmable control module through a communication line, and the classified storage simulation module is a developed software client, mainly simulates a classified storage assembly line and provides an experimental environment for a user to operate and control a workpiece. According to the invention, students can be helpedto understand the professional knowledge of process control automation and the working principle and application method of the PLC, real operation practice equipment (automatic production line) doesnot need to be invested, and the purpose of teaching can be achieved in a virtual simulation mode.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

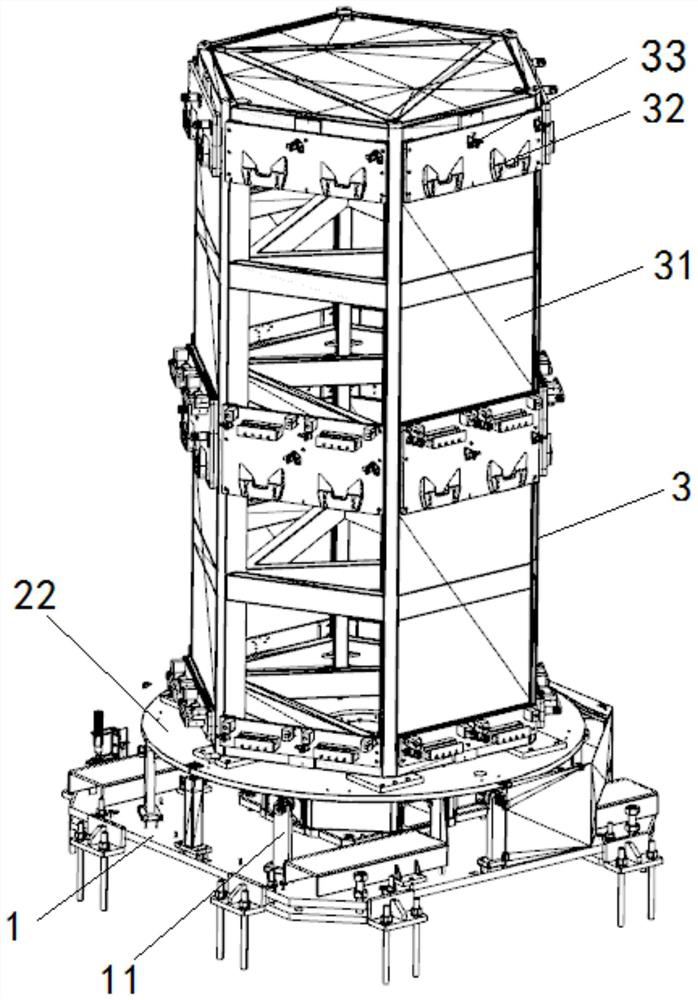

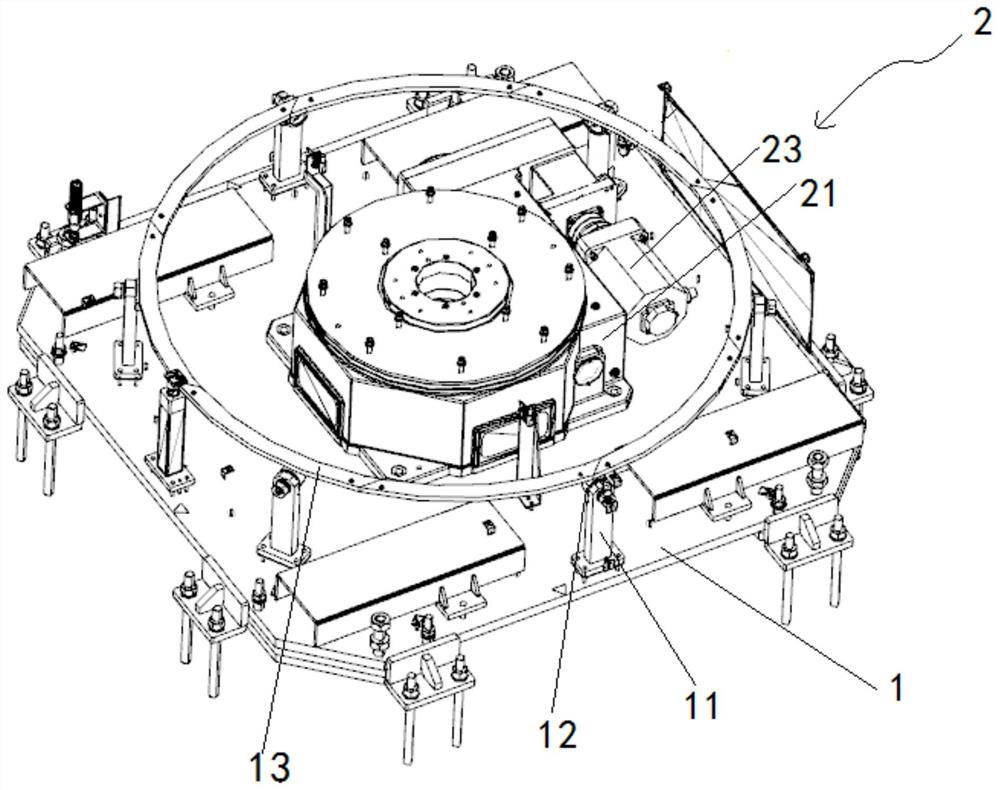

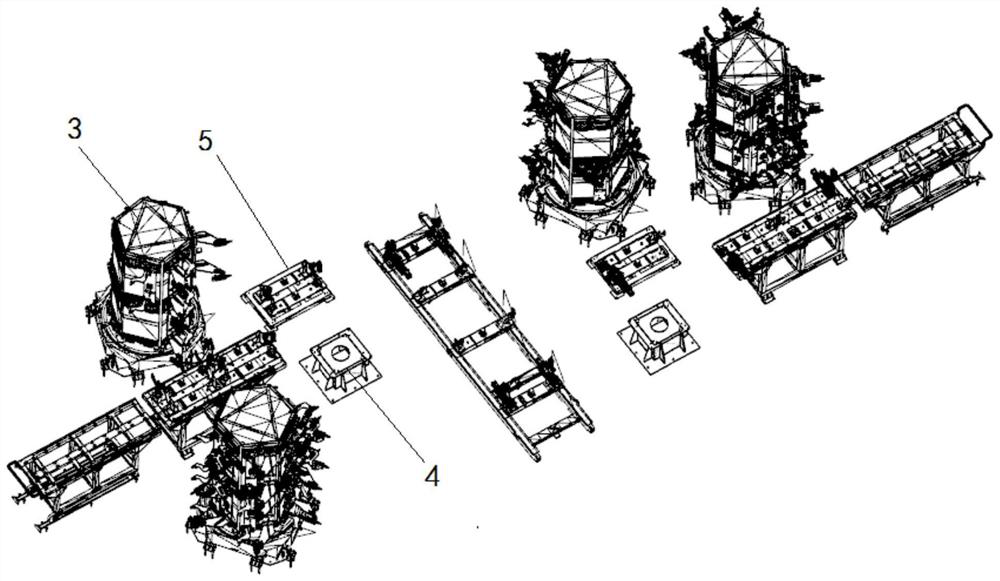

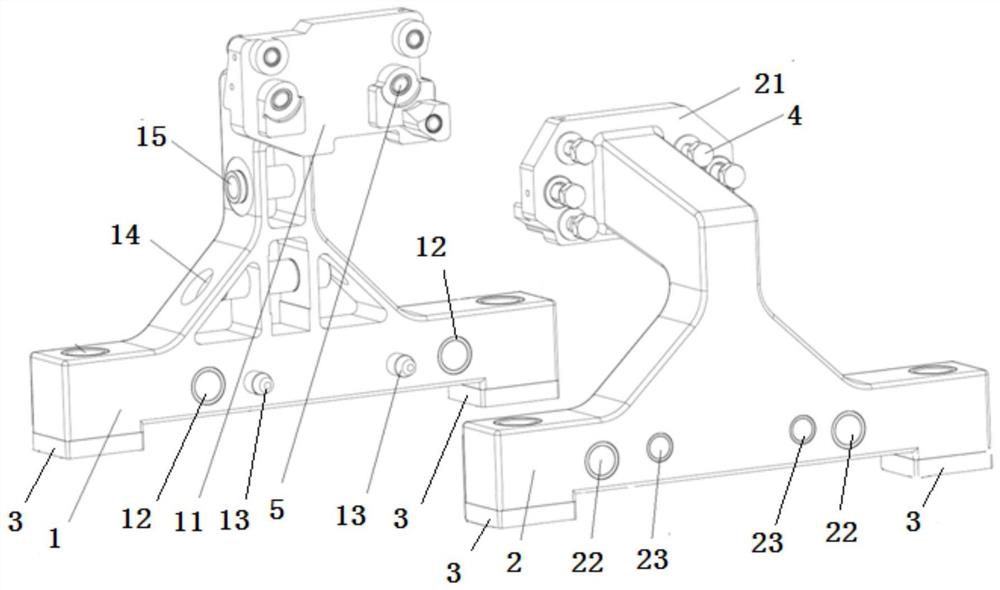

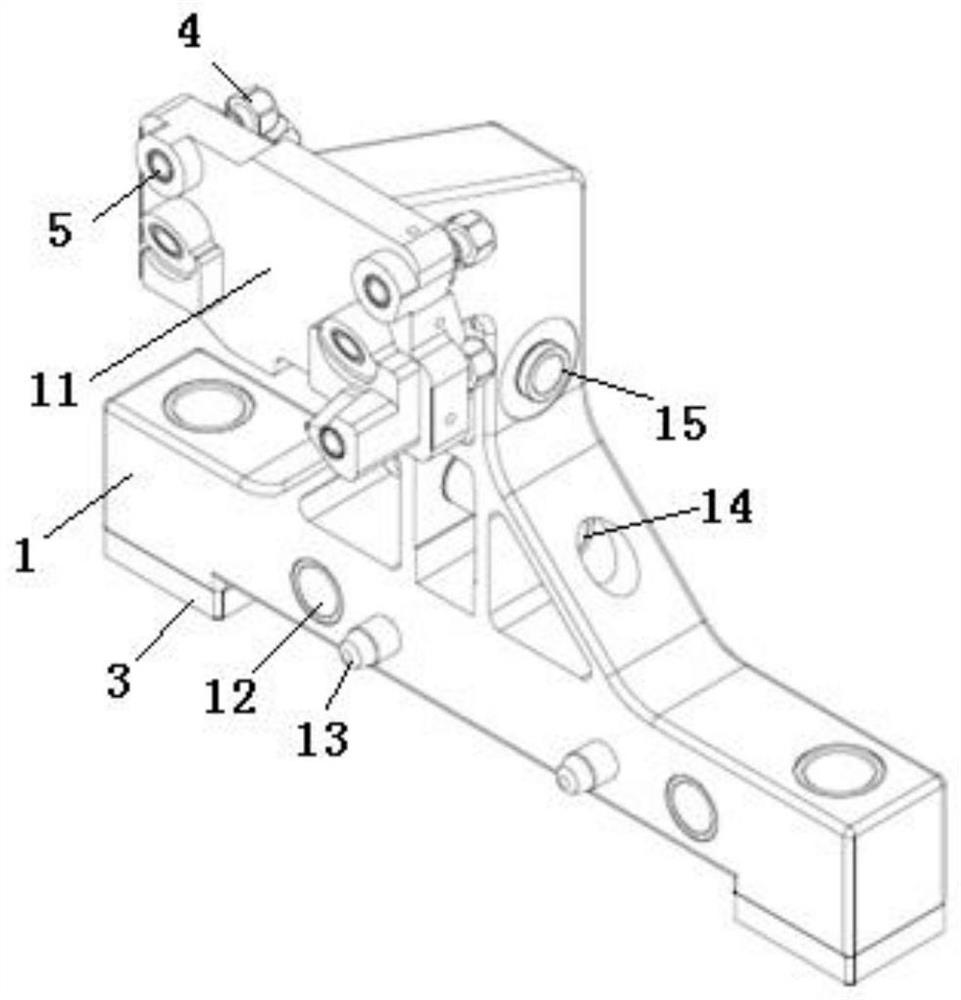

Follow fixture library device and automatic fixture switching system and method

PendingCN112372180AWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringAssembly line

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

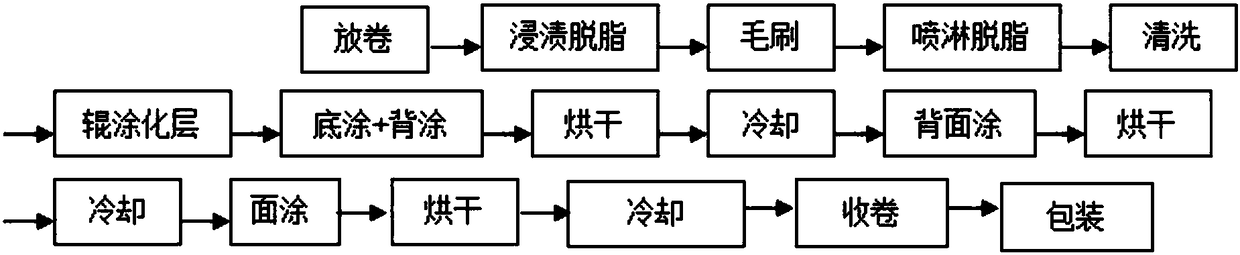

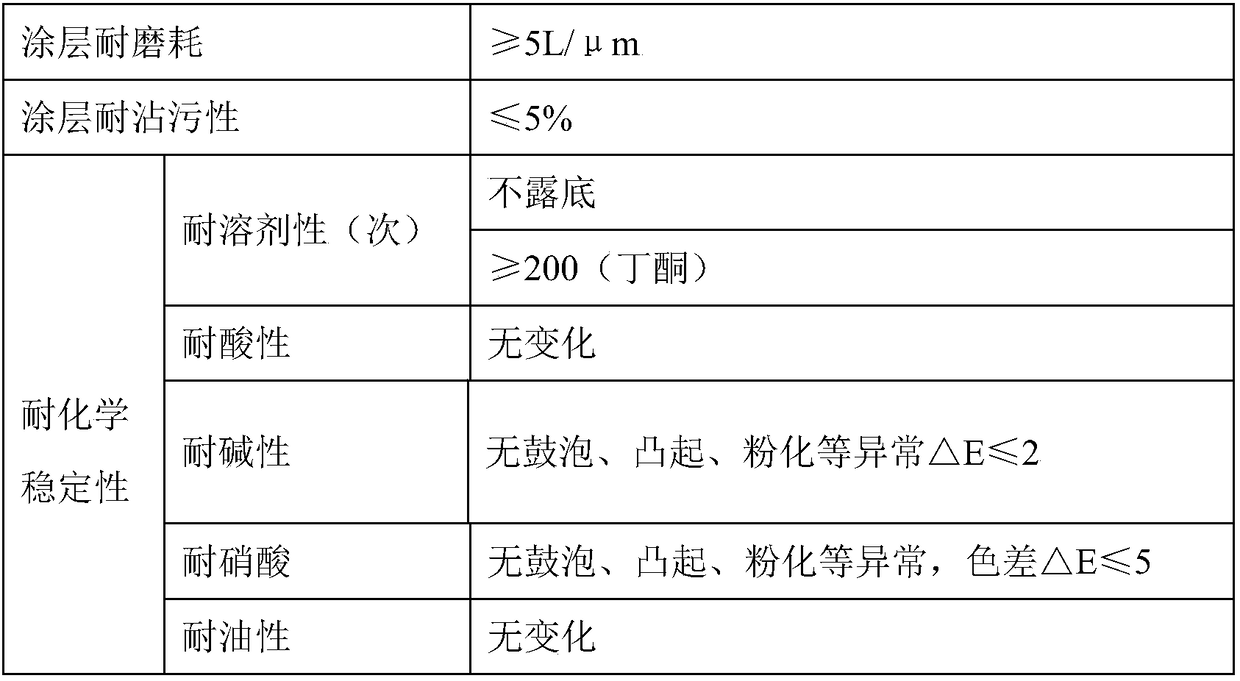

Double-face roller coating color aluminum plate preparing technology

InactiveCN108515010AGood effectImprove adhesionPretreated surfacesCoatingsSurface cleaningAssembly line

Owner:安徽墙煌彩铝科技有限公司

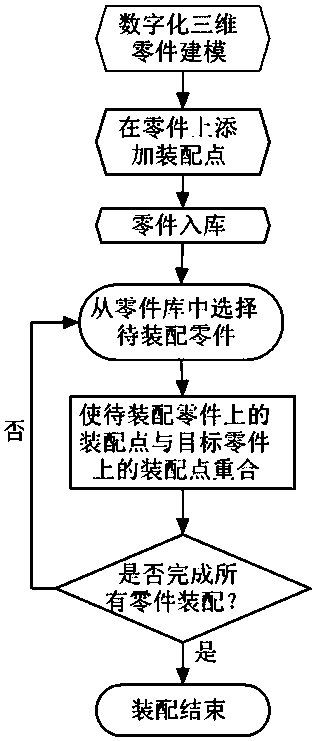

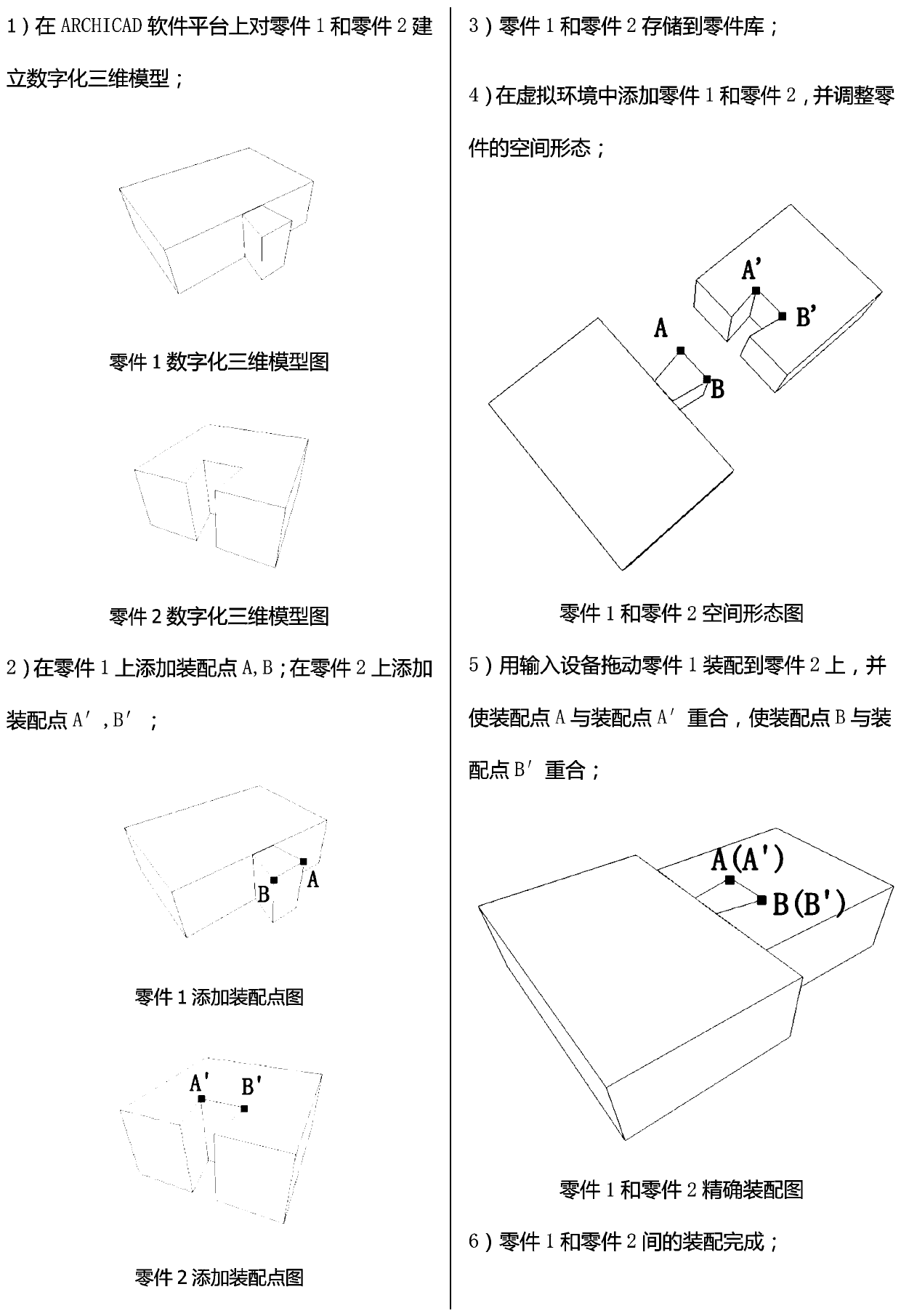

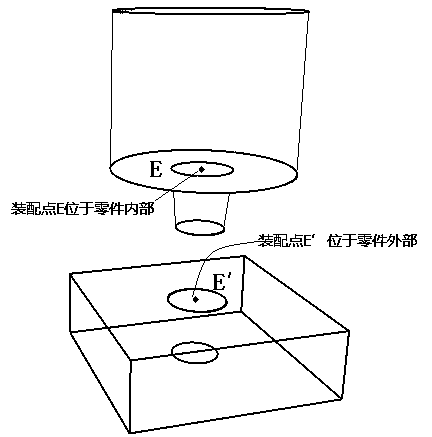

Digital three-dimensional part virtual assembly method based on assembly points

PendingCN110007762AInput/output for user-computer interactionImage data processingAssembly lineSimulation

Owner:石家庄格得乐模型技术服务有限公司

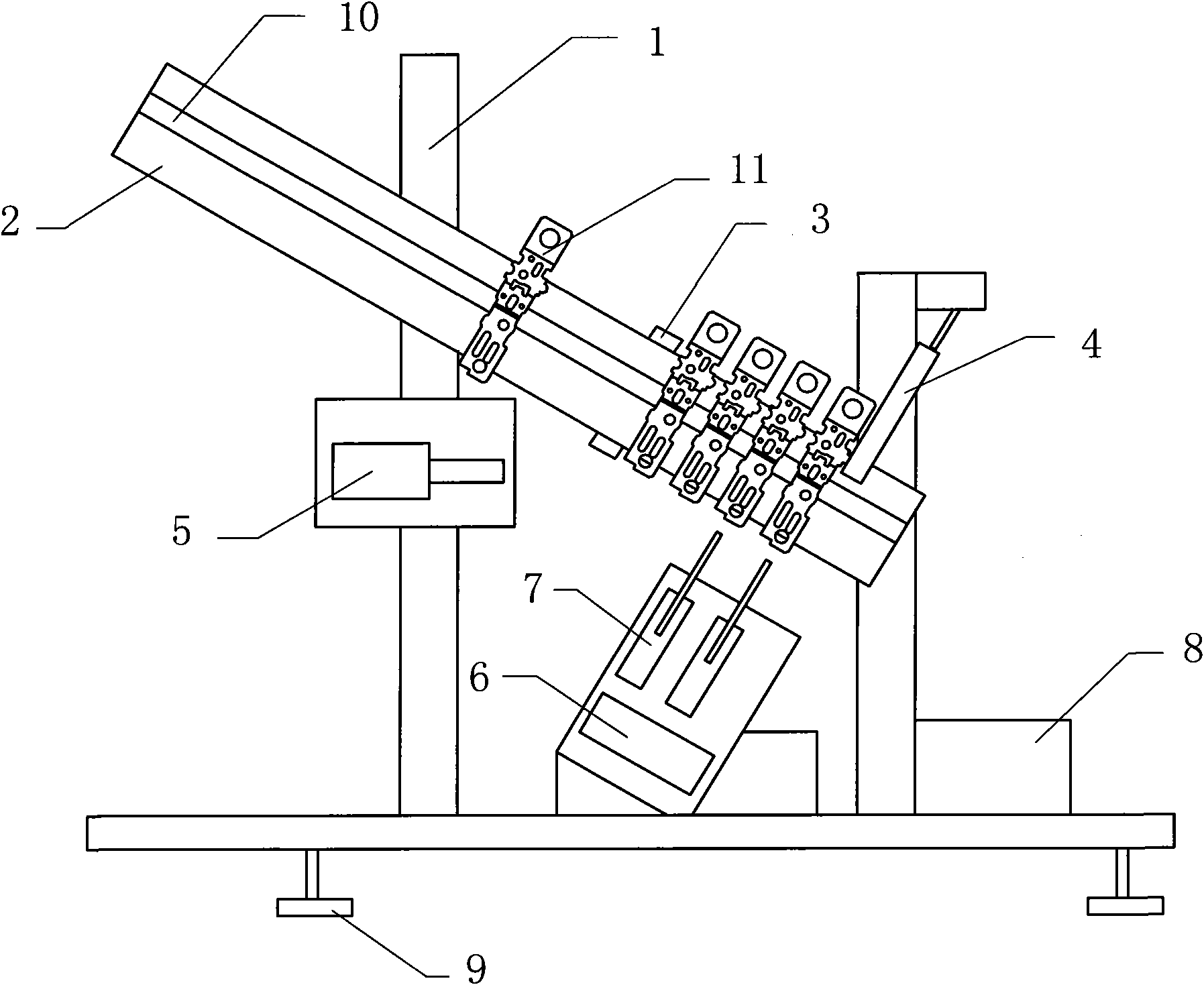

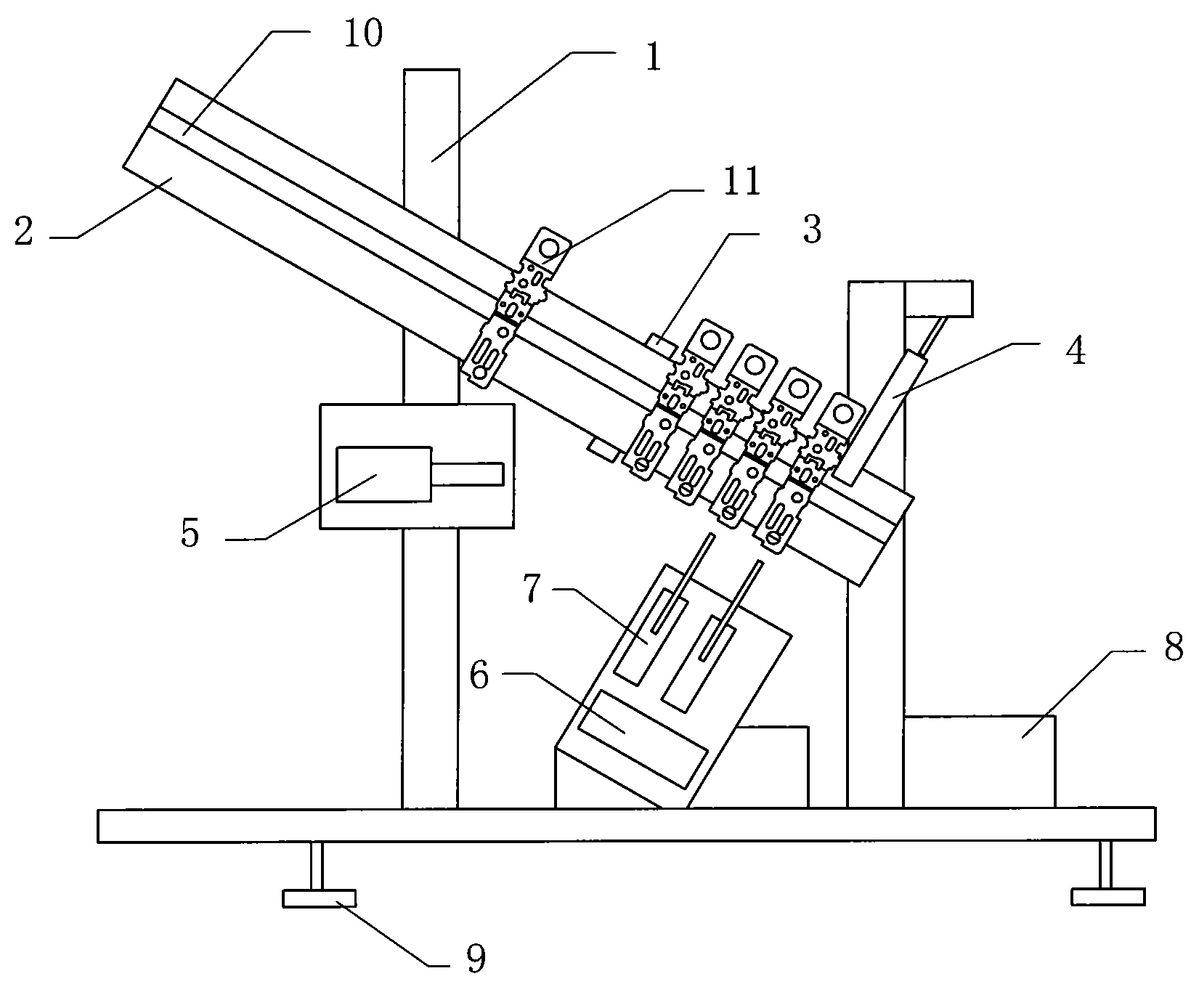

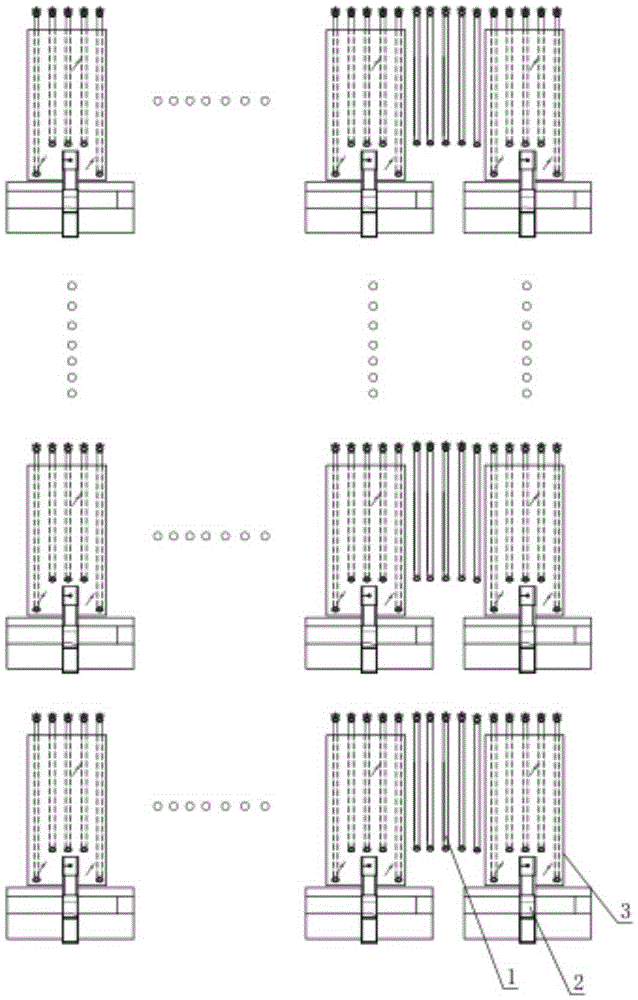

Semi-automatic tapping machine

InactiveCN102398089ANo deformationIncrease productivityThread cutting machinesSemi automaticAssembly line

Owner:INTERPLEX SUZHOU PRECISION ENG LTD

Marking face piece of hard seal with electronic recognition function, and making method of marking face piece

The invention discloses a marking face piece of a hard seal with the electronic recognition function, and a making method of the marking face piece. The marking face piece of the hard seal with the electronic recognition function, and the making method of the marking face piece are used for solving the problem that a hard seal in the prior art lacks in the technical measures for hiding an electronic chip in a seal gasket, and a worker can only carry out carving on the whole assembled seal because the electronic chip is hidden outside the seal gasket. According to the technical scheme, the marking face piece of the hard seal with the electronic recognition function is characterized in that the marking face piece is composed of a plastic marking face piece body, an electronic chip unit and aplastic closed part, a concave area is formed in the plastic marking face piece body, the wall of the concave area extends downwards and inclines inwards, a concave groove is formed in the bottom surface of the concave area, the electronic chip unit is arranged in the concave area, and forming is carried out in the manner that the concave area is filled through a secondary molding technology. Themaking method of the marking face piece is continuously carried out with the successive following technological steps, on a multi-station automatic making assembly line, of molding a plastic markingface piece body on a first molding station, tightly and fixedly bonding the electronic chip unit to the concave area on an installation station, carrying out filling to close the concave area on the secondary molding station, and removing the protruding parts through finishing on a finishing station.

Owner:SHANTOU SPECIAL ECONOMIC ZONE XIEQIN STATIONERY CO LTD

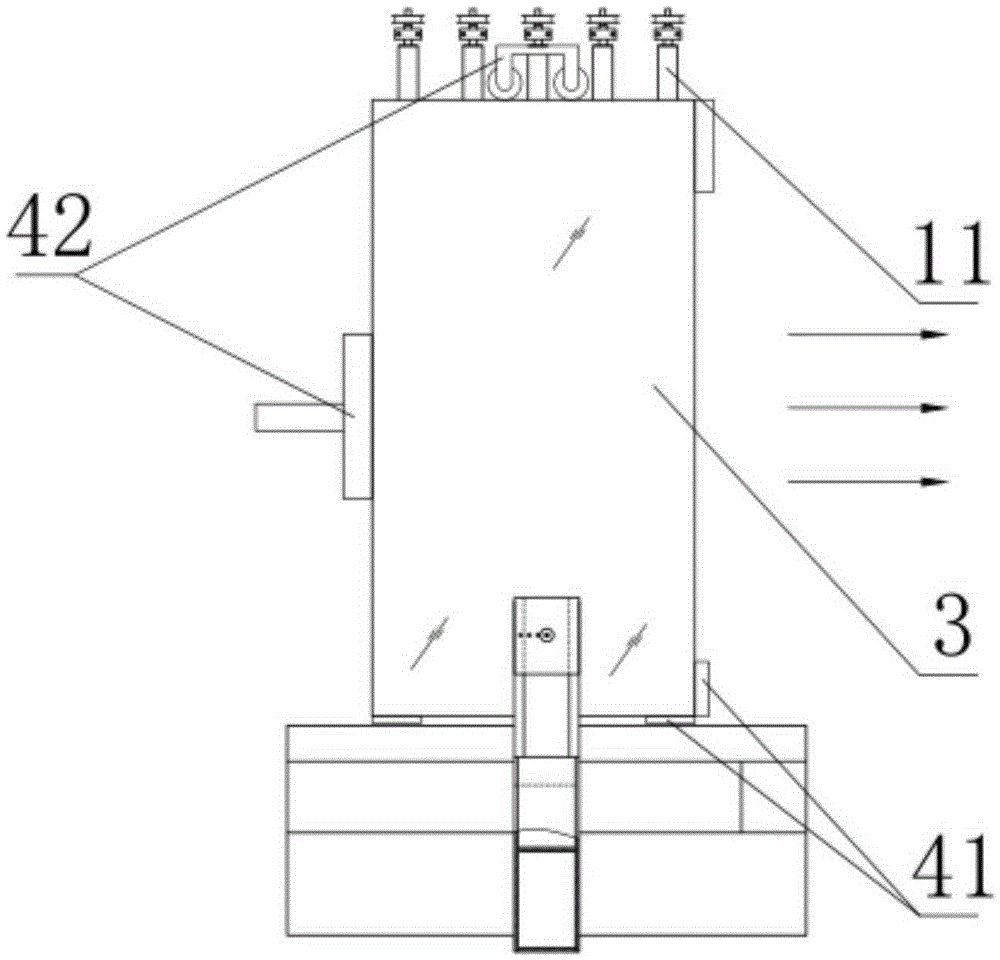

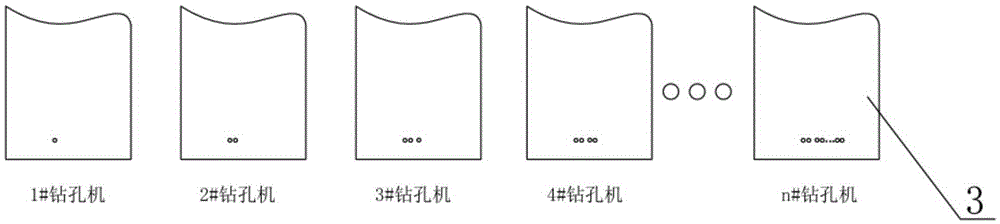

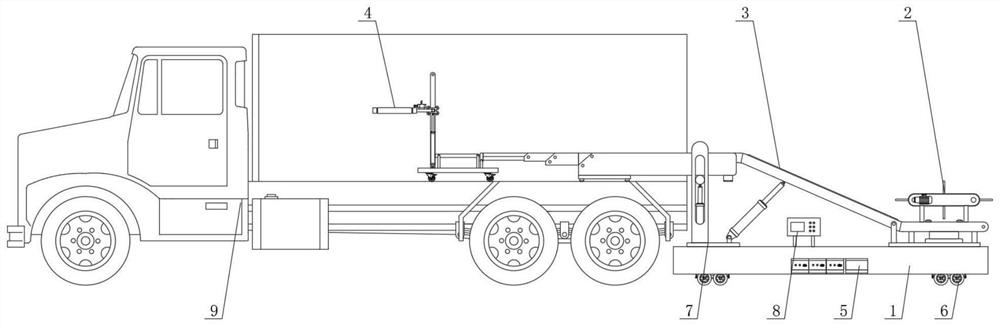

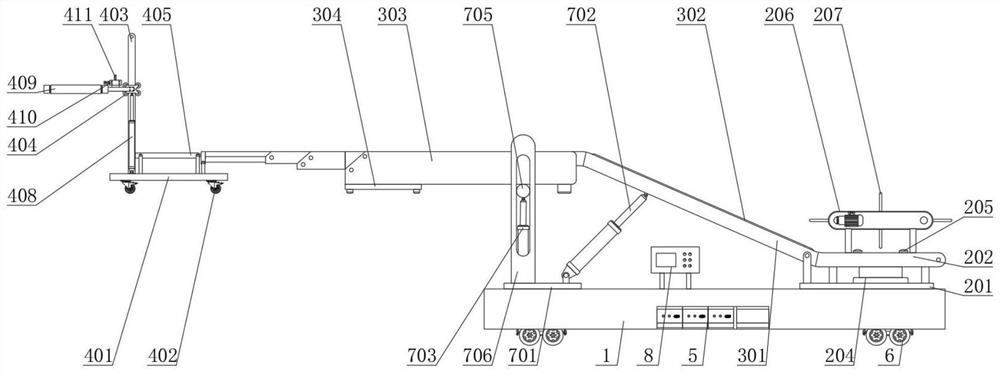

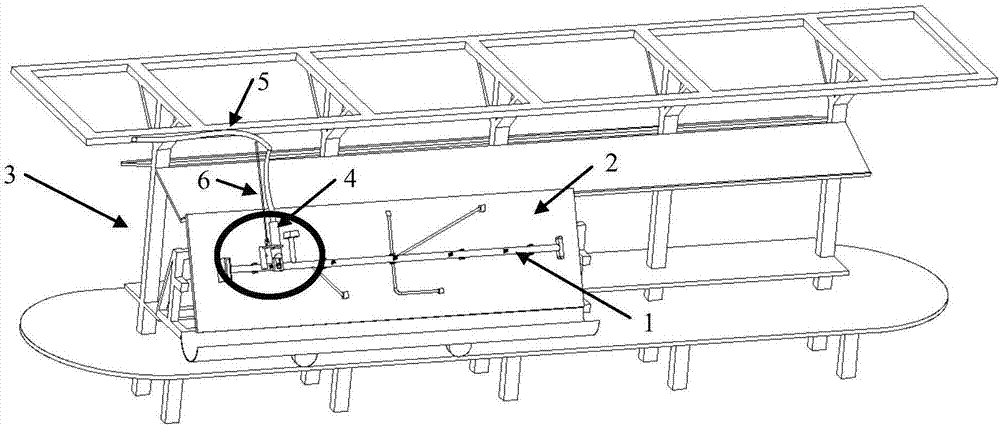

Online series type drilling system for photovoltaic module backboard glass

InactiveCN105382939ARealize online punchingImprove pass rateWorking accessoriesStone-like material working toolsControl signalFirst pass yield

Owner:CHANGZHOU HUAMEI PHOTOVOLTAIC MATERIALS

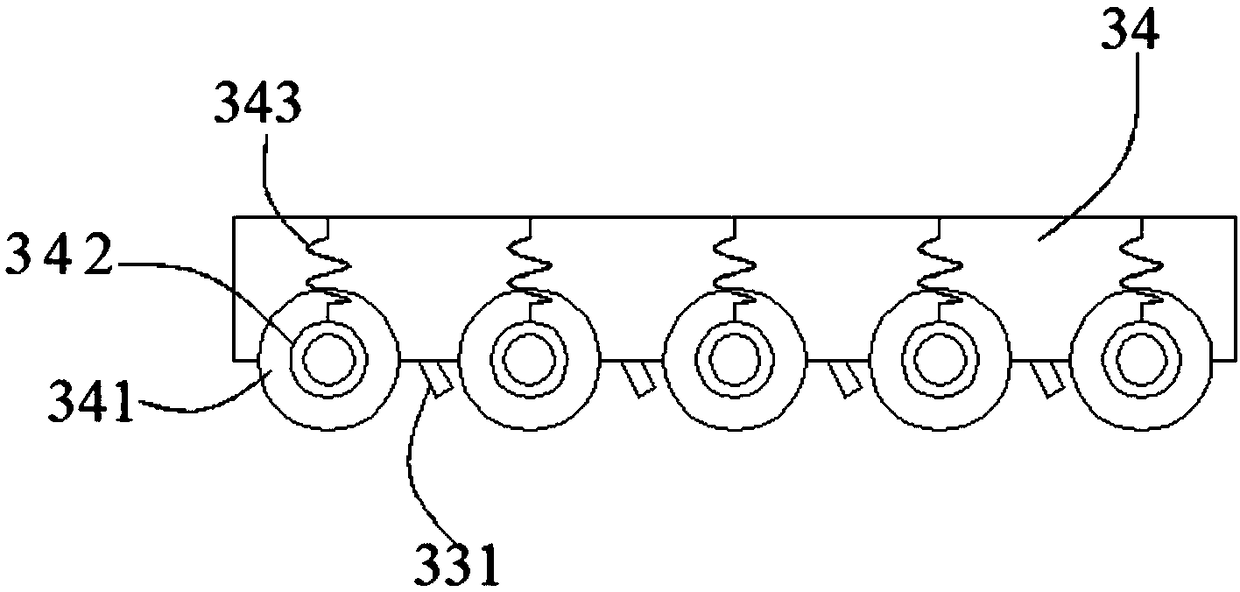

Express package loading assembly line with high automation degree

InactiveCN113830579AEasy loadingSave loading spaceConveyorsLoading/unloadingDrive wheelLogistics management

Owner:溆浦县远宏速递有限责任公司

Shaping processing device of insulated stay strip for transformer

InactiveCN108895075AInductances/transformers/magnets manufactureFastening meansEngineeringAssembly line

Owner:镇江市鑫泰绝缘材料有限公司

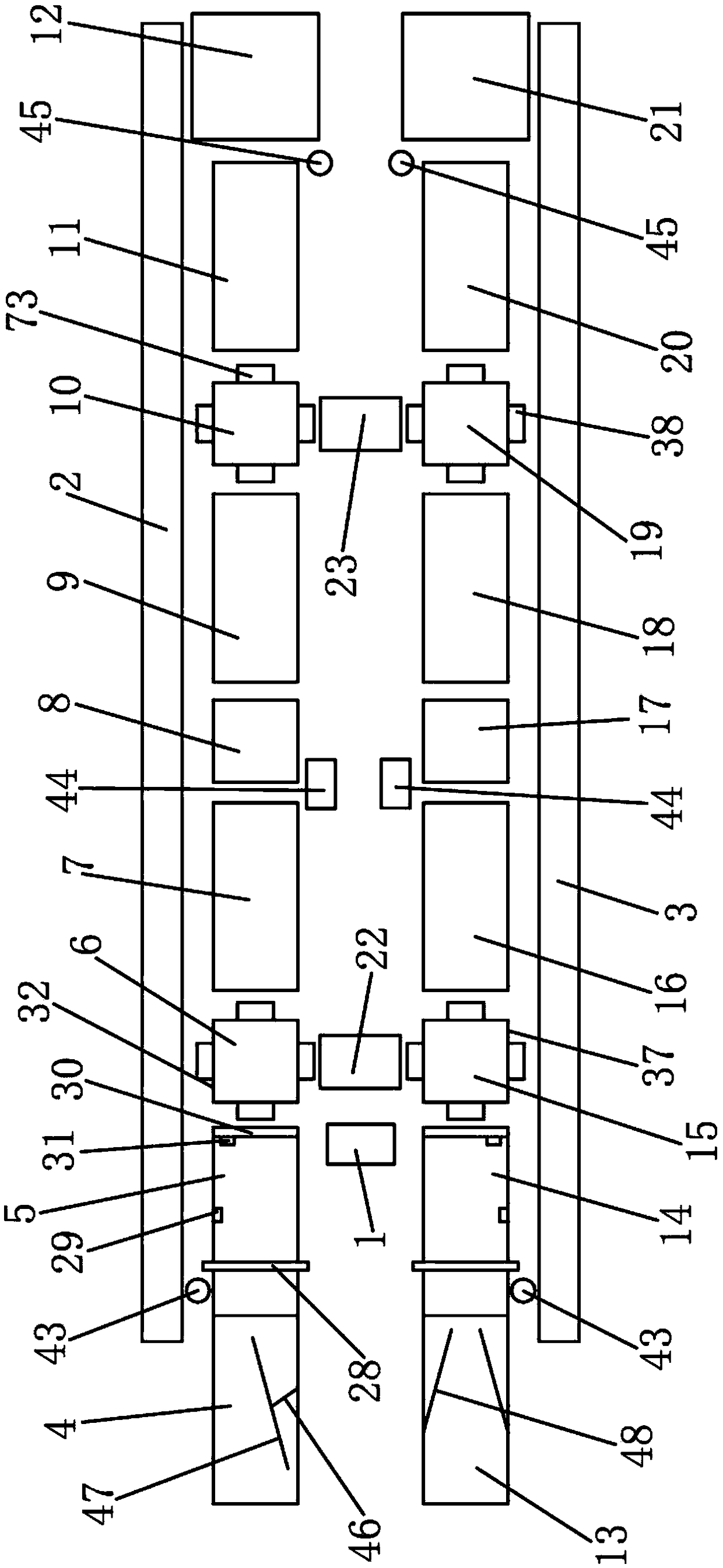

Automatic packaging device for fast food

InactiveCN113120288AAchieve a single separationPrecise positioningPackaging foodstuffsRice dishesAssembly line

The invention relates to an automatic packaging device for fast food, in particular to a packing device for automatically subpackaging rice and dishes in box-packed fast food. The device is characterized in that assembly line type working equipment is arranged, the equipment automatically grabs a fast food box for operation, and the fast food box operates under the fixation of a clamping jaw of an arranged fast food box clamping conveyor, when the fast food box passes through an automatic food distribution machine area where rice and dishes are placed, a food distribution machine places the rice and the dishes into the fast food box according to the quantity according to set requirements, the fast food box continues to operate backwards after placement is completed, automatic cover sealing is achieved when the fast food box passes through a cover adding area, and finally the fast food box is conveyed out of a packaging area through a fast food box conveyor to complete the automatic fast food packaging function. The automatic packaging device is easy to operate, the rice and the dishes can be quantitatively and rapidly subpackaged, soup separation can be achieved when the dishes are subpackaged, the quality and taste of the dishes are ensured, full-automatic processing is achieved in the working process of the device, and the device is convenient, rapid and sanitary and is an intelligent automatic fast food packaging device meeting the current social requirements.

Owner:JINLING INST OF TECH

Process support for flow mixing of engine assembly line

Owner:DONGFENG AUTOMOBILE COMPANY

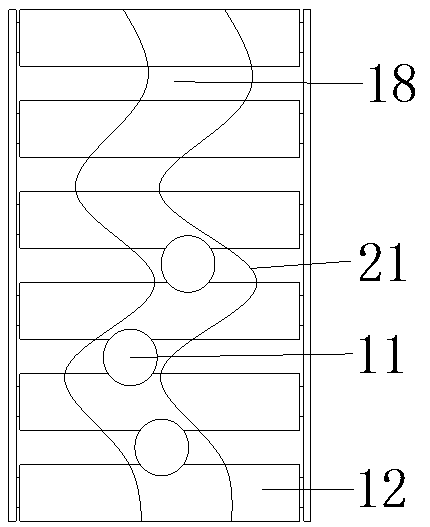

Plate leveling method for plate jointing operation in shipbuilding plane section assembly line

The invention provides a plate leveling method for plate jointing operation in a shipbuilding plane section assembly line. The plate leveling method comprises the following steps of: adopting a linear laser in the plate jointing operation; transmitting laser lines at an angle of 40-45 degrees formed by the linear laser and the horizontal direction for simultaneously projecting plate surfaces with different heights, wherein if the heights of the plate surfaces are different, intersection points of the laser lines reaching the plate surface are different, and if the heights of the plate surfaces are identical, intersection points of the laser lines reaching the plate surfaces are identical; and adjusting the levelness of the joined plate according to information of the intersection points. According to the plate leveling method disclosed by the invention, the problems of lower work efficiency and longer consumed time in the plate jointing work in the prior art can be solved; information judgment of operators is visual, so that the accuracy of the operation position of the plate can be achieved quickly and effectively; and the time consumed by assembling and positioning operation quantity of same weld joints is shortened by 50 percent compared with the prior time, and thus the work efficiency of jointing plate is greatly increased.

Owner:QINGDAO YANGFAN SHIPBUILDING CO LTD

Application of energy-saving heat preservation tank in production line of glove machine

ActiveCN108866799BExtended service lifeReduce replacement costsKnittingCalcium silicateThermal insulation

Owner:上海华新医材有限公司 +2

Fastening type vertical sander

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

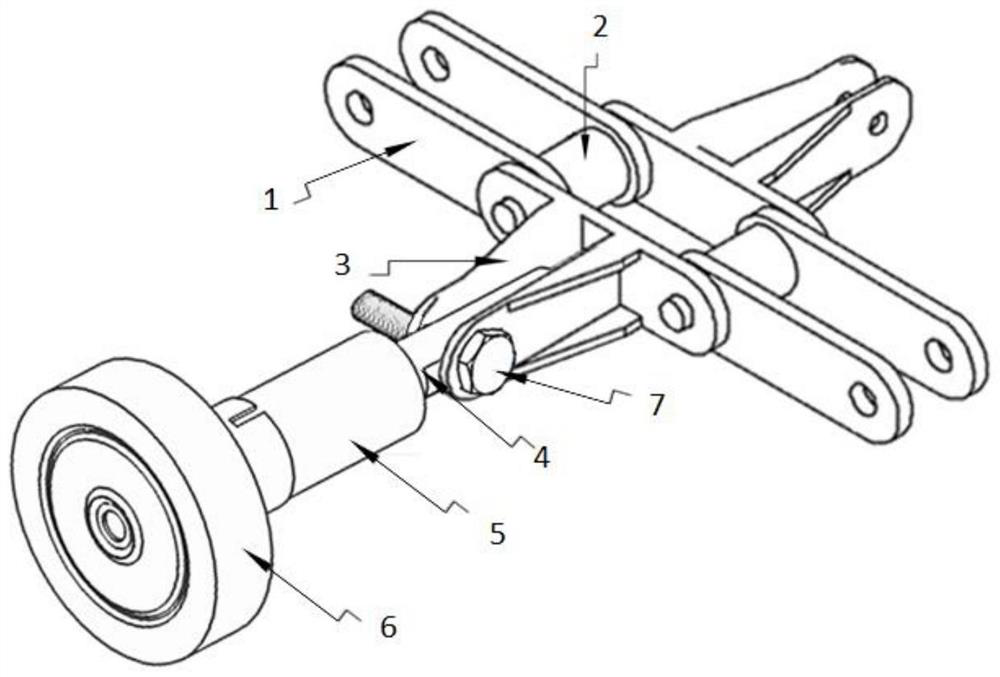

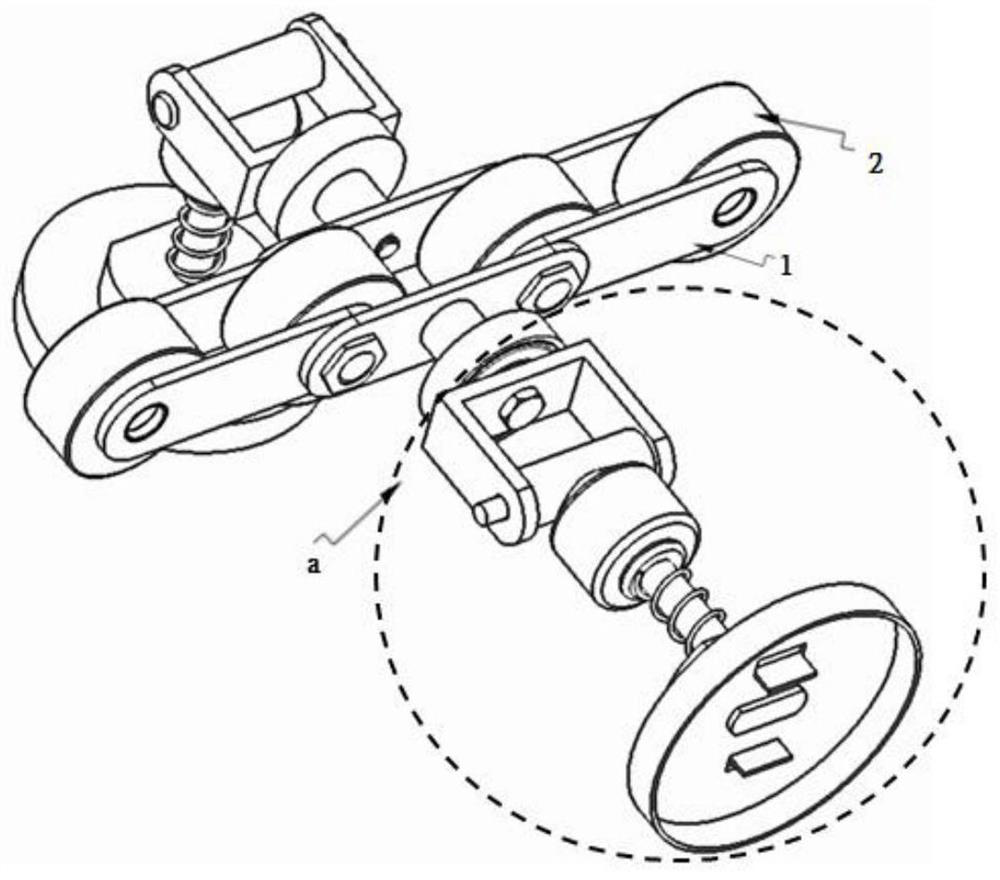

Online cylinder crimping apparatus and method

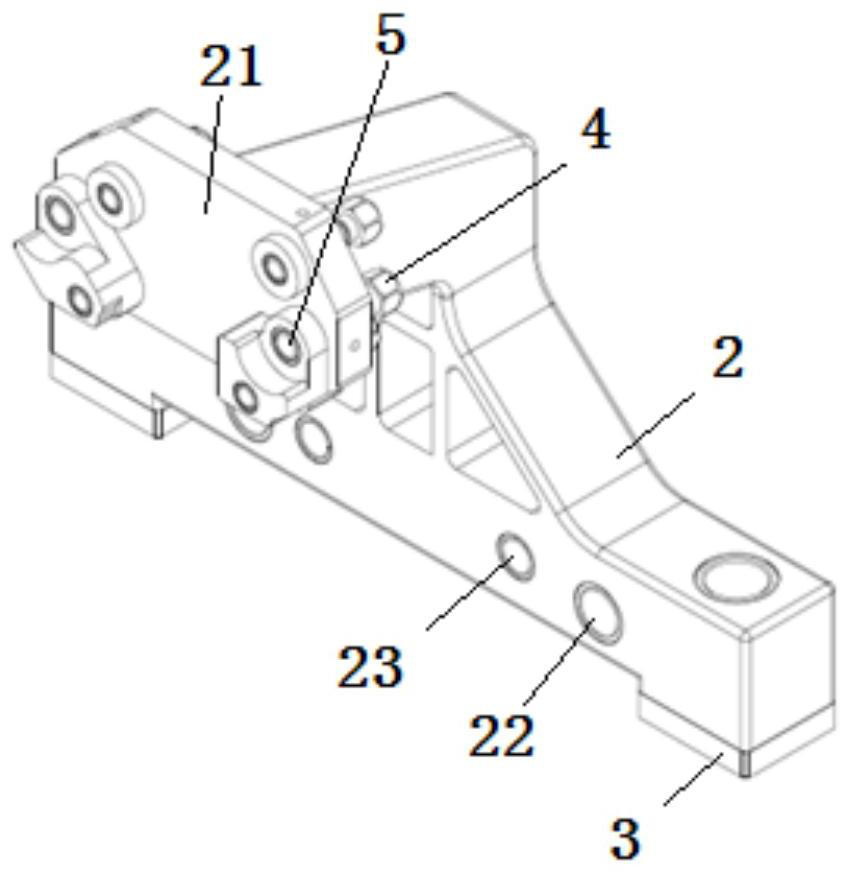

PendingCN107404057AReduce the phenomenon of pulling damage terminalsIncrease productivityConnection formation by deformationAssembly lineSuspension (vehicle)

Owner:湖北正奥汽车附件集团有限公司

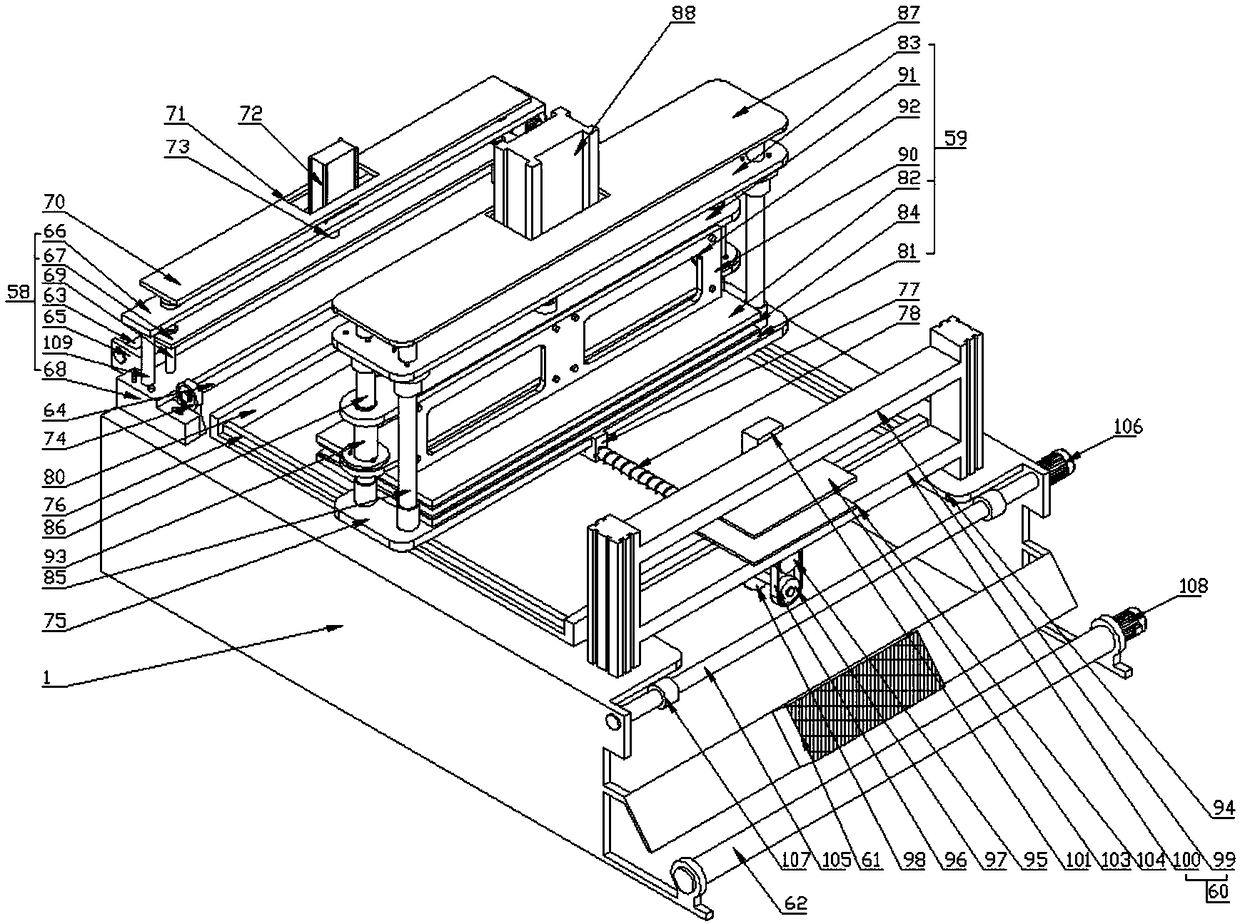

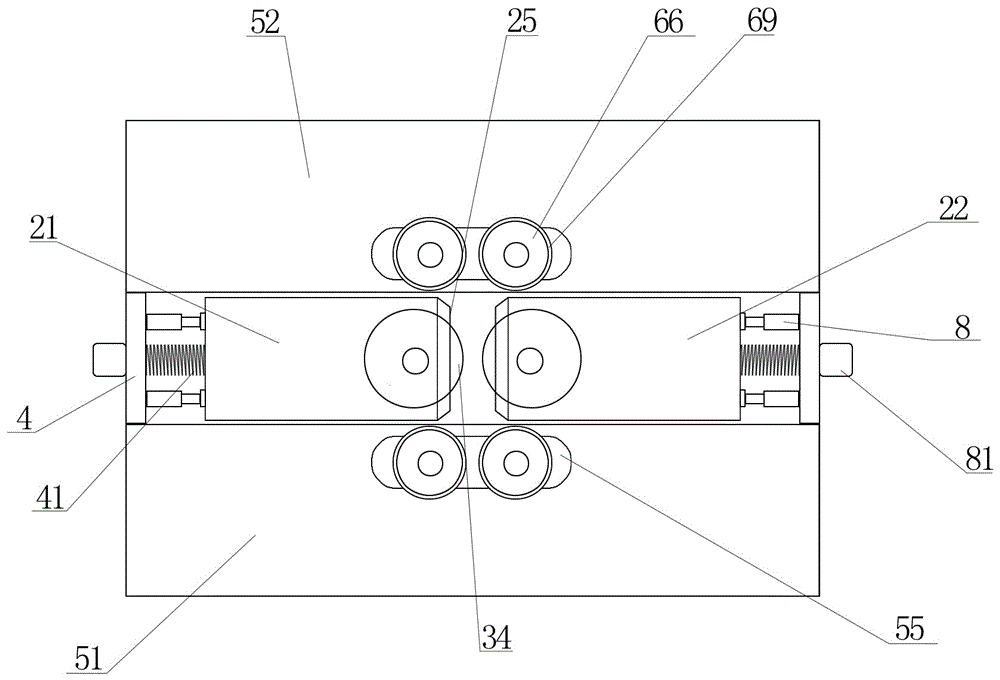

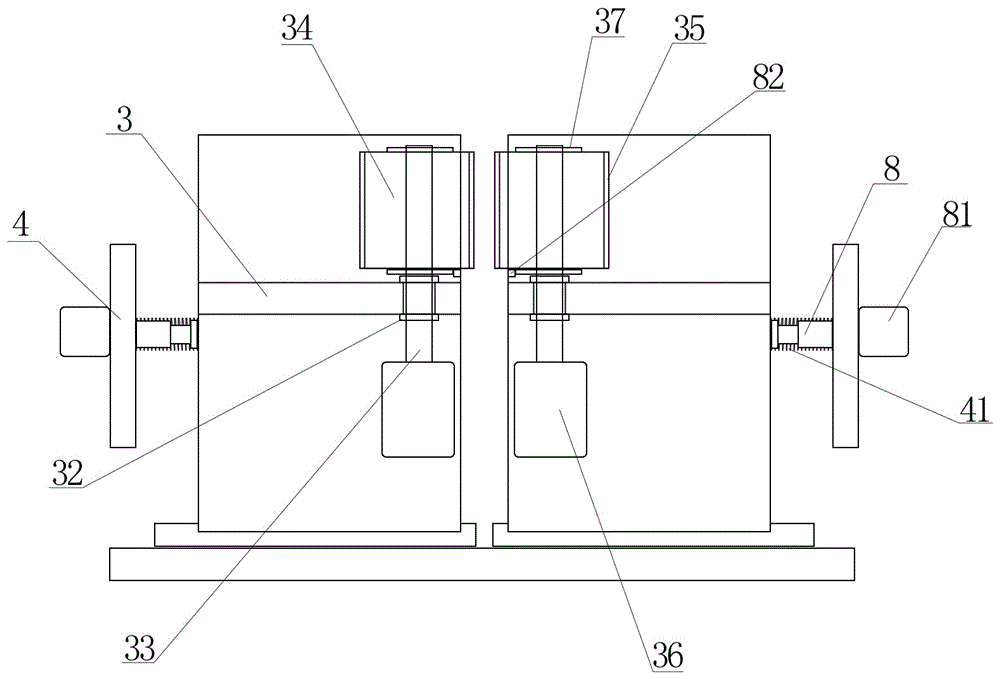

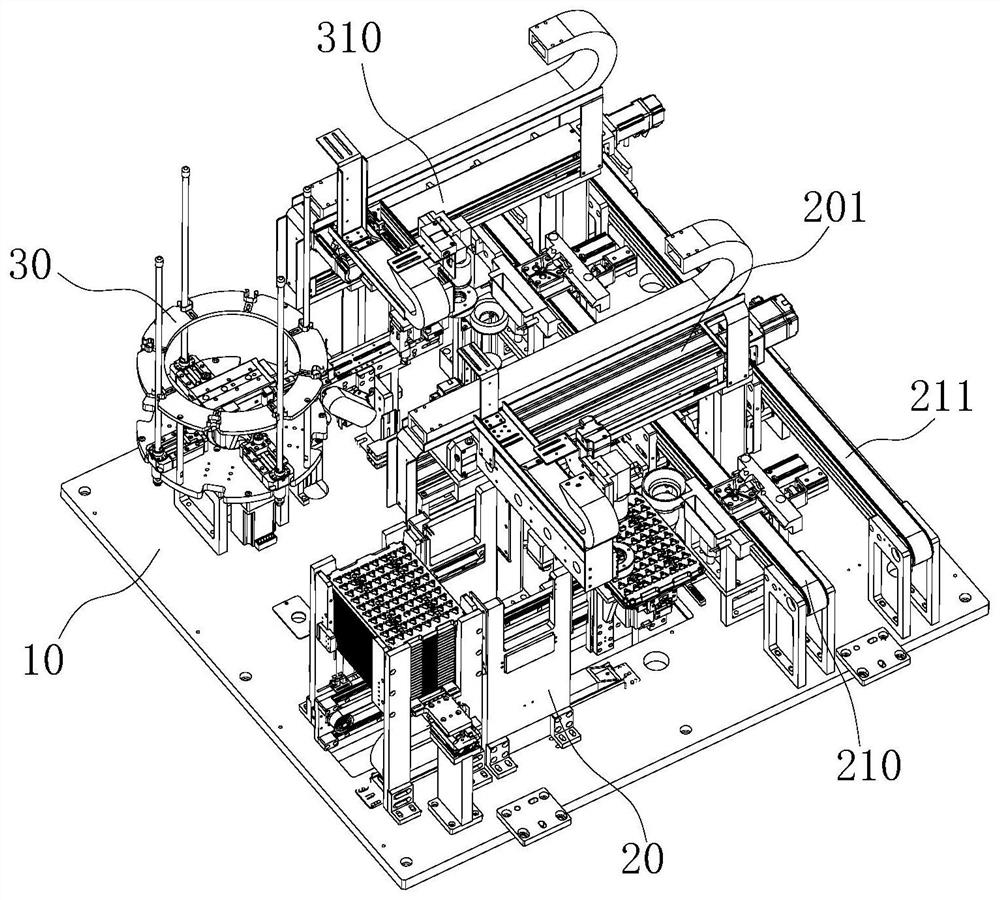

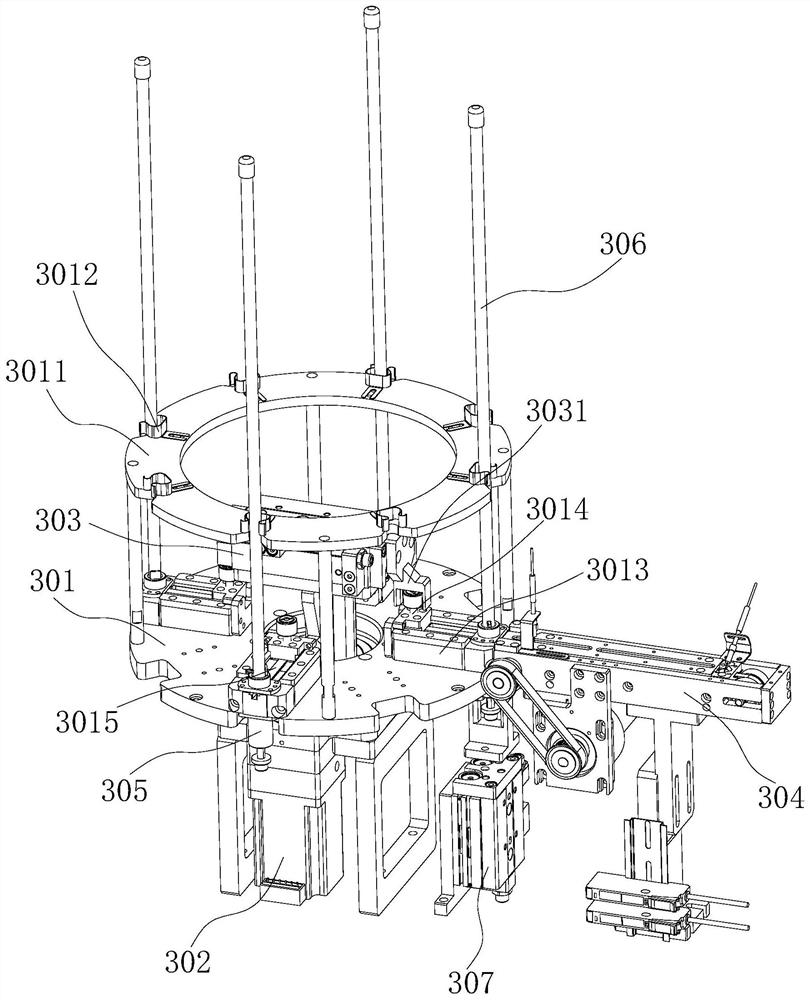

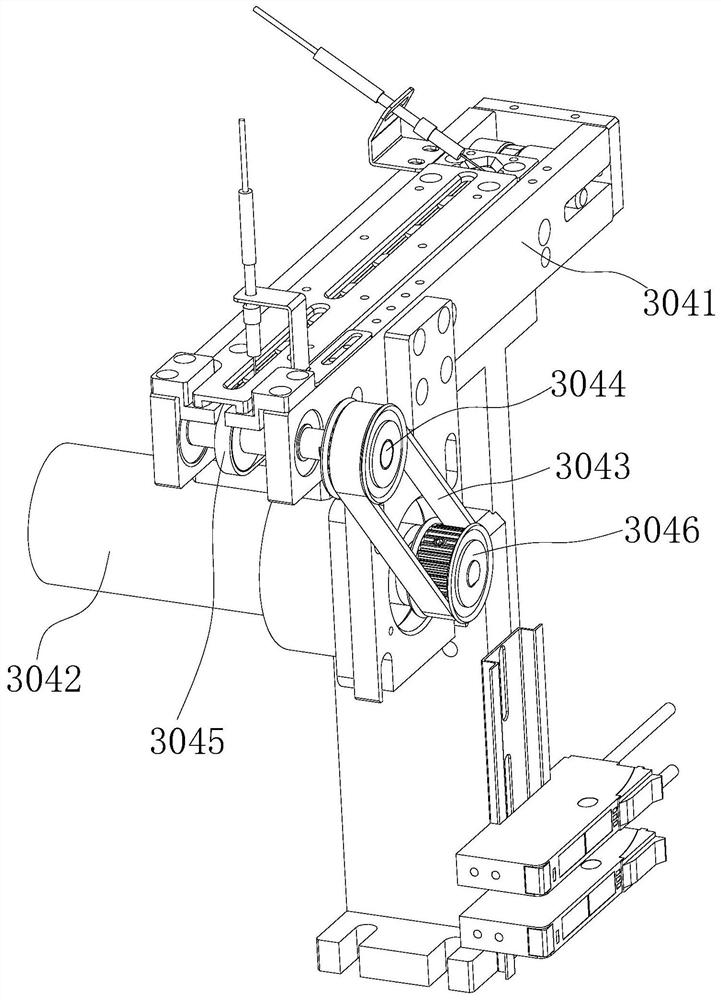

Assembling mechanism for fixing support and weak magnetic sheet

PendingCN111906534ARealize automatic feeding processNon-stop operationAssembly machinesMetal working apparatusStructural engineeringAssembly line

Owner:深圳市罗博威视科技有限公司

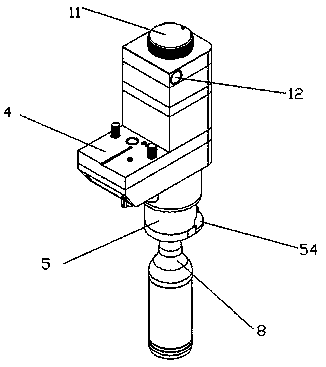

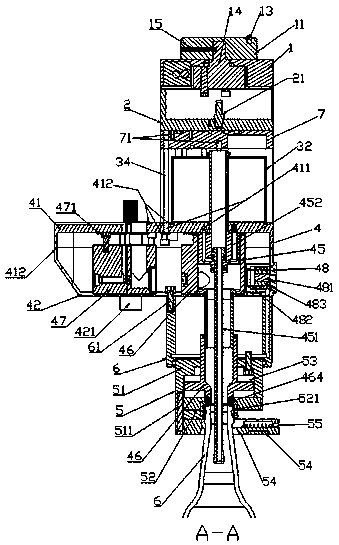

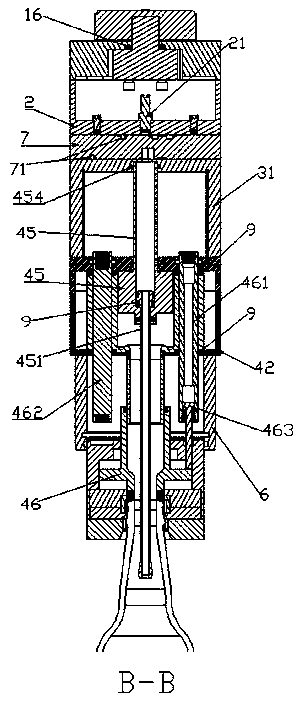

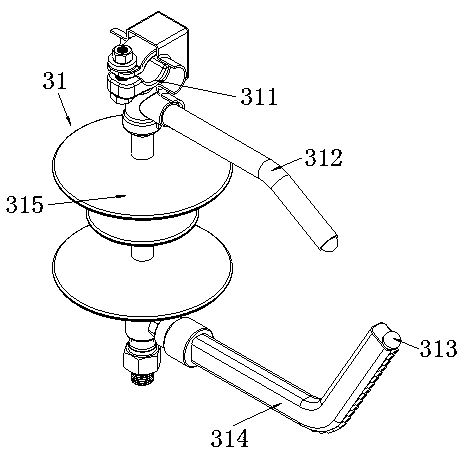

Intelligent integrated valve for filling and capping

ActiveCN110615396ASolve the disadvantages of taking up a lot of spaceReduce the downside of taking up a lot of spaceBio-packagingFlanged caps applicationProduction lineAssembly line

Owner:BOFANN AUTOMATION TECH

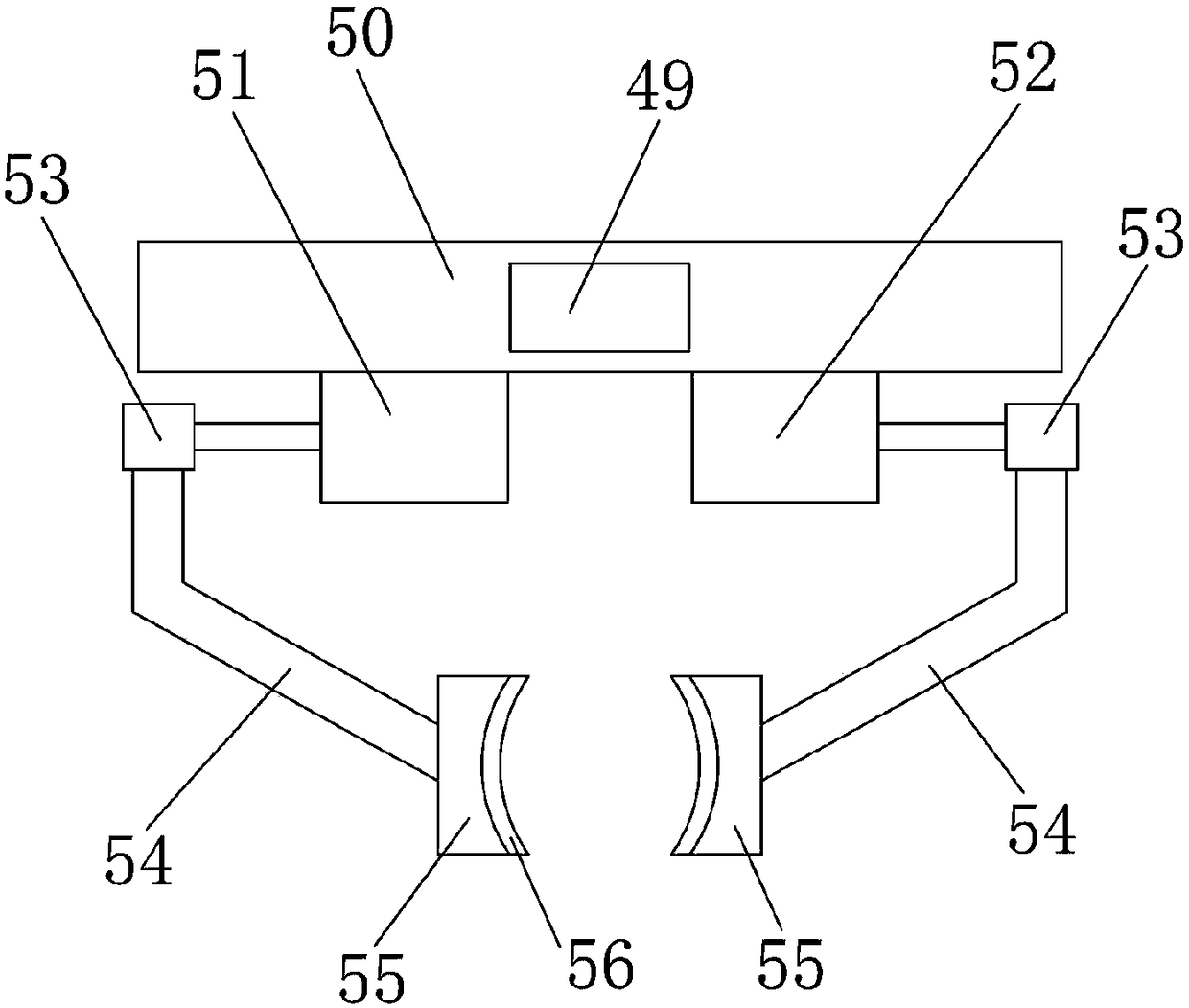

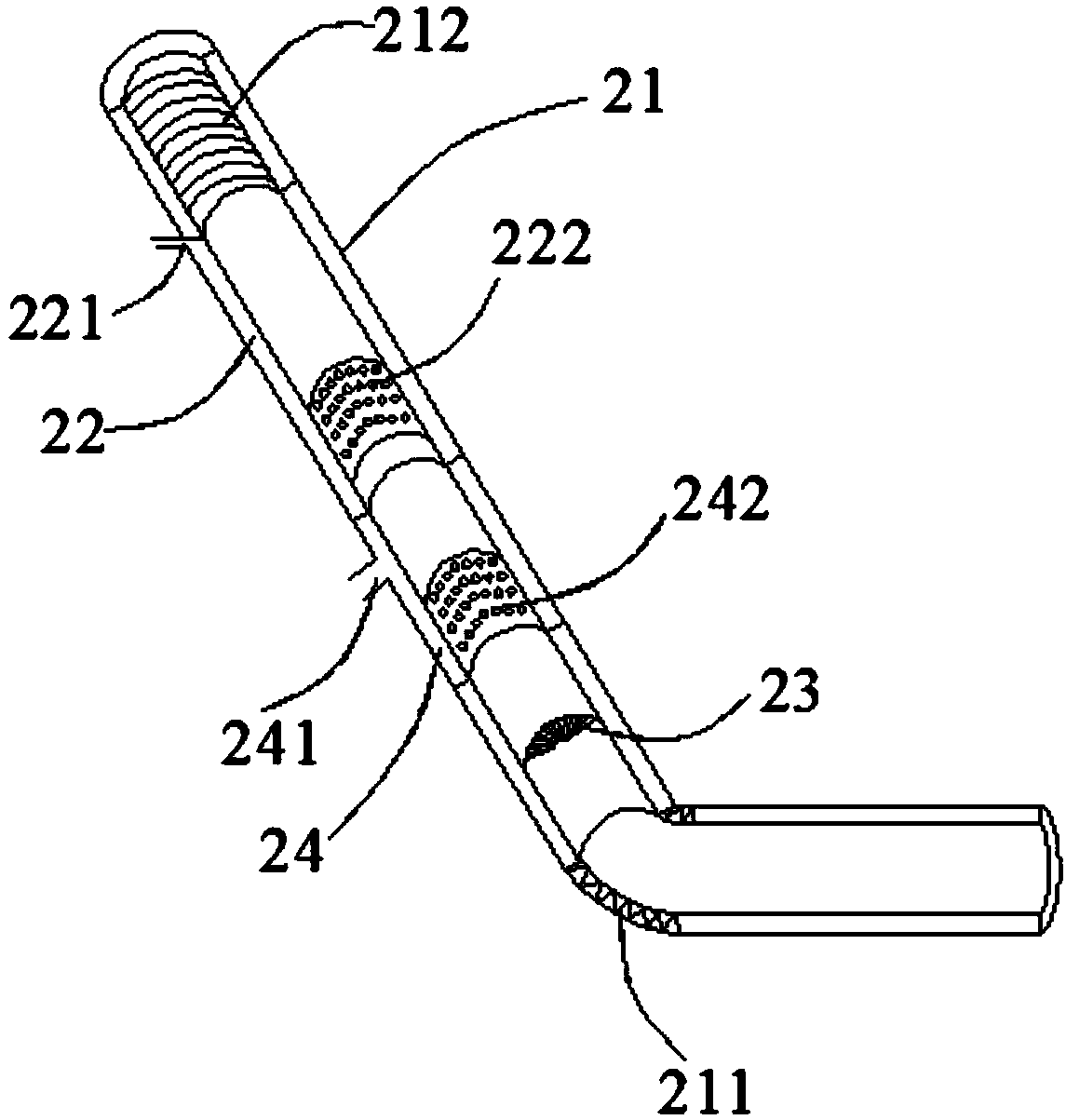

Assembly line-type kiwifruit peeling and slicing device

InactiveCN108077953AAdjustment timeEasy to break awayVegetable peelingMetal working apparatusAssembly lineFood processing

Owner:柳州吉辉机械设计有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap